Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about How to "Efficient cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

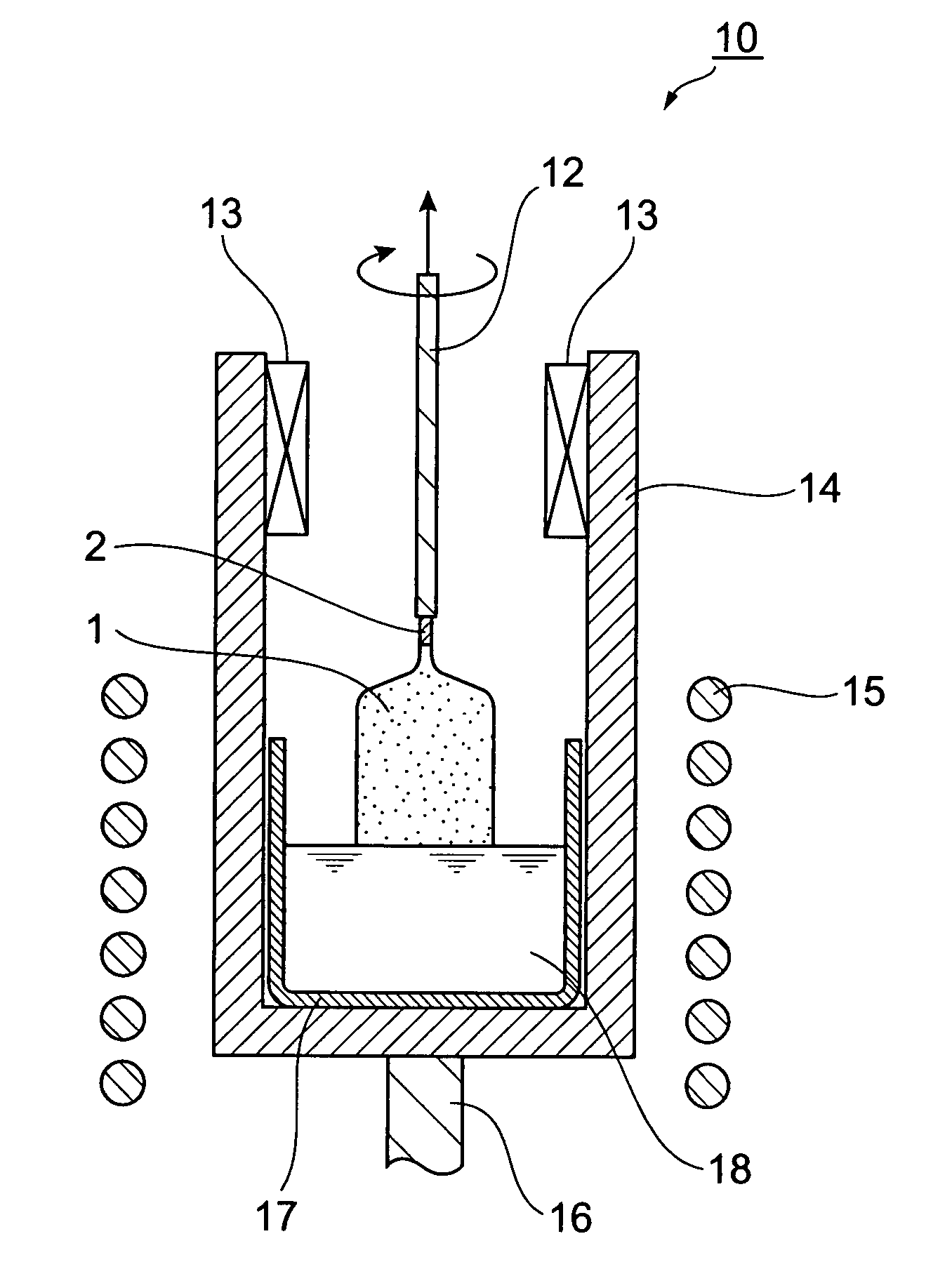

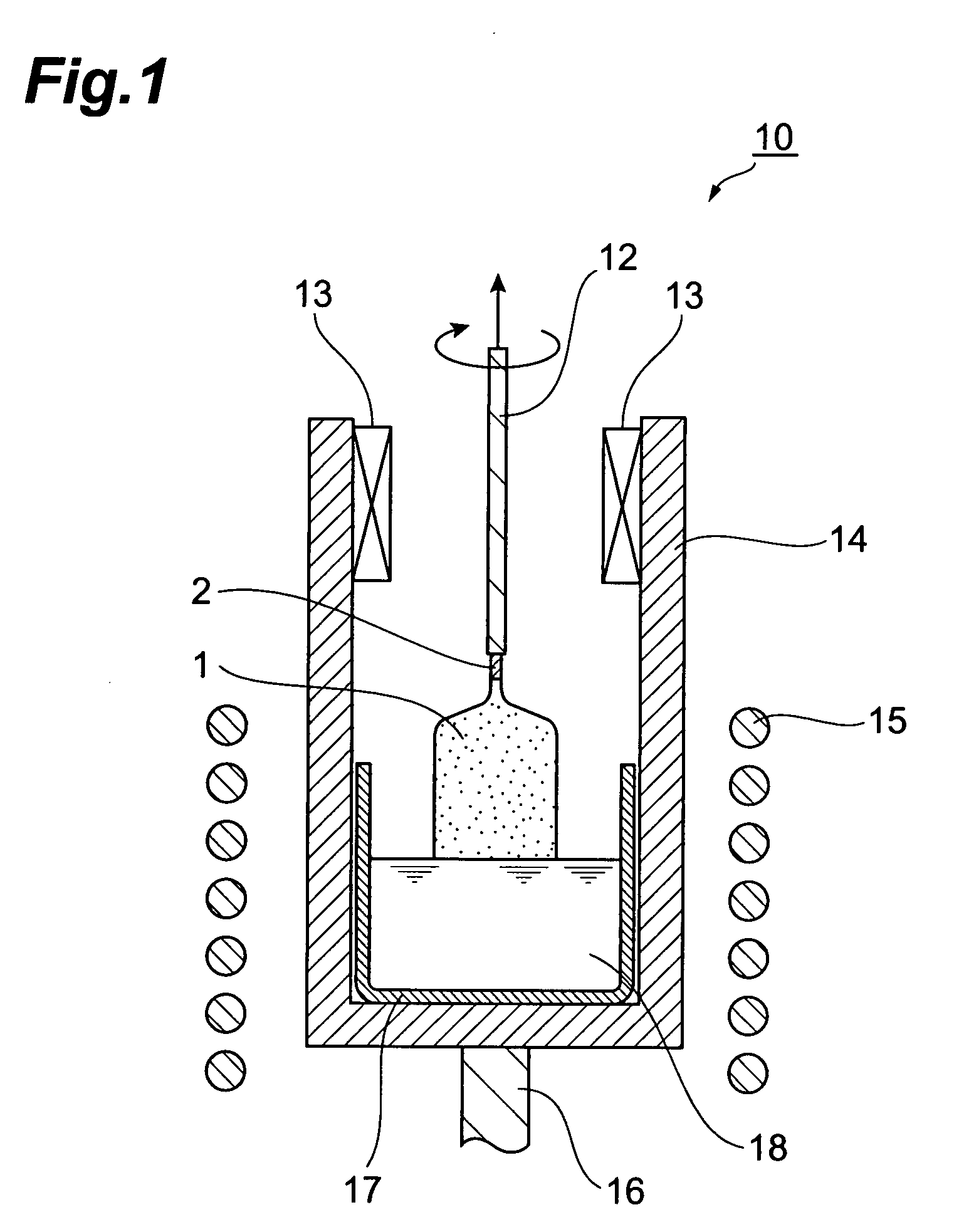

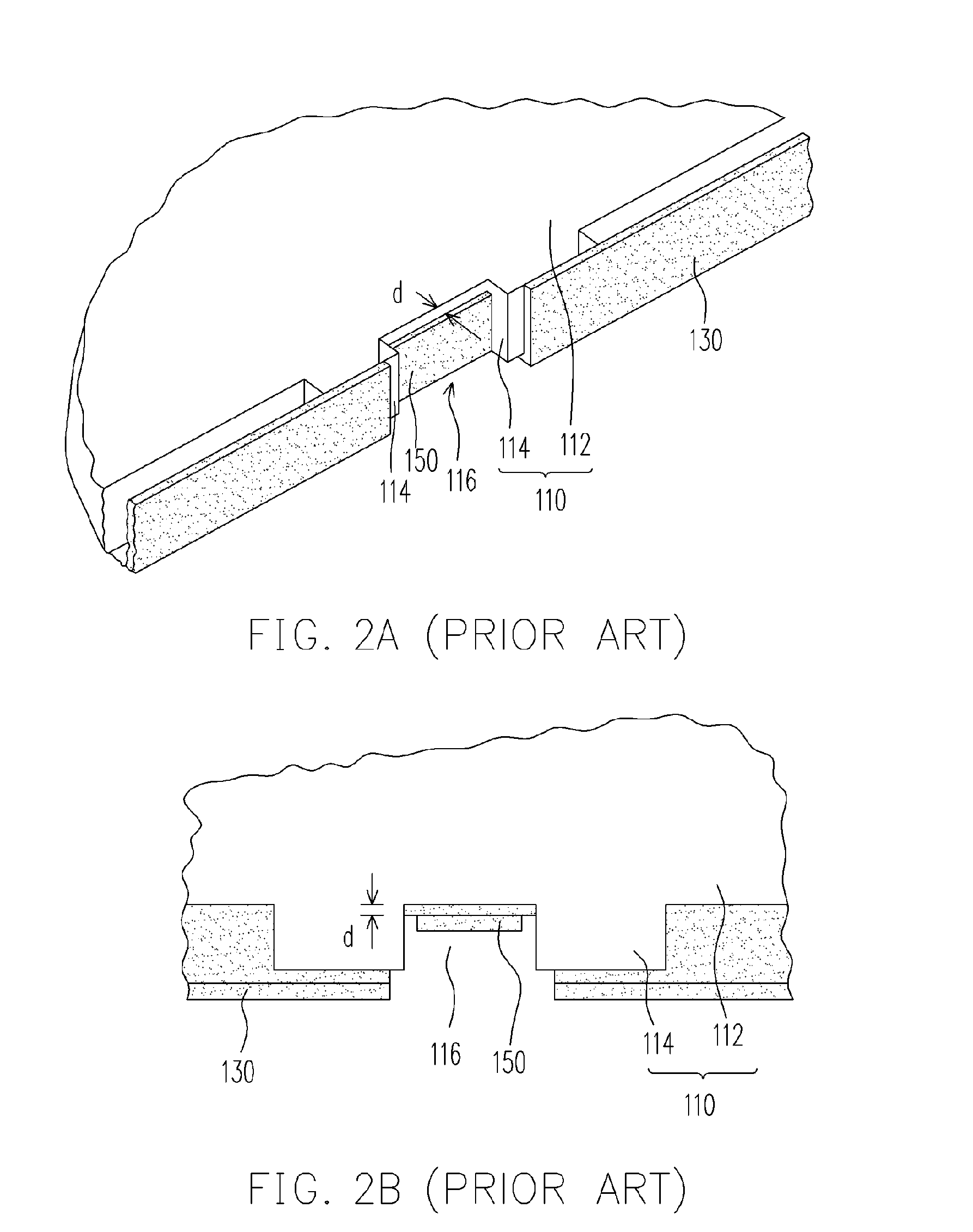

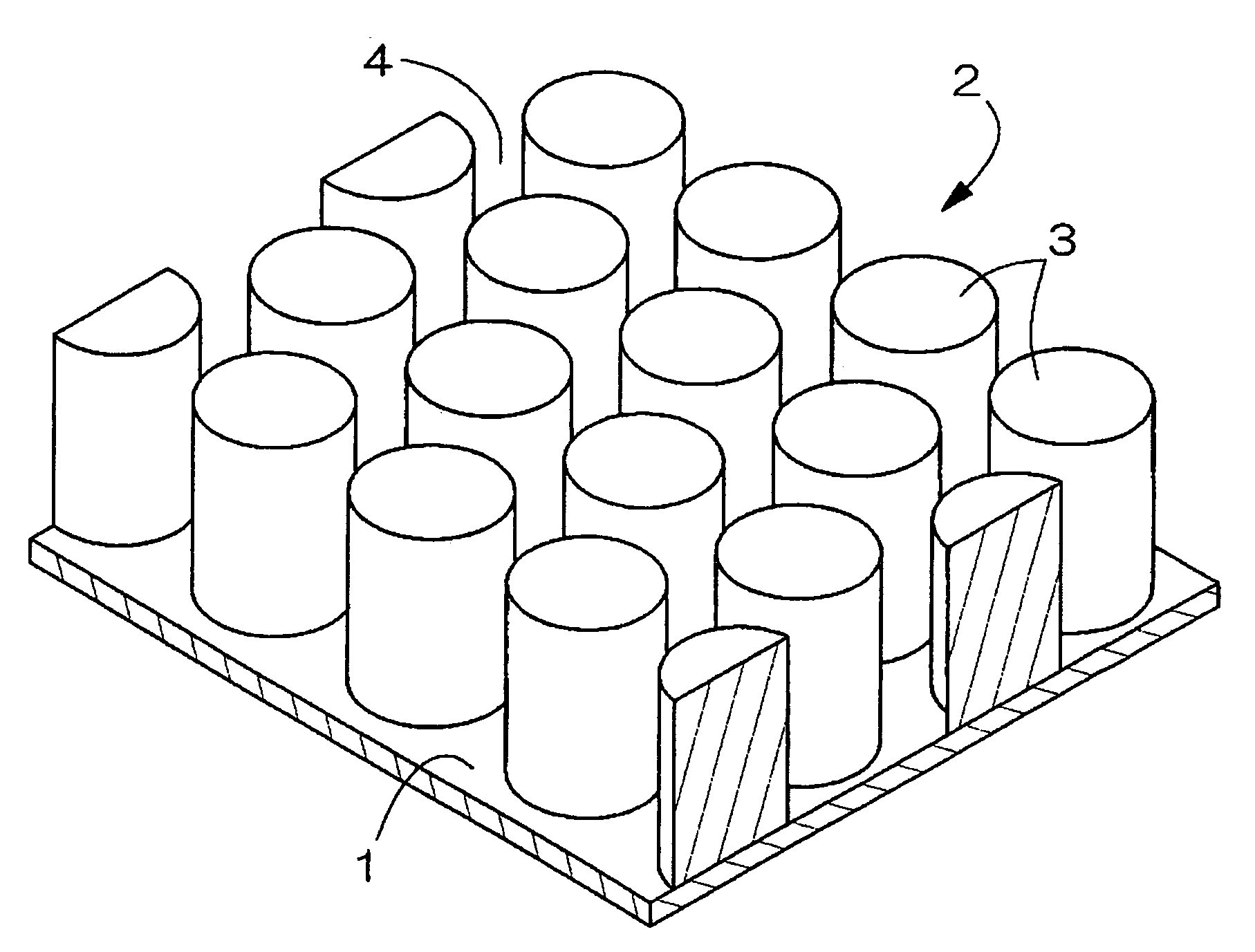

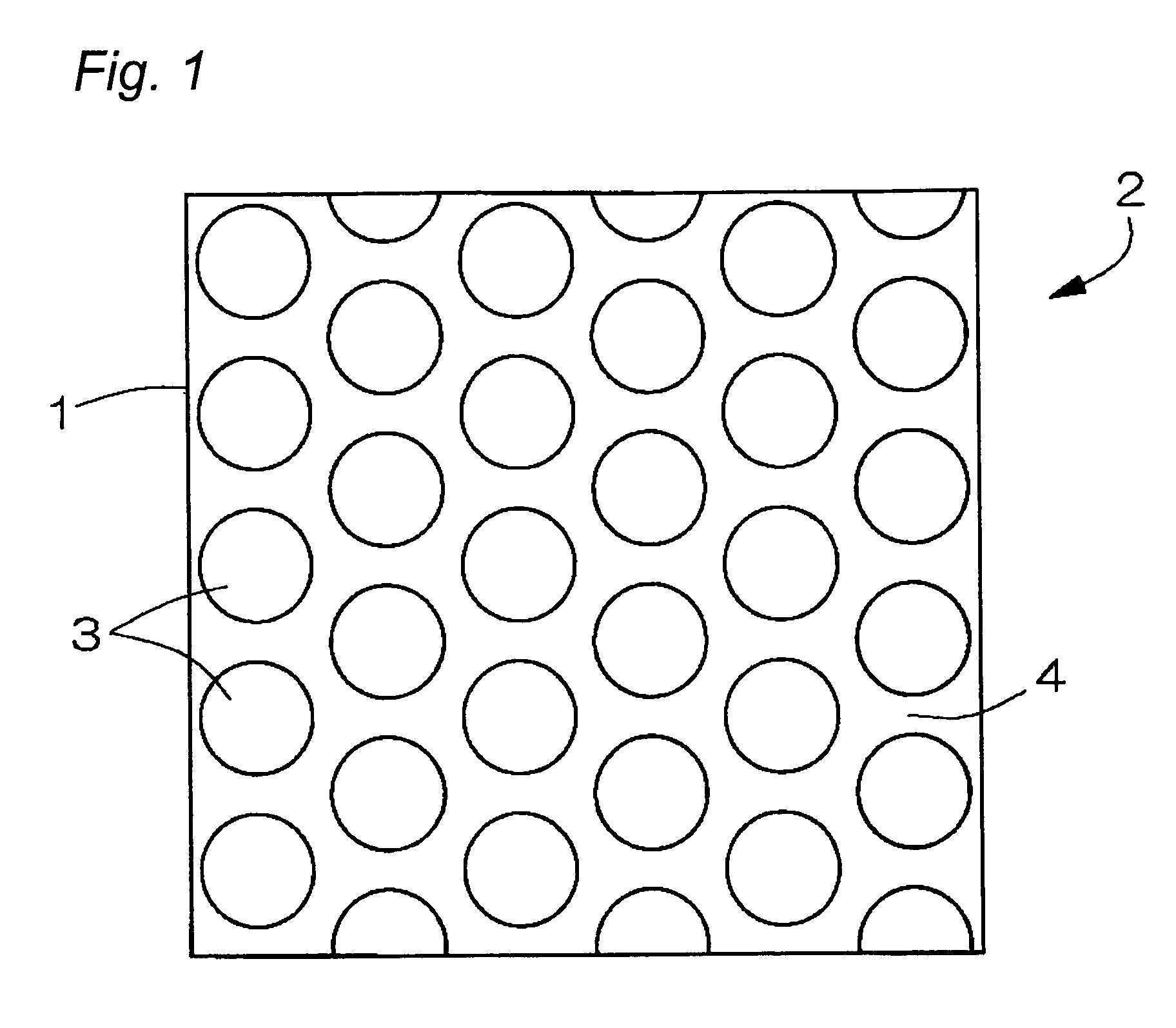

Electrode used for a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery using the same for a negative electrode

InactiveUS20050074671A1Increase capacityInsufficient releaseElectrode carriers/collectorsLi-accumulatorsPorosityMetallic materials

