Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Beautiful exterior" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

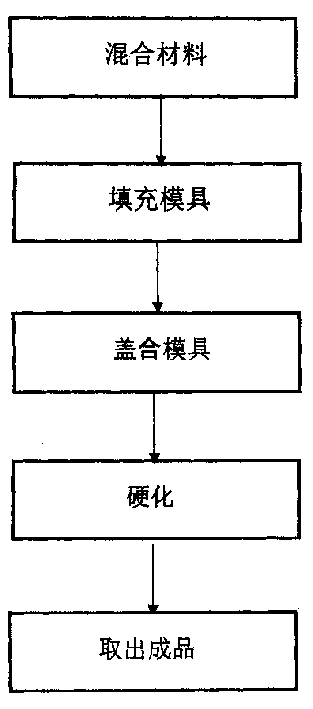

Grey brick mechanically manufactured from lime sludge and construction wastes and method for manufacturing same

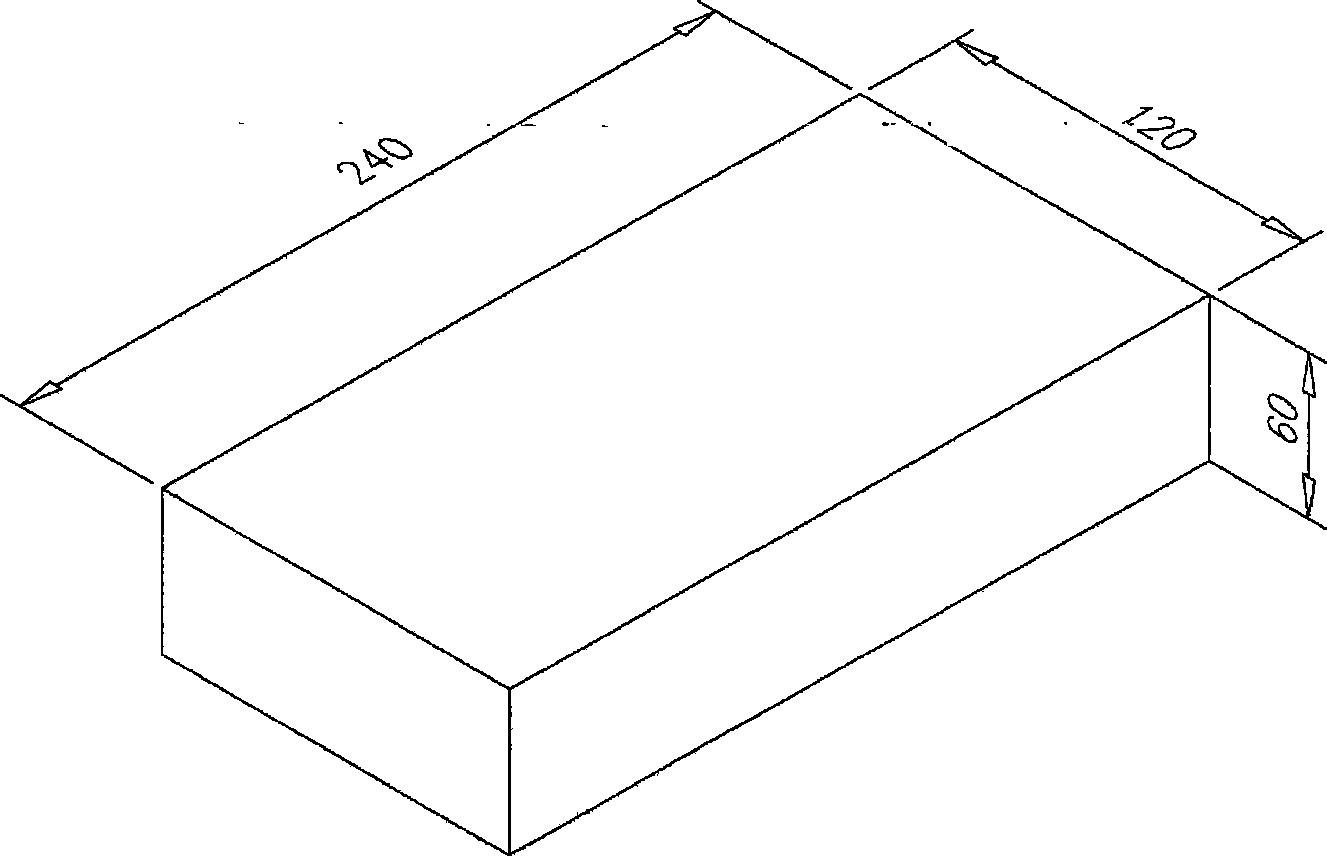

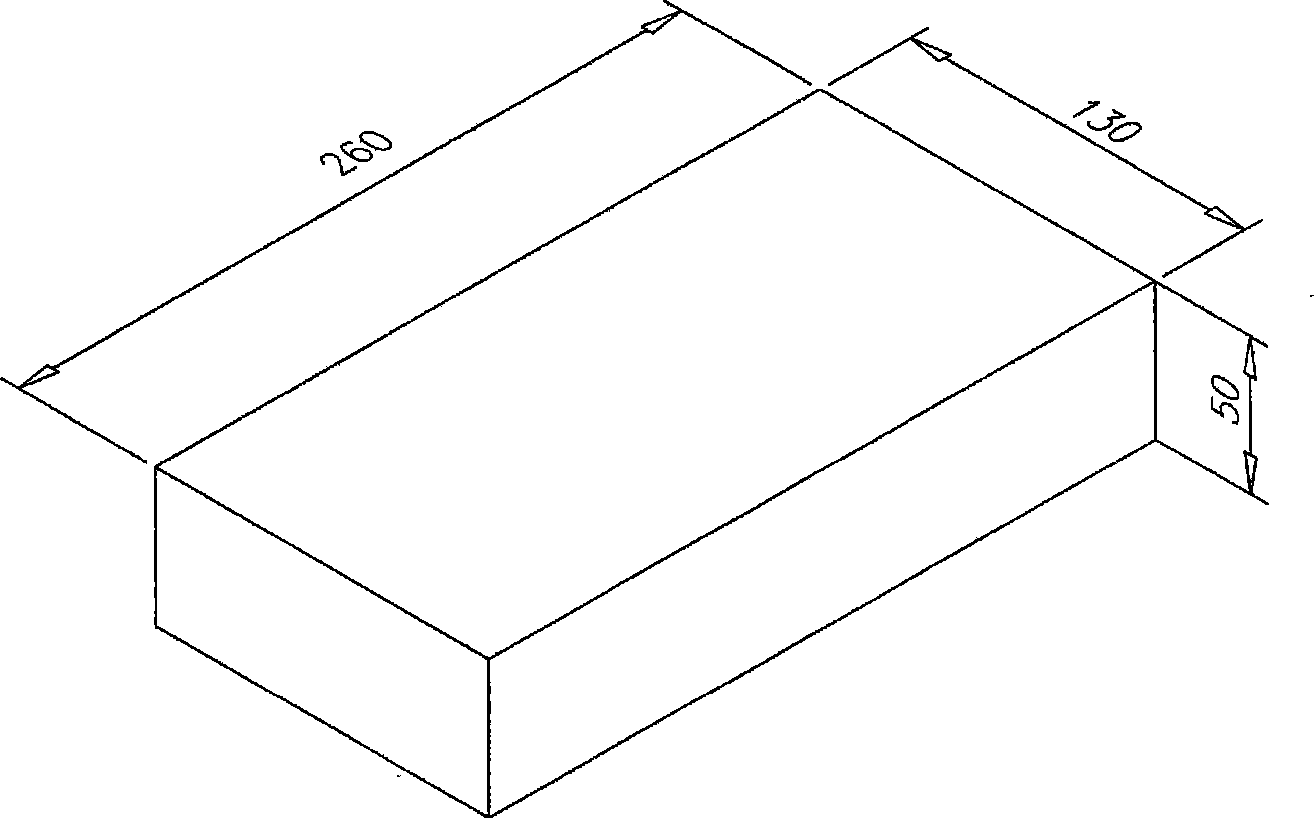

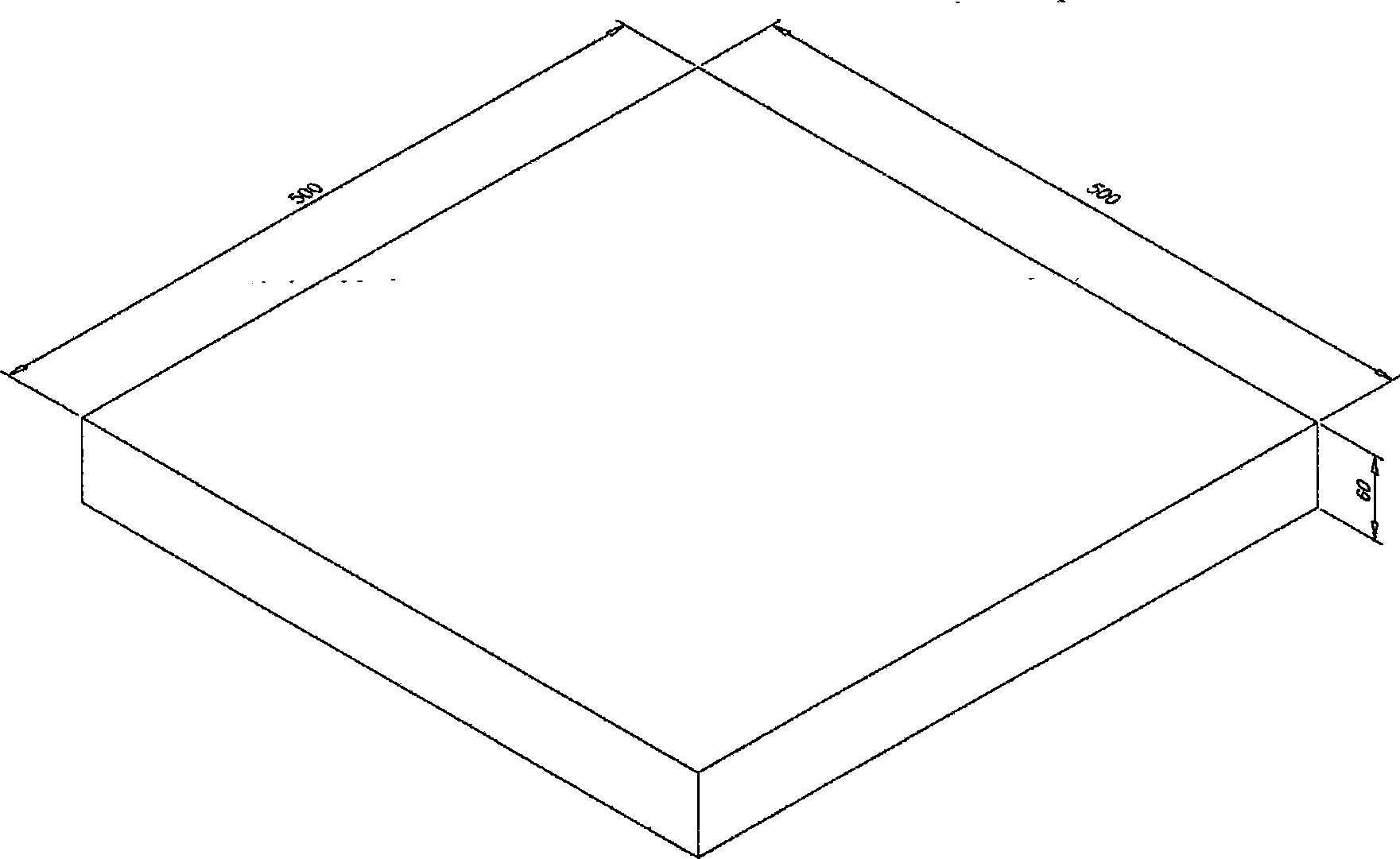

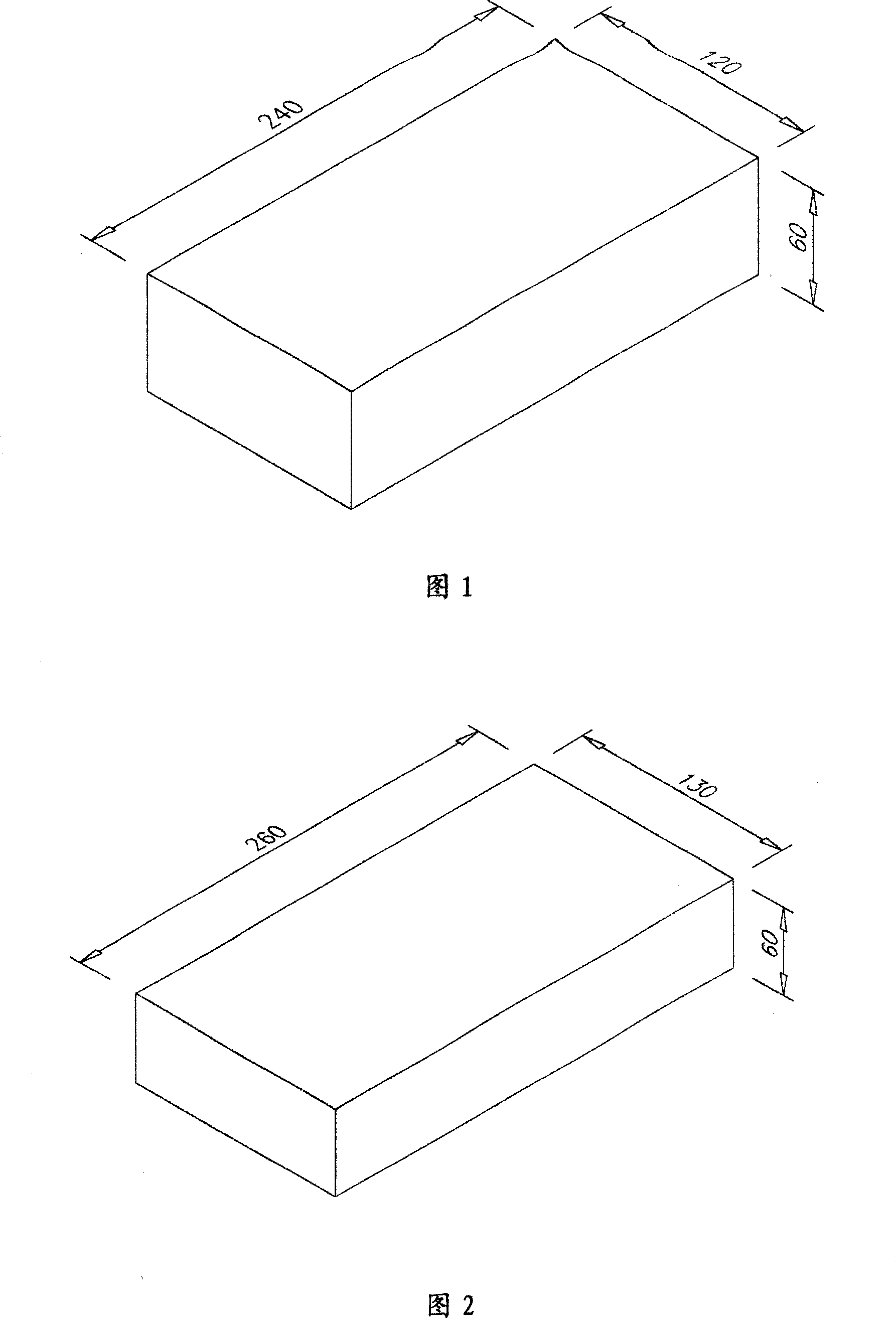

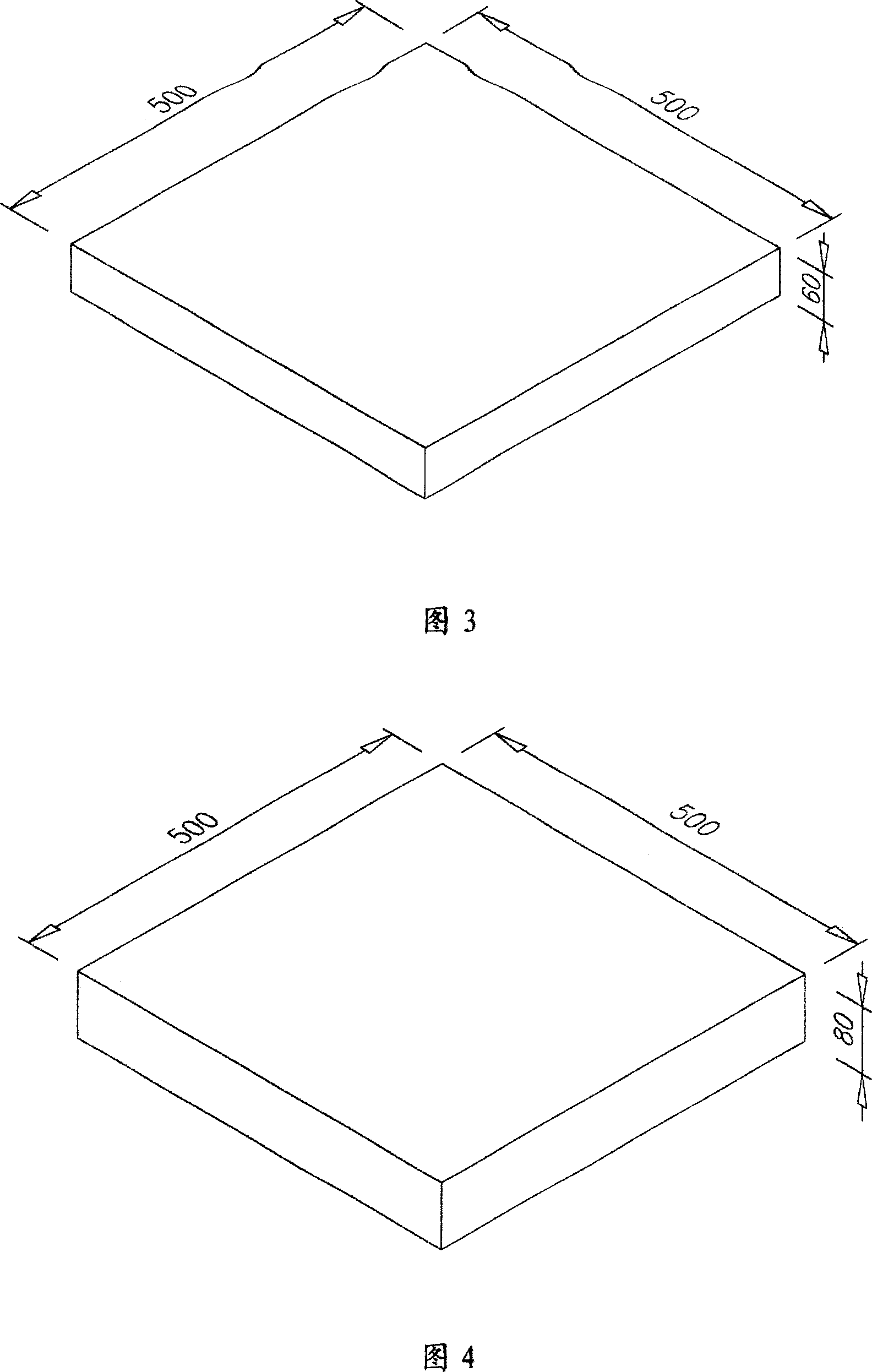

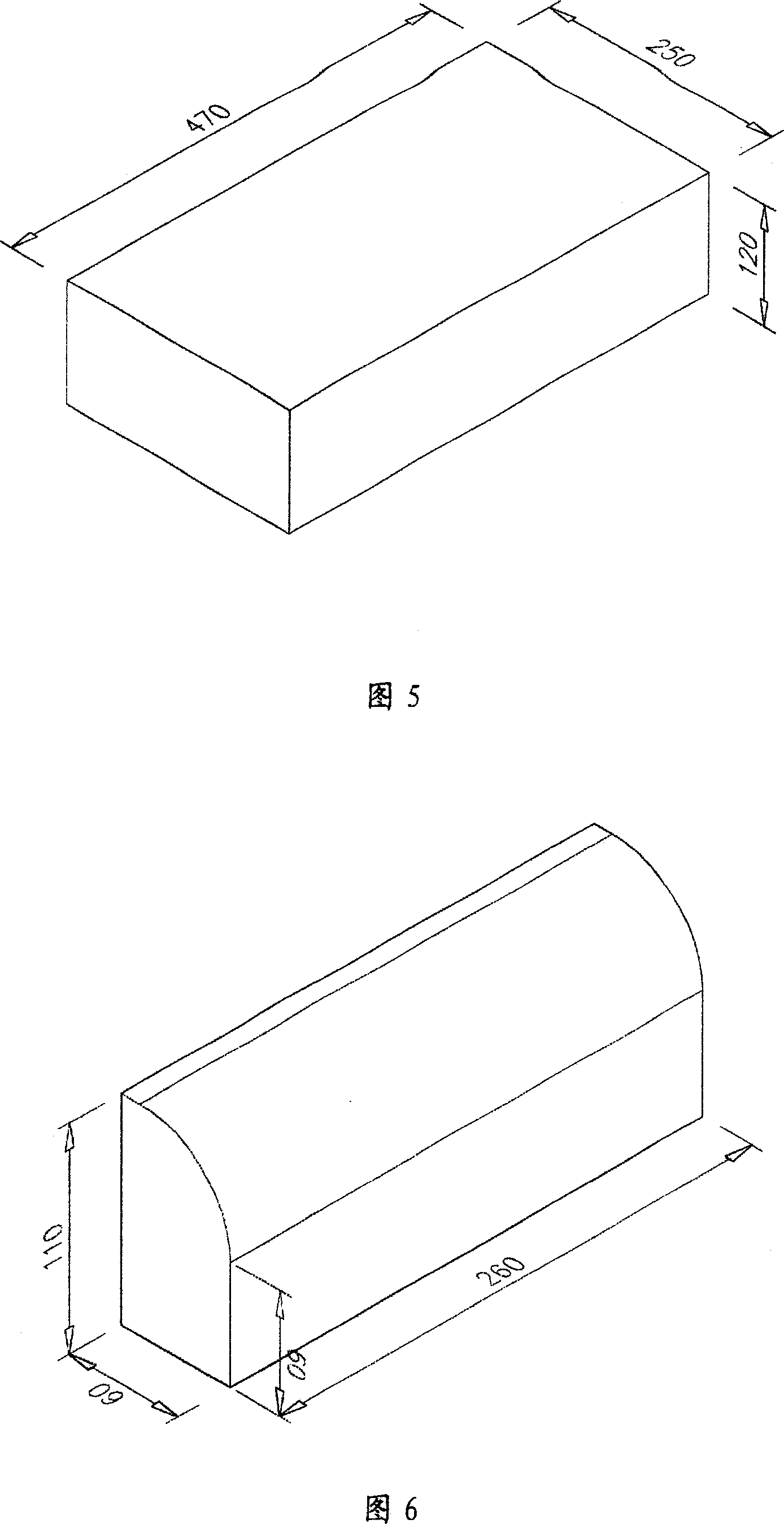

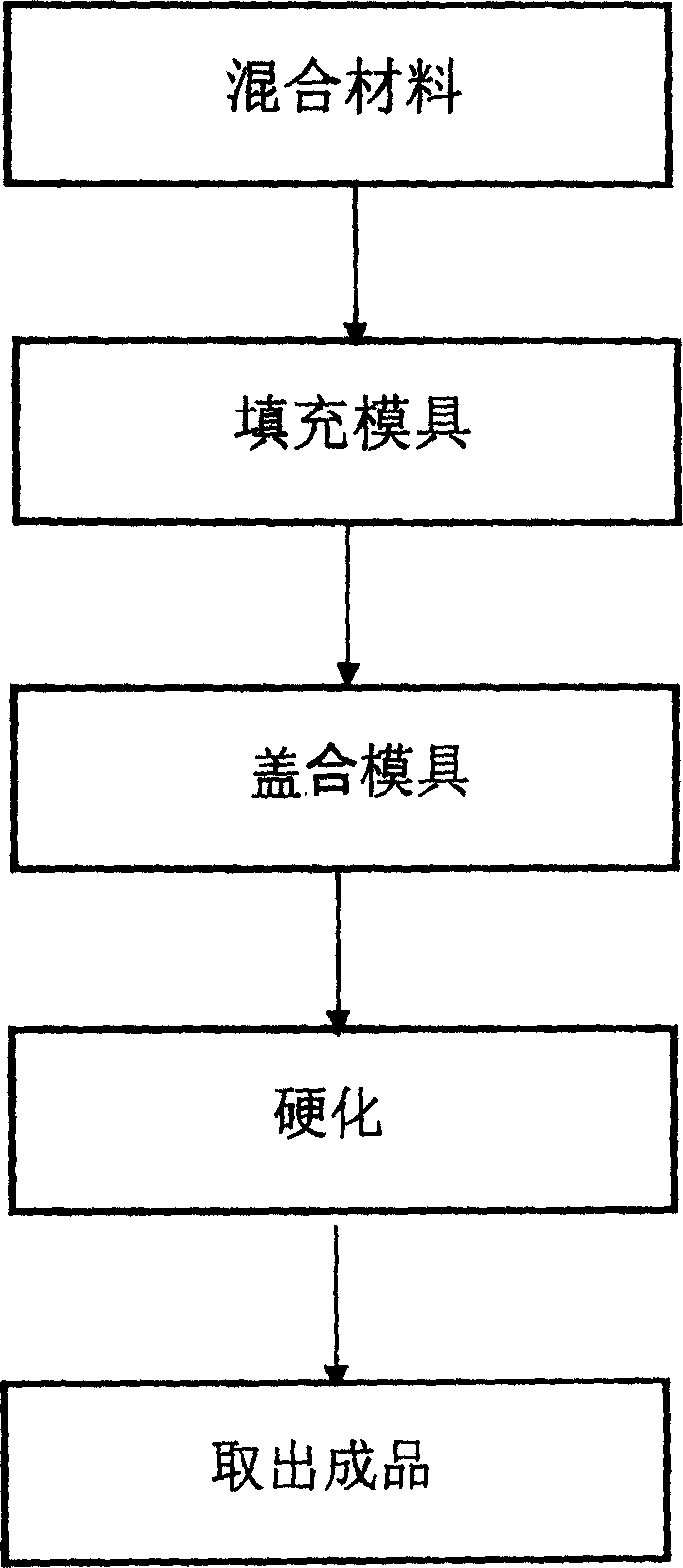

The invention discloses a gray brick mechanically manufactured from lime sludge and construction wastes and a method for manufacturing the same. The materials for mechanically manufacturing the gray brick comprise the following raw materials in portion by weight: 1,015 to 1,135 portions of construction waste crushed materials, 240 to 290 portions of cement, 810 to 1,010 portions of lime sludge, 60 to 75 portions of gray lime, and 100 to 125 portions of water, wherein the particle size of the construction waste crushed materials is less than 15 millimeters. If necessary, less than 20 portions of fly ash and proper amount of activating agent can be added to the materials. The method for mechanically manufacturing gray brick comprises the following steps: firstly, crushing the construction wastes; secondly, mixing the construction waste crushed materials with the other materials according to the proportions; and thirdly, pressing the mixture by adopting a mechanical method so as to produce the gray brick of the invention. The gray brick and the method for manufacturing the same recycle the sludge and the construction wastes in a reducing, harmless and resource-utilizing mode, and solve the problem that substituting materials and products are hard to find after clay bricks are forbidden to use and the problem of gray brick sources for civilian constructions.

Owner:梁林华 +1

Machine-made archaized blue bricks

InactiveCN101003154ASolve processing problemsAvoid pollutionMixing operation control apparatusCeramic shaping apparatusBrickLitter

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Combined process for manufacturing door

InactiveCN101797763AReduce areaReduce consumptionWood mortising machinesFlat articlesConnection formOil paint

The invention relates to the technical field of wood doors and metal (plastic) doors outside which wooden materials are wrapped, in particular to a combined process for manufacturing a door, which is characterized by comprising the following process steps: a, a door frame manufacturing process; b, a surface board or door core manufacturing process; c, an edge strip manufacturing process; and d, a door assembling process. Compared with the prior art, the invention has the key of changing the production process of a surface material, firstly, the surface material and an economically suitable lining material (thickness is determined by design) are compounded (hot pressing) in advance, and then cutting and machining (plain end, rabbet, V-shaped and other plug connection forms) are carried out to obtain designed width or length dimensions and painting is carried out. The whole production process has high degree of mechanization, high production efficiency, esthetic exterior appearance, little manual work and reduction of dependence on people. The production factory area is reduced and the consumption of oil paint (process waste part) is reduced. The concave and convex phenomena of finished product appearances of the existing wood doors can be avoided.

