Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Avoid uneven response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

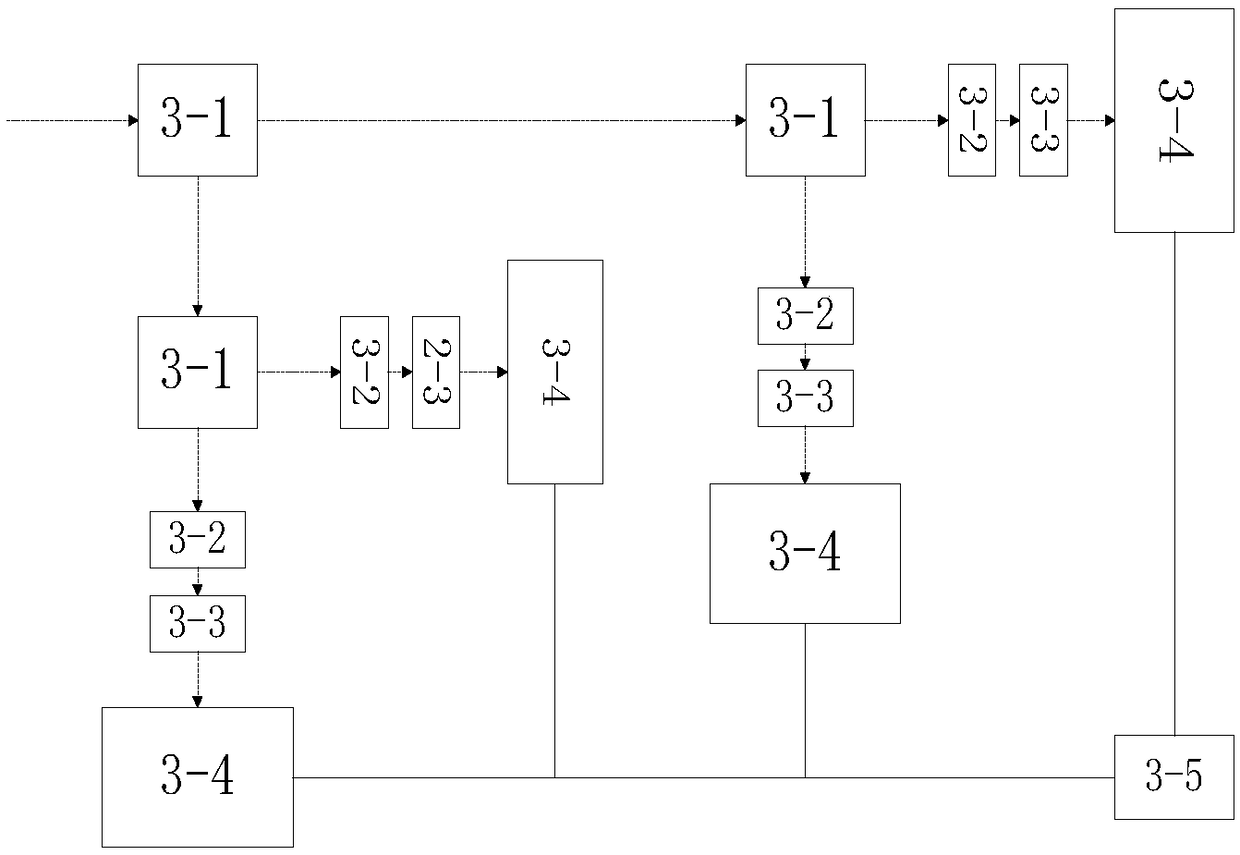

Method for treating kitchen wastes by hydrothermal carbonization coupled anaerobic digestion

ActiveCN109226188AReduce manufacturing costImprove applicabilityTransportation and packagingSolid waste disposalPhysical chemistryAerobic digestion

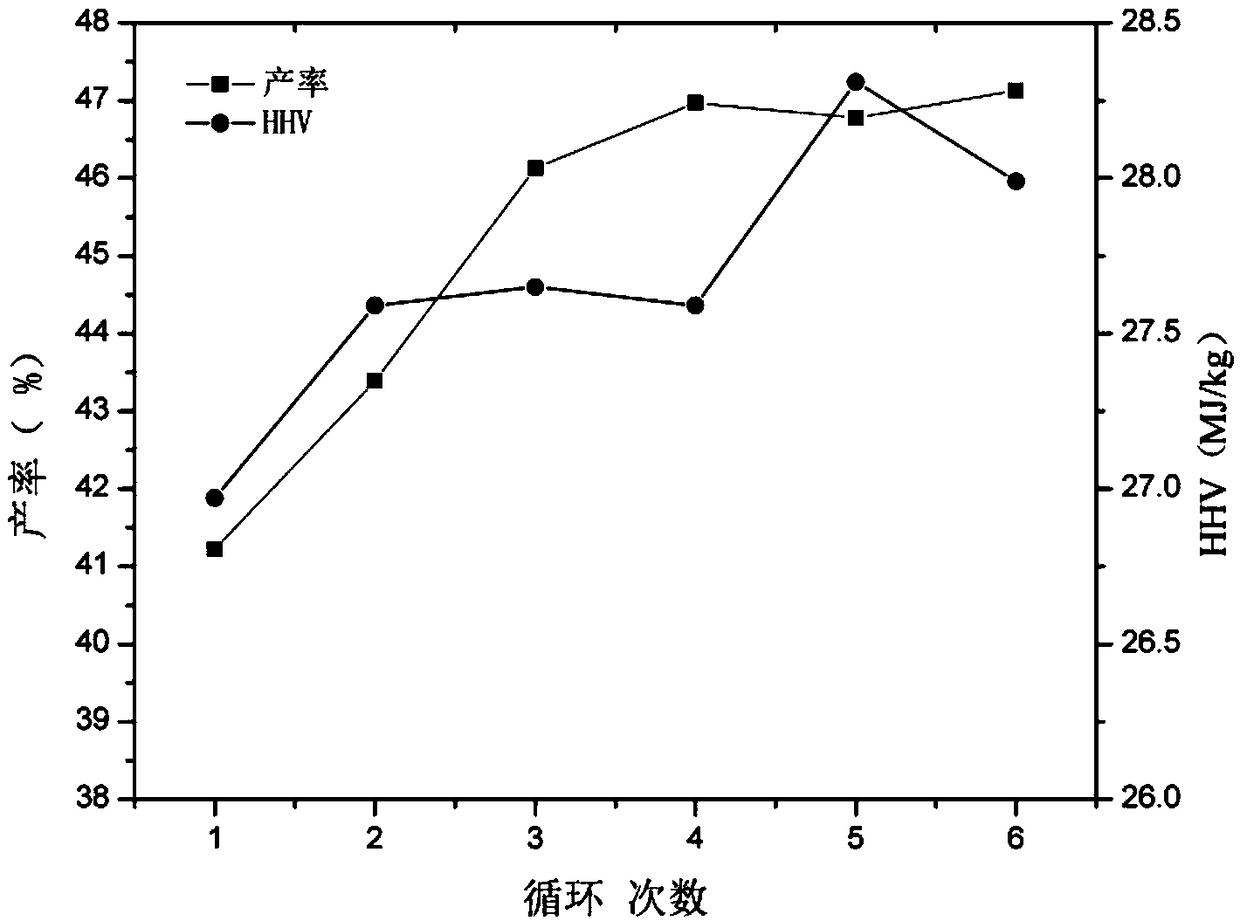

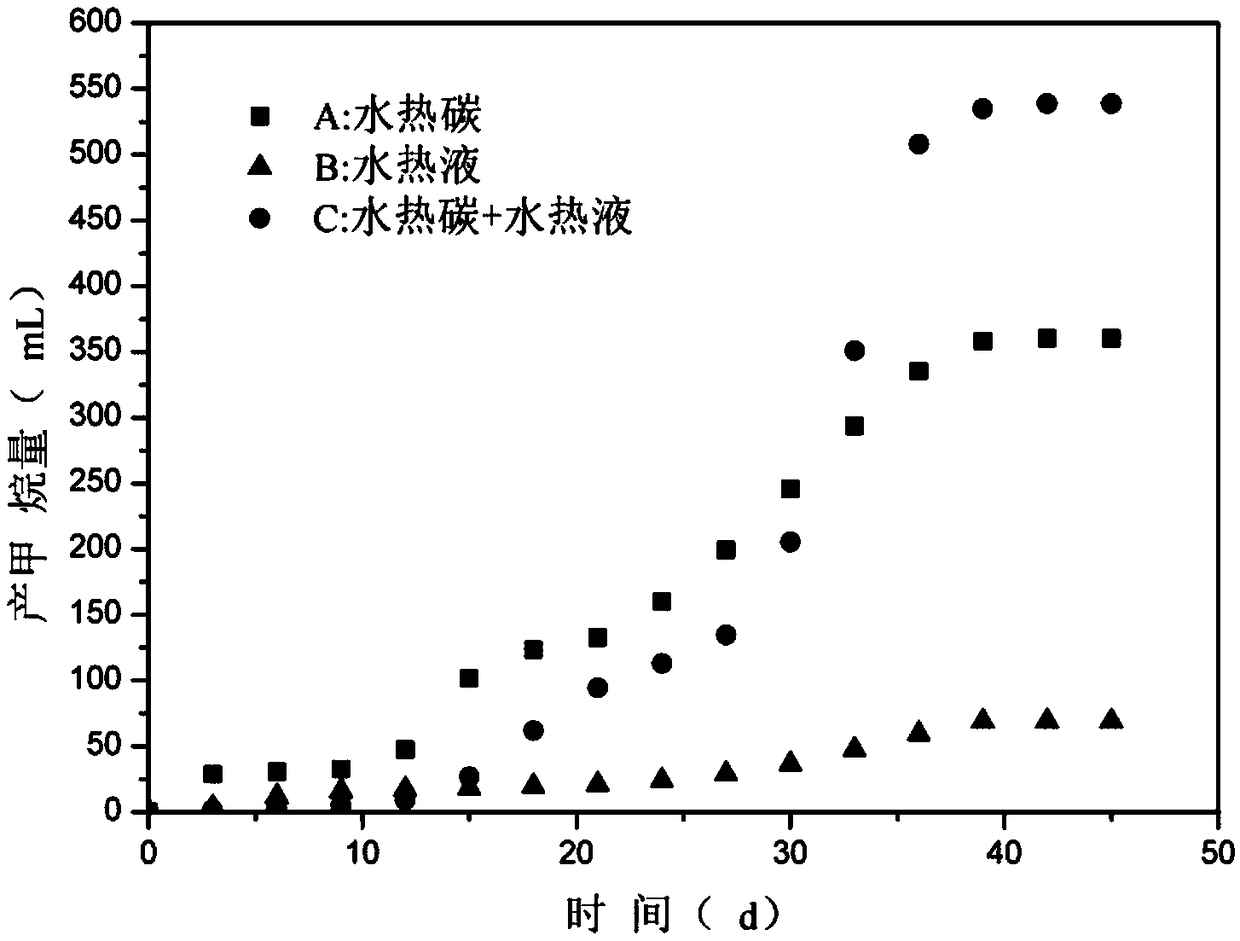

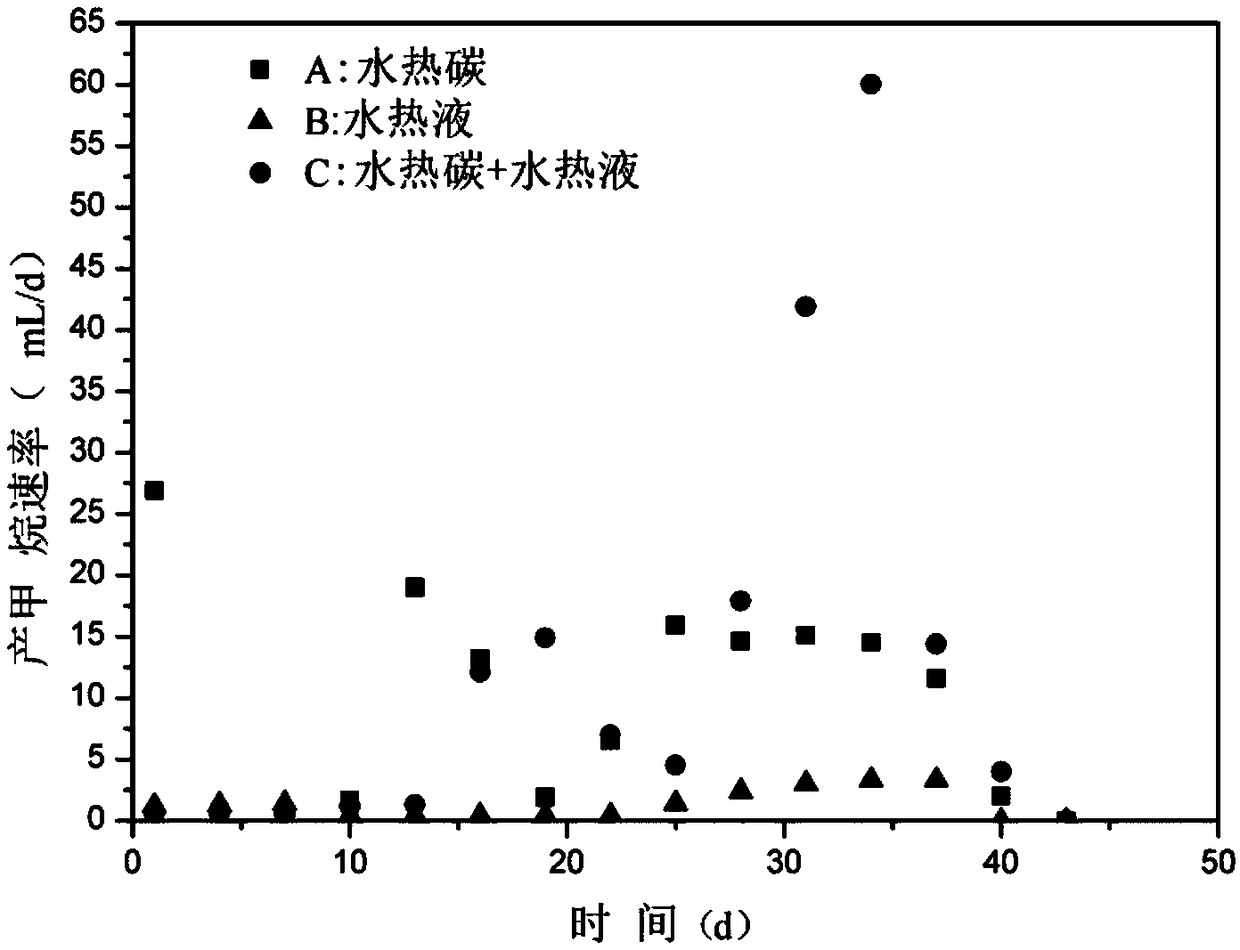

The invention provides a method for treating kitchen wastes by hydrothermal carbonization coupled anaerobic digestion. The method comprises the following steps: (1) carrying out a hydrothermal carbonization reaction on crushed kitchen wastes, separating the hydrothermal carbonization reaction product to obtain a hydrothermal solution and a solid product, and drying the solid product to obtain hydrothermal carbon; and (2) carrying out anaerobic digestion treatment on the hydrothermal carbon and the hydrothermal solution obtained in the step (1) or a mixture of the hydrothermal carbon and the hydrothermal solution. According to the method for treating kitchen wastes by hydrothermal carbonization coupled anaerobic digestion, provided by the invention, a hydrothermal carbonization technology and an anaerobic digestion technology are coupled to treat the kitchen wastes, so that the recycle, harmlessness and reduction of the kitchen wastes can be realized.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