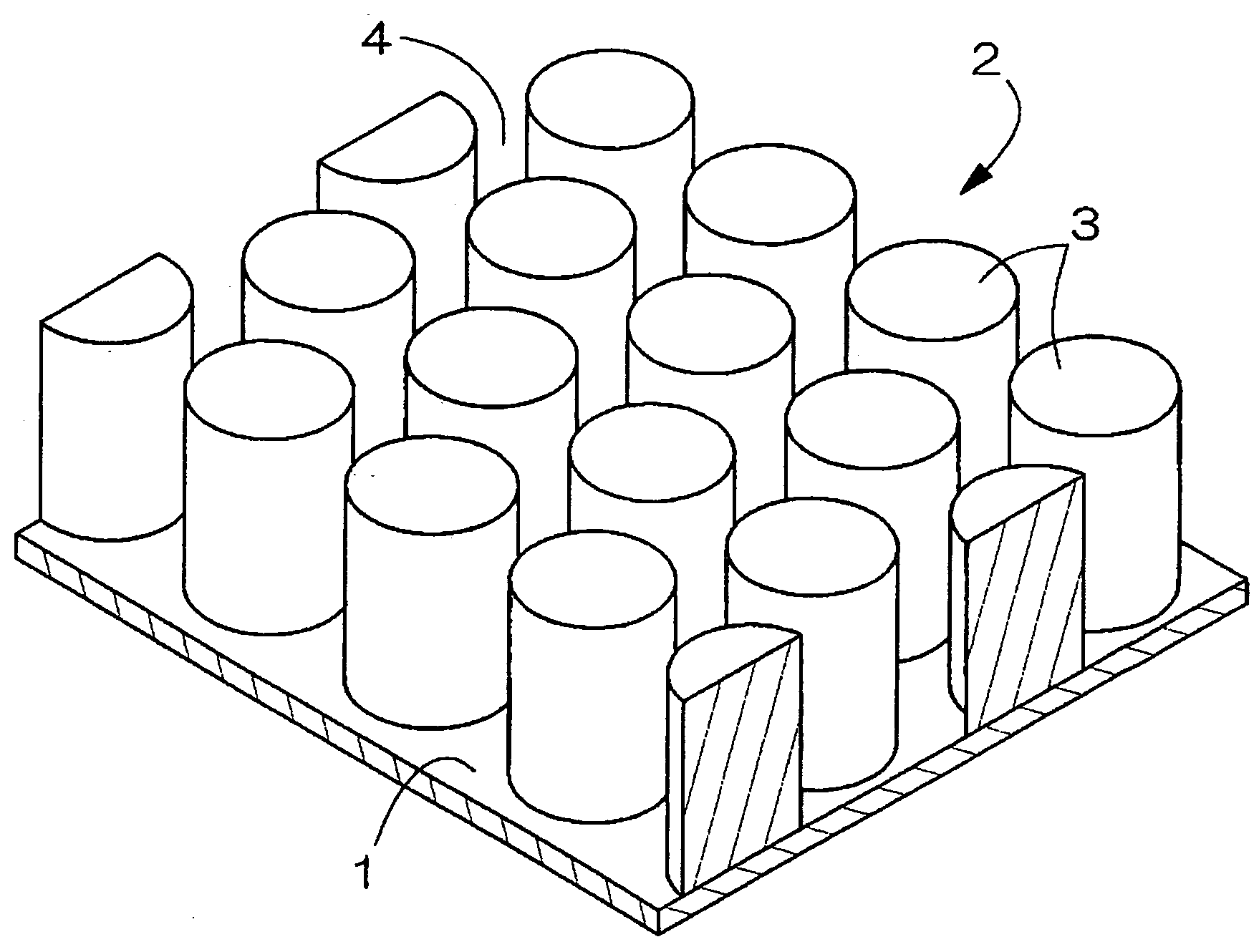

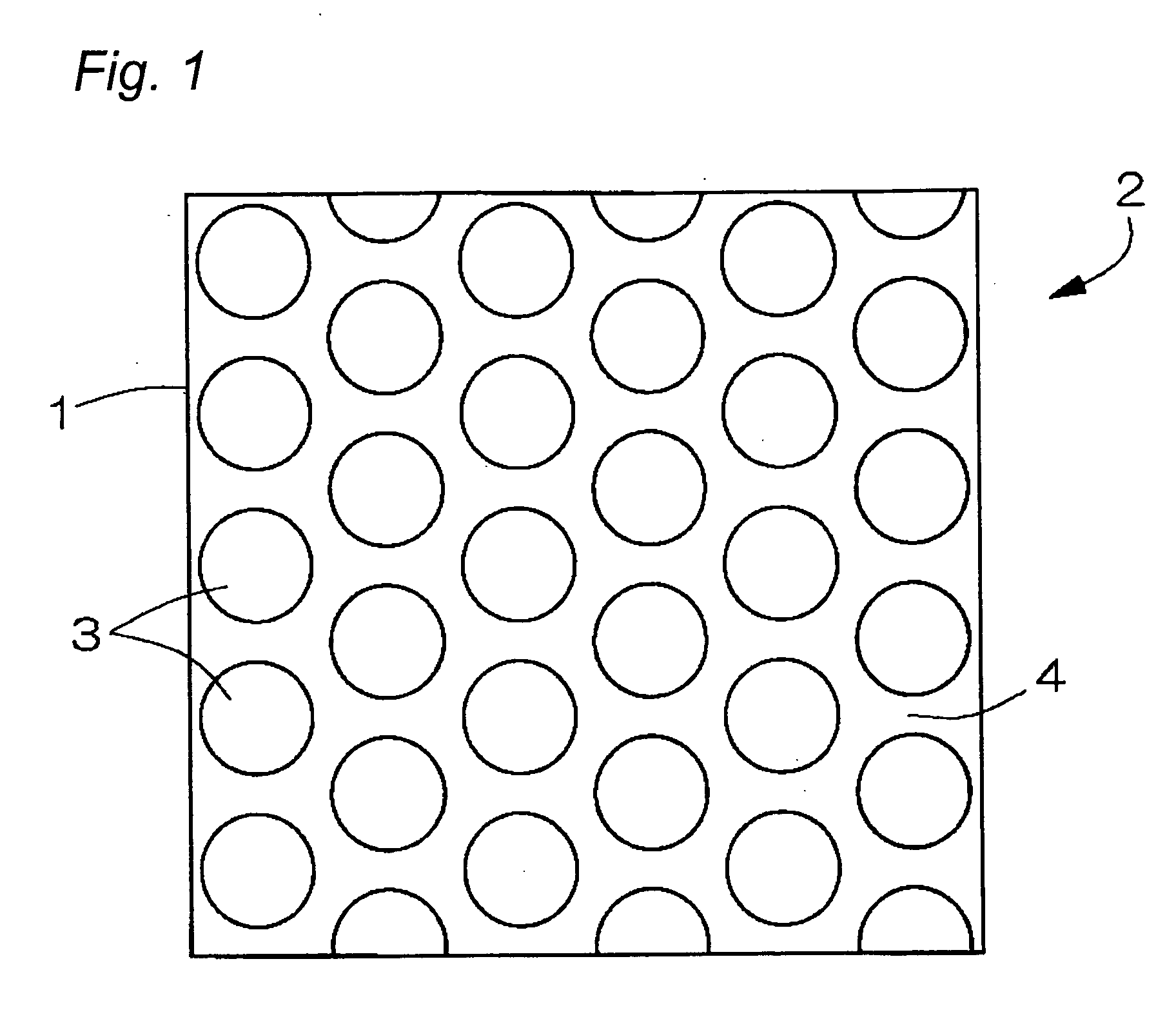

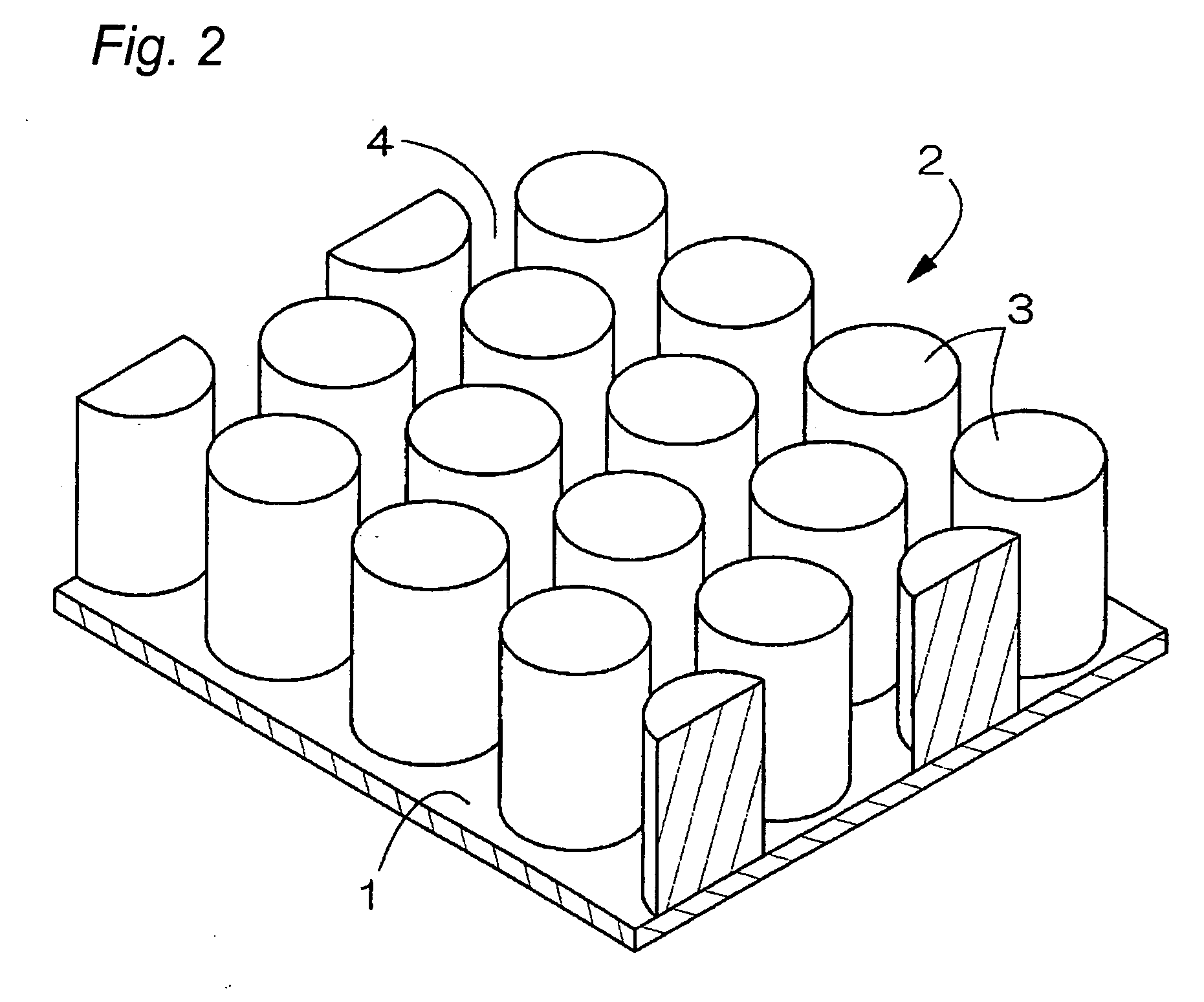

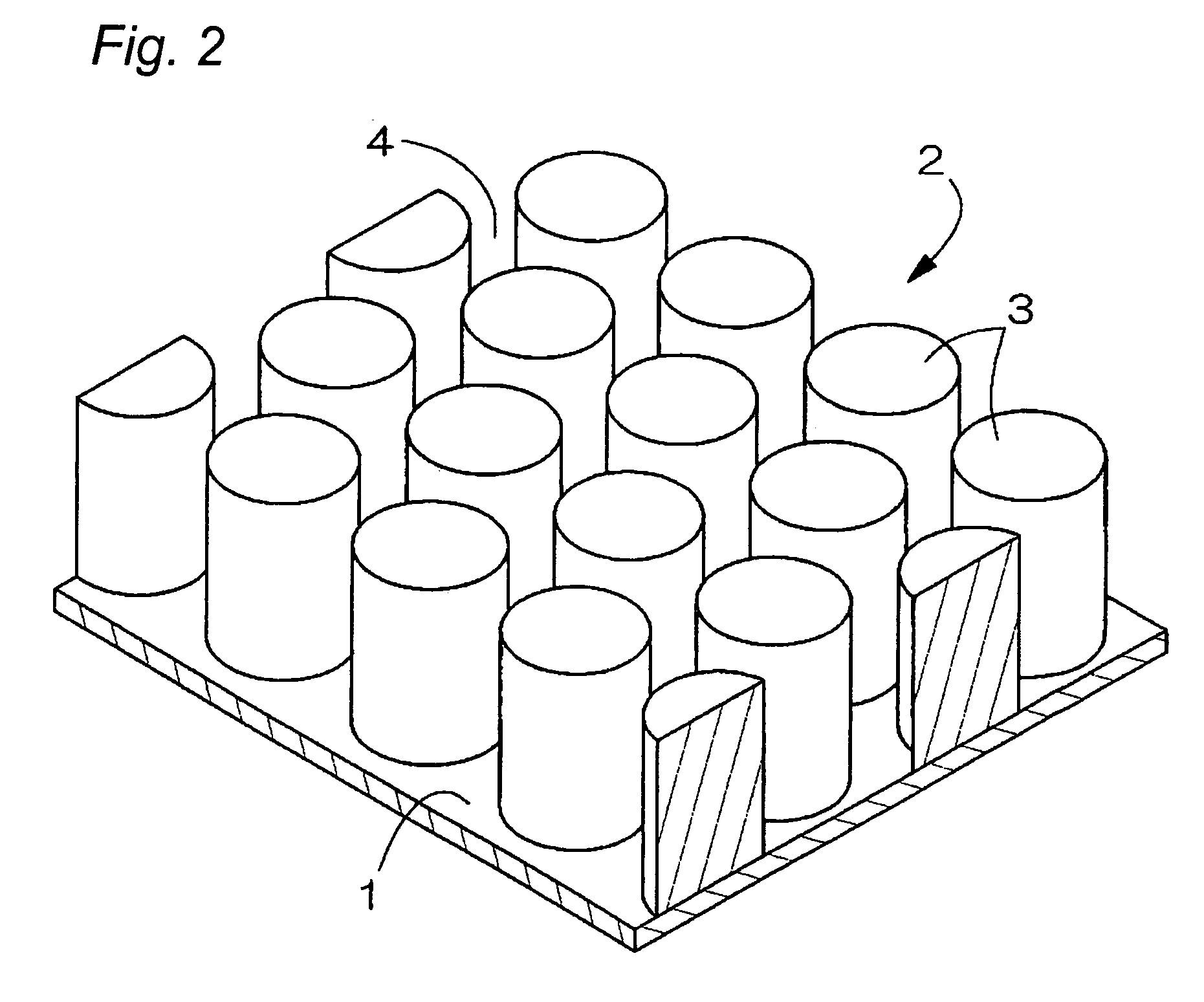

An electrode according to the invention can provide a non-aqueous electrolyte secondary battery having an ability to release a volume expansion at the time of charge and discharge as well as the time of a cycle. The electrode comprises a current collector made of a material which is not alloyed with Li, and a dot pattern 2 of a metallic material able to be alloyed with Li formed on the current collector. At the time of charge, since the volume expansion of each dot 3 is carried out so as to bury adjoining crevices 4 between the dots, a stress generated is released, thereby degradation of an electrode being avoided. Each dot may also be made into porosity.

Owner:HITACHI MAXELL ENERGY LTD

Two-step hydroprocessing method for heavy hydrocarbon oil

ActiveUS20060011510A1Reduce the presence of impuritiesGreat degree of desulfurizationCatalyst activation/preparationHydrocarbon oil crackingHydrogenSulfur

A method is disclosed for hydroprocessing a heavy hydrocarbon oil, comprising a first hydroprocessing step of bringing a heavy hydrocarbon oil into contact with a Catalyst (1) with a certain specific surface area and pore size distribution in the presence of hydrogen in a first reaction zone containing the Catalyst (1), and a second hydroprocessing step of bringing the hydroprocessed oil obtained from the first reaction zone into contact with a Catalyst (2) with a certain specific surface area and pore size distribution in the presence of hydrogen in a second reaction zone containing the Catalyst (2). The method is an improvement in decreasing or inhibiting the sediment formation, while highly hydroprocessing a heavy hydrocarbon oil containing a large amount of impurities such as sulfur, micro carbon residue (MCR), metals, nitrogen and asphaltene, especially a heavy oil containing a large amount of heavy vacuum residue, to adequately remove the impurities.

Owner:EXXON RES & ENG CO

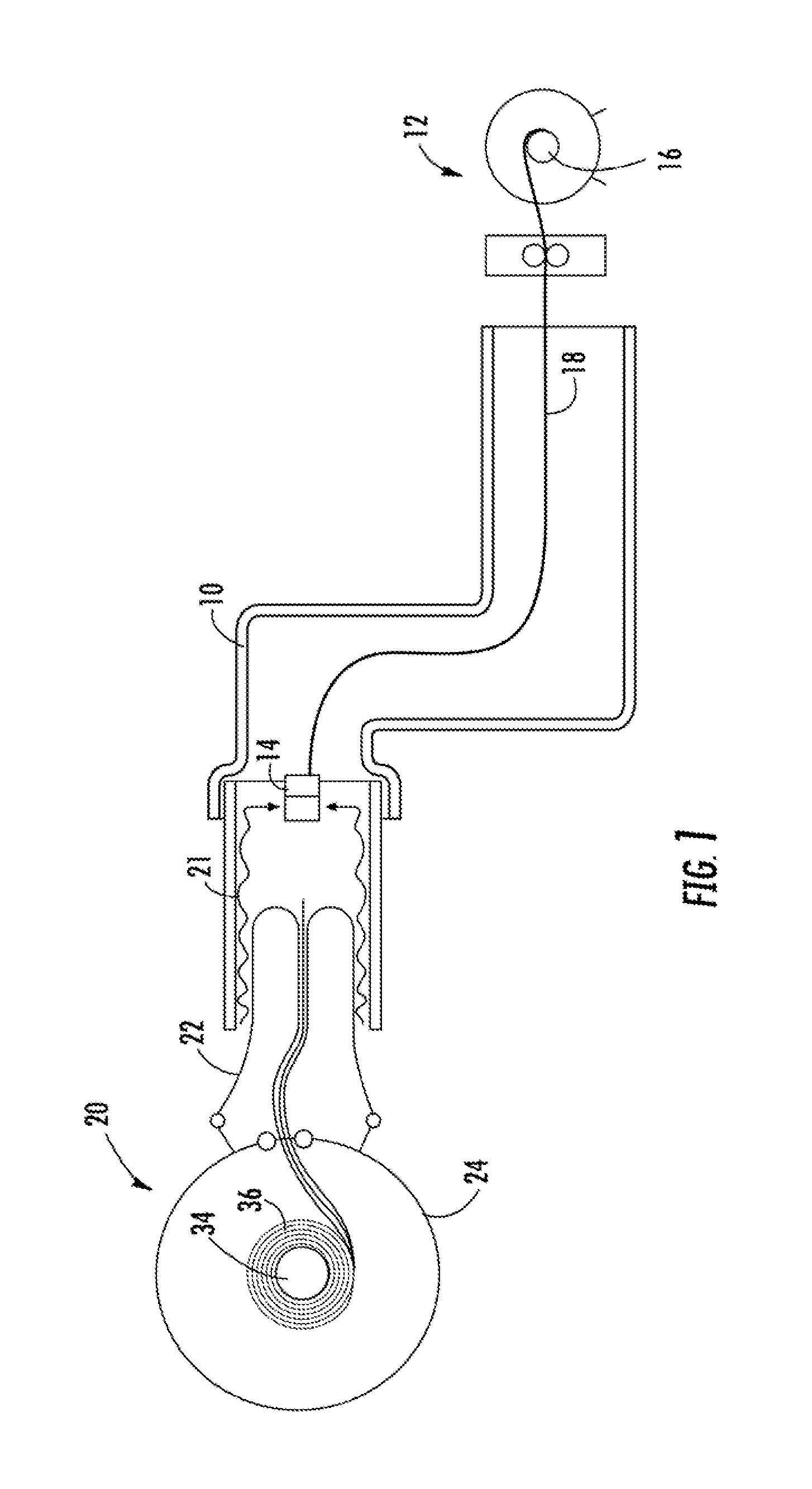

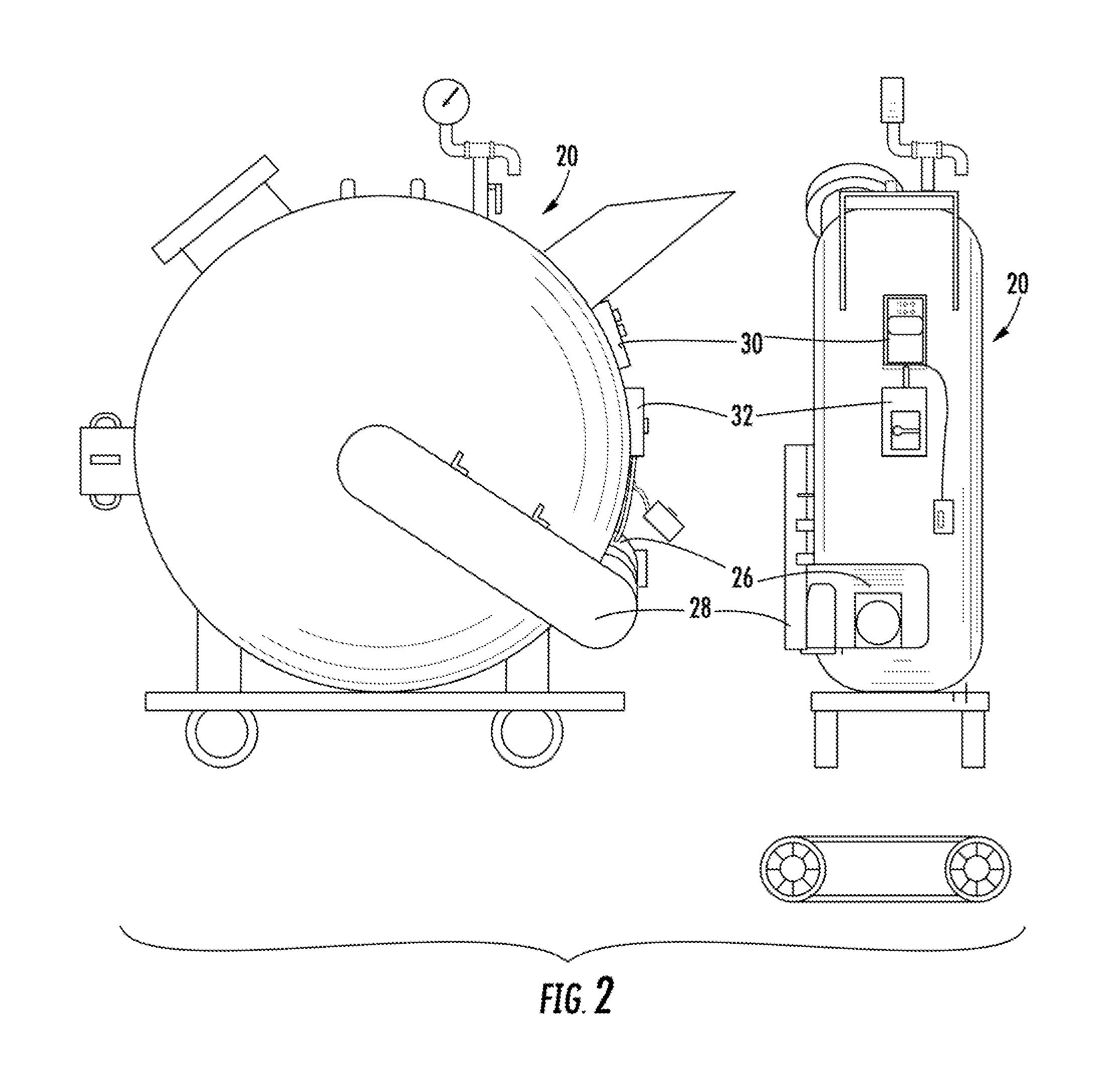

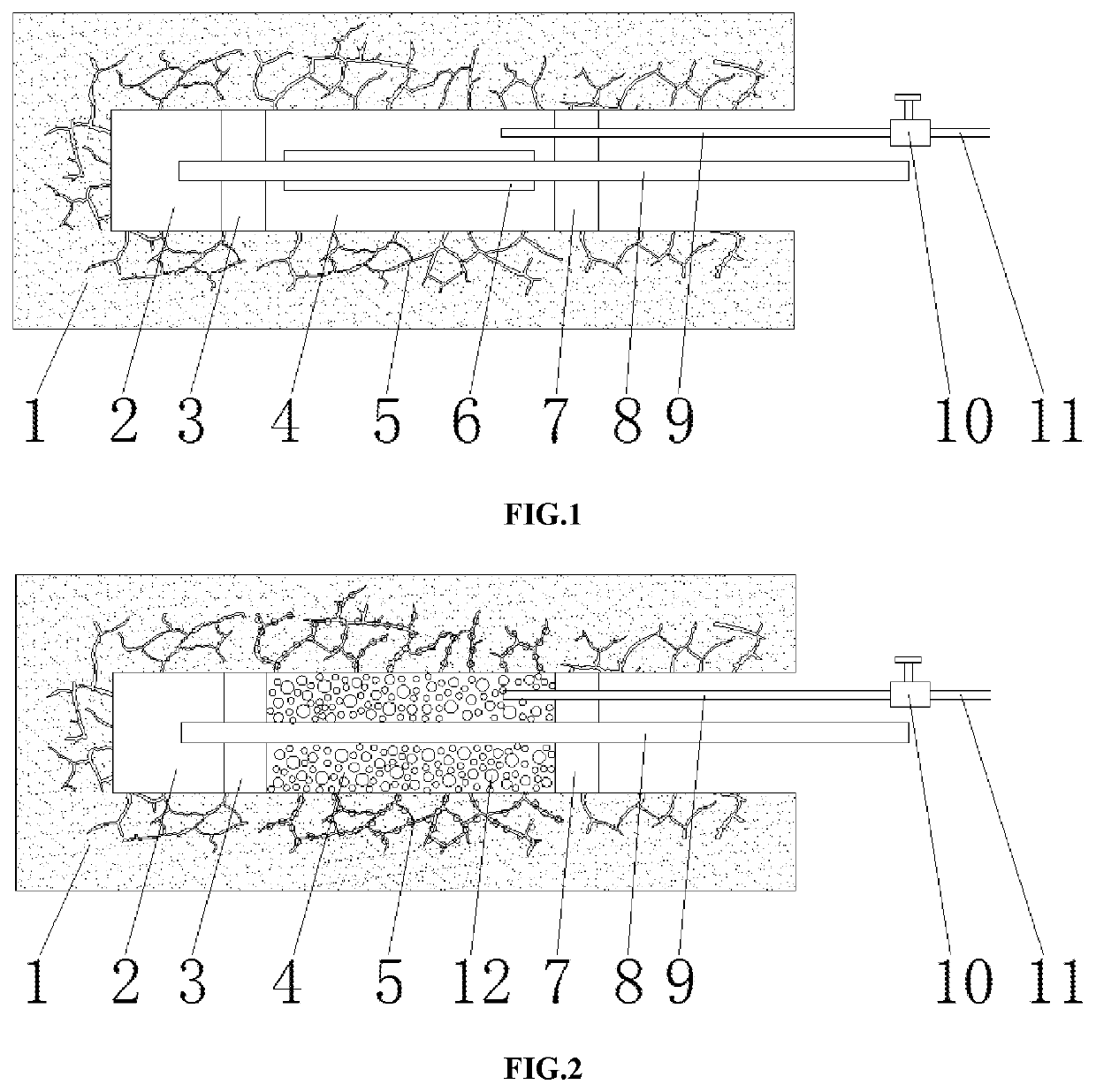

Pressure infusion lining system

InactiveUS20150020908A1Strong stickinessEffectively seal all crackDomestic sealsLayered productsInternal pressureEpoxy

A method and system for applying a liner to an underground utility structure is provided. First a layer of epoxy is applied to the interior surface of the host pipe using a machine such as a spincast machine. A dry liner is inverted into the pipe directly behind the coating application at a limited speed and pressure. A drag is set on the inversion equipment relative to the speed of the epoxy spinner unit to control inversion speed. Once the liner is completely inverted the internal pressure of the liner is raised and infused into the uncured epoxy.

Owner:WARREN ENVIRONMENTAL & COATING LLC

Two-step hydroprocessing method for heavy hydrocarbon oil

ActiveUS7491313B2Reduce the presence of impuritiesGreat degreeCatalyst activation/preparationHydrocarbon oil crackingPtru catalystPhysical chemistry

A method is disclosed for hydroprocessing a heavy hydrocarbon oil, comprising a first hydroprocessing step of bringing a heavy hydrocarbon oil into contact with a Catalyst (1) with a certain specific surface area and pore size distribution in the presence of hydrogen in a first reaction zone containing the Catalyst (1), and a second hydroprocessing step of bringing the hydroprocessed oil obtained from the first reaction zone into contact with a Catalyst (2) with a certain specific surface area and pore size distribution in the presence of hydrogen in a second reaction zone containing the Catalyst (2). The method is an improvement in decreasing or inhibiting the sediment formation, while highly hydroprocessing a heavy hydrocarbon oil containing a large amount of impurities such as sulfur, micro carbon residue (MCR), metals, nitrogen and asphaltene, especially a heavy oil containing a large amount of heavy vacuum residue, to adequately remove the impurities.