Owner:张建岩

Method for manufacturing latex material underlaying appliance

Owner:SIX VICTOR

Sintered water permeable brick with smooth and mildew-proofing surface

The invention discloses a sintered water permeable brick with a smooth and mildew-proofing surface. The water permeable brick is prepared from the following raw materials in parts by weight: 40-43 parts of sludge of a sewage plant, 6-7 parts of rice husks, 4-5 parts of potassium feldspar powder, 5-6 parts of pulverized fuel ash, 3-4 parts of bamboo powder, 8-10 parts of activated pozzolana, 19-21 parts of fluorite tailings, 4-5 parts of noan-silicon carbide, 2-3 parts of sodium carboxymethyl cellulose and 3-4 parts of light magnesium oxide. According to the sintered water permeable brick, the fluorite tailings, palm fibers, nano-silicon carbide and other ingredients are added to serve as aggregate ingredients of a brick blank, so that the tensile strength and crack resistance of a brick body can be enhanced, and the porosity of the brick body is further improved; the bamboo powder added into the brick is turned into a bamboo charcoal ingredient by means of sintering, so that the water permeable brick has excellent antibacterial and mildew-proofing effect. The manufactured water permeable brick has an attractive appearance and smooth surface, and integrates strength, water permeability and corrosion resistance into a whole.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

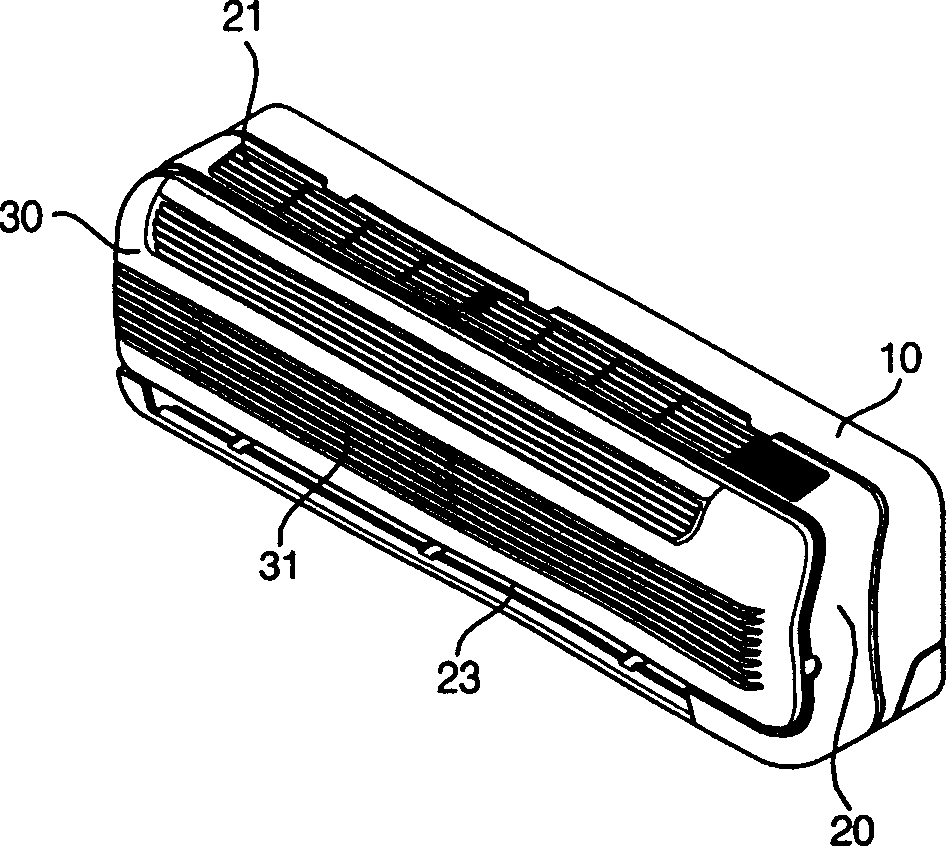

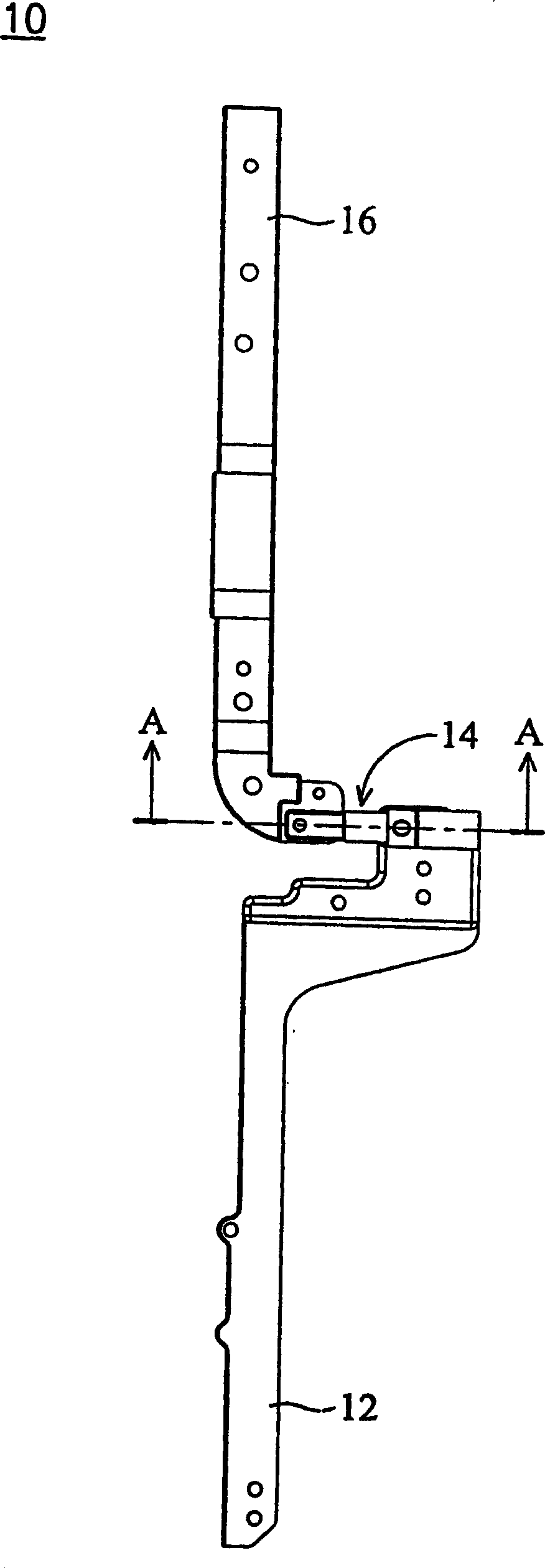

Air inlet board open/close structure for air conditioner

InactiveCN1502933ABeautiful exteriorIncreased intake air capacityAir-flow control membersRefrigerationIndoor air

The present invention relates to an opening and closing structure of air intake board of air conditioner. It includes front panel, air intake board and cover limiting device. The upper side of the front panel is formed into upper surface suction inlet, its front surface is formed into front suction inlet and its lower side is formed into discharge outlet. The lower end of the air intake board can be hung on the front panel by means of removable hooking device to cover the above-mentioned front suction inlet, and the above-mentioned cover limiting device is used for opening front suction inlet covered by air intake board so as to increase the volume of sucked air. Said structure can be used for smoothly sucking indoor air and can raise refrigeration efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Ultrathin thermal insulating decorating integrated plate mounting system

InactiveCN103758317AImprove insulation effectSecure and stable connectionCovering/liningsEngineeringMetal hook

The invention belongs to the field of decorating material production equipment and discloses an ultrathin thermal insulating decorating integrated plate mounting system. The system comprises a wall, a keel, a thermal insulating plate, an ultrathin decorating plate, keel screws, metal hooks and screws. The system is characterized in that the keel is fixed on the outer side of the wall through an upper keel screw and a lower keel screw, one metal hook is sleeved on each of the upper keel screw and the lower keel screw, one end of each metal hook is connected to the thermal insulating plate through one screw, one side of the thermal insulating plate is fixed on the outer side of the keel, and the ultrathin decorating plate is adhered and fixed to the other side of the thermal insulating plate. The ultrathin thermal insulating decorating integrated plate mounting system is attractive in outer wall, good in thermal insulating effect, safe and firm.

Owner:XINJIANG DELIYA ENERGY SAVING TECH

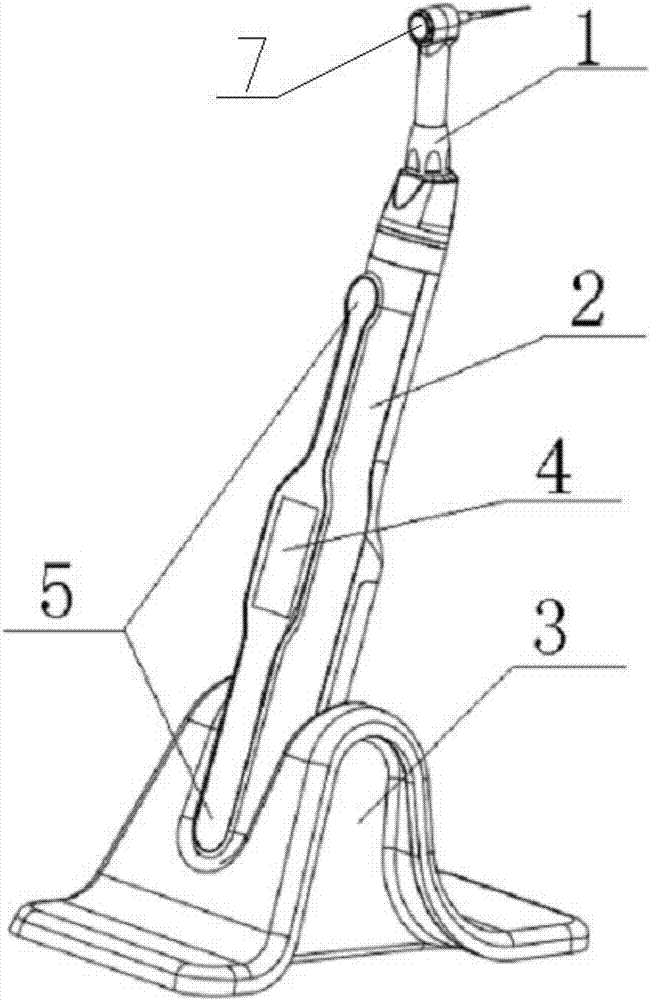

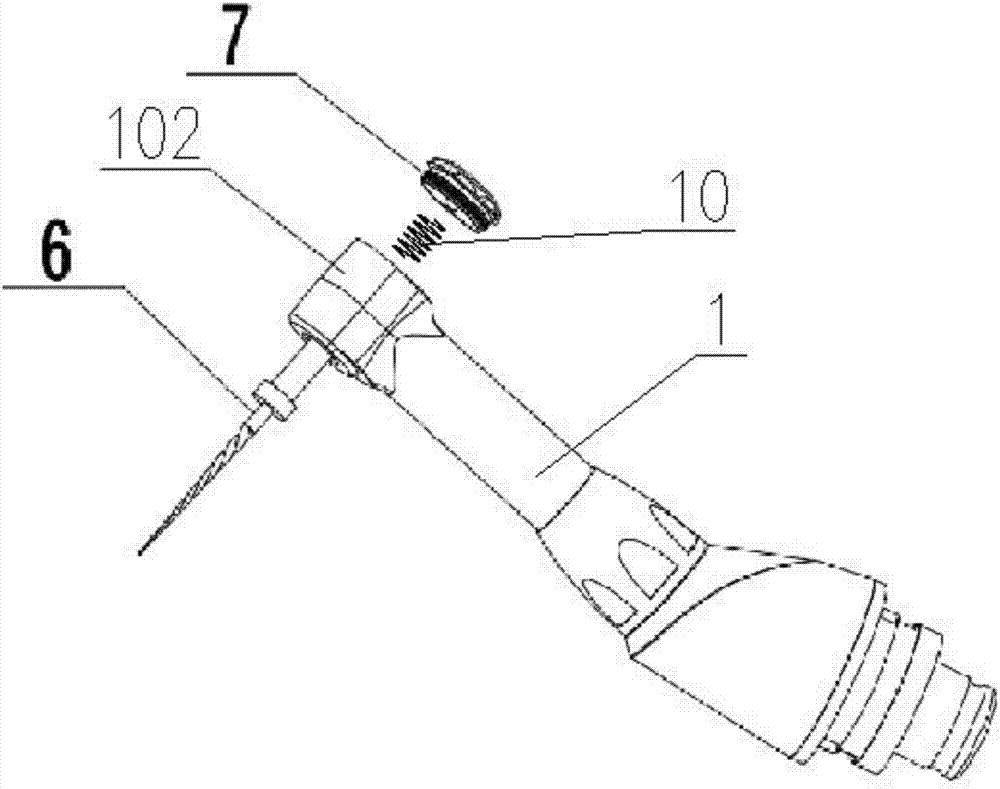

Convenient-to-use root canal apex locator

ActiveCN107007367AGood treatment effectAccurate measurementTeeth fillingTeeth cappingElectricitySilicon rubber

The invention belongs to the field of medical instruments and particularly relates to a convenient-to-use root canal apex locator. The convenient-to-use root canal apex locator comprises a host, wherein a controller and a drive device are arranged in the host; a display screen and a reducing bender are arranged outside the host; the reducing bender is rotationally connected with a root canal file; the drive device drives the root canal file to rotate; a conductive elastic element is clamped between the end surface of the root canal file and the inner side surface of a machine cover; the tail end of the host is connected with a lip hook through a measurement line I; a jack is connected with an input end of the controller; the reducing bender is a metal housing and connected with the input end of the controller through a wire; the controller is used for controlling the length of a display root canal of the display screen; and a silicon rubber case sleeves on the outside of the reducing bender. The convenient-to-use root canal apex locator has the beneficial effects that due to the conductive elastic element, the reducing bender and the root canal file are electrically connected always, the impedance is stable and measurement is accurate; the exposed measurement line does not need to be arranged, signal transmission can be isolated from an oral cavity and measurement is accurate; and an elastic metal clamp does not need to be manually pinched additionally, so that the convenient-to-use root canal apex locator is convenient to use.