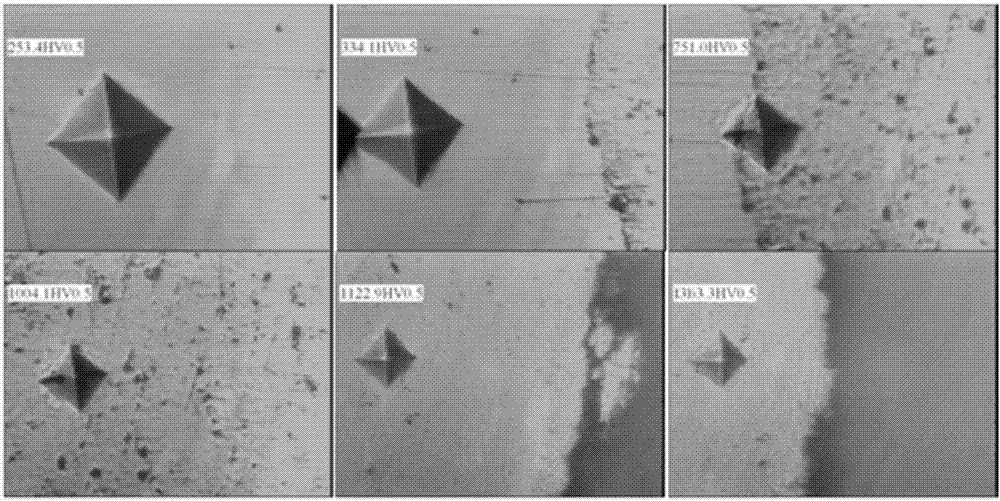

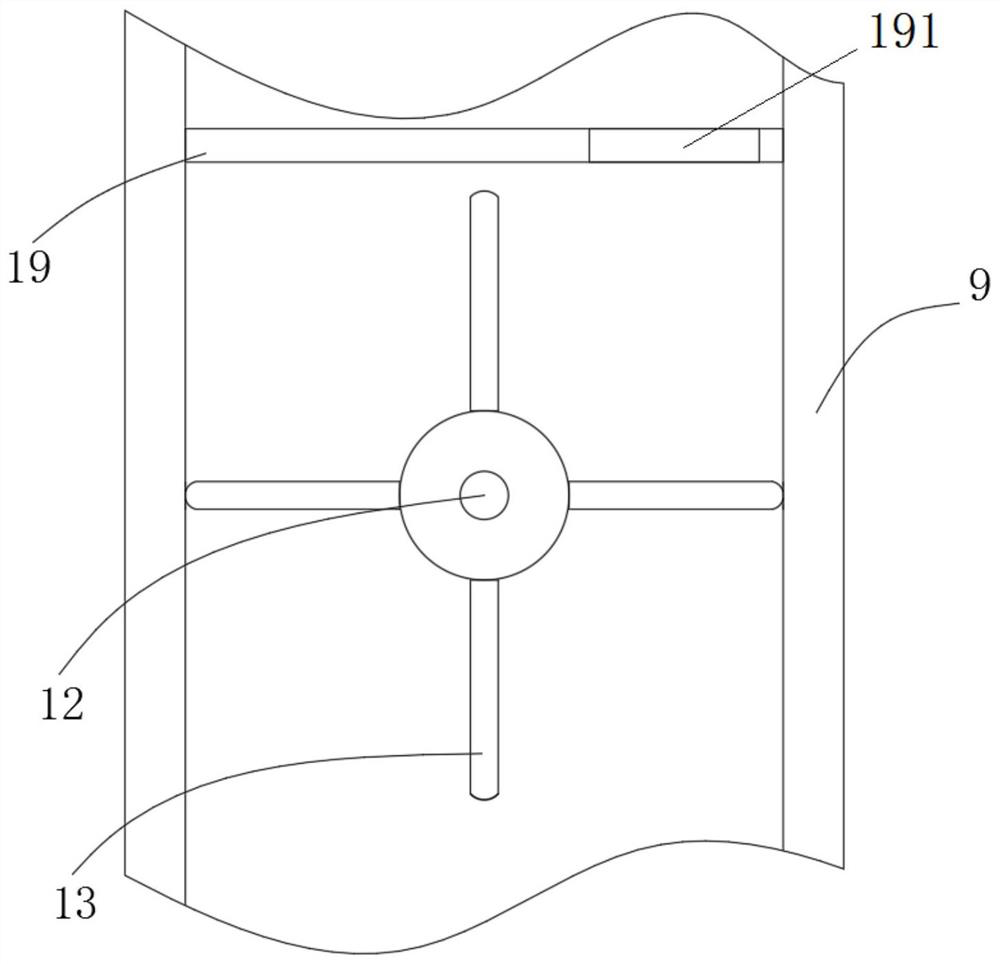

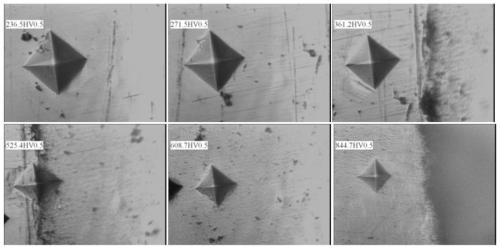

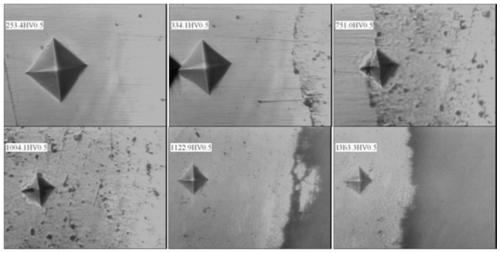

Repairing method for surface of draught fan blade

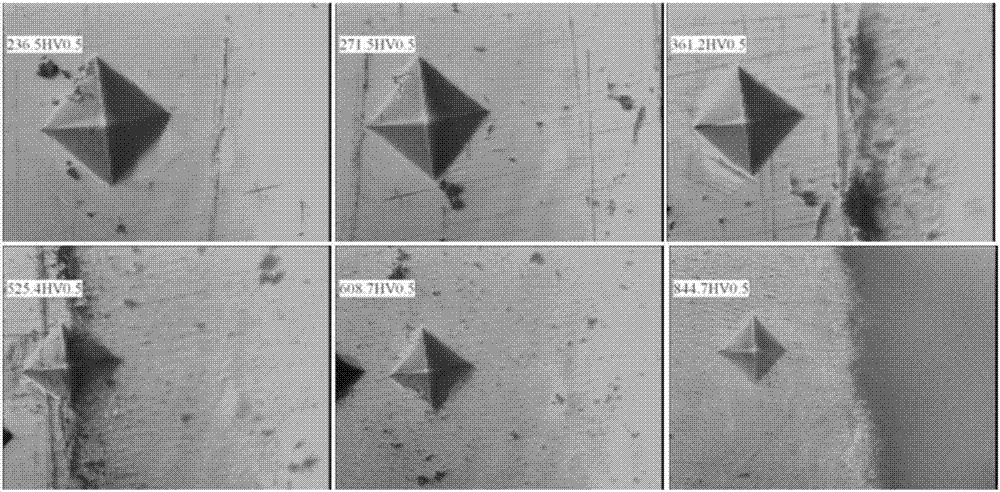

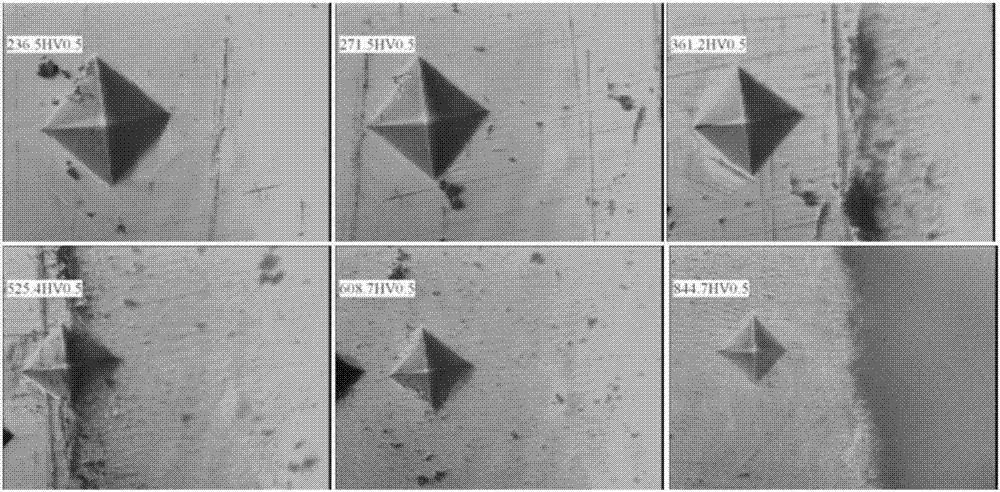

InactiveCN107254650ASolve lossSolve the problem of longevityMolten spray coatingCarbon compoundsPre treatmentMulti element

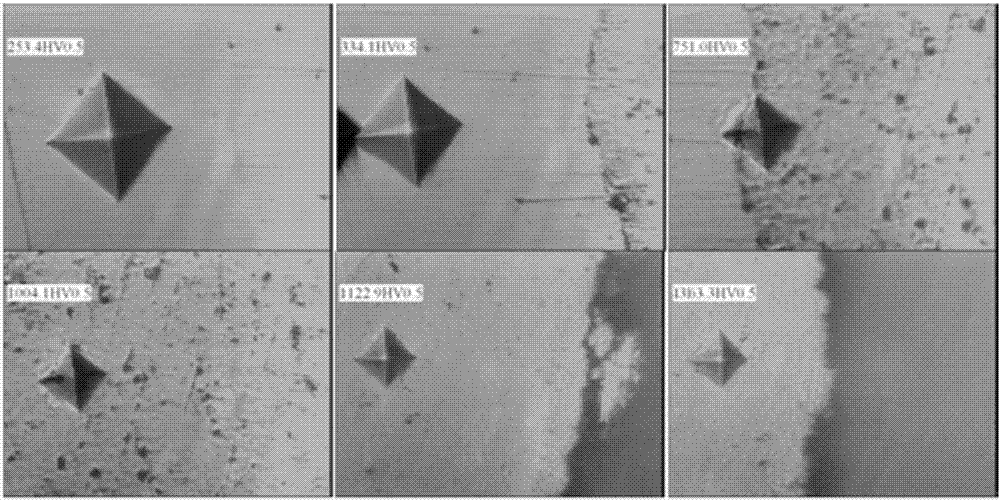

The invention discloses a repairing method for the surface of a draught fan blade and belongs to the technical field of draught fan repairing. According to the repairing method for the surface of the draught fan blade, the method comprises the steps of blade surface pre-treatment, preheating before spraying, preparation before material spraying, ultrasonic spraying and hole sealing treatment. According to a spraying material, an NiAl material is chosen and used to conduct bottoming, and the problem that the material thermal expansion coefficients of an abrasion-resisting work layer and a blade base layer are not matched can be solved, so that thermal stress caused by the fact that the expansion coefficients of the work layer and the blade base layer are not matched is reduced, and the mechanical matching and physical compatibility between the work layer and the blade base layer are improved. The work layer is a WC-12Co composite coating or an NiCr-Cr3C2 composite coating. According to the repairing method for the surface of the draught fan blade, by optimizing the repairing steps, multi-element alloy coating components and distribution, the good erosion and abrasion resistance performance is achieved, and the technical problem that the efficiency of a draught fan is affected due to draught fan blade erosion and abrasion is solved.

Owner:安徽威龙再制造科技股份有限公司

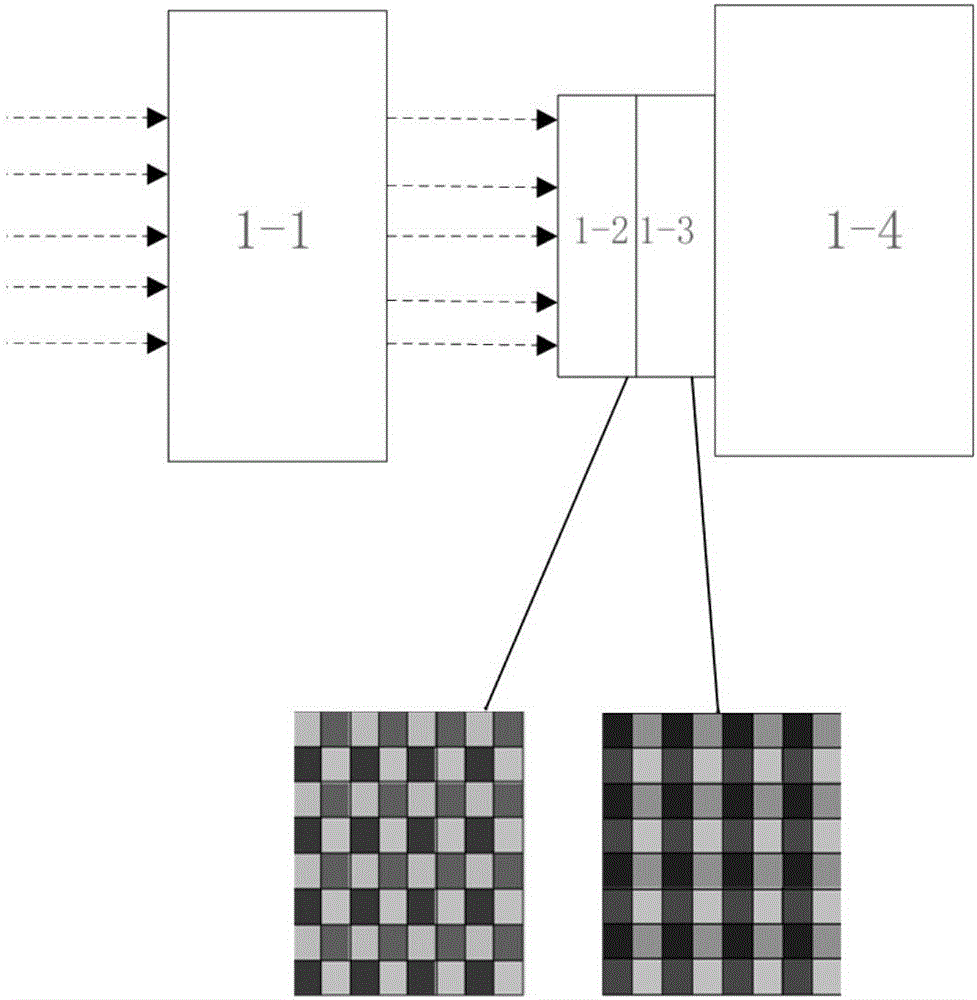

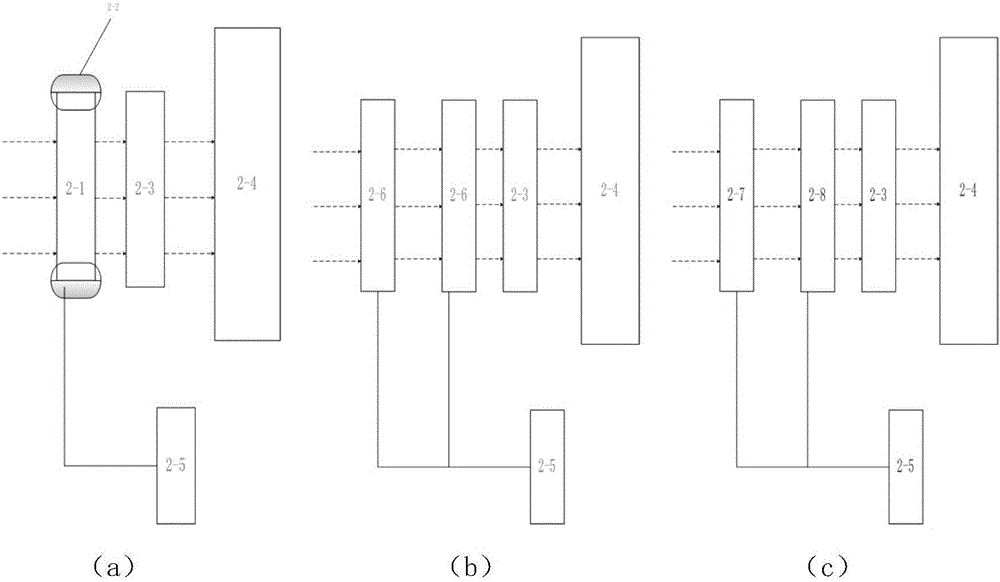

Device for real-time measurement of sun polarization stokes vector

ActiveCN106525242AReal-time measurementAvoid the influence of flickering light intensityLight polarisation measurementMicrowaveSpectral response

The invention provides a device for the real-time measurement of a sun polarization stokes vector. The device comprises a spectral filter, a wave plate array, a polarizer array and a light intensity acquisition camera. A solar magnetic field provides a driving force and an energy source for the activity outbreak of the sun, while the measurement on the sun polarization stokes vector is the only way for the detection of the solar magnetic field. According to the technical scheme of the invention, a novel device for the real-time measurement of the sun polarization stokes vector is provided. Based on the micro-optical technology principle, the microwave plate array is prepared. On the above basis, the micro-polarizer array is prepared and is attached to the photosensitive surface of the light intensity acquisition camera. In this way, the information of the sun polarization stokes vector can be obtained through the single-exposure process. Compared with a conventional device, the above device is compact in structure and high in real-time property. Meanwhile, the device does not need to be finely tuned or manually operated, and is wide in spectral response range, low in cost and suitable for mass production. At the same time, the occurrence of detection errors, due to the non-uniform response of the camera, aberration and the like, can be avoided. The device can be conveniently extended and applied to other application fields.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Bearing seat inner hole abrasion remanufacturing spray repair method

ActiveCN107312995AGood resistance to high temperature oxidationImproved erosion and wear resistanceMolten spray coatingMaterials preparationSpray coating

The invention discloses a bearing seat inner hole abrasion remanufacturing spray repair method and belongs to the technical field of bearing seat repair. Through the steps of bearing seat inner hole surface pretreatment, preheating before spraying, spray material preparation, supersonic spraying and coating processing, a NiCr or NiAl material is selected for spray material priming, the problem that the material thermal expansion coefficients of an abrasion-resistant working layer and a bearing seat inner hole basic layer are not matched can be solved, thus, the thermal stress caused by mismatching of the expansion coefficients of the working layer and the bearing seat inner hole basic layer is reduced, and mechanical matching and physical compatibility of the working layer and the bearing seat inner hole basic layer are improved; and a WC-12Co composite coating or a NiCr-Cr3C2 composite coating is used as the working layer. Through repair step optimization, multicomponent alloy coating compositions and distribution, the good erosive abrasion resistance is achieved, and the problems of high mechanical repair cost of bearing seat abrasion and large shrinkage percentage of spraying coatings are solved.

Owner:济宁拓源精密机械股份有限公司

Diaper with good absorbing, water-locking and antibacterial properties and processing technique thereof

ActiveCN110123528AGood drainage and absorption performanceIncrease the areaAbsorbent padsBaby linensHigh absorptionResin microsphere

The invention relates to a processing technique of a diaper. A diaper body is included and is provided with a surface layer, a flow guide layer, an absorbing core layer and a bottom membrane layer sequentially from top to bottom; the absorbing core layer comprises a dust-free paper layer and a high-absorption material layer sequentially from bottom to top; the high-absorption material layer is made by mixing antibacterial high-absorption resin microspheres and fluff pulp in a mass ratio of (3-4):(7-6). A synthetic method of the antibacterial high-molecular water-absorbing resin microspheres applied in the diaper acts as a modification to a method of synthesizing high-molecular water-absorbing resin via a solution process; magnetic ordered mesoporous carbon nanospheres with multiple ducts,regular pore size and large specific surface area are used as a carrier; therefore, polymerization efficiency is improved, the finished high-molecular water-absorbing resin microspheres have uniform character, and the post-treatment procedures are simple.

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

Synthesis method and application of superabsorbent resin microspheres with antibacterial properties

ActiveCN110272517AIncrease the areaImprove liquid storage capacityAbsorbent padsBandagesResin microsphereSynthesis methods

The invention relates to a synthesis method and application of superabsorbent resin microspheres with antibacterial properties. The synthesis method comprises the following steps: (1) adding a certain amount of magnetic ordered mesoporous carbon nanospheres and a polymer dispersing agent to a certain amount of water, performing full and even stirring, then performing vacuum and / or ultrasonic-assisted degassing treatment for 1-2 h, adding a certain amount of acrylic acid, performing even stirring, and controlling the temperature at 35-45 DEG C; (2) adding a certain amount of sodium hydroxide to the system obtained in the step (1) while stirring, and controlling the temperature at 65-75 DEG C in the reaction process; (3) adding a certain amount of a composite crosslinking agent and an initiator, and controlling the temperature at 80-90 DEG C for a reaction for 2-3 hours so as to form a semi-finished product superabsorbent resin colloid, wherein the composite crosslinking agent is a mixture of NMBA and PEGDA; and (4) putting the superabsorbent resin colloid obtained in the step (3) in a certain amount of a solvent, performing rinsing for 1-3 times, adding a certain amount of a nano-silver antibacterial agent, performing drying until the moisture content at less than 3%, performing pulverization to a certain particle size, and performing magnetic separation so as to obtain the superabsorbent resin finished product.

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

Sink roll multicomponent alloy coating and preparing and spraying method thereof

InactiveCN106929788AGood resistance to high temperature oxidationSolve lossMaterial nanotechnologyHot-dipping/immersion processesHeat resistanceHardness

The invention discloses a sink roll multicomponent alloy coating and a preparing and spraying method thereof, and belongs to the technical field of sink roll repair. The sink roll multicomponent alloy coating sequentially comprises a sink roll base layer, a transition layer and a work layer from inside to outside, the transition layer is a NiCrAlY spraying layer, NiCrAlY is sprayed to the sink roll base layer to serve as a metal bonding layer, that is the transition layer, and the problem of mismatching of material heat expansion coefficients between a wear-resisting heat-resisting work layer and the sink roll base layer can be solved; the work layer is the NiCr-Cr3C2 composite coating, the NiCr alloy has the excellent heat resistance, corrosion resistance, high-temperature oxidation resistance and other properties, Cr3C2 has the good high-temperature hardness and high-temperature oxidation resistance, the hard phase effect is achieved, the coating is not soluble in zinc liquid and is not wetted, coating peeling and even failures caused by heat impact can be greatly reduced, and the technical problems are solved.

Owner:安徽威龙再制造科技股份有限公司

Multicomponent alloy coating for hot rolling roll and preparation method and coating method of multicomponent alloy coating

InactiveCN107119250ASolve lossSolve the problem of longevityMolten spray coatingWear resistantSpray coating

The invention discloses a hot roll multi-element alloy coating and a preparation and spraying method thereof, belonging to the technical field of roll repair. A kind of hot roll multi-element alloy coating of the present invention, from inside to outside is hot roll base layer, transition layer and working layer successively, and transition layer is NiCr or NiCrAl spray coating, sprays NiCr or NiCrAl on hot roll base layer as metal bonding layer namely The transition layer can eliminate the problem of thermal expansion coefficient mismatch between the wear-resistant and heat-resistant working layer and the base layer of the hot roll; the working layer is NiCr‑Cr3C2 composite coating, and NiCr alloy has excellent heat resistance, corrosion resistance, high temperature oxidation resistance, etc. Performance, while Cr3C2 has good high temperature hardness and high temperature oxidation resistance, and acts as a hard phase. Moreover, NiCr-Cr3C2 has a linear expansion coefficient similar to that of hot rolling rolls, thereby greatly reducing the peeling or even failure of the coating caused by thermal shock, and solving the technical problem of the present invention.