Owner:EXXON RES & ENG CO

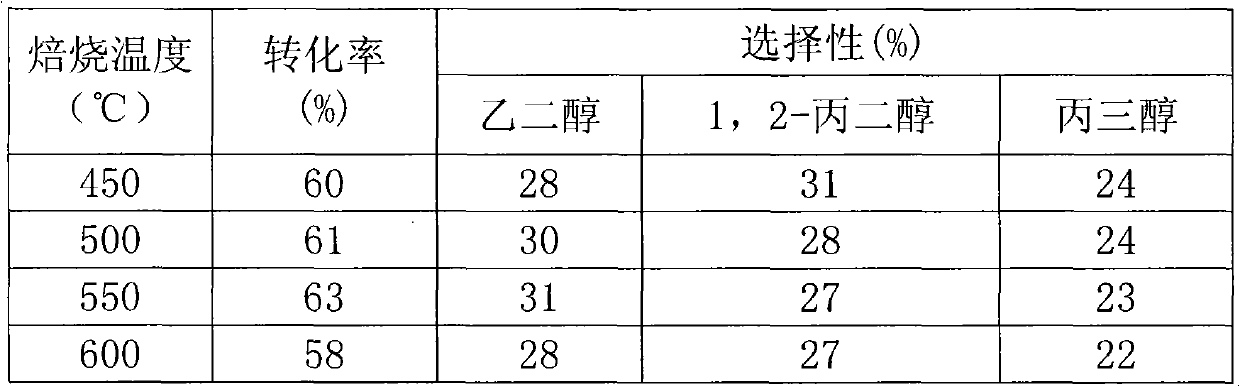

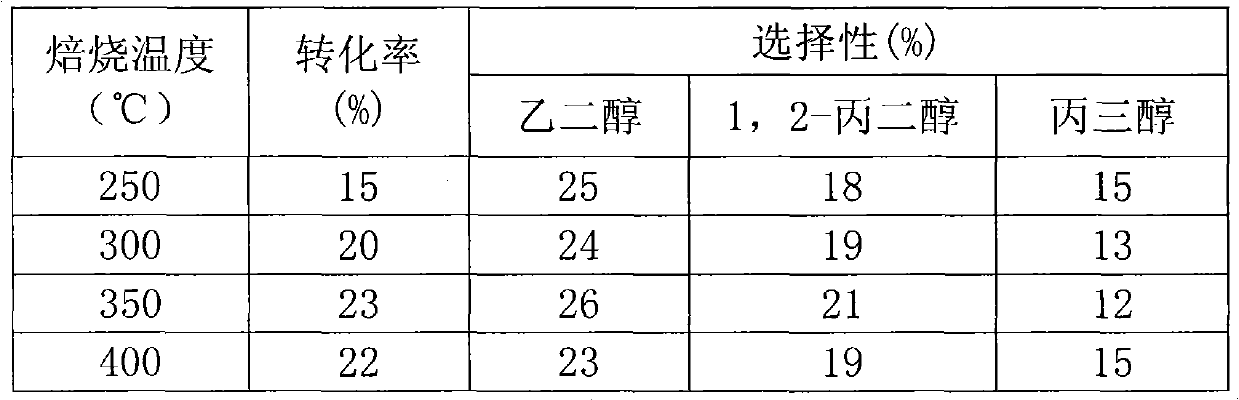

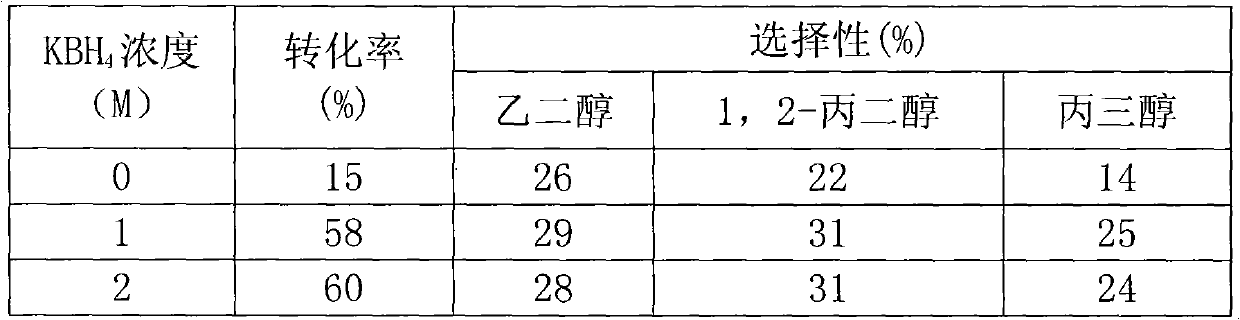

Supported catalyst and application thereof in hydrocracking reaction of xylitol

ActiveCN102019185AEfficient crackingEfficient hydrocrackingOrganic compound preparationHydroxy compound preparationGlycerolBULK ACTIVE INGREDIENT

The invention relates to a catalyst for hydrocracking of xylitol, in particular to a supported catalyst and application thereof in hydrocracking reaction of xylitol. A non precious metal Ni is used as a hydrogenation active ingredient; an aid is one or more of Ru, Pd, Pt, Mo, Sn, Mg, Zn, Ce, Cu, Al and Zr; a carrier is active carbon; and a preparation method comprises the following steps of: supporting aqueous solution of soluble metal salt on the active carbon carrier; performing carbothermic reduction by roasting a metal salt precursor supported on the active carbon carrier at high temperature of between 450 and 650 DEG C to obtain a metal catalyst; and treating the metal catalyst for 1 to 4 hours by using 1-2mol / L KBH4 solution. Under the action of the catalyst, the xylitol is efficiently hydrocracked to form glycol, 1,2-propylene glycol and glycerol, the conversion rate is over 80 percent, and the total selectivity is over 90 percent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

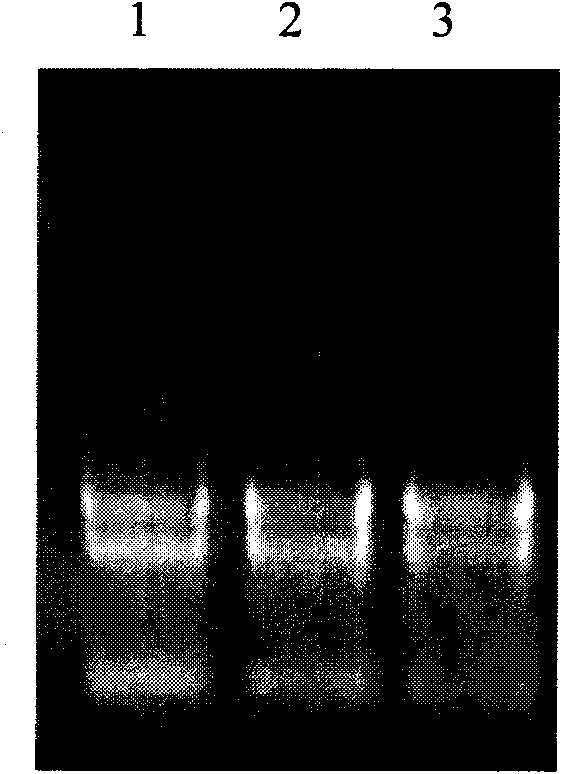

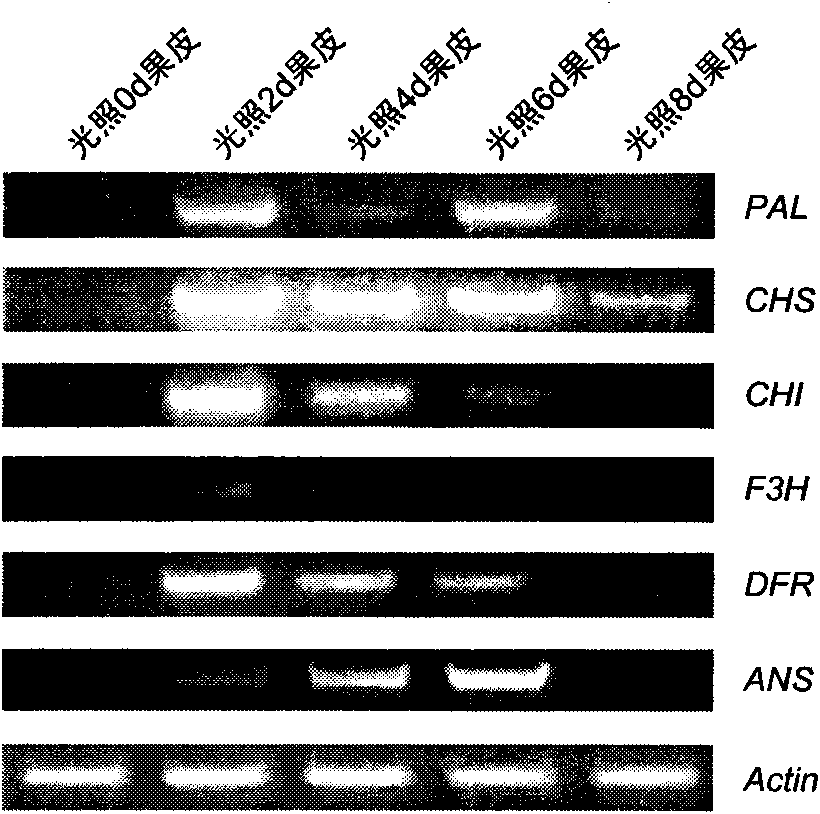

Method for extracting total RNA from plant tissue rich in polysaccharides and polyphenols and secondary metabolites

InactiveCN101638651AQuality improvementEfficient crackingSugar derivativesDNA preparationGuanidine isothiocyanateIsothiocyanate

The invention provides an extration method of plant RNA by utilizing guanidinium isothiocyanate-chloroform extractive and Tris purification. The invention improves traditional guanidinium isothiocyanate method, adopts the two steps of chloroform extration after cracking and phenol-adding for purification, and respectively extract high-quality total RNA from the leaf blade and seed case of red-skinned pears, the leaf blade, fruit flesh and seed case tissues of grapes, the fruit of strawberries and the callus of arnebia euchroma. The extraction buffer liquid in the method contains guanidinium isothiocyanate, sodium dodecyl sarcosinate, sodium citrate, soluble polyvinylpyrrolidone and beta-mercaptoethanol, which can not only crack plant cells efficiently and release RNA, but also effectivelyinhibit the activity of RNA enzyme, and can also prevent the oxidation of phenolic compounds and suppress the interference of secondary metabolites. In the second step, Tris purification is utilized for crude extraction of RNA solution, which can eliminate the polysaccharides and protein which can coprecipitate with RNA. The invention is simple in operating steps, economic and practical, good in stability, and suitable for extracting high-quality total RNA from plant tissue rich in polysaccharides and polyphenols and secondary metabolites.

Owner:KUNMING UNIV OF SCI & TECH

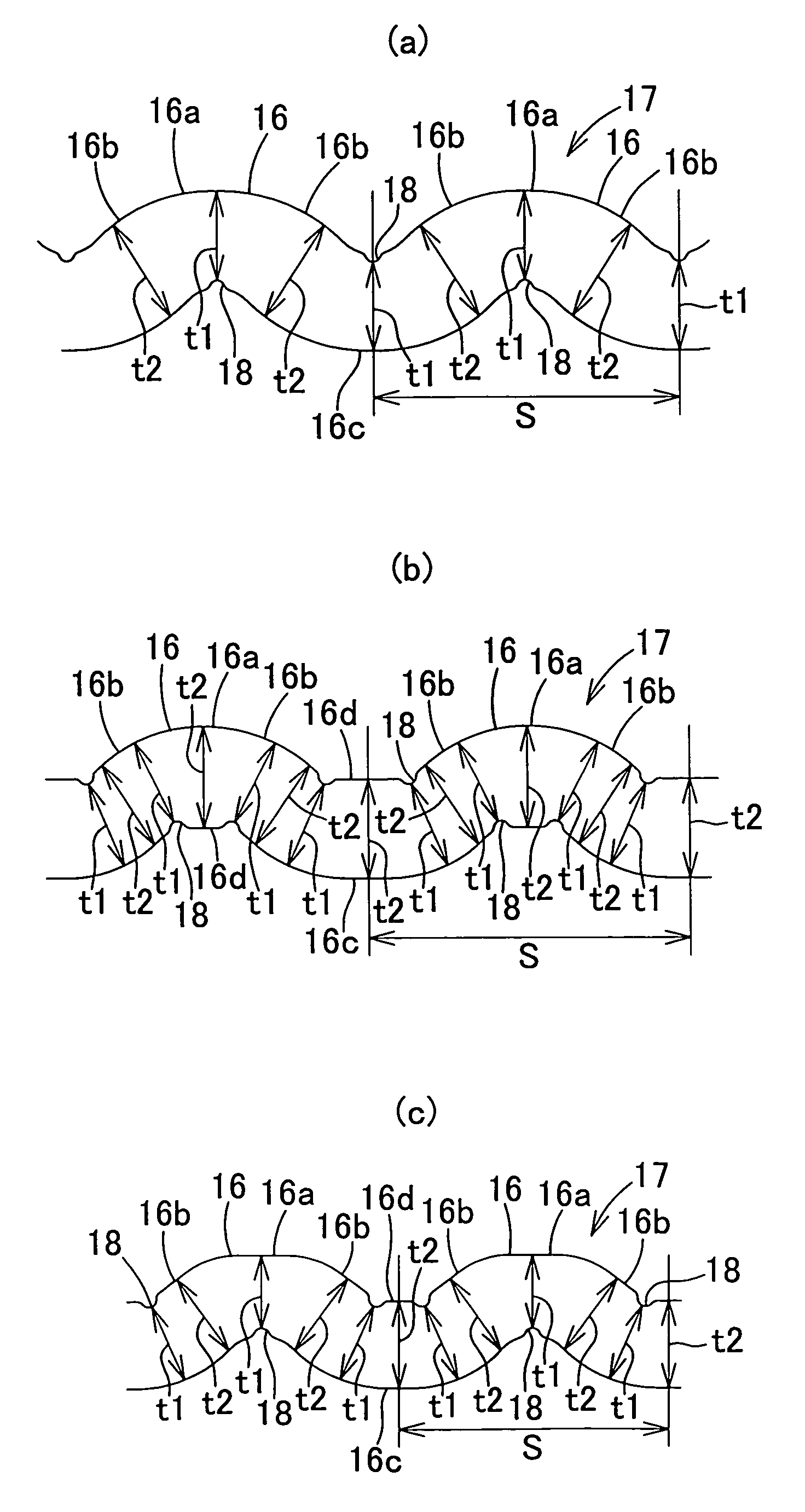

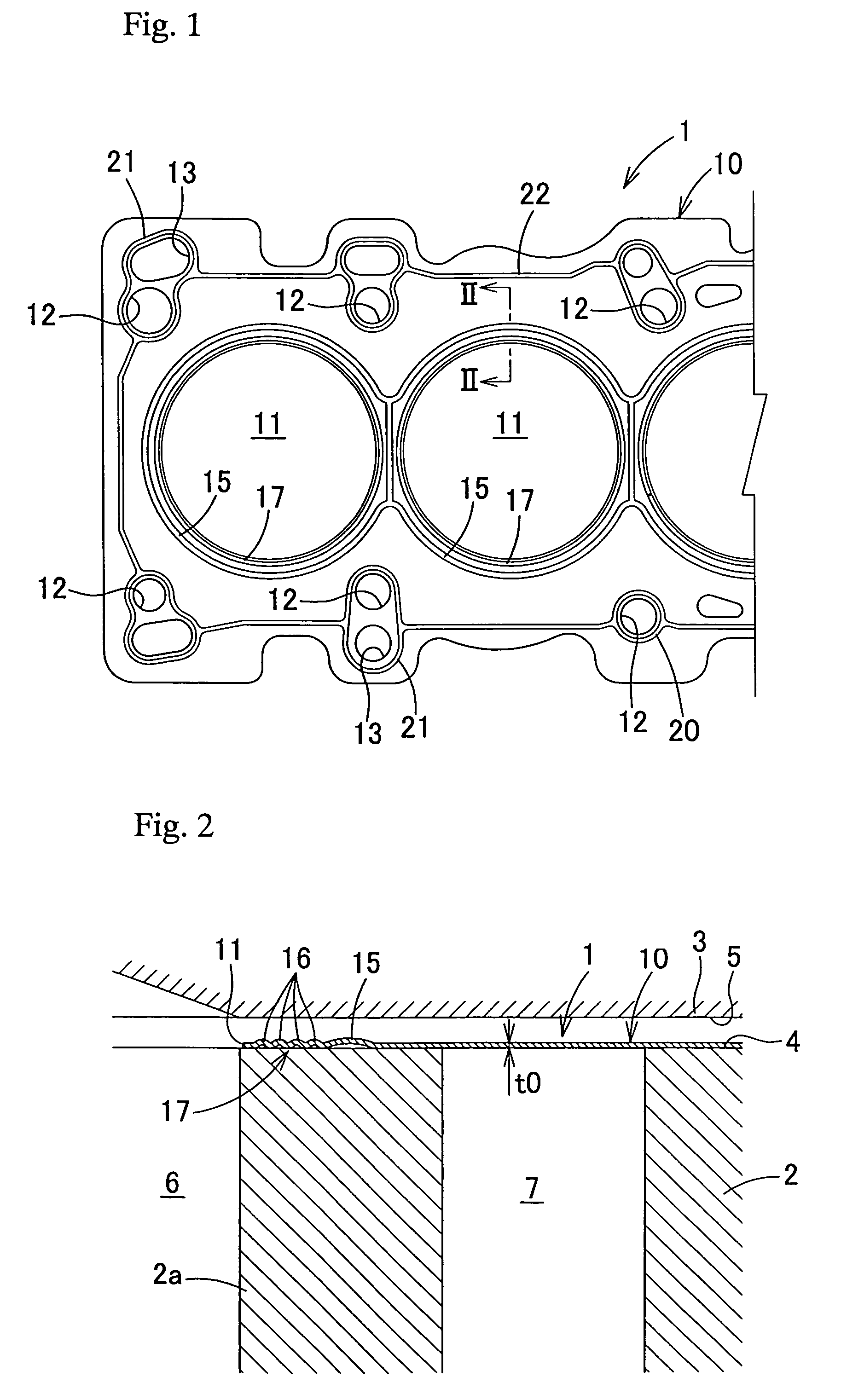

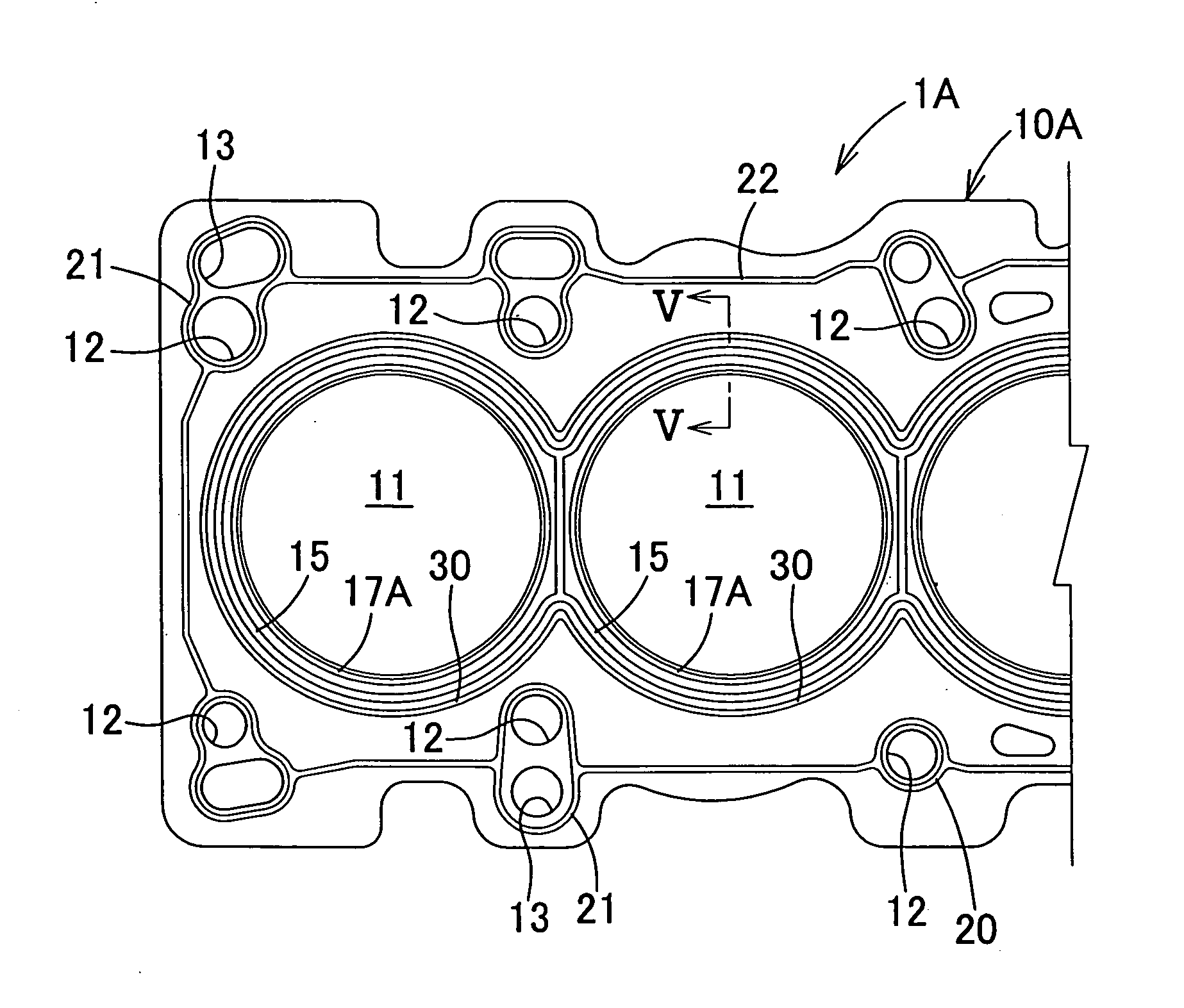

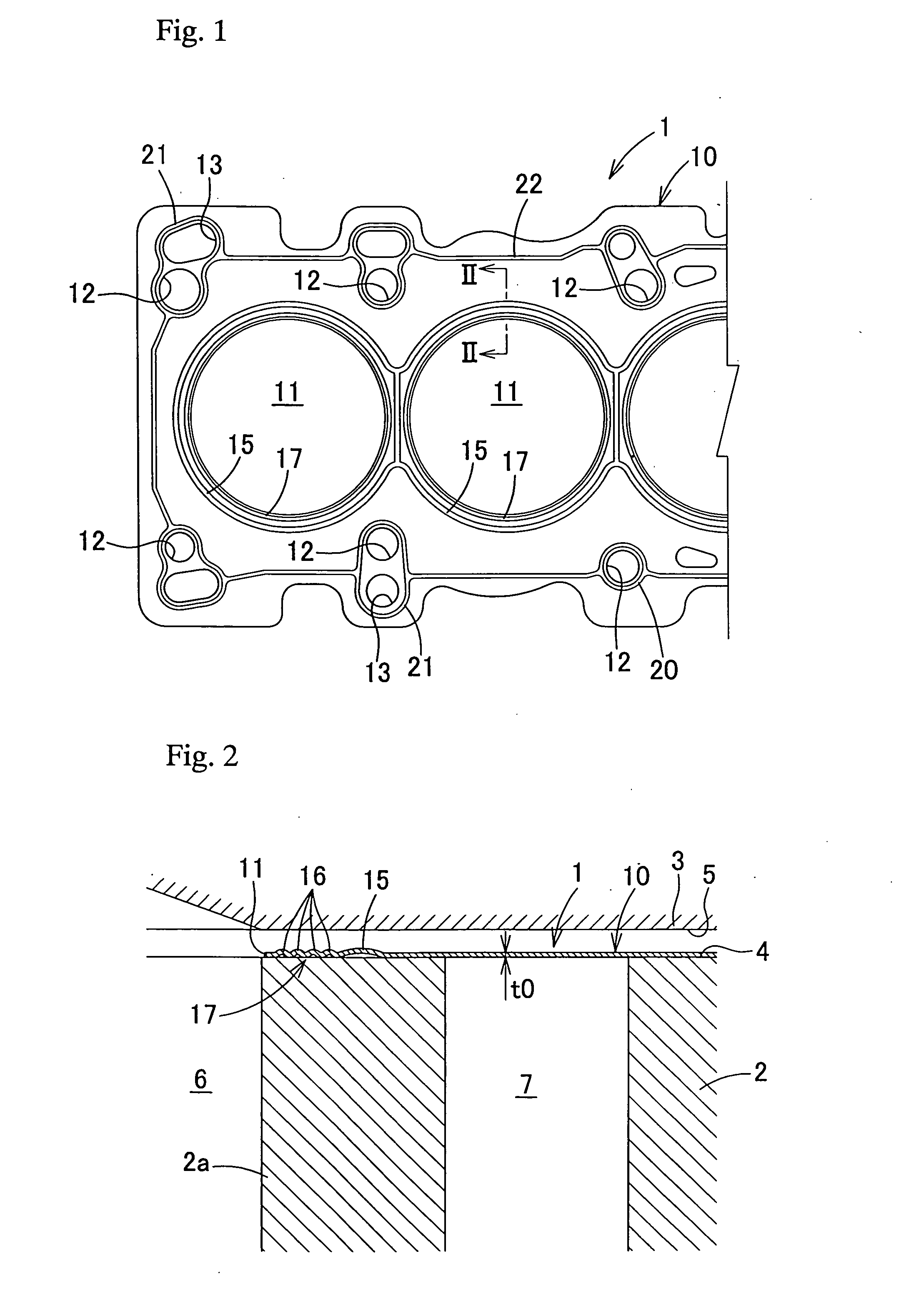

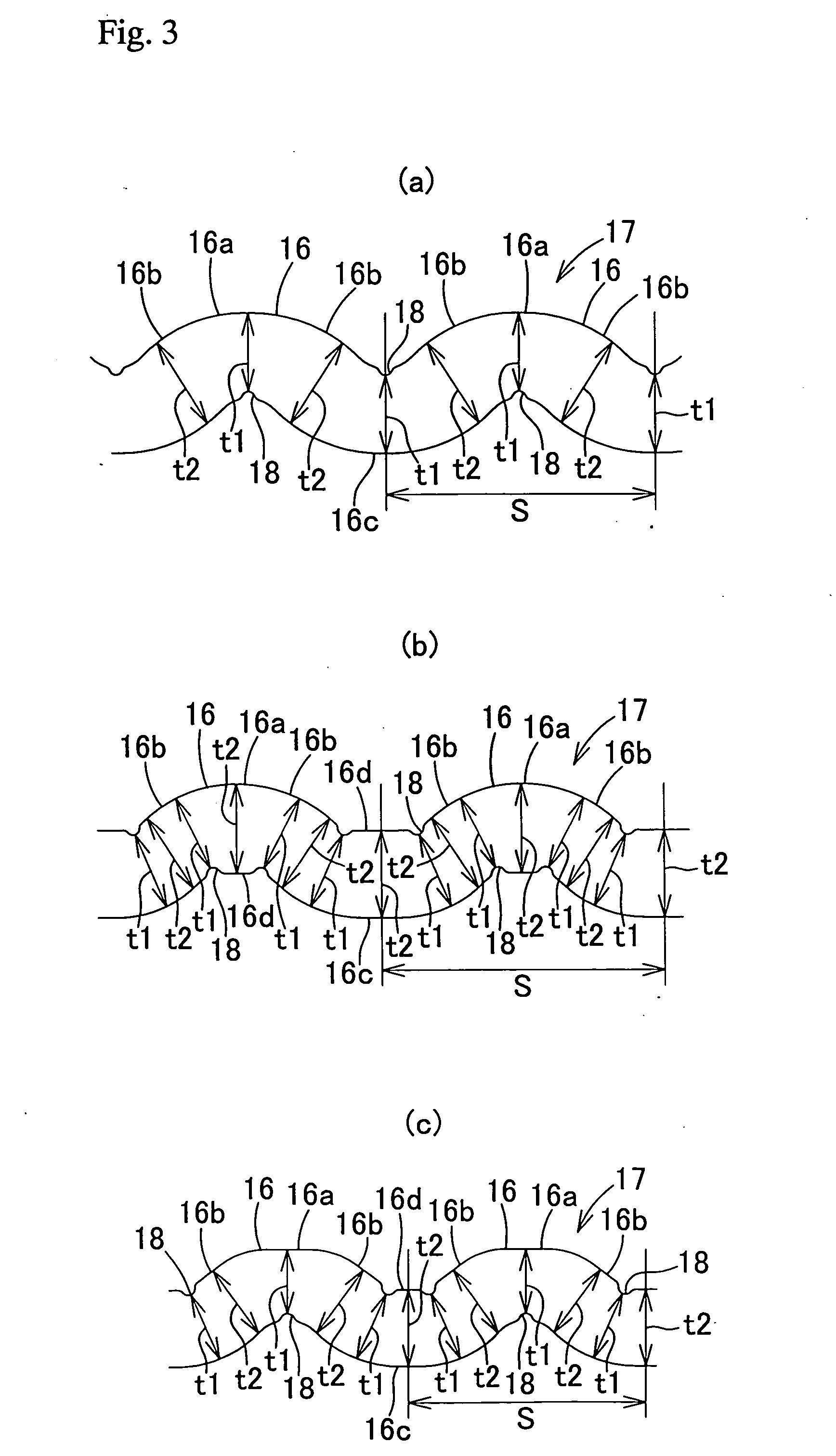

Metal gasket

InactiveUS7204491B2Effectively preventing occurrencePromotes stress balanceEngine sealsSealing arrangements for enginesCombustion chamberContact pressure

A metal gasket capable of preventing the occurrence of cracks in a stopper while employing a wave-shaped stopper, improving the contact pressure balance around the bead to enhance the engine performance, and improving the durability of the stopper. The metal gasket is constituted by a gasket component sheet having an opening formed to face a combustion chamber, and the gasket component sheet is provided with a combustion chamber bead surrounding the opening. An inner circumference side stopper lower than the height of the combustion chamber bead is formed along the combustion chamber bead in a portion between the combustion chamber bead and the opening such that at least a section of each wave where stress amplitude is large becomes thin, a thin portion and a thick portion are arranged alternately in each wave, and the hardness of the thin portion is higher than that of the thick portion.