Owner:常州博美医疗科技有限公司

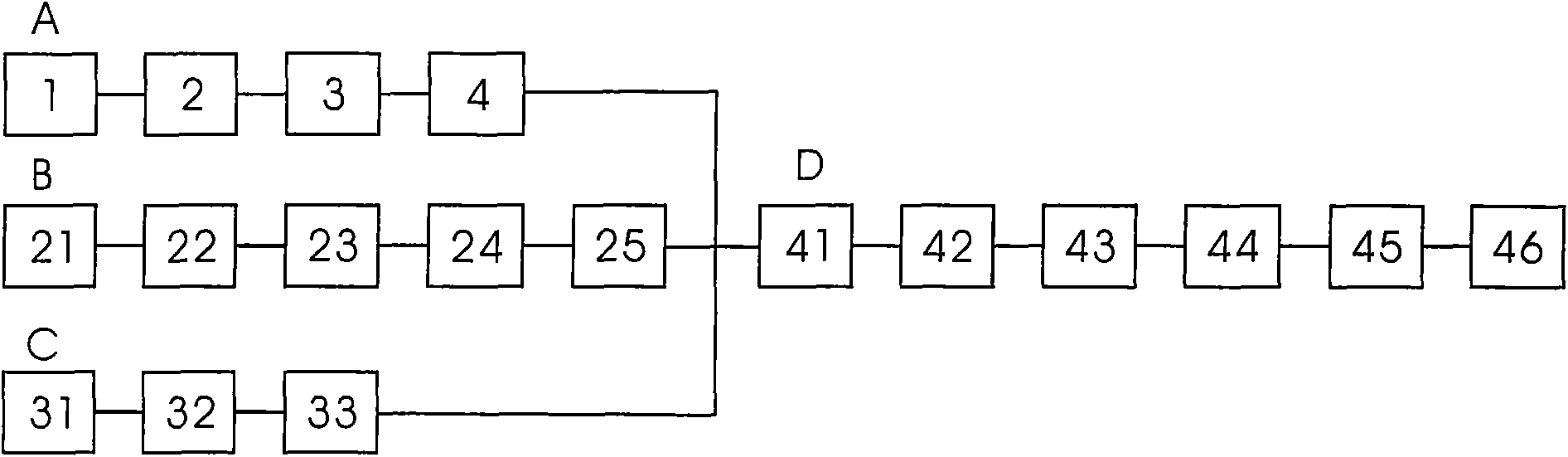

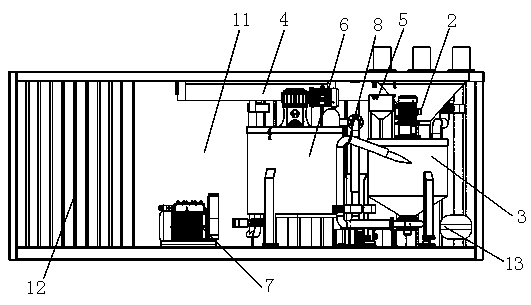

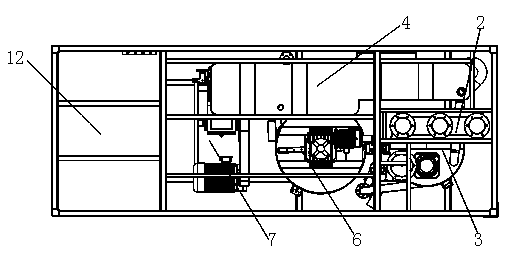

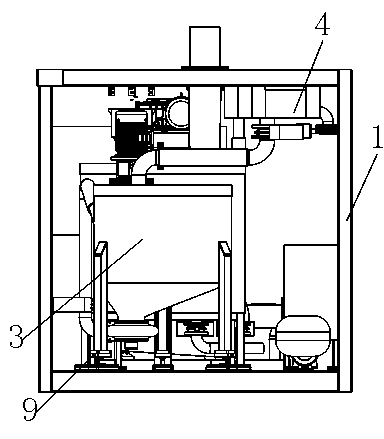

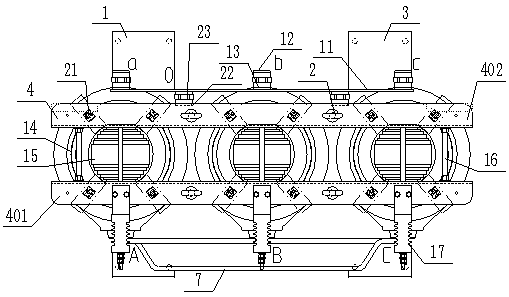

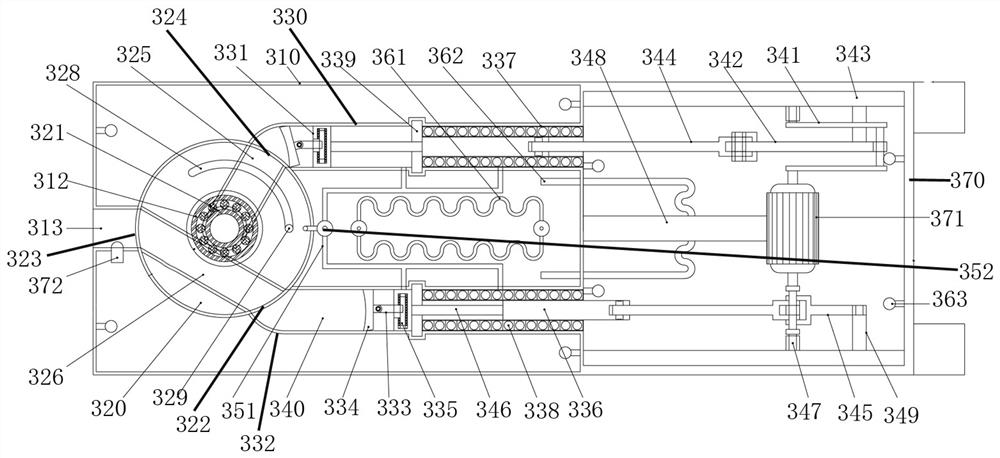

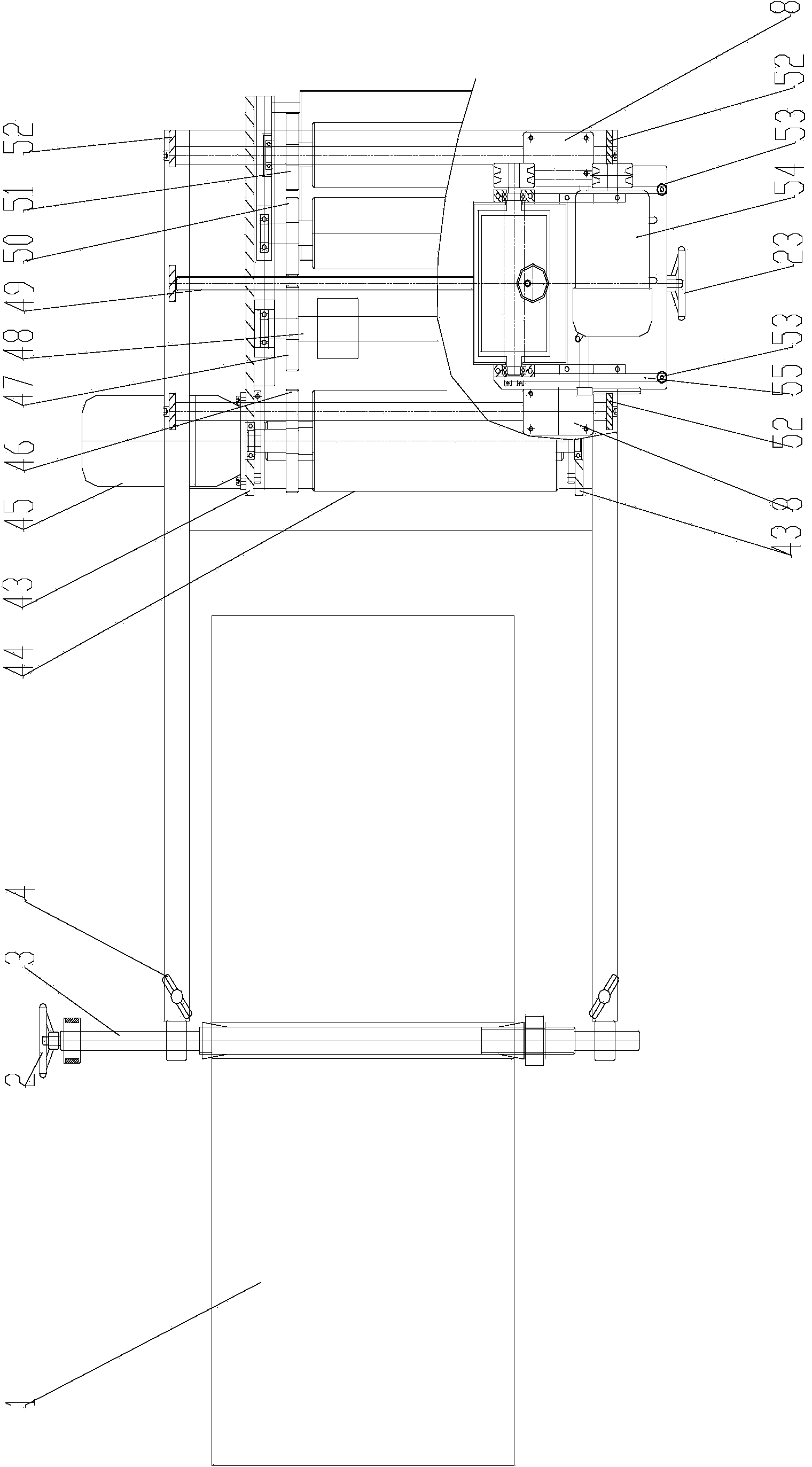

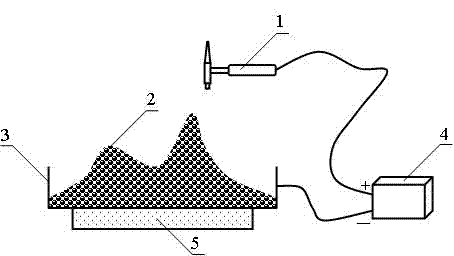

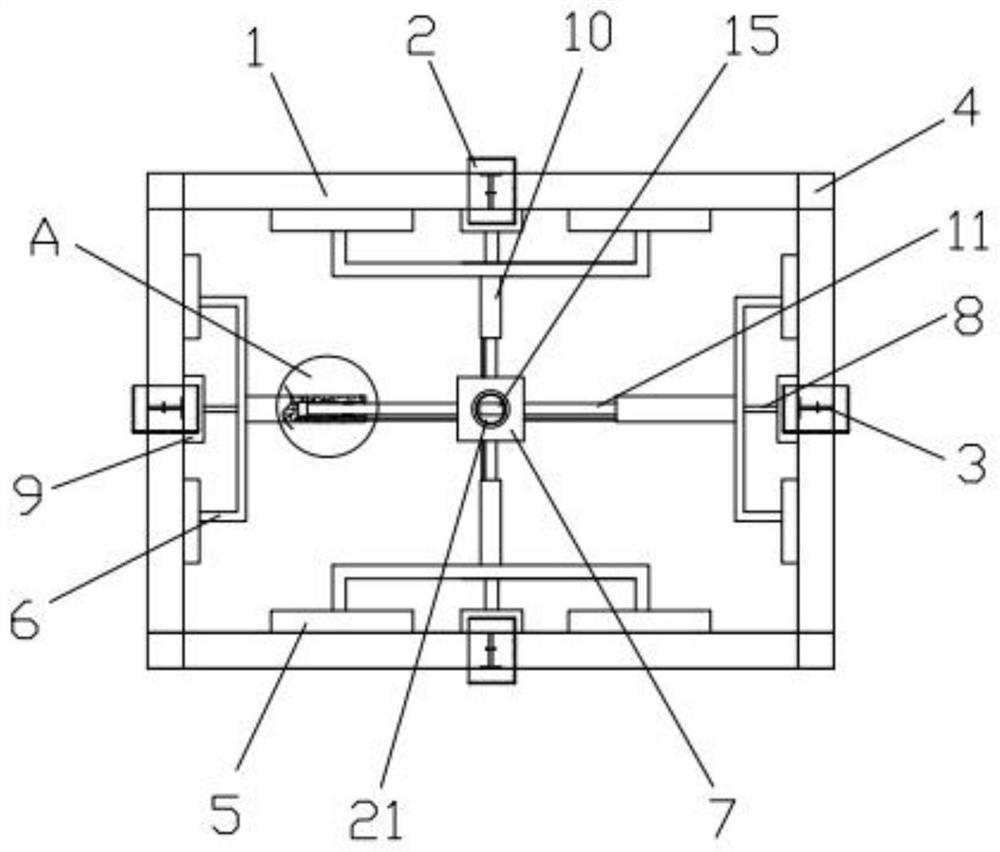

Integrated pulping system

ActiveCN103538151ASmall footprintReduce labor intensityMixing operation plantControl systemPulp and paper industry

The invention discloses an integrated pulping system. The integrated pulping system mainly solves the problems of large floor area, waste of labor and time in disassembly and assembly, loss and damage of components in transportation, easiness in environmental pollution in work, low degree of automation and low effect in the conventional pulping station. The pulping system comprises an openable and closable container, a centralized feed hopper, a pulping tank, a water tank, an additive supply device, a pulp storage tank, a pulp delivery device, a power system and a control system, wherein the centralized feed hopper is arranged on the upper part in the container; the pulping tank is positioned below a discharge port of the centralized feed hopper; the water tank and the additive supply device are communicated with the upper part of the pulping tank through pipelines respectively; the pulp storage tank is communicated with the lower part of the pulping tank through a pipeline; the pulp delivery device is connected with the pulp storage tank; the power system is used for providing power for the operation of the integrated pulping system; the control system is used for controlling the operation of the integrated pulping system; the centralized feed hopper, the pulping tank, the water tank, the additive supply device, the pulp storage tank and the pulp delivery device are all arranged in the container. According to the integrated pulping system, the pulping system is highly integrated, the floor area of the pulping system is reduced, and the degree of automation of the equipment is improved.

Owner:SINOHYDRO FOUND ENG

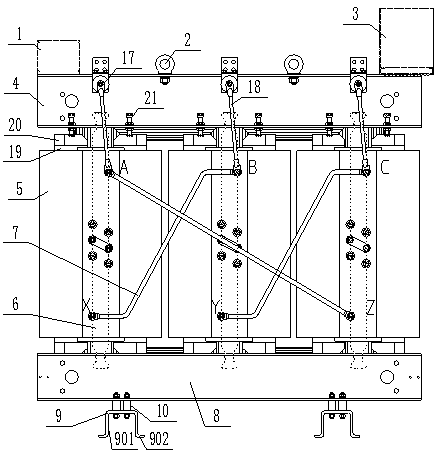

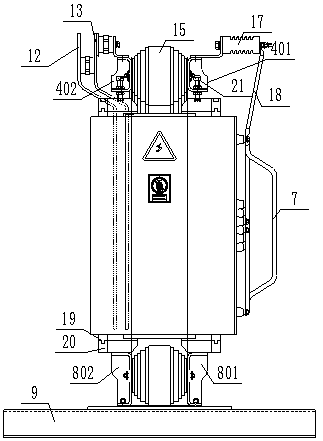

Dry type transformer

PendingCN109411198AReduce dosageLow costTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsCopper wireLow voltage

The invention relates to the technical field of transformers, and in particular to a dry type transformer. The dry type transformer comprises a transformer main body, an upper clamping member and a lower clamping member, wherein the transformer main body comprises iron cores and high-voltage coils and low-voltage coils which are assembled on the iron cores. The dry type transformer has the beneficial effects that a low-pressure mold formed by combining two half molds is adopted to facilitate the operation; when copper bars and copper foils are welded, the copper bars inside the copper foils are cut along the diagonal line to reduce the cost of raw materials; a pouring hole is reserved in a limiting board between an inner mold and an outer mold of the high-voltage coils and the height of resin is measured by adopting a limiting gauge to ensure that the usage amount of the resin is reduced and the outer surface is beautiful; the clamping members are formed by bending steel plates and circular arcs are formed by adopting laser cutting to ensure that the mechanical strength is high and the appearance is beautiful; steel pull plates adopt magnetic isolating steel plates and long circular grooves are milled in the middle parts of the steel pull plates to avoid eddy current heating; the iron cores adopt cross-core screw structures and the stacking adopts a seven-step in-out joint process to reduce the noise and the loss of the transformer; and the high-voltage coils adopt cake structures to reduce the usage amount of the iron cores, the copper wires and the copper foils.