Owner:安徽威龙再制造科技股份有限公司

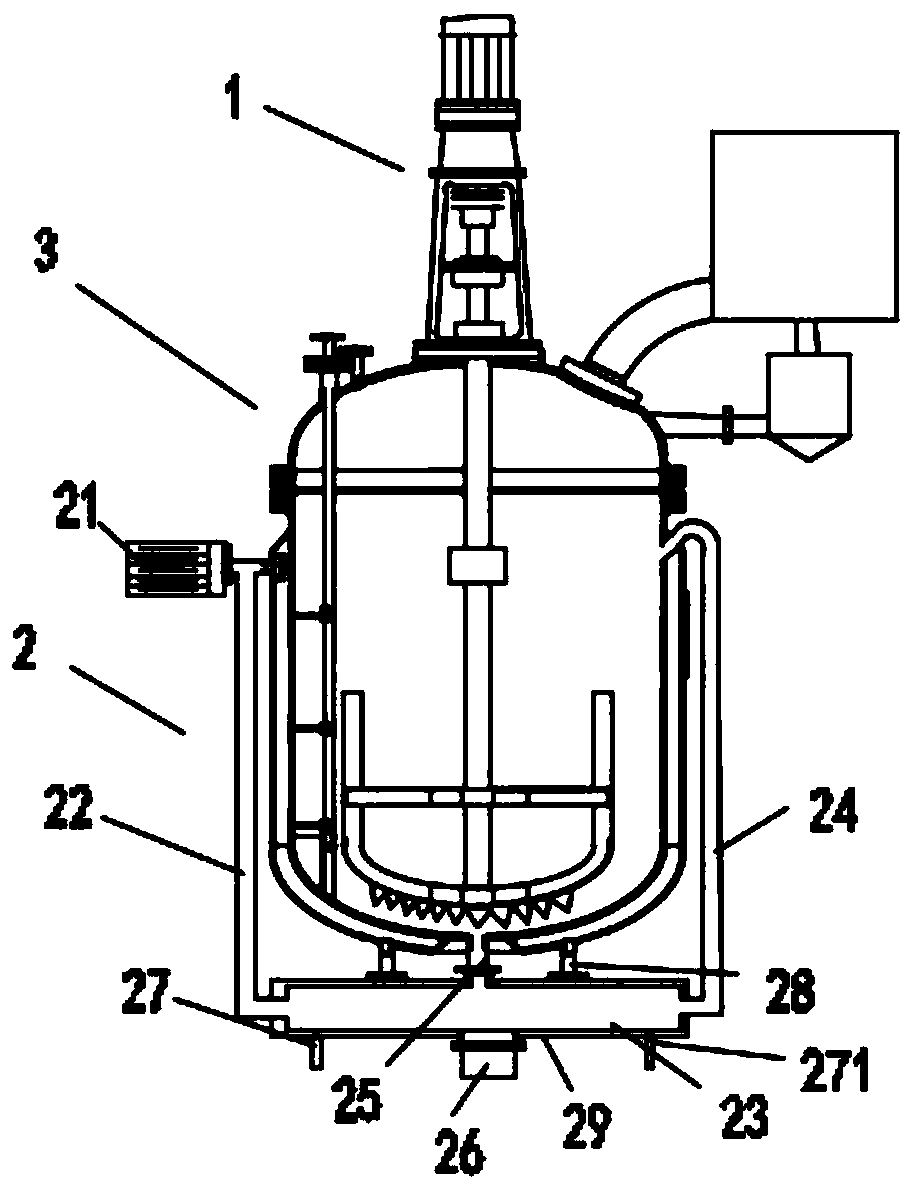

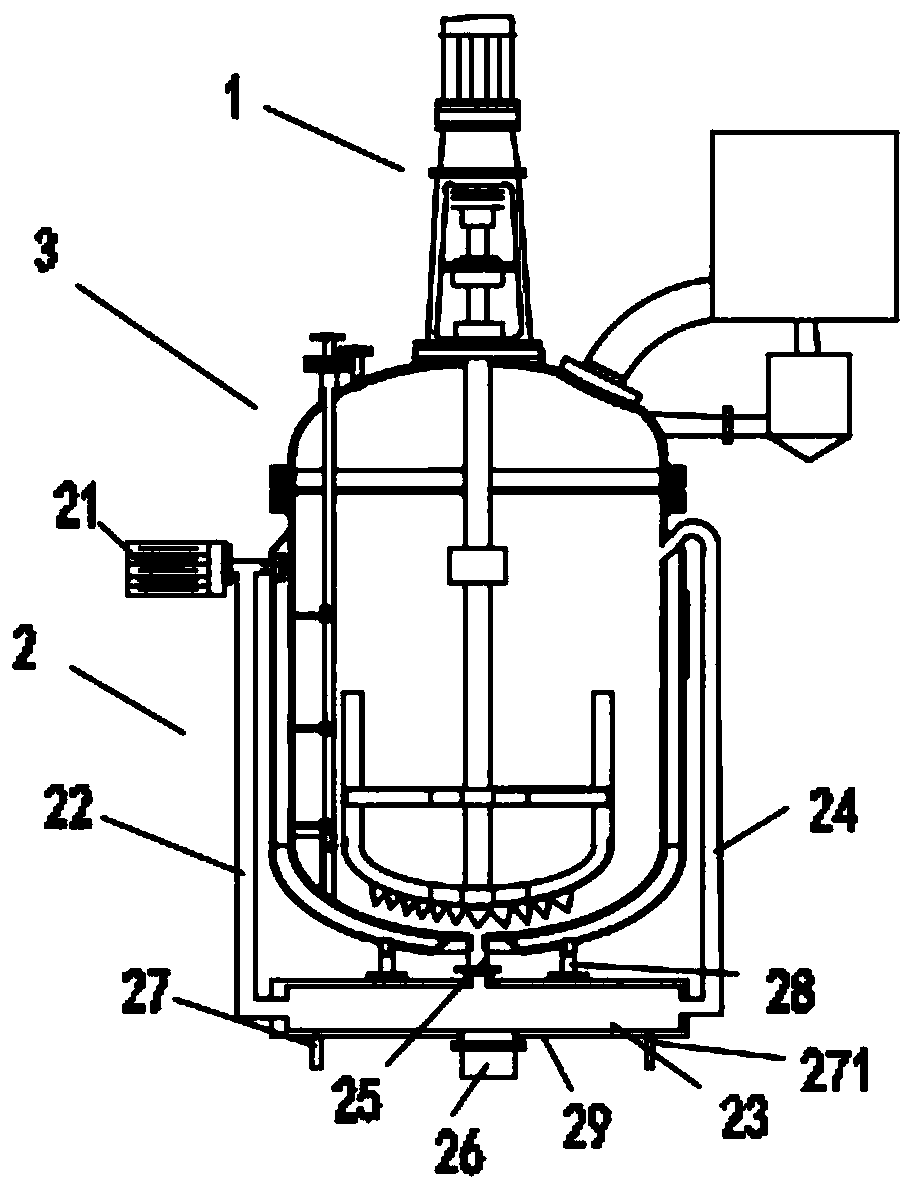

Esterification process of cyanate ester resin

ActiveCN110227401AQuality damageAvoid damageProcess control/regulationChemical/physical/physico-chemical stationary reactorsWater bathsEthylamine

The invention discloses an esterification process of cyanate ester resin. The process comprises the following steps: step S1, weighing the following raw materials in parts by weight: 10-15 parts of diphenolyl propane, 0.5-1.0 part of triethylamine, 35-50 parts of acetone, 25-35 parts of absolute ethanol, and 20-30 parts of cyanogen chloride; step S2, adding diphenolyl propane and triethylamine toa beaker containing acetone, performing heating in a 45 DEG C water bath, performing stirring for 45 min at a rotation speed of 100 r / min, performing taking out, and performing standing for 30 min toobtain a mixed liquid A; and step S3, carrying out a reaction through a reaction kettle. In the process, the reaction kettle has high heat exchange efficiency and good heat exchange effect, reaction heat can be quickly taken away, and thus occurrence of side reactions is not easy to cause. Materials can be subjected to cutting during stirring to avoid uneven reaction due to increased viscosity ofthe materials along a reaction is carried out, and heat exchange efficiency can be further improved by mixing with remaining materials after heat exchange is completed.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

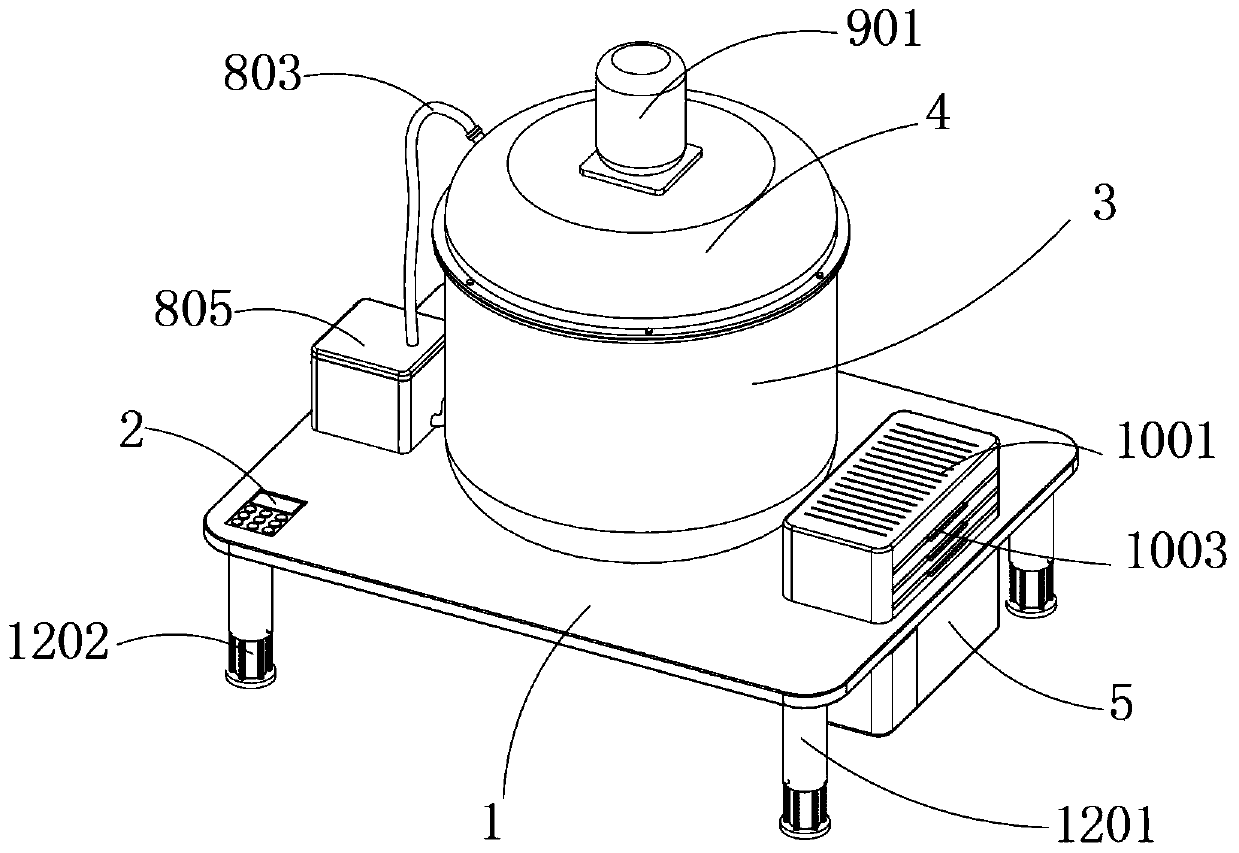

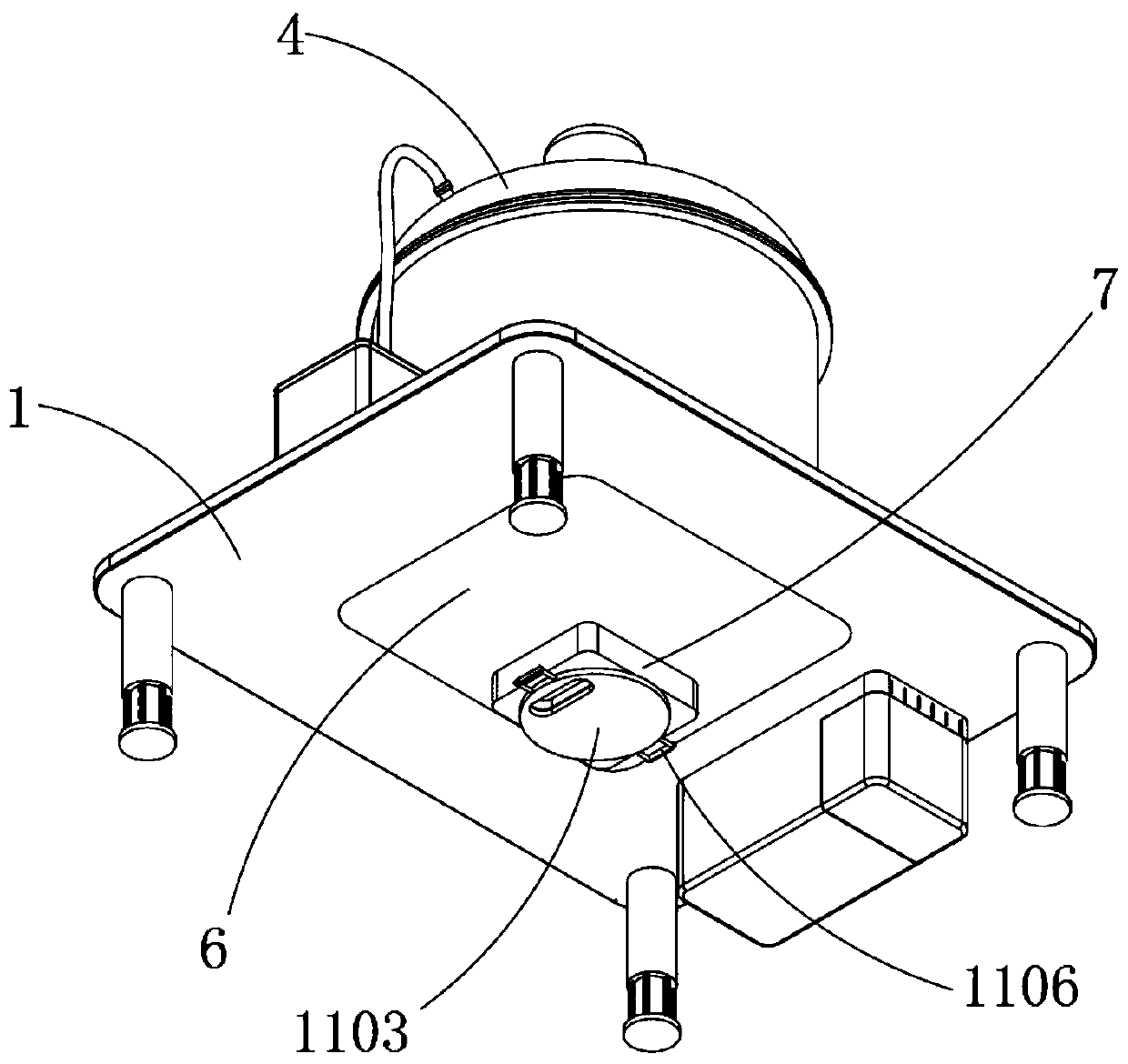

Highly-efficient reaction device for environmentally-friendly resin production

InactiveCN110898787AScientific and reasonable structureEasy to useChemical/physical/physico-chemical stationary reactorsProcess engineeringControl switch

The invention discloses a highly-efficient reaction device for environmentally-friendly resin production. The highly-efficient reaction device comprises a bottom plate, wherein a control switch is mounted at the top end of the bottom plate in an embedded manner; the position of the center of the top end of the bottom plate is connected with a reaction kettle; and a reaction kettle cover is mountedat the top end of the reaction kettle. The highly-efficient reaction device provided by the invention has the following advantages: the structure is scientific and reasonable; use is safe and convenient; through arrangement of a conveying pump, a second conveying pipe, a heat insulation liner and a cavity, heat insulation oil can be conveyed to the cavity between the heat insulation liner and thereaction kettle, and before the reaction kettle and the reaction kettle cover are opened, the heat insulation oil is pumped back into a storage bin for storage, so the heat insulation capability of the reaction kettle is improved, and the heat insulation oil can be recycled; and through arrangement of a stirring motor, a rotating shaft, connecting plates, stirring shafts and scraping plates, added resin raw materials can be stirred through operation of the stirring motor, so the amount of the resin raw materials attached to the inner wall of the heat insulation liner can be reduced, and the situation of nonuniform reaction of the resin raw materials in the reaction kettle can be avoided from occurrence.

Owner:湖州互融新材料科技有限公司

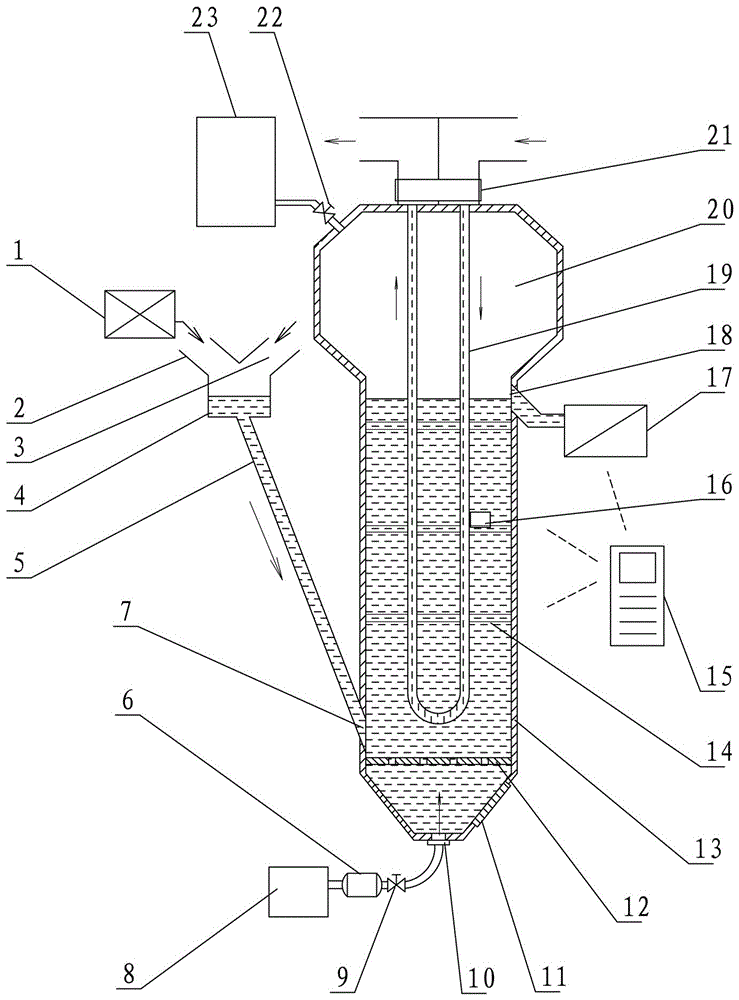

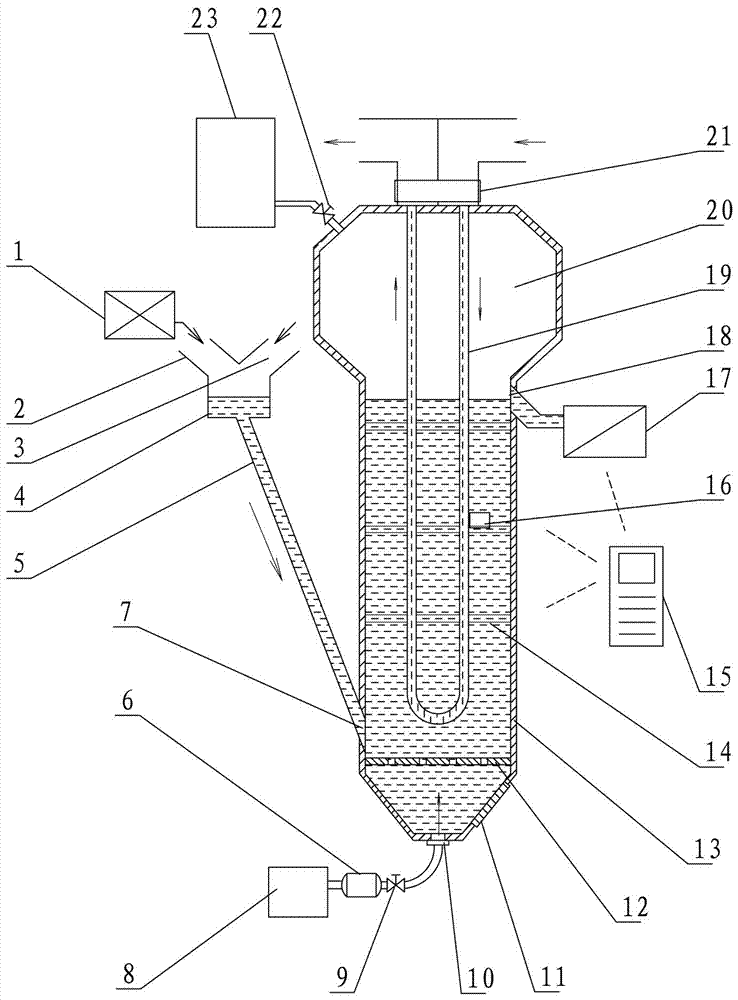

Method of continuously preparing artificial rutile and dedicated device thereof

ActiveCN106430297AReduce frictionSolve the problem of particle shrinkageTitanium dioxideHigh energyRutile

The invention provides a method of continuously preparing artificial rutile and a dedicated device thereof. The method and the dedicated device thereof solve the problems that a conventional reactor can not achieve continuous and mass productions and has high energy consumptions. According to the technical scheme, the method comprises the steps of adding hydrochloric acid and materials into an elevatus mingled storehouse, and conducting mixing on the hydrochloric acid and the materials; making the mixture flow into a reactor along a feed pipe; injecting the heated hydrochloric acid to the reactor from the bottom of the reactor to be subjected to upward flow, conducting acid leaching reaction on the heated hydrochloric acid with a pasty material, using a U-shaped heating tube to conduct heating on the reaction solution, and sending the reaction solution to a negative pressure type liquid-solid separator when the reaction solution reaches the height of a discharge gate; emitting gas generated by the reaction solution to a gas / liquid collector. On the premises of improving the safety, protecting the environment, improving efficiency and stability of quality, the whole system achieves continuous leaching, is applicable to mass production, and has low energy consumption.