Owner:HATAMURA KOICHI +1

Metal gasket

InactiveUS20050173868A1Effectively preventing occurrence of crackPromotes stress balanceEngine sealsSealing arrangements for enginesCombustion chamberContact pressure

A metal gasket capable of preventing the occurrence of cracks in a stopper while employing a wave-shaped stopper, improving the contact pressure balance around the bead to enhance the engine performance, and improving the durability of the stopper. The metal gasket is constituted by a gasket component sheet having an opening formed to face a combustion chamber, and the gasket component sheet is provided with a combustion chamber bead surrounding the opening. An inner circumference side stopper lower than the height of the combustion chamber bead is formed along the combustion chamber bead in a portion between the combustion chamber bead and the opening such that at least a section of each wave where stress amplitude is large becomes thin, a thin portion and a thick portion are arranged alternately in each wave, and the hardness of the thin portion is higher than that of the thick portion.

Owner:HATAMURA KOICHI +1

Process for methanol coupled catalytic cracking reaction of naphtha using a modified zsm-5 molecular sieve catalyst

ActiveUS20140051900A1Improving catalytic cracking efficiencyLow carbon olefinsCatalytic crackingLiquid hydrocarbon mixture productionCyclic alkaneNaphtha

The present invention provides a process for methanol coupled catalytic cracking reaction of naphtha using a modified ZSM-5 molecular sieve catalyst, comprising performing a co-feeding reaction of methanol and naphtha on the modified ZSM-5 molecular sieve catalyst to produce low carbon olefins and / or aromatic hydrocarbons. In the process, the modified ZSM-5 molecular sieve catalyst comprises, in term of weight percent, 25-80 wt % of a ZSM-5 molecular sieve, 15-70 wt % of a binder, and 2.2-6.0 wt % of lanthanum and 1.0-2.8 wt % of phosphorus loaded on the ZSM-5 molecular sieve. The naphtha comprises 63.8-89.5 wt % of saturated chain alkanes and 5.6-29.8 wt % of cyclic alkanes. The naphtha and methanol concurrently pass through the catalyst bed, which are reacted during contacting with the catalyst under a reaction condition of a reaction temperature of 550-670° C., a mass ratio of methanol to naphtha of 0.05-0.8, and a total mass space velocity of naphtha and methanol of 1.0-5 h−1.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Liquid bacterial agent for rooting

InactiveCN103183567AQuick refillQuickly replenish crop deficient elements, crackingFertilizer mixturesDiseaseSolubility

The invention discloses a liquid bacterial agent for rooting, which comprises the following raw materials by weight parts: 20-80 parts of concentrated amino acid fermented liquid, 15-30 parts of urea, 5-20 parts of potassium fulvic acid, 10-20 parts of alginic acid, 5-15 parts of chitosan, 10-30 parts of bacillus subtilis, 5-20 parts of Alpha-pimacol, 10-35 parts of sodium nitrophenolate, 1-4 parts of indole butyric acid potassium, 5-15 parts of 5-nitrate and 10-20 parts of calcium nitrate. According to the invention, the liquid bacterial agent contains various high-activity strains including bacillus laterospor, bacillus licheniformis, bacillus subtilis and the like and dozens of high-purity nutritional ingredients. The liquid bacterial agent has super strong activity, and can quickly reach nutrient deficiency parts and bacteria infection parts of crops after being used so as to quickly complement the deficient elements, and can split mycelium and spore and remove soil-borne diseases so as to allow the crops to be quickly back to health. The liquid bacterial agent has the advantages of good water solubility, strong absorption ability, non-public hazard, no residue and no volatility after being used, and can not cause poison damage for the crops in the greenhouse.

Owner:张元宝

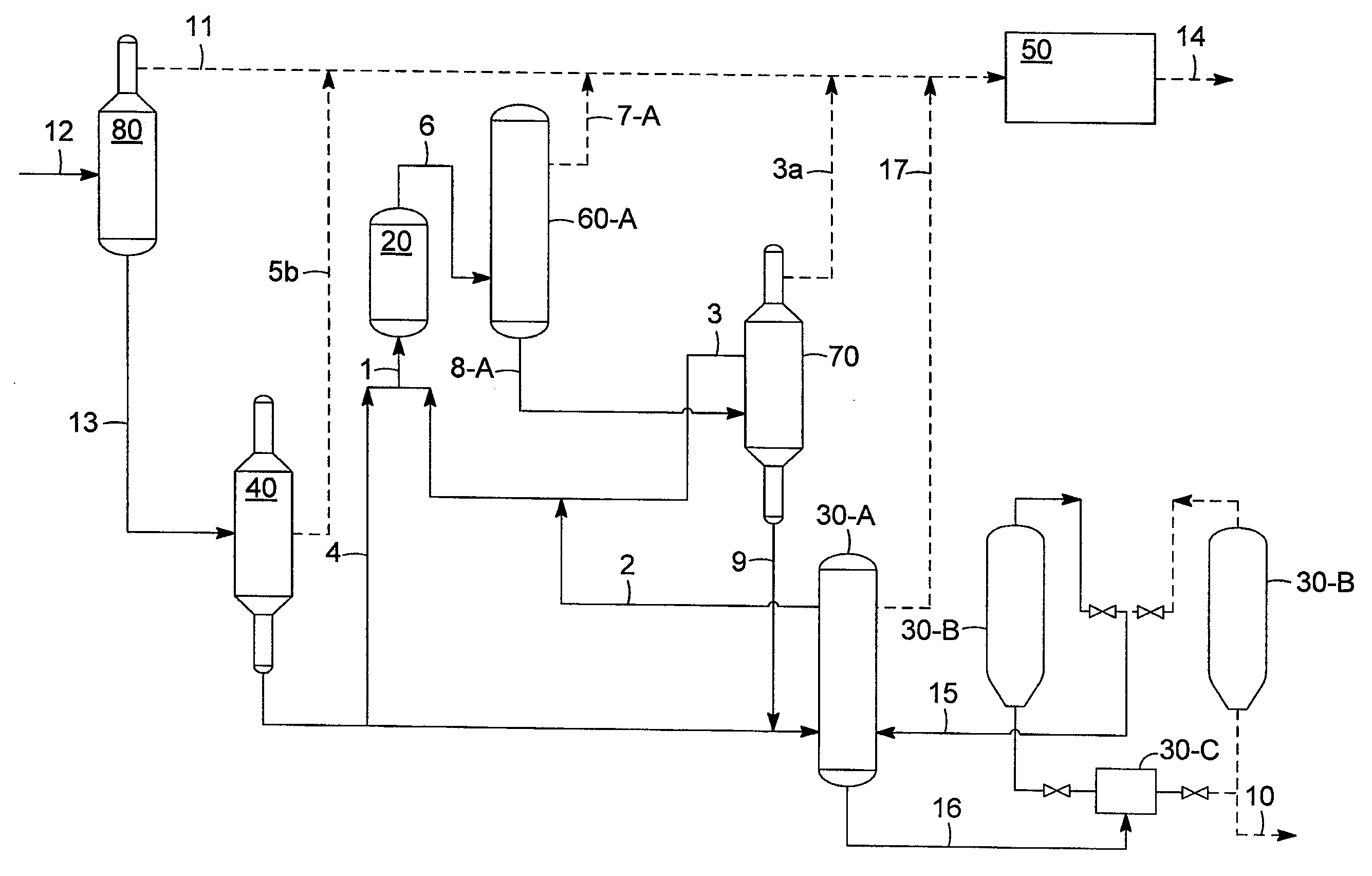

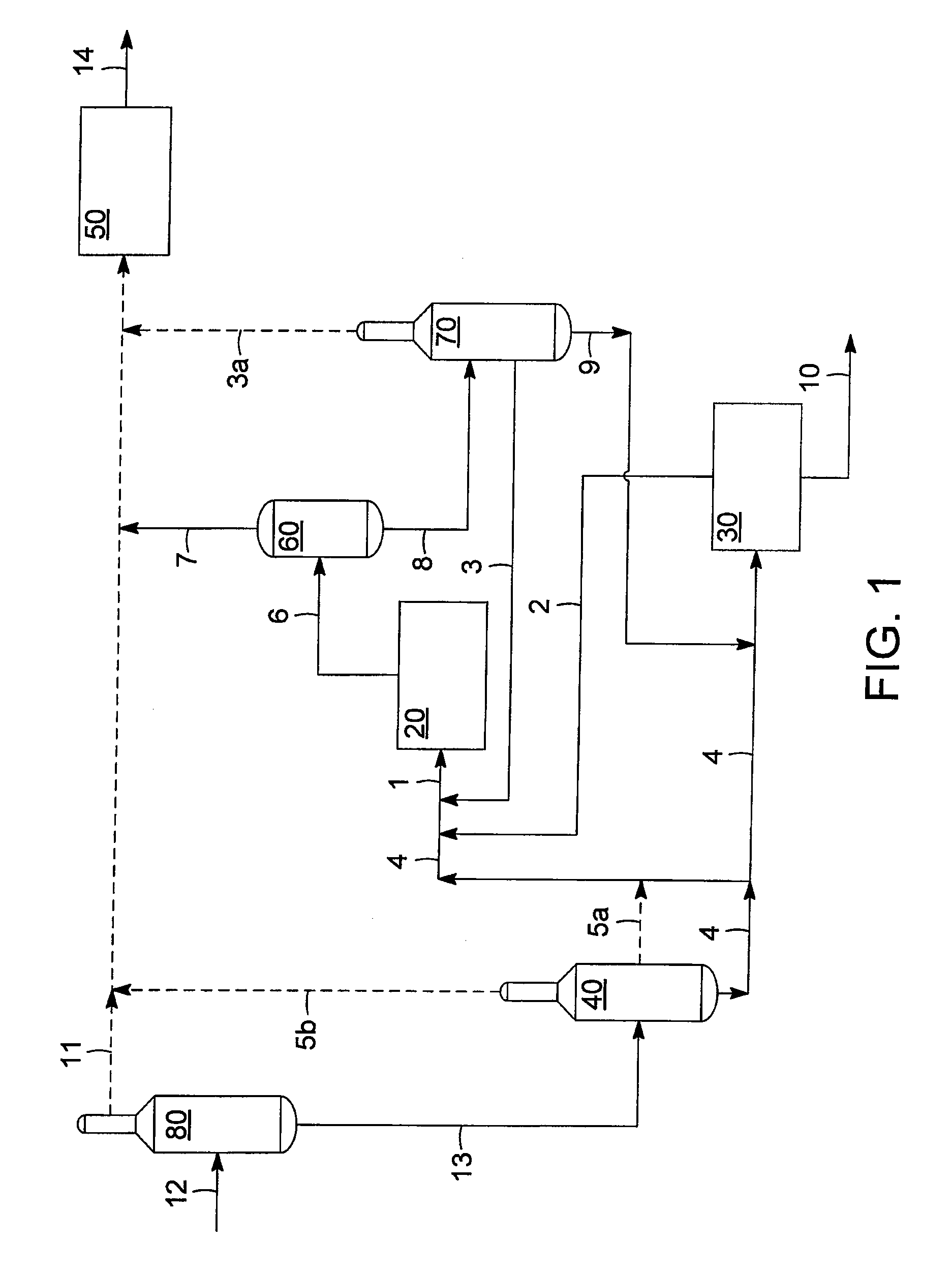

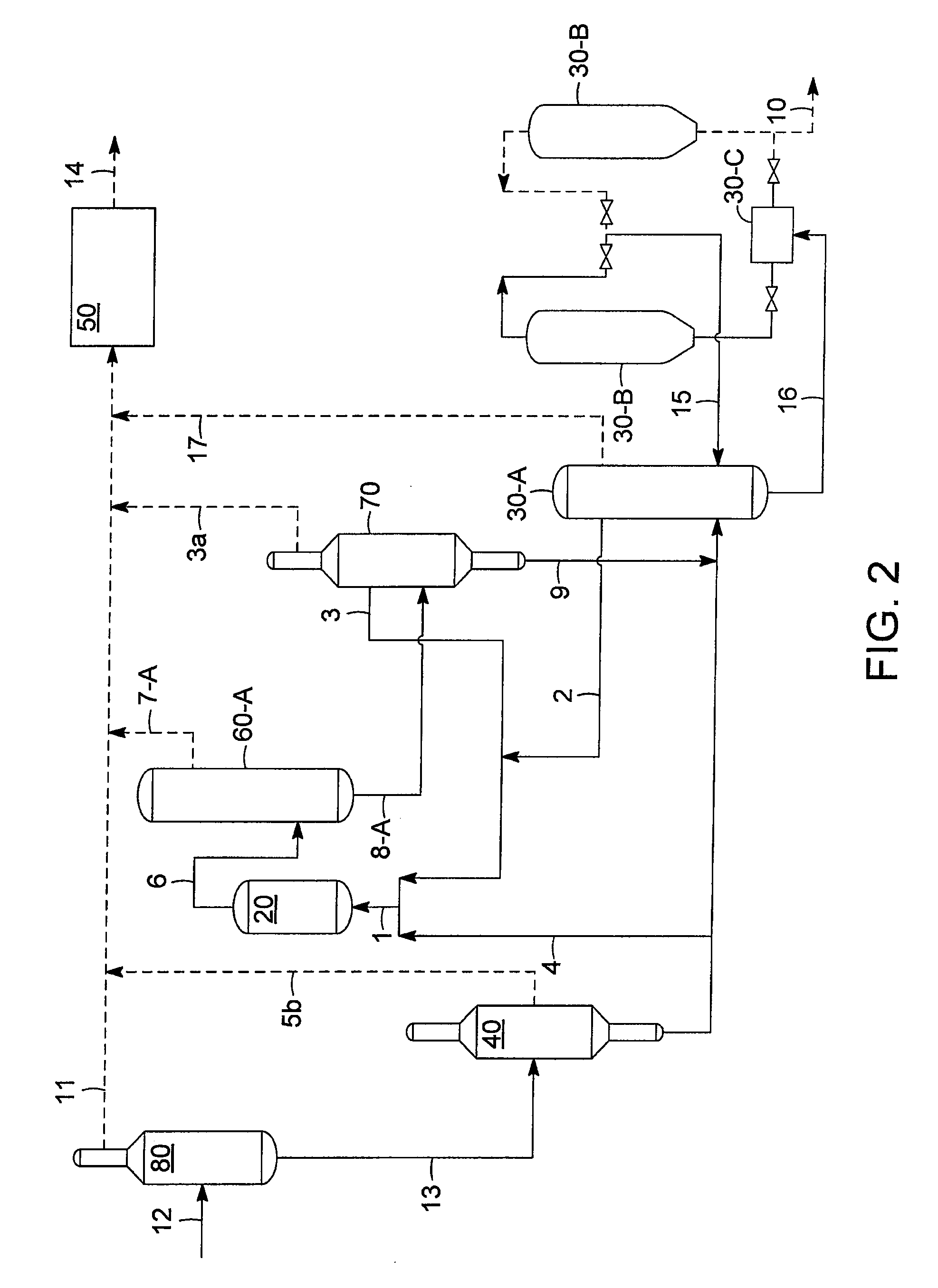

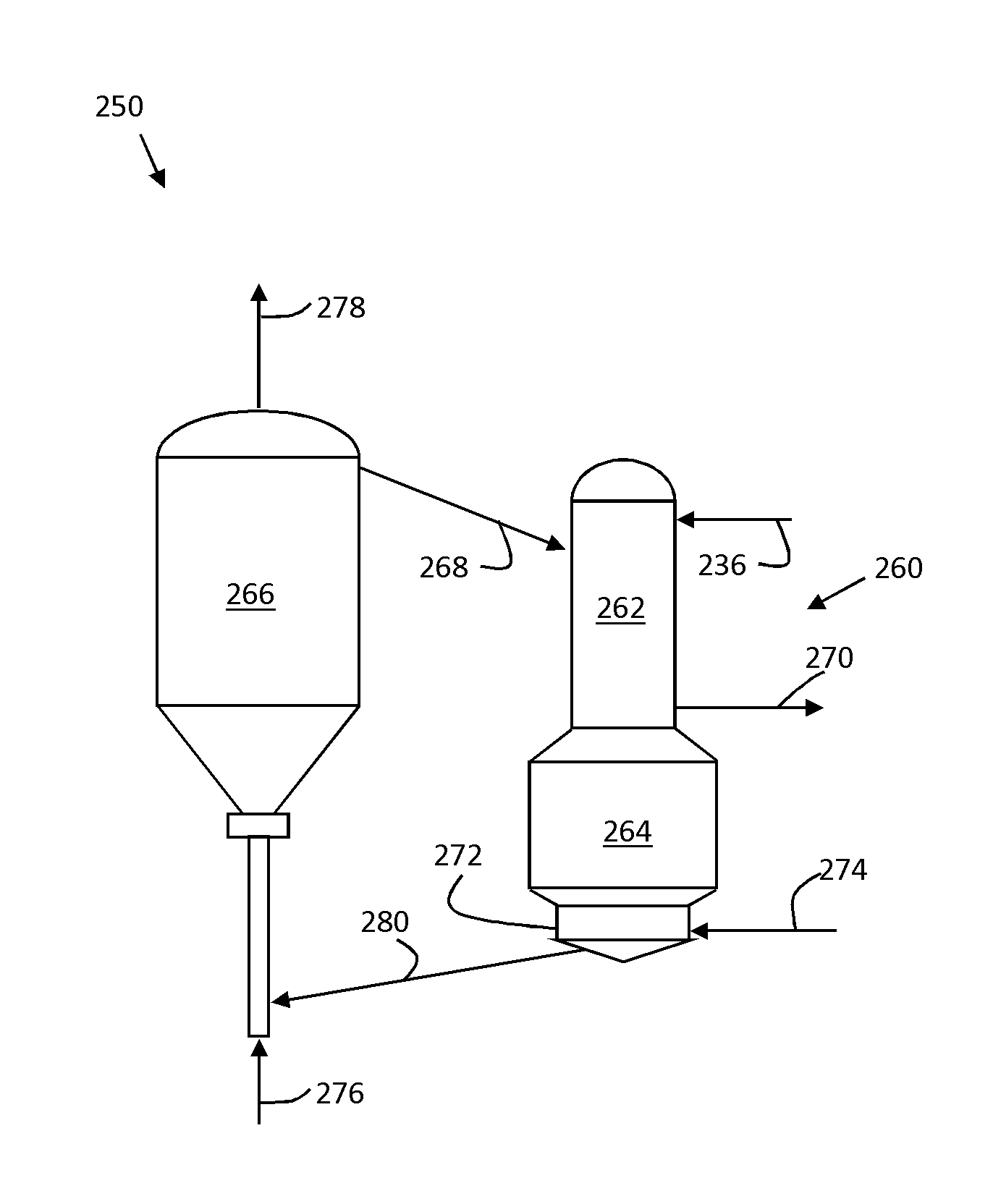

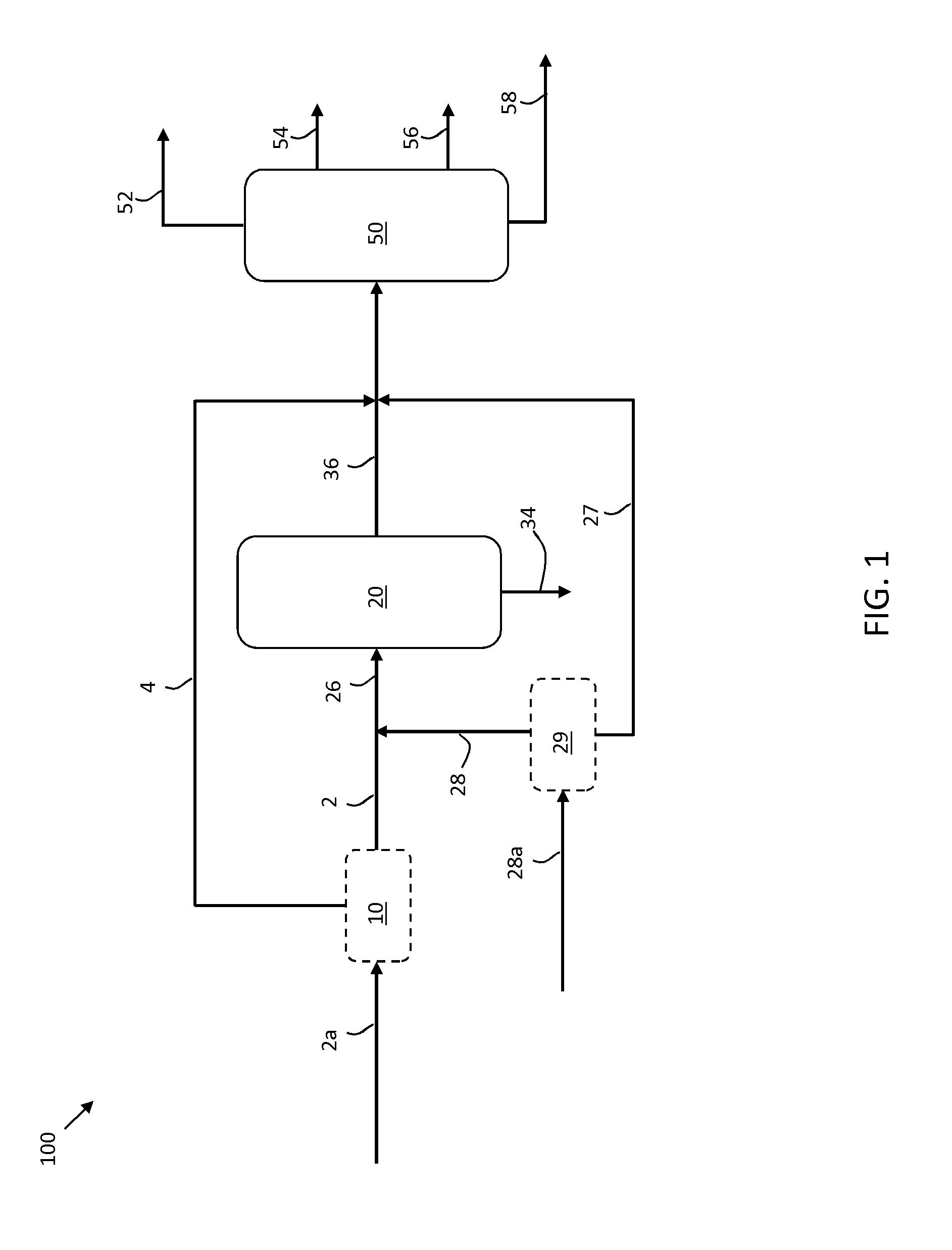

Integrated Slurry Hydrocracking and Coking Process

InactiveUS20100122932A1High value distillateIncrease valueThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesHydrogen

Integrated slurry hydrocracking (SHC) and coking methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a recycle SHC gas oil, a coker gas oil, a vacuum column resid, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Recovery of an SHC pitch from fractionation of the SHC reaction zone effluent provides an additional possibility for integration with the coker, and particularly via the upgrading of the SHC pitch in the coker to provide coke and lighter hydrocarbons such as SHC vacuum gas oil (VGO).