Owner:SHANDONG ALFADACHI ELECTRIC

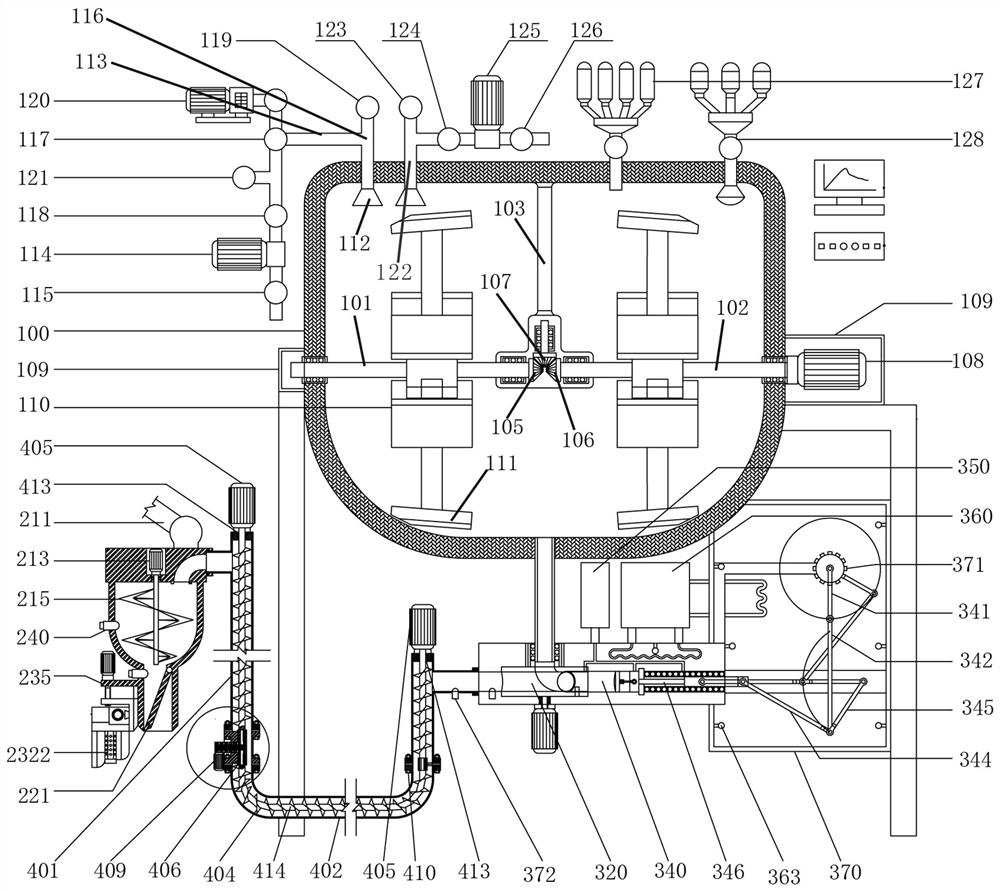

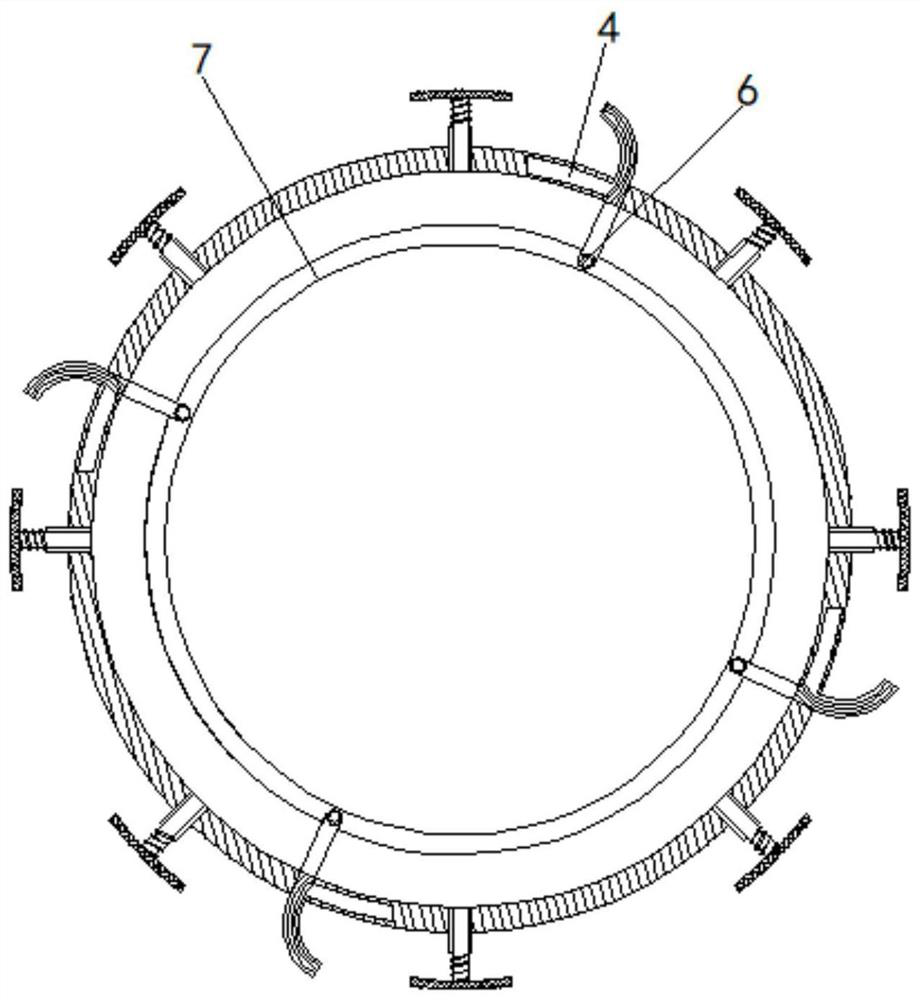

Feeding system for 3D printing of ultra-high performance concrete

PendingCN112829040AImprove homogeneityImprove compactnessAdditive manufacturing apparatusFeeding arrangmentsComputer printingStructural engineering

The invention belongs to the technical field of 3D printing of ultra-high performance concrete. A feeding system for 3D printing of ultra-high performance concrete comprises a stirring tank, a vacuumizing unit, a main stirring unit, a feeding unit, a conveying pump and a 3D printer nozzle, wherein the stirring tank is of a sealed structure and is supported by a main body rack; the vacuumizing unit is connected to the top of the stirring tank and is used for vacuumizing the stirring tank; the main stirring unit is used for stirring materials in the stirring tank; the feeding unit is arranged at the top of the stirring tank and is used for feeding the materials into the stirring tank; the feeding end of the conveying pump is connected with the bottom of the stirring tank through a material receiving pipe; and the discharging end of the conveying pump is connected with the 3D printer nozzle. The feeding system is reasonable in structural design, environmentally friendly, efficient, high in intelligent degree and green degree and more suitable for 3D printing of ultra-high performance concrete (UHPC).

Owner:ZHENGZHOU UNIV

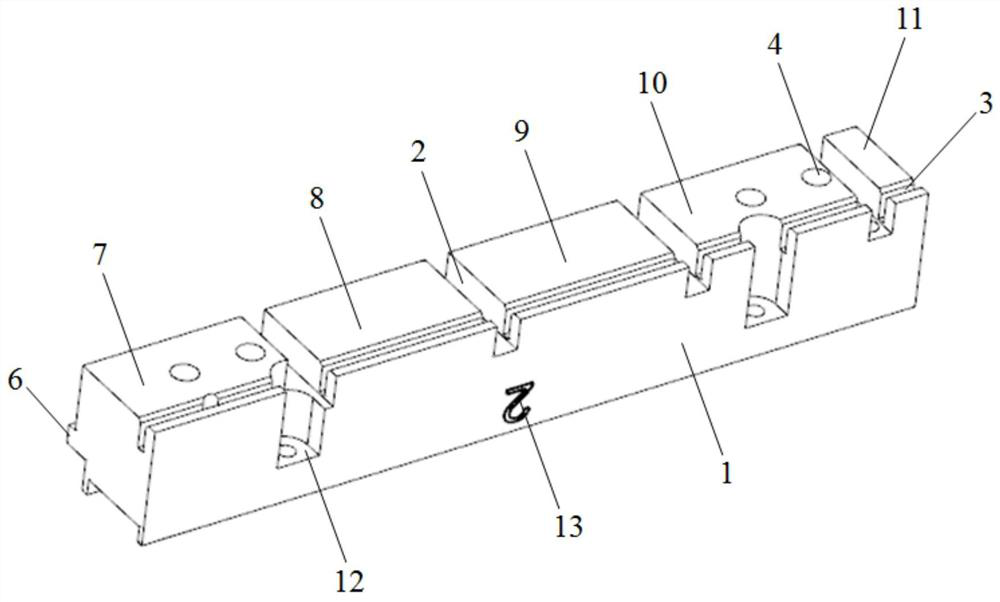

Locking module part for battery fixing device, and numerical control machining method thereof

PendingCN113161680AImprove assembly convenienceAvoid sliding displacement situationsCell component detailsBatteriesNumerical controlNew energy

The invention relates to a locking module part for a new energy automobile battery fixing device, and a numerical control machining method thereof The locking module part comprises a base, a plurality of longitudinal positioning grooves formed in the top of the base side by side, a transverse positioning groove formed in the top of the base and penetrating through the longitudinal positioning grooves, a plurality of mounting positioning holes formed in the top of the base in a penetrating mode, a sliding rail arranged at the bottom of the base and a transverse mounting beam arranged on the rear side of the base. Compared with the prior art, a new energy automobile battery can be clamped and fixed between the two locking module parts, and the assembling convenience of the locking module parts is improved through the side face sliding rail structure connected with the automobile bottom cross beam in a sliding mode; and through the transverse positioning grooves and the longitudinal positioning grooves which are formed in a staggered mode, the adaptability with the edge structure of the battery is improved, so that the position of the battery of the new energy automobile is specifically enhanced, the strength requirement and the safety requirement are met, and the mounting state of the battery is ensured.

Owner:上海建桥学院有限责任公司 +1

Semi-precast lightweight white concrete curtain wall and construction method thereof

The invention discloses a semi-precast lightweight white concrete curtain wall, which is characterized in that the curtain wall is sandwich sandwich structure, and the curtain wall comprises a left side surface template, a right side surface template and a middle sandwich layer, wherein the left side surface template and the right side surface template are lightweight white concrete molding members, and the middle sandwich layer is a self-compacting concrete layer. A light white concrete component and a weight portion thereof are as follow: (img file= 'DDA0001745311660000011. TIF' wi= '700' he= '534' / ) The beneficial effects of the present invention are: The invention provides a concrete curtain wall form integrating decoration, heat preservation and structure, which is neat and beautiful,the number of splicing joints is small and the weight is light.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

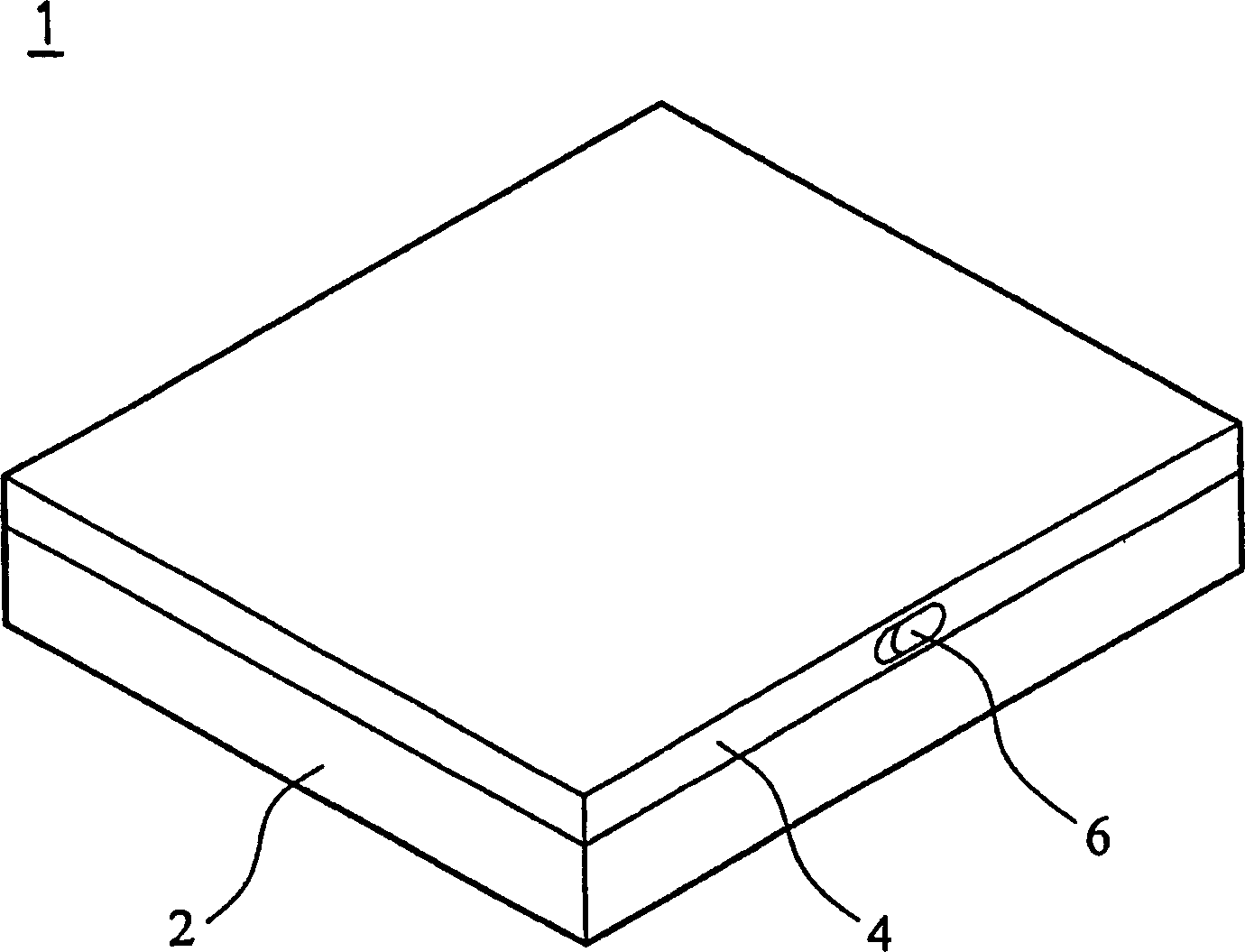

Buckle lock structure

InactiveCN1480617ABeautiful exteriorSave external spaceWing fastenersMechanical engineeringEngineering

Owner:QUANTA COMPUTER INC

Process for preparing metal wire drawing hose for aerospace

InactiveCN106862297ABrushed strongGood flexibilityLiquid surface applicatorsExtrusion cleaning devicesShock resistanceToughness

The invention discloses a process for preparing a metal wire drawing hose for aerospace. The process comprises the following steps that a metal wire material is subjected to surface treatment, water cleaning, neutralization and drying sequentially; at the same time, wire drawing oil raw materials are prepared, wire drawing oil is prepared, the prepared wire drawing oil is added onto the surface of the dried metal wire material in a wire drawing machine, wire drawing is conducted, and a metal wire is formed; and finally the obtained metal wire is subjected to a primer spraying procedure, an intermediate coat spraying procedure and a finishing coat spraying procedure, and the metal hose is obtained. The process is simple in step, wire drawing of the metal wire is firm, the metal wire has the advantages of being high in toughness, scalability, bending resistance, shock resistance and bearing ability and good in corrosion resistance, meanwhile, the metal texture feeling is high, the outer surface is beautiful, and light keeping and color keeping time is long.