Owner:于京辉 +2

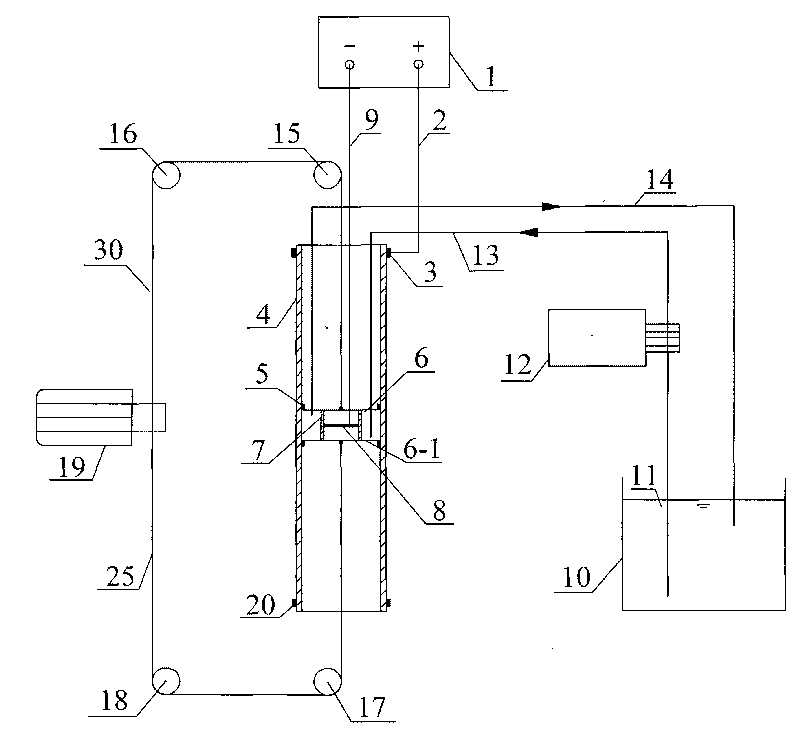

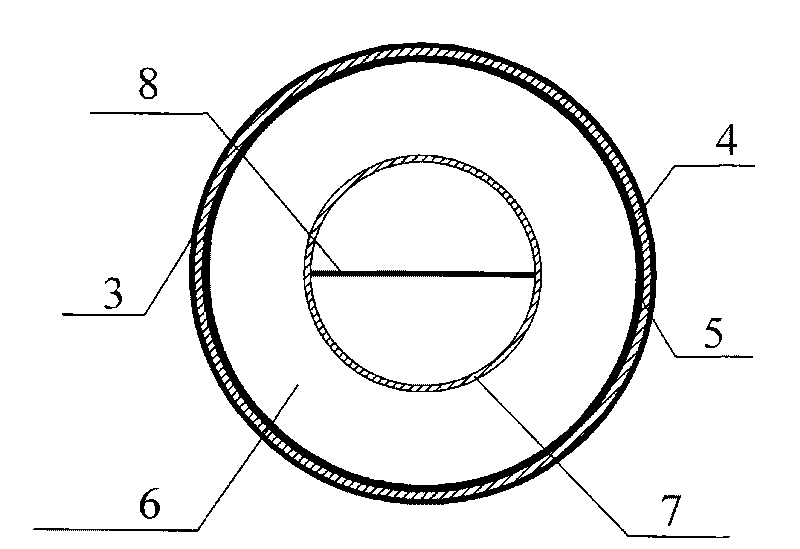

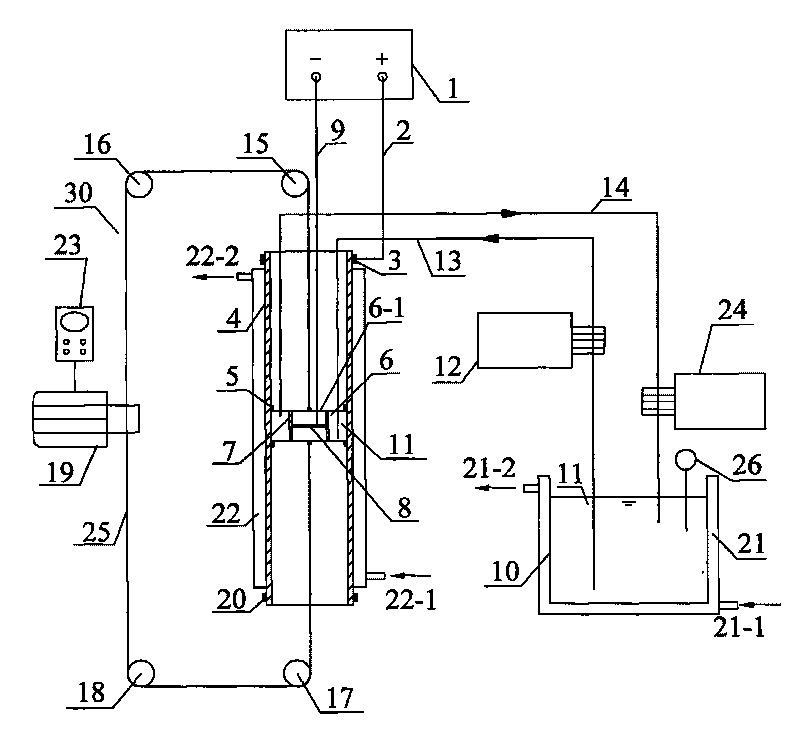

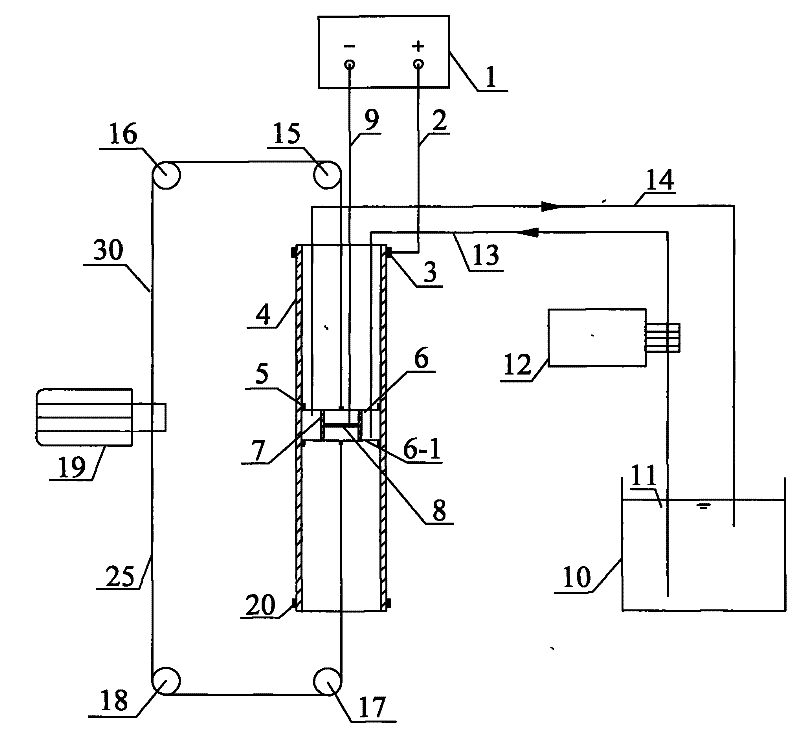

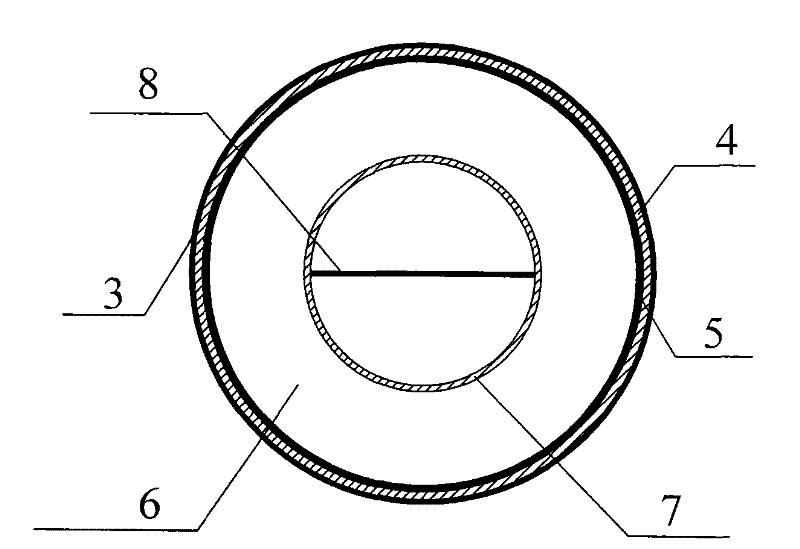

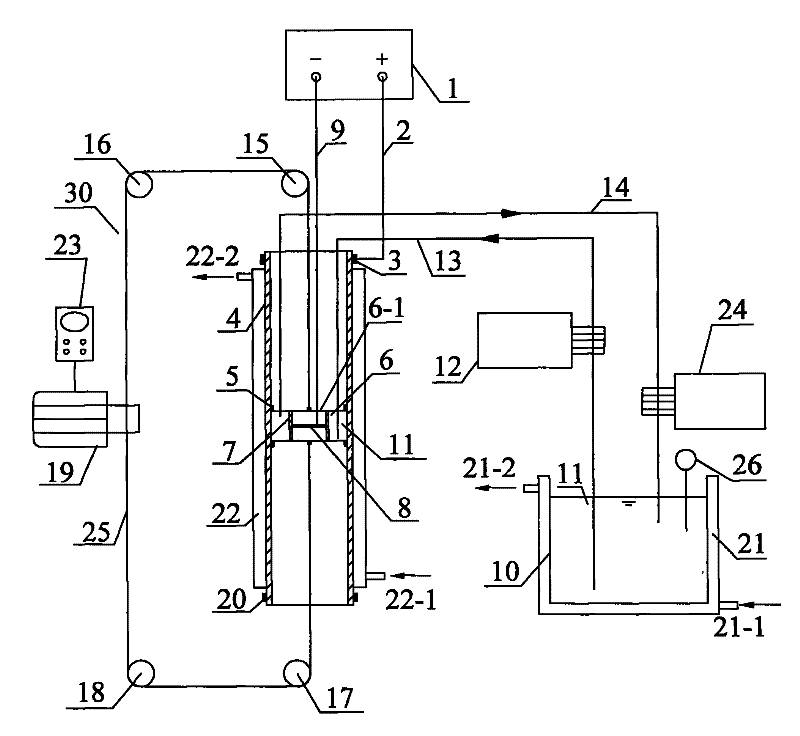

Preparation device of large-area titanium dioxide thin film catalyst and preparation method thereof

The invention provides a preparation device of a large-area titanium dioxide thin film catalyst and a preparation method thereof, relating to the preparation device and the method of a titanium dioxide catalyst and solving the problem that the continuous and high-efficiency preparation of the large-area titanium dioxide thin film catalyst is hardly realized under the condition of low-power power supply. The electrolyte in a reaction monomer tank is in contact with the side of an anode made of titanium and the side of a cathode synchronously, a driving mechanism is used for enabling the reaction monomer tank to make relative movement along the side of the anode made of the titanium. The preparation method mainly comprises the following steps of: circularly flowing the electrolyte between an electrolyte tank and the reaction monomer tank; applying voltage or current between the anode and the cathode, wherein the current density is below 200mA / cm2 and the voltage is below 300V; and enabling the reaction monomer tank to make relative movement along the side of the anode made of the titanium according to set requirements. The device can prepare the large-area titanium dioxide thin film catalyst under the condition of the low-power power supply by arranging the reaction monomer tank capable of moving relative to the anode made of the titanium. The method has good production flexibility and high efficiency.

Owner:HARBIN INST OF TECH

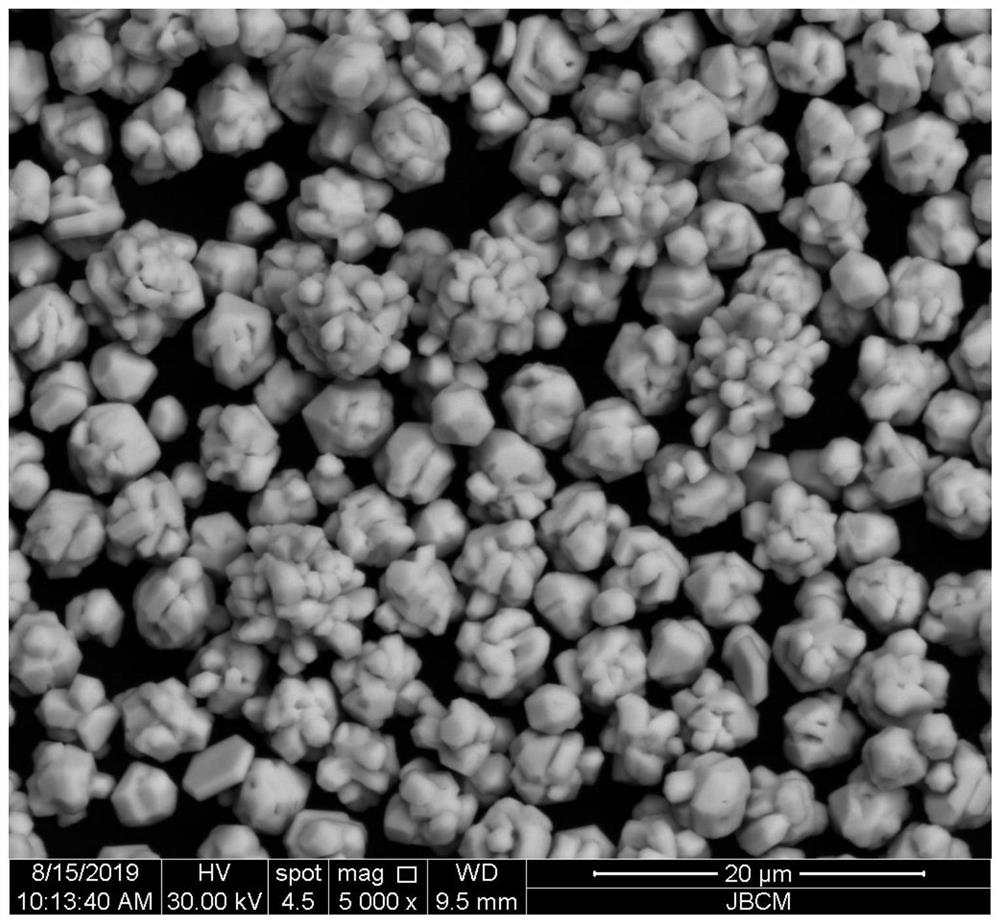

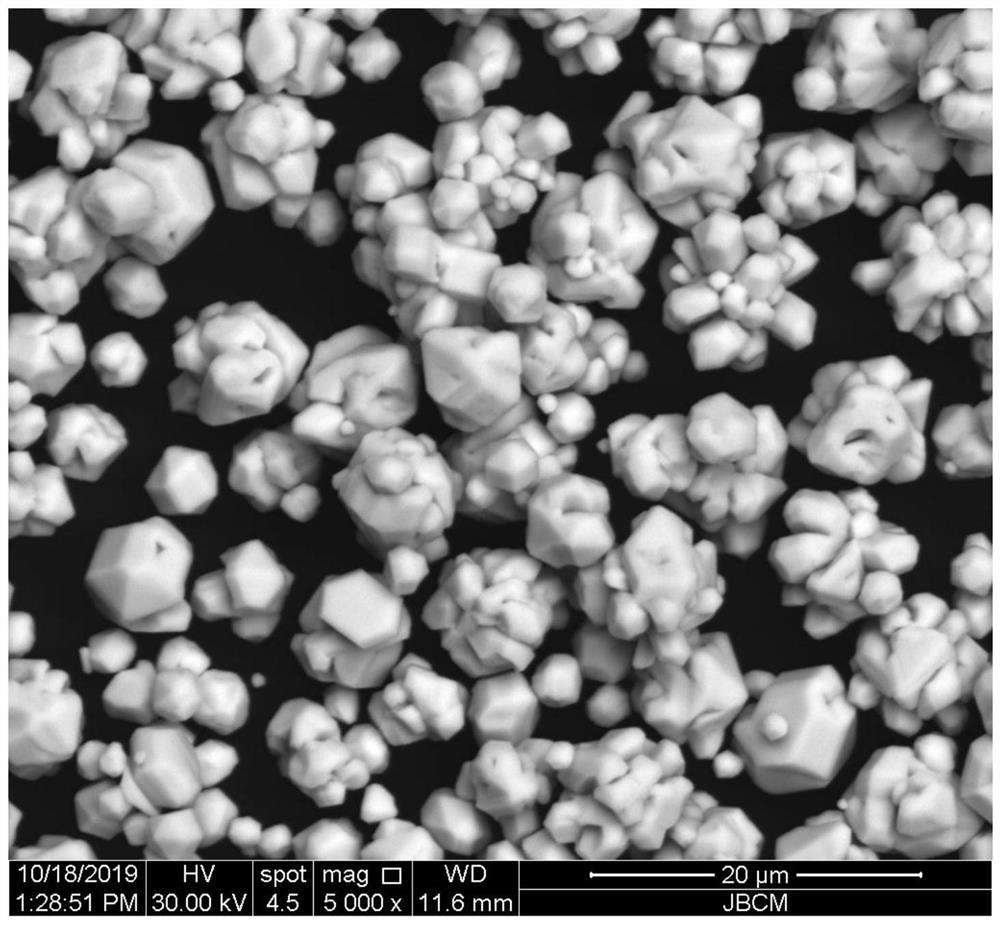

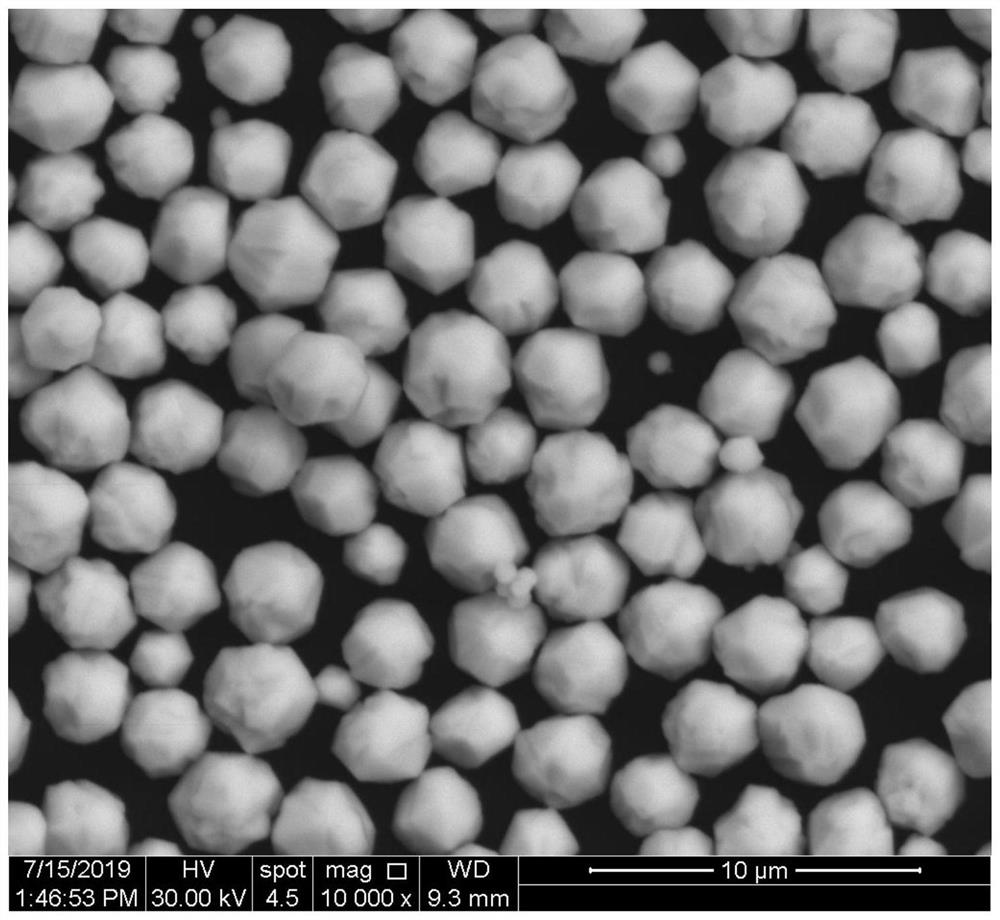

Large-particle silver powder with supporting ridge structure as well as preparation method and application thereof

ActiveCN113649585AAchieve productionHigh crystallinityNon-insulated conductorsPolycrystalline material growthSingle crystalSlurry

The invention discloses large-particle silver powder with a supporting ridge structure as well as a preparation method and application thereof. The large-particle silver powder is composed of single-crystal silver powder and a protruding branch prism structure on the surface of the single-crystal silver powder, the morphology of the large-particle silver powder is approximately spherical, and the particle size of the large-particle silver powder is 5-10 micrometers. According to the large-particle silver powder with the supporting ridge structure, the crystallinity is high, and the conductive performance of the large-particle silver powder is not affected while the bonding strength of low-temperature slurry and conductive adhesive is improved; the preparation method is simple in step, mild in reaction condition, short in production period, good in repeatability, energy-saving and environment-friendly, and suitable for industrial amplification and industrial application.