Owner:UOP LLC

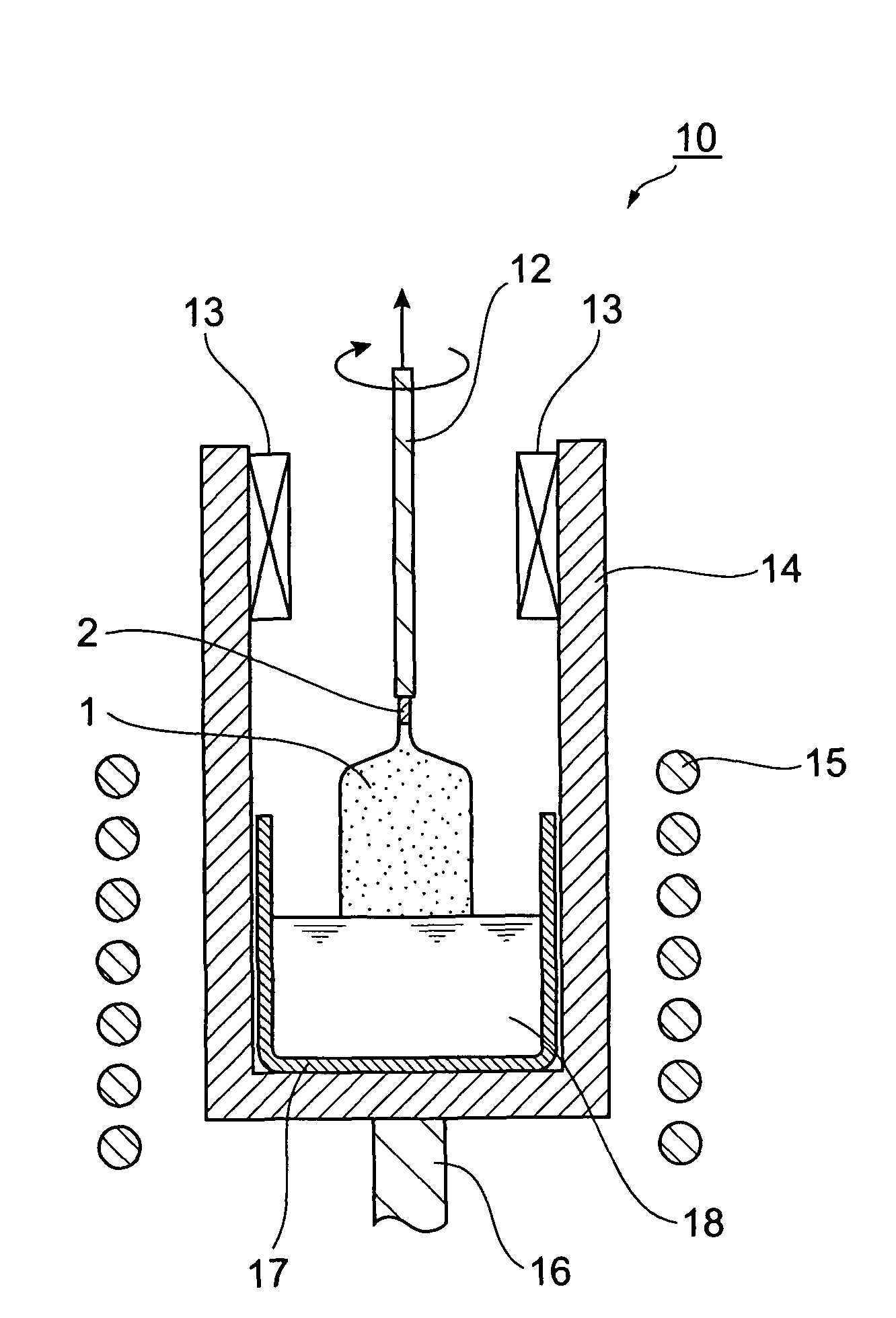

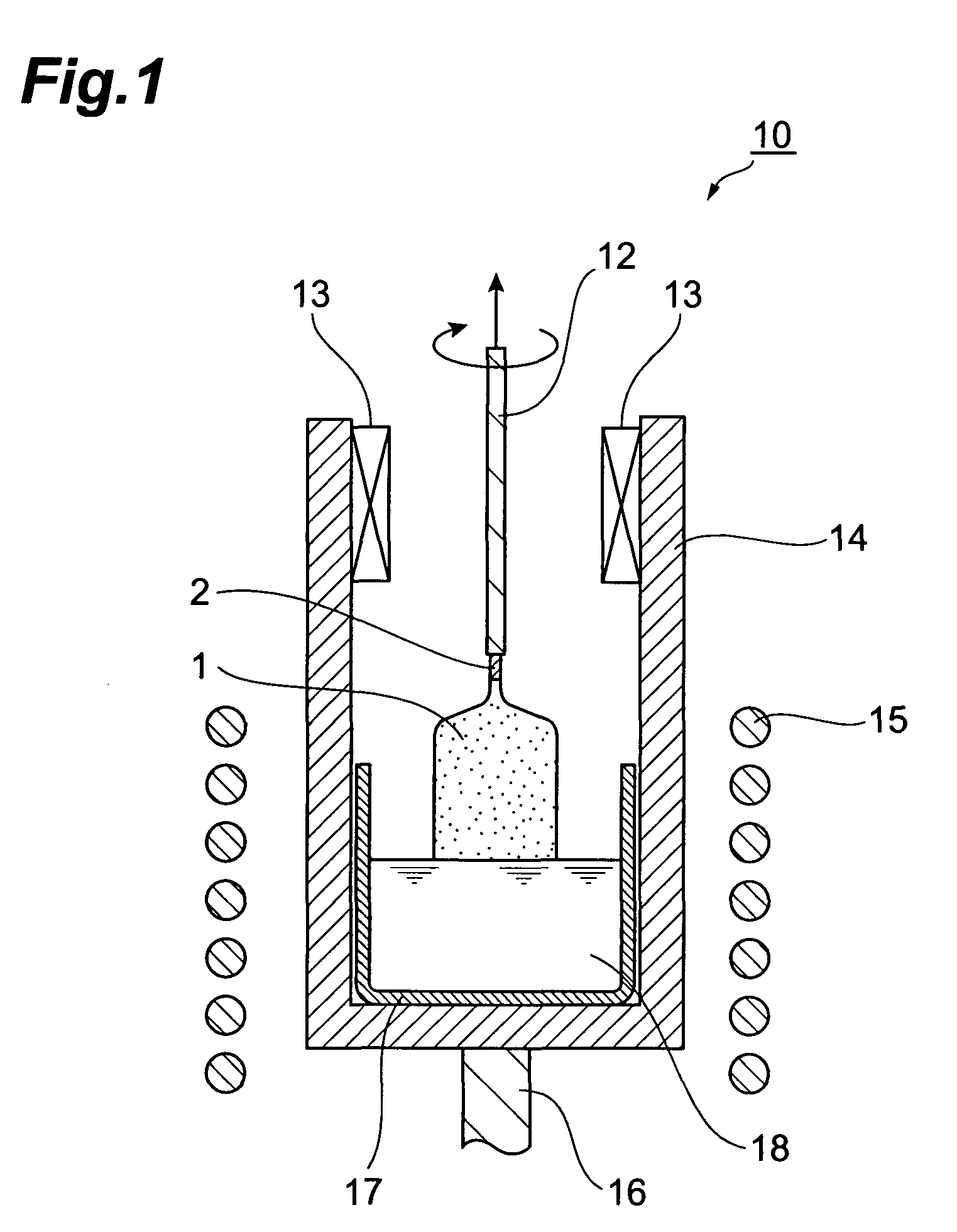

Single crystal for scintillator and method for manufacturing same

ActiveUS20080089824A1Decreased background of fluorescence outputImprove featuresFrom gel statePolycrystalline material growthCeriumSingle crystal

A single crystal for a scintillator that is a specific single crystal of a cerium-activated orthosilicate compound that comprises 0.00005 to 0.1 wt. %, based on the entire weight of the single crystal, of at least one element selected from a group consisting of elements belonging to Group 13 of the periodic table.

Owner:OXIDE

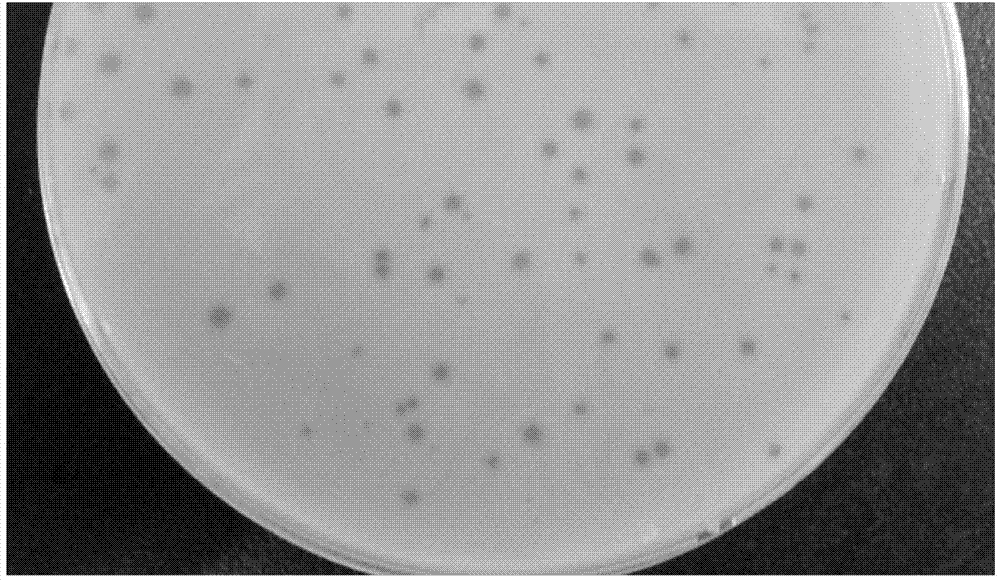

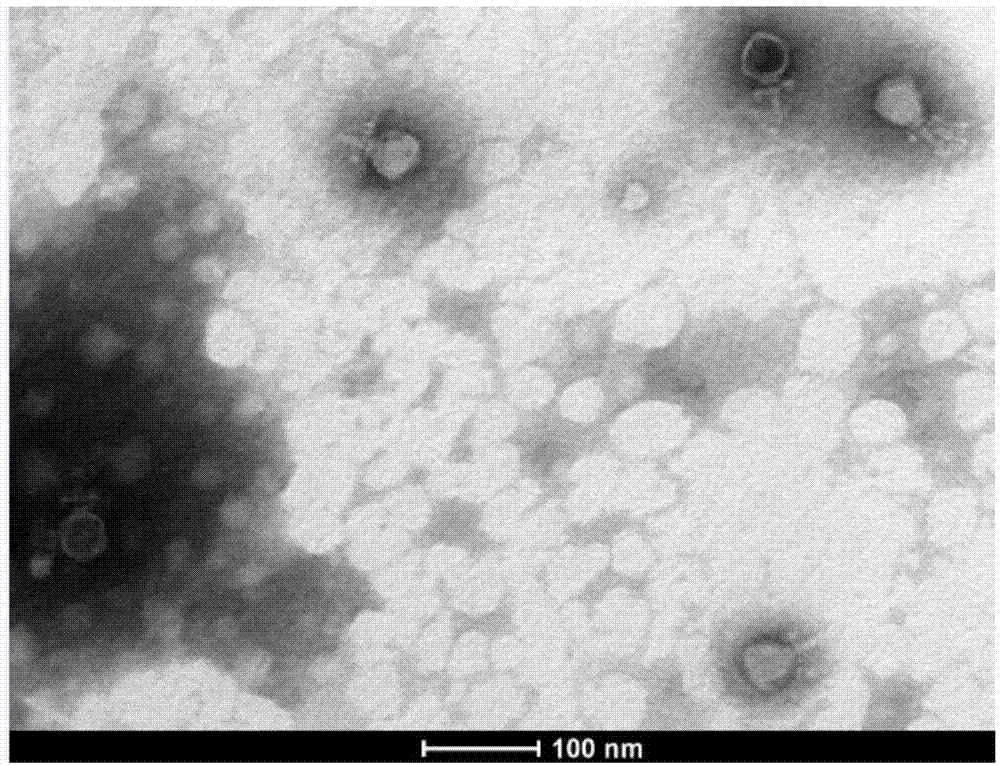

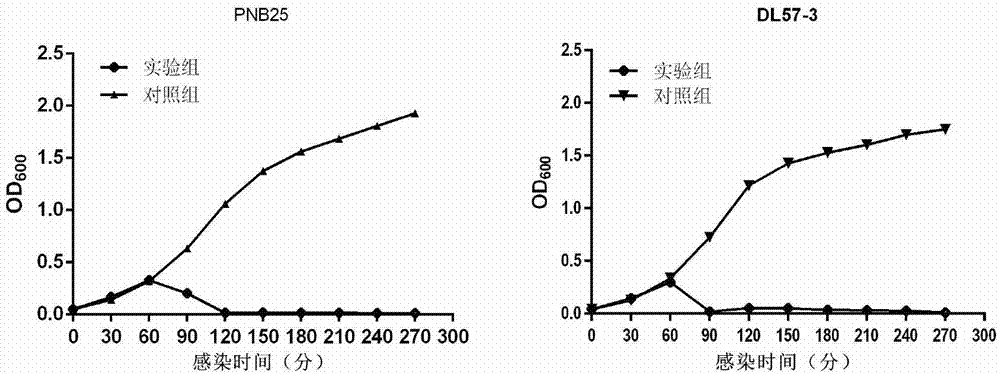

Bacteriophage able to split multiple resistant staphylococcus aureus, separation method and application thereof

InactiveCN104845942AEfficient crackingSpecific crackingAntibacterial agentsBiocideBacteroidesDisinfectant

The invention discloses a bacteriophage able to specifically and efficiently kill multiple resistant staphylococcus aureus, a separation method and application thereof. According to the invention, the bacteriophage able to specifically and efficiently split multiple resistant staphylococcus aureus is screened out from the environment, and the bacteria splitting spectrum is wide. On the basis of a two-layer agar method, a large number of bacteriophages with bacteria splitting activity can be obtained, and the bacteria splitting activity, bacteria splitting spectrum, in vitro bacteria splitting ability and physicochemical properties of the bacteriophages can be determined. The bacteriophage has strong specificity, is difficult to make bacteria generate resistance, also does not produce adverse effect on hosts, and is a feasible method for solving the increasingly serious bacterial resistance problem. The bacteriophage provided by the invention is expected to become a novel antibacterial preparation or environmental disinfectant for preventing and controlling resistant staphylococcus aureus infection.

Owner:SHANGHAI JIAO TONG UNIV

Method of treating oil or gas well with biodegradable emulsion

ActiveUS7392845B2Efficient crackingImprove efficiencyCleaning apparatusFluid removalParaffin waxDemulsifier

A biodegradable water-in-synthetic oil base emulsion, effective in the removal of filter cakes, consists of an external phase of a surfactant emulsified in a paraffinic base oil. The emulsion is particularly effective in breaking-down the interfacial rheological properties of oil base mud and synthetic oil base mud filter cakes and acts as a demulsifier to break the water-in-oil emulsions present in such oil base and synthetic oil base muds.

Owner:BAKER HUGHES INC

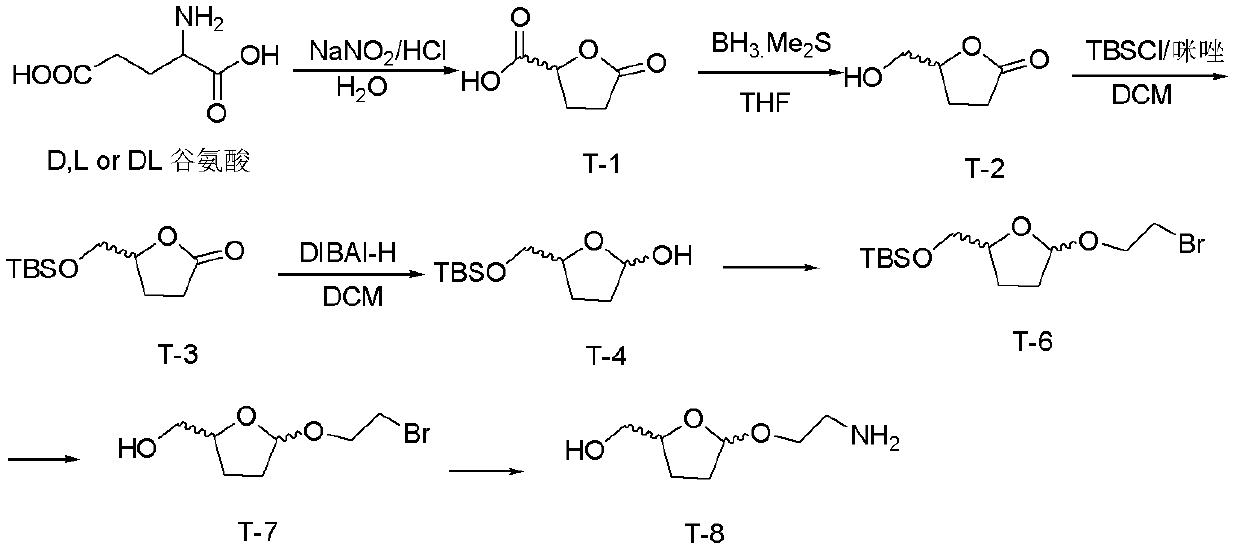

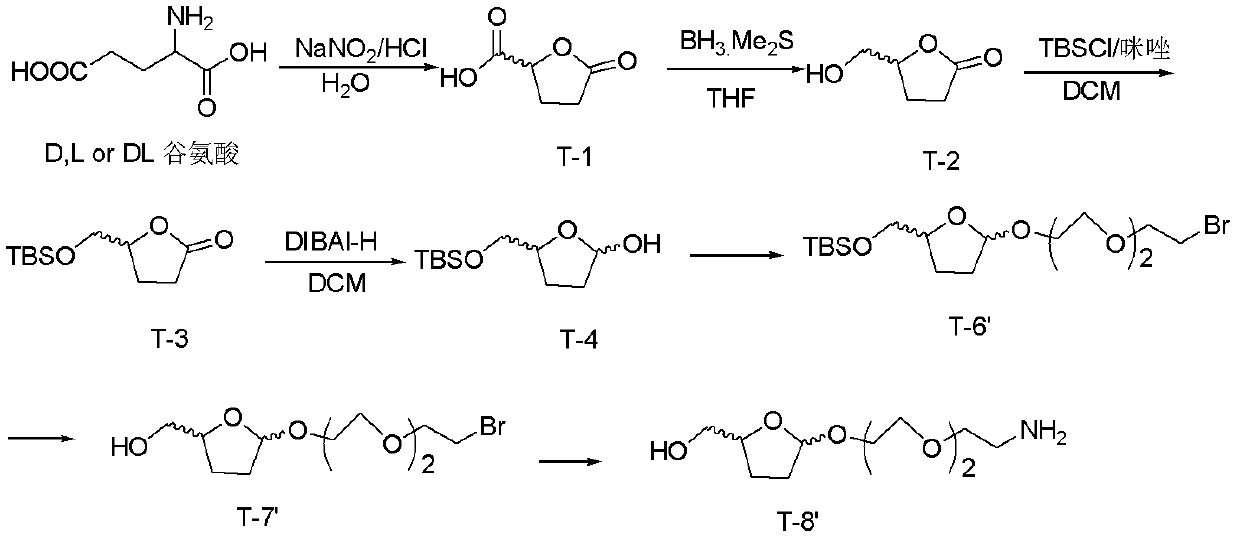

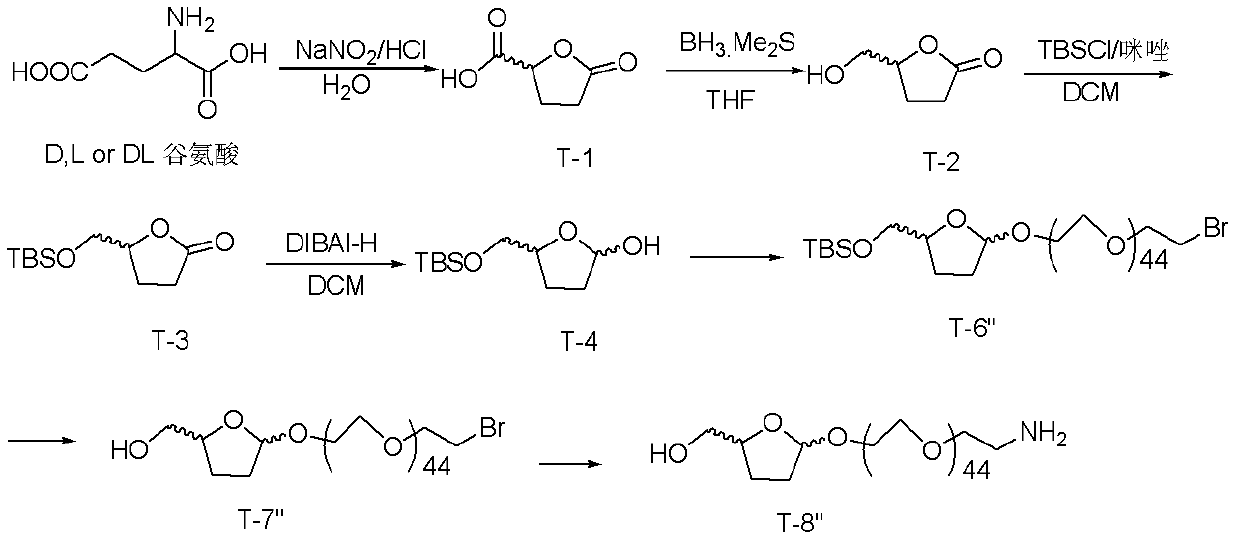

Cracking connecting unit for tetrahydrofuran ether derivatives and application of cracking connecting unit

ActiveCN102675262AHigh efficiency crackingEfficient crackingOrganic chemistryMicrobiological testing/measurementChemistryFluorescein

The invention discloses a cracking connecting unit for tetrahydrofuran ether derivatives and application of the cracking connecting unit. The cracking connecting unit has the following structural formula, wherein n is any integer of 0 to 44. The cis-tetrahydrofuran ether derivatives, the trans-tetrahydrofuran ether derivatives or the cis- and trans-tetrahydrofuran ether derivatives can be used for sequencing, and have the same effect; the synthesizing raw materials for the compounds are simple and readily available, the synthesizing process is conventional chemical reaction, and massive synthesis is easy to realize; the compounds can be efficiently connected with nucleotide and fluorescein; and by researching the cracking performance of the compounds, the compounds can realize efficient cracking under mild conditions, and can be applied to DNA sequencing.

Owner:SHANGHAI JIAO TONG UNIV

Integrated solvent-deasphalting and fluid catalytic cracking process for light olefin production

InactiveUS20150152027A1Raise the ratioEfficient crackingCatalytic crackingMolecular sieve catalystNatural-gas condensateNaphtha

The process described herein broadly comprehends an integrated process that permits the use of straight run residual fractions as a feedstock to produce lighter olefins including propylene. A blend of natural gas condensate and / or naphtha, and heavy oil residue(s), is catalytically cracked to produce a light olefin-rich product stream. In particular, the light natural gas condensate and / or naphtha stream is used as both solvent in a solvent-deasphalting unit and a portion for the feedstock to a fluidized catalytic cracking process. In addition, blending a heavy boiling hydrocarbon stream with a light natural gas condensate or naphtha stream enables efficient cracking in fluidized catalytic cracking process processes while sustaining the heat balance within the cracking unit.

Owner:SAUDI ARABIAN OIL CO

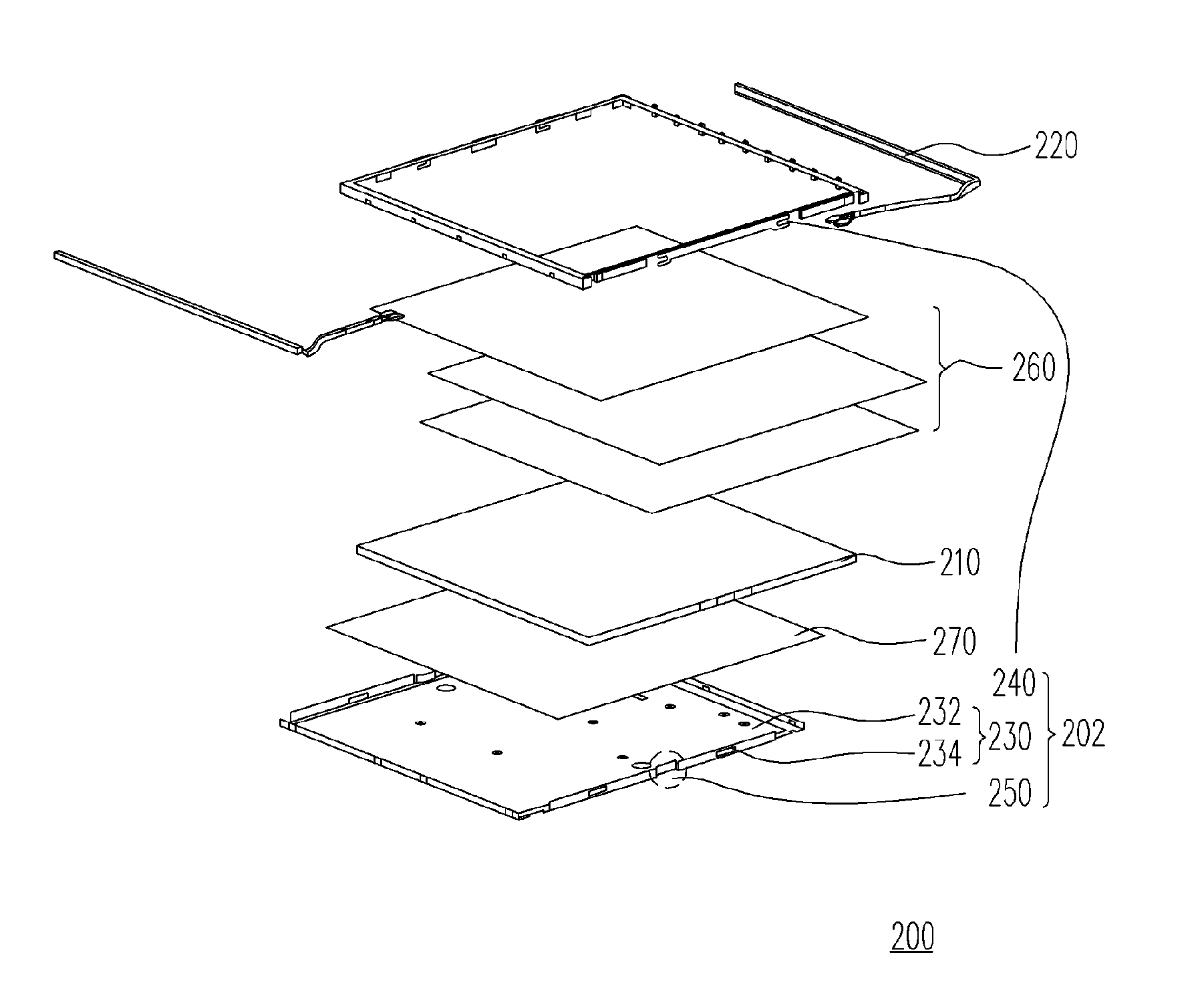

Back light module

ActiveUS20060098459A1Improve display qualityAvoid crackingMechanical apparatusVehicle interior lightingEngineeringShock test

The present invention provides a back light module, having an optical element, a light source and an outer supporting means. The optical element includes main body and protrusions which protrude from an edge of the main body. Contiguous protrusions with the main body form a positioning groove. The conjunction region between protrusion and main body is a fillet. The outer supporting means fixes the optical elements and the light source, which has at least one positioning component disposed on the edge of the back plate. The positioning component includes one inner wall near to edge of the main body, a side wall near to the protrusion and a transition wall connecting the side wall and the inner wall. A separate distance g between the fillet and the side wall so that the optical element can be prevented from cracking during the impact or shock test of the back light module.

