Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Avoid large contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

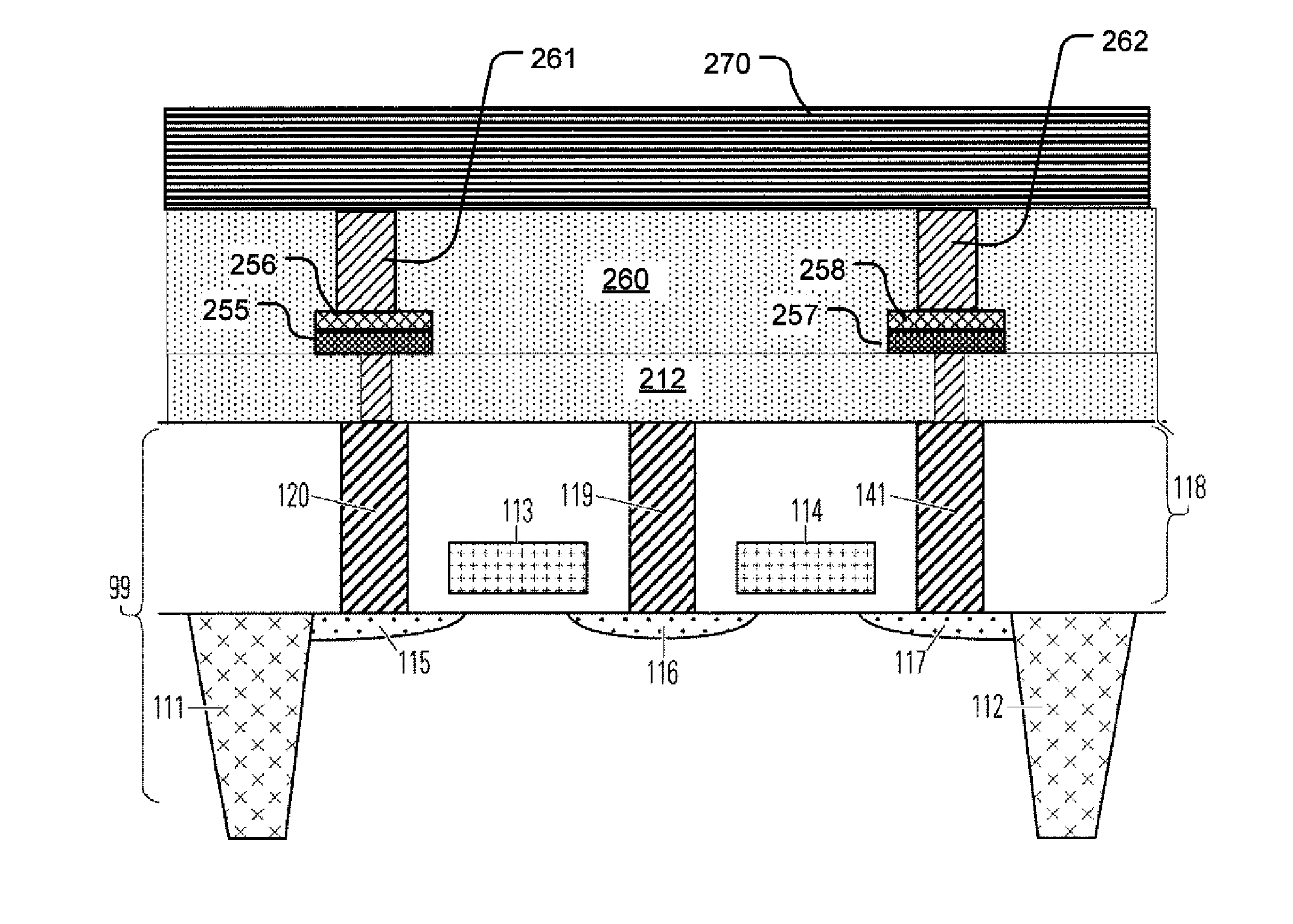

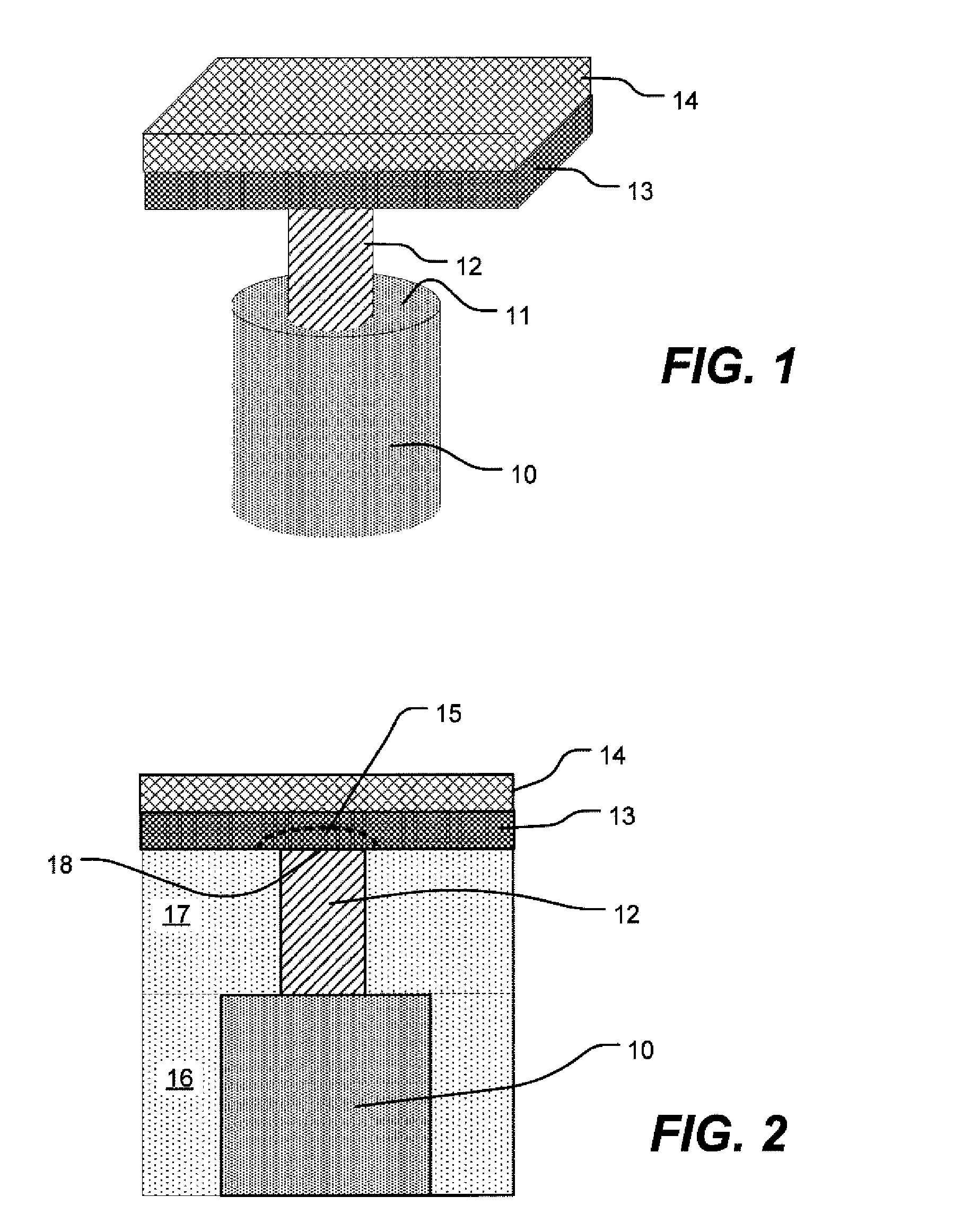

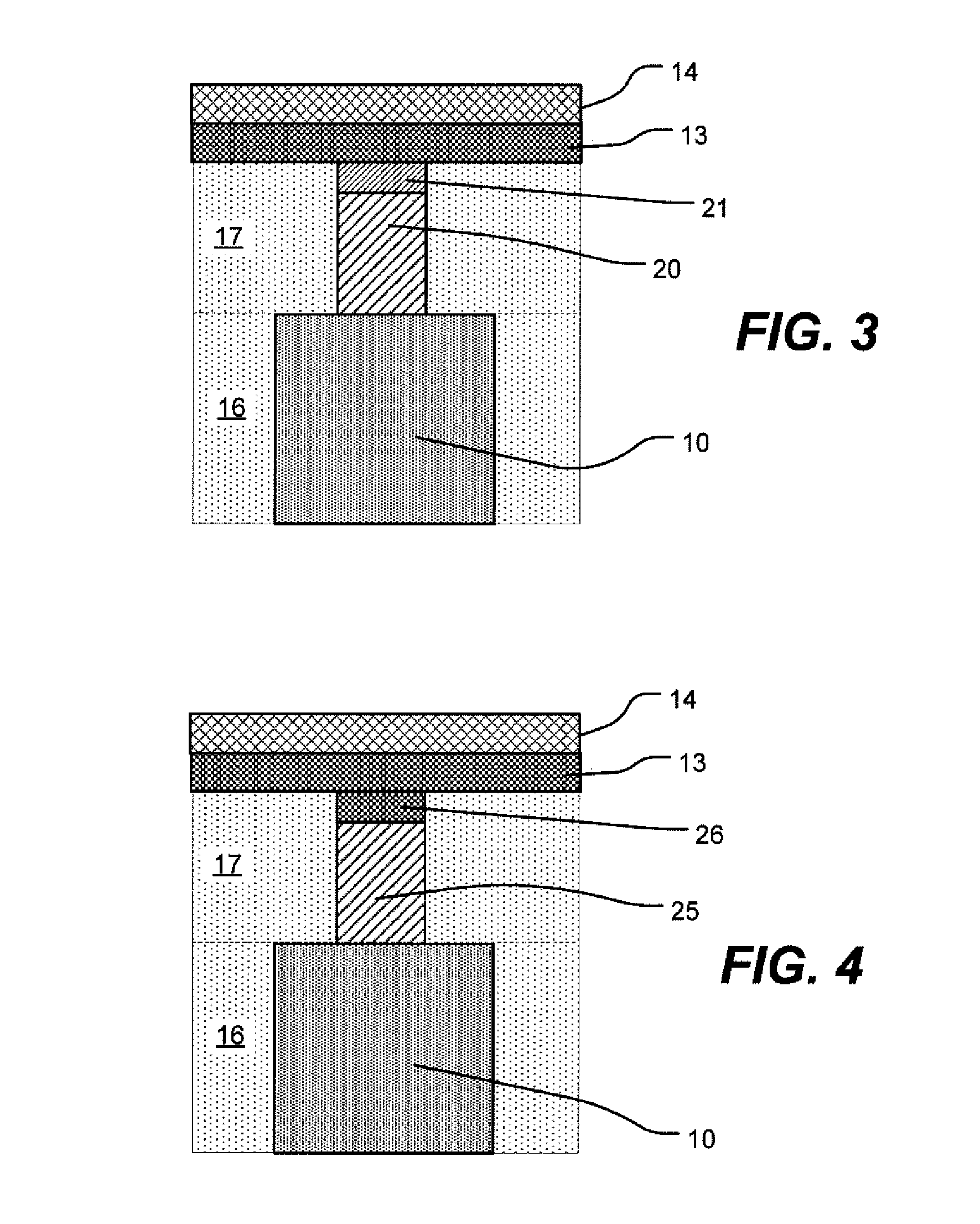

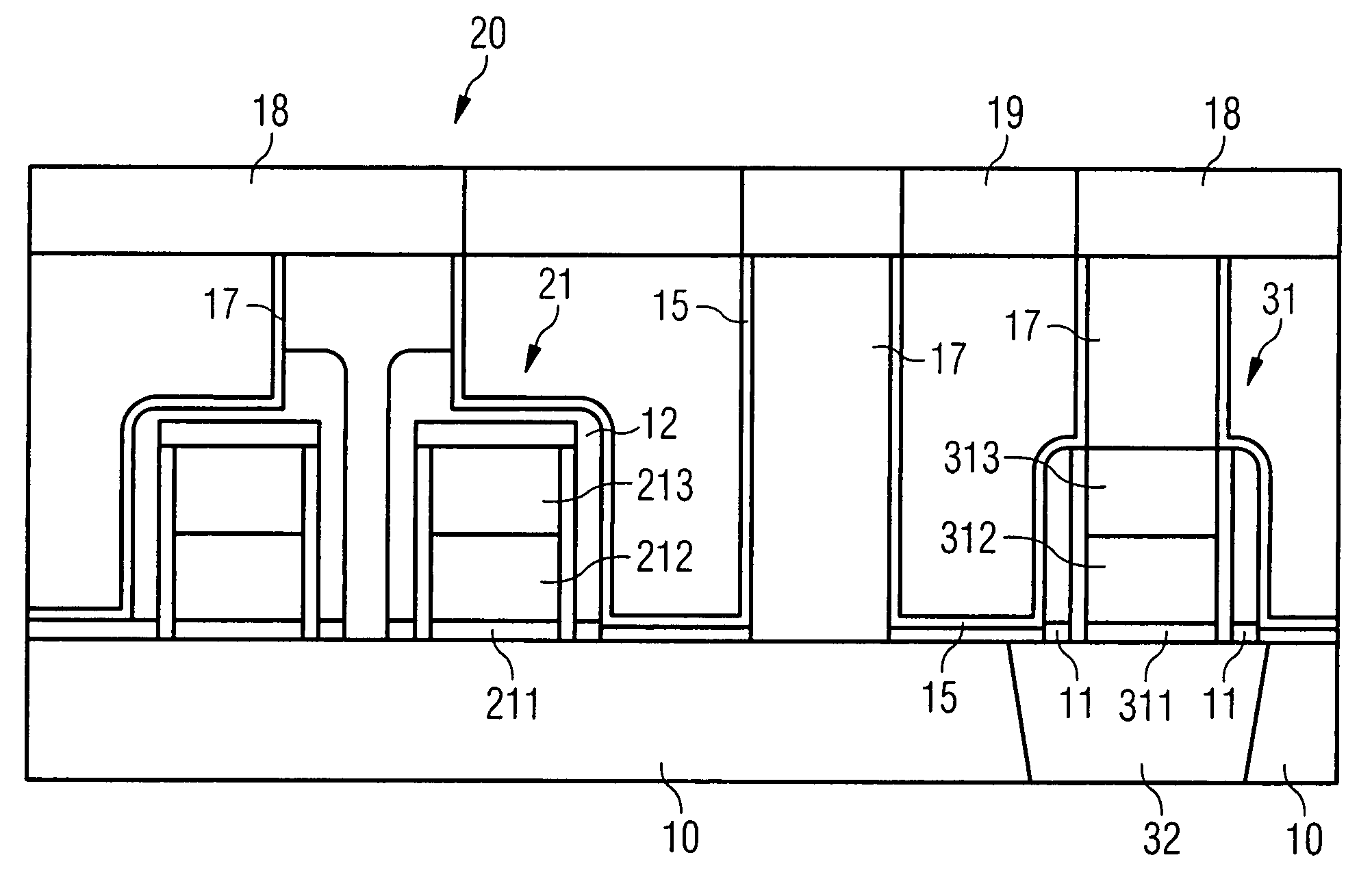

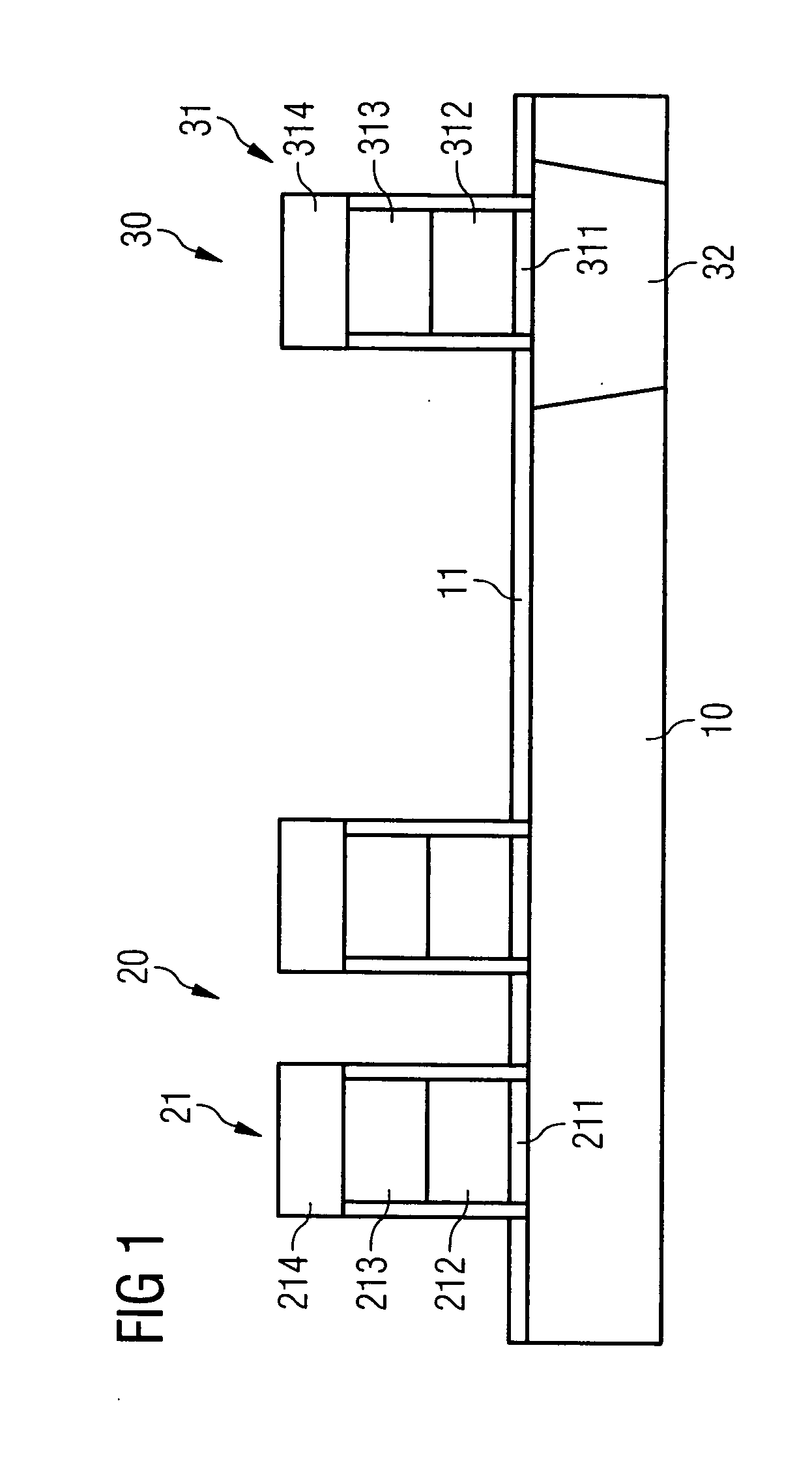

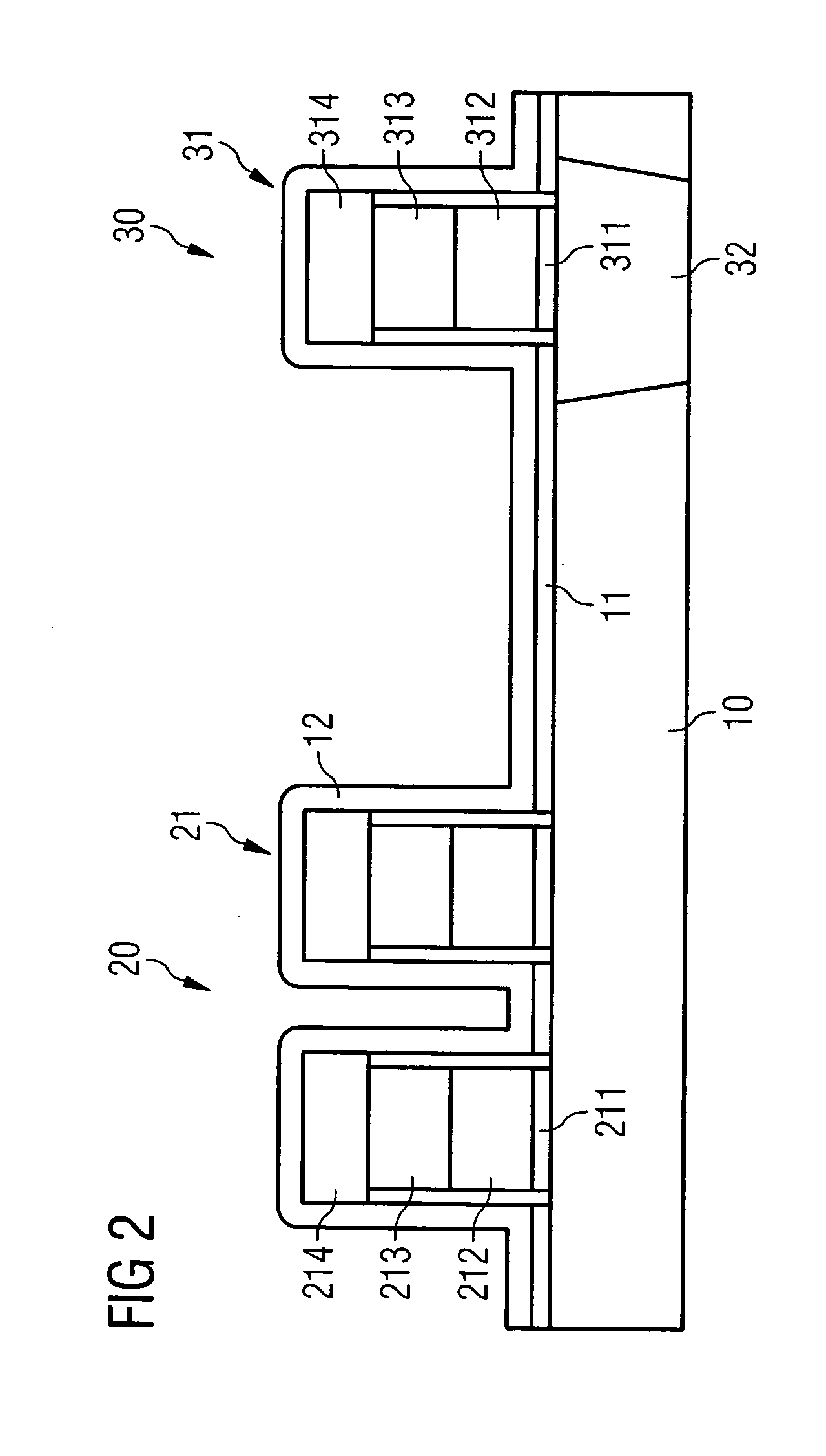

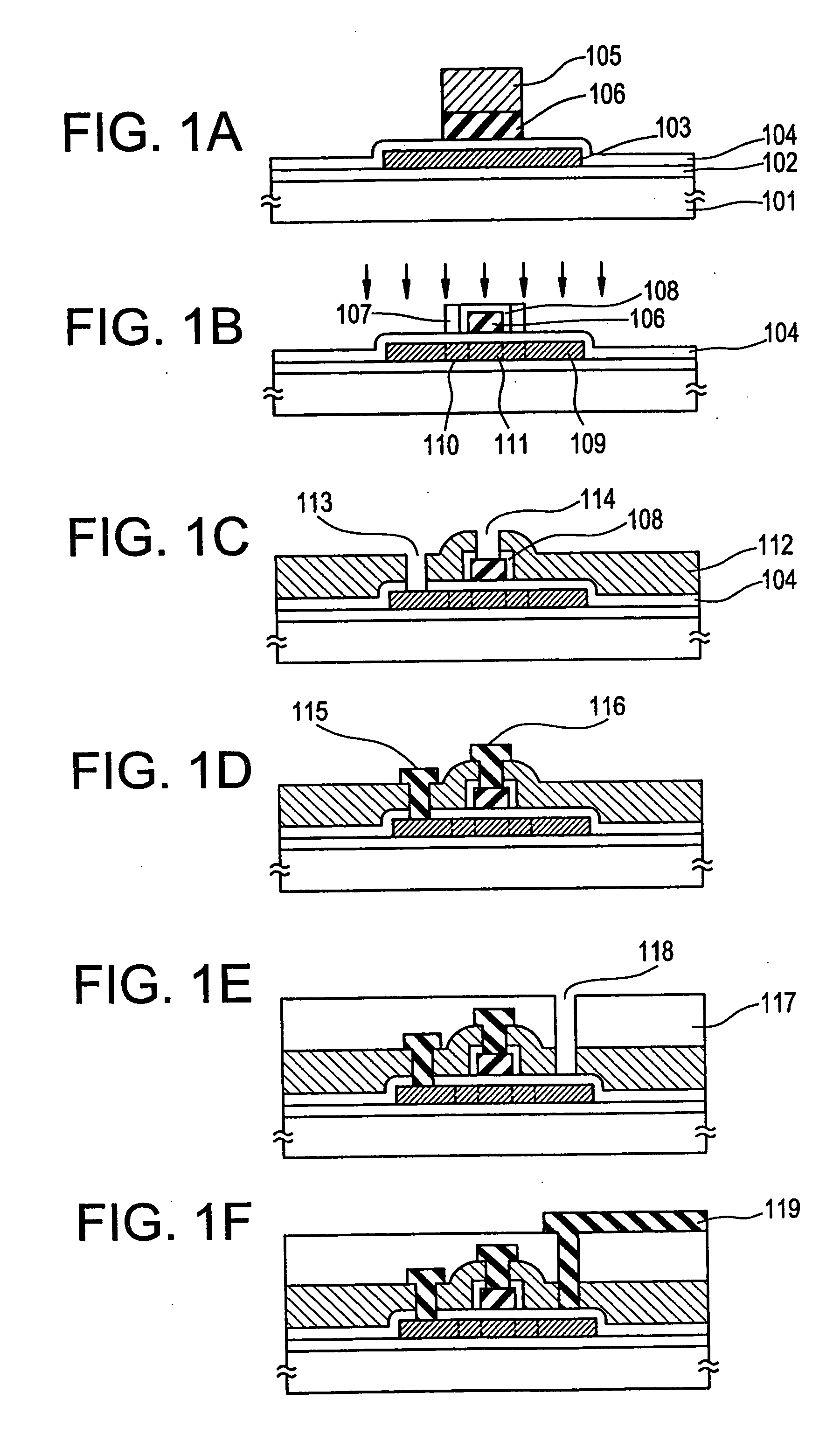

Method for manufacturing a phase change memory device with pillar bottom electrode

ActiveUS20080191187A1Improve operationHigh densitySolid-state devicesSemiconductor/solid-state device manufacturingChalcogenidePhase-change material