Owner:山东建邦胶体材料有限公司

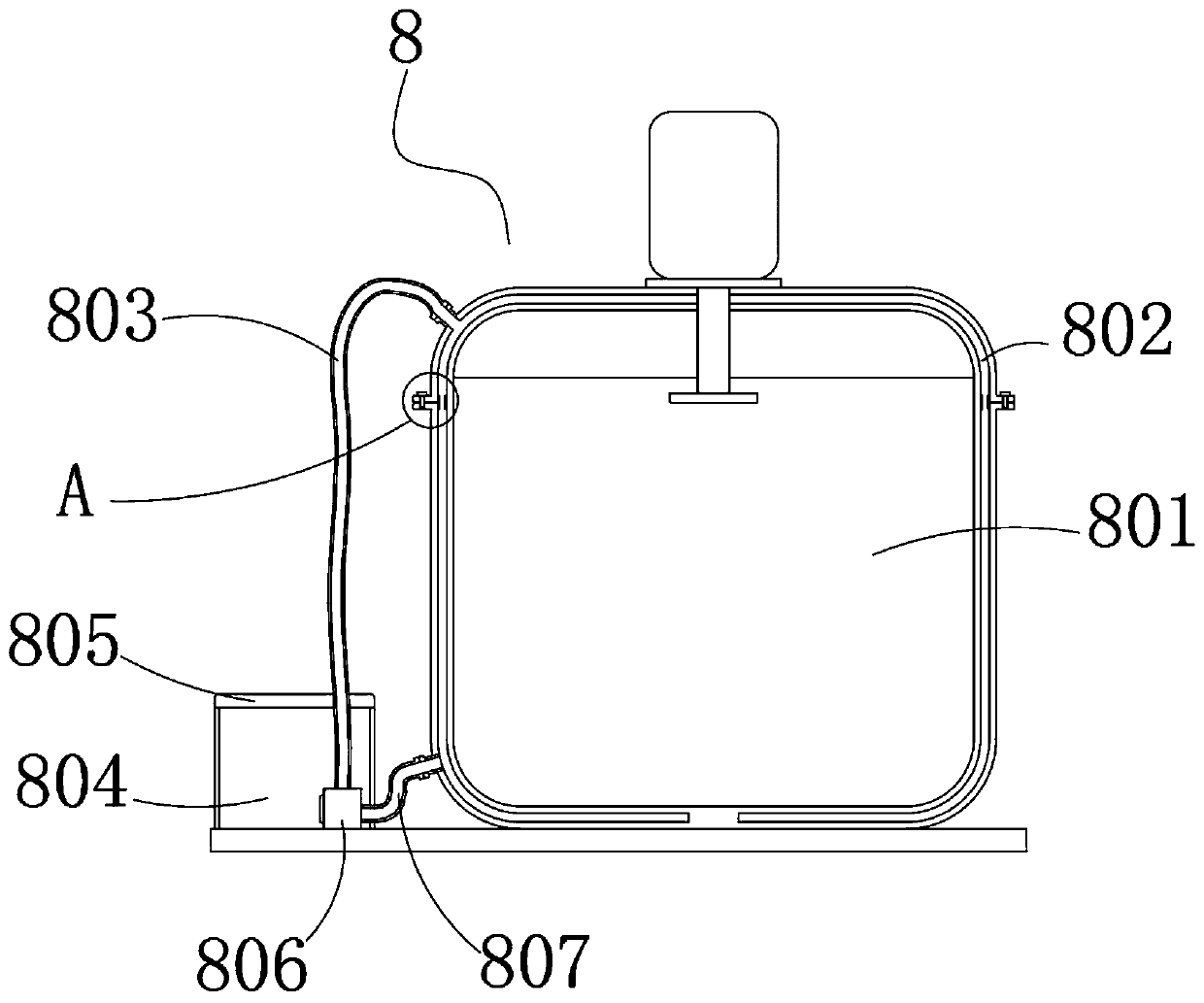

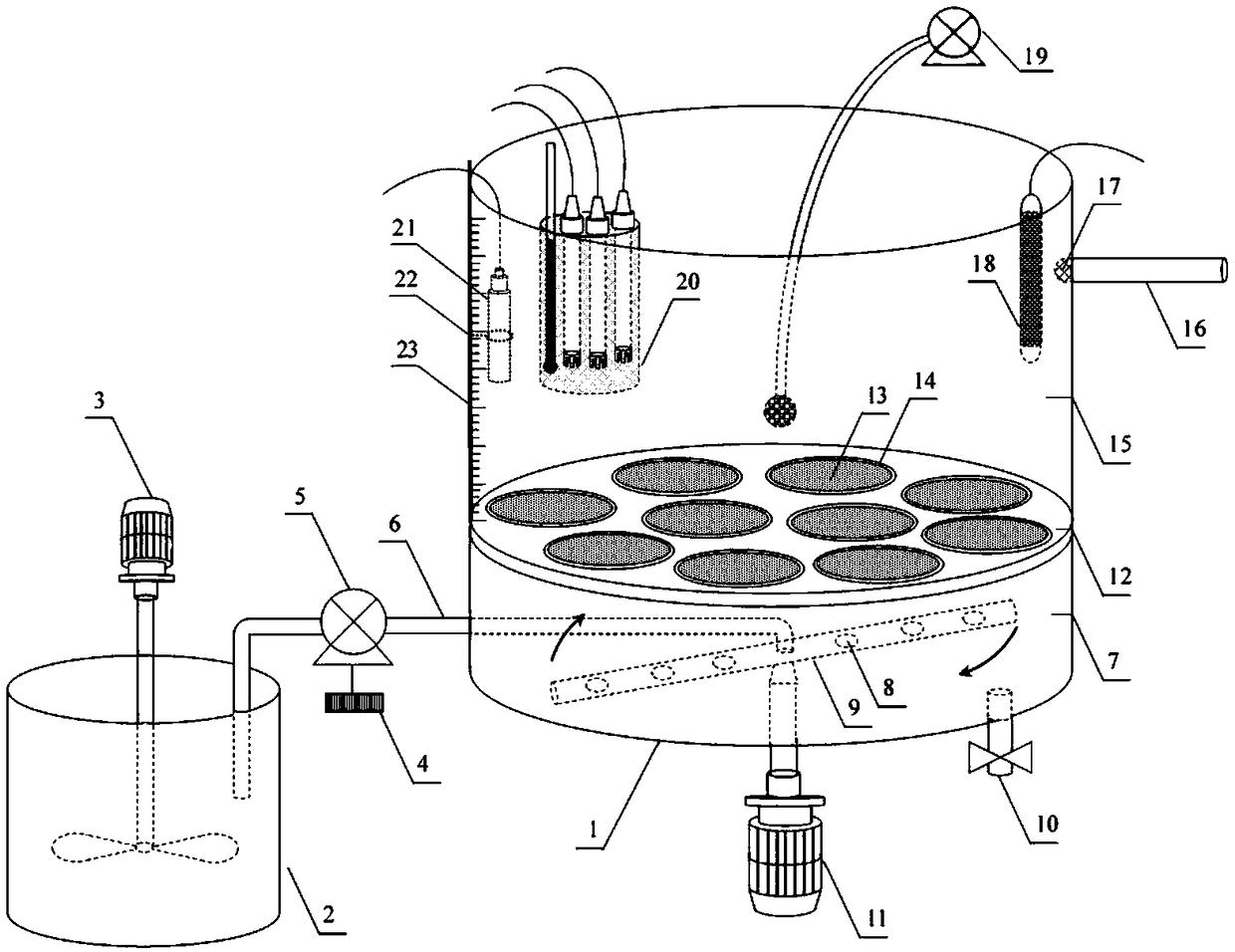

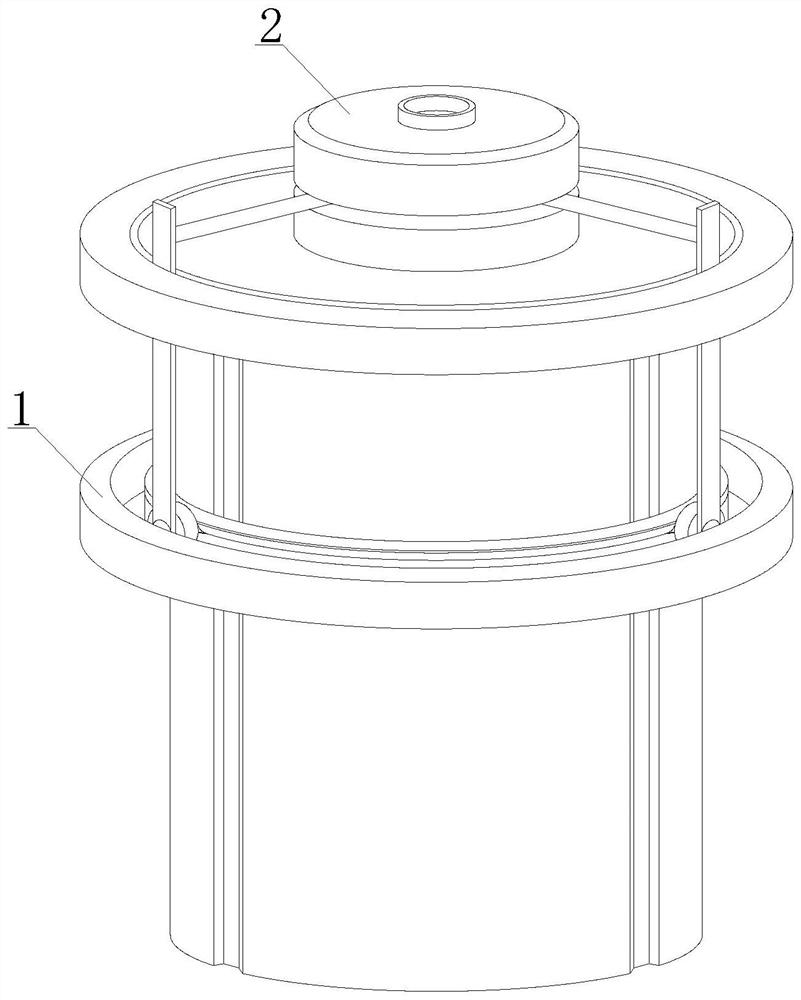

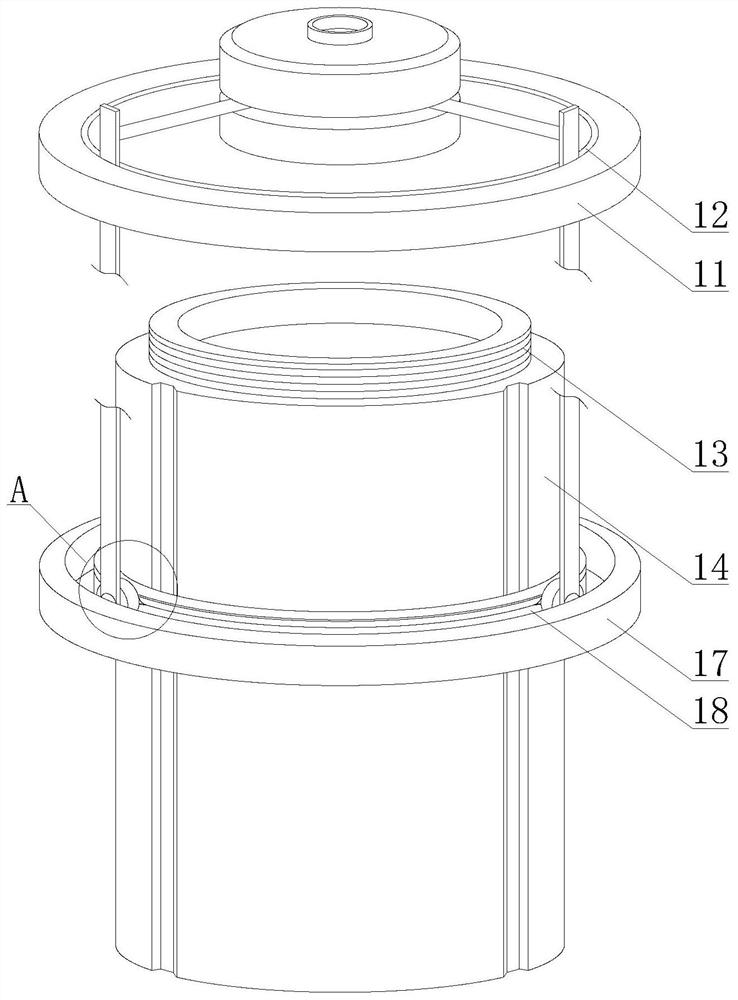

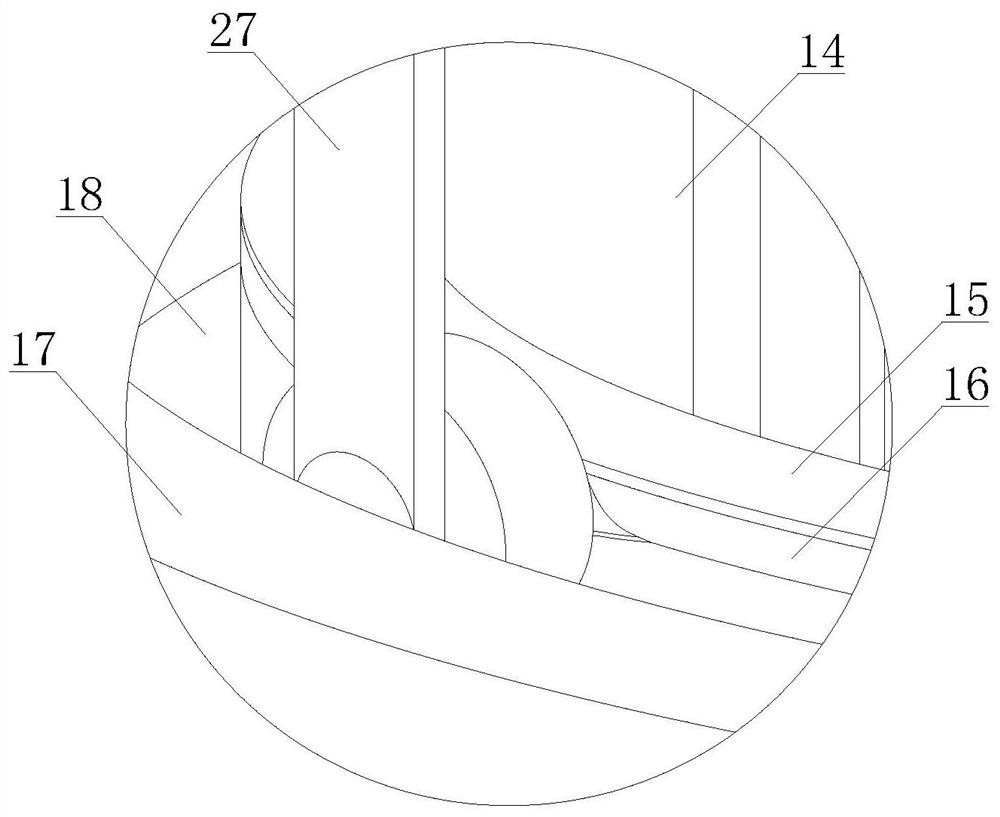

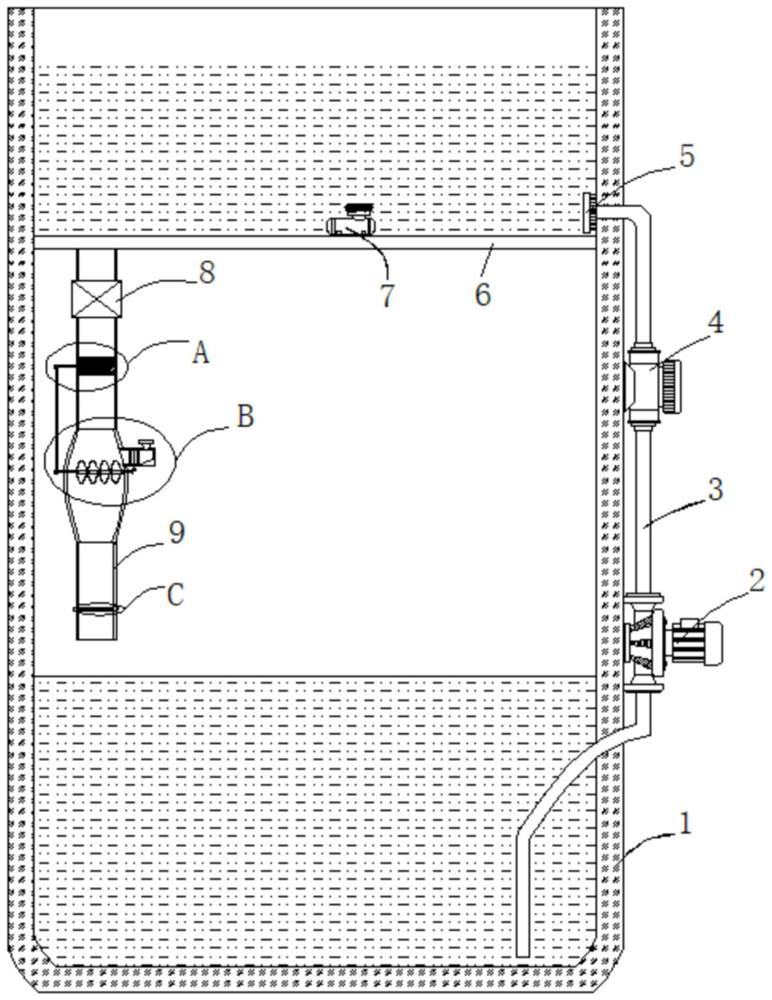

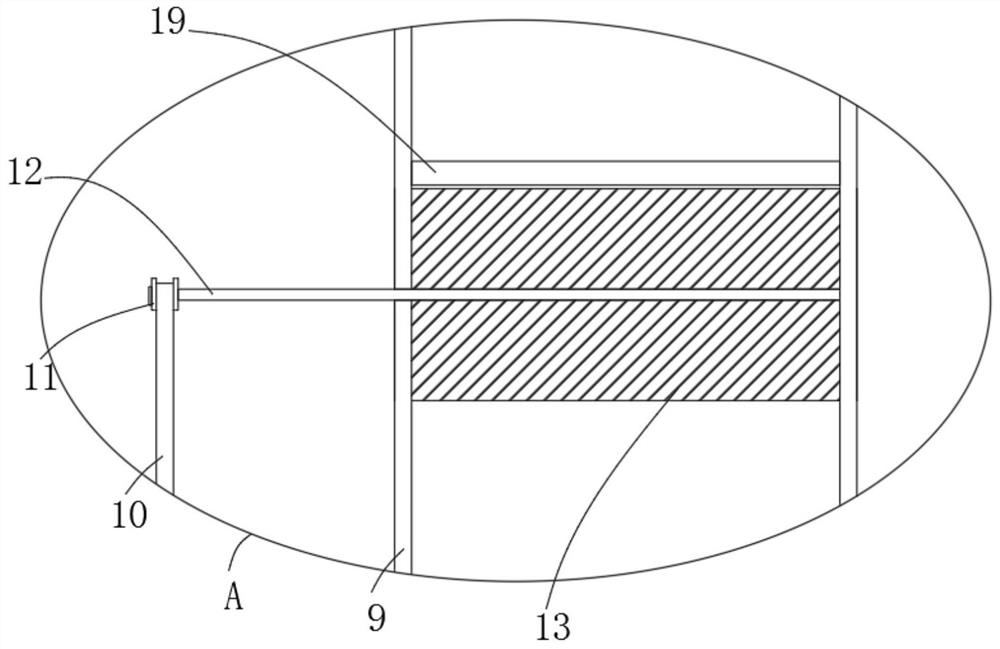

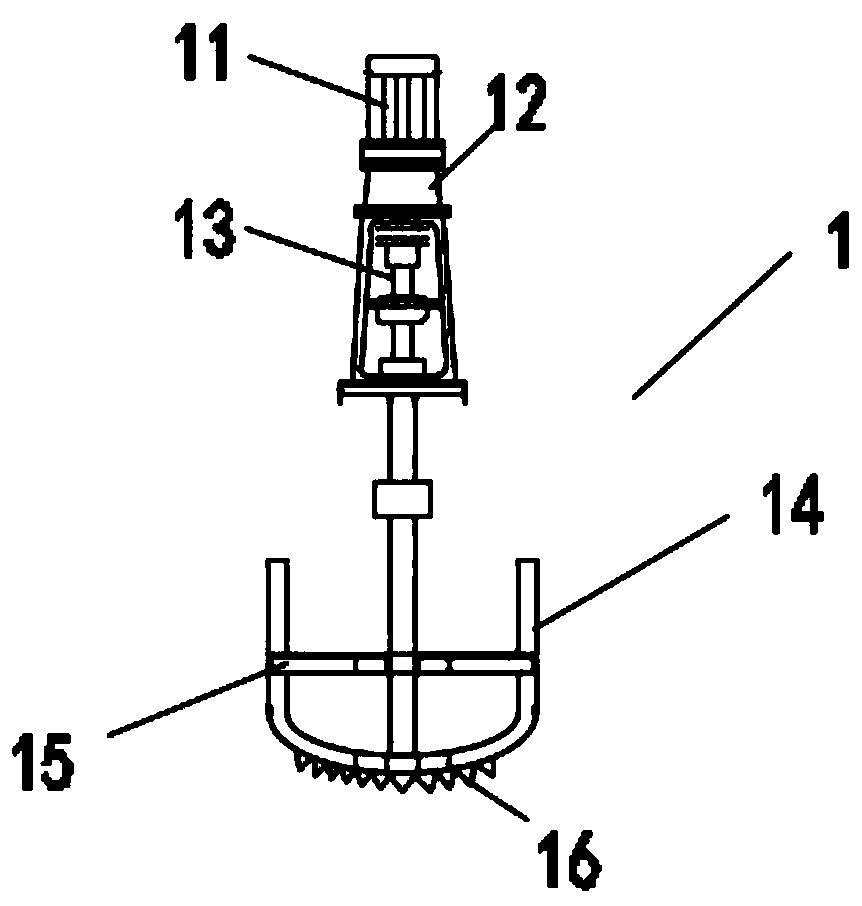

Exposure device used for researching chronic toxicity of polluted sediments for fishes

PendingCN109307746AAchieve direct exposureAchieve indirect exposurePreparing sample for investigationGlass fiberAdsorption equilibrium

The invention discloses an exposure device used for researching the chronic toxicity of polluted sediments for fishes, and belongs to the field of aquatic organism toxicity detection. The device mainly comprises an exposure container and a sediment pre-balancing container, wherein sediments are fully mixed with a target pollutant in the pre-balancing container to achieve adsorption balance, then,the mixture is input into a sediment stabilization chamber on the lower part of the exposure container, and is evenly dispersed through a rotary hollow conduit, and then, the mixture enters a tested organism exposure chamber on the upper part of the exposure container along with a bottom-up hydraulic function. The sediment stabilization chamber and the exposure chamber are separated through a waterproof clapboard, the clapboard can be provided with glass fiber filter screens or filter membranes of different apertures through an annular clamping plate so as to control the form of pollutants which enter the tested organism exposure chamber, and the adsorption states of particular matters of different particle sizes under a dissolved state can be distinguished. A turbidimeter or a suspended particulate matter measurement probe is installed on a lantern ring capable of vertically moving on the inner wall of the exposure chamber so as to be convenient in monitoring the concentration of particulate matters of different depths in the exposure chamber in real time.

