Large-particle silver powder with supporting ridge structure as well as preparation method and application thereof

A technology of large particles and silver powder, applied in chemical instruments and methods, conductive materials dispersed in non-conductive inorganic materials, conductors, etc., can solve problems such as low bonding strength and poor electrical conductivity, and achieve increased bonding strength , Improve electrical conductivity, avoid the effect of uneven reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

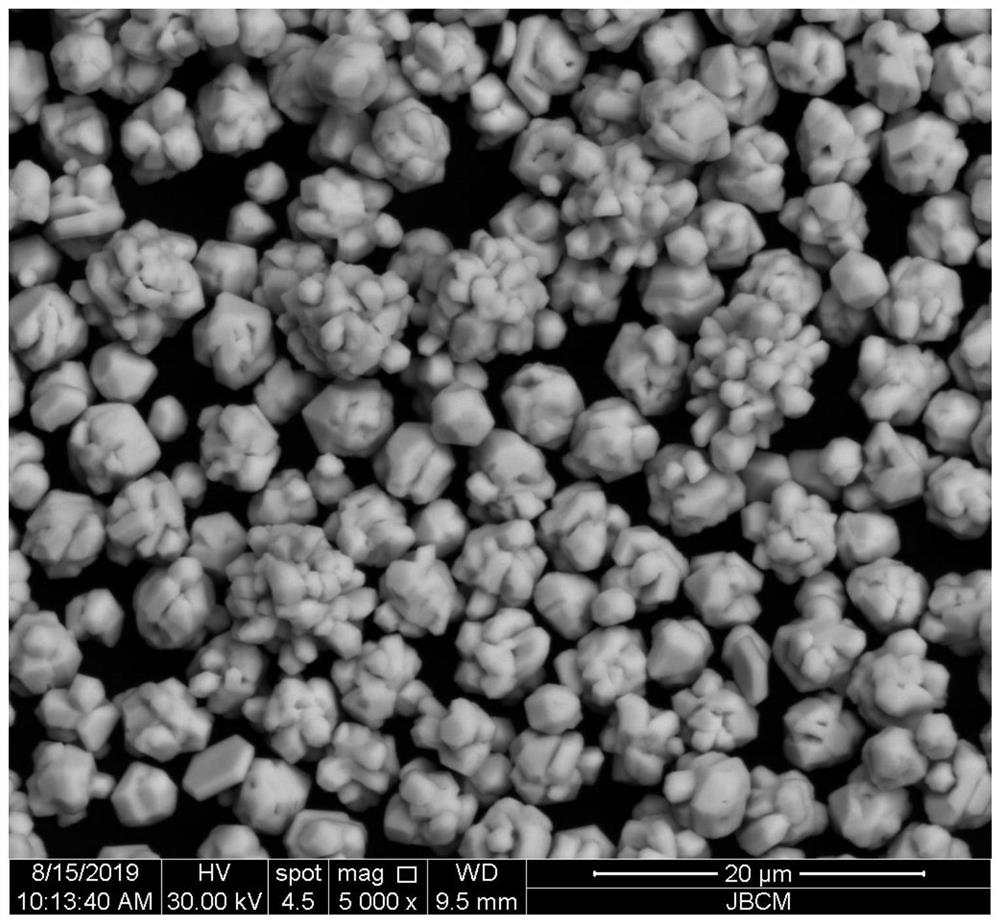

[0061] Large particles having a branched silver rib structure 1 prepared in Example 1, a particle size of 6 microns #

[0062] 1) Dosing

[0063] Solution A: 500 g of silver nitrate were dissolved in 2,750 g of deionized water and dissolved with stirring, and 25 g of concentrated nitric acid to prepare a silver nitrate solution A. Wherein the concentration of silver nitrate solution is 1.0mol / L, the amount of concentrated nitric acid was 0.05 times mass of silver nitrate;

[0064] Solution B: 250 g of polyvinylpyrrolidone K30 was dissolved in a dispersant 3,300 g of deionized water and dissolved with stirring to prepare a solution B. ingredient powders Wherein the amount of the dispersant is 0.5 times the mass of the silver nitrate solution A; solution B is used in an amount of deionized water A solution of deionized water, 1.2 times the amount;

[0065] Solution C: 360 g of ascorbic acid dissolved in a 2750 g of deionized water and dissolved with stirring, ascorbic acid formula...