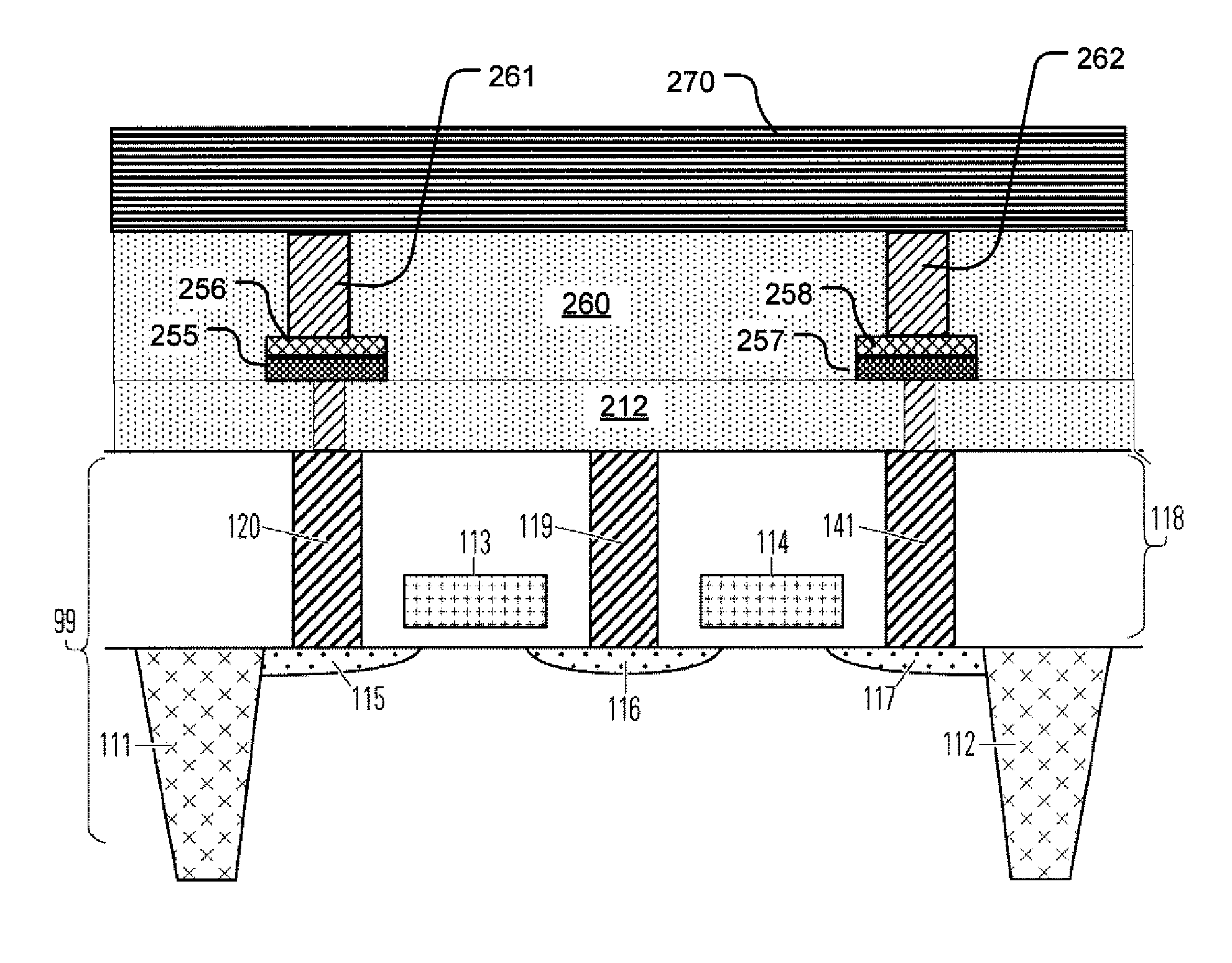

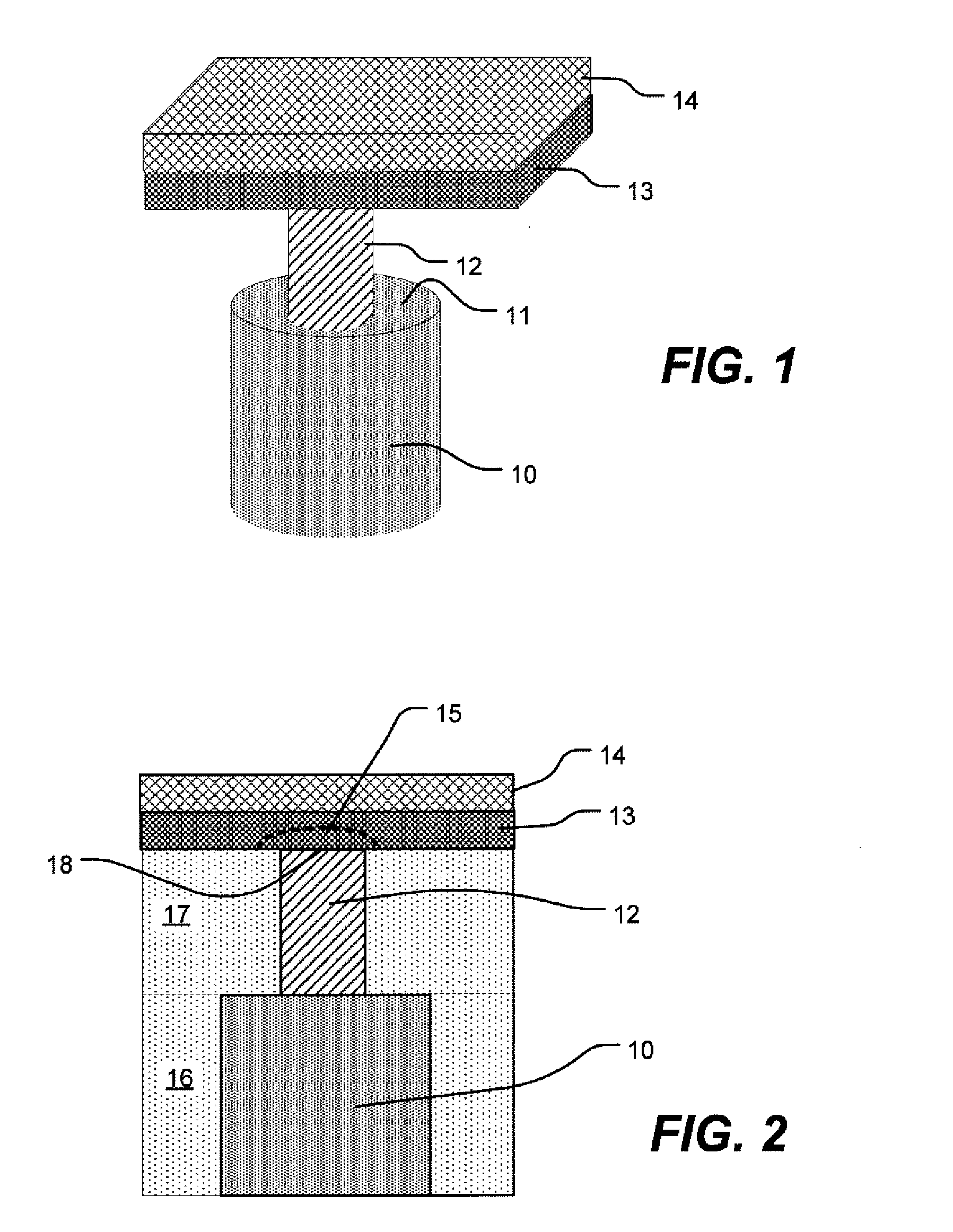

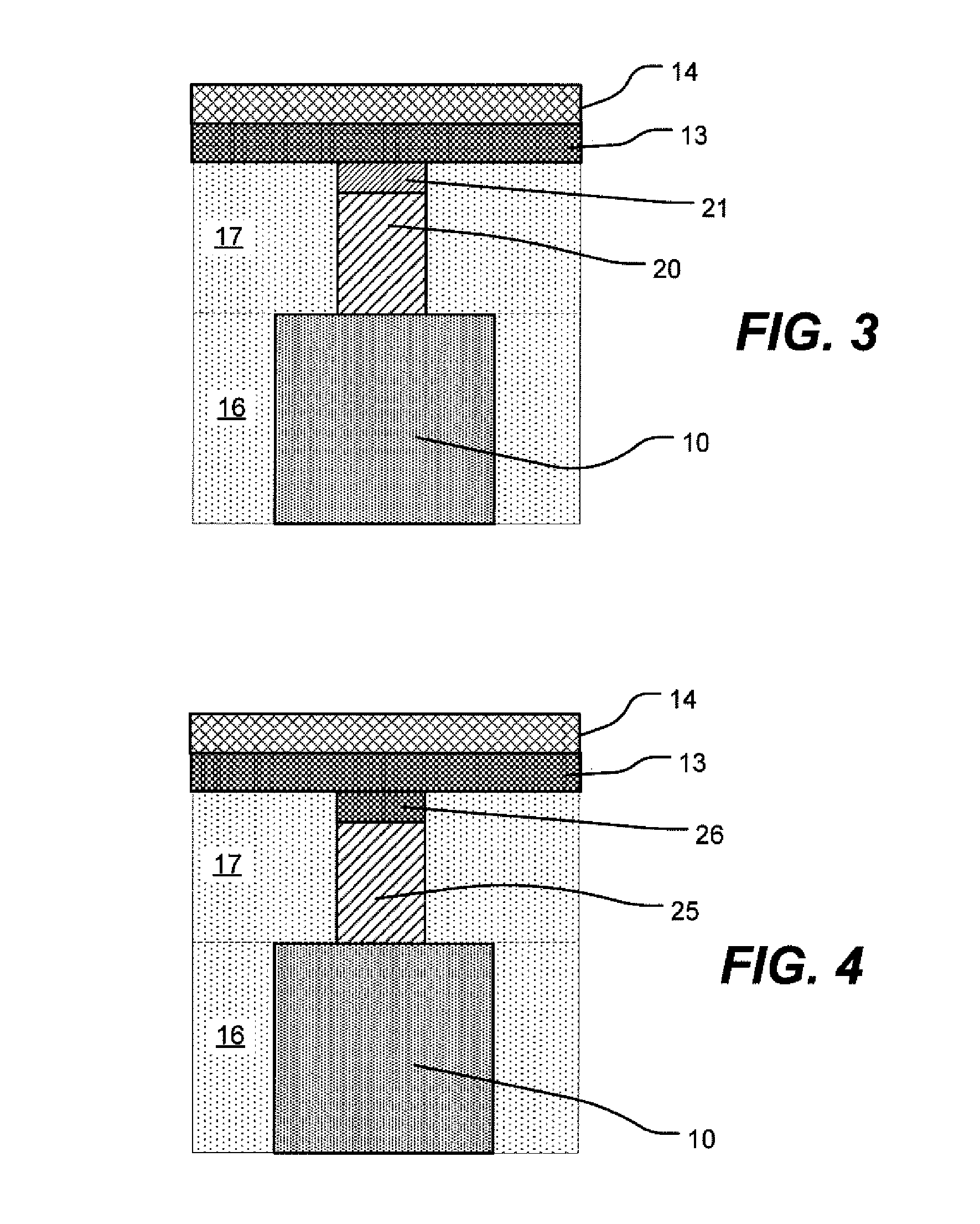

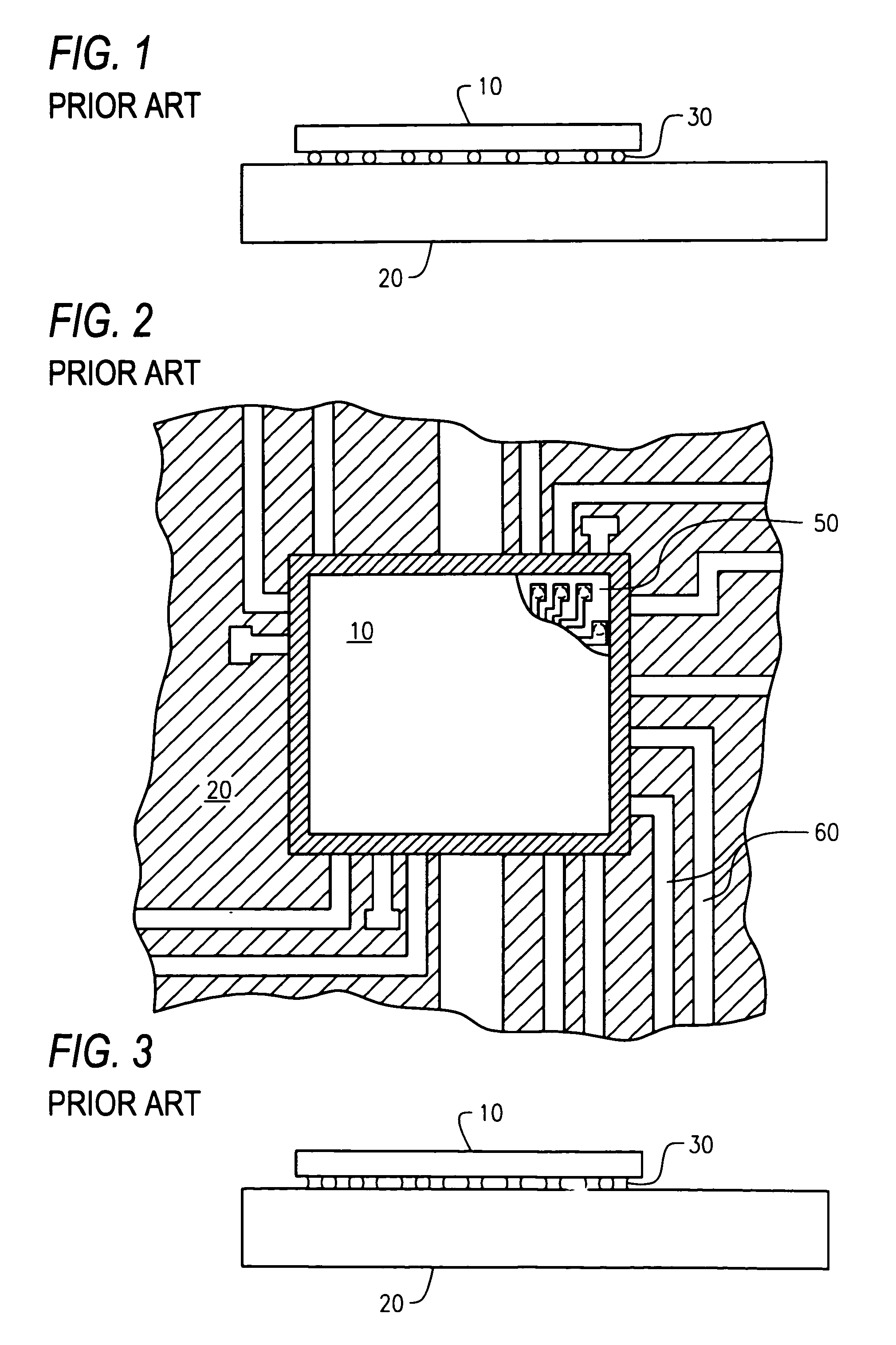

A method for manufacturing a mushroom-cell type phase change memory is based upon manufacturing a pillar of bottom electrode material upon a substrate including an array of conductive contacts in electrical communication with access circuitry. A layer of electrode material is deposited making reliable electrical contact with the array of conductive contacts. Electrode material is etched to form a pattern of electrode pillars on corresponding conductive contacts. Next, a dielectric material is deposited over the pattern and planarized to provide an electrode surface exposing top surfaces of the electrode pillars. Next, a layer of programmable resistive material, such as a chalcogenide or other phase change material, is deposited, followed by deposition of a layer of a top electrode material. A device including bottom electrode pillars with larger bottom surfaces than top surfaces is described.

Owner:GLOBALFOUNDRIES US INC +2

Patterning crystalline compounds on surfaces

InactiveUS20070190783A1Block compoundImprove throughputMaterial nanotechnologyNanoinformaticsCompound (substance)Organic semiconductor

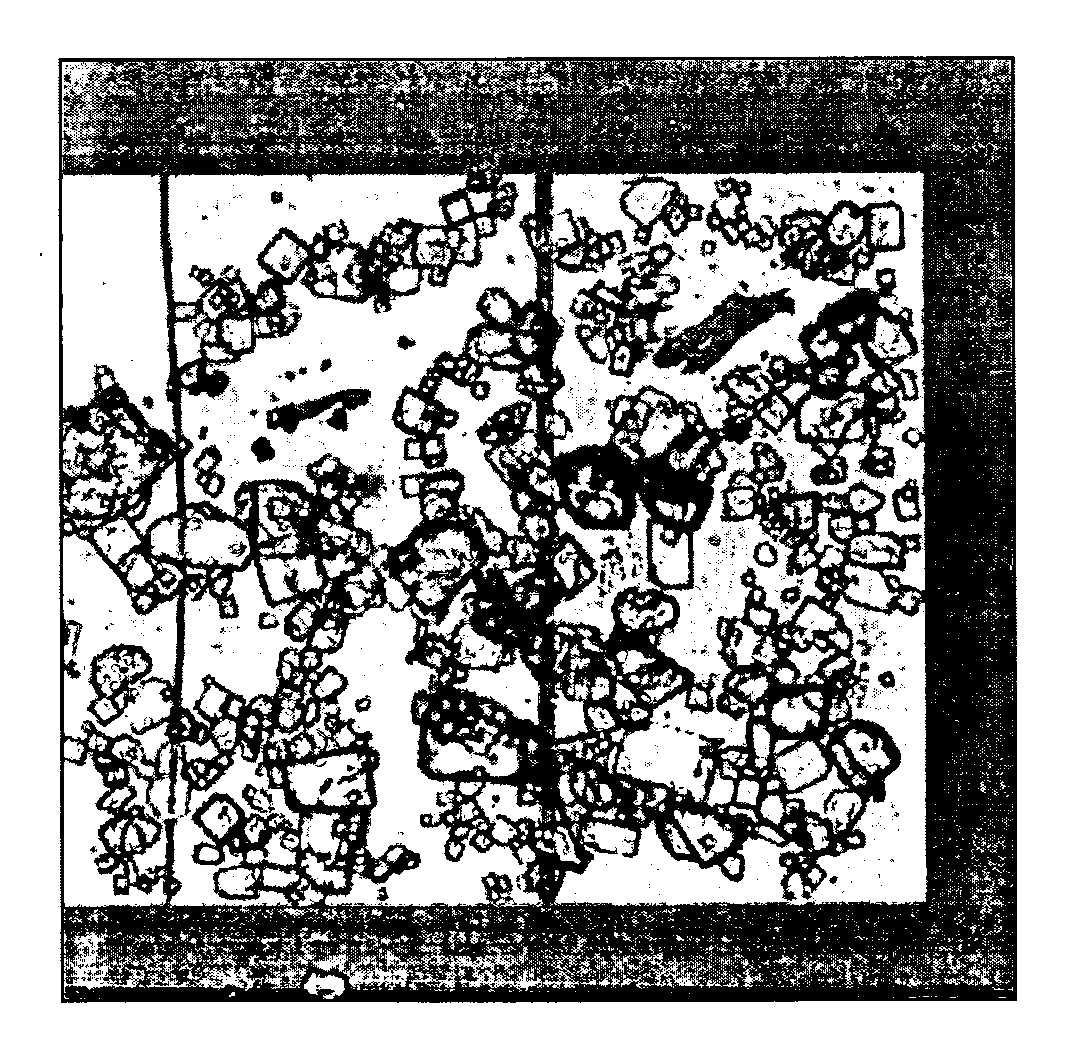

A method of patterning the surface of a substrate with at least one organic semiconducting compound, comprising the steps of: (a) providing a stamp having a surface including a plurality of indentations formed therein defining an indentation pattern, said indentations being contiguous with a stamping surface and defining a stamping pattern, (b) coating said stamping surface with at least one compound (C1) capable of binding to the surface of the substrate and of binding at least one organic semiconducting compound (S), (c) contacting at least a portion of the surface of a substrate with said stamping surface to allow deposition of said compound (C1) on the substrate, (d) removing said stamping surface to provide a pattern of binding sites on the surface of the substrate, (e) applying a plurality of crystallites of the organic semiconducting compound (S) to the surface of the substrate to enable at least a portion of the applied crystallites to bind to at least a portion of the binding sites on the surface of the substrate.

Owner:BASF AG +1

Method for manufacturing a phase change memory device with pillar bottom electrode

ActiveUS8138028B2Improve uniformityUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryEngineering

A method for manufacturing a mushroom-cell type phase change memory is based upon manufacturing a pillar of bottom electrode material upon a substrate including an array of conductive contacts in electrical communication with access circuitry. A layer of electrode material is deposited making reliable electrical contact with the array of conductive contacts. Electrode material is etched to form a pattern of electrode pillars on corresponding conductive contacts. Next, a dielectric material is deposited over the pattern and planarized to provide an electrode surface exposing top surfaces of the electrode pillars. Next, a layer of programmable resistive material, such as a chalcogenide or other phase change material, is deposited, followed by deposition of a layer of a top electrode material. A device including bottom electrode pillars with larger bottom surfaces than top surfaces is described.

Owner:GLOBALFOUNDRIES US INC +2

Method for fabricating a first contact hole plane in a memory module

InactiveUS20060148227A1Simple and reliable processSimple processSolid-state devicesSemiconductor/solid-state device manufacturingBit lineConductive materials

A silicon dioxide layer is formed and a mask layer is deposited and then patterned to produce openings in the mask layer in the region around the gate contacts onto the gate electrode tracks in the logic region. The surface is uncovered around the gate contacts to the gate electrode tracks in the logic region, reducing the silicon dioxide layer. A sacrificial layer covering the gate electrode tracks is formed and patterned to form sacrificial layer blocks above the contact openings for the bit line contacts between the mutually adjacent gate electrode tracks in the cell array region and above the contact openings for the substrate contacts to the semiconductor surface and the gate contacts onto the gate electrode tracks in the logic region. A filling layer is formed between the sacrificial layer blocks, and the sacrificial layer blocks are removed. The contact opening regions are filled with conductive material.

Owner:INFINEON TECH AG

Method of forming a micro solder ball for use in C4 bonding process

InactiveUS6998711B1Avoid large contactWell formedSemiconductor/solid-state device detailsSolid-state devicesResistMetallurgy

Owner:MICRON TECH INC

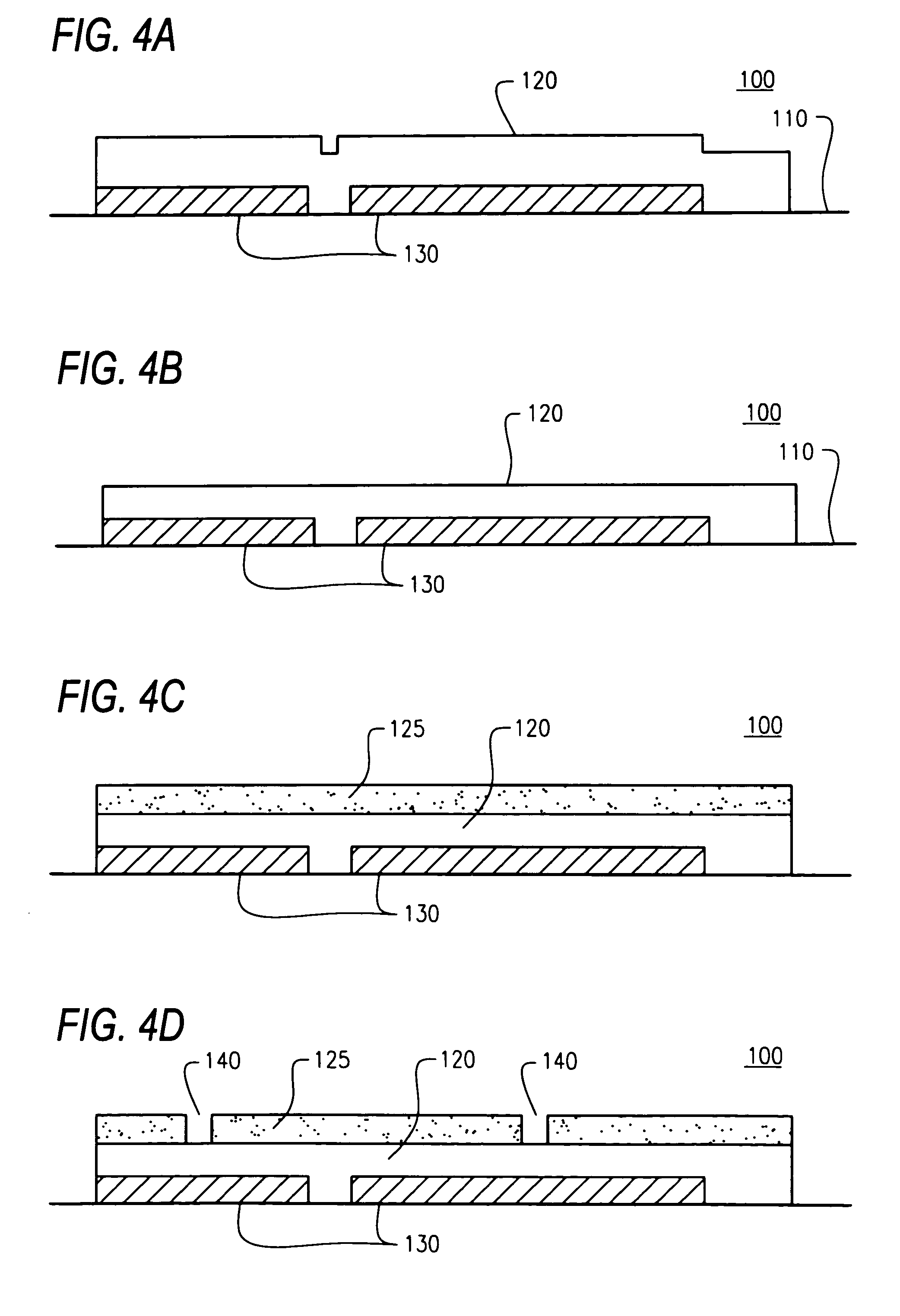

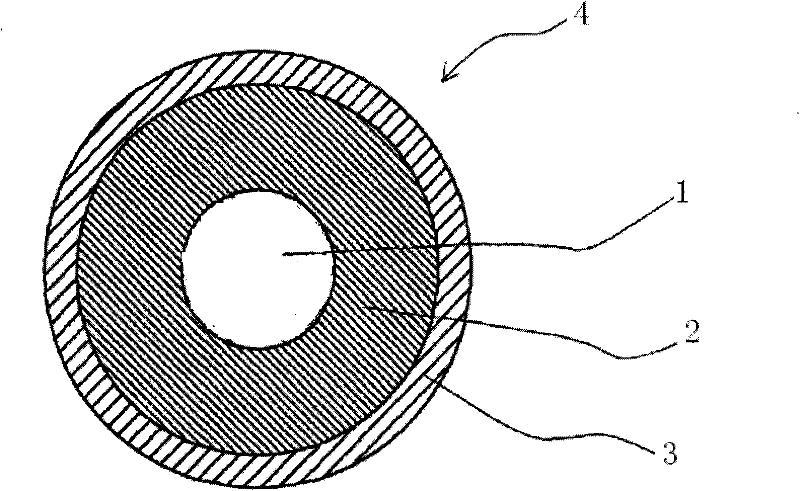

Conductive rubber roller

ActiveCN102193361AIncrease elasticitySolve the problem of thermo-oxidative agingElectrographic process apparatusHardness ratioNitrile rubber

The invention relates to a conductive rubber roller. The conductive rubber roller consists of a metal shaft core and a double-layer rubber layer covered on the surface of the metal shaft core; the inner layer is a foamed rubber layer formed by adding a foaming agent into a mixed glue stock consisting of epichlorohydrin rubber and natural rubber; and the outer layer is a high-crosslink-degree non-foamed rubber layer in which mixed rubber consisting of butadiene rubber and nitrile rubber is used as a main body. The hardness of the rubber on the inner layer is more than Shore C15 degrees and less than Shore C70 degrees; the hardness of the rubber on the outer layer is more than Shore A40 degrees and less than Shore A90 degrees; and the hardness ratio of the rubber on the outer layer to the rubber on the inner layer is 1.5 to 2.1; and a hardness difference value is 10 to 40.

