Dry type transformer

A dry-type transformer and transformer technology, applied in the field of transformers, can solve the problems of large no-load loss, waste of raw materials, large distance between axial sections, etc., and achieve the effects of reducing noise and loss, reducing raw material costs, and increasing mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

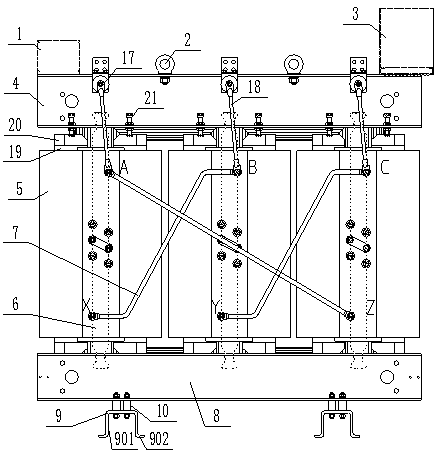

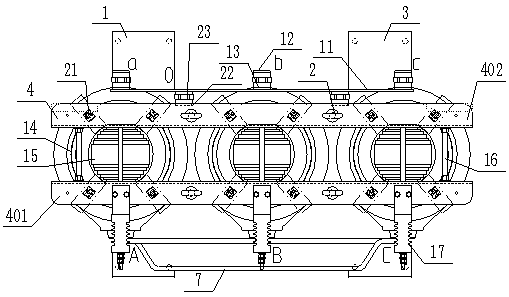

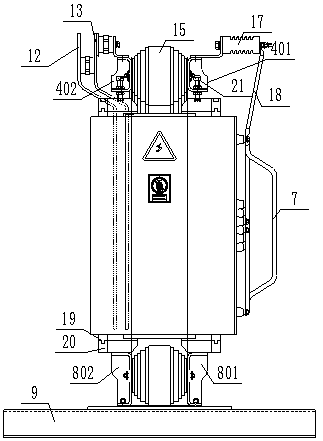

[0028] Such as Figures 1 to 12 As shown, a dry-type transformer with 3 sets of coils is taken as an example for illustration.

[0029] A dry-type transformer, including 3 sets of transformer main bodies, upper clamps 4 and lower clamps 8, the transformer main body includes an iron core 15 and a high-voltage coil 5 and a low-voltage coil 14 assembled on the iron core 15, the transformer main body and the upper A shock-absorbing pad 19 and a resin spacer 20 are respectively fixed between the clip 4 and the lower clip 8 .

[0030]The low-voltage coil 14 is casted with a low-voltage mold, and the low-voltage mold is rolled into a cylindrical shape with 3mm cold-rolled steel plate 1401. The outer diameter of the cylinder is the same as the inner diameter of the low-voltage coil 14, and the two ends of the cylinder are welded with flange plates. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com