System and method for producing propylene by oxidative dehydrogenation of propane with chemical chain

A technology for oxidative dehydrogenation and chain propane, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of reducing propylene yield, increasing operating costs, unfavorable equipment safe operation, etc., and achieves the elimination of thermodynamic flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

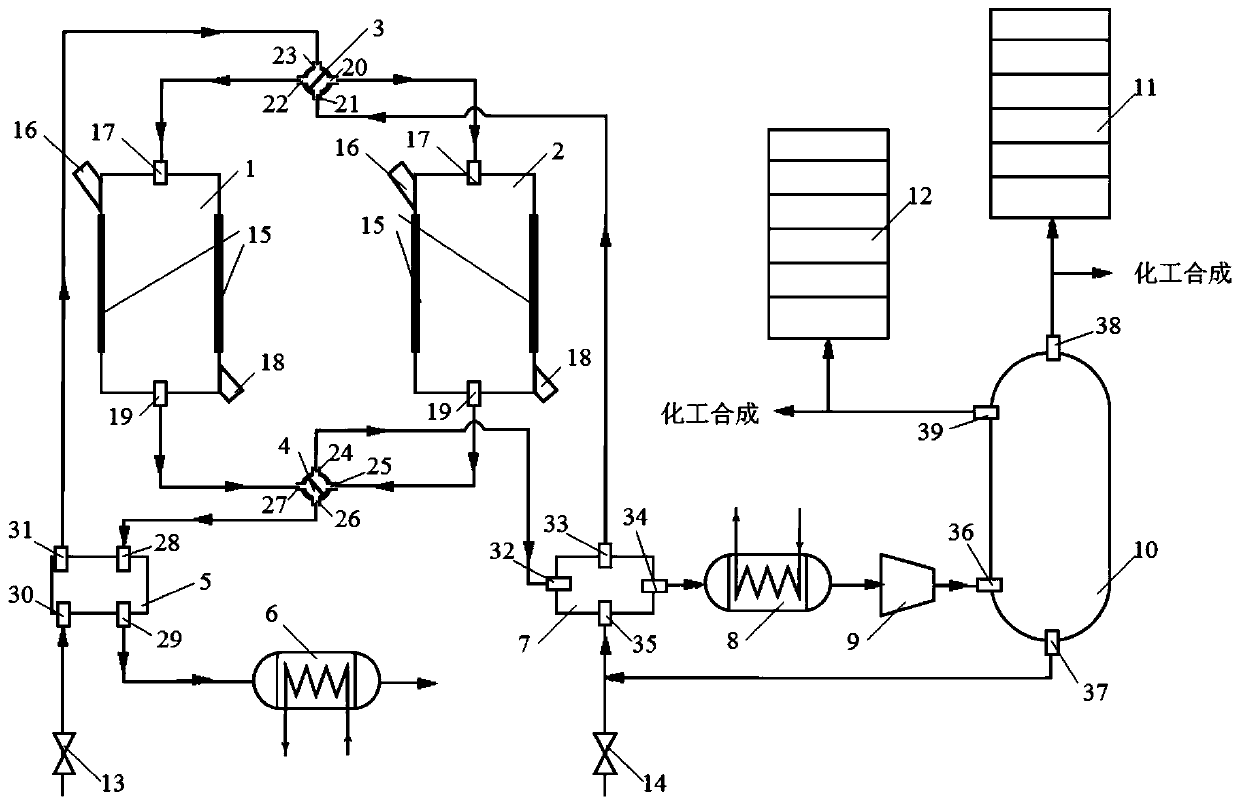

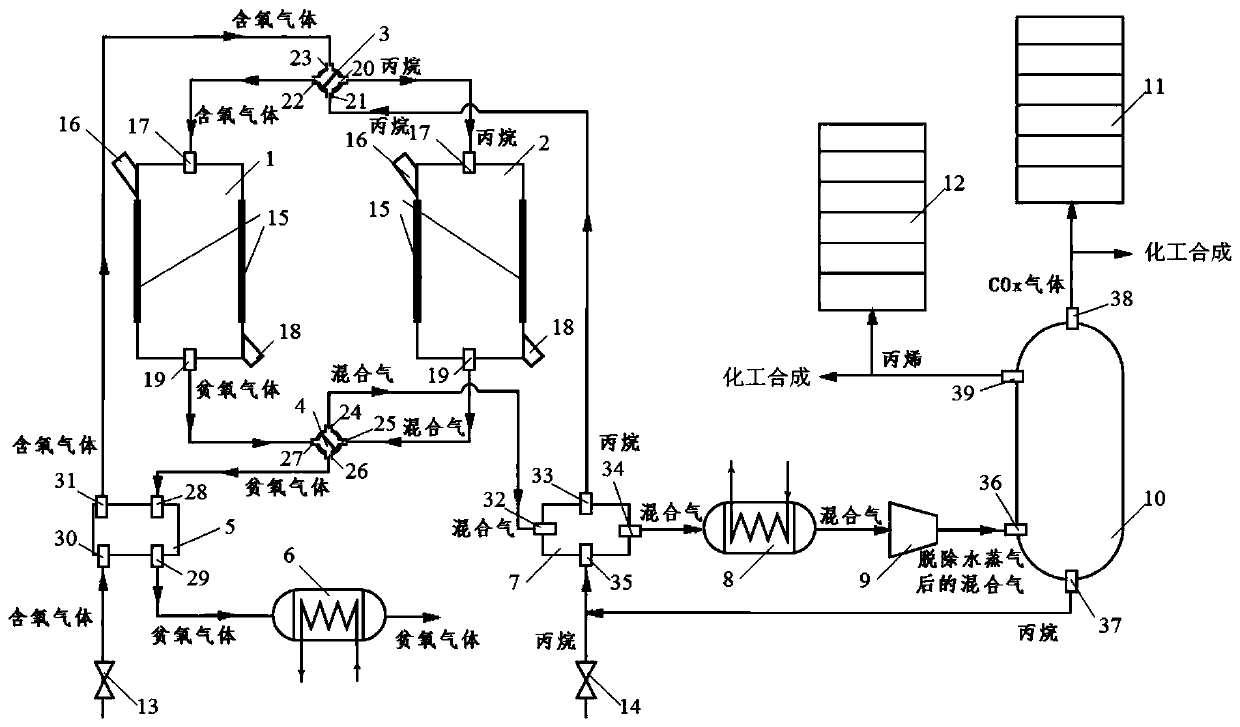

[0033] refer to figure 1 and figure 2 , this embodiment provides a system for producing propylene by oxidative dehydrogenation of chemical chain propane, the system includes a first fixed bed 1, a second fixed bed 2, an inlet reversing valve 3, an outlet reversing valve 4, a mixed gas heat exchange Device 7, mixed gas waste heat boiler 8, mixed gas dehydration equipment 9, mixed gas separation equipment 10, COx gas storage 11, propylene storage 12, oxygen-deficient gas heat exchanger 5, oxygen-depleted gas waste heat boiler 6.

[0034] Oxygen carrier particles can be fixed in the first fixed bed 1 and the second fixed bed 2, and both the first fixed bed 1 and the second fixed bed 2 are connected with the inlet reversing valve 3 and the outlet reversing valve 4, and the inlet reversing valve 3 and the outlet reversing valve 4 are linked so that the first fixed bed 1 and the second fixed bed 2 act as dehydrogenation reactors and oxidation reactors alternately, that is, the fir...

Embodiment 2

[0081] This embodiment provides a method for producing propylene by oxidative dehydrogenation of chemical chain propane. The method adopts the system in Embodiment 1, and the inlet reversing valve 3 and the outlet reversing valve 4 are linked to make the first fixed bed 1 and the second fixed bed 1 The fixed bed 2 acts as the dehydrogenation reactor and the oxidation reactor alternately, that is, the first fixed bed 1 acts as the dehydrogenation reactor and the oxidation reactor alternately, the second fixed bed 2 acts as the dehydrogenation reactor and the oxidation reactor alternately, and at the One fixed bed 1 is used as a dehydrogenation reactor while the second fixed bed 2 is used as an oxidation reactor, and the second fixed bed 2 is used as a dehydrogenation reactor while the first fixed bed 1 is used as an oxidation reactor.

[0082] Among them, in the fixed bed as a dehydrogenation reactor, propane and oxygen carrier particles react at high temperature, and a part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com