Owner:SHENZHEN LEPUTAI TECH CO LTD

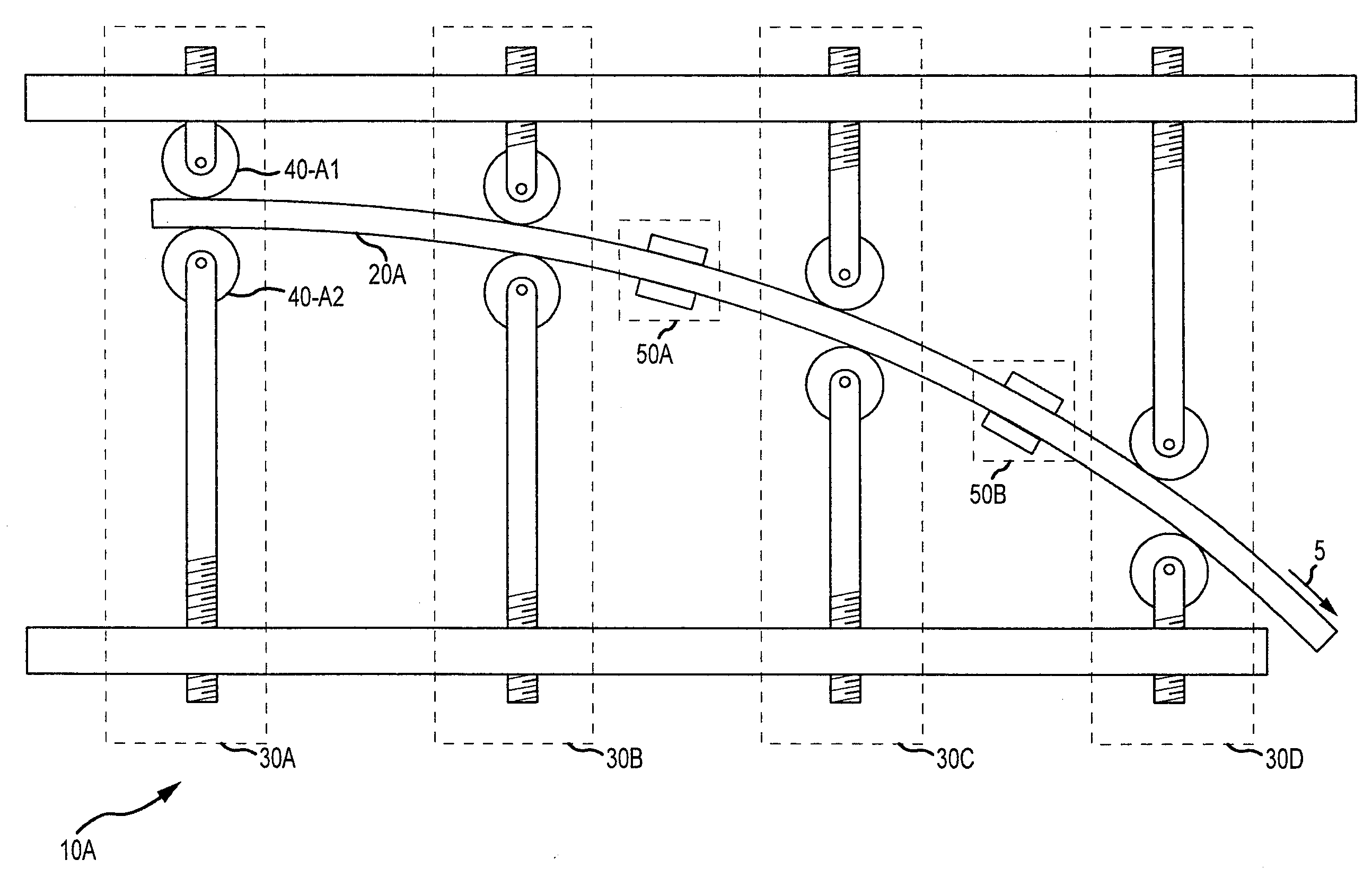

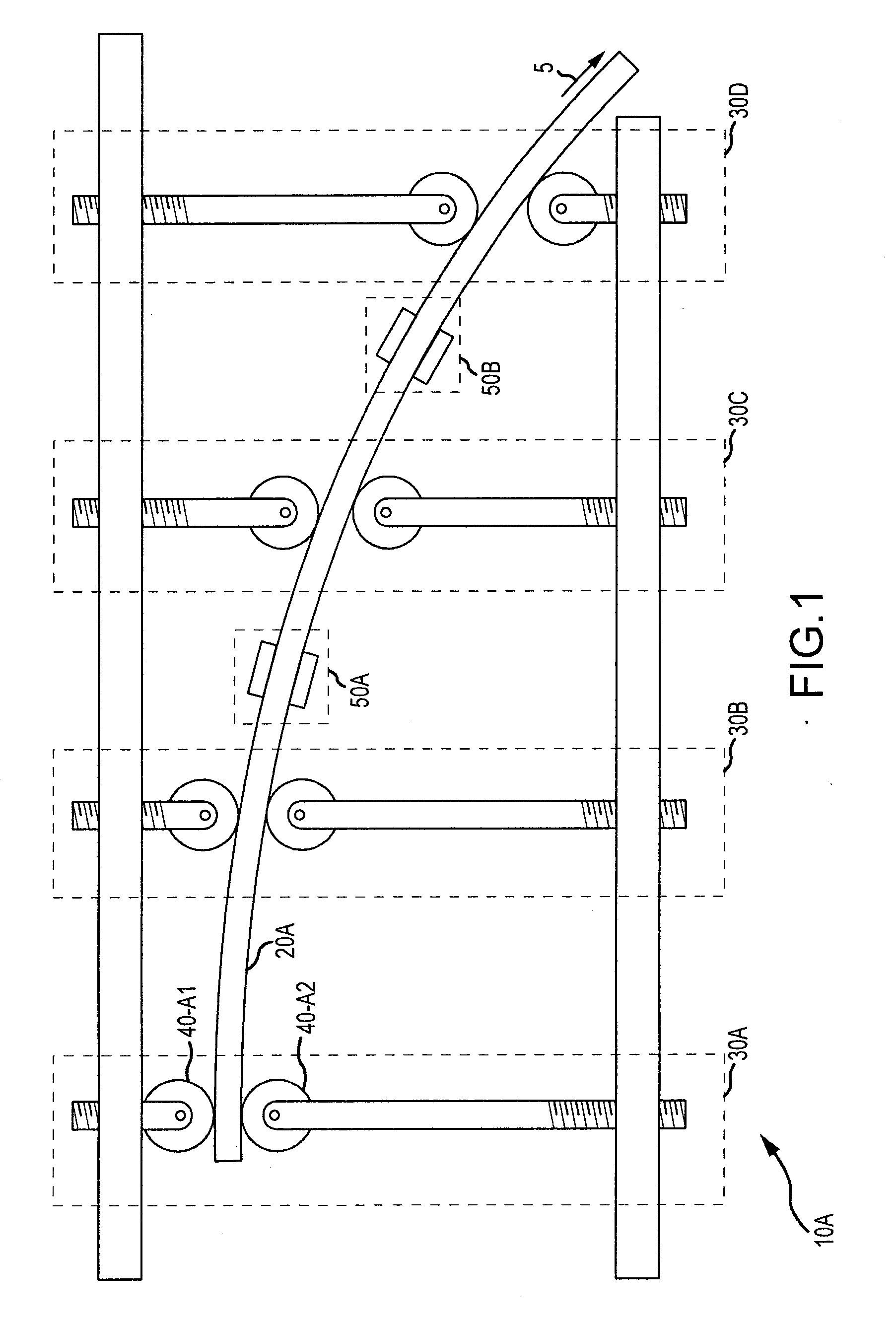

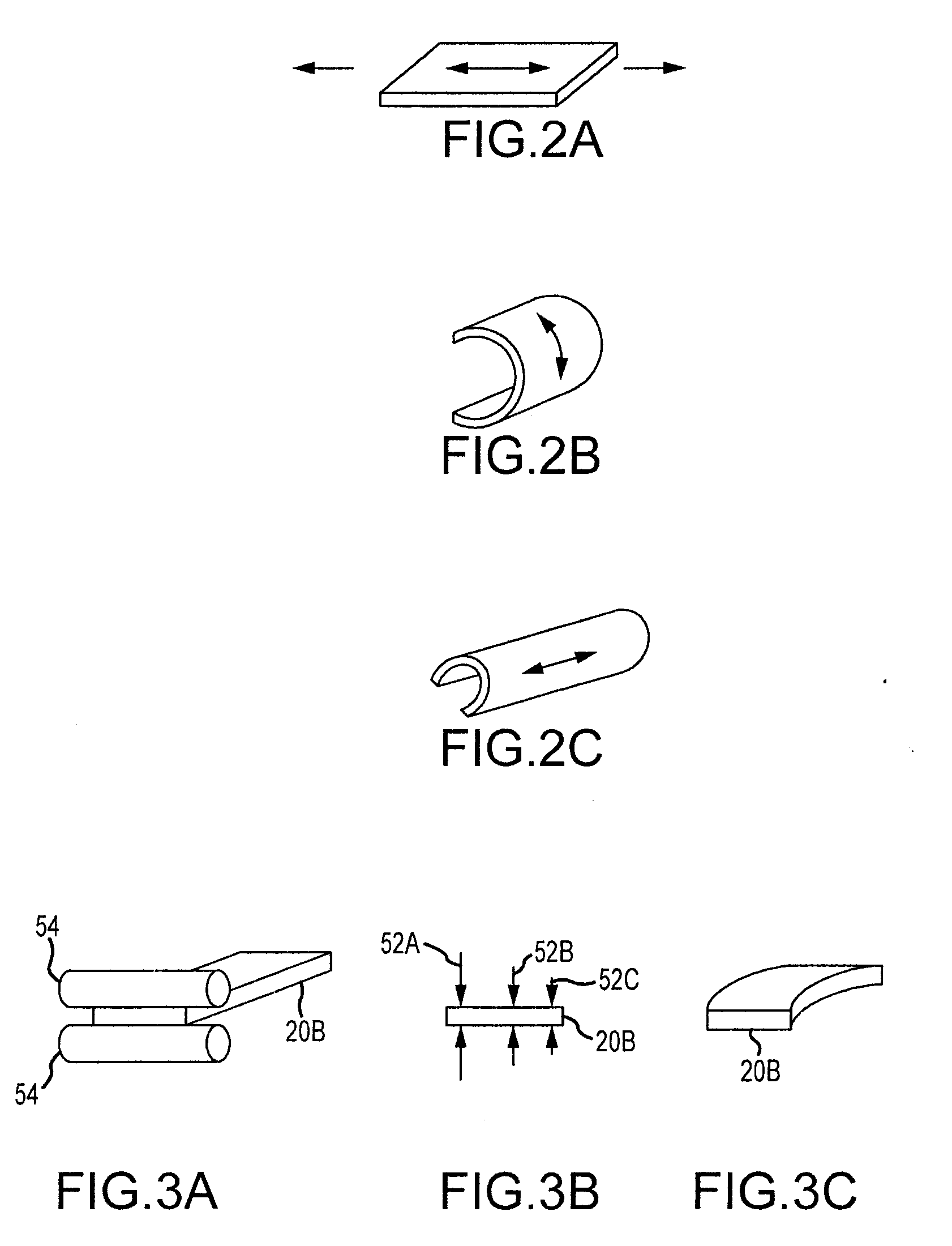

Stretch Roll Forming

ActiveUS20100263424A1Lighter and strong partEvenly distributedMetal-working feeding devicesPositioning devicesRoll formingEngineering

Owner:FAIRMOUNT TECH

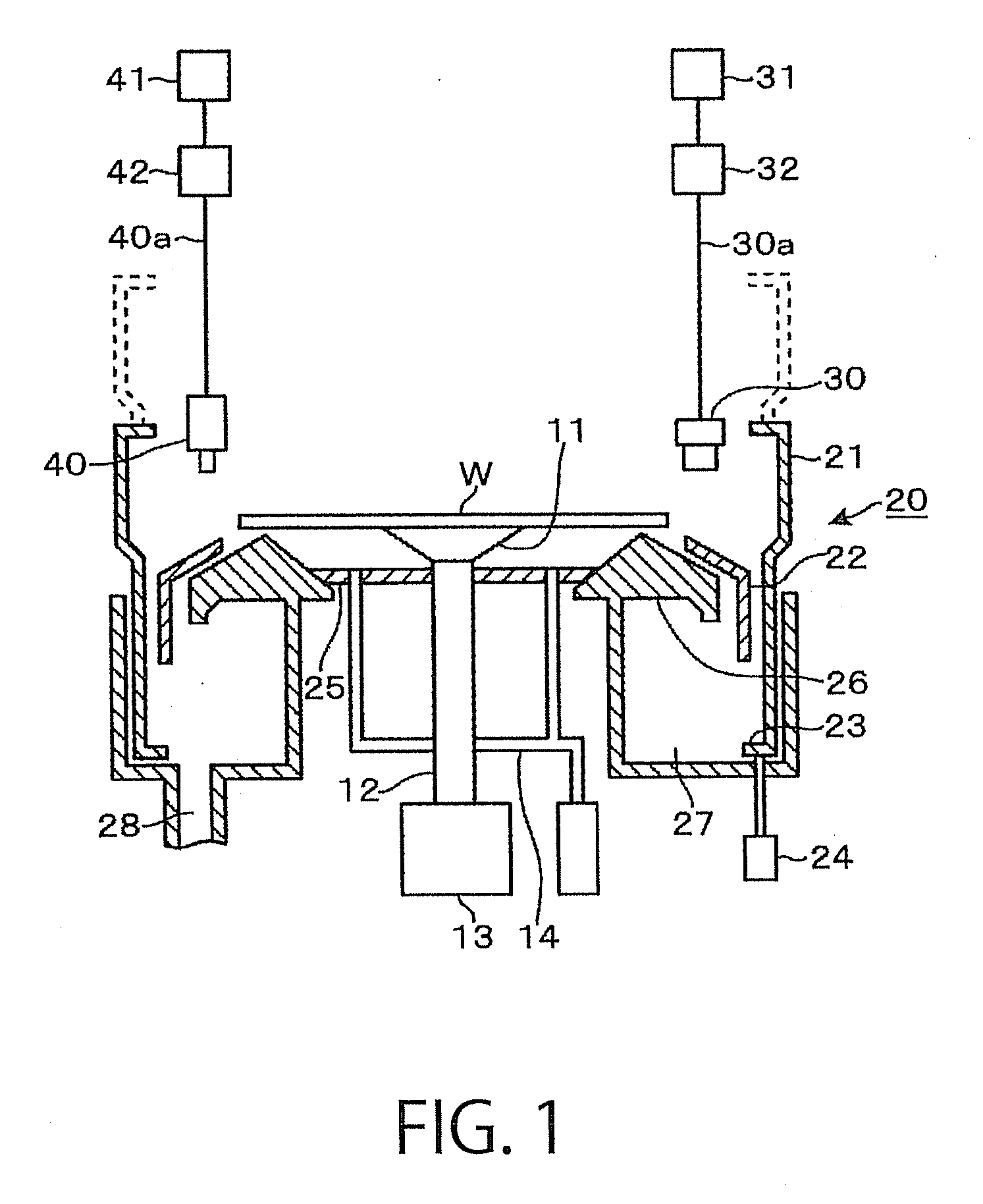

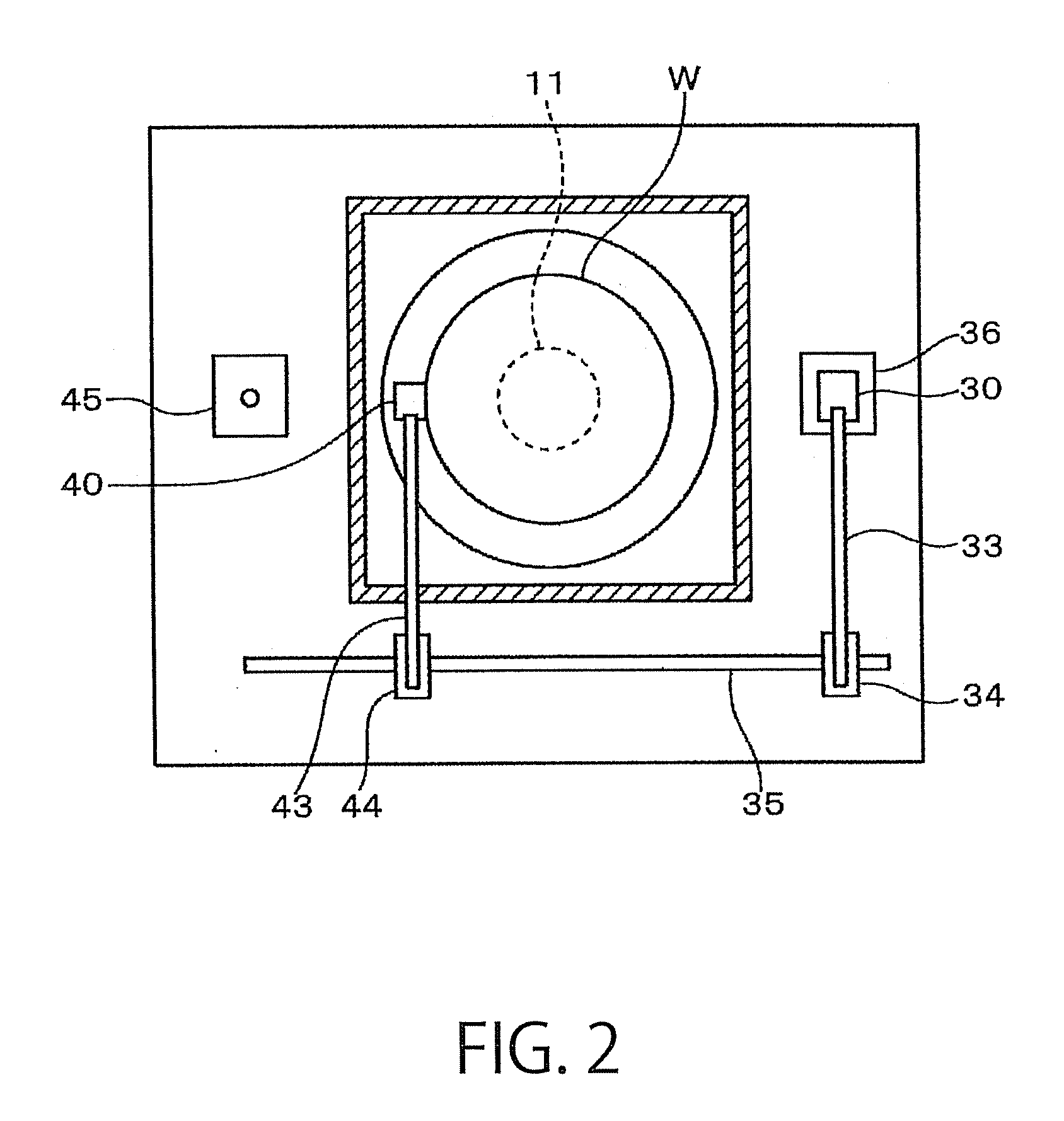

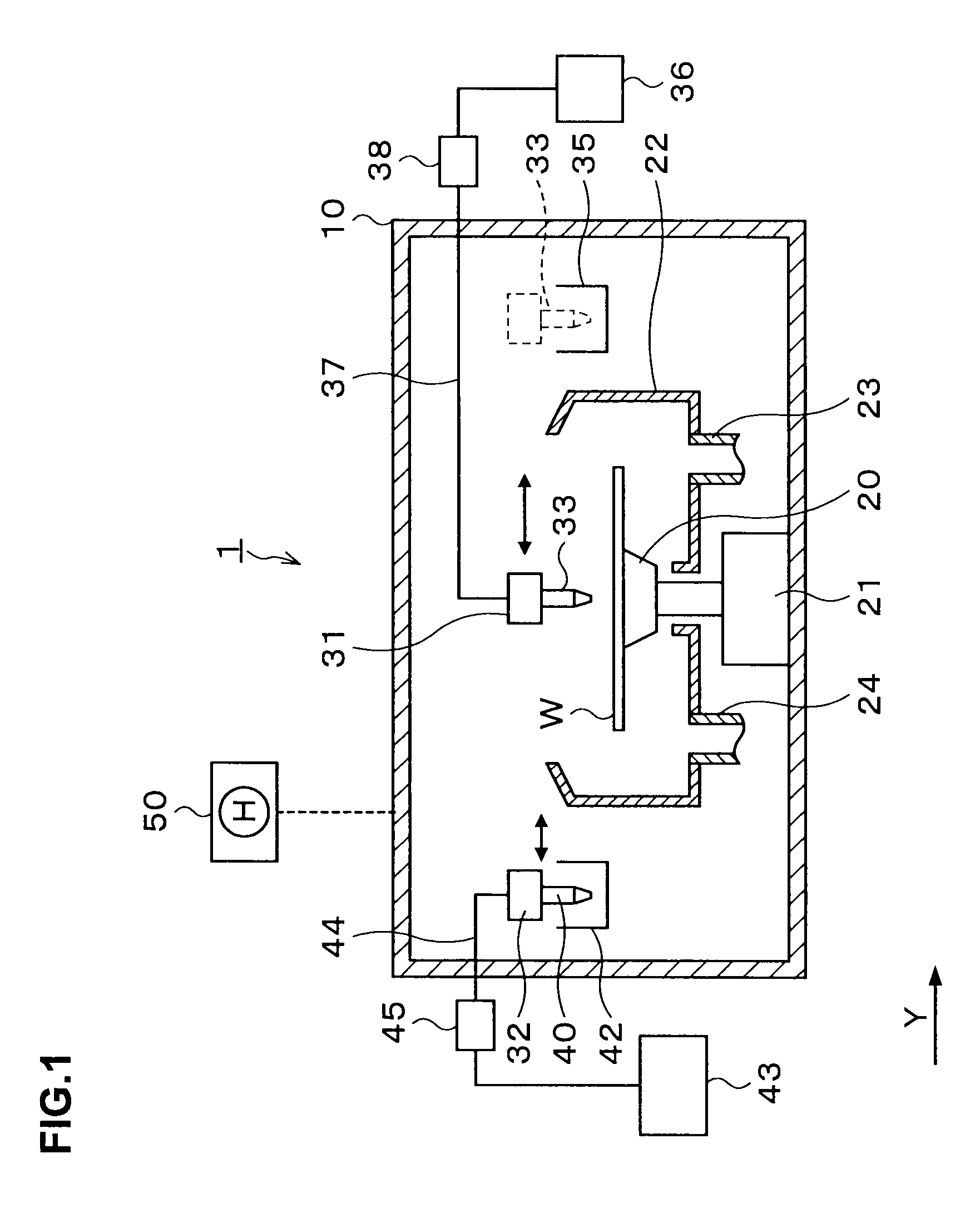

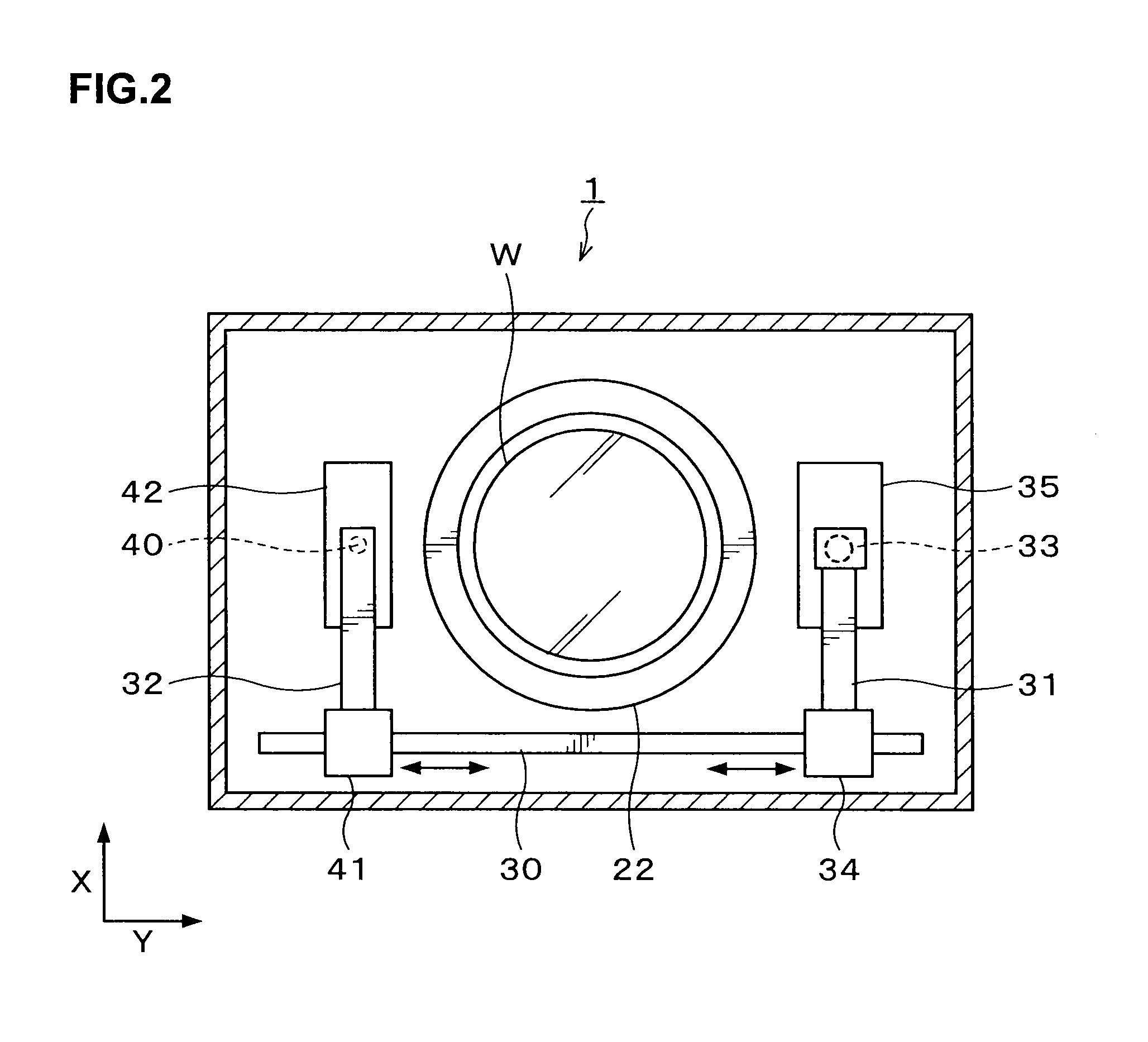

Developing apparatus, developing method and storage medium

ActiveUS20110096304A1Highly uniformly processing surfaceHigh water repellencyLiquid processingReversal processingResistWaste management

A pretreatment process, carried out prior to a developing process, spouts pure water, namely, a diffusion-assisting liquid for assisting the spread of a developer over the surface of a wafer, through a cleaning liquid spouting nozzle onto a central part of the wafer to form a puddle of pure water. The developer is spouted onto the central part of the wafer for prewetting while the wafer is rotated at a high rotating speed to spread the developer over the surface of the wafer. The developer dissolves the resist film partly and produces a solution. The rotation of the wafer is reversed, for example, within 7 s in which the solution is being produced to reduce the water-repellency of the wafer by spreading the solution over the entire surface of the wafer. Then, the developer is spouted onto the rotating wafer to spread the developer on the surface of the wafer.