Owner:JIANGNAN UNIV

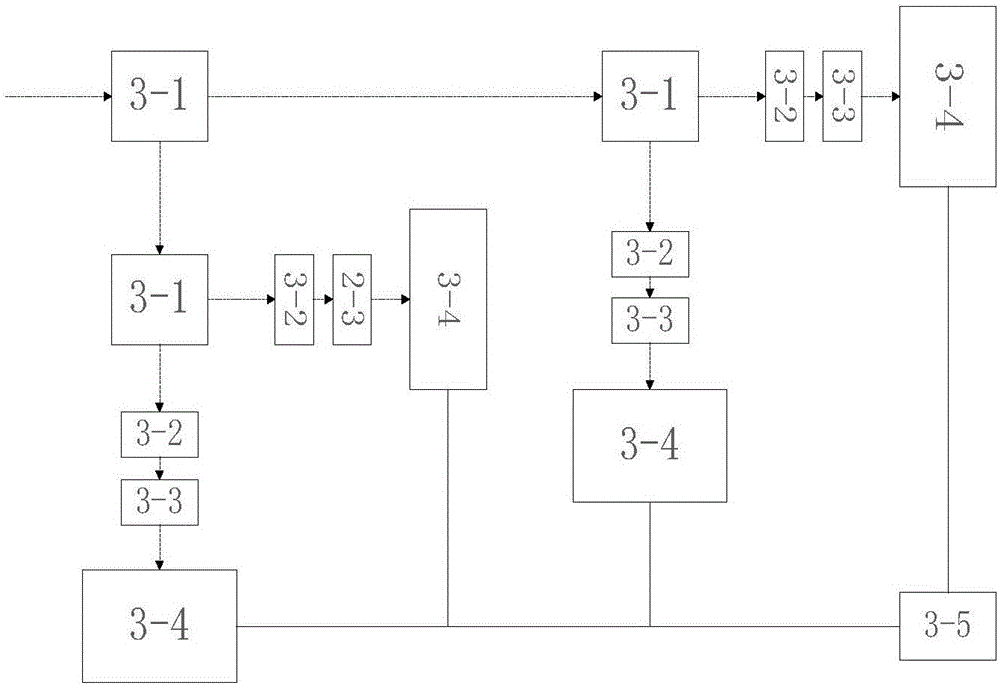

Formation method for soft package lithium-ion battery with lithium iron phosphate as anode

ActiveCN102891336AAvoid local overchargingAvoid uneven responseFinal product manufactureElectrolyte accumulators manufactureCharge voltageSecondary stage

The invention provides a formation method for a soft package lithium-ion battery with lithium iron phosphate as an anode, which belongs to the technical field of lithium-ion battery manufacturing processes. The whole formation process is mainly divided into four stages of charging, storage, recharging and re-storage; the charging voltage in the first stage is controlled at a low voltage section; and when the battery is stored for a longer time at the low voltage section, local overcharge of the surface of a pole piece can be preferably avoided; a vacuum-pumping step is available after the charging in both the first stage and the third stage; as the gas generated by the battery formation is eliminated as much as possible, non-uniform reaction of the pole piece caused by internal gas can be also preferably avoided; and as voltage drop screening is carried out in both the second stage (low voltage section) and the fourth stage (high voltage section), a problem that capacity graded battery with poor voltage maintaining performance is hard to screen can be also solved. According to the invention, problems that local overcharge is caused by large gas production and poor pole piece surface consistency and the battery with poor voltage maintaining performance is hard to screen in the formation process of the lithium iron phosphate soft package lithium-ion battery are solved.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

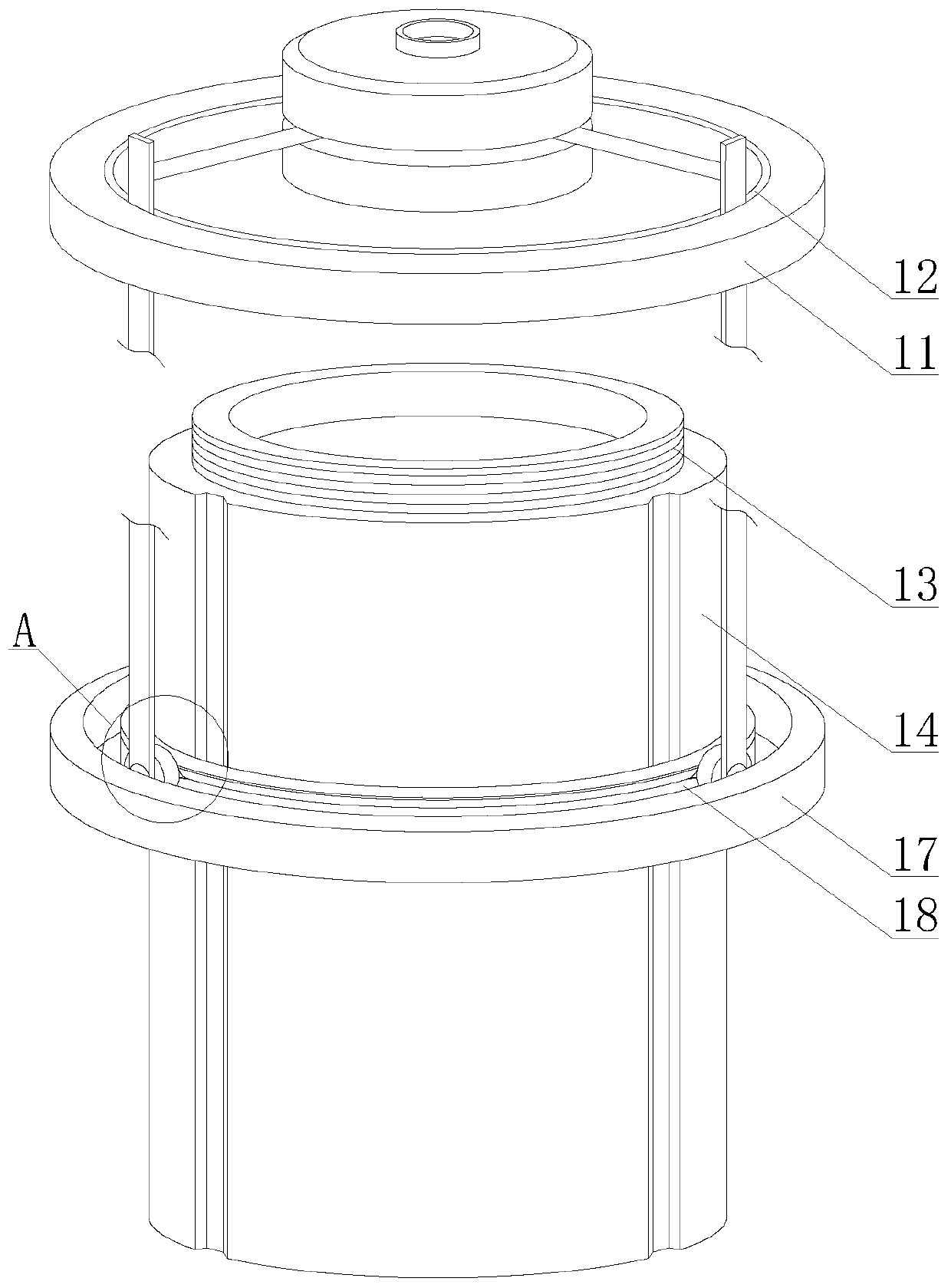

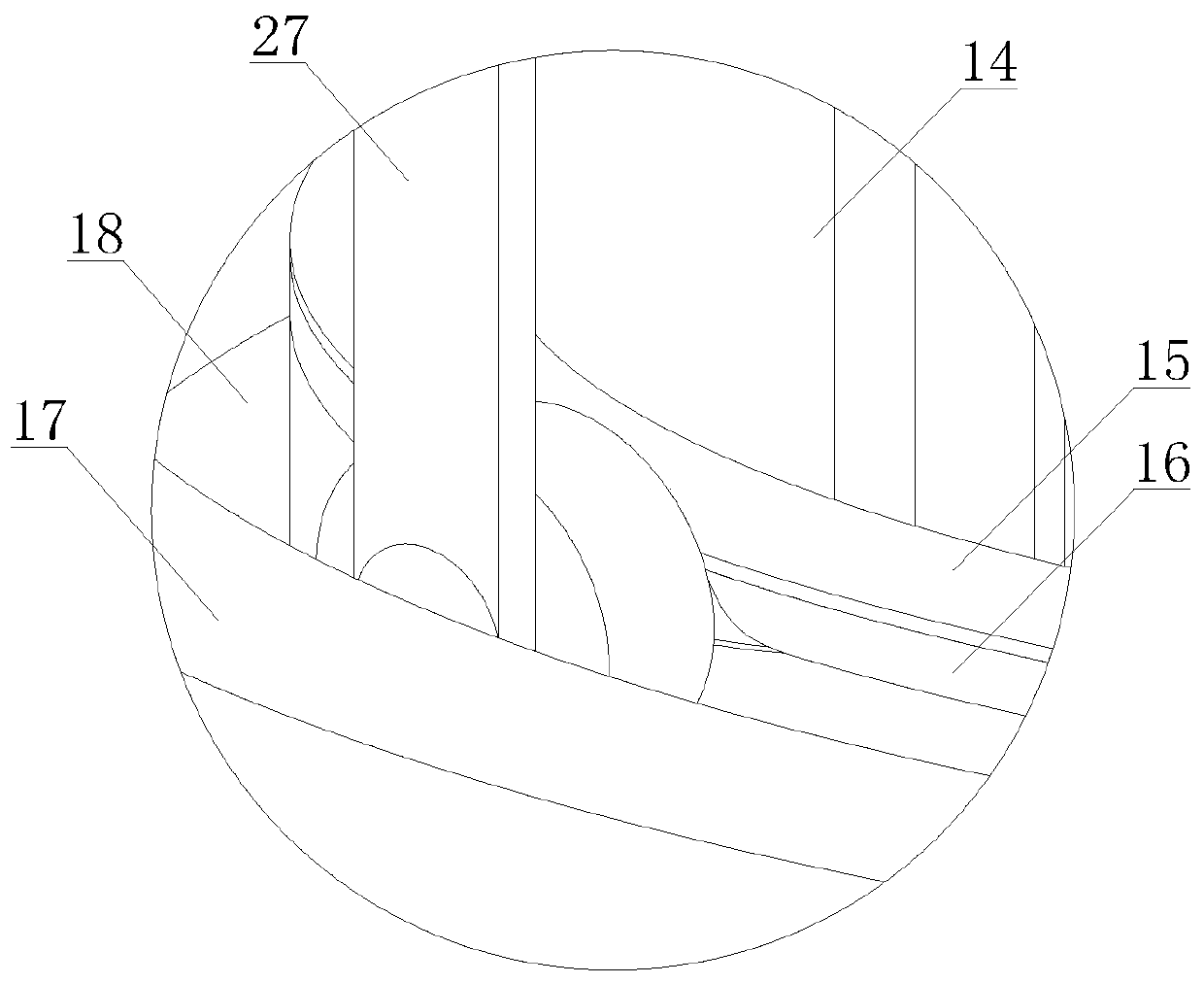

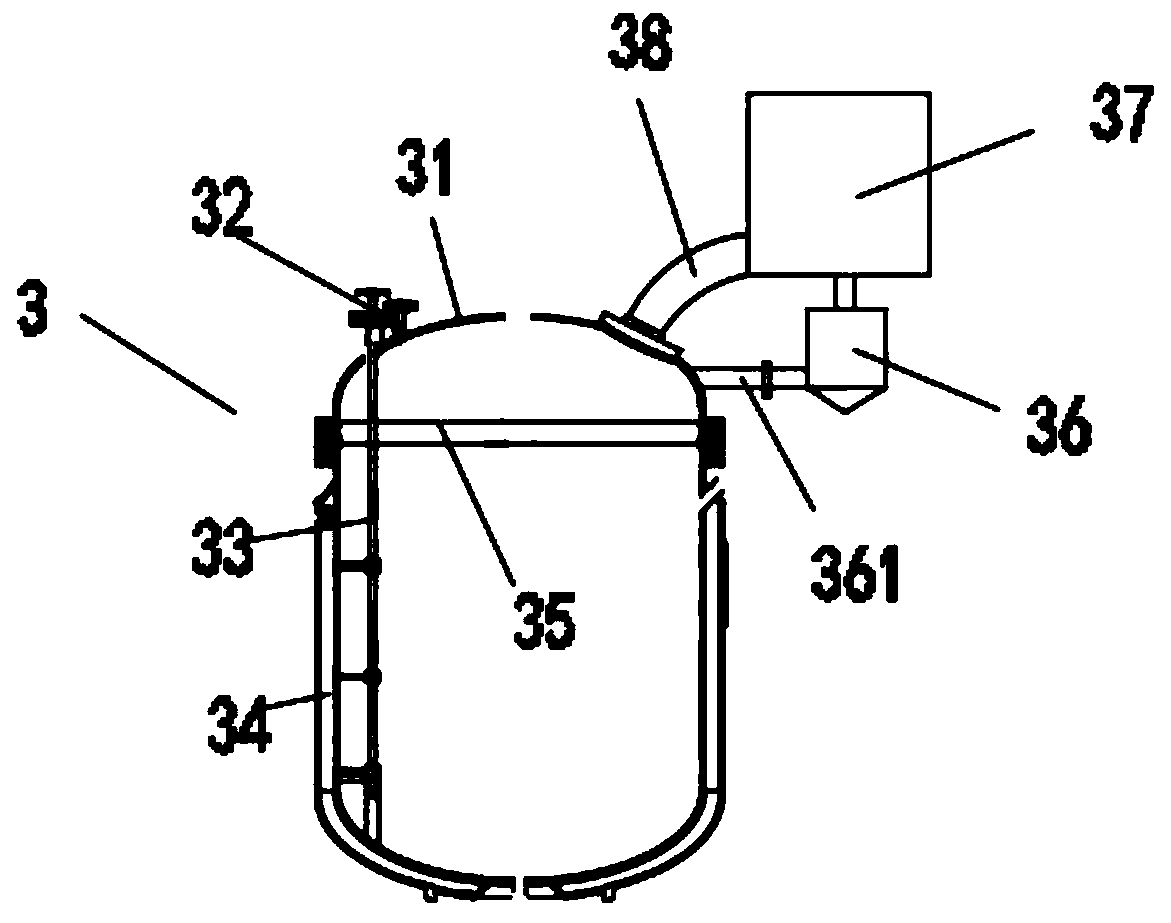

A high temperature and high dust scr denitrification device for cement kiln

ActiveCN110787629BAvoid uneven responseAdequate responseDispersed particle separationRubber ringAmmonia storage

The invention discloses a high-temperature and high-dust SCR denitrification device for a cement kiln, which includes a reaction component and an ammonia injection component. The hole overflows into the connecting pipe, and the connecting pipe, connecting plate and ammonia storage tank form an ammonia circulation pipeline. The ammonia gas enters the nozzle from the circulation pipeline and overflows into the reaction vessel body to react with flue gas. The power output end of the motor Drive the rotating cover to rotate to realize the rotation process of the connecting pipe. The connecting pipe drives the connecting plate, ammonia storage tank and ammonia delivery pipe to move together, so that the overflow point of ammonia gas changes continuously inside the reaction vessel body, and the setting of the rubber ring does not affect The moving process of the ammonia pipe can also ensure the airtightness of the reaction vessel to the greatest extent, so that the flue gas inside the reaction vessel can fully react with the ammonia gas, avoid the uneven reaction between the flue gas and the ammonia gas, and improve the denitrification reaction efficiency.

