Rare-earth modification material and preparation method thereof

A rare earth modification and raw material technology, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of low comprehensive performance of rare earth modified materials and complicated preparation methods, so as to avoid a significant decrease in remanence. , excellent performance, strengthen the effect of demagnetization coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

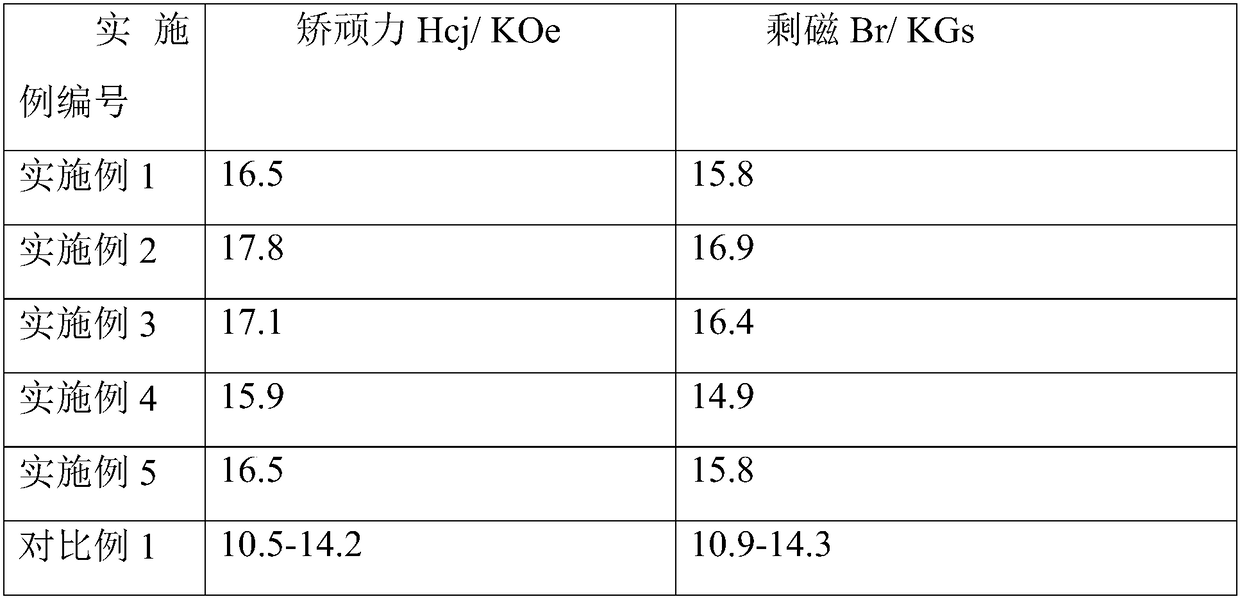

Examples

preparation example Construction

[0017] The invention provides a preparation method of a rare earth modified material, characterized in that the preparation method comprises:

[0018] (1) Preparation of material A: mix the first waste material, Nd, Re, In and Yb after alkali treatment, obtain alloy liquid after smelting, and obtain material A through atomization treatment of alloy liquid; wherein, waste material Raw material components include: C, Mn, Si, S, P and Fe;

[0019] (2) Preparation of material B: Al 2 o 3 , Fe 2 o 3 , CaO, MgO, K 2 O, Na 2 O, Nd 2 o 3 , Yb, Re 2 o 7 and SiO 2 Enter the mixed ingredients, obtain material B after drying, sieving and sintering;

[0020] (3) Preparation of material C: mix the second waste material, Nd, In and Yb treated with lye, and obtain an alloy solution after smelting, and atomize the alloy solution to obtain material C; wherein, the raw material composition of the waste material Including: Pb, Sn, Zn and Cu;

[0021] (4) Preparation of material D: B,...

Embodiment 1

[0050] According to the above preparation method, wherein, material A includes the following raw materials in weight percentage: C 0.09%, Mn 0.25%, Si 0.1%, S 0.02%, P 0.015%, Nd 0.05%, Re 0.01%, In 0.01% , Yb 0.05% and balance Fe; Material B includes raw materials in the following weight percentages: Al 2 o 3 20%, Fe 2 o 3 1%, CaO 0.5%, MgO 2%, K 2 O1%, Na 2 O 0.1%, Nd 2 o 3 0.1%, Yb 2 o 3 0.1%, Re2O7 0.001% and balance SiO2; material C includes the following raw materials in weight percentage: Pb 1.5%, Sn 3%, Zn 3%, Nd 0.04%, Yb 0.05%, In 0.01% and balance Cu; material D Including raw materials in the following weight percentages: B 4.5%, Nd 24%, Re 0.3%, In 0.8%, Yb 0.05%, S0.8% and the balance Fe; material A, material B, material C and material D according to the mass ratio Mix in a ratio of 0.03:0.006:0.01:1.

Embodiment 2

[0052] According to the above preparation method, wherein, material A includes the following raw materials in weight percentage: C 0.11%, Mn 0.45%, Si 0.2%, S 0.04%, P 0.035%, Nd 0.07%, Re 0.03%, In 0.02% , Yb 0.07% and balance Fe; Material B includes the following raw materials in weight percentage: Al 2 o 3 22%, Fe 2 o 3 2%, CaO 0.9%, MgO 3%, K 2 O2%, Na 2 O 0.3%, Nd 2 o 3 0.3%, Yb 2 o 3 0.3%, Re2O7 0.003% and balance SiO2; material C includes the following raw materials in weight percentage: Pb 2.5%, Sn 4%, Zn 4%, Nd 0.06%, Yb 0.07%, In 0.02% and balance Cu; material D Including raw materials in the following weight percentages: B 5%, Nd 26%, Re 0.4%, In 1.1%, Yb 0.079%, S0.9% and the balance Fe; material A, material B, material C and material D according to the mass ratio Mixed at a ratio of 0.04:0.009:0.02:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com