Owner:TOKYO ELECTRON LTD

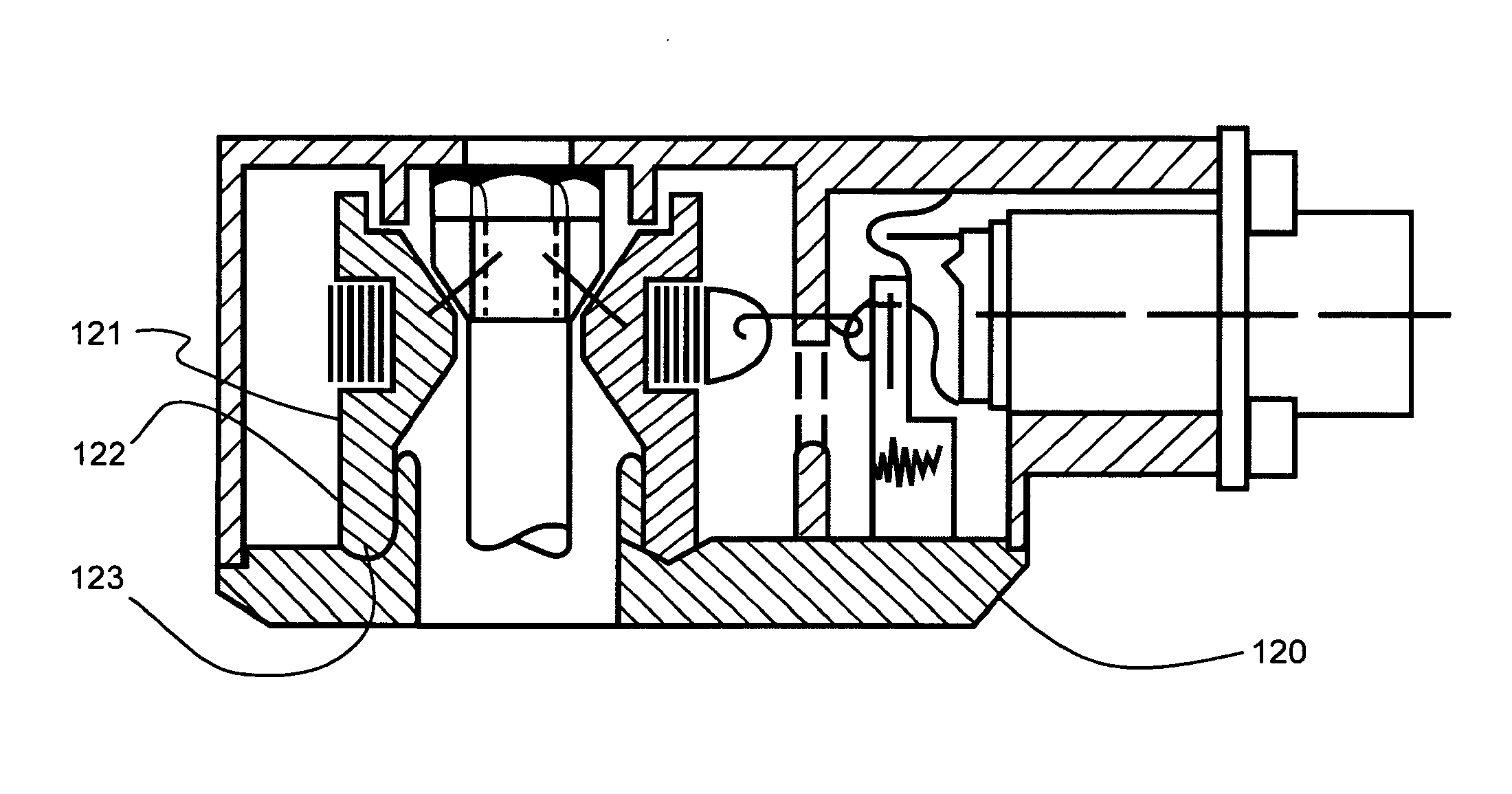

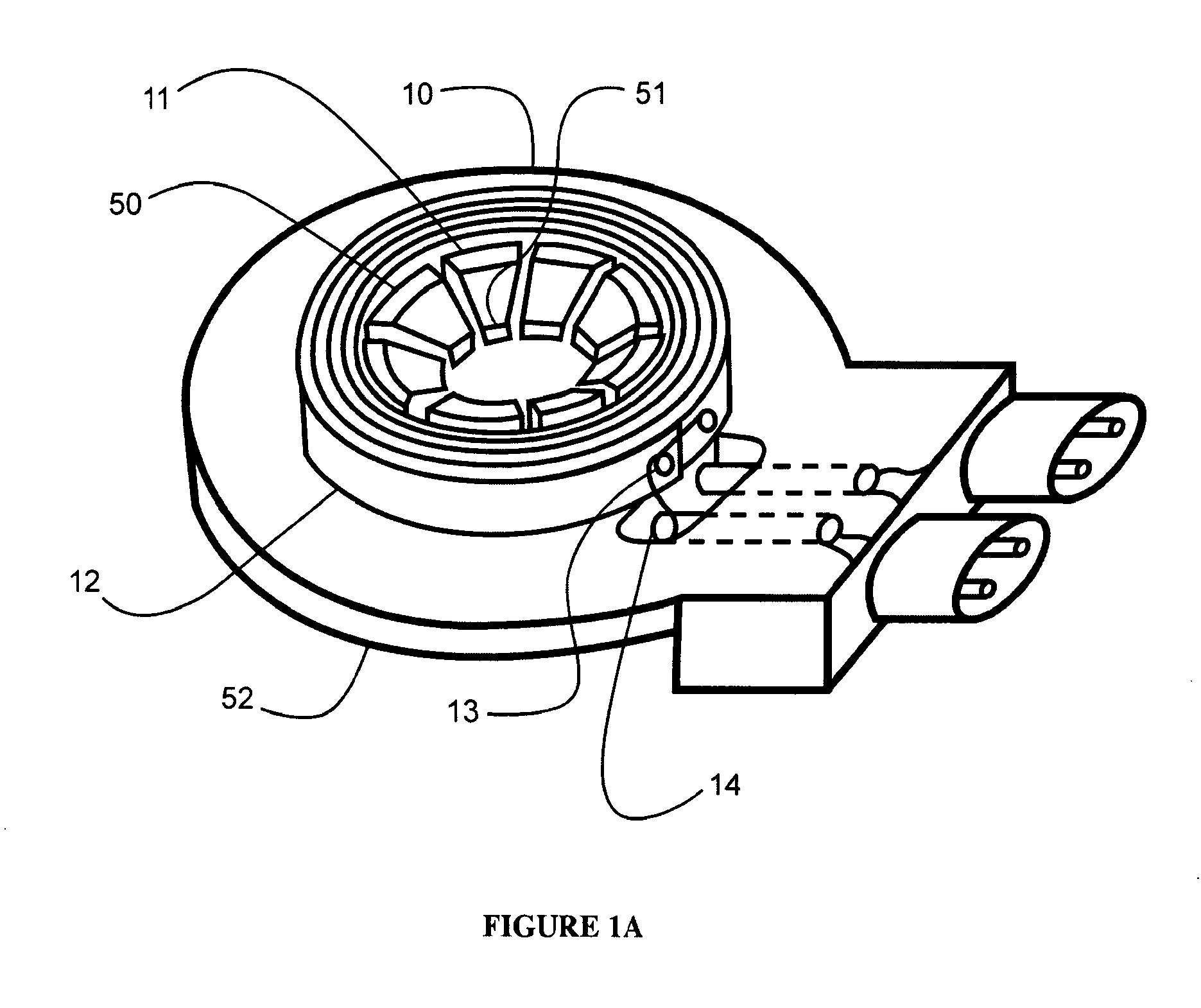

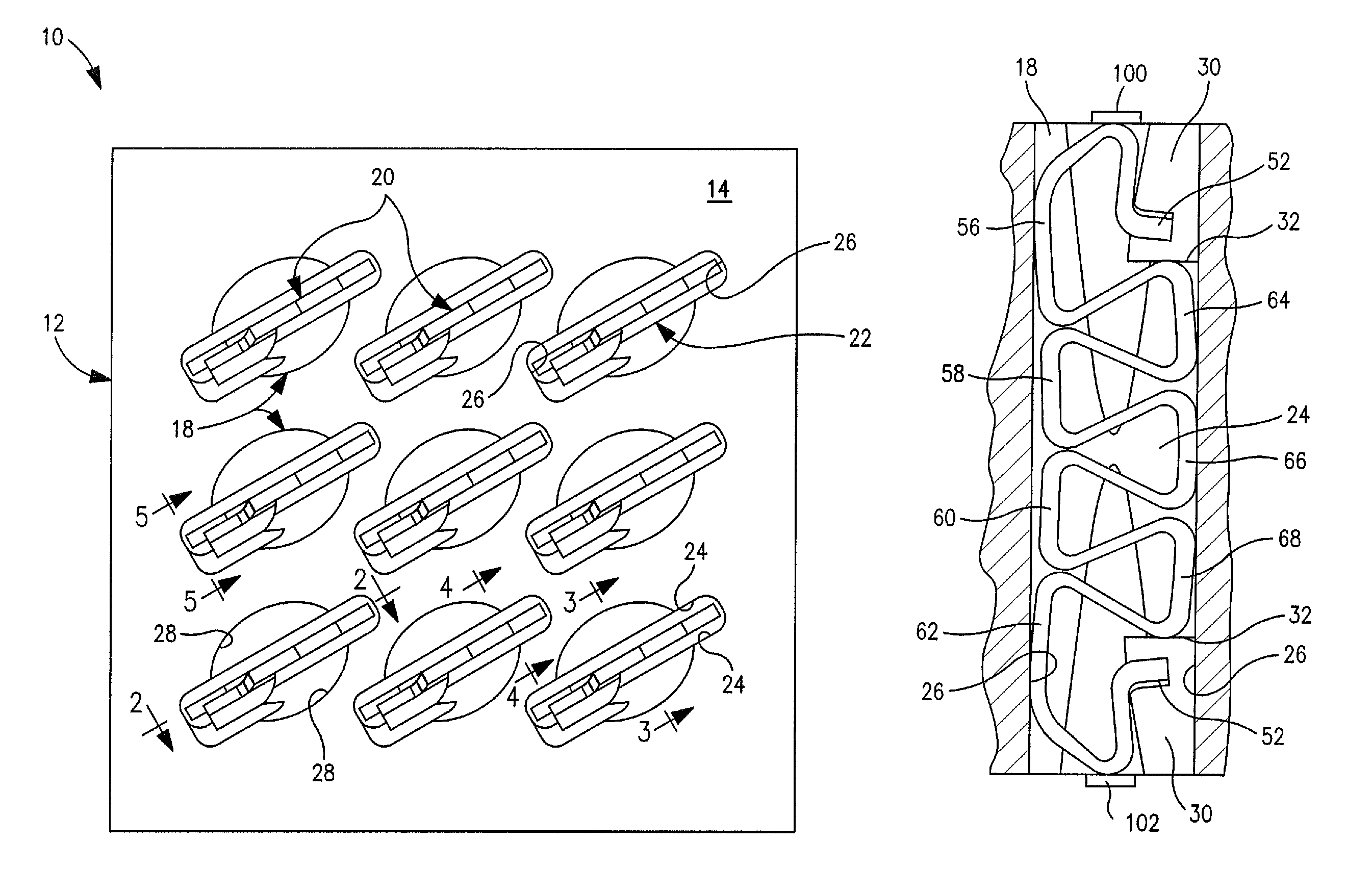

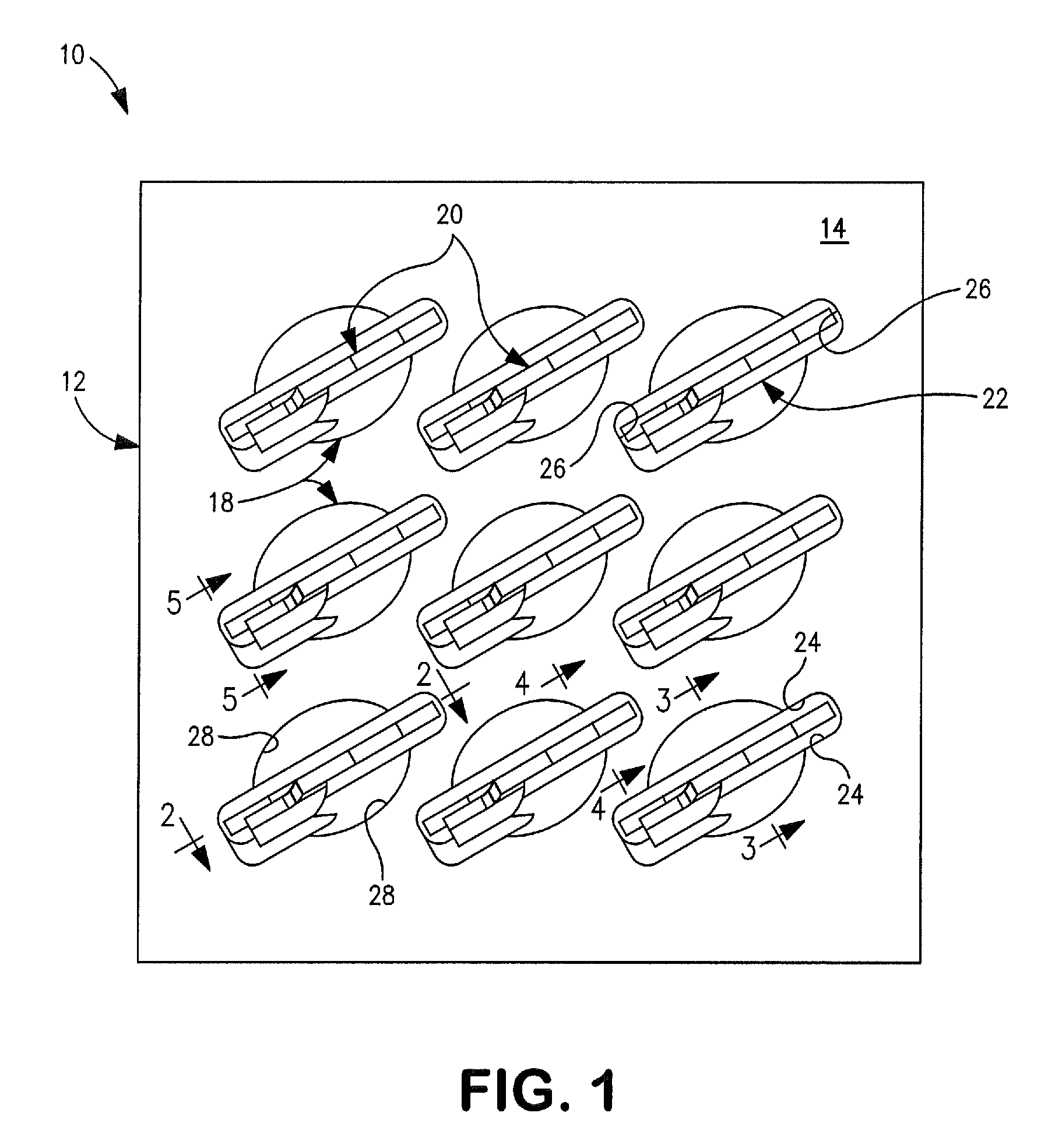

Radial release device

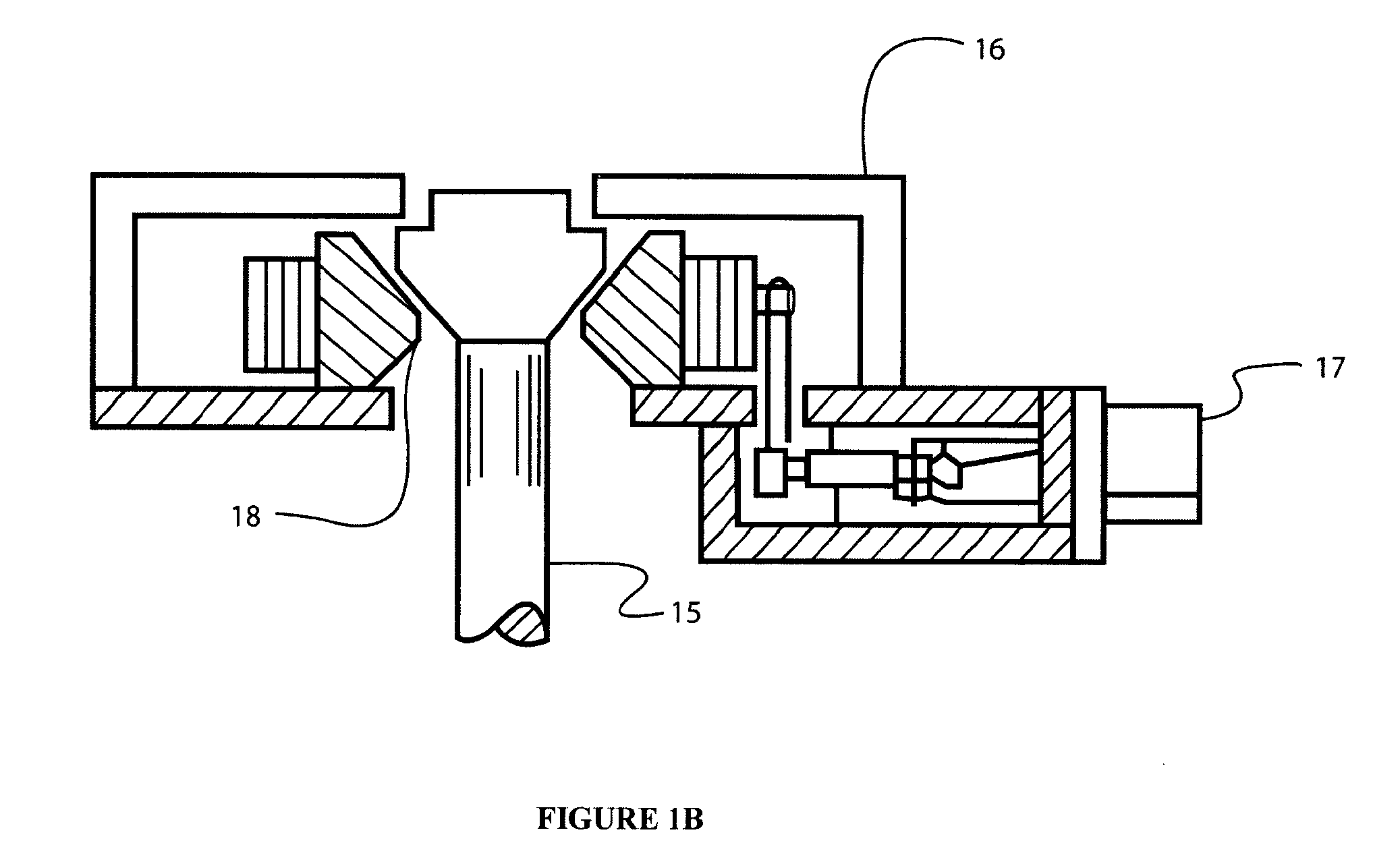

ActiveUS8568053B2Prevent radial movementLow profileCosmonautic vehiclesCosmonautic power supply systemsRadial motionEngineering

A release device having a multi-segment split spool with a central bore adapted to axially restrain a tensioned member. A tensioned tape is overlappingly wound around the spool segments thereby preventing radial movement of the spool segments. The overlapping winding allows for a low profile housing for the release device. The multiple segments require less radial motion for release of the tensioned member.

Owner:MAXAR SPACE LLC

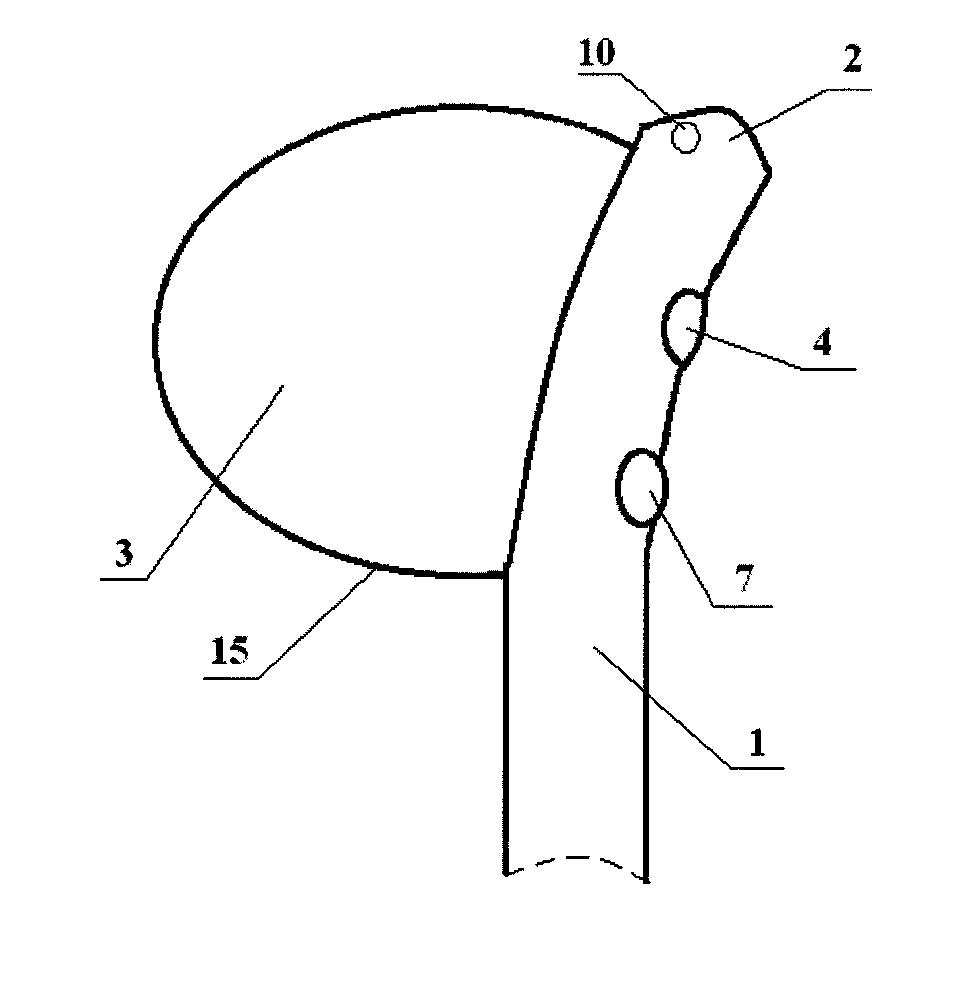

Contact-Limiting Side Balloon Double-Hole Urinary Catheter

InactiveUS20150352339A1Avoid large contactWeak elasticityBalloon catheterWound drainsUrinary catheterReflux valve

The invention relates to a contact-limiting side balloon double-hole urinary catheter, pertaining to the field of medical auxiliary devices; wherein a catheter body is made from a polymer blend, a side balloon is provided at one side of the catheter body close to a tip, the other side is provided with an excretion cavity drainage lower hole and an upper hole, and a flushing lumen liquid flow outlet is provided at the tip. After the urinary catheter is placed in the bladder, the side balloon automatically tilts in a water or gas injection state, the balloon wall and the catheter body do not press the trigone of the bladder and the orificium ureteris, the excretion cavity drainage lower hole is adjacent to the orificium ureteris to completely empty the bladder, and there is no residual urine. The tip, the side balloon, the excretion cavity drainage lower hole and upper hole, the excretion cavity, a water or gas injection lumen, the flushing lumen, the flushing lumen liquid flow outlet, an anti-reflux valve, an excretion cavity conical interface, a flushing cavity conical interface and a flushing cavity clipping switch of the urinary catheter are connected into an integral piece via the catheter body, and have a significant effect in clinical application.

Owner:WANG LIANG

Method for Preparing Molybdenum Doped Titanium Dioxide Thin Film by Sol-Gel

InactiveUS20170282159A1Large specific surface areaGood transmissivityGas treatmentDispersed particle separationPorosityGlass ball

The present invention discloses a method for preparing molybdenum doped titanium dioxide thin film by sol-gel, comprising following steps: preparing a mixed solution containing tetrabutyl titanate, adding a thickener to obtain solution I, preparing solution II containing ammonium molybdate solution, dropwise adding solution II into solution I and obtaining a titanium dioxide sol; dipping the titanium dioxide sol on the surface of a glass ball and oven drying, repeating such for several times, removing a solvent by vacuum drying, carrying out high-temperature calcination, keeping warm and obtaining molybdenum doped titanium dioxide thin film. The molybdenum doped titanium dioxide thin film prepared by the present invention has higher specific surface area, and the catalyst after modeling deposition has better transmissivity and porosity, large reaction contact area, high light efficiency and good photocatalytic effect.

