Iron picture manufacturing device and processing method

A processing method and technology of iron painting, applied in special decorative structures, decorative arts, etc., can solve the problems of openness and non-technical solutions, and achieve the effect of simple process, fast speed and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

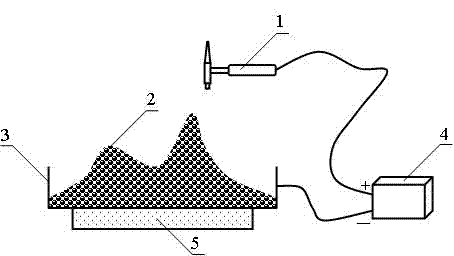

[0025] Instance 1, such as figure 1 As shown, the present invention consists of an argon arc welding torch 1, a steel ball 2, a metal box 3, an argon arc welding machine 4, and a magnet 5. The negative pole of machine 4 is connected to metal box 3, and the positive pole of argon arc welding machine 4 is connected to argon arc welding torch 1. When in use, steel ball 2 is put into metal box 3, and steel ball 2 is drawn according to the iron drawing by magnet 5 to steel ball 2. Place the mountain shape required by the material, then turn on the power supply and argon gas of the argon arc welding machine 4, and then use the argon arc welding torch 1 to weld the outer surface of the shaped steel ball. After the welding is completed, the surface is welded into a block-shaped mountain The shaped steel ball 2 is removed from the metal box, and the iron painting material in the shape of mountains is obtained, so as to achieve the purpose of quickly making the iron painting material. ...

example 2

[0026] Instance 2, such as figure 1 As shown, the technical features of the present invention are the same as those of Example 1. When in use, the steel ball 2 is put into the metal box 3, and the steel ball 2 is placed according to the shape of the branch required by the iron painting material by utilizing the attraction force of the magnet 5 to the steel ball 2, and then opened. The power supply and argon gas of the argon arc welding machine 4, and then use the argon arc welding torch 1 to weld the outer surface of the shaped steel ball, and after the welding is completed, the steel ball 2 with the surface welded into a block-shaped branch shape is removed from the metal box, that is, Obtain iron painting materials in the shape of branches to achieve the purpose of quickly making iron painting materials.

example 3

[0027] Example 3, such as figure 1 As shown, the technical features of the present invention are the same as those in Example 1. When in use, put the steel ball 2 into the metal box 3, use the attraction force of the magnet 5 to the steel ball 2 to place the steel ball 2 according to the magpie shape required by the iron painting material, and then open it. The power supply of the argon arc welding machine 4 and the argon gas, then use the argon arc welding torch 1 to weld the outer surface of the steel ball after the molding, after the welding is completed, the steel ball 2 of the magpie shape whose surface is welded into a block is removed from the metal box, that is, Obtain iron painting materials in the shape of magpies to achieve the purpose of quickly making iron painting materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com