Embodiment 2

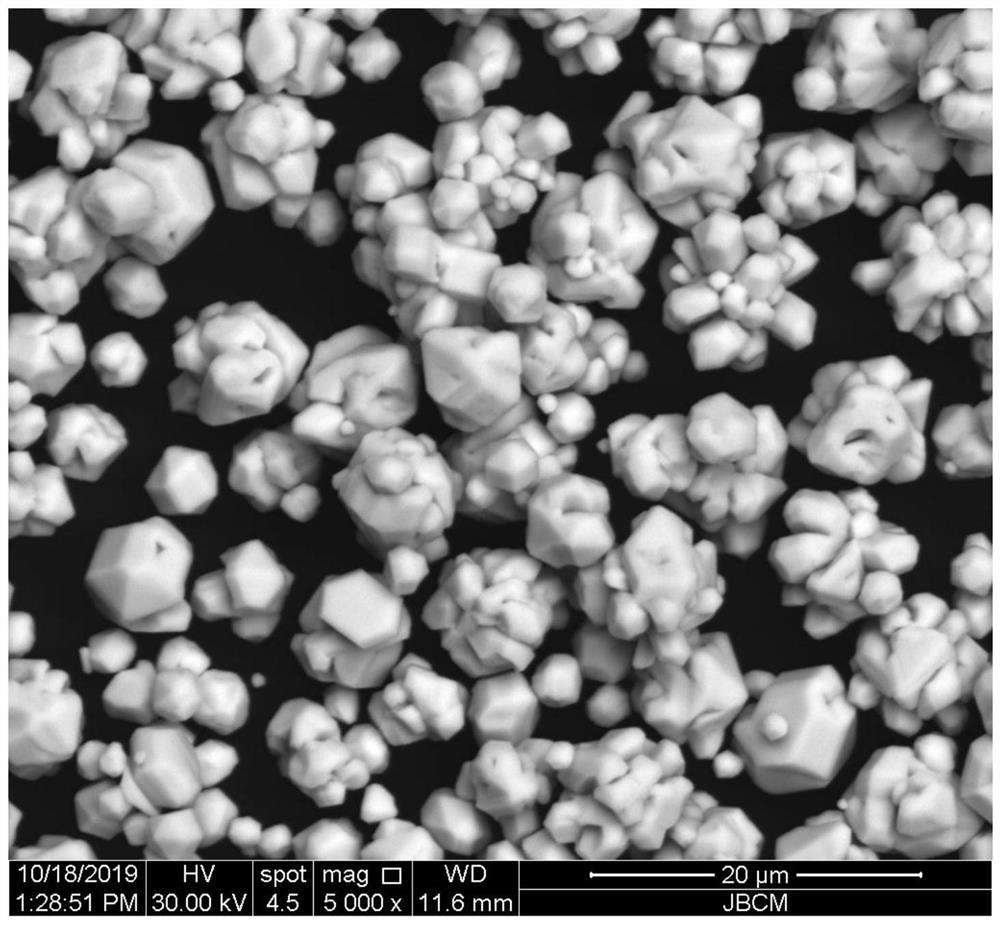

[0076] Example 2 Preparation of a particle size of 8 micron silver particles having a large supporting rib structure # 2

[0077] 1) Dosing

[0078] First Solution A: 750 g of silver nitrate were dissolved in 2,750 g of deionized water and dissolved with stirring, and 60 g of concentrated nitric acid to prepare a silver nitrate solution A. Wherein the concentration of silver nitrate solution is 1.5mol / L, the amount of concentrated nitric acid was 0.08 times mass of silver nitrate;

[0079] Second Solution A: 760 g of silver nitrate were dissolved in 2,750 g of deionized water and dissolved with stirring, and 60 g of concentrated nitric acid to prepare a silver nitrate solution A. Wherein the concentration of silver nitrate solution is 1.6mol / L, the amount of concentrated nitric acid is 0.079 times the mass of silver nitrate;

[0080] A first solution B: 300 grams of Dispersant polyvinylpyrrolidone K30 was dissolved in 3850 g of deionized water and dissolved with stirring to pr...

Embodiment 3

[0093] Example 3 Preparation of a particle size of 7 microns of silver particles having a large supporting rib structure # 3

[0094] 1) Dosing

[0095] Solution A: 750 g of silver nitrate were dissolved in 2,750 g of deionized water and dissolved with stirring, and 60 g of concentrated nitric acid to prepare a silver nitrate solution A. Wherein the concentration of silver nitrate solution is 1.5mol / L, the amount of concentrated nitric acid was 0.08 times mass of silver nitrate;

[0096] Solution B: 260 grams of Dispersant polyvinylpyrrolidone K30 was dissolved in 3300 g of deionized water and dissolved with stirring to prepare a solution B. ingredient powders Wherein the amount of the dispersant is 0.35 times the mass of the silver nitrate solution A; solution B is used in an amount of deionized water A solution of deionized water, 1.2 times the amount;

[0097] Solution C: 425 g of ascorbic acid dissolved in a 2750 g of deionized water and dissolved with stirring, ascorbic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com