Owner:YANCHENG INST OF TECH

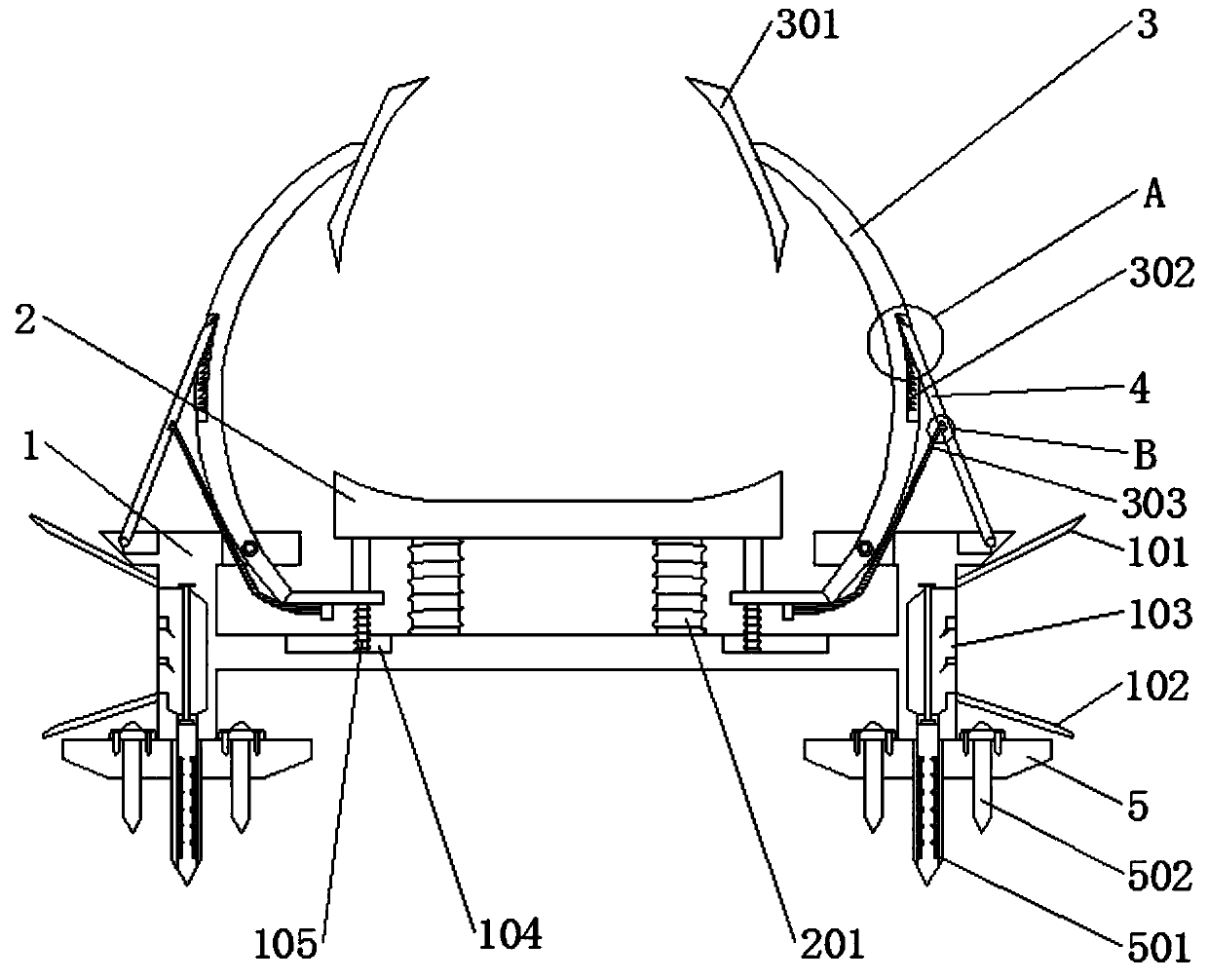

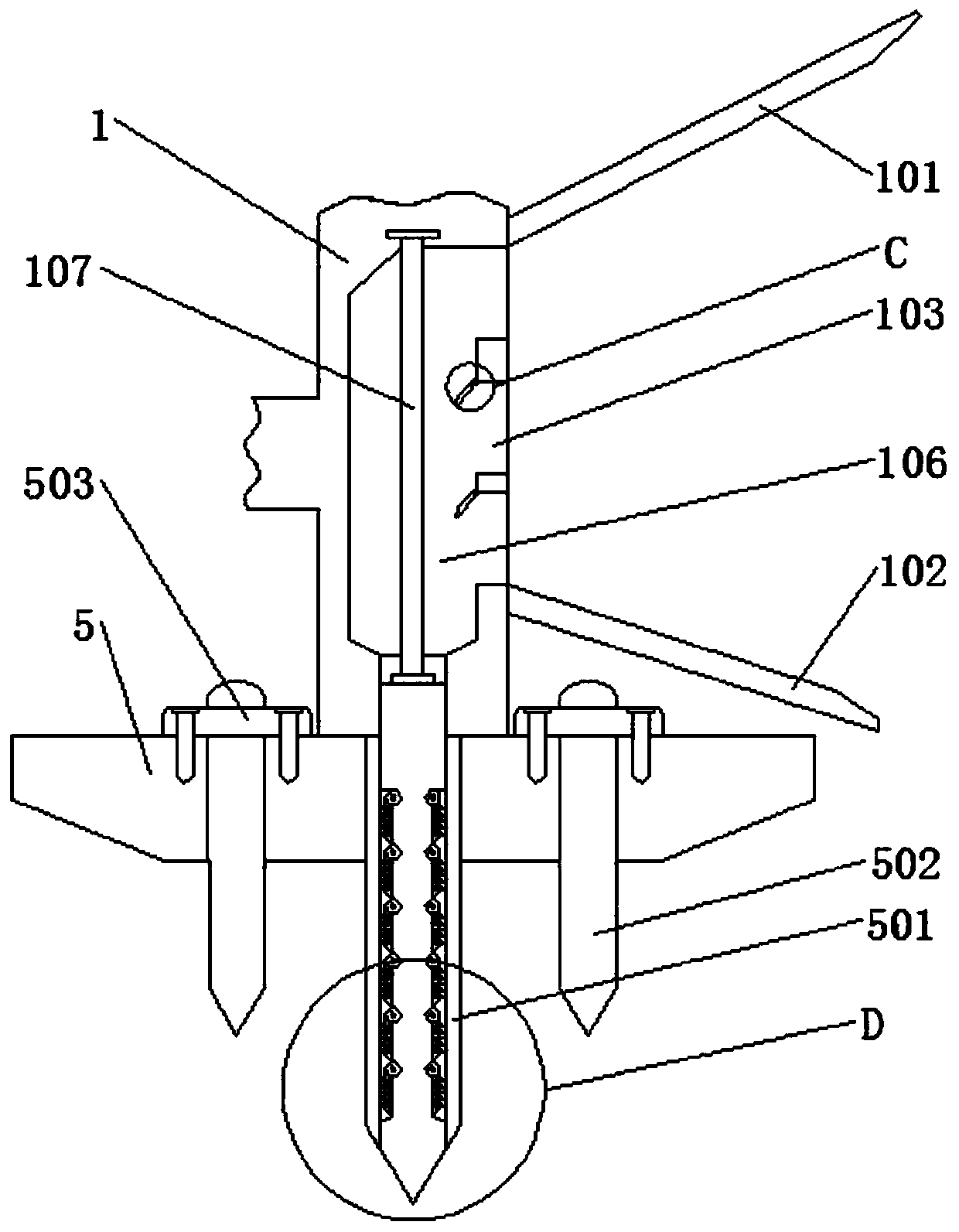

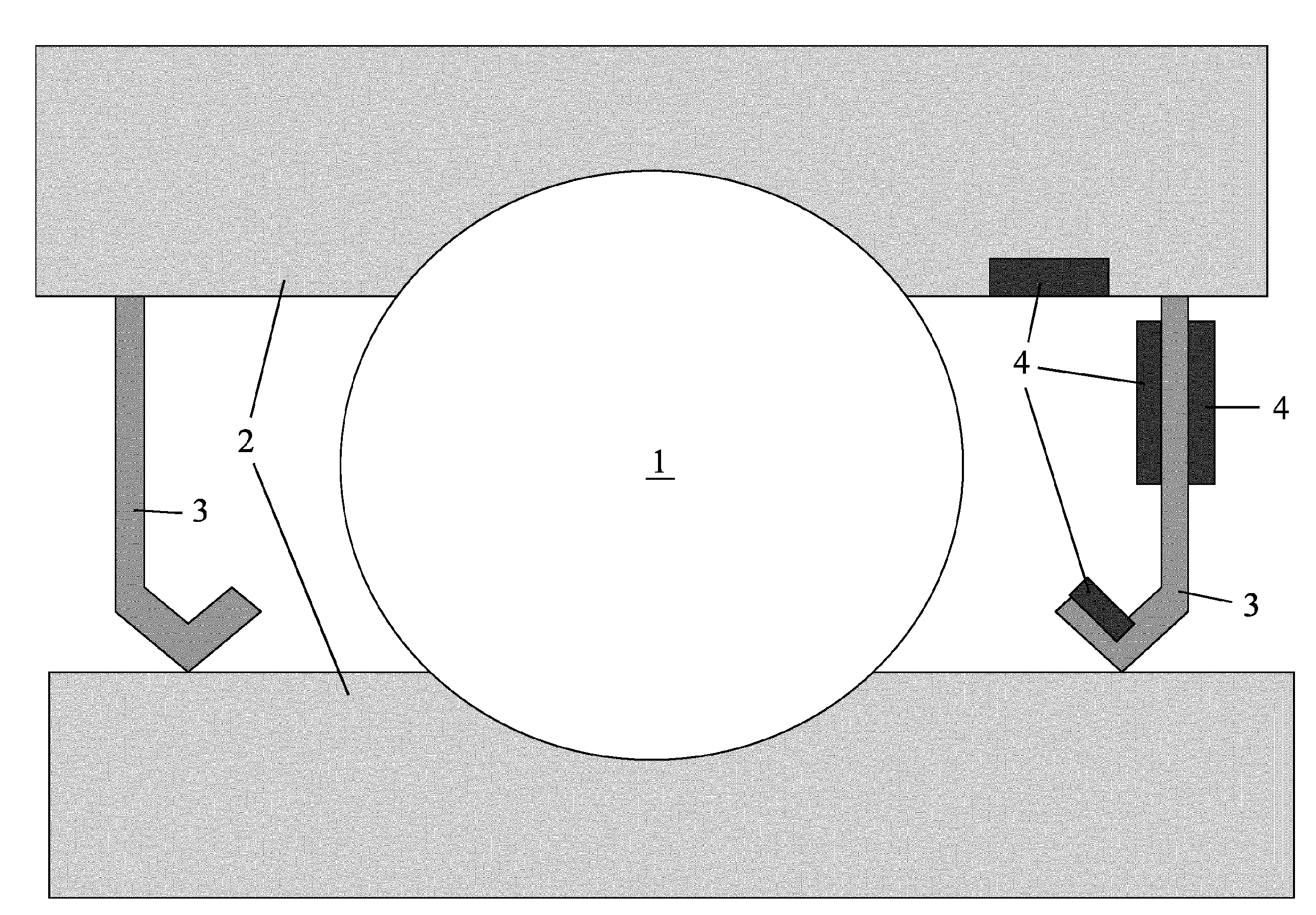

Marine engineering submarine pipeline erecting device

ActiveCN109882661AEasy to fixAvoid affecting the support and fixationPipe supportsEngineeringSubmarine pipeline

The invention provides a marine engineering submarine pipeline erecting device. The device comprises a supporting under-frame, a middle supporting plate, side supporting plates, buckling plates and bottom plates, wherein the top end of the supporting under-frame is movably connected with a middle supporting plate through spring columns, the side supporting plates are movably connected to the middle parts of the left side and the right side of the supporting under-frame through rotating shafts, buckling plates are movably connected to the top ends of the left side and the right side of the supporting under-frame, the bottom plates are welded to the left side and the right side of the bottom end of the supporting under-frame, upper flow guide plates are welded to the top ends of the left side and the right side of the supporting under-frame, lower flow guide plates are welded to the bottom ends of the left side and the right side of the support under-frame, guide holes are embedded in the middle parts of the left side and the right side of the support under-frame, the left side and the right side of the top end of the supporting under-frame are embedded with movable grooves, the middle of the movable grooves are fixedly connected with side spring columns, collecting chambers are embedded in the middle of the left end and the right end of the supporting under-frame, and anti-dropping elastic ropes are fixedly connected to the bottom ends of the middle of the collecting chambers. The device has the advantages that the structure is stable, the fixing capability is good, the ground grabbing force can be improved along with the increase of the potential flow, and the mounting and fixing operation is convenient.

