Feeding system for 3D printing of ultra-high performance concrete

An ultra-high performance, feeding system technology, applied in the direction of supply device, clay preparation device, cement mixing device, etc., can solve the problem of not being able to well guide the design and construction of 3D printed concrete, and difficult to meet the requirements of ultra-high performance concrete mixture. , low level of intelligence and greening, etc., to ensure long-term service performance, beautiful external contours, and good environmental adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

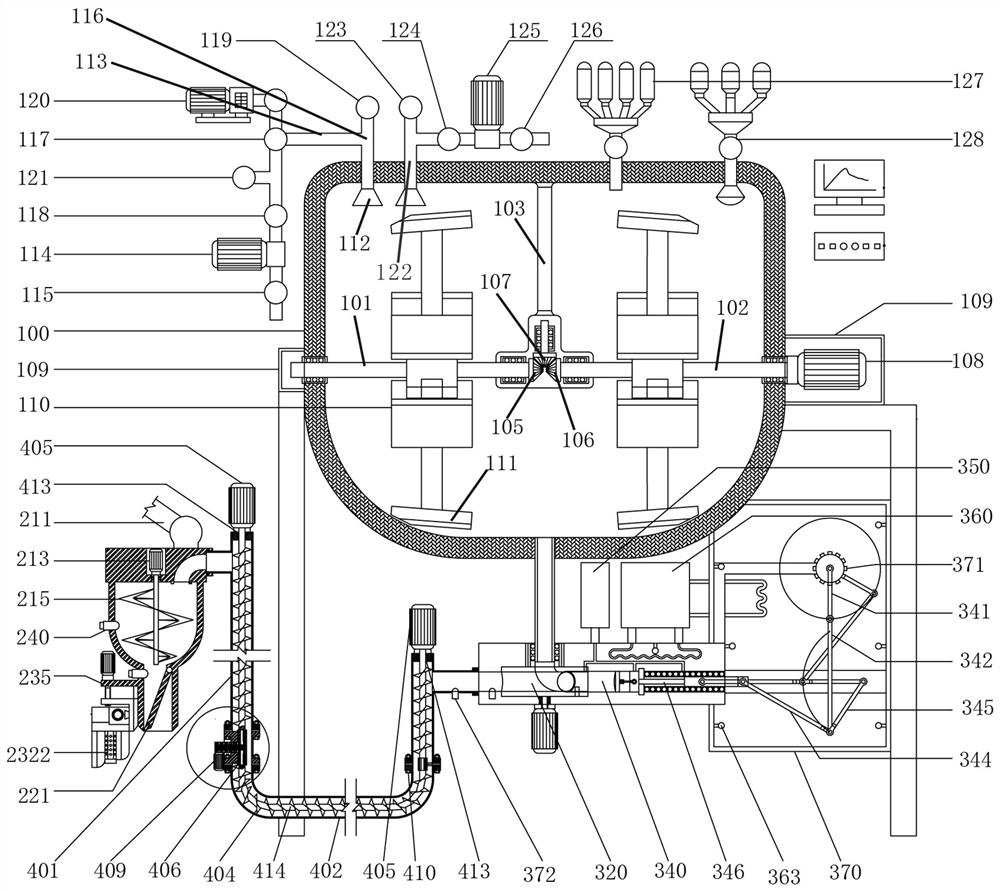

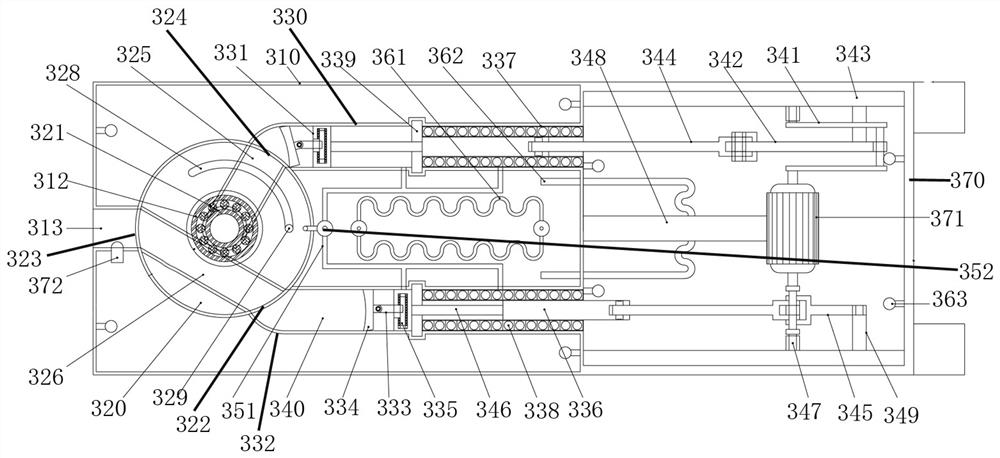

[0094] The following will clearly and completely describe the exemplary schemes of the embodiments of the present invention with reference to the accompanying drawings of the specific embodiments of the present invention. Unless otherwise defined, the technical terms or scientific terms used in the present invention shall have the usual meanings understood by those skilled in the art.

[0095] In the description of the present invention, it should be understood that the expressions "first" and "second" are used to describe each element of the present invention, and do not represent any order, quantity or importance limitation, but are only used to describe One component is distinguished from another.

[0096] It should be noted that when an element is "connected", "coupled" or "connected" to another element, it may mean that it is directly connected, coupled or connected, but it should be understood that there may be Intermediate elements; that is, positional relationships co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com