Owner:泰州法尔斯特不锈钢线有限公司

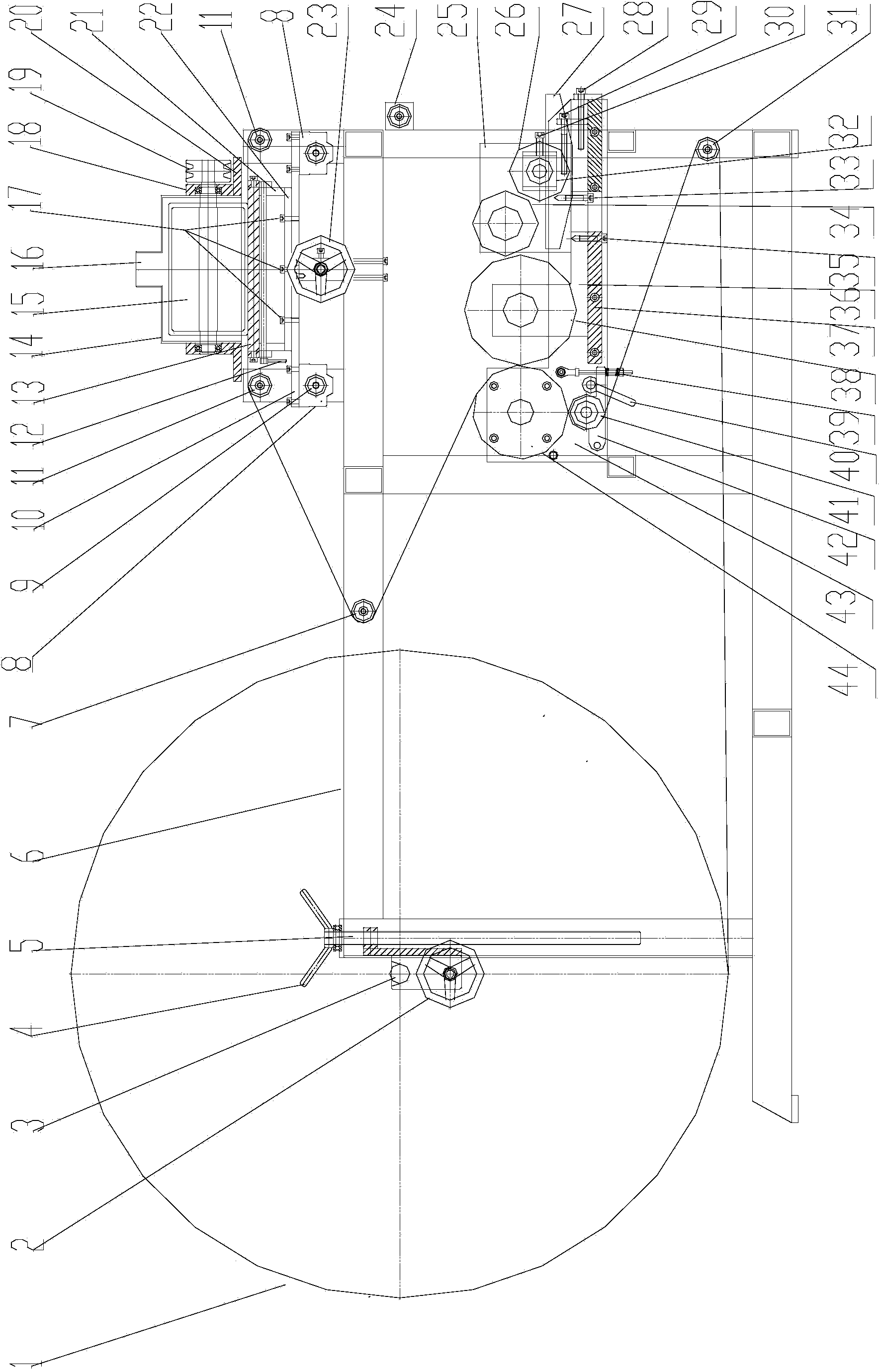

Edge grinding printing device of firework rolling machine

ActiveCN103862850AReasonable structural designPractical and convenient assemblyRotary pressesPulp and paper industryPaper sheet

The invention discloses an edge grinding printing device of a firework rolling machine. The edge grinding printing device comprises a paper feeding frame, a printing mechanism and an edge grinding mechanism in work sequence, and the paper feeding frame, the printing mechanism and the edge grinding mechanism are arranged on a rack. The body paper edge grinding printing paper feeding mechanism is simple and practical, structural design is reasonable, assembling is practical and convenient, edge grinding printing can be synchronously carried out on body paper for the rolling machine, rolling and printing are carried out at the same time, the process of pasting bark paper is eliminated, production cost is greatly lowered, and production efficiency is improved. The body paper edge grinding mode is adopted, a paper barrel is sealed well, the appearance is attractive, and sealing protruding steps do not exist. Meanwhile, the edge grinding mechanism can fully meet production practice needs, and the adjusting mode is accurate, reliable, convenient and practical.

Owner:江西省万载县国丰烟花制造有限公司

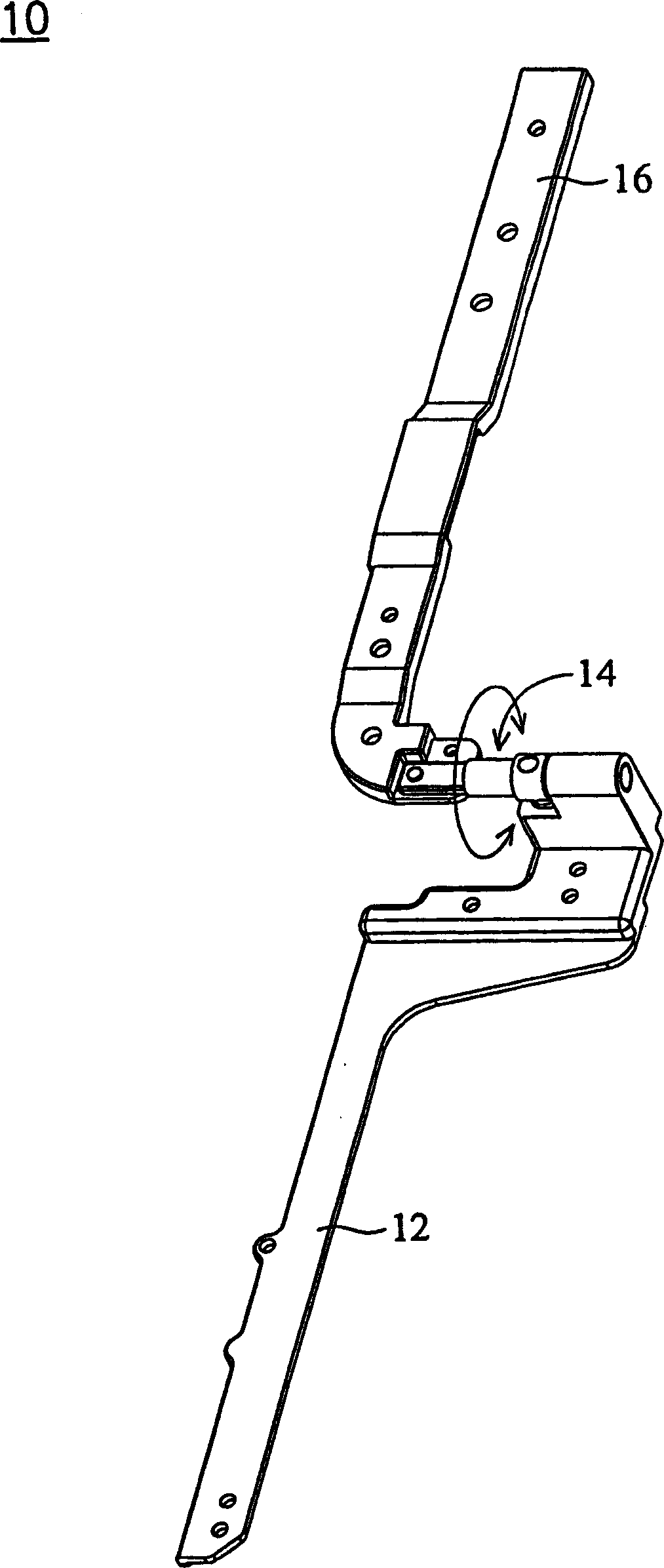

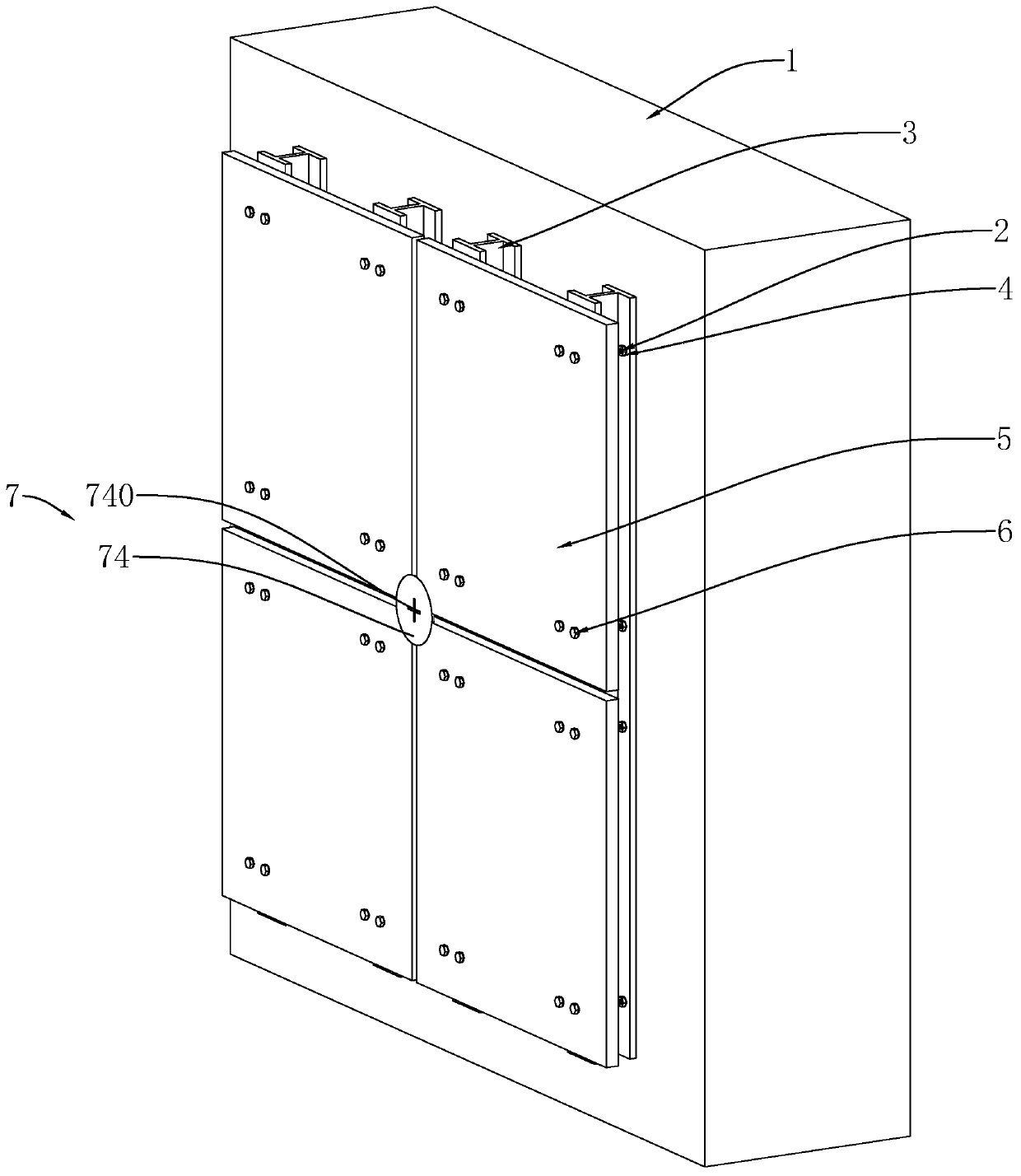

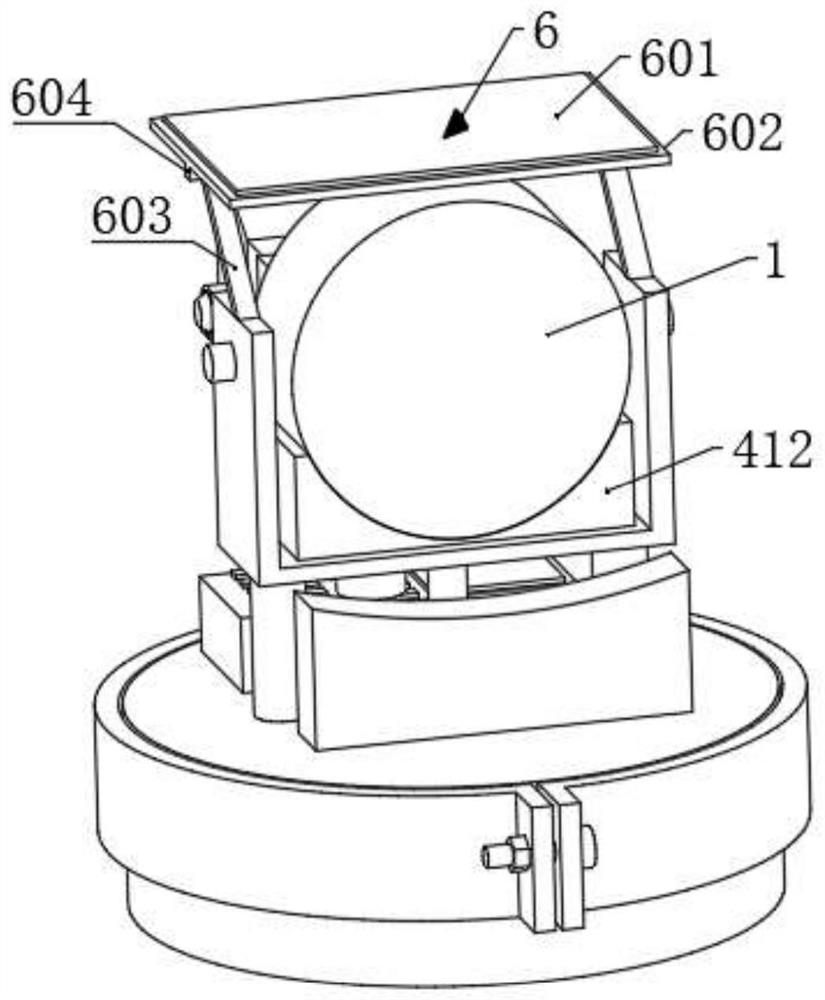

Curtain wall structure, curtain wall plate fixing device and curtain wall installation method

The invention relates to a curtain wall plate fixing device. The curtain wall plate fixing device comprises a fixing plate, a threaded barrel, a bearing plate, a pressuring plate and a threaded rod. The curtain wall plate fixing device has the effect of adapting and fixing curtain wall plates of different thickness and making the edges and corners of the adjacent curtain wall plates be flush withone another. The invention also relates to a curtain wall structure. The curtain wall structure comprises a wall body, a embedded screw rod, H-shaped steel, a nut, curtain wall plates and a fixing bolt. The curtain wall structure also has the characteristic that the overall external surface of a curtain wall is flat and attractive. The invention also relates to a curtain wall installation method.The curtain wall installation method comprises the following steps that a, the H-shaped steel is fixed on the wall body; b, a fixing plate of the fixing device is fixed on the wall body; c, the four corners of each curtain wall plate are cut into arc-shaped slopes, so that the arc-shaped slopes are adapted to the arc of the lower surface of the pressuring plate in a transition manner; and d, the combination structure of the pressuring plate and the screw rod are screwed in, so that the upper surface of the pressuring plate is flush with the four adjacent curtain wall plate surfaces. The curtain wall structure, the curtain wall plate fixing device and the curtain wall installation method also has the characteristics of convenient installation of the curtain wall, and flat and attractive external surface.

