Method for treating kitchen wastes by hydrothermal carbonization coupled anaerobic digestion

A technology of hydrothermal carbonization and anaerobic digestion, which is applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., and can solve problems such as difficult treatment of biogas residue and biogas slurry, acidification of anaerobic environment, and impact on treatment efficiency , to achieve the effect of realizing resource utilization, obvious application effect and increasing methane production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a method for hydrothermal carbonization coupling anaerobic digestion to treat food waste, wherein, the method adopts such as Figure 4 Described processing system realizes, and this method comprises the following specific steps:

[0060] (1) Pretreatment of kitchen waste

[0061] After the food waste is collected and transported, it is first subjected to rough sorting to separate out substances that cannot undergo hydrothermal carbonization reactions, such as glass, metal, stone, etc.; then, centrifugal deoiling is carried out in the deoiling tank 1 to separate the oily phase The solid phase and oil phase are sent to process biodiesel, and the solid phase enters the next crushing system 2 for crushing; after the crushing is completed, it enters the preheating tank 3 for stirring and preheating, and the preheating temperature is 80-90°C.

[0062] (2) Hydrothermal carbonization of kitchen waste

[0063] The preheated food waste is sent to the hy...

Embodiment 2

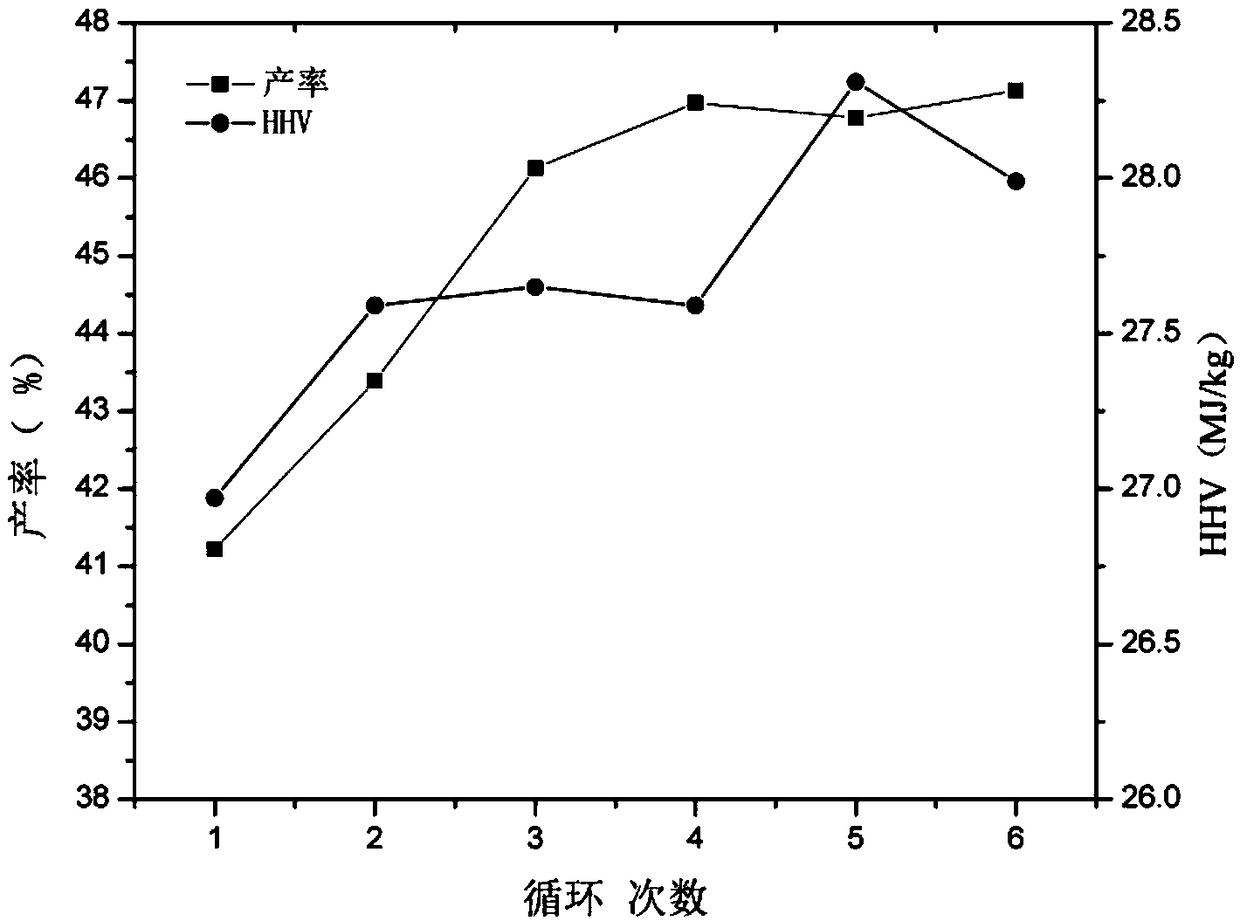

[0070] This embodiment provides a method for reusing the liquid phase obtained after hydrothermal carbonization of kitchen waste to increase the solid phase yield and calorific value, which includes the following steps:

[0071] (1) After the food waste is collected and transported, it is firstly sorted to separate substances that cannot undergo hydrothermal carbonization reaction, such as glass, metal, stone, etc.; then, centrifugal deoiling is carried out to separate the oil phase and solid phase , the oil phase is sent to process biodiesel, and the solid phase enters the next crushing system for crushing; after the crushing is completed, it enters the preheating tank for stirring and preheating, and the preheating temperature is 80-90°C.

[0072] Wherein, the kitchen waste described in step (1) includes meat, rice, steamed buns, fruits and vegetables and the like.

[0073] (2) Get 50g of the kitchen waste (moisture content 80%) gained in step (1) and mix it with 25mL deioni...

Embodiment 3

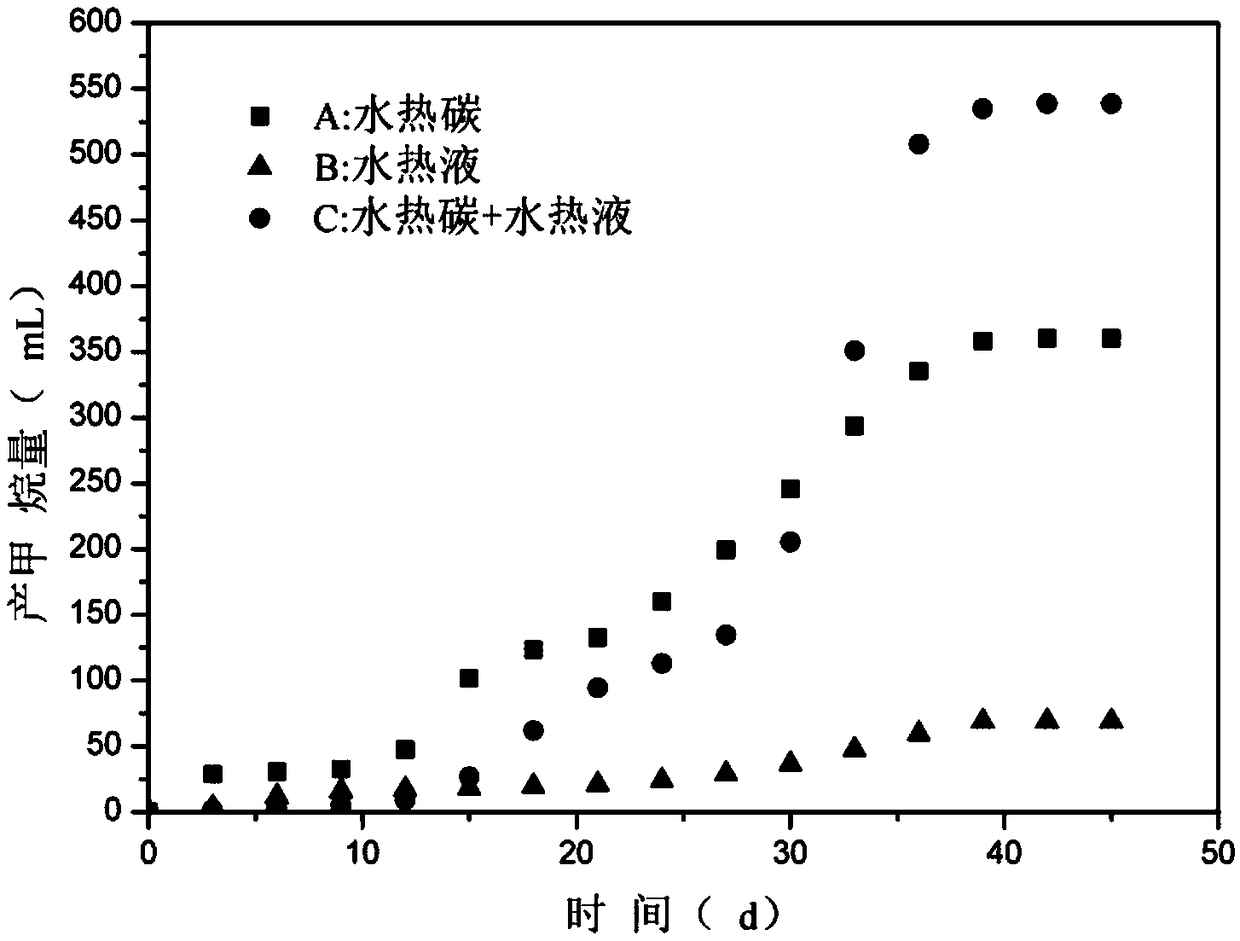

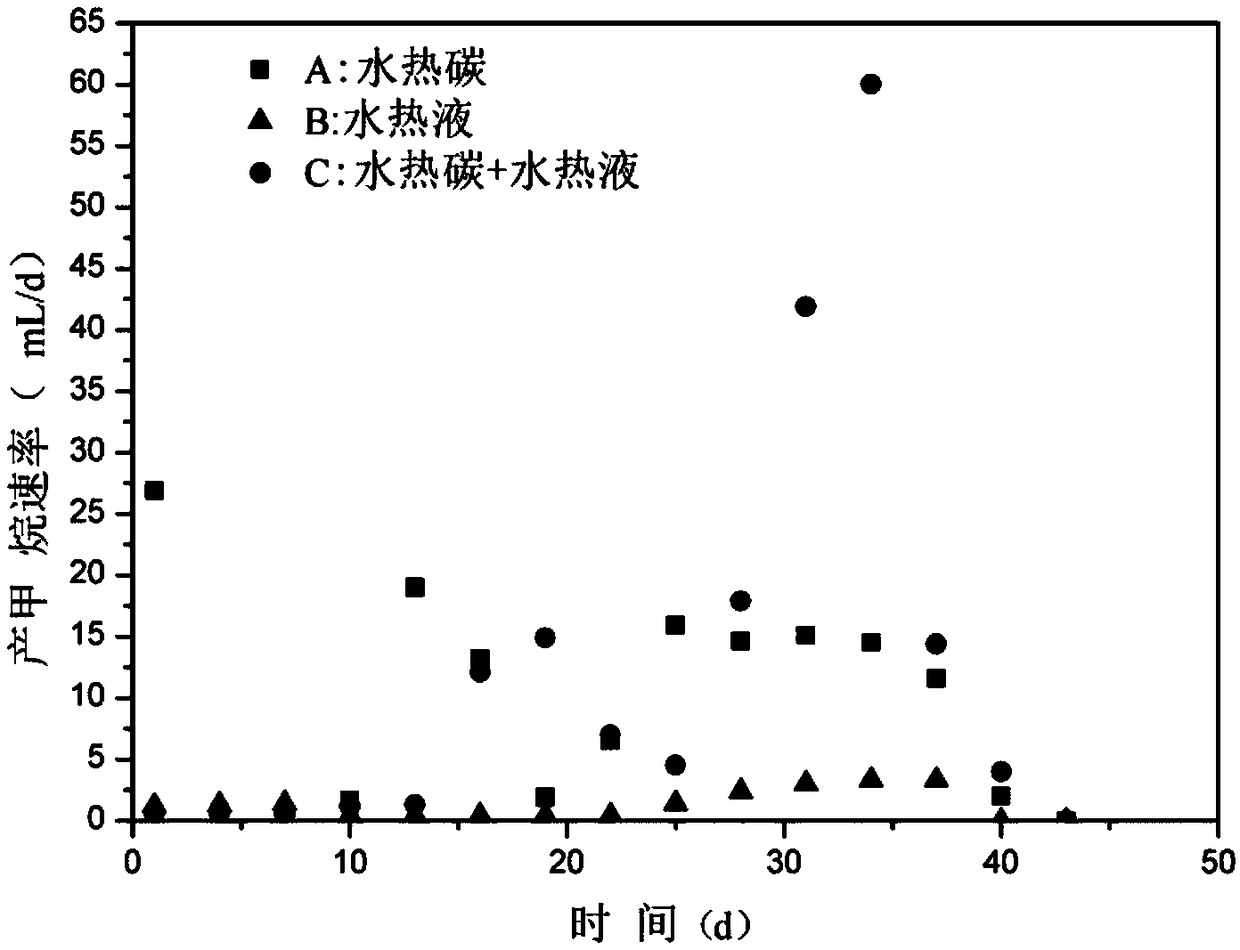

[0079] This embodiment provides a method for fermenting hydrothermal charcoal, hydrothermal liquid, and a mixture of hydrothermal charcoal and hydrothermal liquid obtained after the hydrothermal carbonization reaction to increase gas production, which includes the following steps:

[0080] (1) Experimental group A: The fermentation raw material is the hydrothermal charcoal prepared in Example 1, the fermentation concentration is 10g / L (calculated based on the total volume of the inoculum used), the total reaction volume is 250mL, and the inoculum is the biogas from the landfill. Liquid, such as biogas slurry from Asuwei Landfill (Changping District, Beijing), does not add any accelerator.

[0081] (2) Experimental group B: The fermentation raw material is the hydrothermal solution prepared in Example 1, the fermentation volume is 100mL / L (calculated based on the total volume of the inoculum used), the total reaction volume is 250mL, and the inoculum is the biogas from the landf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com