Supported catalyst and application thereof in hydrocracking reaction of xylitol

A technology for supporting catalysts and catalysts, applied in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve problems such as environmental pollution and waste of renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 catalyst preparation

[0018] For preparing catalyst of the present invention, carrier adopts coconut shell activated carbon, and its characteristics are as follows:

[0019] Specific surface: 1306.80m 2 / g; average pore size: 2.4nm; particle size: 80-100 mesh. Dry before use.

[0020] Catalyst preparation process: Weigh a certain mass of nickel nitrate, dissolve it in water, then add 10 g of dried activated carbon carrier (nickel loading is 10%), impregnate for 24 hours, and dry overnight. After the preparation of the supported nickel nitrate precursor is completed, it is calcined at 250-600°C for 3h; then use 0-2M KBH containing 0.2MNaOH 4 Disposal of the reduced catalyst.

Embodiment 2

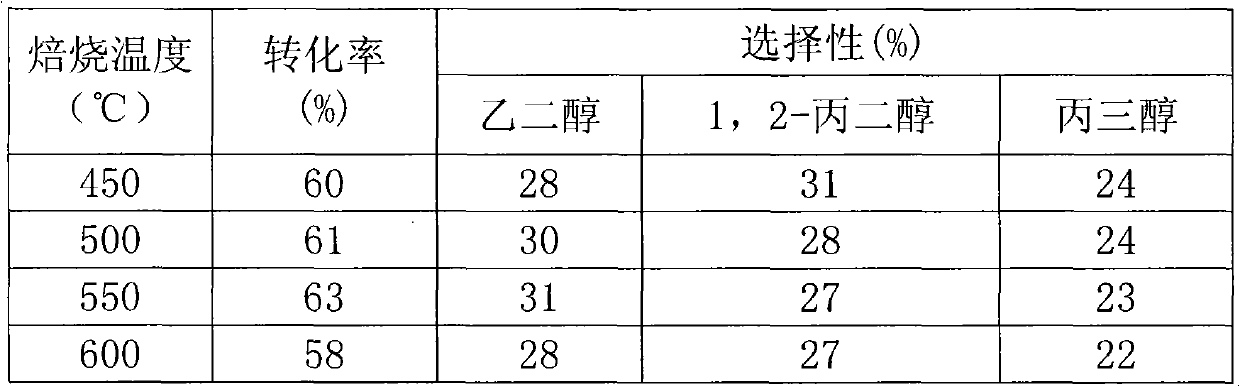

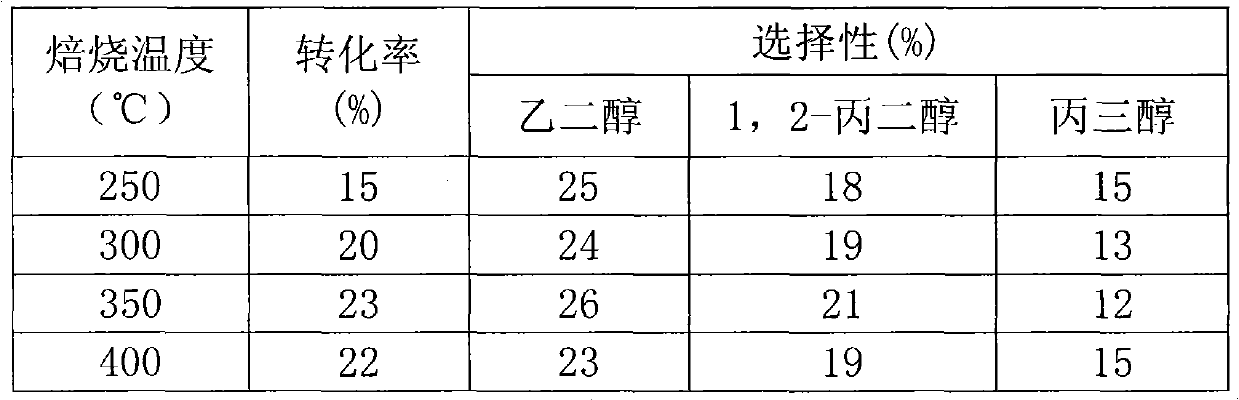

[0021] Example 2 The activity evaluation of the catalyst prepared by carbothermal reduction at different calcination temperatures

[0022] This example studies the influence of one of the key steps in the catalyst preparation process - high temperature calcination for carbothermal reduction on the performance of the catalyst. KBH 4 The concentration is 2M.

[0023] Catalyst performance evaluation: 5 g of the catalyst prepared in Example 1 and 150 g of 10% xylitol aqueous solution were added to a 600 ml autoclave, and the air was replaced with hydrogen for 5 times after sealing. Heat the reaction vessel, and when the temperature reaches 200°C, fill it with hydrogen at a pressure of 5 MPa, stir rapidly, and start timing the reaction. After 6 hours, the stirring was stopped, and the hydrogen gas was released after the temperature of the reaction kettle was lowered to room temperature. Sampling analysis, xylitol quantitative analysis using liquid chromatography-differential ref...

Embodiment 3

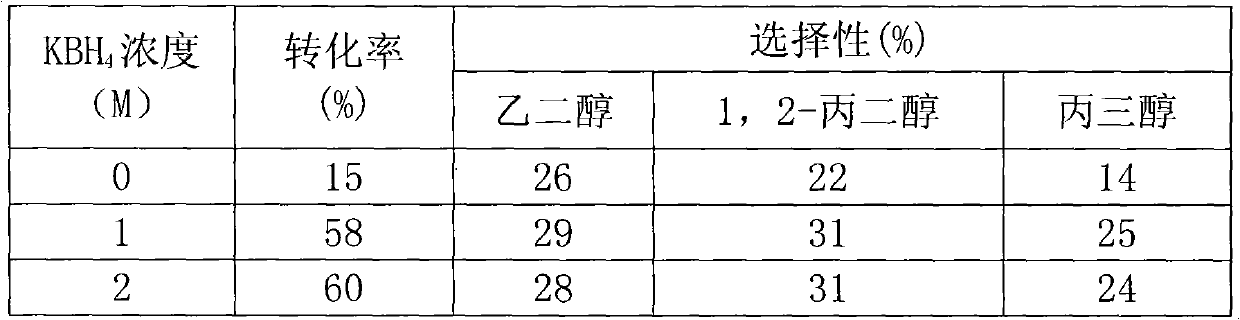

[0030] Example 3KBH 4 The effect of adding on the catalyst performance

[0031] This example studies the second key step in the catalyst preparation process—passing the carbon-thermally reduced catalyst through KBH 4 After treatment, the effect on catalyst performance. The catalyst is the catalyst in Example 1, and the carbothermal reduction temperature is 450°C.

[0032] The performance evaluation of the catalyst is the same as in Example 2, and the results are shown in Table 3.

[0033] table 3

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com