Owner:BUCG THE EIGHTH CONSTR DEV

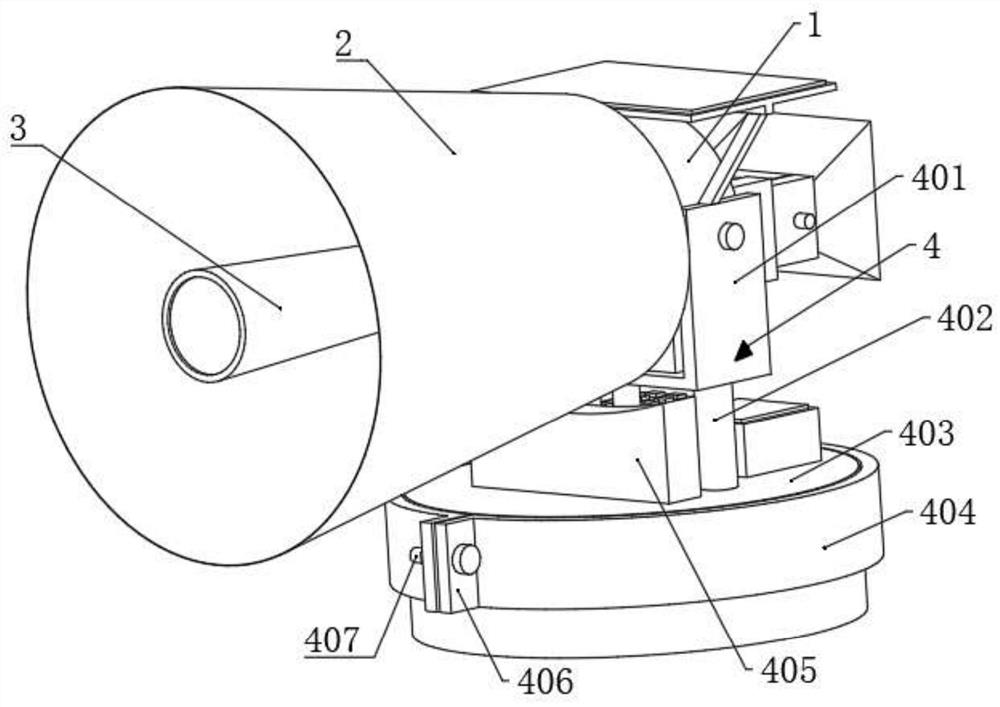

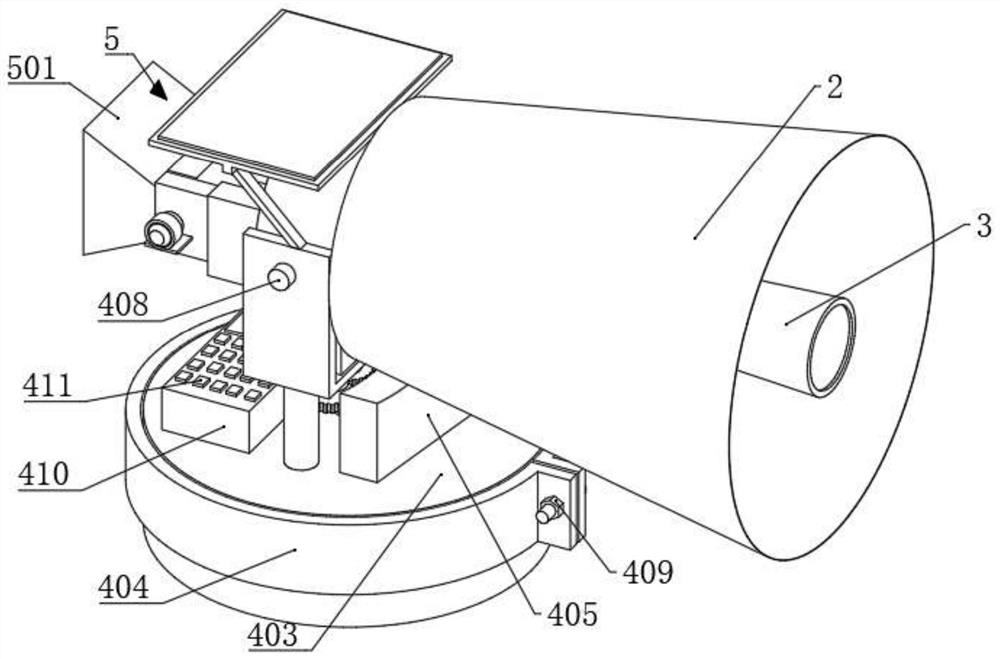

Outdoor loudspeaker based on broadcast and movie and television technology

InactiveCN113329304AAvoid small inaudible problemsAvoid troubles caused by unclear soundsLoudspeakersFrequency/directions obtaining arrangementsElectric machineryEngineering

The invention discloses an outdoor loudspeaker based on broadcast and movie and television technology, and relates to the technical field of broadcast and movie and television. The outdoor loudspeaker comprises a mounting body, an adjusting mechanism is fixedly mounted at the bottom of the outer surface of the mounting body, and the middle of the outer surface of the mounting body is rotatably connected with the top of the outer surface of a U-shaped plate through a short rod; the middle of the bottom end of the outer surface of the U-shaped plate is welded to the top end of the outer surface of the rotating pipe. Through the arrangement of the first motor, the U-shaped plate and the mounting body and through the mutual cooperative use of the structures, the structures such as the sound amplifying body can rotate by an angle circumferentially, and the sound generator can slowly face different directions, so that the defects caused by fixed mounting can be avoided, and the trouble caused by unclear sound hearing is avoided; therefore, the device can avoid the problem that the sound transmission efficiency is low due to the fact that the direction of the broadcast loudspeaker is fixed, and a plurality of loudspeakers do not need to be installed at the same position, so the efficiency is improved.

Owner:安徽竣阳信息技术有限公司

Drawing technique of metal hosepipe for nuclear power

InactiveCN106734274ABrushed strongGood flexibilityExtrusion cleaning devicesMetal working apparatusNuclear powerPliability

The invention discloses a drawing technique of a metal hosepipe for nuclear power. The drawing technique comprises the following steps that the surface of a metal wire is pretreated; after the drawing mould temperature is controlled, the metal wire is placed in a chain type drawbench for machining; lubricating agents are added for lubricating; a drawing mould is selected for machining, then powder paint is subjected to electrostatic spraying, heat transfer printing is conducted through thermosensitive transfer paper, and the surface with the drawing effect is obtained; and the metal wire with the surface with the drawing effect is manufactured into the metal hosepipe. The steps are simple, metal wire drawing is firm, the metal hosepipe has the advantages of high flexibility, retractility, bending performance, vibration resistance and bearing capacity and good corrosion resistance, meanwhile, the metal texture is high, the outer surface is attractive, and the brightness and color keeping time is long.

Owner:泰州法尔斯特不锈钢线有限公司

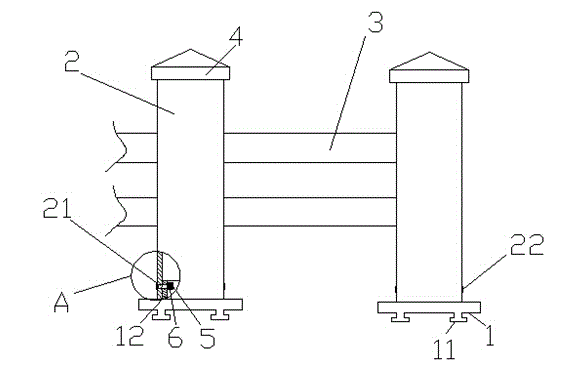

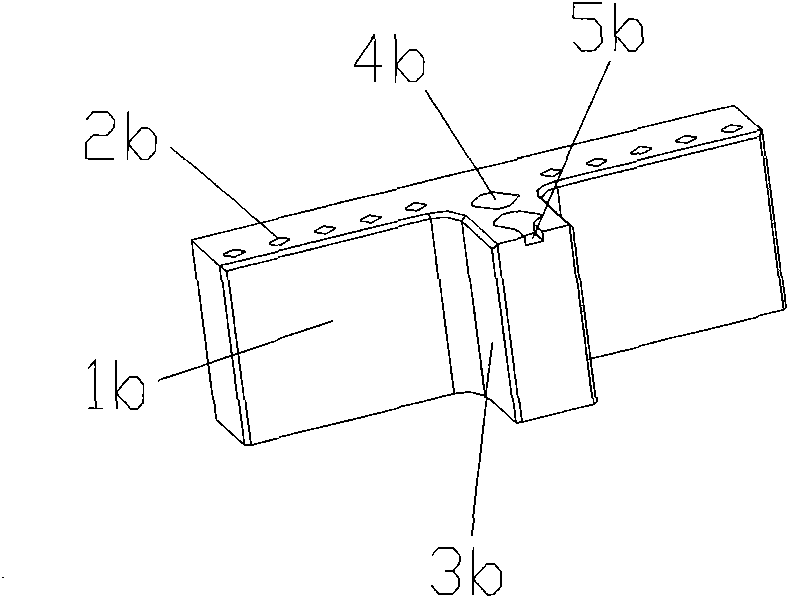

Bolt-connection-free assembled bridge guardrail

InactiveCN104911994AControl displacementQuick displacementBridge structural detailsBolt connectionBuilding construction

The invention discloses a bolt-connection-free assembled bridge guardrail. The bolt-connection-free assembled bridge guardrail comprises fixed bases and hollow pipe stand columns which are sequentially arranged at intervals, and transversely-arranged connecting rods are arranged between the hollow pipe stand columns; a connecting pipe extending to the interior of the corresponding hollow pipe stand column is vertically arranged on each fixed base, and through holes are formed in the lower portions of the two sides of each hollow pipe stand column; guide holes corresponding to the through holes and limiting rods arranged in the guide holes are arranged on the side faces of the connecting pipes, and the outer portions of the limiting rods are sleeved with springs; and downward slope surfaces are arranged at the tail ends of the limiting rods. Through the manner, by means of the bolt-connection-free assembled bridge guardrail, the slope surfaces are utilized for pushing the limiting rods to the interiors of the connecting pipes, and after the hollow pipe stand columns descend to the bottoms, the through holes are communicated with the guide holes to enable the limiting rods to be pulled into the through holes under the effect of the springs; displacement of the hollow pipe stand columns is limited, and the bridge guardrail is rapid in construction, firm in structure, attractive in appearance and convenient to maintain.

Owner:CHANGSHU HUACHENG CONSTR ENG

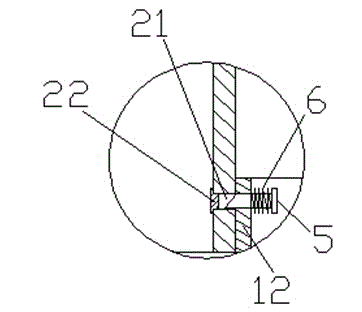

Iron picture manufacturing device and processing method

ActiveCN102963204AStrong three-dimensional senseBeautiful exteriorSpecial ornamental structuresSteel ballArgon gas

The invention discloses an iron picture manufacturing device and a processing method, which belong to the technical field of iron picture processing. According to the iron picture manufacturing device, the magnetic field of a magnet is used for fixed modeling, and steel balls are taken as a welding carrier. The iron picture manufacturing device comprises an argon arc welding gun, the steel balls, a metal box, an argon arc welding machine and the magnet and is characterized in that the metal box is arranged on the magnet and internally provided with the steel balls, a negative pole of the argon arc welding machine is connected with the metal box, and a positive pole of the argon arc welding machine is connected with the argon arc welding gun; and when the iron picture manufacturing device is used, the steel balls are placed in the metal box and are arranged according to modeling required by iron picture materials by virtue of the attraction of the magnet to the steel balls, a power source and argon of the argon arc welding machine are switched on, then the argon arc welding gun is used for welding the outer surfaces of the modeled steel balls, and after the welding is finished, the steel balls, the surfaces of which are welded to be blocky, are moved out from the metal box, thus obtaining the iron picture material with the needed modeling, and fulfilling the purpose of rapidly manufacturing the iron picture material.

Owner:QUZHOU YIFAN DESIGN

Robot dust collecting device convenient for cleaning dead angles

ActiveCN111728537AImprove practicalityBeautiful exteriorAutomatic obstacle detectionTravelling automatic controlSmart applianceEngineering

The invention relates to the technical field of intelligent household appliances and discloses a robot dust collecting device convenient for cleaning dead angles. The device comprises an outer shell;the interior of the outer shell is movably connected with a telescopic rod; a protective pad is movably connected to the outer part of the telescopic rod; a storage groove is formed in the outer shell; a fine brush is movably connected to the upper portion of the storage groove; a limiting pin is movably connected to the lower portion of the fine brush; a chassis is movably connected to the outerportion of the limiting pin; universal wheels are movably connected to the inner portion of the chassis; limiting rods are movably connected to the inner portions of the universal wheels; movable rodsare movably connected to the right sides of the limiting rods; and connecting rods are movably connected to the upper portions of the movable rods. And through cooperation of the dust collection boxand the dust suction box, when the dust in the dust suction box reaches a certain amount, the device reaches a set position, the dust in the dust suction box is discharged through the dust outlet pipeline, continuous work is not affected, and the practicability is high.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

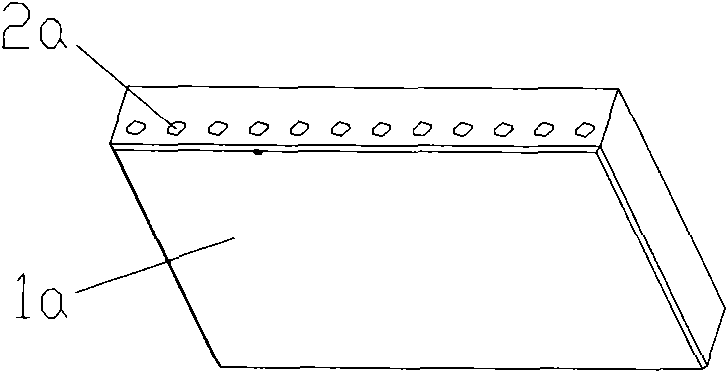

Wallboard assembled air duct

The invention discloses a wallboard assembled air duct. The wallboard assembled air duct comprises wallboards, bolts matched with the wallboards and sealing base plates of T-shaped structures arranged between the adjacent wallboards; and the four sets of wallboards are bent, and corner fittings are arranged at the bent positions of the wallboards. Compared with the prior art, the air duct structure is assembled in a wallboard assembling mode, welding can be omitted, the appearance is attractive, disassembling is convenient, and overhauling, storing and transporting are convenient.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD

Fire-proof insulation board for external wall and use method thereof

The invention discloses a fire-proof insulation board for an external wall and a use method thereof, including an insulation board main body. The insulation board main body is made by mixing insulation materials and cementing materials together or by compounding high-efficiency insulation materials on a reinforcing steel bar or fiber concrete board, and rows of small through holes or grooves are arranged on the insulation main body; according to the fire-proof insulation board for an external wall in the solution of the invention, rows of small through holes or grooves are arranged on the insulation main body; during installation, small through holes or grooves on adjacent fire-proof insulation boards for the external wall are communicated to form groups of airflow through holes outside the wall of a building, and the airflow through holes can be used for insulation of the external wall; if the airflow through holes are then communicated with underground airflow, the insulation effect is better; simultaneously, in the solution, hollow cavities are arranged on the outer side of the insulation board main body to hang flower baskets and contain soil to plant flowers and bushes, so that the external wall surface can become more beautiful and environmentally friendly.

Owner:史世英

Invisible bandage for orthopaedics

The invention relates to an invisible bandage, which is composed of a composition A and a composition B. The composition A is prepared from bee wax, peach gum, propolis, rosin, dalbergia wood, amber,frankincense, and myrrh. The composition B is prepared from wolfberry extract, natural indigo, radix rehmanniae preparata extract, and carotene. The invention further relates to a preparation method and use method of the invisible bandage.

Owner:东贝医疗器械(山东)有限公司

Manufacturing method of instrument warm box

Disclosed is a manufacturing method of an instrument warm box. Hot press molding is carried out on a sheet, and a main body of a box body and a main body of a box door are manufactured; the main body of the box body and the main body of the box door are put into corresponding foamed moulds respectively, and aluminum foil film layers are attached to the outer surfaces of core moulds of the foamed moulds; a foaming machine is used for manufacturing the box body with a warm layer and the box door with a warm layer through a polyurethane foaming technology, and then, the box body and the box door are assembled into a finished product; and the sheet is formed by sequentially arranging a C layer, a D layer and a C layer, wherein the C layers are short glass fiber reinforced unsaturated polyester resin composite material layers, and the D layer is a copper wire mesh layer with the wire diameter ranging from 0.3mm to 0.7mm.