Owner:HANNSTAR DISPLAY CORPORATION

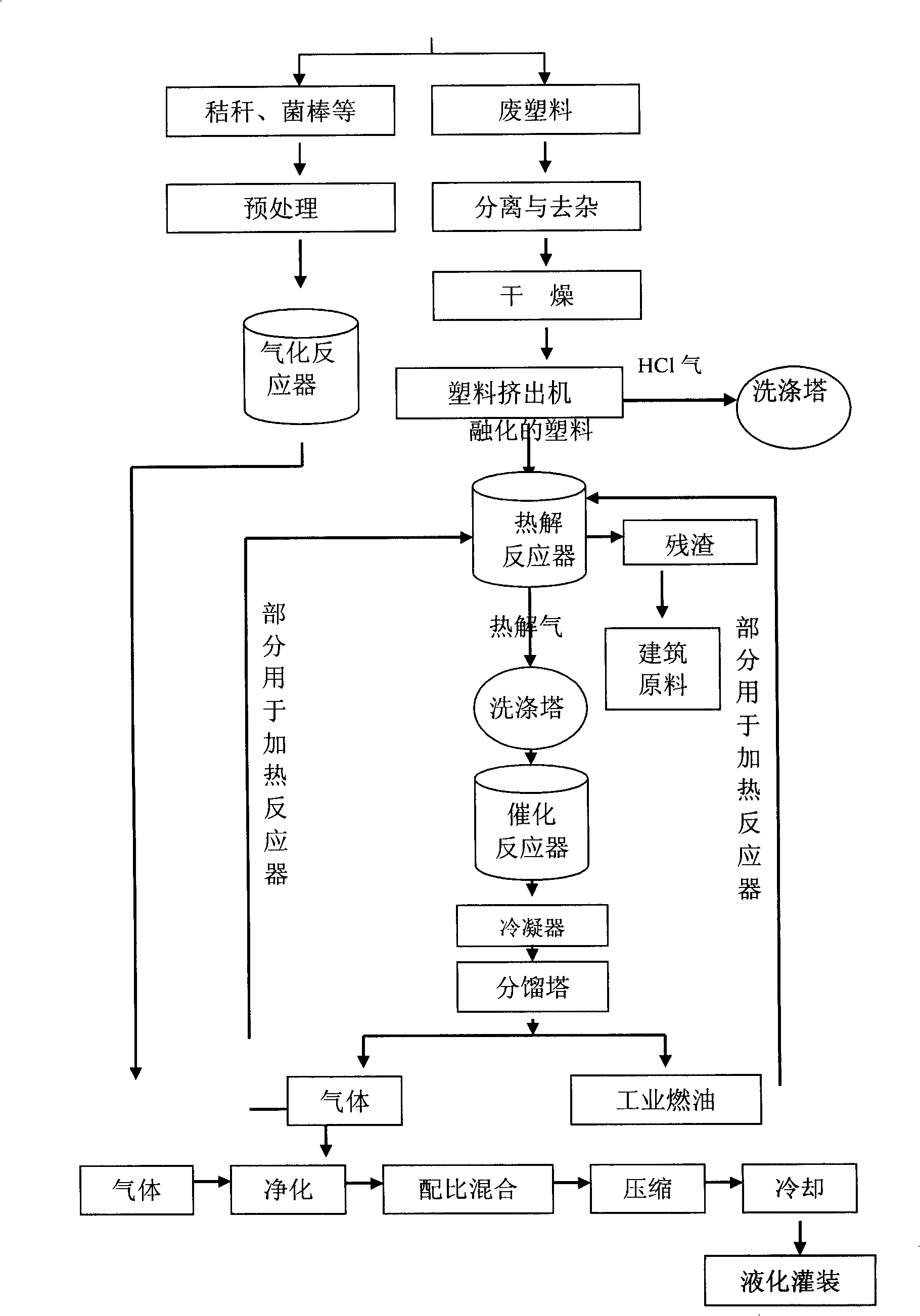

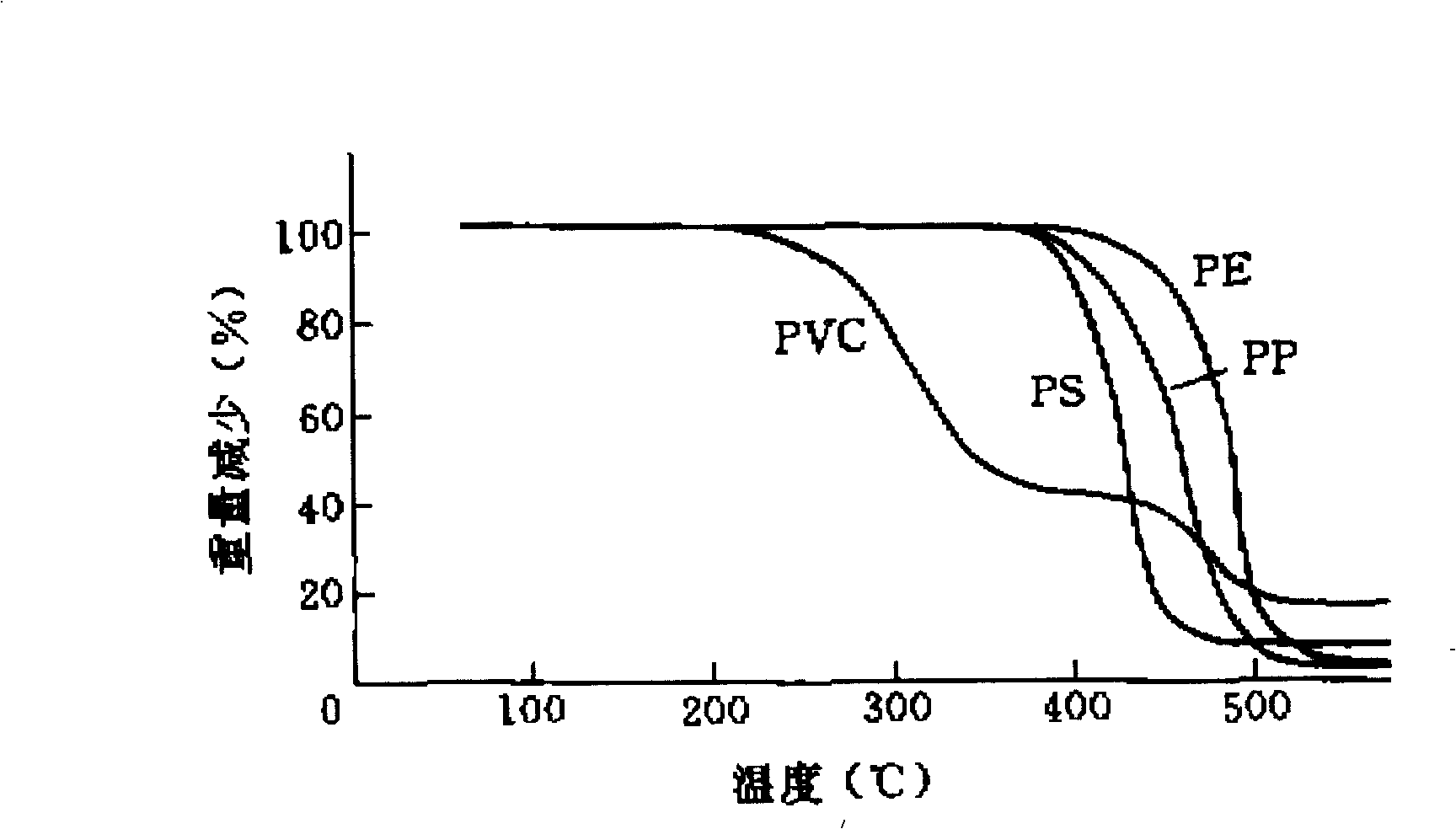

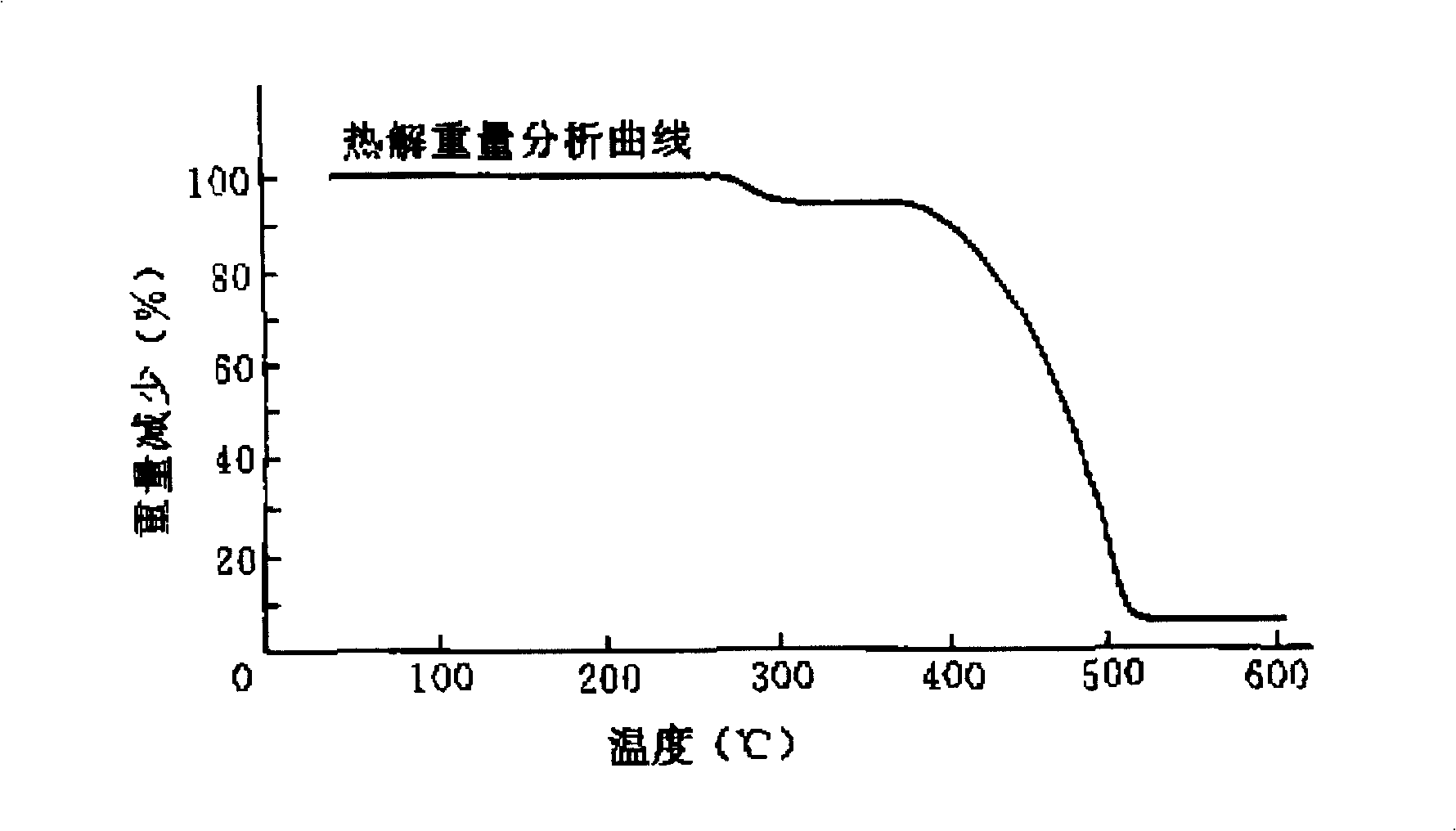

Comprehensive utilization method for agricultural wastes and plastic garbage

InactiveCN101343543AEfficient crackingSolve processing problemsSolid waste disposalLiquid hydrocarbon mixture productionPlastic wasteAgricultural engineering

The invention provides a comprehensive utilizing method for agricultural wastes and plastic wastes, which belongs to the waste treatment and utilization field. The comprehensive utilizing method for agricultural wastes and plastic wastes of the invention comprises the following steps that: firstly, the agricultural wastes and the plastic wastes are classified for sorting, wherein, the agricultural wastes adopt crop straws or edible mushroom sticks; secondly, the agricultural wastes are processed to form flammable gas; thirdly, the plastic wastes are processed to form flammable gas; fourthly, the flammable gas obtained through the second and the third steps is stored in a mixed way. The agricultural wastes and the plastic wastes are transformed from wastes into treasure through harmless treatment performed on the agricultural wastes and the urban plastic wastes, and the whole process is safe and reliable without secondary pollution.

Owner:LISHUI WEIDA NEW ENERGY TECH

Back light module

ActiveUS7172329B2Improve display qualityAvoid crackingOptical light guidesReflectorsEngineeringShock test

The present invention provides a back light module, having an optical element, a light source and an outer supporting means. The optical element includes main body and protrusions which protrude from an edge of the main body. Contiguous protrusions with the main body form a positioning groove. The conjunction region between protrusion and main body is a fillet. The outer supporting means fixes the optical elements and the light source, which has at least one positioning component disposed on the edge of the back plate. The positioning component includes one inner wall near to edge of the main body, a side wall near to the protrusion and a transition wall connecting the side wall and the inner wall. A separate distance g between the fillet and the side wall so that the optical element can be prevented from cracking during the impact or shock test of the back light module.

Owner:HANNSTAR DISPLAY CORPORATION

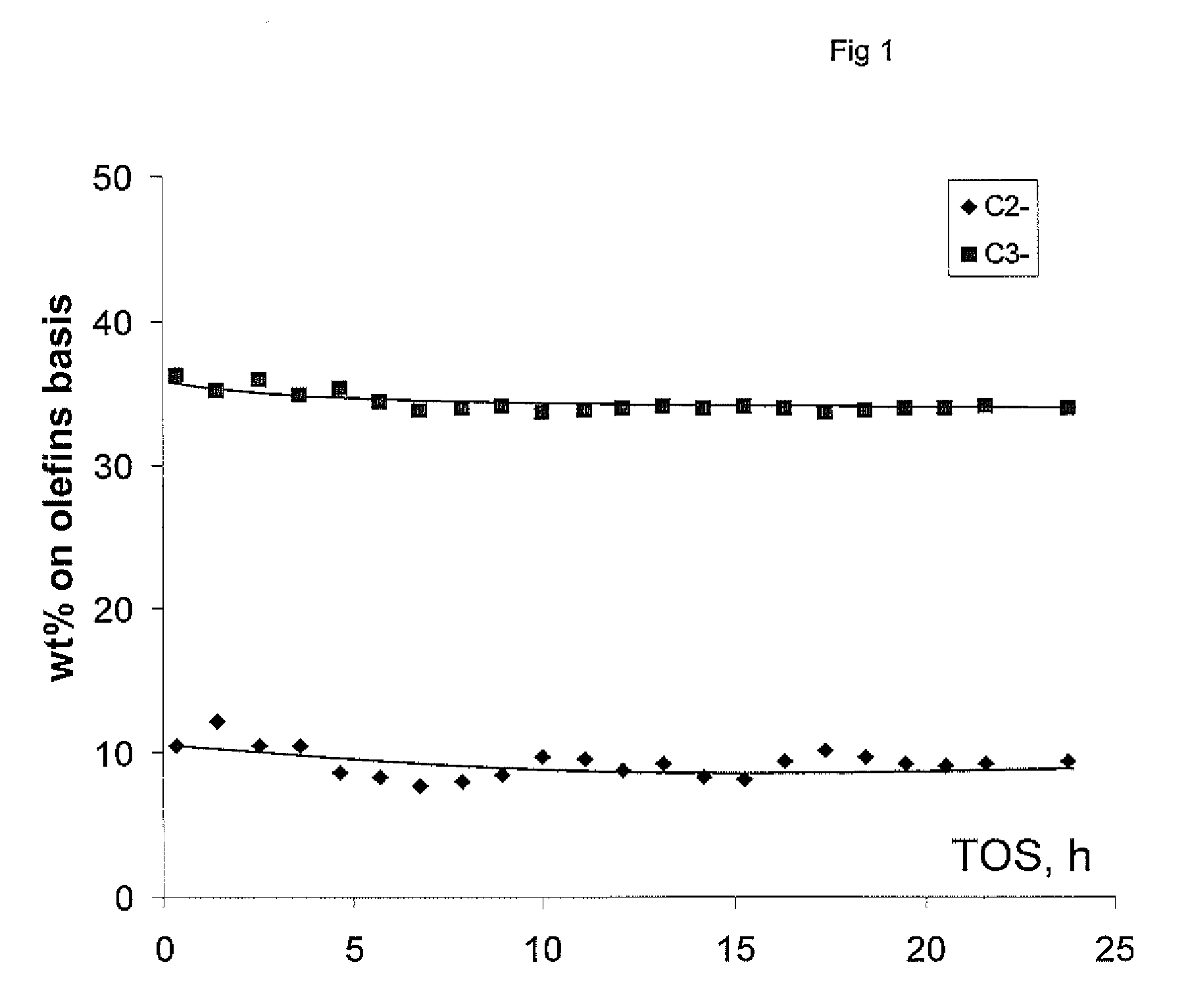

Cracking of Olefins on Phosphorus Modified Molecular Sieves

InactiveUS20100256431A1Smooth transitionTime stableCatalytic crackingMolecular sieve catalystsMolecular sieveAqueous solution

The present invention provides a process for the catalytic cracking of an olefin-rich feedstock which is selective towards light olefins in the effluent, the process comprising contacting a hydrocarbon feedstock containing one or more olefins, with a catalyst made of a phosphorus-modified zeolite (A), to produce an effluent with an olefin content of lower molecular weight than that of the feedstock, wherein said phosphorous modified zeolite (A) is made by a process comprising in that order:selecting a zeolite with low Si / Al ratio (advantageously lower than 30) among H+ or NH4+-form of MFI, MEL, FER, MOR, clinoptilolite, said zeolite having been made preferably without direct addition of organic template;steaming at a temperature ranging from 400 to 870° C. for 0.01-200 h;leaching with an aqueous acid solution containing the source of P at conditions effective to remove a substantial part of Al from the zeolite and to introduce at least 0.3 wt % of P;separation of the solid from the liquid;an optional washing step or an optional drying step or an optional drying step followed by a washing step;a calcination step.Said cracking of an olefin-rich feedstock is often referred in the following description and claims as OCP (Olefin Cracking Process).The catalyst made of a P-modified zeolite (A) can be the P-modified zeolite (A) itself or it can be the P-modified zeolite (A) formulated into a catalyst by combining with other materials that provide additional hardness or catalytic activity to the finished catalyst product.The zeolite with low Si / Al ratio has been made previously with or without direct addition of an organic template. The zeolite can be made with the help of seeds techniques but without template, the seeds could have been made with a template which means that the zeolite is made without direct addition of a template.

Owner:TOTAL RES & TECH FELUY

Method for dynamic water feeding and hole sealing using high water-absorbent resin

InactiveUS20190360336A1Strong impact resistanceEfficient crackingMaterial fill-upDrilling compositionSwelling pressureWater flow

A method for dynamic water feeding and hole sealing using high water-absorbent resin is applicable to sealing of a borehole on which extraction has a great impact. Two ends of a hole-sealed section of the borehole are sealed. Fine mixed high water-absorbent resin powder wrapped in a piece of cotton cloth is disposed in the hole-sealed section of the borehole, a water injection pipe and a gas extraction pipe are inserted in the borehole, and an automatic feed water valve is used to inject water into the hole-sealed section. The fine mixed high water-absorbent resin powder that fills the hole-sealed section and surrounding cracks with the water flow rapidly swells up after soaking up water to fill the hole-sealed section, and maintains at a swelling pressure. After the powder swells up and hole sealing is completed, the extraction pipe is connected to an extraction apparatus to perform gas extraction. This method has advantages such as tight hole sealing, high automation degree, and dynamic hole sealing, thus effectively solving problems that pores around the borehole are poorly sealed, it is difficult to seal cracks newly produced by extraction and so on. Moreover, the powder for hole sealing is low in price, and therefore the hole sealing cost is low.