Owner:浙江华勘海洋工程有限公司

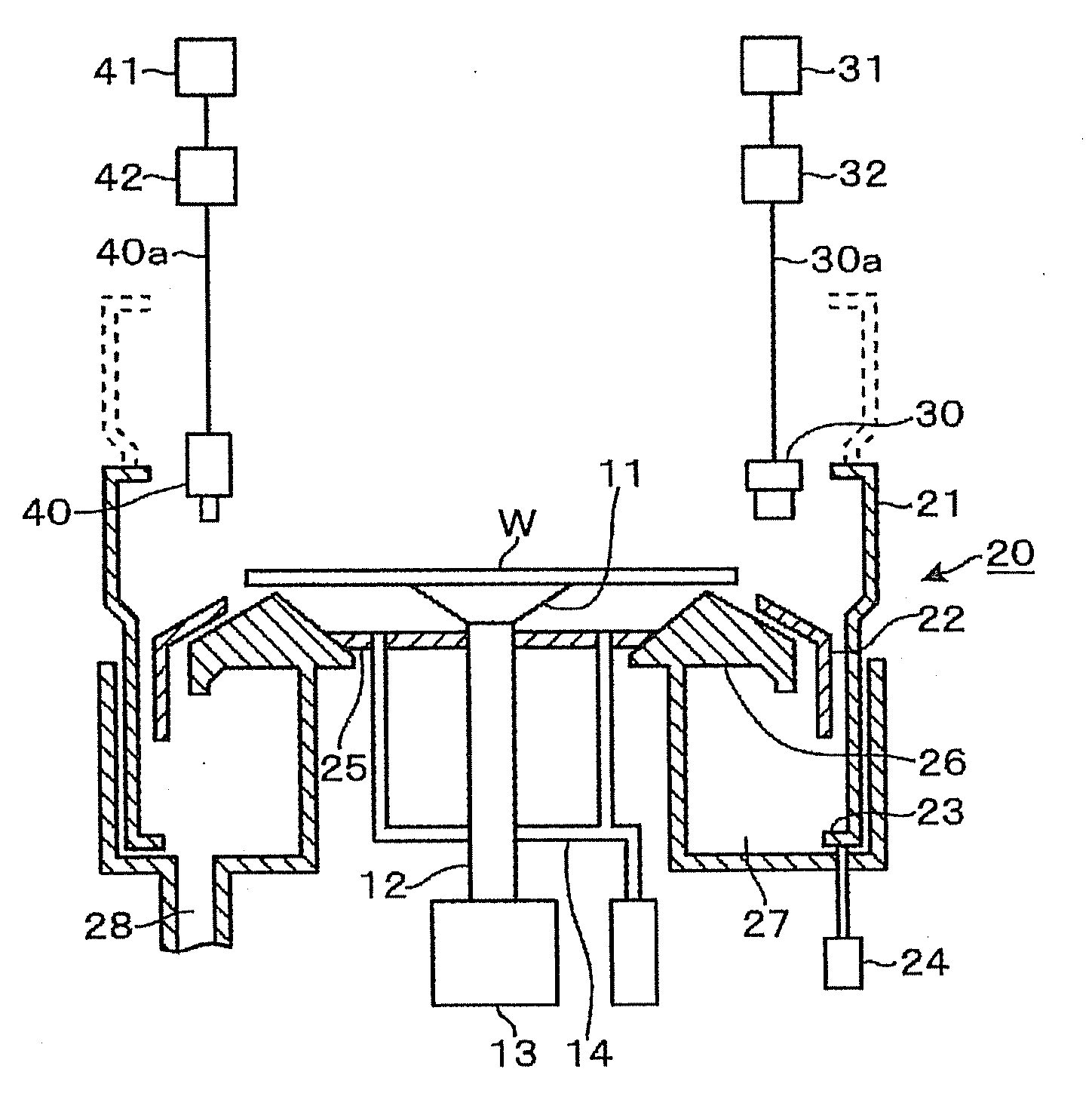

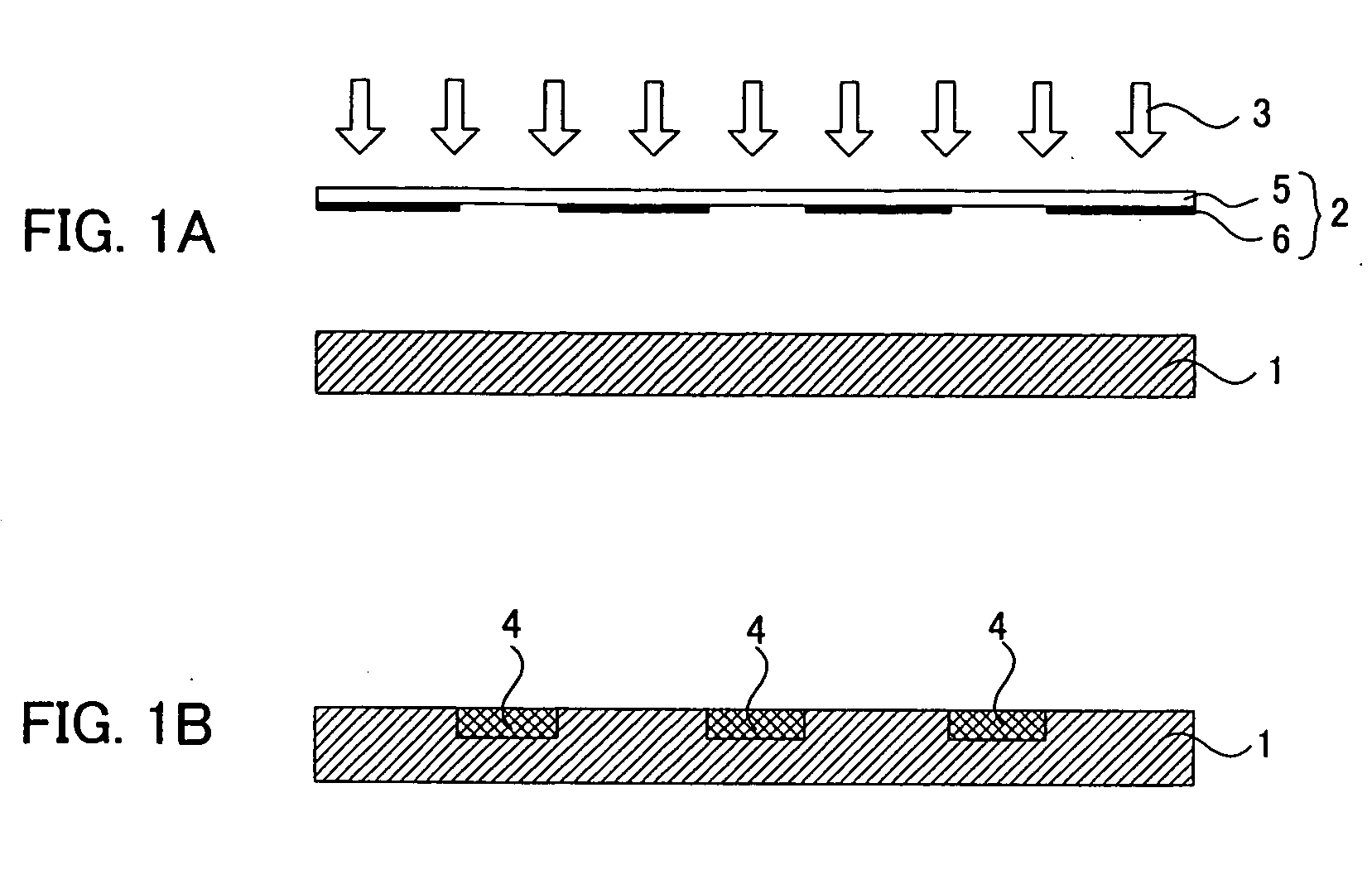

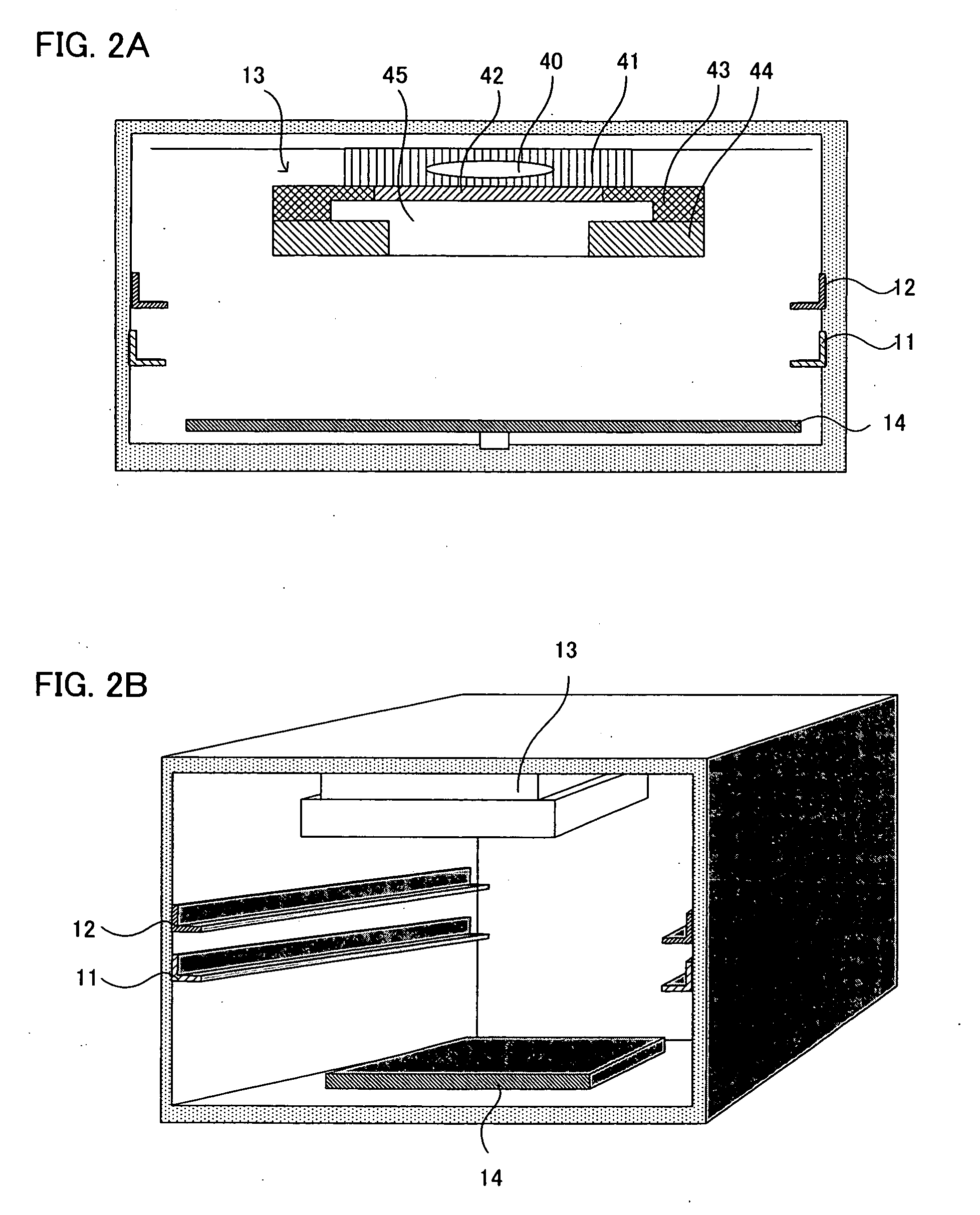

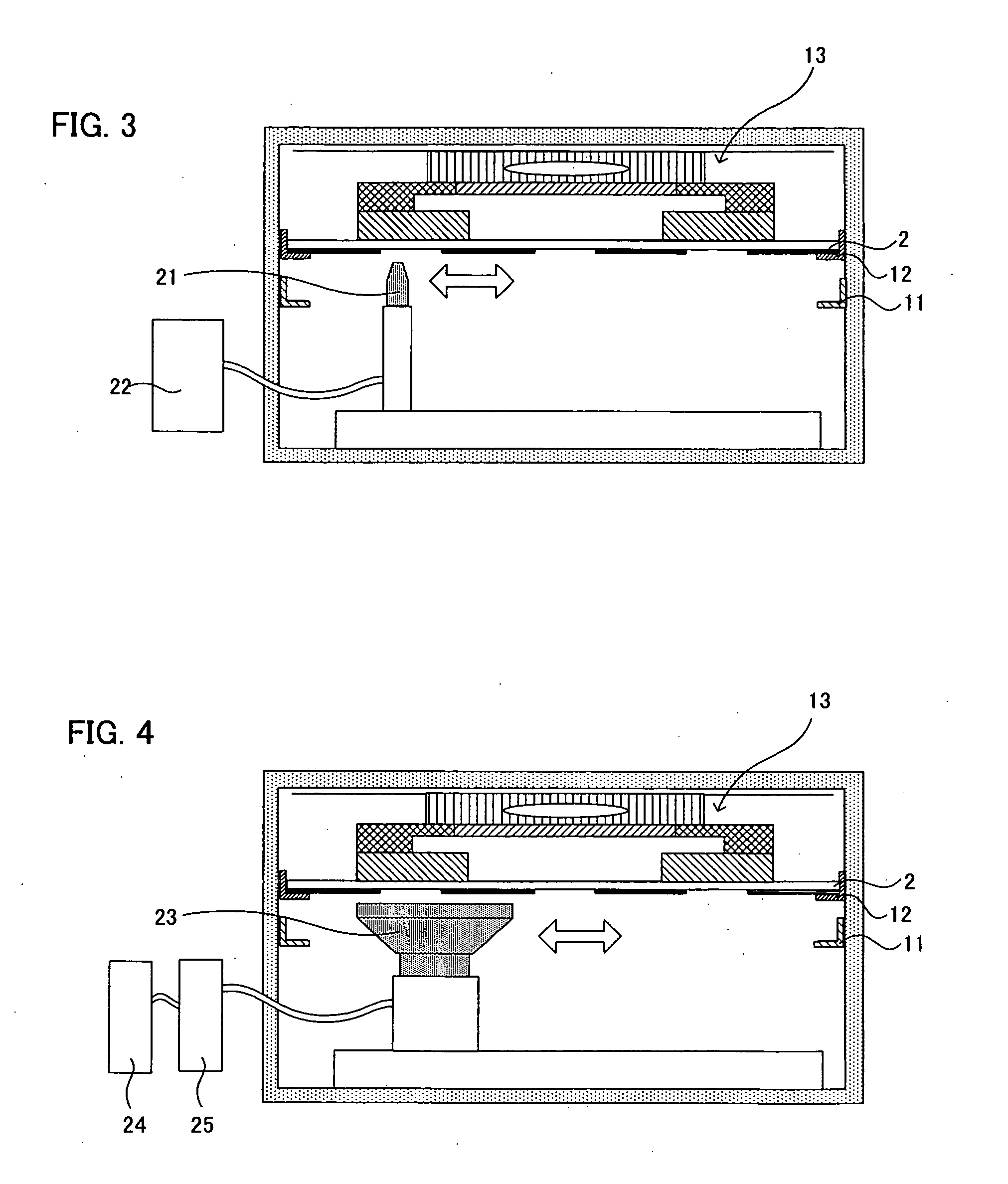

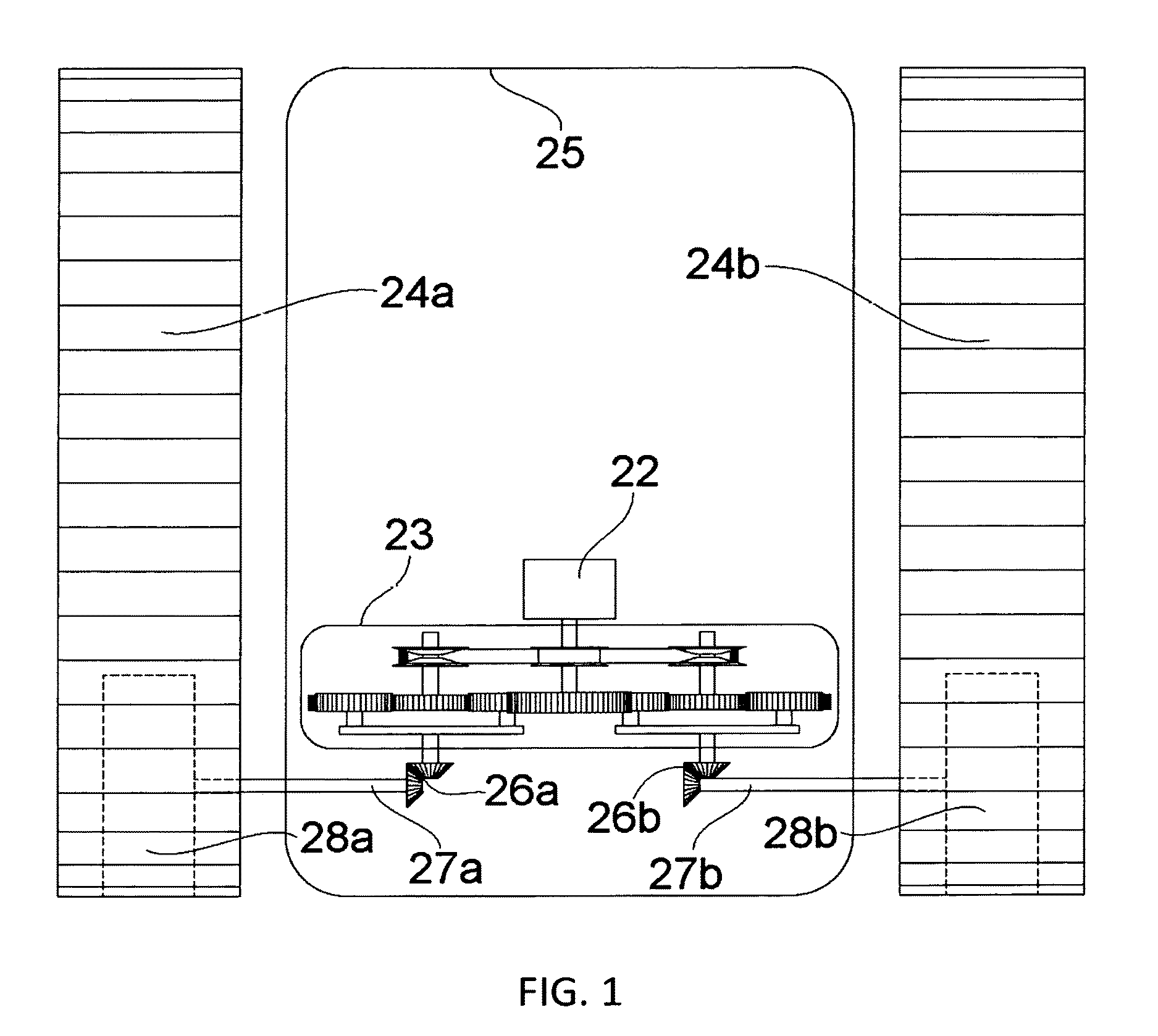

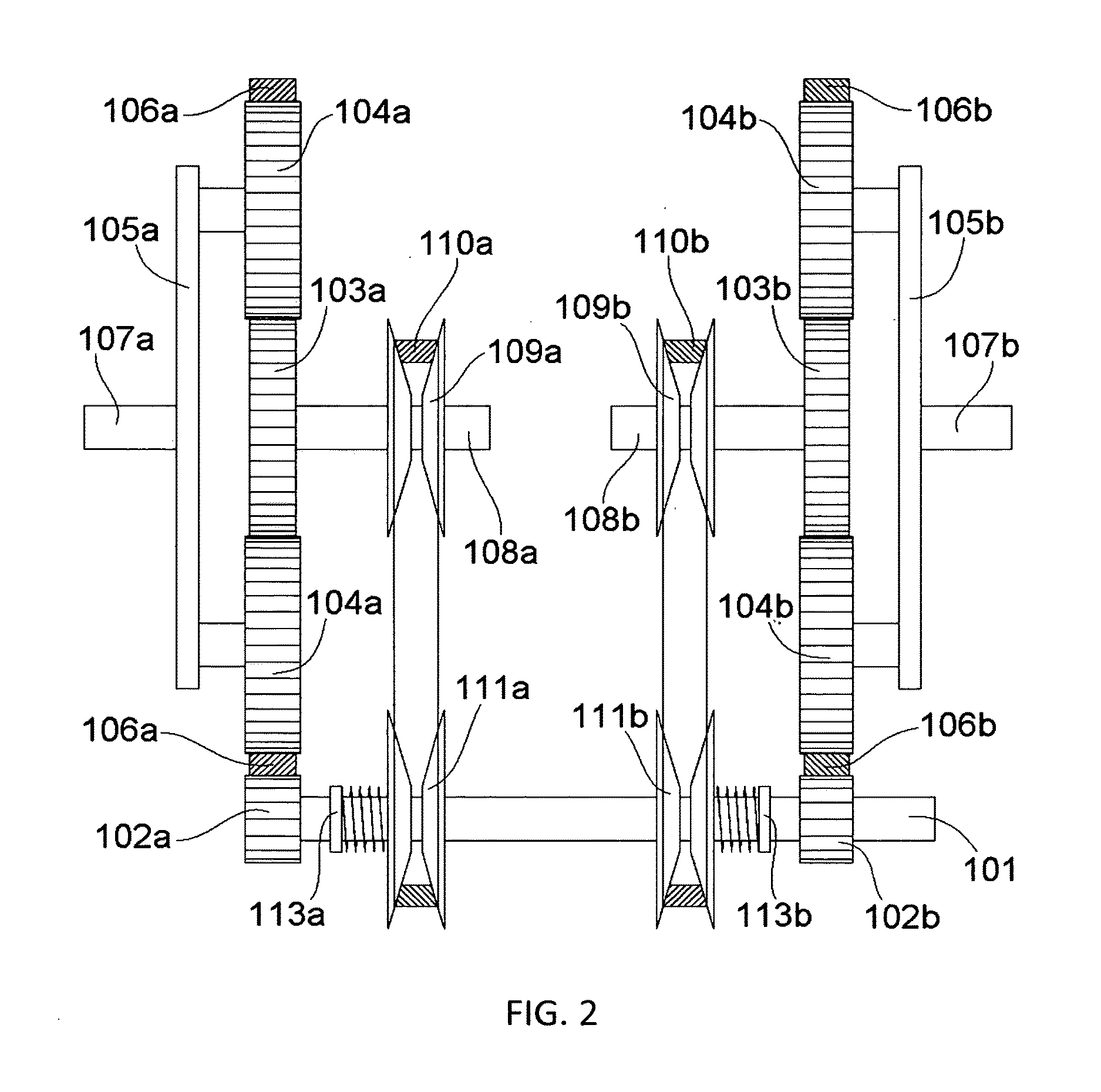

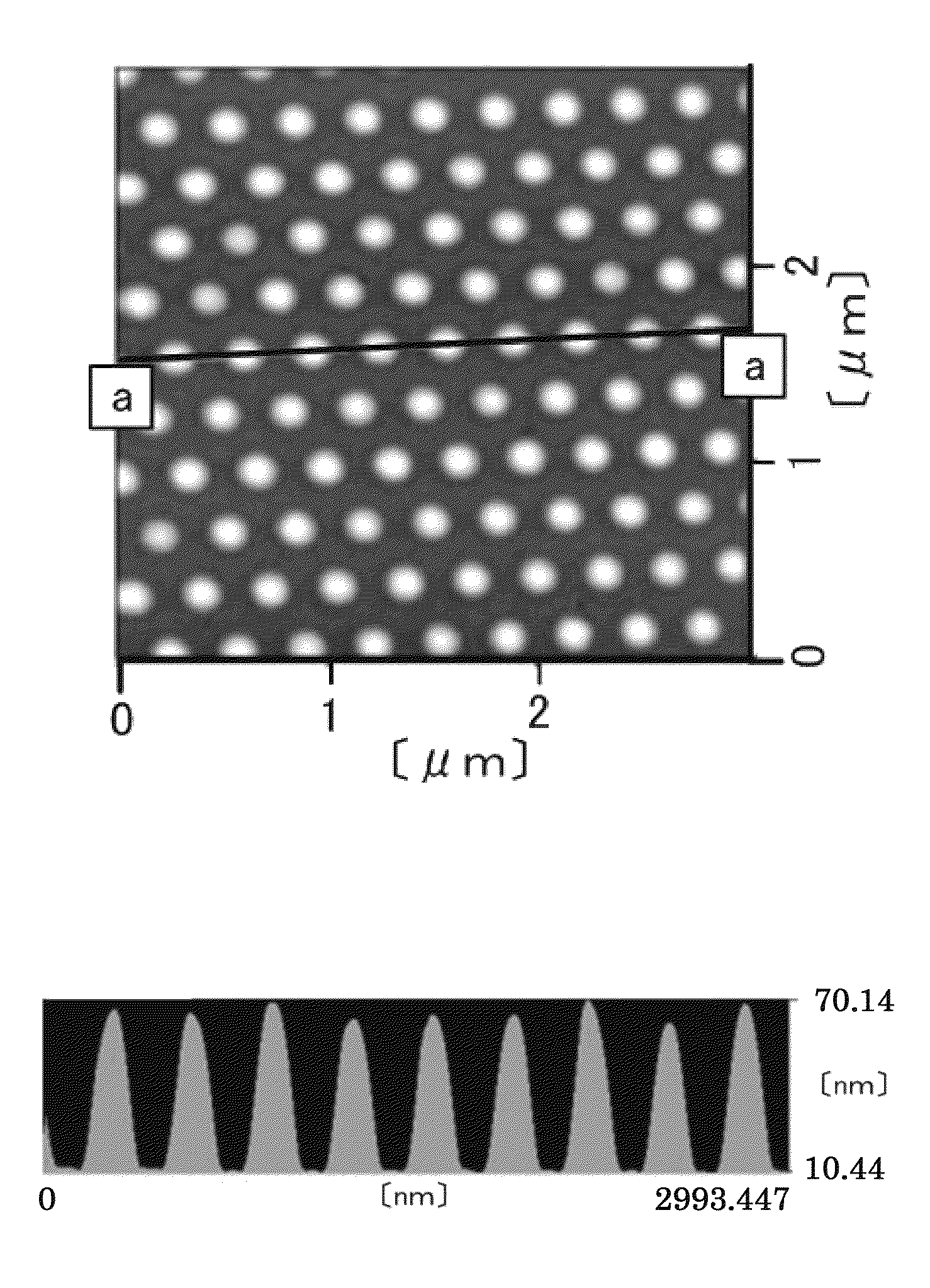

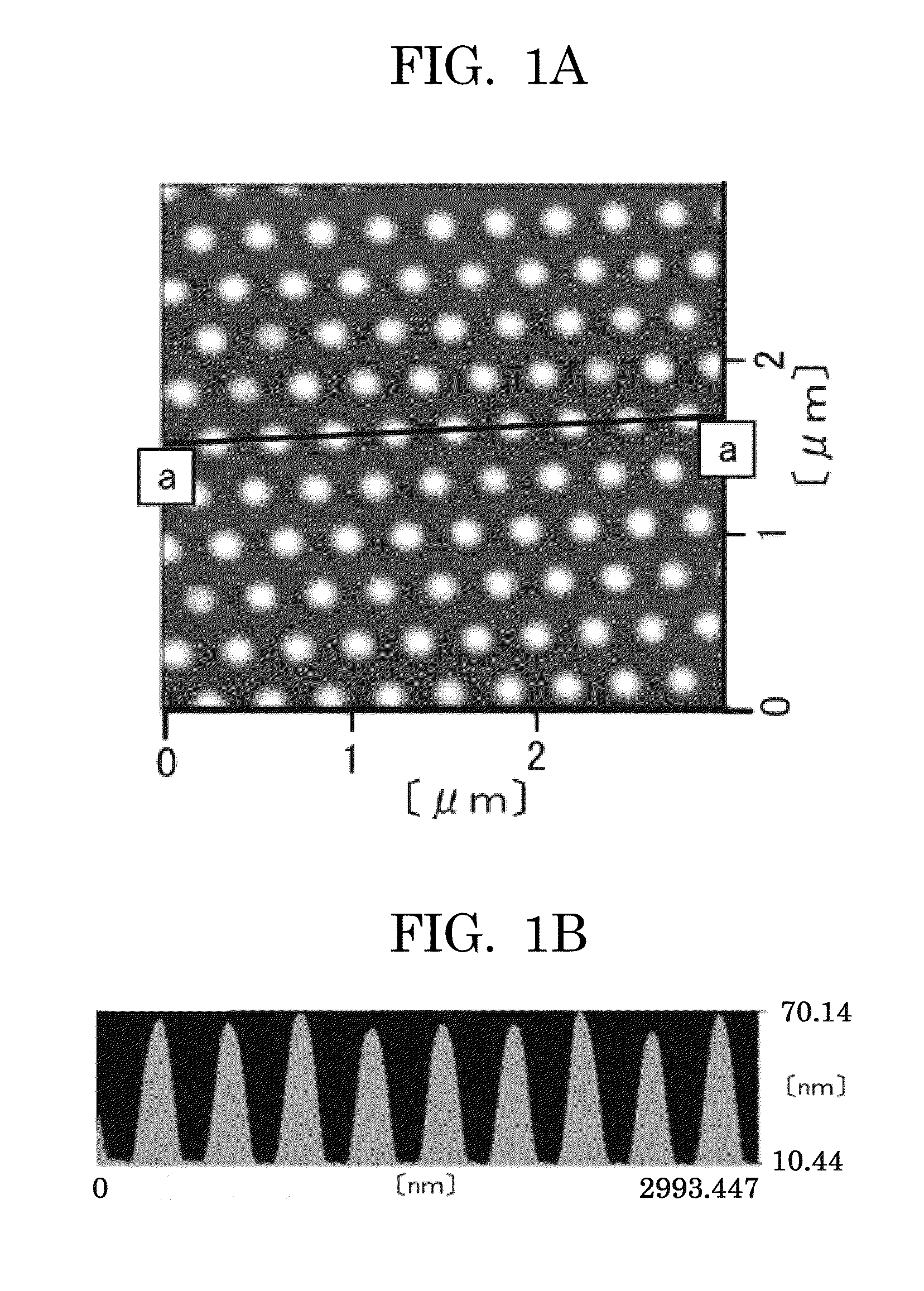

Manufacturing method of pattern formed body and pattern formed body manufacturing apparatus

InactiveUS20070128552A1Highly precise pattern formImprove wettabilityPhoto-taking processesOptical filtersForeign matterRepeat pattern

A main object of the invention is to provide a a manufacturing method of a plurality of pattern formed bodies which makes it possible that even if the pattern formed bodies are continuously manufactured, their property varied patterns are each made into a target pattern form with high precision; and a pattern formed body manufacturing apparatus used in the manufacturing method. To achieve the object, the invention provides a manufacturing method of a plurality of pattern formed bodies comprising a pattern forming step and a foreign matter removing step, wherein the pattern forming step is a step of radiating vacuum-ultraviolet light through a photomask to a pattern forming substrate, varying a surface property by the vacuum-ultraviolet light, and forming a property varied pattern with the property varied on a surface of the pattern forming substrate to form a pattern formed body; the pattern forming step is repeated plural times to manufacture a plurality of the pattern formed bodies; and the foreign matter removing step is a step of removing a foreign matter deposited to the photomask performed between the repeated pattern forming steps.

Owner:DAI NIPPON PRINTING CO LTD

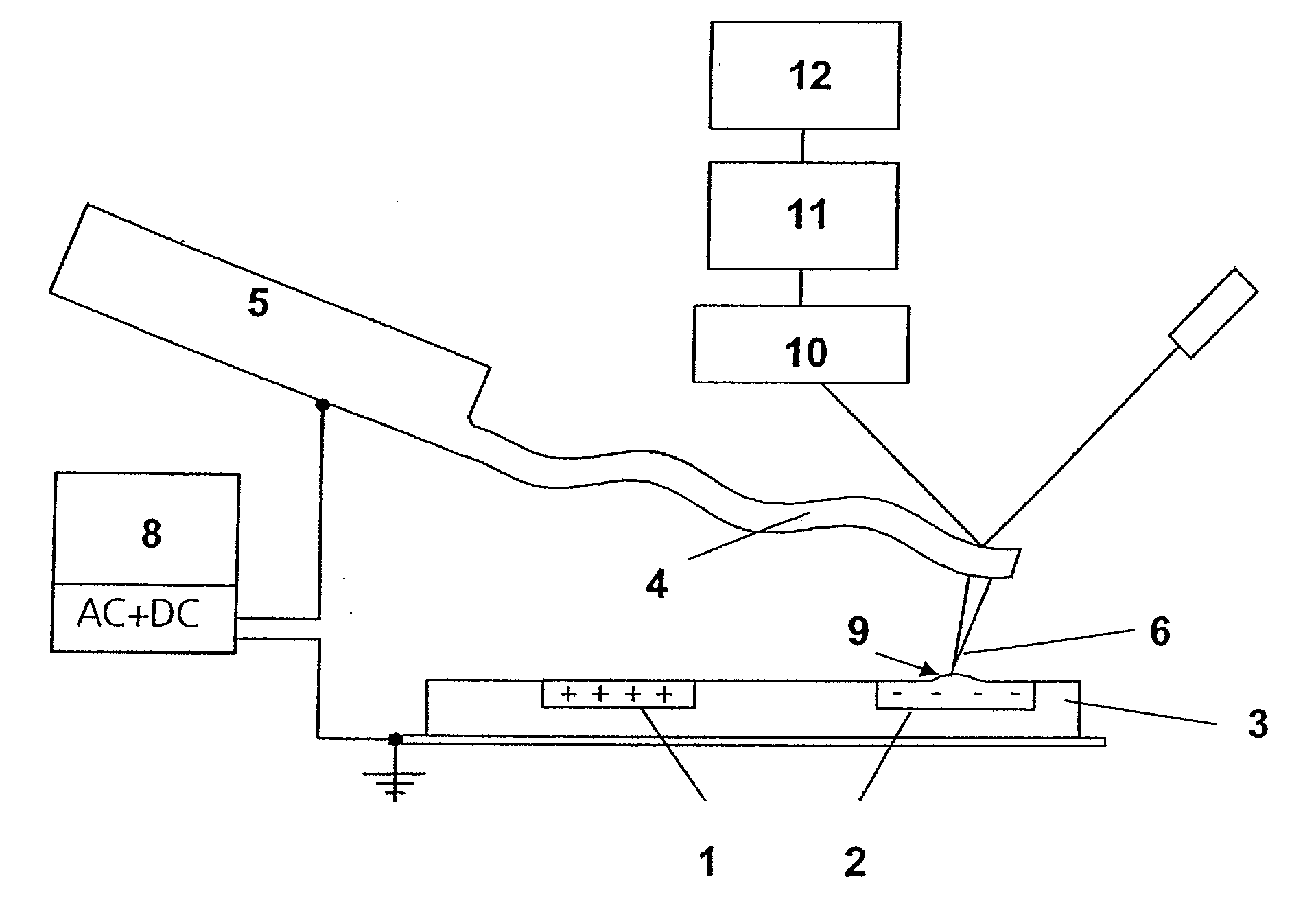

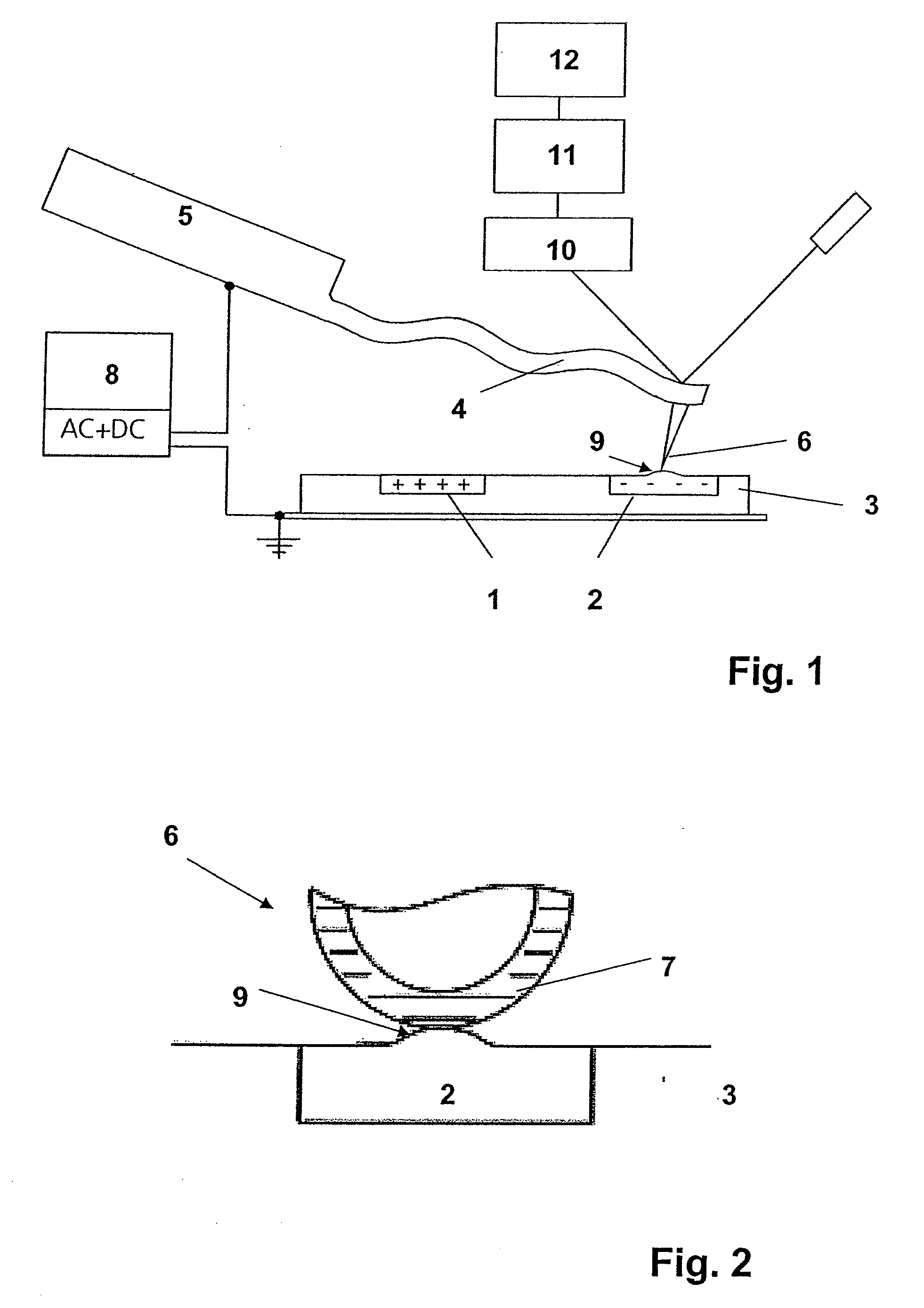

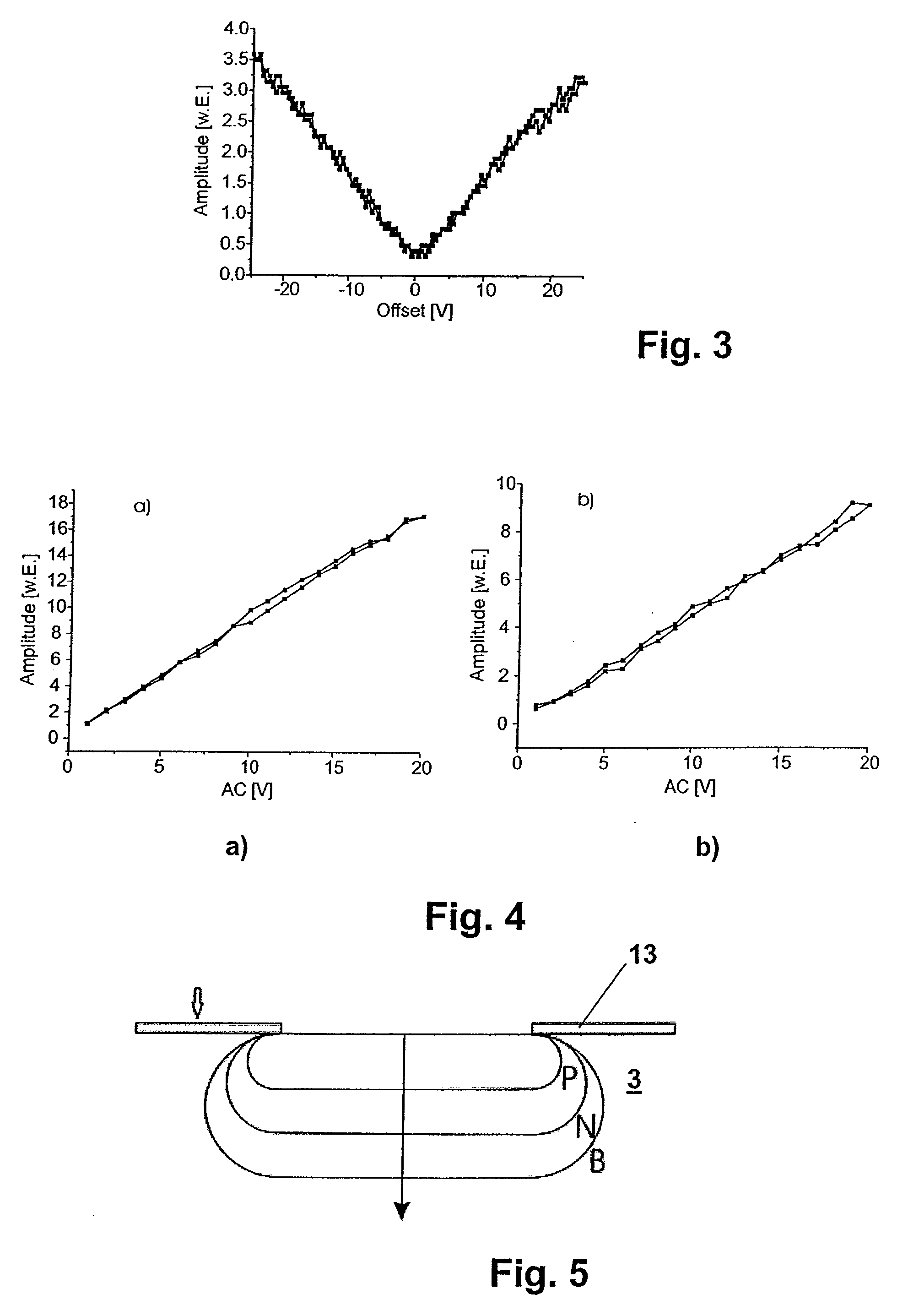

Method for determining a dopant concentration in a semiconductor sample

InactiveUS20090100554A1Size can be large or smallSmall contact radiusSurface/boundary effectNanotechnologyDopantSchottky barrier

A method is described for determining a dopant concentration on a surface and / or in layer region lying close to the surface of a semiconductor sample using an atomic force microscope, whose leaf-spring tip is brought into contact with the semiconductor sample, forming a Schottky barrier, wherein an electric alternating potential is applied between the spring-leaf tip and the semiconductor sample in the region of the Schottky barrier in such a way that a space charge region inside the semiconductor sample defining the three-dimensional extension of the Schottky barrier is excited and begins to oscillate within the confines of its spatial extension, said oscillations are transmitted to the leaf-spring, are detected and form the basis for determining the dopant concentration.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Solution applying apparatus and method

InactiveUS20050064641A1Good solution circulationPromote circulationSemiconductor/solid-state device manufacturingResistUltraviolet lights

In etching using an etching solution, irradiating ultraviolet light is irradiated into a resist patterned on an etching substrate or a film formed on the etching substrate and then an etching solution is applied to the etching substrate while rotating the etching substrate. Also, ozone water is applied in contact with the resist and then an etching solution is applied to the etching substrate while rotating the etching substrate. In crystallization using a metal element such as nickel for promoting crystallization of silicon, irradiating ultraviolet light is irradiated into a resist patterned on an substrate or a film formed on the substrate and then a nickel solution is applied to the substrate while rotating the substrate. Also, ozone water is applied in contact with the resist and then the nickel solution is applied to the substrate while rotating the substrate.