Owner:MAANSHAN SHUNDA ENVIRONMENTAL PROTECTION EQUIP

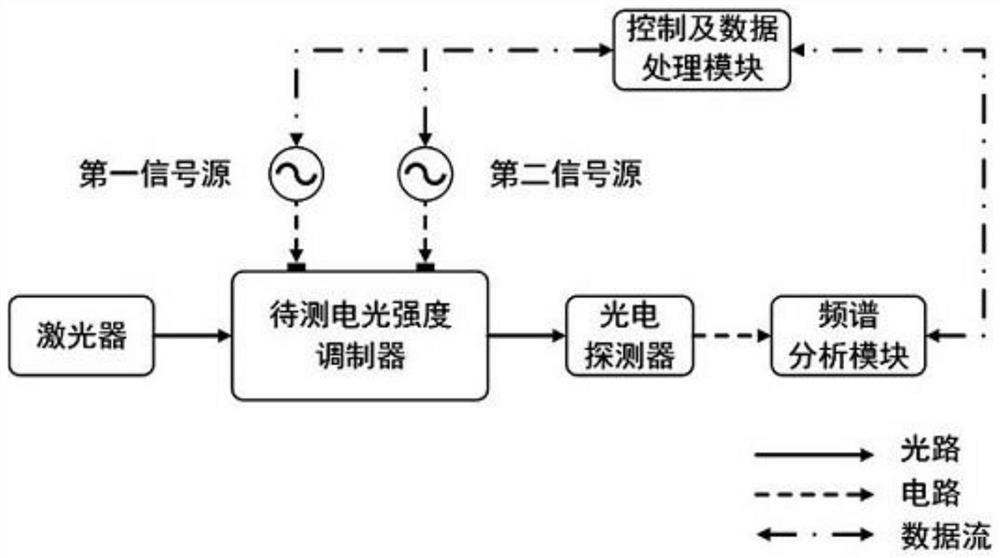

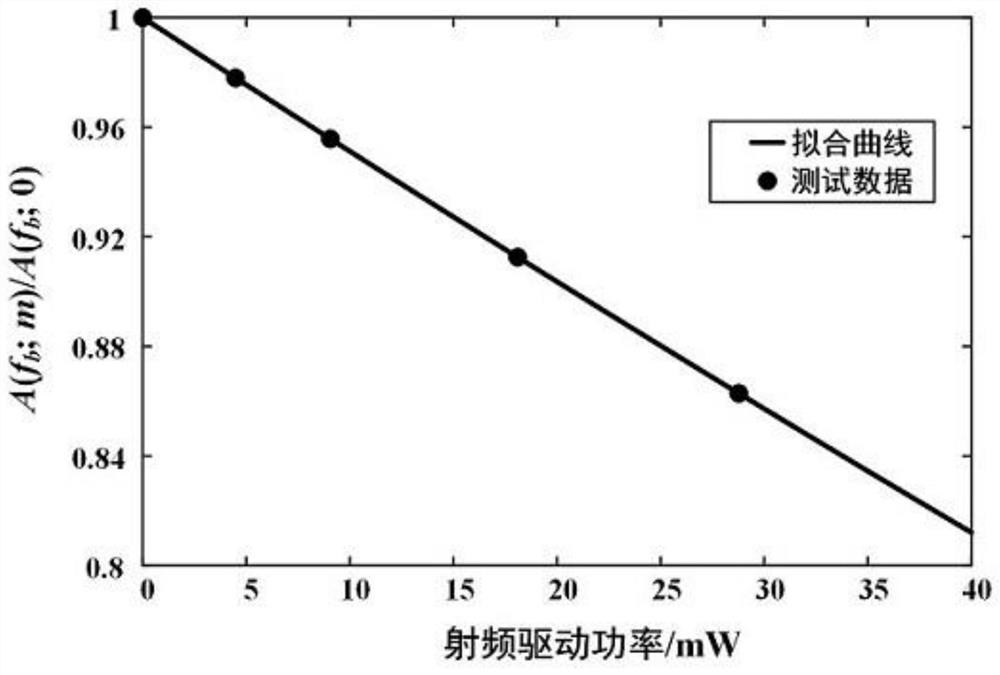

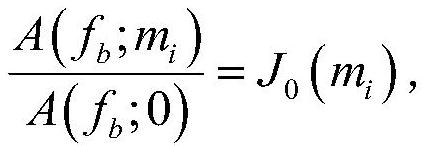

Electro-optic intensity modulator frequency response testing device and method

PendingCN114389692AReduce bandwidth requirementsAvoid uneven responseElectromagnetic transmittersRadio frequencyElectro-optics

The invention discloses an electro-optic intensity modulator frequency response testing device and method, a laser is utilized to emit a beam of optical carrier wave, the optical carrier wave is sent to a to-be-tested electro-optic intensity modulator, a radio frequency driving electrode of the to-be-tested electro-optic intensity modulator is connected with a first signal source, a bias electrode is connected with a second signal source, the first signal source outputs a sinusoidal signal with the frequency f1, and the second signal source outputs a sinusoidal signal with the frequency f2; the second signal source outputs sinusoidal signals with the frequency of fb, optical carriers are modulated, and optical modulation signals output by the electro-optical intensity modulator to be detected enter a photoelectric detector for frequency beating; the output power of the first signal source is controlled, the signal amplitude with the frequency being fb in the beat frequency signal and the output power of the first signal source are extracted through a spectrum analysis module, and the modulation coefficient and the half-wave voltage of the electro-optic intensity modulator to be measured at the frequency f1 are obtained through calculation and fitting analysis of extracted data; the first signal source is controlled to scan under different driving powers, and the frequency response of the electro-optical intensity modulator to be measured can be obtained by repeating the operation.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

High-temperature and high-dust SCR denitrification apparatus for cement kiln

ActiveCN110787629AAvoid uneven responseAdequate responseDispersed particle separationAmmonia storageFlue gas

The invention discloses a high-temperature and high-dust SCR denitrification apparatus for a cement kiln. The apparatus comprises a reaction assembly and an ammonia spraying assembly, wherein the ammonia spraying assembly is fixedly installed on the reaction assembly, an ammonia gas delivery pipe is connected with an ammonia inlet, ammonia gas overflows into connecting pipes through through-holes,the connecting pipes, connecting plates and ammonia storage tanks form an ammonia circulation pipeline, and ammonia gas enters nozzles through the circulation pipeline and overflows into a reaction container body to react with flue gas. A power output end of a motor drives a rotation cover to rotate, a rotating process of the connecting pipes is realized, and the connecting pipes drive the connecting plates, the ammonia storage tanks and ammonia conveying pipes to move together, so that overflow points of ammonia gas are constantly changed inside the reaction container body, and the arrangement of rubber rings has no effects on the moving process of the ammonia conveying pipes, and can ensure the airtightness of the reaction container body to the greatest extent, so that the flue gas inside the reaction container body can fully react with ammonia gas, the uneven reaction between the flue gas and ammonia gas is avoided, and the denitrification reaction efficiency is improved.