Owner:CHINA UNIV OF MINING & TECH

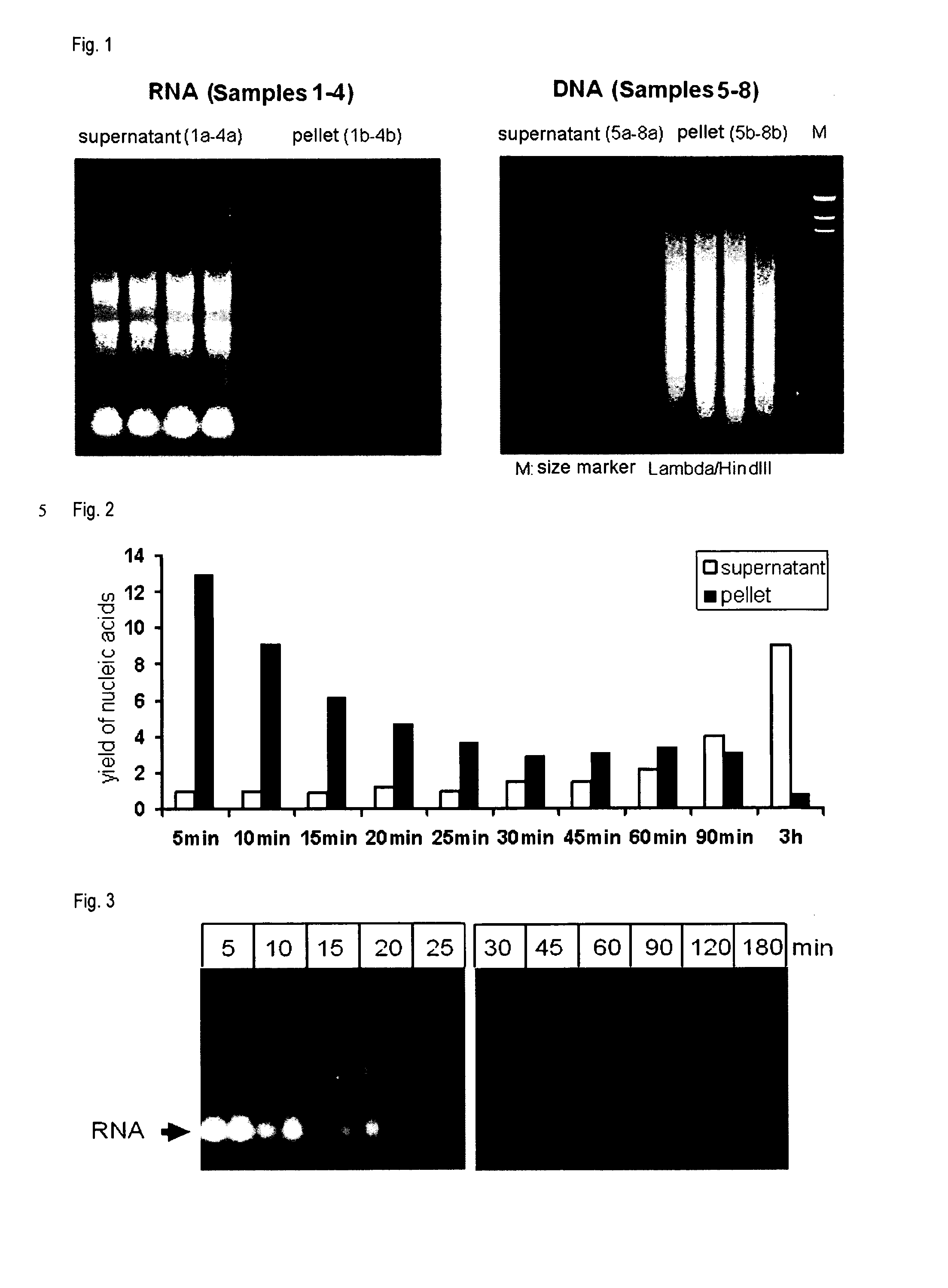

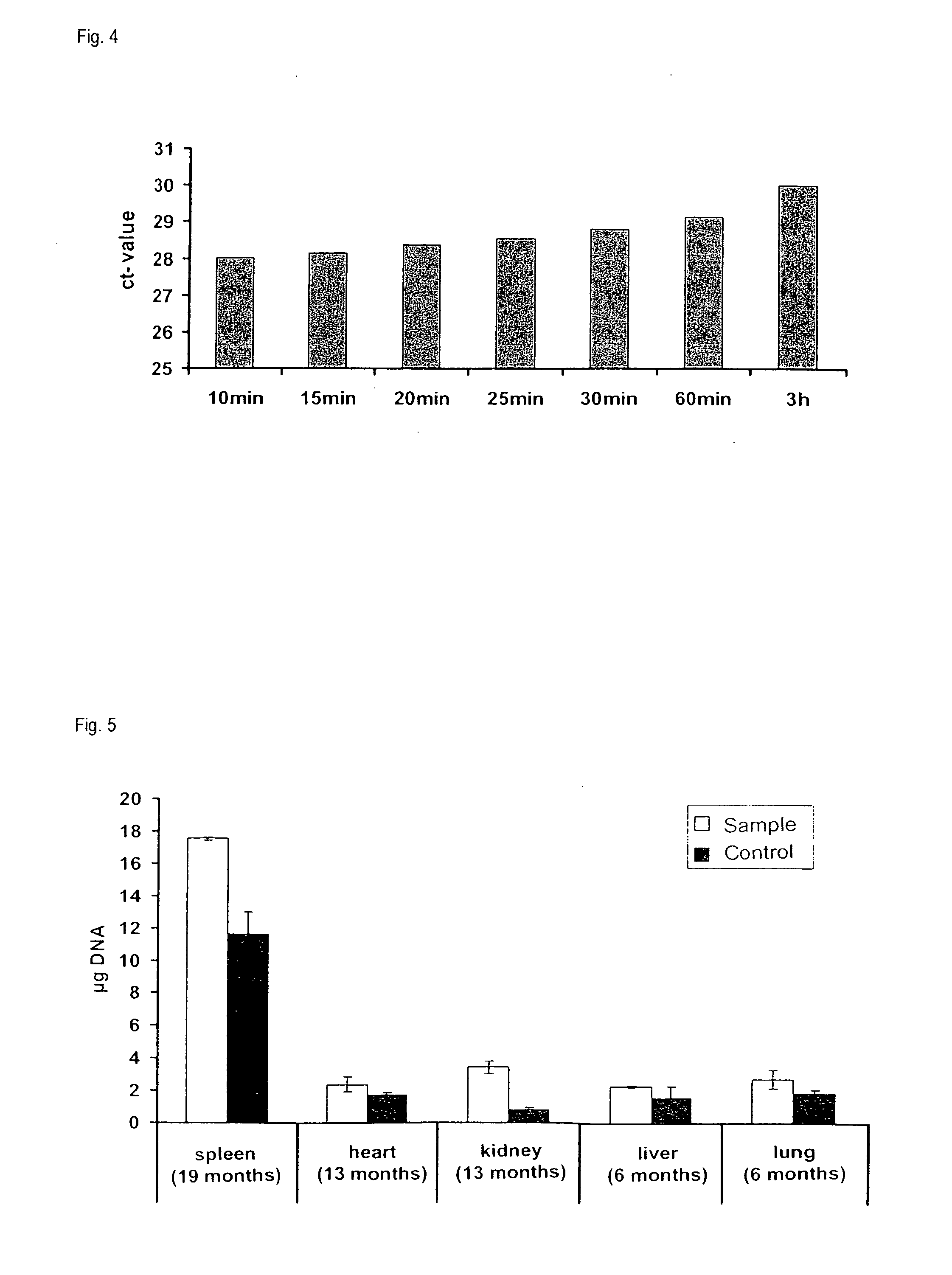

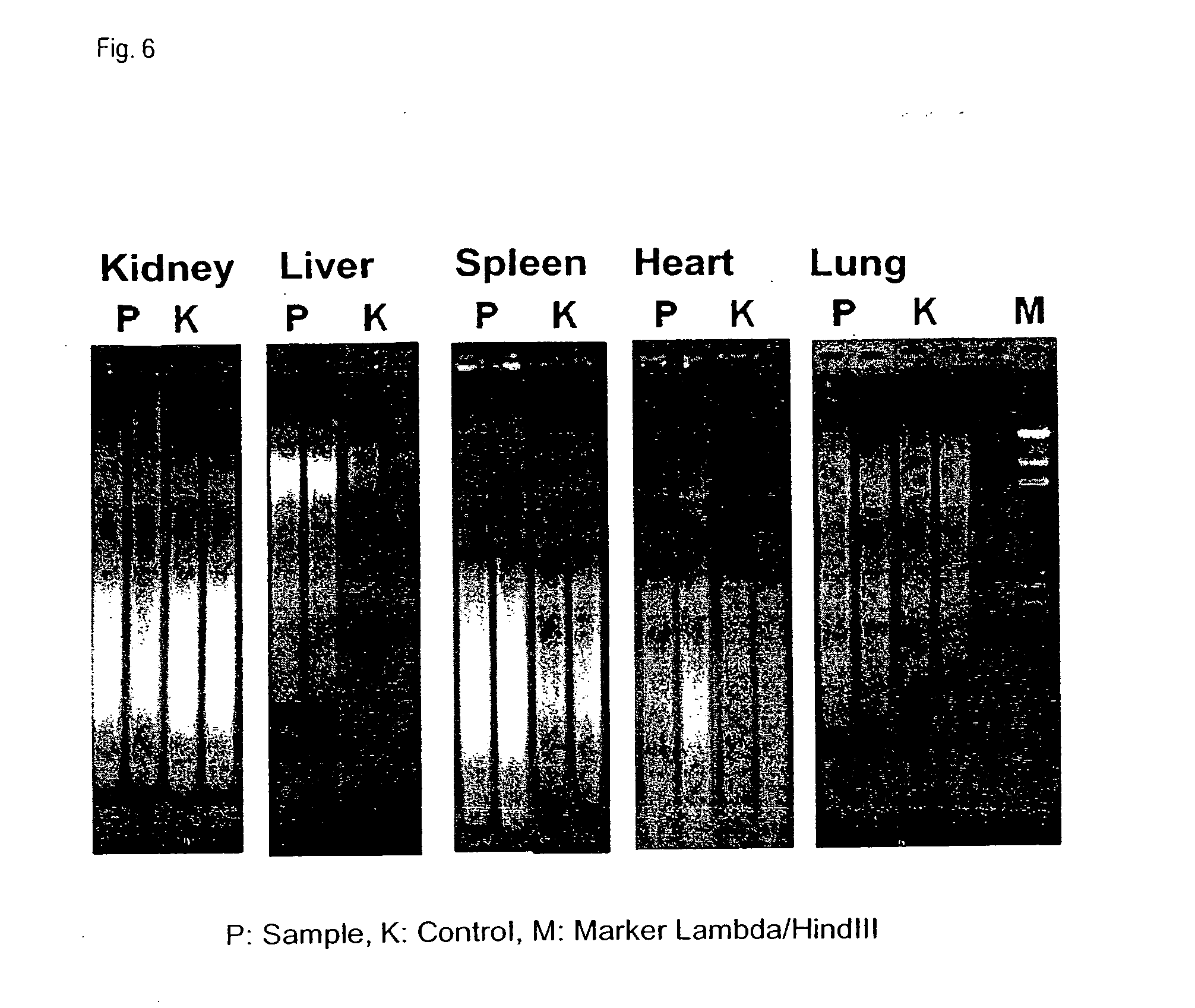

Process for parallel isolation and/or purification of RNA and DNA

ActiveUS20130053254A1Easy to separateEasily and efficiently separatedElectrolysis componentsHydrolasesBiologyDNA

The present invention relates to a process for the parallel isolation and / or purification of RNA and DNA from the same fixed biological sample, the quantification and analysis of the nucleic acids isolated by the process according to the invention, to a kit for the parallel isolation and / or purification of RNA and DNA from a fixed sample and to the use of this kit for the diagnosis, prognosis, decision with respect to therapy and / or the monitoring of the therapy of a disease.

Owner:QIAGEN GMBH

Single crystal for scintillator and method for manufacturing same

ActiveUS7749323B2Stable outputEasy to spreadFrom gel statePolycrystalline material growthCeriumSingle crystal

A single crystal for a scintillator that is a specific single crystal of a cerium-activated orthosilicate compound that comprises 0.00005 to 0.1 wt. %, based on the entire weight of the single crystal, of at least one element selected from a group consisting of elements belonging to Group 13 of the periodic table.

Owner:OXIDE

Electrode used for a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery used the same for a negative electrode

InactiveUS7407727B2Avoid crackingReduce expansionElectrode carriers/collectorsLi-accumulatorsPorosityMetallic materials

An electrode according to the invention can provide a non-aqueous electrolyte secondary battery having an ability to release a volume expansion at the time of charge and discharge as well as the time of a cycle. The electrode comprises a current collector made of a material which is not alloyed with Li, and a dot pattern 2 of a metallic material able to be alloyed with Li formed on the current collector. At the time of charge, since the volume expansion of each dot 3 is carried out so as to bury adjoining crevices 4 between the dots, a stress generated is released, thereby degradation of an electrode being avoided. Each dot may also be made into porosity.

Owner:HITACHI MAXELL ENERGY LTD

Method of treating oil or gas well with biodegradable emulsion

ActiveUS20070225174A1Efficient crackingImprove efficiencyCleaning apparatusFluid removalParaffin waxDemulsifier

A biodegradable water-in-synthetic oil base emulsion, effective in the removal of filter cakes, consists of an external phase of a surfactant emulsified in a paraffinic base oil. The emulsion is particularly effective in breaking-down the interfacial rheological properties of oil base mud and synthetic oil base mud filter cakes and acts as a demulsifier to break the water-in-oil emulsions present in such oil base and synthetic oil base muds.

Owner:BAKER HUGHES INC

Method for manufacturing membrane electrode assembly of fuel cell by printing processes

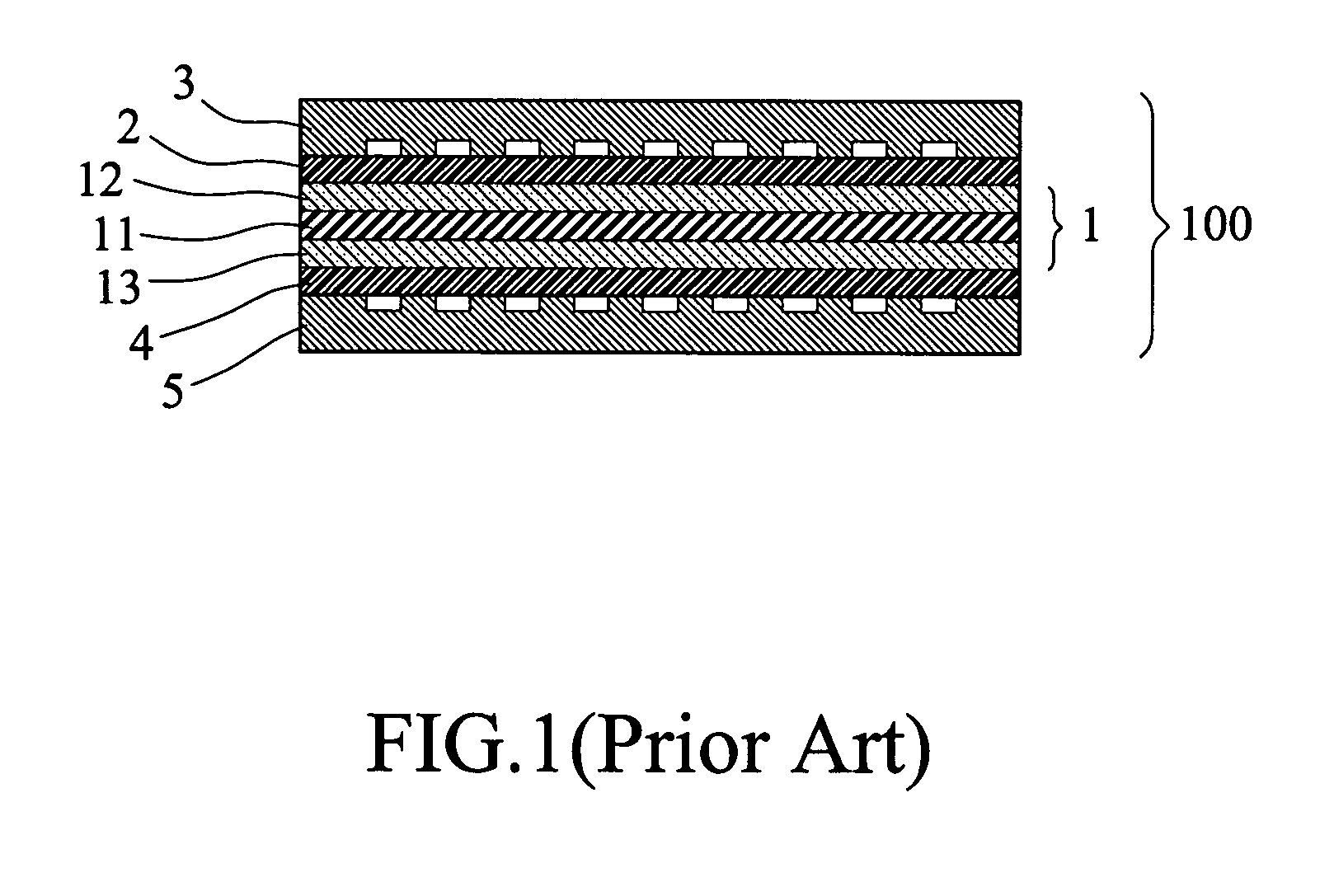

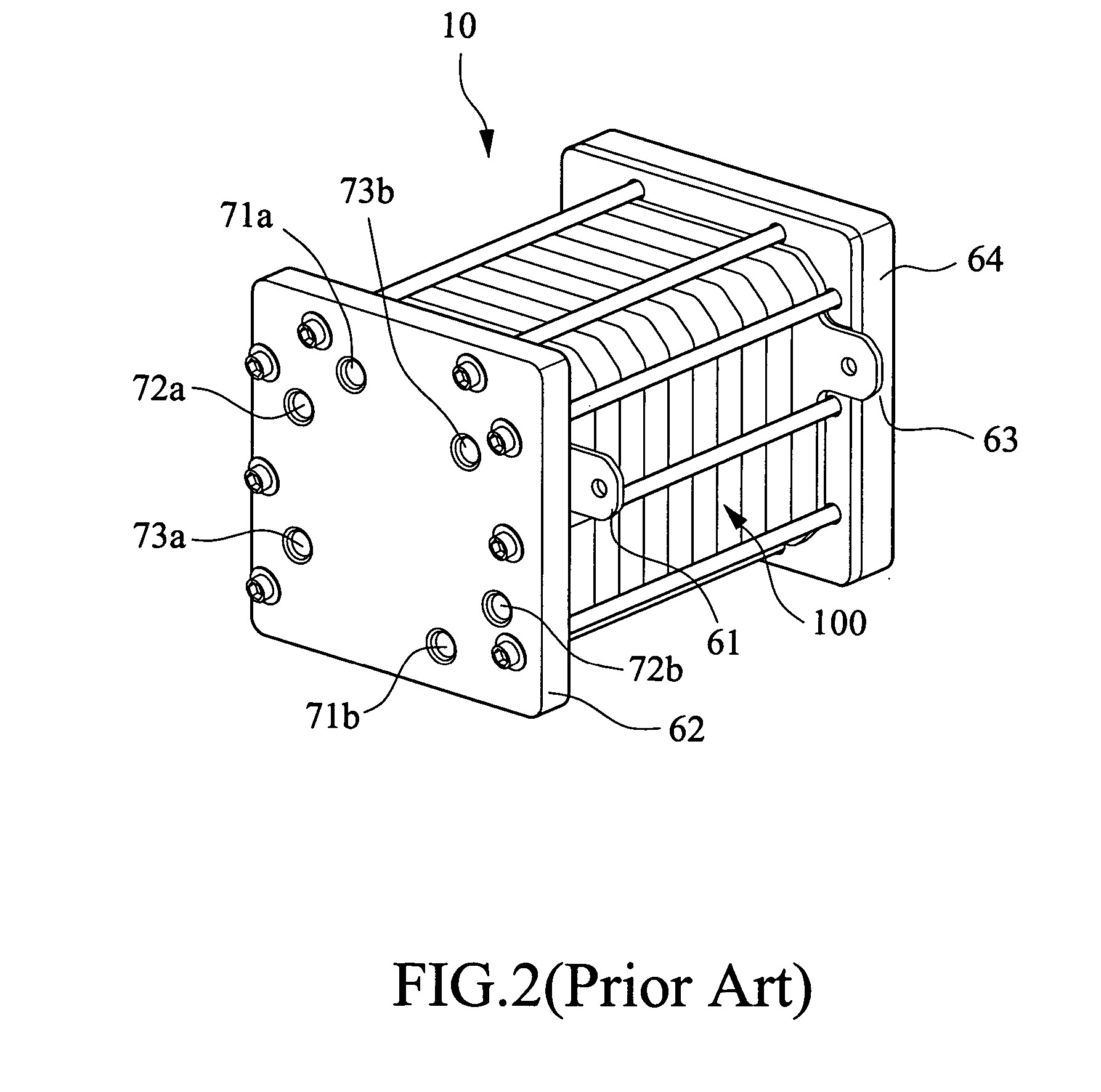

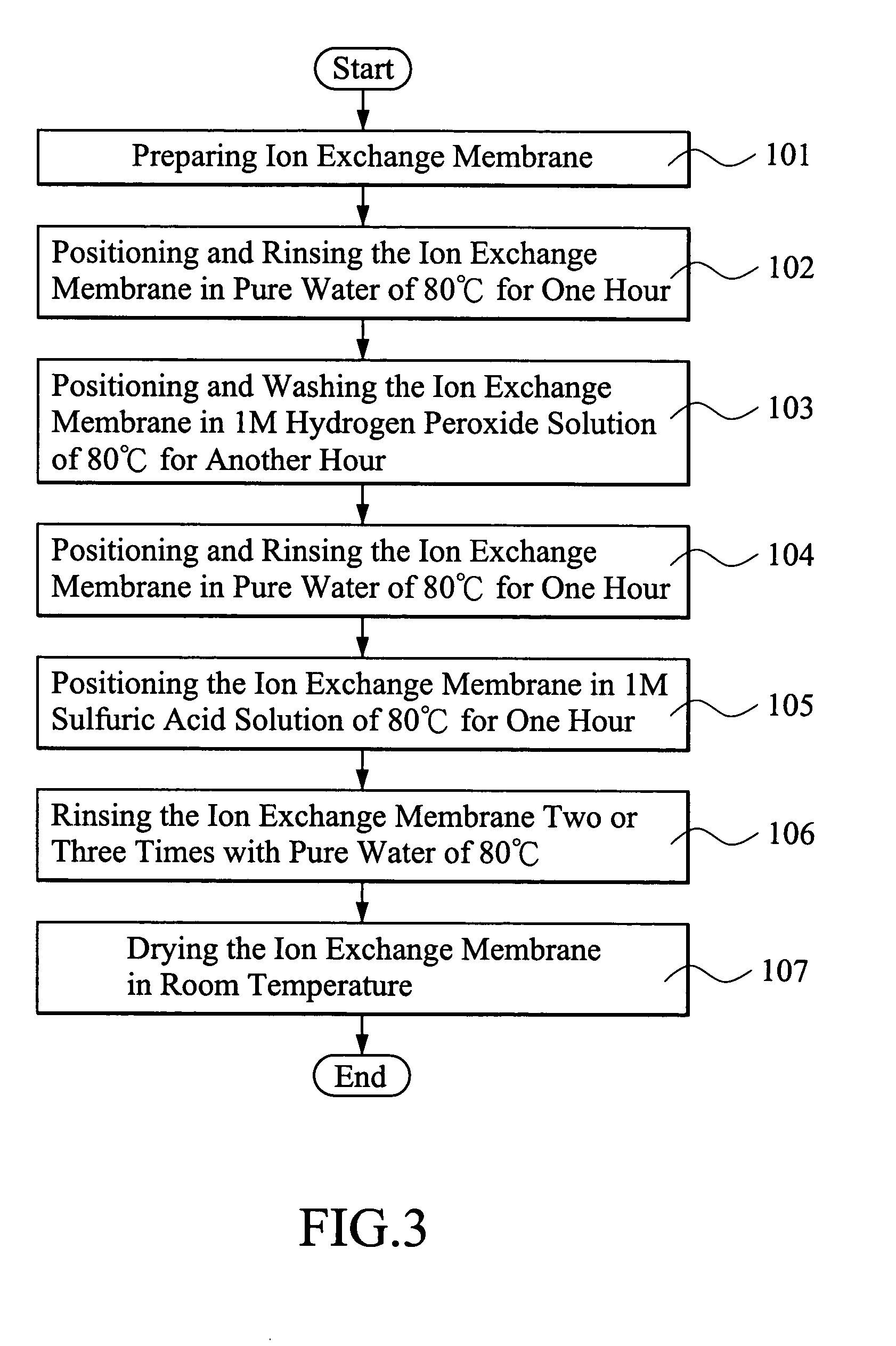

InactiveUS20050276913A1Small local thickness variationQuality improvementLamination ancillary operationsIon-exchanger regenerationFuel cellsEngineering

A method for manufacturing membrane electrode assembly of fuel cell includes positioning an ion exchange membrane that is cleaned and trimmed to a predetermined size in advance to a base plate, mounting the base plate to a printing platform, attaching a printing plate to the platform, coating a catalyst solution on the printing plate with a scraper, printing the catalyst solution onto the ion exchange membrane with the scraper, heating the ion exchange with a heating board to a temperature of 70-80° C., and waiting for the ion exchange membrane to return flat to complete the coating of the catalyst solution on the ion exchange membrane. The printing and heating steps are repeated for both anode and cathode of the ion exchange membrane. The ion exchange membrane is further subject to hot pressing and then a piece of carbon cloth is positioned on the catalyst coating to serve as a diffusion layer. This completes the manufacturing of the membrane electrode assembly.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Nucleic acid extraction lysate for cast-off cells in human feces and preparation method and application of nucleic acid extraction lysate

ActiveCN107937391AHigh purityHigh yieldMicrobiological testing/measurementDNA preparationEthylenediamineGuanidinium thiocyanate

The invention provides a nucleic acid extraction lysate for cast-off cells in human feces. The nucleic acid extraction lysate comprises 1-8 mol / L guanidinium, a 1-20 mM metal ion chelating agent and a100 mM Tris-HCl buffer solution with the pH of 7.5-8.0, wherein guanidinium is selected from at least one of guanidine hydrochloride, guanidinium isothiocyanate and guanidine thiocyanate; the metal ion chelating agent is selected from at least one edetic acid and water soluble salt of edetic acid. Preferably, the nucleic acid extraction lysate further comprises a surfactant with the volume of 1-20%, the surfactant is a non-ionic detergent, and the non-ionic detergent is selected from at least one of Tween-20, Tween-80, Brij-35, NP40 and Triton-100. The invention further provides a related preparation method and application. The nucleic acid extraction lysate can quickly and efficiently realize cell lysis, fully releases nucleic acid, meets the consumption demand for follow-up nucleic aciddetection and is suitable for large-scale popularization.