Owner:SEMICON ENERGY LAB CO LTD

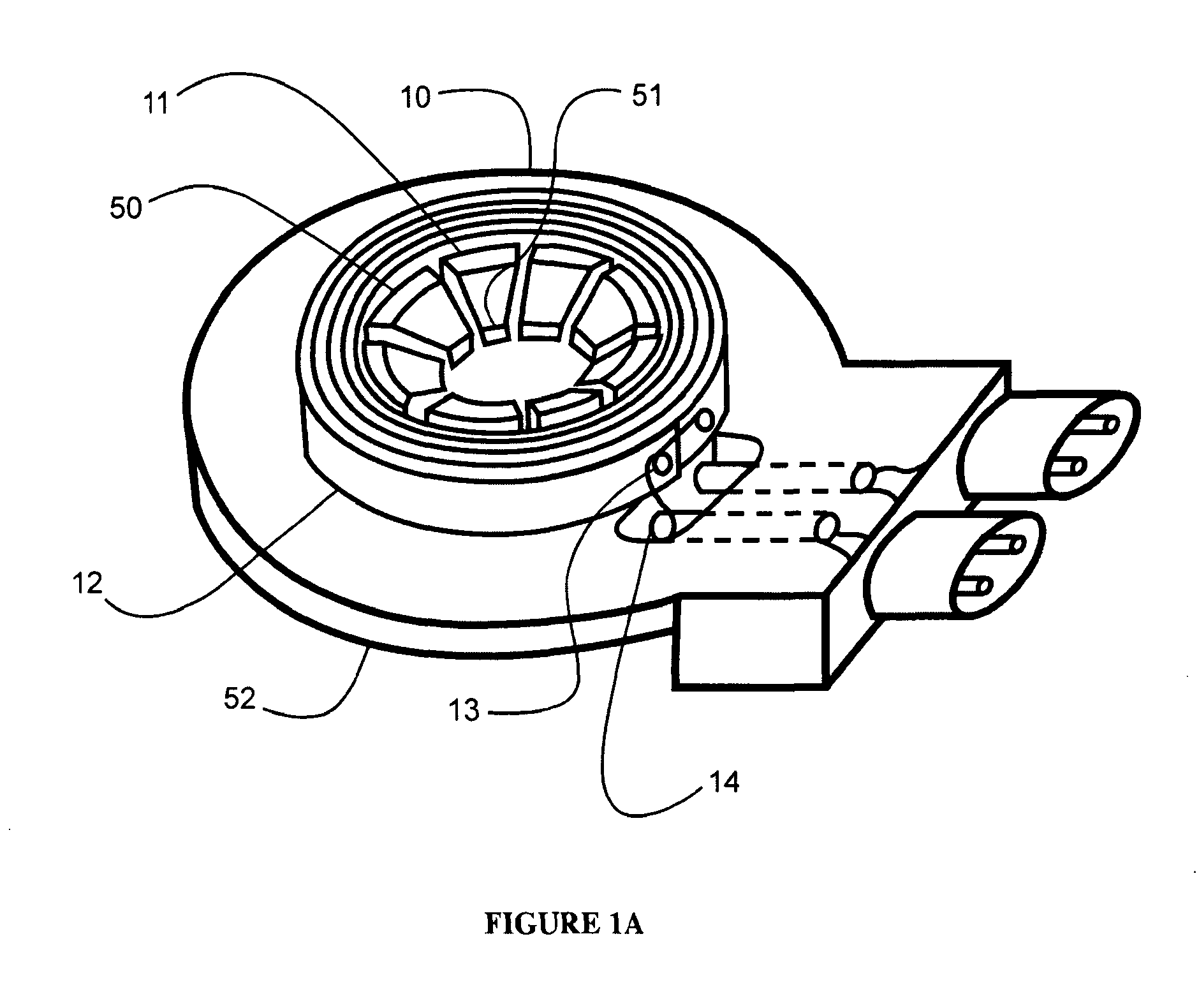

Radial release device

ActiveUS20100005913A1Prevent radial movementLow profileCosmonautic vehiclesGearing controlRadial motionEngineering

A release device having a multi-segment split spool with a central bore adapted to axially restrain a tensioned member. A tensioned tape is overlappingly wound around the spool segments thereby preventing radial movement of the spool segments. The overlapping winding allows for a low profile housing for the release device. The multiple segments require less radial motion for release of the tensioned member.

Owner:MAXAR SPACE LLC

Coating treatment method, computer-readable storage medium, and coating treatment apparatus

InactiveUS20090226621A1Improve wettabilitySmall contact anglePretreated surfacesSemiconductor/solid-state device manufacturingWater solubleMaterials science

The present invention is a coating treatment method of applying a water-soluble coating solution onto a substrate, including: a first step of supplying pure water to a central portion of the substrate in a manner that the pure water does not diffuse over an entire surface of the substrate; a second step of subsequently supplying the water-soluble coating solution to a central portion of the pure water on the substrate to form a mixed layer of the coating solution and the pure water, under the coating solution; and a third step of subsequently diffusing the mixed layer over the substrate to diffuse the coating solution over the entire surface of the substrate.

Owner:TOKYO ELECTRON LTD

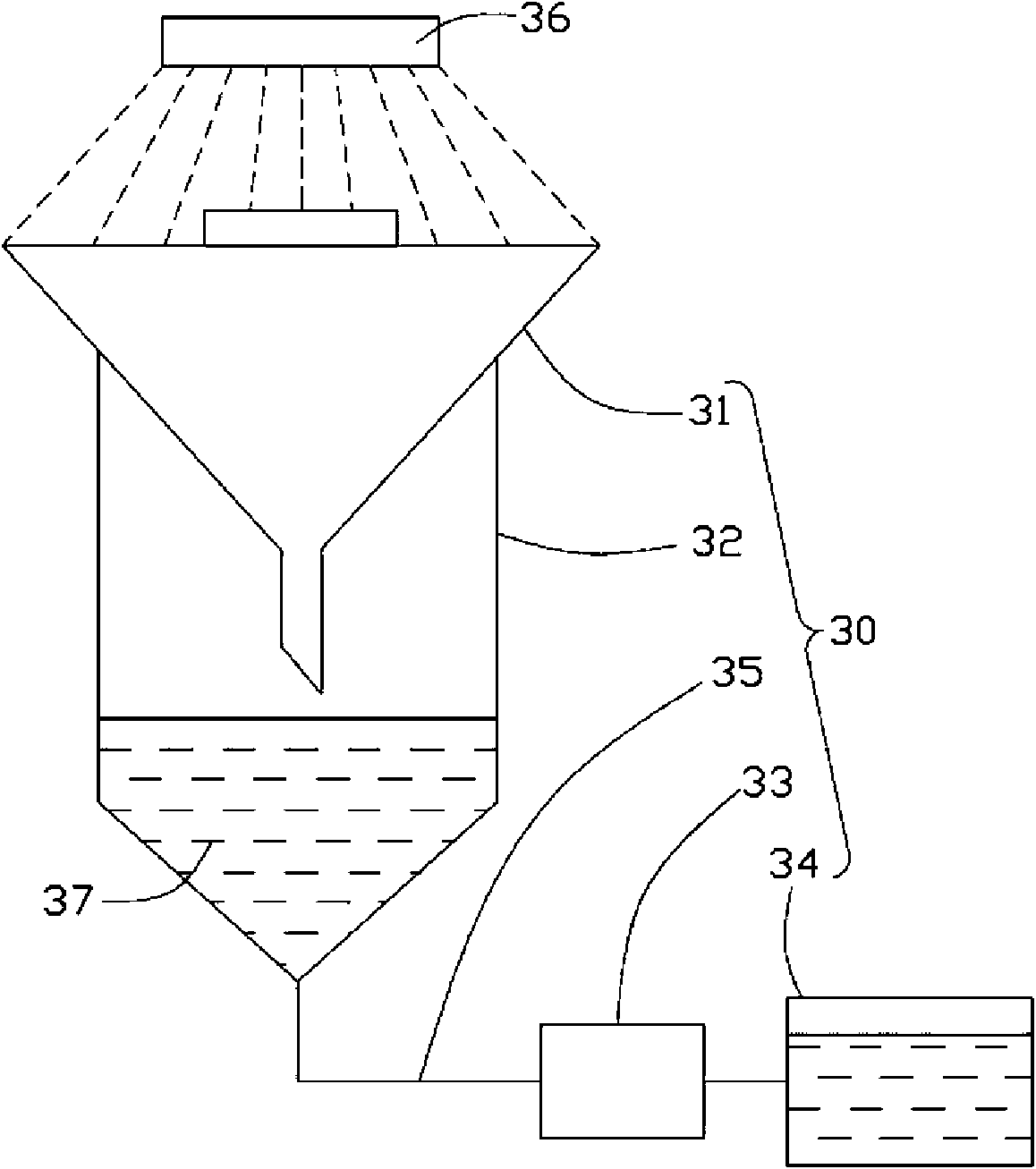

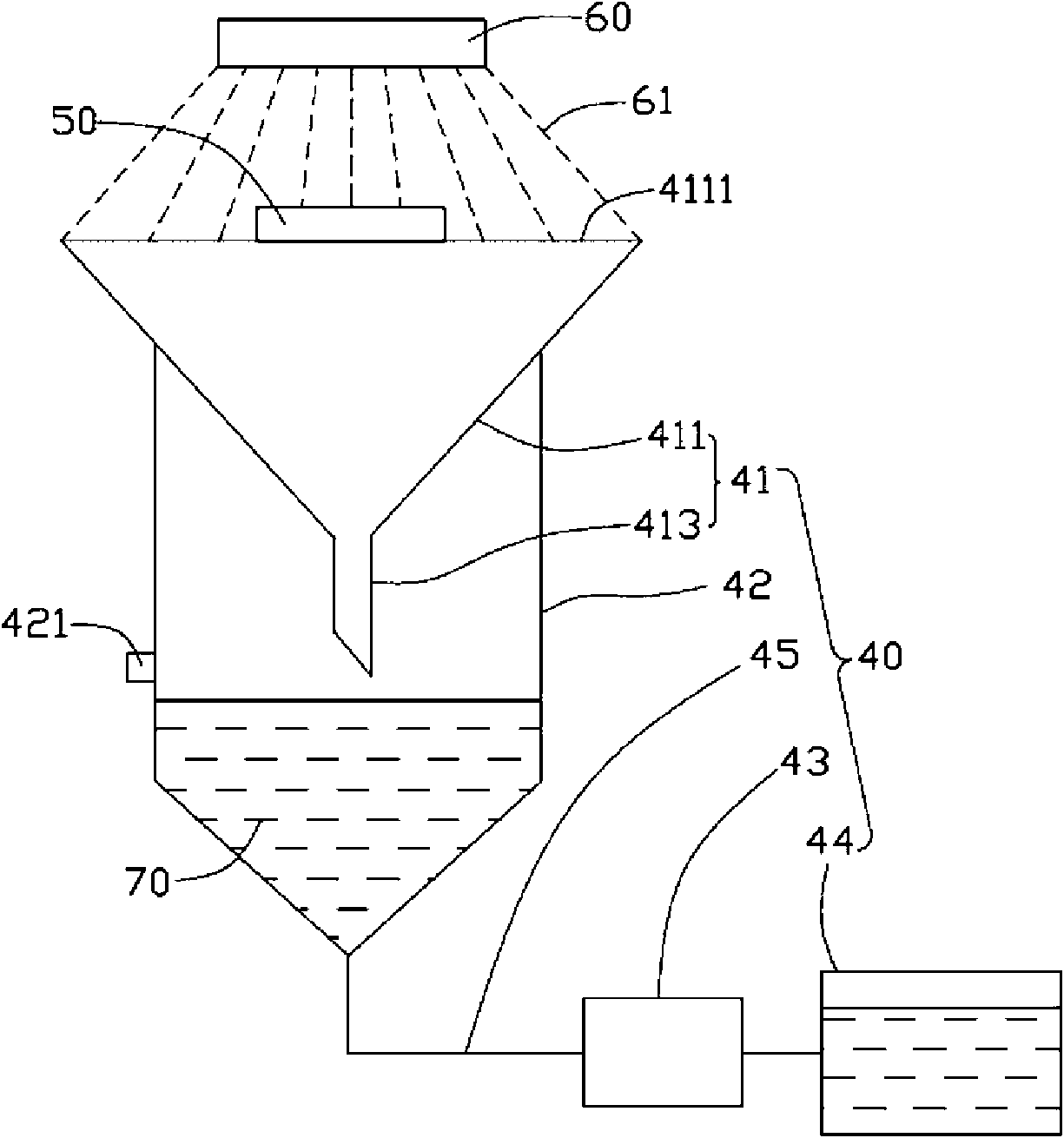

Liquid recovery device and liquid recovery method by using same

InactiveCN102078847AAvoid empty pumpingViscosity will not be too highLiquid surface applicatorsSpraying apparatusRecovery methodPulp and paper industry

The invention relates to a liquid recovery device which comprises a collection box, a recovery pump, a liquid storage bottle and a pipeline sequentially communicated with the collection box, the recovery pump and the liquid storage bottle, wherein in a recovery process, the recovery pump is periodically opened and closed. When the liquid recovery device is used for recovering liquid, the recovery rate and the quality of recovery liquid can be guaranteed. The invention also provides a liquid recovery method by using the recovery device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

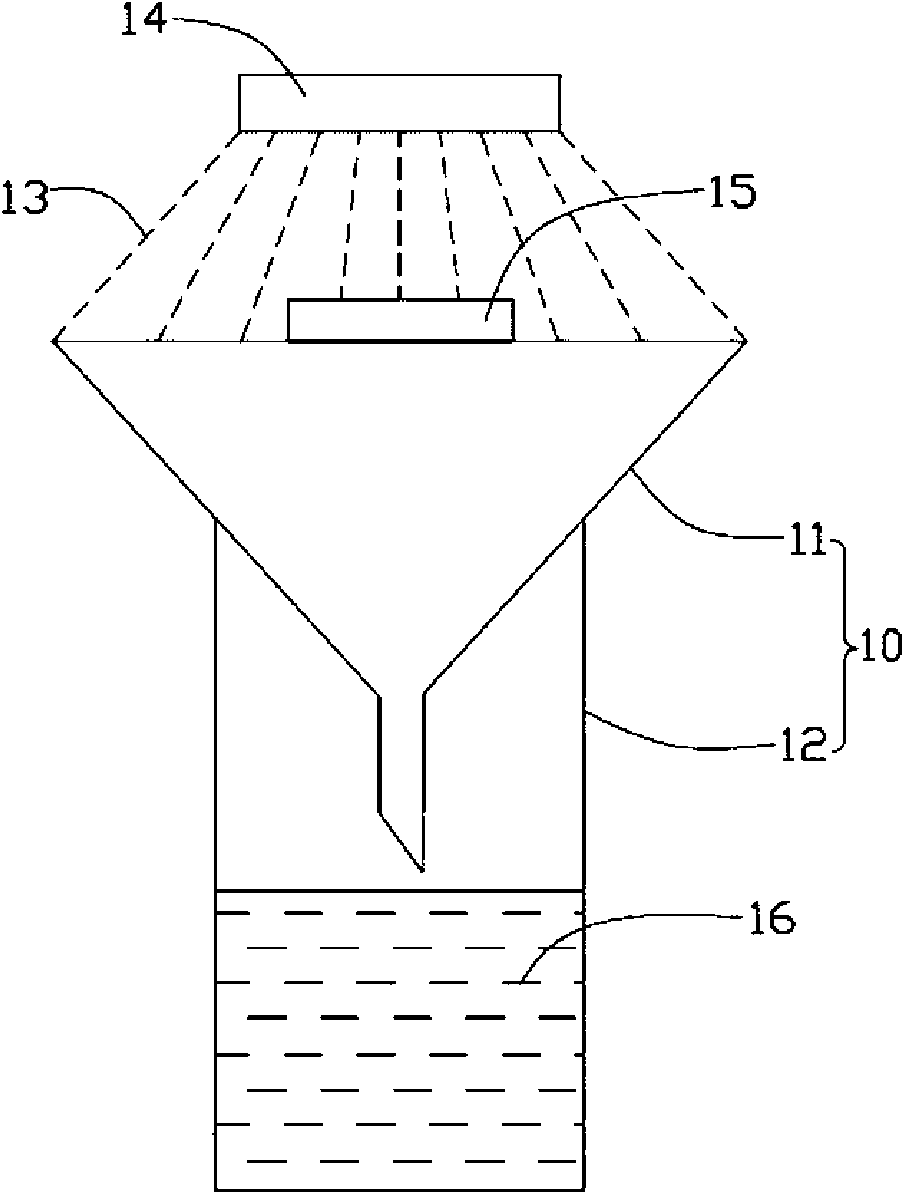

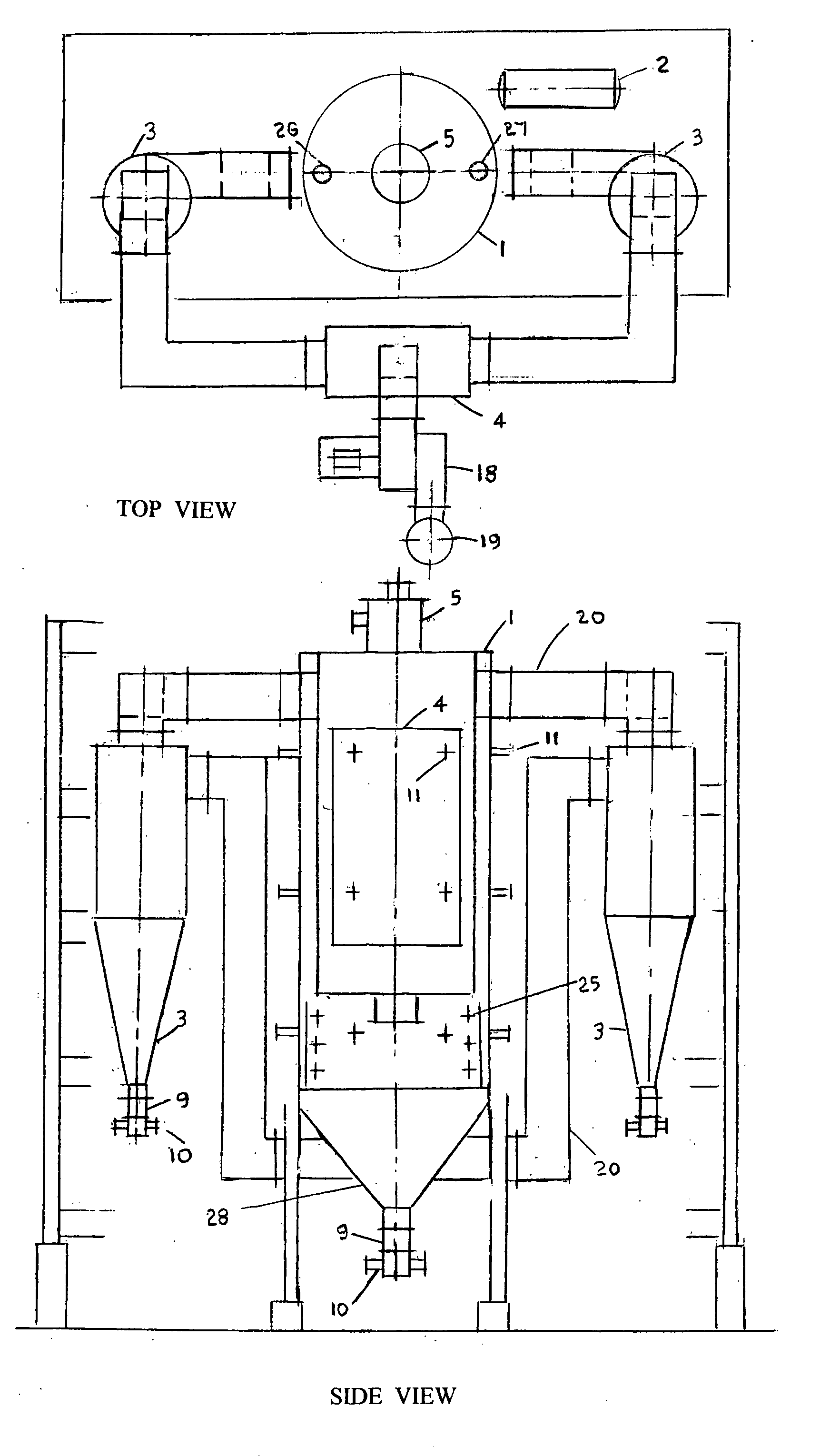

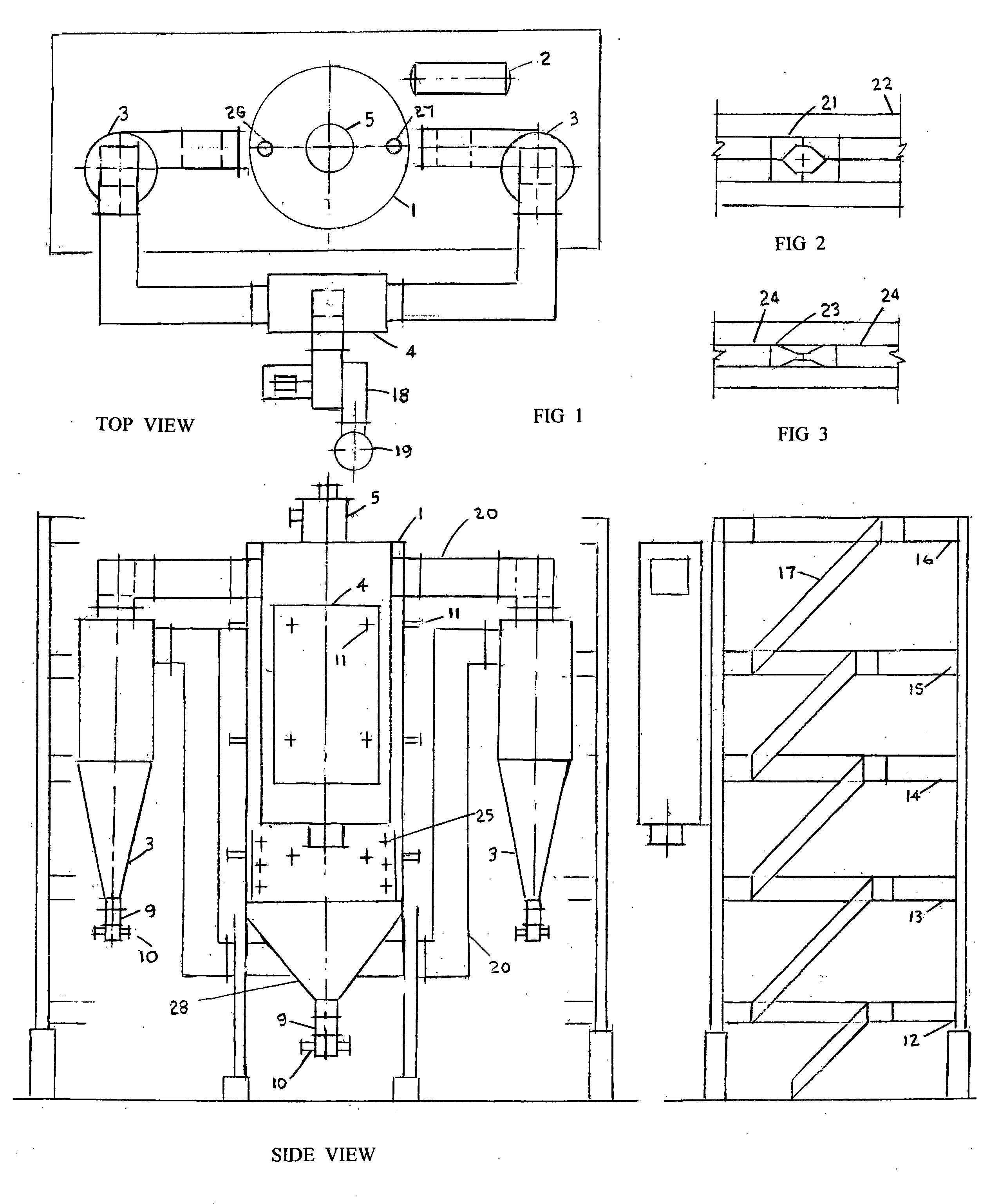

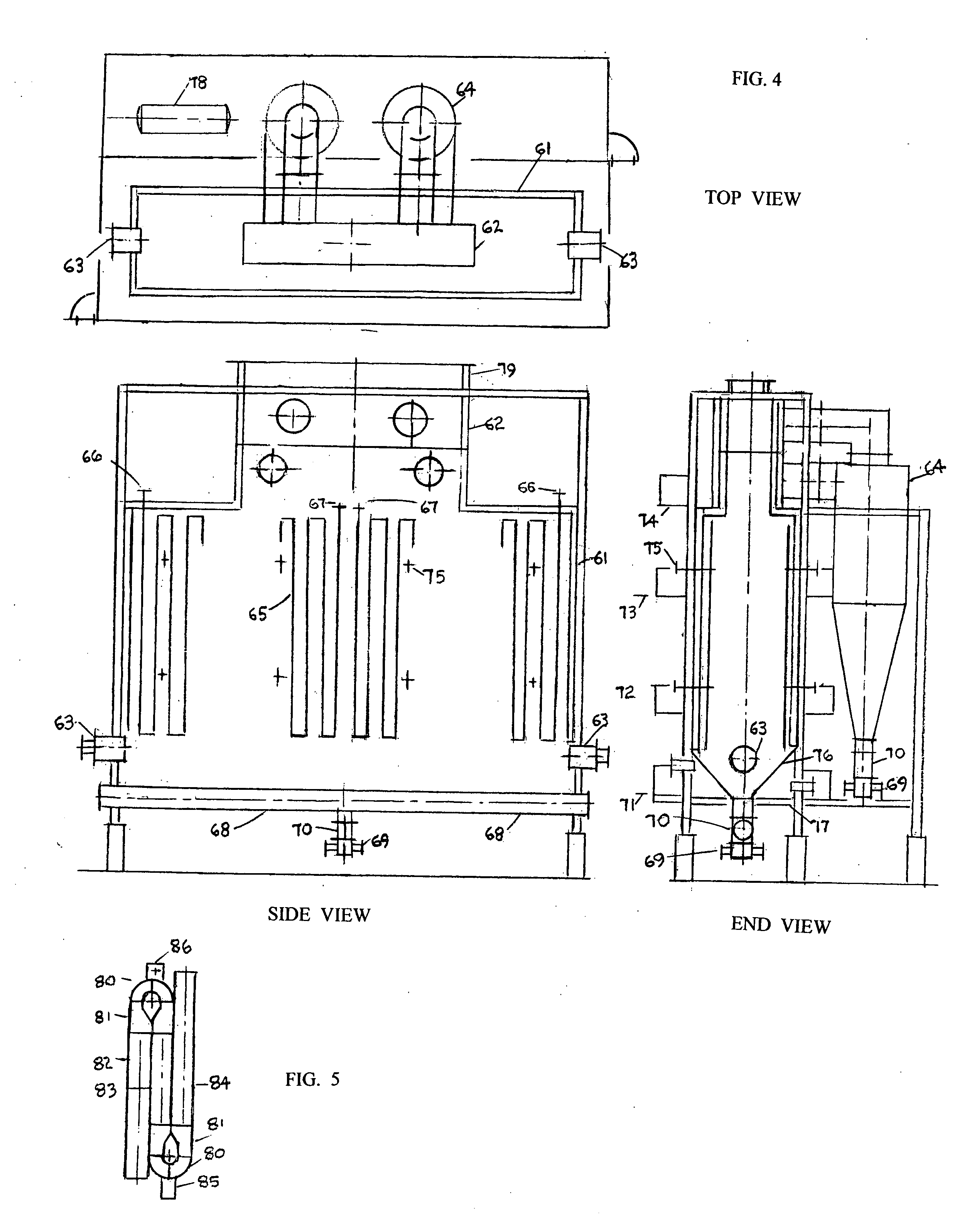

Coal fired process heaters

InactiveUS20080271657A1Interaction is limitedAvoid large contactCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelVertical tubeParticulates

One embodiment of the invention consists of a vertical cylindrical process heater with an overhead convection section, a radiant section containing a contiguous, helical, down flow, tubular radiant coil, and one or more top, downward fired, pulverized coal burners. A second embodiment consists of a cabin type heater having a radiant section of rectangular cross section, a contiguous vertical tube serpentine coil, an overhead convection section, and one or more bottom, horizontally fired, pulverized coal, end wall burners. A third embodiment consists of a process heater with a radiant section and overhead convection section, the radiant section having a vertical cylindrical, contiguous, helical, down-flow tubular coil, contained in a refractory lined enclosure of square cross-section. A continuous chain grate coal stoker is provided at the base of the radiant section. A coarse coal feed with a minimum of fines is fed thru a hopper located at one end of the traveling chain grate and essentially coal free ash is removed at the opposite end of the chain grate, thru a nozzle provided with a water seal. One or more centrifugal solids-gas separators are provided at the radiant section flue gas outlets in the case of all three embodiments, for the purpose of removing ash particulates from the flue gas streams, before the latter enter the overhead convection sections. Since the flue gas enters the convection sections very nearly devoid of particulates, the convection sections may be of conventional design utilizing bare and / or finned tubes on closely spaced equilateral or quadrilateral centers.