Owner:MAANSHAN SHUNDA ENVIRONMENTAL PROTECTION EQUIP

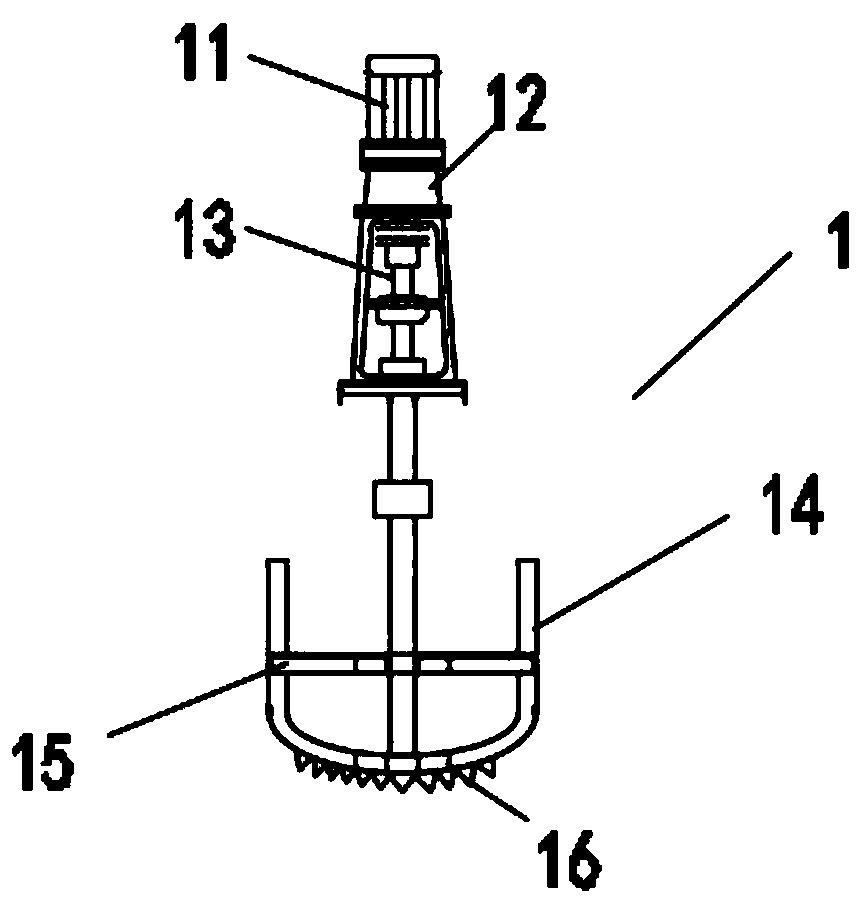

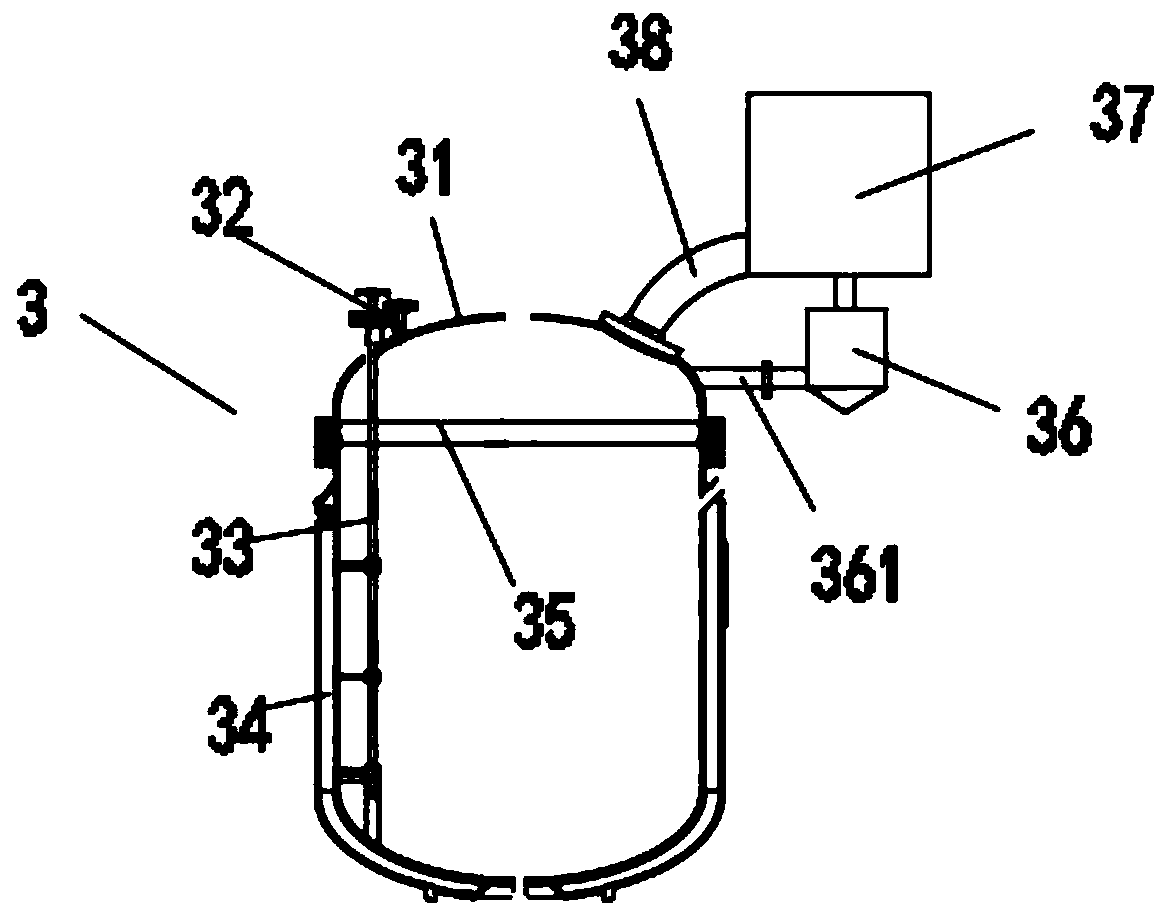

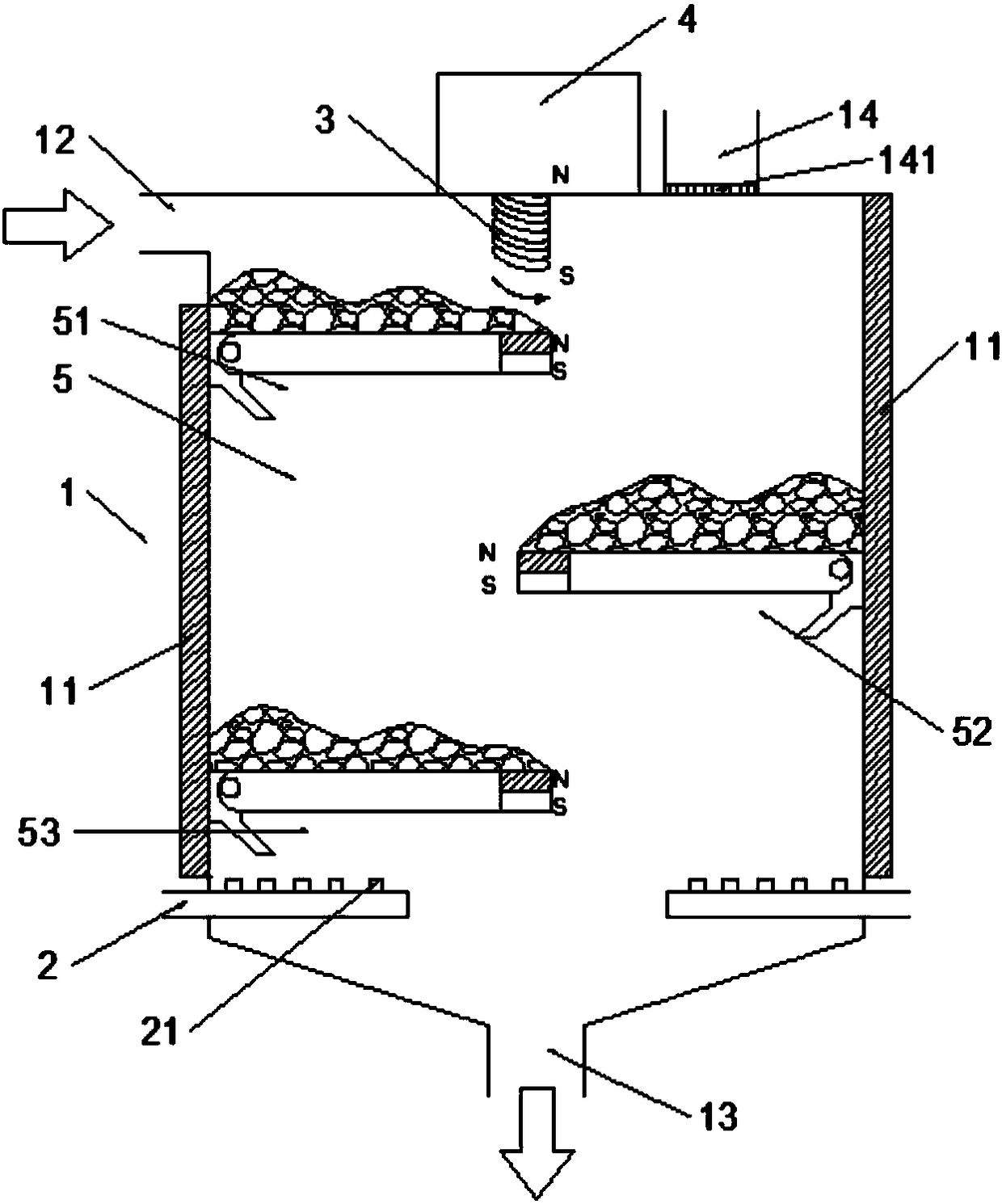

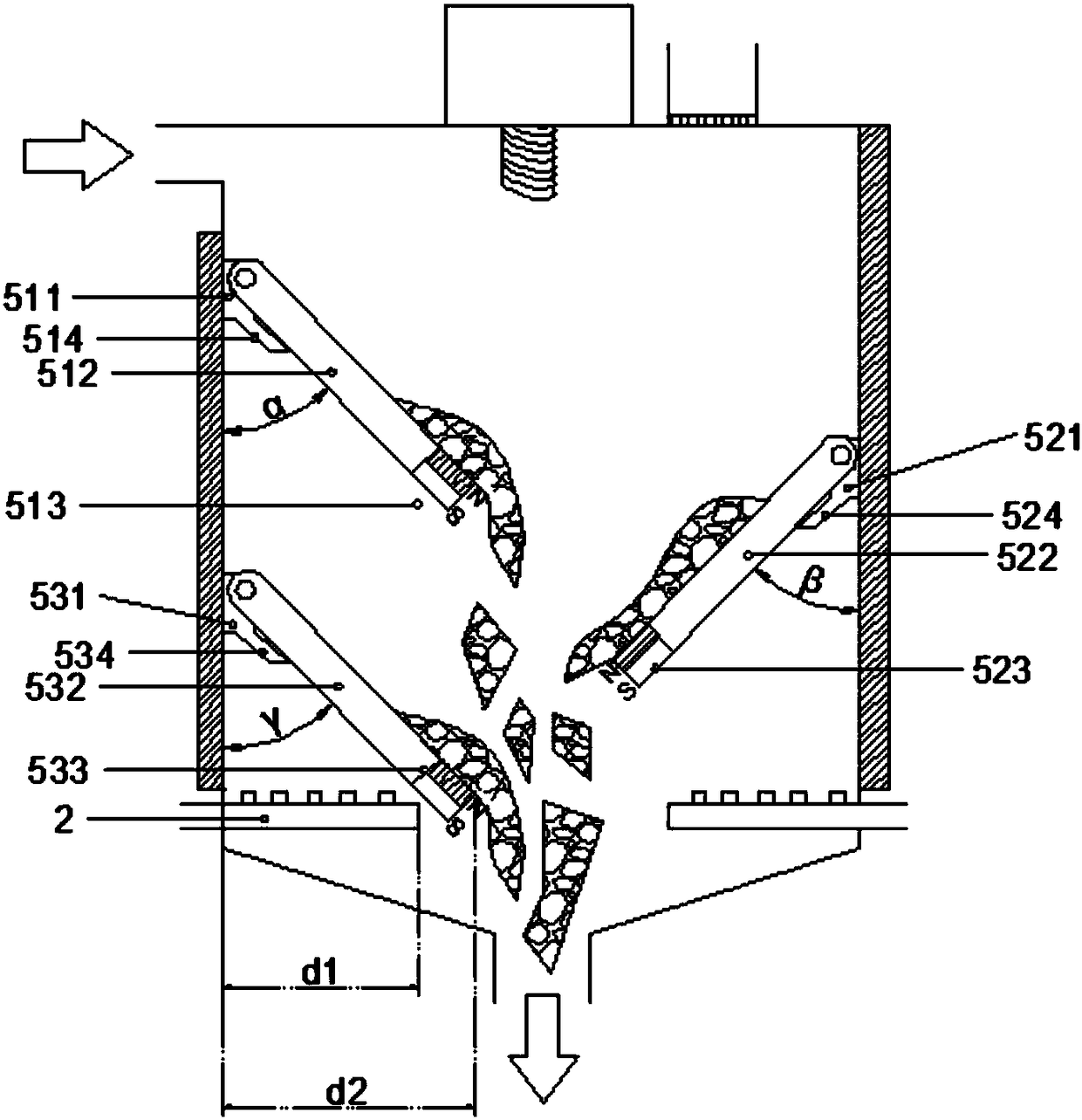

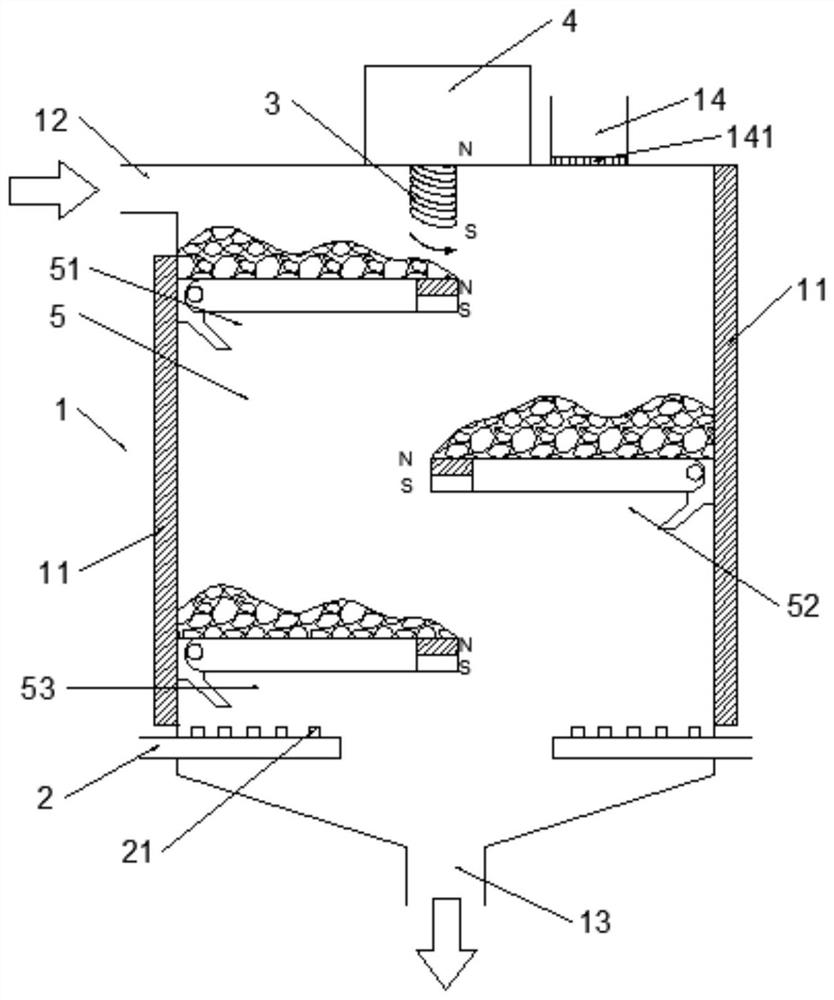

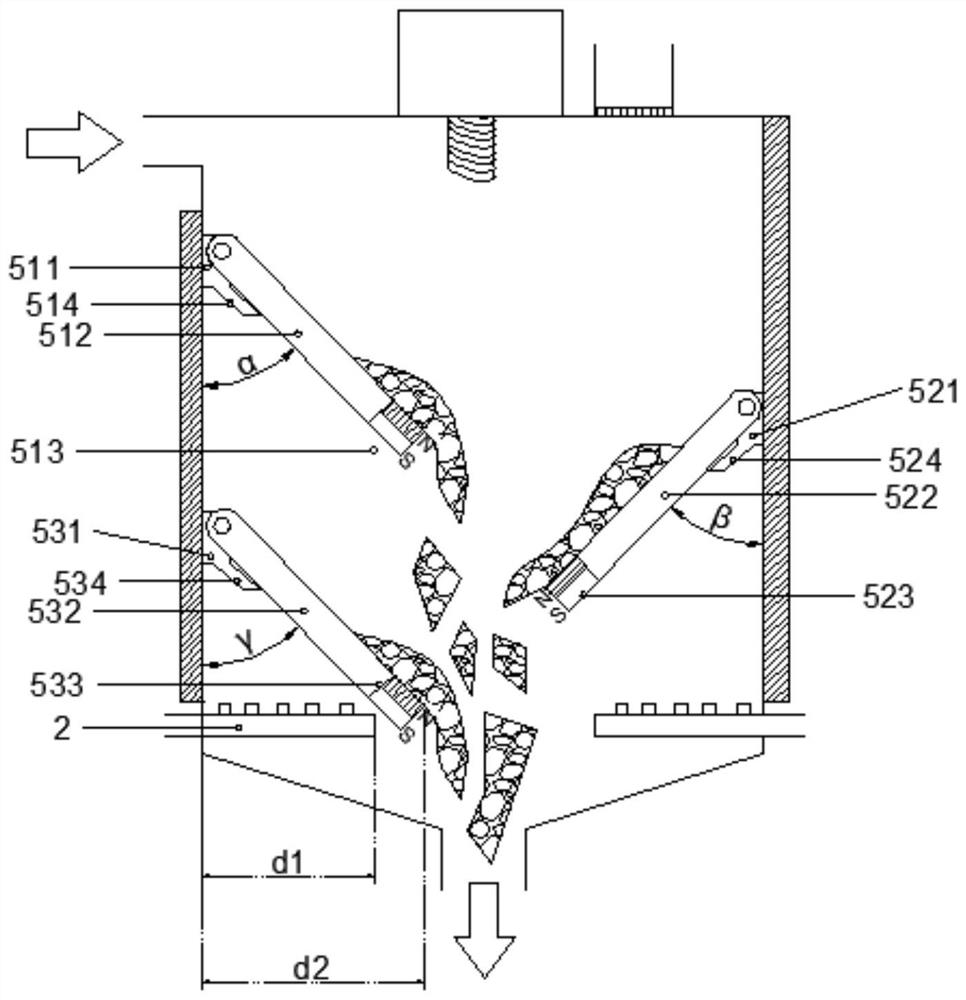

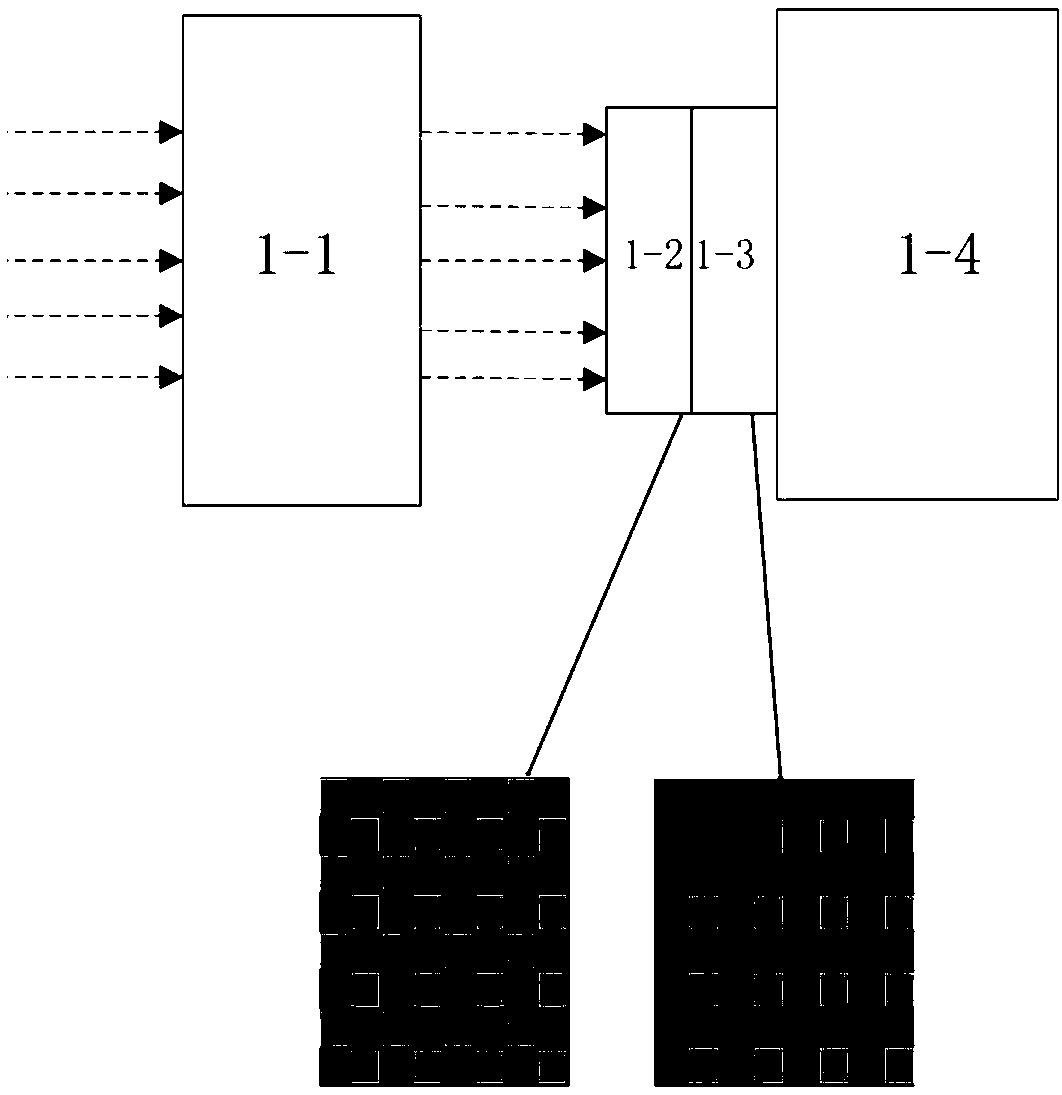

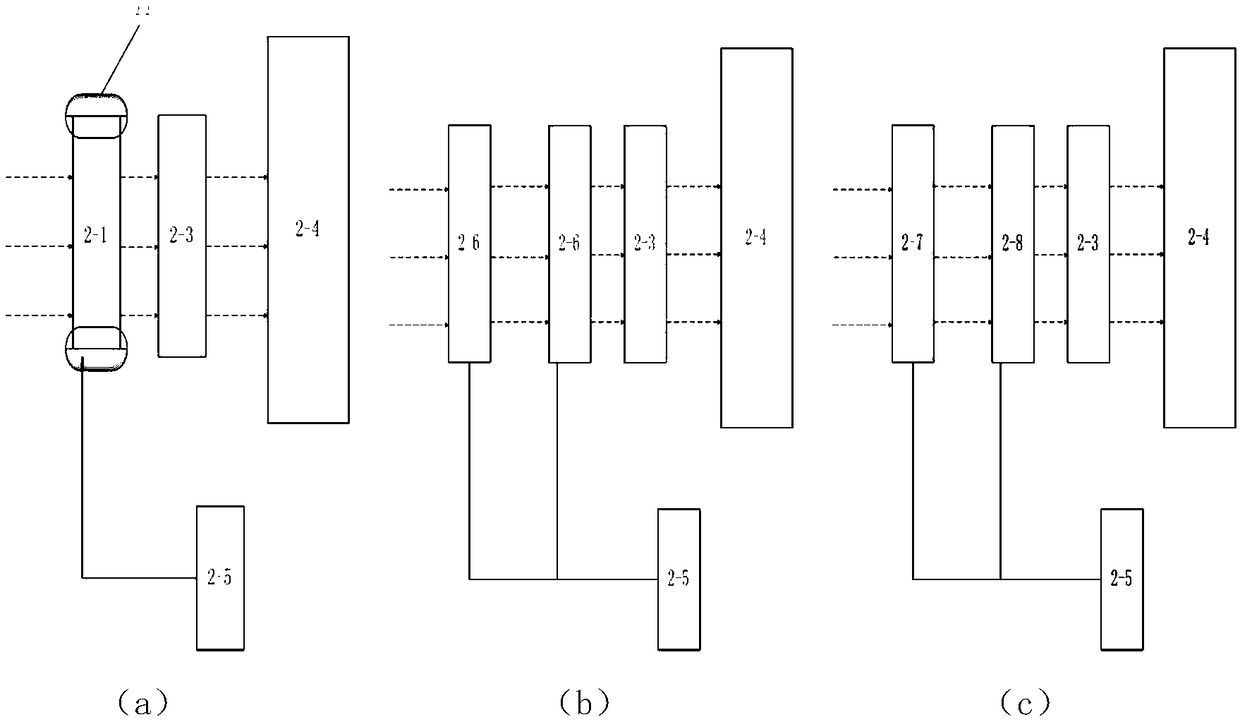

Efficient composting device

ActiveCN108395303AThe final beneficial effect is obviousRationalizeBio-organic fraction processingOrganic fertiliser apparatusElectricityCompost

The invention provides an efficient composting device. The efficient composting device comprises a reaction tank, a ventilation pipe, a coil, an electrification mechanism and a placement mechanism, wherein the ventilation pipe is arranged below the reaction tank in a transverse penetration manner; the coil is longitudinally arranged at the top in the reaction tank; the coil is electrically connected with the electrifying mechanism; the placement mechanism is arranged on an inner wall of the reaction tank. The efficient composting device provided by the invention has the beneficial effects that(1) electrification operation is carried out and placement and discharge of compost manure on the placement plate are controlled through a magnetic force; inconvenience and cost increasing, caused bymanual operation, are avoided; (2) the efficient composting device is simple to operate, simple in structure and low in cost; reasonable treatment of agricultural garbage and wastes is solved and a treatment method also has environment-friendly and energy-saving advantages; (3) final beneficial effects of the compost manure are remarkable and easy to control; oxygen supply is sufficient and uniform and a phenomenon that reaction is not uniform is avoided.

Owner:湖北鑫福农生物科技股份有限公司

Paper diapers with excellent water-absorbing and antibacterial properties and their processing technology

ActiveCN110123528BGood drainage and absorption performanceIncrease the areaAbsorbent padsBaby linensPolymer scienceResin microsphere

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

A kind of preparation method of 1,2-dioxane derivatives

ActiveCN105085569BAvoid uneven responseAvoid safety hazardsGroup 5/15 element organic compoundsWittig reactionPhosphorylation

The invention relates to a preparation method of a 1, 2-dioxetane derivative. The 1, 2-dioxetane derivative is a compound shown in a formula I. The preparation method comprises the following steps of taking a compound shown in a formula II and adamantanone; performing Wittig reaction to synthesize a compound shown in a formula III; performing phosphorylation to obtain a compound shown in a formula IV; and performing oxidation reaction to obtain the 1, 2-dioxetane derivative. The preparation method of the 1, 2-dioxetane derivative has the advantages that safety is high; production cost is low; and industrial production of the 1, 2-dioxetane derivative is facilitated.

Owner:SUZHOU YACOO SCI CO LTD

A high-efficiency composting device

ActiveCN108395303BThe final beneficial effect is obviousRationalizeBio-organic fraction processingFertiliser treatment heating/coolingElectrical connectionProcess engineering

Owner:湖北鑫福农生物科技股份有限公司

Synthesis method and application of superabsorbent resin microspheres with antibacterial properties

ActiveCN110272517BIncrease the areaImprove liquid storage capacityAbsorbent padsBandagesPolymer scienceResin microsphere

The present invention relates to a synthesis method and application thereof of superabsorbent resin microspheres with antibacterial properties. The steps of the synthesis method are as follows: Step S1: Add a certain amount of magnetically ordered mesoporous carbon nanospheres and Polymer dispersant, fully stirred evenly, then vacuum and / or ultrasonic assisted degassing treatment for 1‑2h, added a certain amount of acrylic acid and stirred evenly, and the temperature was controlled at 35‑45°C; Step S2: Add a certain amount of sodium hydroxide to In the system of step S1, stir while adding, and control the temperature of the reaction process at 65-75°C; step S3: add a certain amount of composite crosslinking agent and initiator, control the temperature at 80-90°C and react for 2-3 hours to form a semi-finished product with high water absorption Resin colloid, the composite cross-linking agent is a mixture of NMBA and PEGDA; step S4: the superabsorbent resin colloid of step S3 is placed in a certain amount of solvent and rinsed for 1-3 times, mixed with a certain amount of nano-silver antibacterial agent, Dried until the water content is lower than 3%, crushed to a certain particle size, and magnetically separated to obtain the finished product of the superabsorbent resin.

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

A device for real-time measurement of solar polarization Stokes vector

ActiveCN106525242BReal-time measurementAvoid the influence of flickering light intensityLight polarisation measurementMicrowaveSpectral response

The invention provides a device for the real-time measurement of a sun polarization stokes vector. The device comprises a spectral filter, a wave plate array, a polarizer array and a light intensity acquisition camera. A solar magnetic field provides a driving force and an energy source for the activity outbreak of the sun, while the measurement on the sun polarization stokes vector is the only way for the detection of the solar magnetic field. According to the technical scheme of the invention, a novel device for the real-time measurement of the sun polarization stokes vector is provided. Based on the micro-optical technology principle, the microwave plate array is prepared. On the above basis, the micro-polarizer array is prepared and is attached to the photosensitive surface of the light intensity acquisition camera. In this way, the information of the sun polarization stokes vector can be obtained through the single-exposure process. Compared with a conventional device, the above device is compact in structure and high in real-time property. Meanwhile, the device does not need to be finely tuned or manually operated, and is wide in spectral response range, low in cost and suitable for mass production. At the same time, the occurrence of detection errors, due to the non-uniform response of the camera, aberration and the like, can be avoided. The device can be conveniently extended and applied to other application fields.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

A kind of synthetic method of castor oil polyoxyethylene polyoxypropylene ether

The invention relates to method for synthesizing castor oil polyoxyethylene polyoxypropylene ether, and belongs to the technical field of synthesis of organic compounds. Raw materials comprise castor oil, ethylene oxide and epoxypropane, A Mg-Al catalyst is added to the castor oil, and vacuum dehydration is carried out for 1-3 hours; ethylene oxide is added, temperature is kept at 110 DEG C to 180 DEG C, epoxypropane is added after curing is carried out for 1-5 hours, and curing is carried out for 3-10 hours at the temperature of 110 DEG C to 180 DEG C; the temperature is reduced to 80 DEG C to 120 DEG C, after vacuum degassing is carried out for 0.5-3 hours, the temperature is reduced to 40 DEG C to 80 DEG C, and discharging is carried out to obtain finished castor oil polyoxyethylene polyoxypropylene ether. The method is applied to synthesizing castor oil polyoxyethylene polyoxypropylene ether, and synthesized castor oil polyoxyethylene polyoxypropylene ether has the advantages of being light in color and luster, transparent in appearance, excellent in physicochemical index, high in compatibility performance, large in molecular weight control range and the like, can be used for the industries of daily use chemicals, medicine and the like with high requirements.

Owner:ZHEJIANG HUANGMA TECH

A method for continuous preparation of artificial rutile and its special equipment

ActiveCN106430297BReduce frictionSolve the problem of particle shrinkageTitanium dioxideHigh energyPhysical chemistry

The invention provides a method of continuously preparing artificial rutile and a dedicated device thereof. The method and the dedicated device thereof solve the problems that a conventional reactor can not achieve continuous and mass productions and has high energy consumptions. According to the technical scheme, the method comprises the steps of adding hydrochloric acid and materials into an elevatus mingled storehouse, and conducting mixing on the hydrochloric acid and the materials; making the mixture flow into a reactor along a feed pipe; injecting the heated hydrochloric acid to the reactor from the bottom of the reactor to be subjected to upward flow, conducting acid leaching reaction on the heated hydrochloric acid with a pasty material, using a U-shaped heating tube to conduct heating on the reaction solution, and sending the reaction solution to a negative pressure type liquid-solid separator when the reaction solution reaches the height of a discharge gate; emitting gas generated by the reaction solution to a gas / liquid collector. On the premises of improving the safety, protecting the environment, improving efficiency and stability of quality, the whole system achieves continuous leaching, is applicable to mass production, and has low energy consumption.

Owner:于京辉 +2

Novel deep cleaning device and method for fruits and vegetables

PendingCN112545009AProlong gas-liquid contact timeHigh ozone concentrationFood treatmentStationary filtering element filtersElectric machineryPhotocatalysis

The invention discloses a novel deep cleaning device and method for fruits and vegetables. The novel deep cleaning device comprises a cleaning box, a fixing plate is fixedly connected to the side wallof the upper end of the cleaning box, an air pump is fixedly connected to the upper end of the fixing plate, a water pipe is installed on the outer side wall of the cleaning box, one end of the waterpipe penetrates through the side wall of the bottom end of the cleaning box and extends into the cleaning box, the side wall of the upper end of the water pump penetrates through the side wall of theupper end of the cleaning box and extends into the cleaning box, a nano-bubble spray head is fixedly installed at the end of the water pipe and located above the fixing plate, a water pump is installed on the side wall of the lower end of the water pipe, and an ozone generator is installed on the outer side wall of the upper end of the water pipe. Quantitative addition of a photocatalyst is achieved through flowing force of water, meanwhile, rotary stirring of stirring and mixing blades is achieved, the traditional mode that a motor is used for achieving the function is replaced, and energy consumption is effectively reduced.

Owner:卫华

A method for remanufacturing and spraying repair of inner hole wear of bearing seat

ActiveCN107312995BGood resistance to high temperature oxidationImproved erosion and wear resistanceMolten spray coatingMaterials preparationSpray coating

The invention discloses a bearing seat inner hole abrasion remanufacturing spray repair method and belongs to the technical field of bearing seat repair. Through the steps of bearing seat inner hole surface pretreatment, preheating before spraying, spray material preparation, supersonic spraying and coating processing, a NiCr or NiAl material is selected for spray material priming, the problem that the material thermal expansion coefficients of an abrasion-resistant working layer and a bearing seat inner hole basic layer are not matched can be solved, thus, the thermal stress caused by mismatching of the expansion coefficients of the working layer and the bearing seat inner hole basic layer is reduced, and mechanical matching and physical compatibility of the working layer and the bearing seat inner hole basic layer are improved; and a WC-12Co composite coating or a NiCr-Cr3C2 composite coating is used as the working layer. Through repair step optimization, multicomponent alloy coating compositions and distribution, the good erosive abrasion resistance is achieved, and the problems of high mechanical repair cost of bearing seat abrasion and large shrinkage percentage of spraying coatings are solved.

Owner:济宁拓源精密机械股份有限公司

A kind of preparation equipment and preparation method of large-area titanium dioxide thin film catalyst

The invention relates to a preparation equipment and a preparation method of a large-area titanium dioxide thin film catalyst, which relates to a preparation equipment and a method of a titanium dioxide catalyst. It solves the problem that it is difficult to continuously and efficiently prepare large-area titanium dioxide thin film catalysts under the condition of low-power power supply. The electrolyte in the reaction monomer tank is in direct contact with the side of the anode made of titanium and the side of the cathode at the same time, and the driving mechanism is used to make the reaction monomer tank relatively move along the side of the anode made of titanium. The main steps are: make the electrolyte circulate between the electrolyte tank and the reaction monomer tank; apply voltage or current between the anode and the cathode, the current density is below 200mA / cm2, and the voltage is below 300V; make the reaction monomer tank Relative movement is made along the side of the anode made of titanium according to the set requirements. The device prepares a large-area titanium dioxide film catalyst under the condition of a low-power power supply by setting a reaction monomer tank that can move relative to the anode made of titanium. The method has good production flexibility and high efficiency.

Owner:HARBIN INST OF TECH

A kind of cyanate ester resin esterification process

ActiveCN110227401BImprove heat transfer efficiencyAvoid affecting the reaction heat transferProcess control/regulationChemical/physical/physico-chemical stationary reactorsSide reactionViscosity

The invention discloses an esterification process of cyanate ester resin. The process comprises the following steps: step S1, weighing the following raw materials in parts by weight: 10-15 parts of diphenolyl propane, 0.5-1.0 part of triethylamine, 35-50 parts of acetone, 25-35 parts of absolute ethanol, and 20-30 parts of cyanogen chloride; step S2, adding diphenolyl propane and triethylamine toa beaker containing acetone, performing heating in a 45 DEG C water bath, performing stirring for 45 min at a rotation speed of 100 r / min, performing taking out, and performing standing for 30 min toobtain a mixed liquid A; and step S3, carrying out a reaction through a reaction kettle. In the process, the reaction kettle has high heat exchange efficiency and good heat exchange effect, reaction heat can be quickly taken away, and thus occurrence of side reactions is not easy to cause. Materials can be subjected to cutting during stirring to avoid uneven reaction due to increased viscosity ofthe materials along a reaction is carried out, and heat exchange efficiency can be further improved by mixing with remaining materials after heat exchange is completed.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com