Owner:SHANGHAI TELLGEN LIFE SCI CO LTD +1

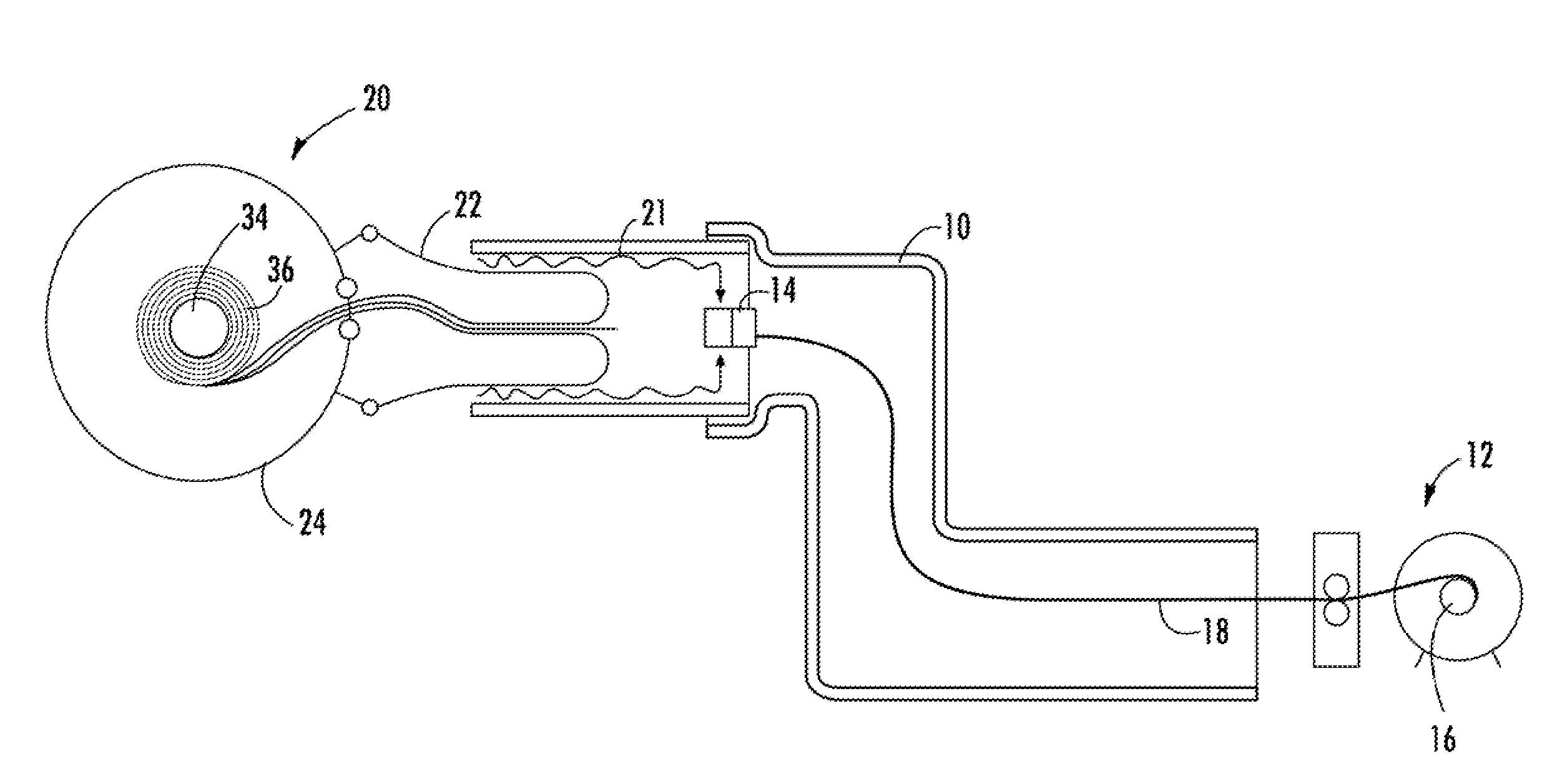

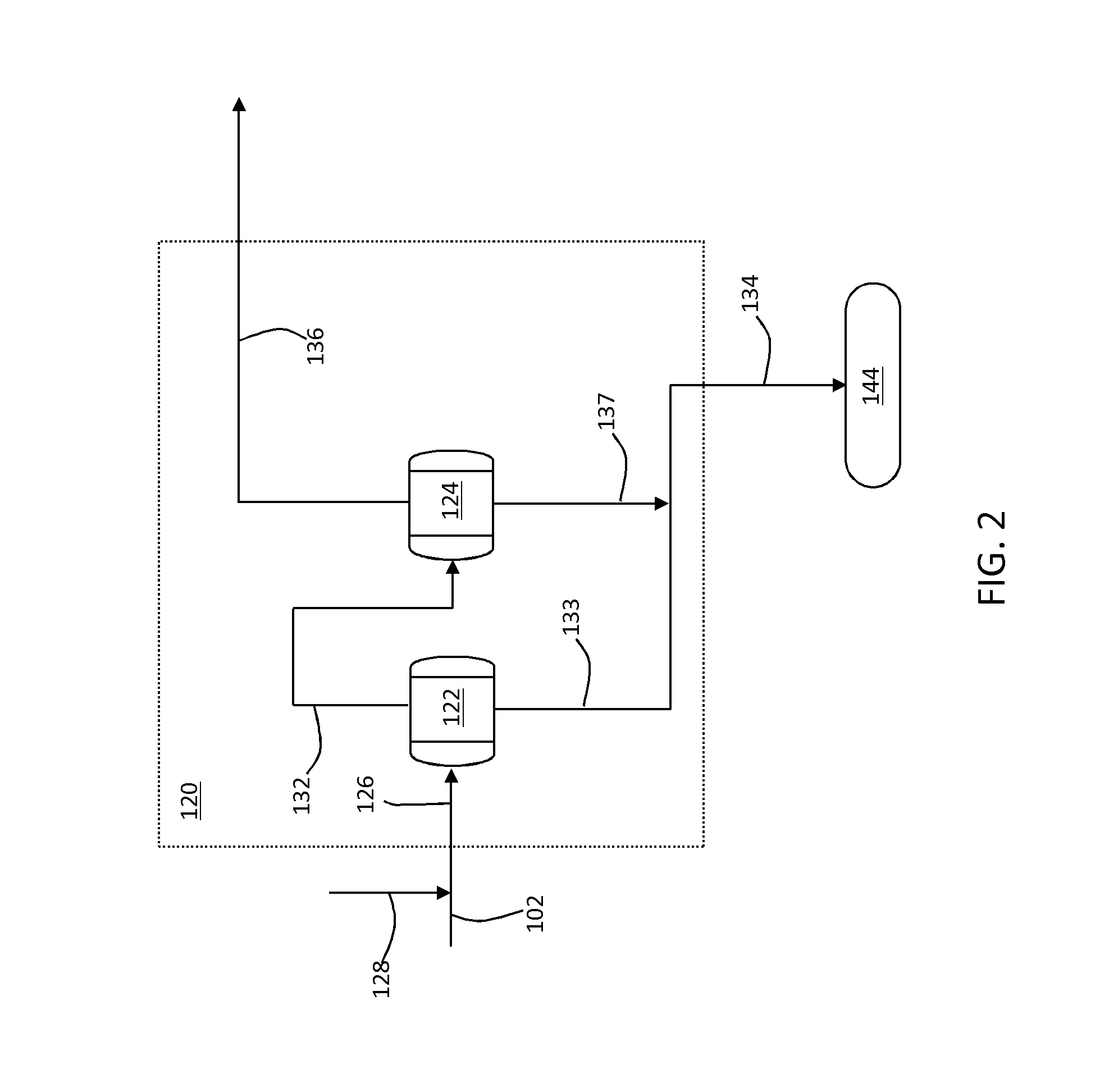

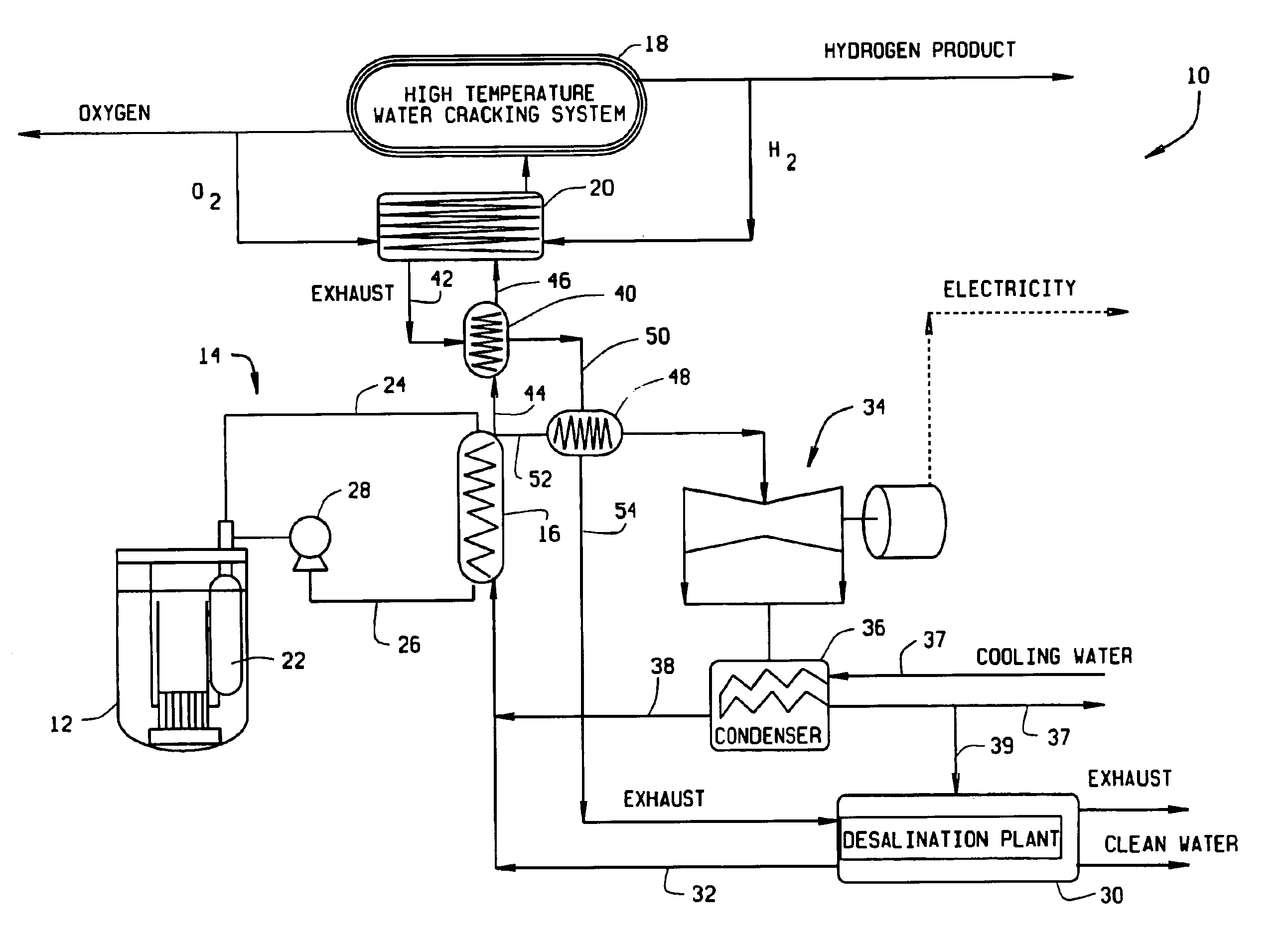

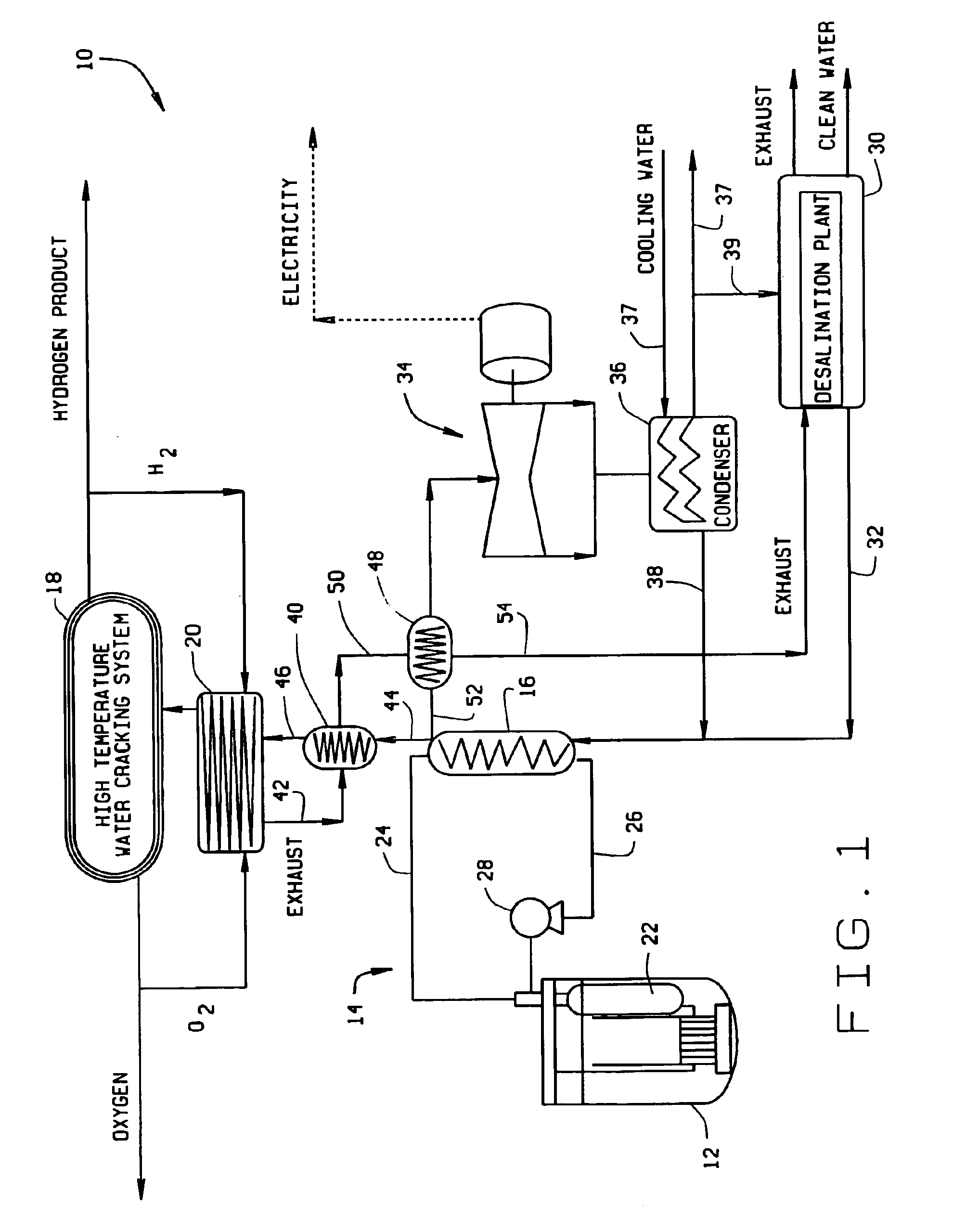

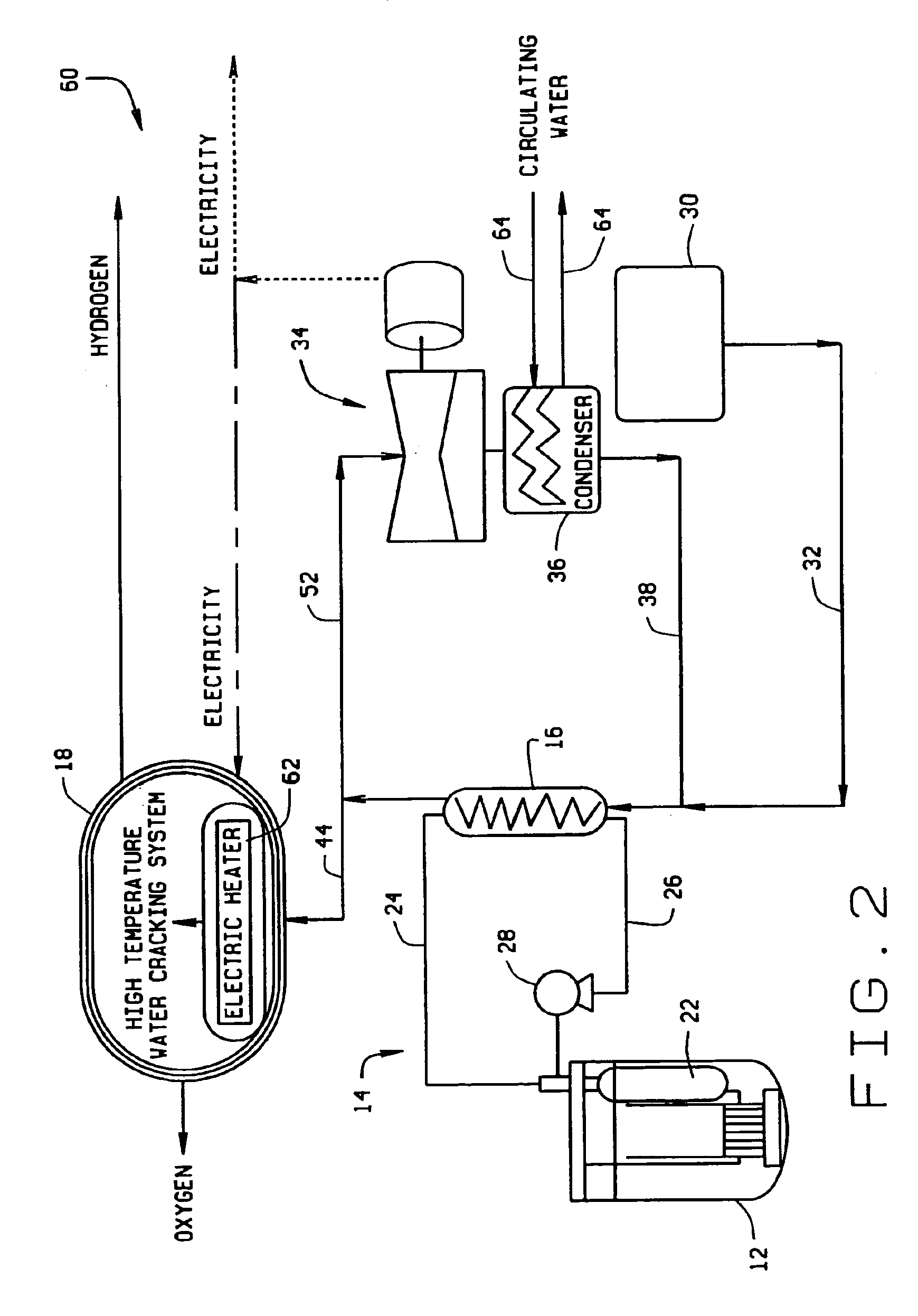

Systems and methods of producing hydrogen using a nuclear reactor

InactiveUS6862330B2Low costEfficient crackingNuclear energy generationConversion in nuclear reactorNuclear reactor coreNuclear reactor

A system for generating hydrogen includes a liquid metal nuclear reactor having a non-radioactive secondary heat loop, a steam generator connected to the secondary heat loop, a high temperature water cracking system, and a topping heater. The heat produced by the nuclear reactor is used to raise the temperature of the feed water for the cracking system to between about 450° C. to about 550° C. The topping heater raises the feed water temperature from the 450° C. to 550° C. range to at least 850° C. so that the cracking system can operate efficiently to produce hydrogen and oxygen.

Owner:GENERAL ELECTRIC CO

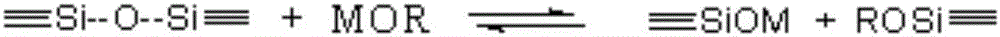

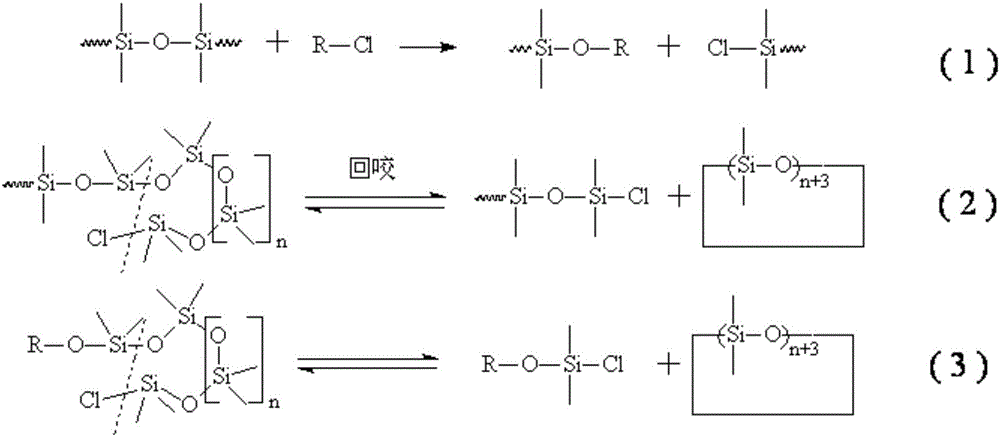

Method for recovering organosilicon micro-molecules and organosilicon cyclic compounds through cracking silicone rubber serial substances

The invention relates to a method for recovering organosilicon micro-molecules and organosilicon cyclic compounds through cracking silicone rubber serial substances. The method comprises the following steps: a chemical reaction of an organosilicon halogenation agent and a polysiloxane main chain in silicone rubber is carried out to break the polysiloxane main chain into polysiloxanes with silicon-chlorine bonds, and the polysiloxanes with silicon-chlorine bonds undergo a series of back-biting reactions and are degraded into an organosilicon micro-molecule and organosilicon cyclic compound mixture; and organosilicon micro-molecules and organosilicon cyclic compounds obtained after cracking undergo a rearrangement reaction to obtain highly pure D4 used for synthesizing various organosilicon polymers and materials as a basic raw material.

Owner:SHANDONG UNIV

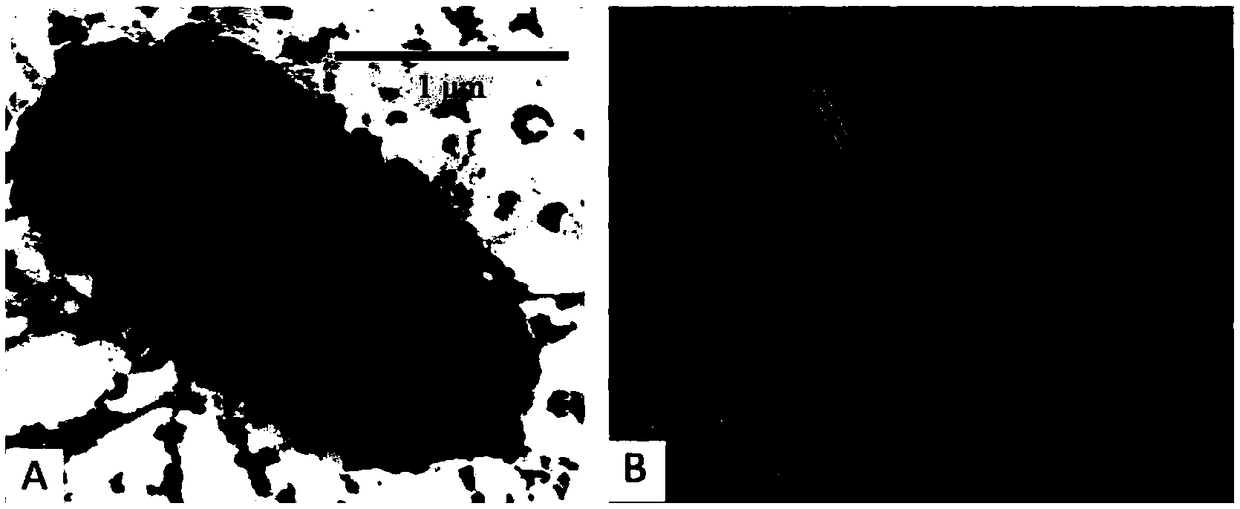

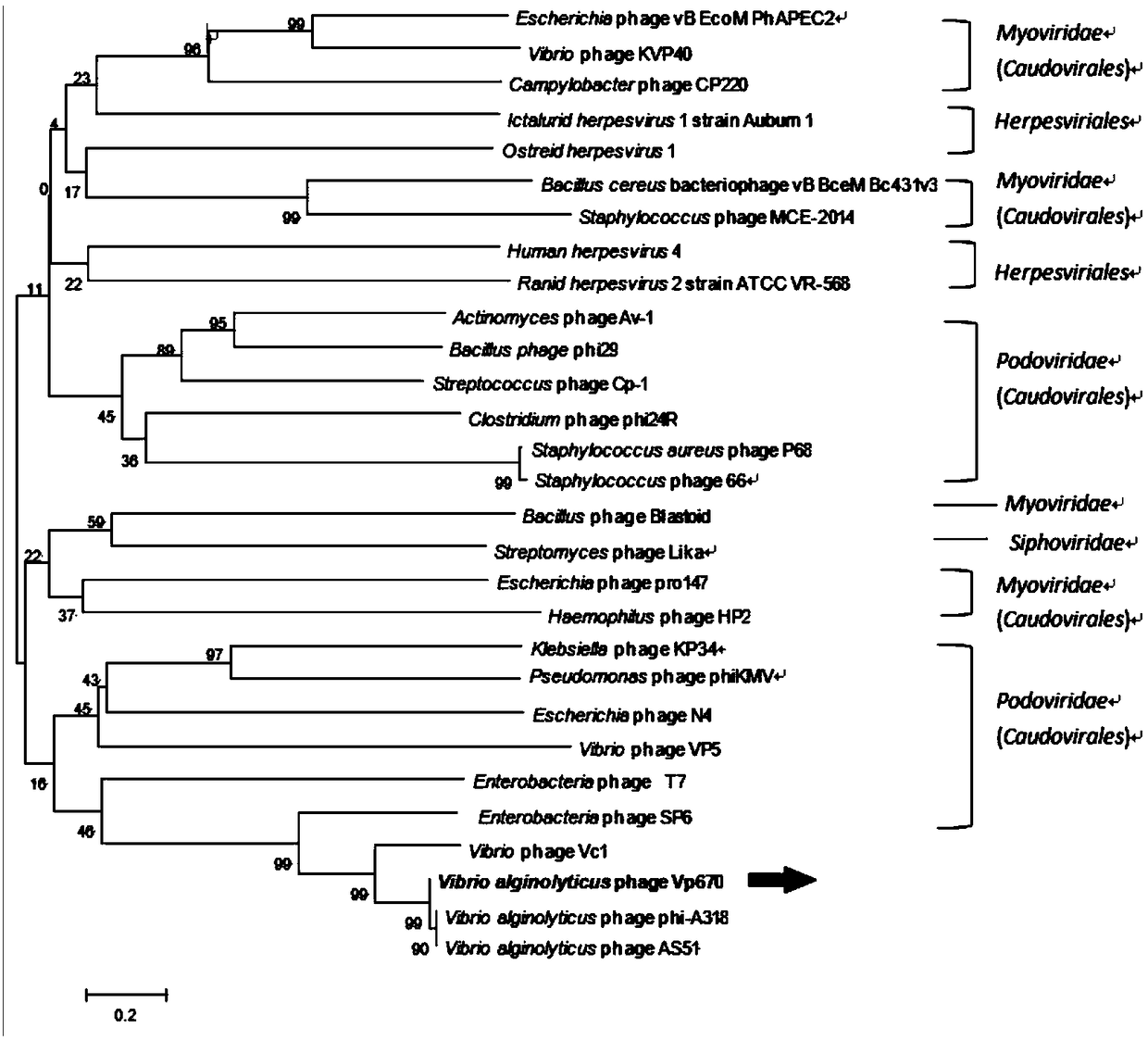

Vibrio alginolyticus bacteriophage preparation and preparation method and application thereof

InactiveCN108651522AEfficient crackingAvoid infectionAntibacterial agentsBiocideAquaculture industryMarine aquaculture

The invention discloses a vibrio alginolyticus bacteriophage preparation and a preparation method and application thereof. Auxiliary agents such as vibrio alginolyticus bacteriophage Vp670 and trehalose are adopted for developing the corresponding bacteriophage preparation. After application, the bacteriophage preparation continuously exists in a water environment for a long time to keep quantitybalance of pathogenic host bacteria and bacteriophage, so that effect durability and low consumption are achieved as compared with those of antibiotics. The bacteriophage Vp670 preparation is free oftoxic and side effects, is a novel green biological sterilization preparation and can be used for prevention and control of vibrio alginolyticus infection of animals in marine aquaculture to promote healthy development of the aquaculture industry.

Owner:广州诺晶生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com