Combined process for manufacturing door

A combined process and manufacturing process technology, applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., can solve problems such as flatness errors, large quality fluctuations, high-efficiency coating, etc., to achieve reduced paint consumption and high mechanization , to avoid the effect of concave and convex phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

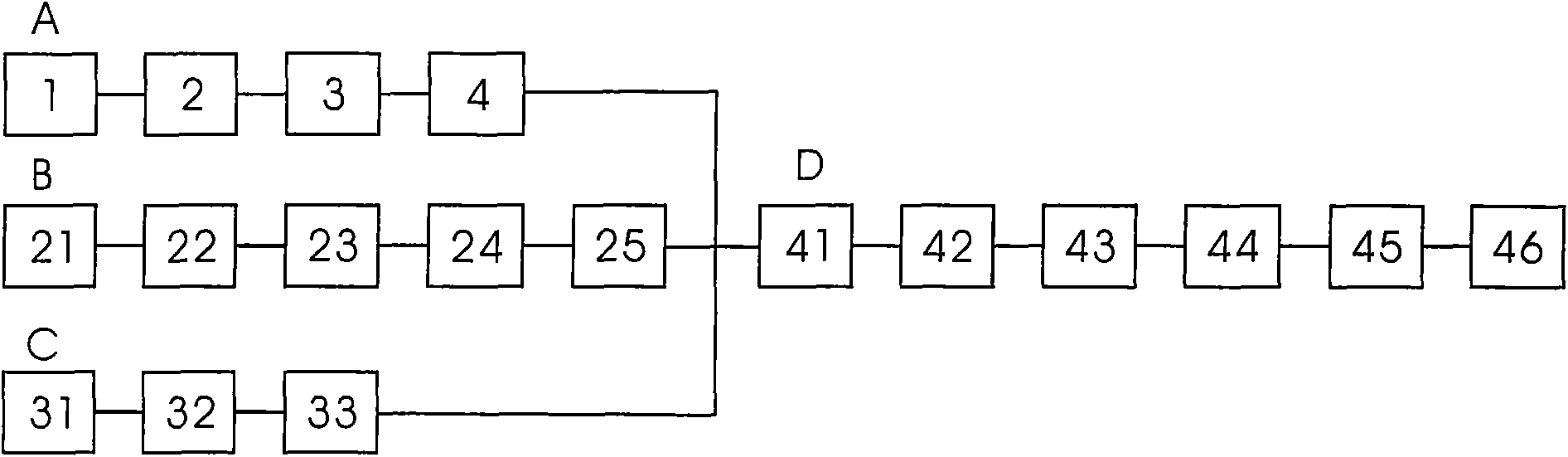

Method used

Image

Examples

example 1

[0014] Example 1: Flat door

[0015] Door frame part: The door frame is processed according to the design size, and the surrounding is processed to the tolerance size. The thickness error is large, and the thickness is machined (pressed), and the thickness is sent to the sander to meet the design tolerance. Go to assembly.

[0016] Edge strip part: with UV veneer. Or use solid wood strips for four-sided planing to size, carry out UV coating three-sided roll coating and curing, and primary sand. Go to assembly.

[0017] Panel part: choose appropriate plywood (particle board, medium and high density fiberboard) as the lining board, use solid wood veneer as the panel, apply glue and hot press, cut to the design size, groove or trim the edges evenly, and enter the surface with UV line for roller coating Painting, initial sanding. Go to assembly.

[0018] Assembly: Put the panel on the surface of the door frame, use wood glue and gun nails to assemble the panel and the door fr...

example 2

[0019] Example 2: Frame Door

[0020] Frame part: Make solid wood glulam according to the design size, cut and process it to the tolerance size, the thickness error is large, carry out thickness machining (planing), and send it to the thickness-setting sander to reach the design tolerance. Heat pressed with component panels.

[0021] Component panel part: choose appropriate plywood (particle board, medium and high-density fiberboard) as the lining board, use solid wood veneer as the panel, apply glue and hot press, cut to the frame design size, trim the edges evenly, and rely on glue hot pressing with the frame parts, Carry out surface sanding, and then enter the roller coating UV line for surface coating, initial sanding, and enter assembly.

[0022] Door core board part: use plywood with a set thickness (particle board, medium and high density fiberboard) as the lining board, use solid wood veneer as the double-sided panel, apply glue and hot press, cut to the door core des...

example 3

[0024] Example 3: Metal doors covered with wooden materials

[0025] When the steel structure material is used inside and the flat outsourcing wooden material is used as the external material, the surface of the wooden material is compounded with impregnated melamine urea-formaldehyde resin glue or solid wood veneer is hot-pressed, and then installed on the metal frame panel after cutting (solid wood veneer material cutting UV curing will be carried out later, and then assembled with the metal frame), and the edges will be sealed with metal buckles. That is to say, it has a certain fireproof function and has a solid wood texture and aesthetic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com