Owner:吉林市吉化北方华丰仪表有限公司

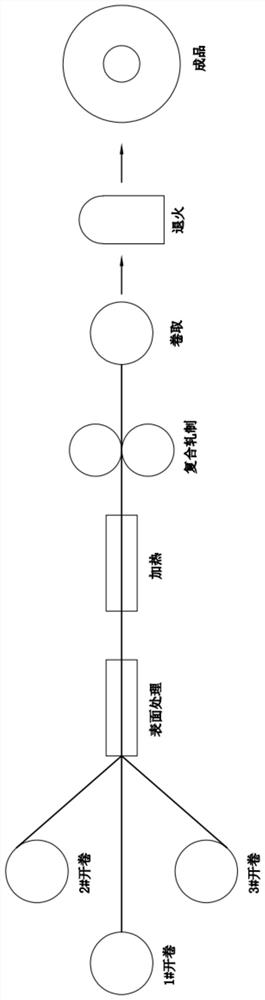

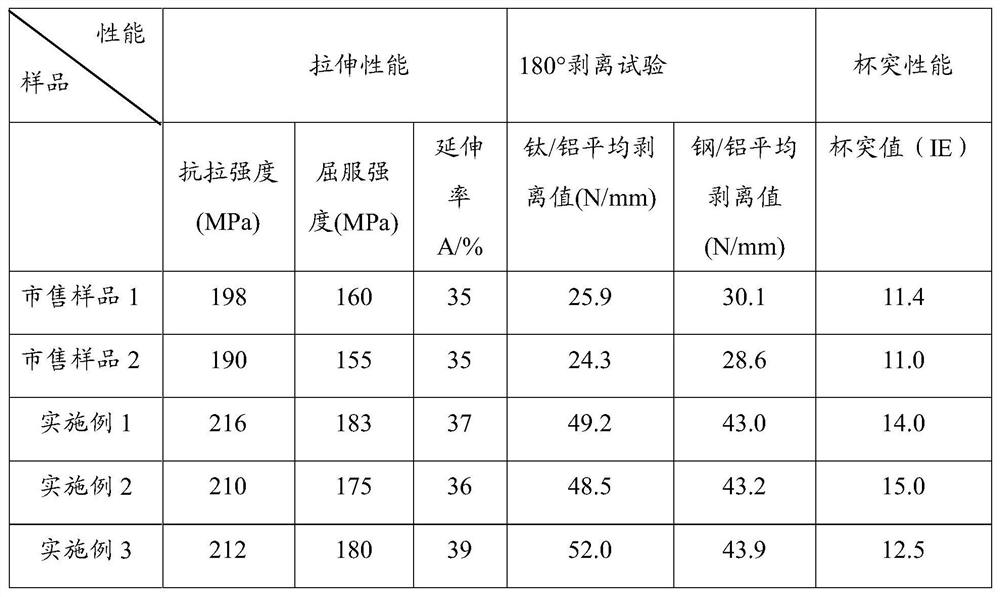

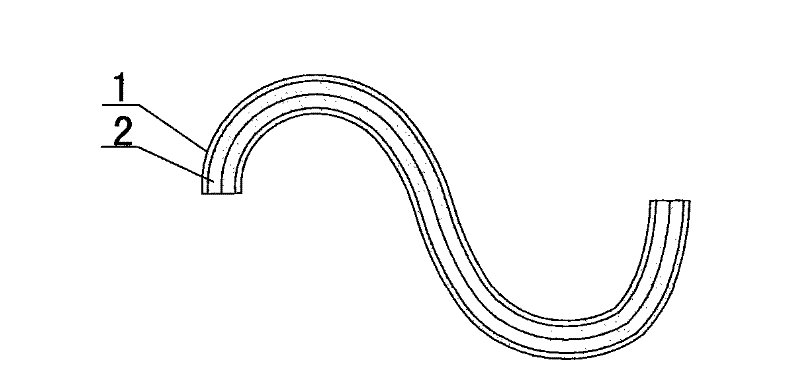

Layered titanium-aluminum steel composite strip coil material and preparation method thereof

ActiveCN112090961ACorrosion resistanceTitanium Corrosion ResistanceFurnace typesAuxillary arrangementsSS - Stainless steelTitanium

The invention discloses a layered titanium-aluminum-steel composite strip coil material and a preparation method thereof. According to the layered titanium-aluminum-steel composite strip coil material, an aluminum strip coil serves as a base material, a pure titanium strip coil is compounded on the upper surface of the aluminum strip coil, and a stainless steel strip coil is compounded on the lower surface of the aluminum strip coil; and the thickness ratio of the aluminum strip coil to the pure titanium strip coil to the stainless steel strip coil is 8: (1.5-3): (2-3). The production processflow comprises the steps of uncoiling, carrying out surface treatment, heating, rolling, coiling, annealing and obtaining a finished product coiled material, and the production processes in the process flow are continuous production line type production except annealing. The composite coiled material prepared by the method has the characteristics of being corrosion-resistant, wear-resistant, freeof toxicity, bacteria-resistant, and good in magnetic conductivity and thermal conductivity; and the interlayer binding force of the composite strip coil material is greatly improved.

Owner:新疆湘润新材料科技有限公司

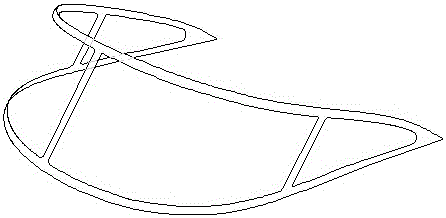

Fishing boat wind shield making process

InactiveCN106347582AImprove corrosion resistanceImprove connection strengthVessel partsFishing vesselsAdhesiveEngineering

The invention discloses a fishing boat wind shield making process. The fishing boat wind shield making process comprises the following steps that 1, a mold is cleaned; 2, an inner frame and an outer frame are made; 3, the inner frame and the outer frame obtained in the step 2 are cut and grinded; 4, trial installation is conducted on the inner frame and the outer frame obtained in the step 3; 5, the inner frame is fixed to a support, the periphery of the inner frame is coated with a special structure sealing adhesive, acrylic glass prepared in advance is installed and is fixed by using a clamp; 6, after the sealing adhesive on the inner frame is dried, then the clamp is taken down, the contact position of the glass surface and the outer frame is coated with the sealing adhesive, the periphery of the inner frame and the joint position of the outer frame are coated with putty for a boat, and then the inner frame and the outer frame are closed up and are fixed by using the clamp; surplus sealing adhesive and the putty are cleared away; standing is performed till the sealing adhesive and the putty are cured completely. The fishing boat wind shield making process makes a fishing boat wind shield long in service life and convenient to manufacture.

Owner:江阴澳玛斯特游艇有限公司

Glass tube for lighting accessories

InactiveCN102490532AIncrease varietyPromoting Diversified UseElongated constructional elementsSpecial ornamental structuresSand blastingEngineering

The invention relates to a glass tube used for lighting accessories. The outer side of the glass tube wall is provided with a sandblast layer. The sand blasting process of the glass tube comprises the following steps of: 1, preparing glass tube accessories to be processed and a sand blasting machine, meanwhile, arranging the glass tube according to a processing pattern which is designed in advance, including the location, direction and shape of the glass tube; 2, starting the sand blasting machine, blasting to obtained the required effect on the glass tube by the sand blasting machine, including pattern, color and thickness; and 3, processing for completing the lighting accessories. The glass tube for lighting accessories disclosed by the invention can be applied to various glass tube sand blasting accessories to be processed, has the advantages of cost reduction, beautiful appearance, simple structure and the like and increases the type of lighting accessories; compared with other popular lighting accessories, the glass tube is in favor of diversified use of accessory resources; compared with the popular lightings on the market, new concepts and elements can be provided for the improvement of old lightings and the creativity of new lightings through the application of the lighting accessories of the sand blasted glass tube to lighting.

Owner:ZHONGSHAN LIANGCHENG LIGHTING

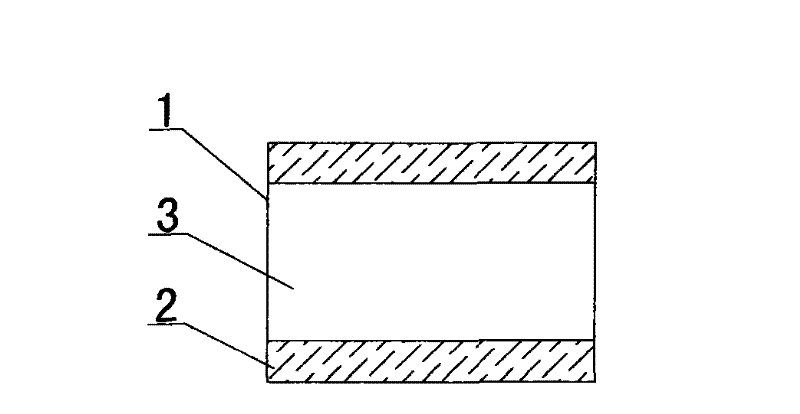

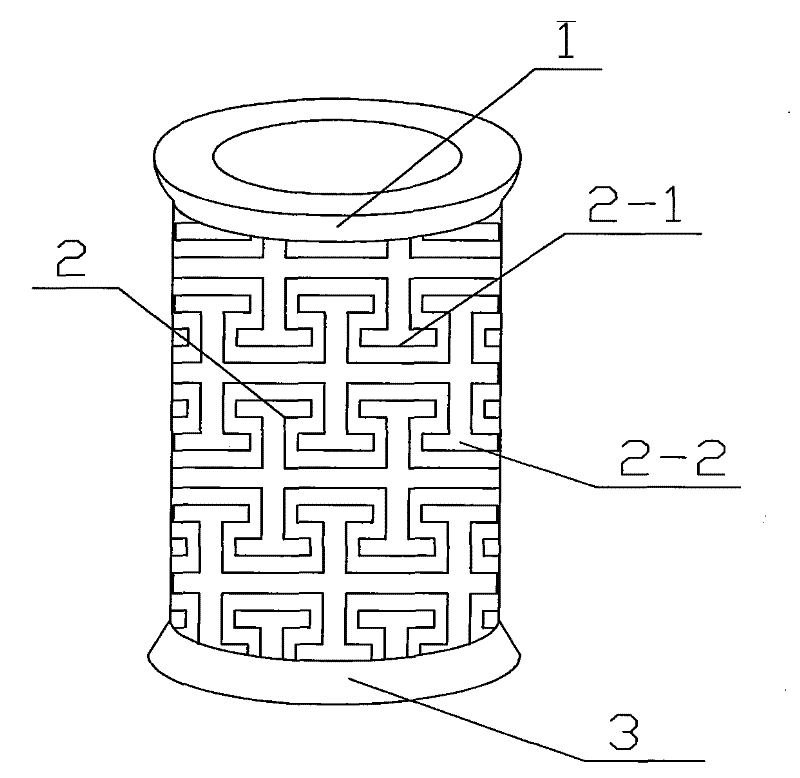

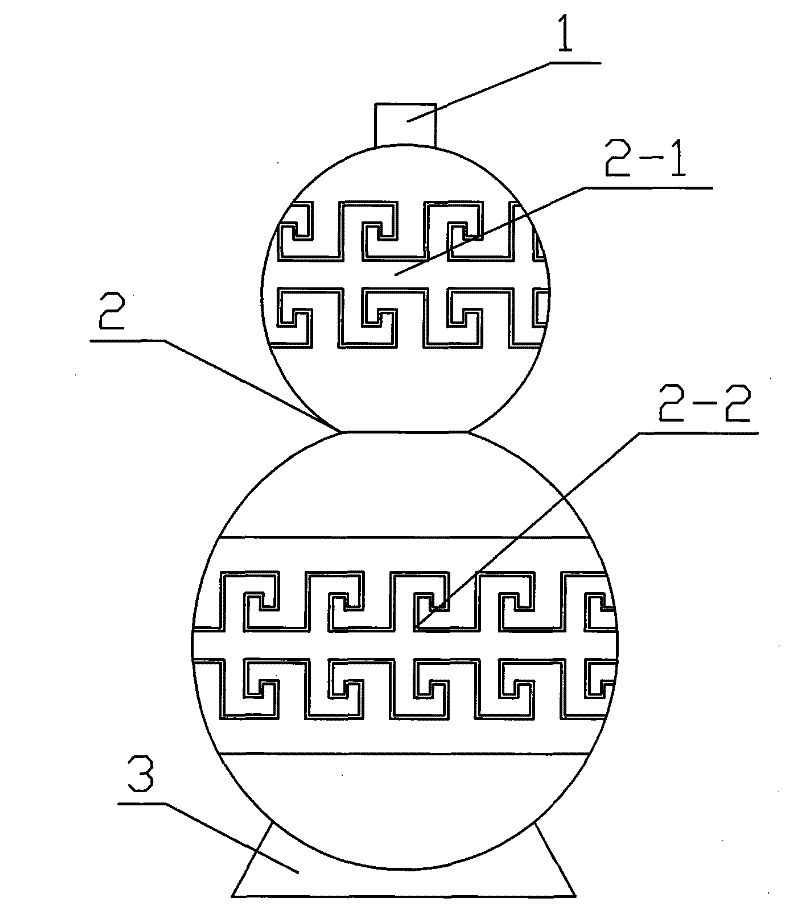

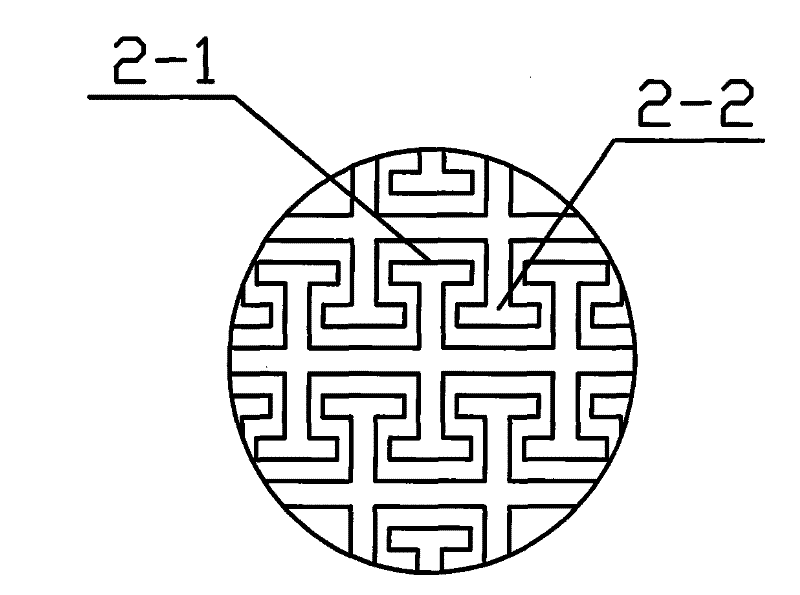

Inlaid structure ornament

InactiveCN101774325BBeautiful exteriorAchieve artistic fantasy effectOrnamental structuresSpecial ornamental structuresEngineeringMetal

The invention relates to an inlaid structure ornament, which comprises a base, a middle part and a top part. The internal part of the middle part is a cavity and the surrounding of the middle part is a multilayer structure. A plurality of convex parts are arranged on each layer of the multilayer structure of the middle part and are arranged in a central symmetry way. The top part of each convex part is wider than the bottom part of the convex part. A plurality of concave parts are formed among convex parts. The bottom part of each concave part is wider than the top part of the concave part. The convex parts of each layer are inlaid in the concave parts of the previous layer or the next layer. Since the convex parts of each layer are inlaid in the concave parts of the previous layer or thenext layer and the convex parts of each layer are arranged in the central symmetry way, the layers do not slide out even though the layers are not fixedly connected. Small displacement occurs becauseclearances exist among the layers, so the fantastic artistic effect that the inlaid structure ornament is apparently loose but is actually hooked up is obtained, the external appearance of the ornament is beautiful, the corrosion resistance is high, the air permeability is good, the material is saved, and the ornament is suitable for a plurality of kinds of centrally symmetrical appliances such as metal products, ceramic products, wooden product and the like.

Owner:牛瑞胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com