Owner:CROSS ALAN

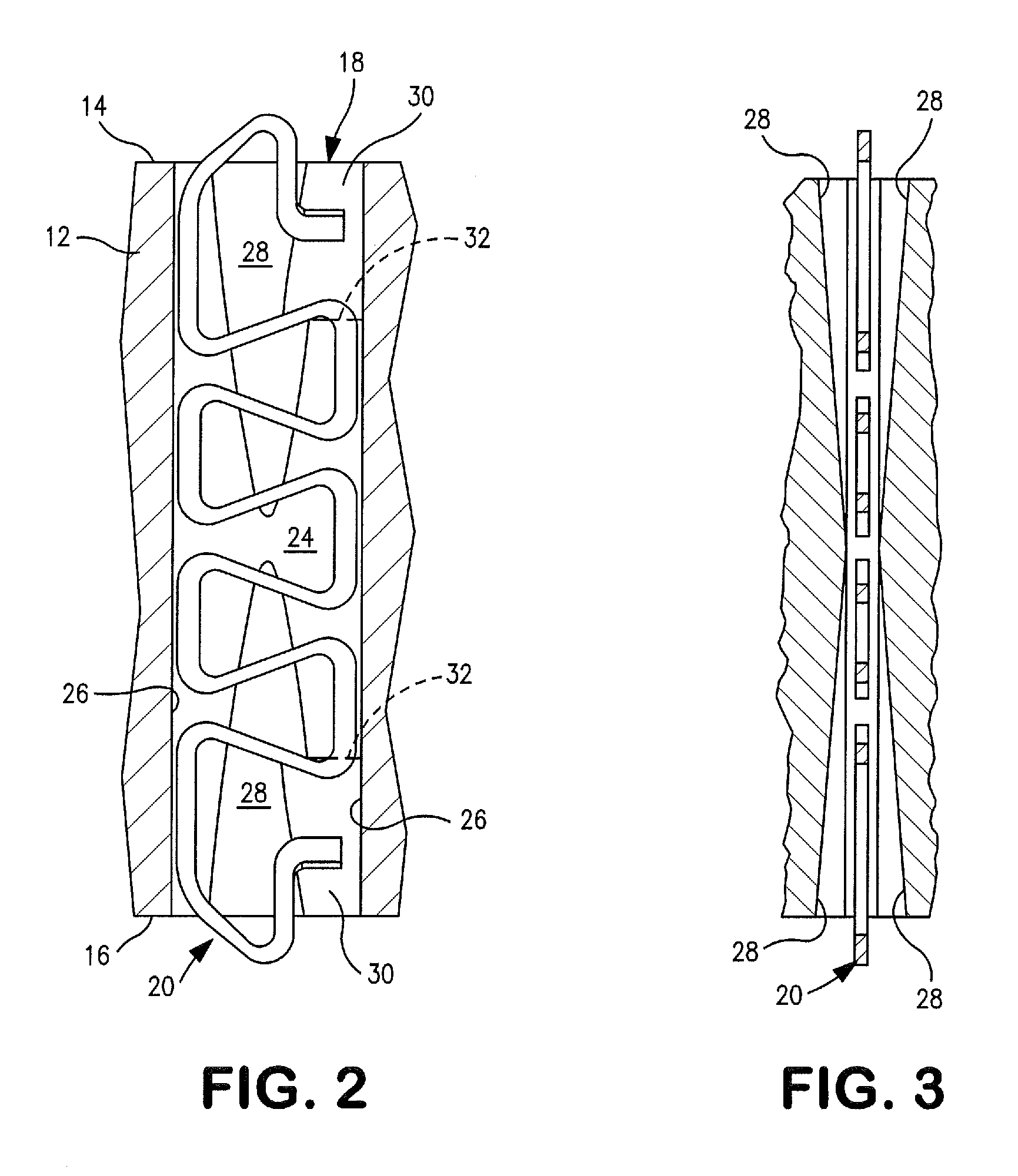

Interposer assembly with flat contacts

InactiveUS7775804B2Limited lateral shiftingAvoid large contactCoupling contact membersPrinted circuitsElectrical and Electronics engineeringEngineering

Interposer assembly includes an insulating plate with slots extending through the thickness of the plate and a flat metal contacts confined in the slots.

Owner:AMPHENOL CORP

Hydrophilic composition for use with a lubricating system as well as an apparatus and method for using the same

InactiveUS20130302609A1Wide choiceWide flexibilityMaterial nanotechnologyOther chemical processesFiberPolymer chemistry

A hydrophilic composition for use with a lubricating system comprises hydrophilic fibers having a diameter between 50 nm and 10 microns and a length that is at least 5 times the diameter. The hydrophilic fibers having a strong affinity for at least one of water and other hydrophilic fluids and may remove or eliminate free or dissolved water in a lubricating system comprising at least one of an oil and a lubricating fluid.

Owner:AB SKF

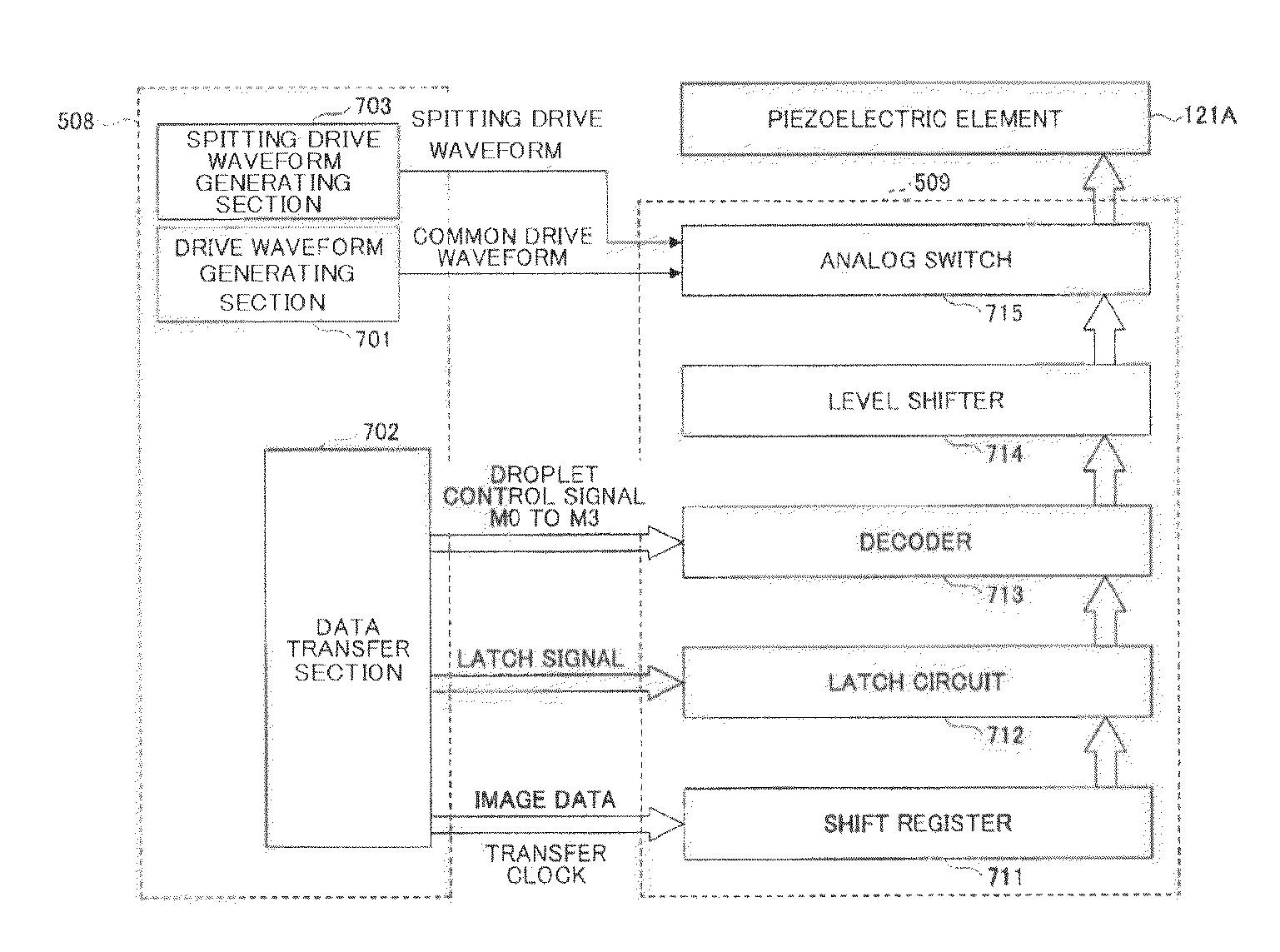

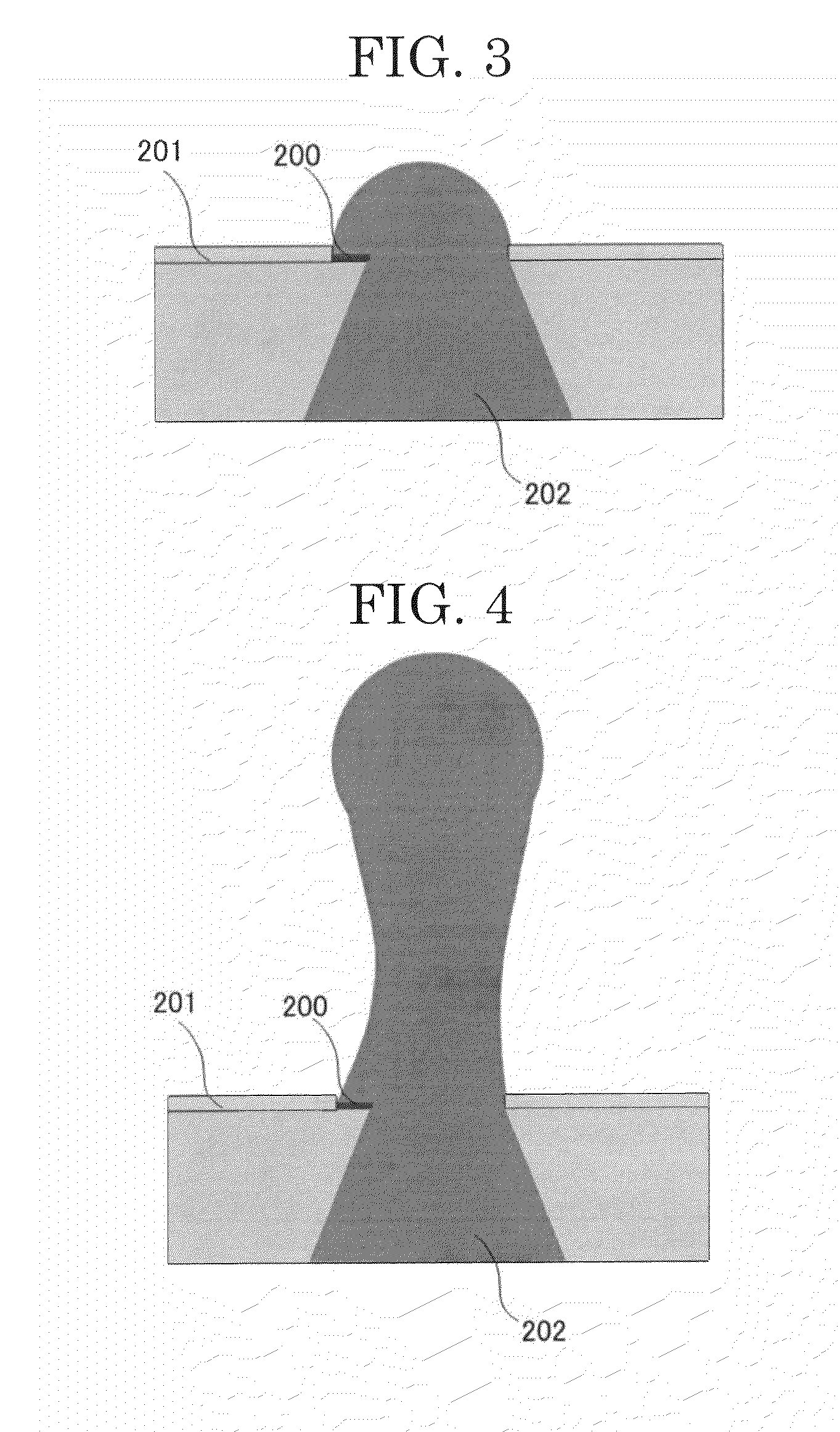

Inkjet recording method and inkjet recording device

ActiveUS20160144620A1Reduce surface tensionAvoid large contactDecorative surface effectsDuplicating/marking methodsSpray nozzleTwo step

An inkjet recording method performed by inkjet recording device including nozzle plate with nozzle to eject droplets of ink; recording head including liquid chamber with which the nozzle is in communication, and pressure-generating unit configured to generate pressure in the liquid chamber; and signal-generating unit configured to generate signal applied to the pressure-generating unit, and allowing the droplets of the ink to eject by the pressure generated by the pressure-generating unit according to the signal, wherein the ink has static surface tension of 18.0 mN / m to 27.0 mN / m at 25° C., the ink has receding contact angle on the nozzle plate of less than 50°, the signal has two-step pull pulse for pulling the ink into the nozzle in two-step manner within one printing unit cycle, and the method includes pulling the ink located in proximity to nozzle outlet into the nozzle of the two-step pull pulse, to form meniscus at predetermined position.

Owner:RICOH KK

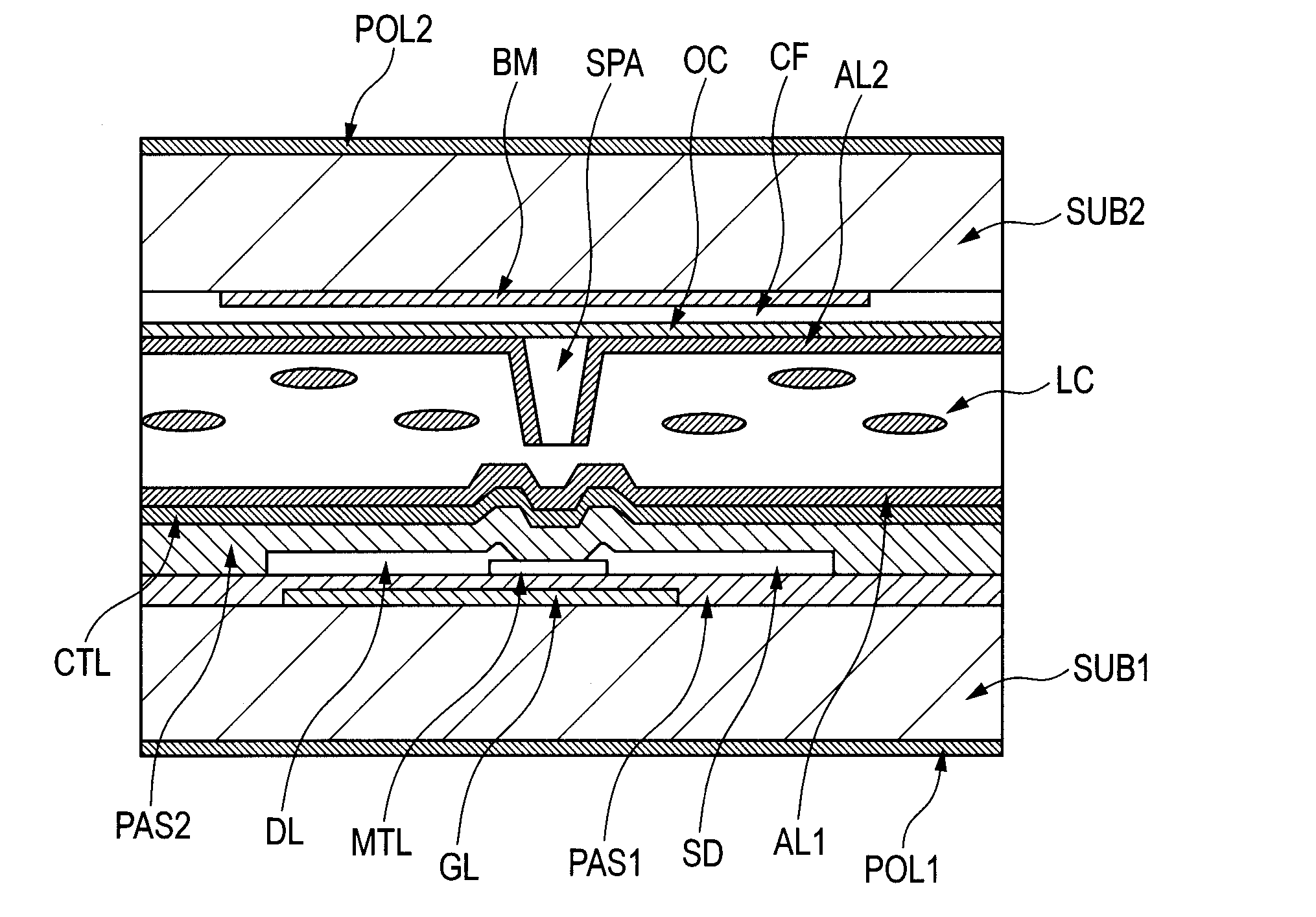

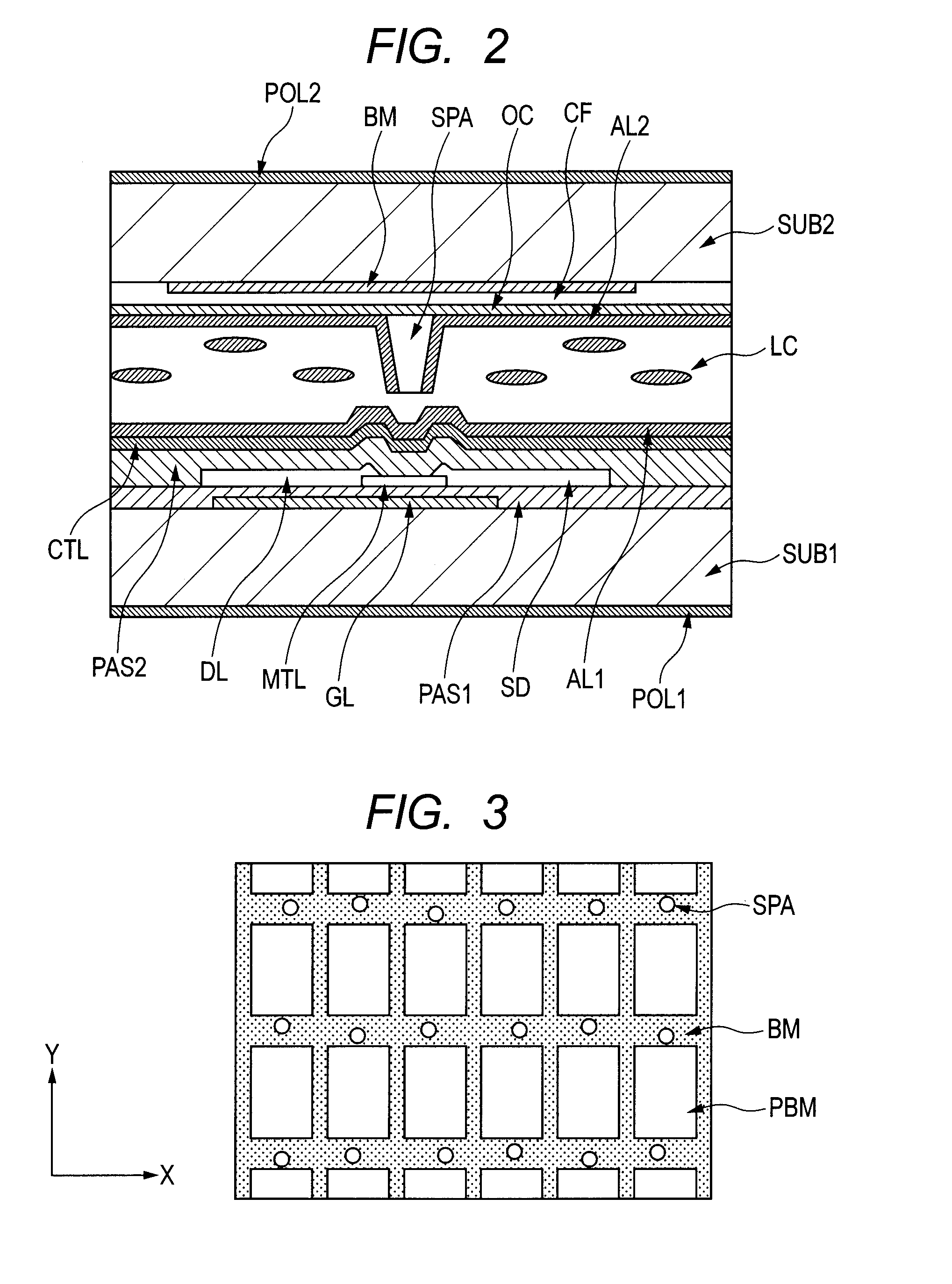

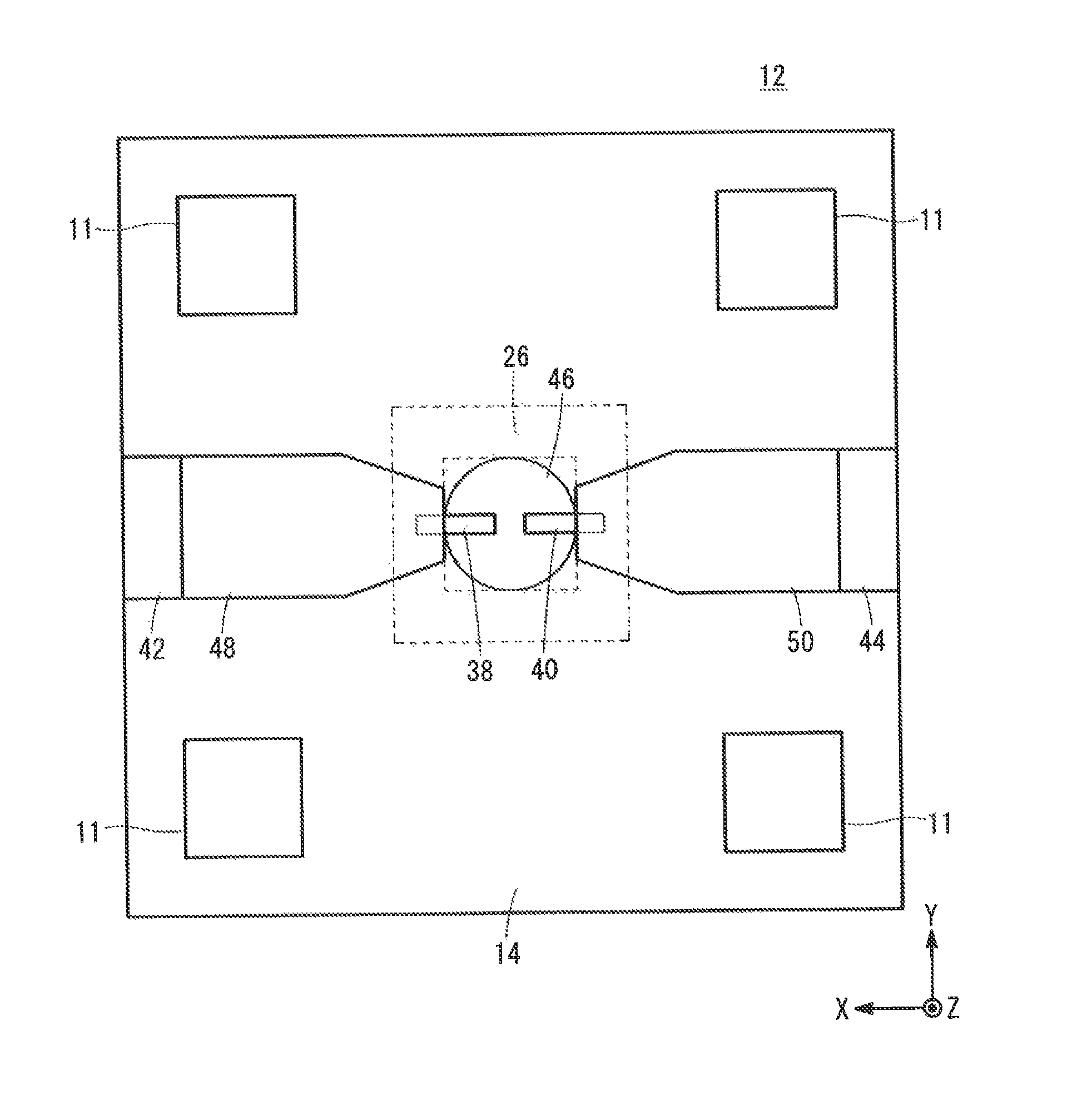

Display device

InactiveUS20120314178A1Reduce push resistanceReduce resistanceNon-linear opticsLiquid-crystal displayScan line

The present invention relates to a display device such as a liquid crystal display device including a first substrate and a second substrate with liquid crystal injected between the first and second substrates. In the display device, the second substrate includes a plurality of columnar spacers, and the first substrate has a protrusion in an area facing the top of the columnar spacer. The plurality of columnar spacers formed on the second substrate are not arranged at even intervals in the longitudinal direction of the scan line, and / or are not aligned on the line but are arranged at random.

Owner:JAPAN DISPLAY INC

Analytical cell

ActiveUS9455117B2Inhibiting and suppressing side reactionHigh precision analysisElectric discharge tubesFinal product manufactureElectronPhysics

An analytical cell includes a first holder and a second holder. The first holder and the second holder each contain a substrate including a through-hole and a transmission membrane having an electron beam permeability. The through-hole is covered with the transmission membrane. The first holder and the second holder are stacked to form an overlapping portion such that the transmission membranes face toward each other. A negative electrode active material and a positive electrode active material, which are arranged at a distance from each other and are in contact, respectively, with an electrolytic solution, are connected electrically to a negative electrode collector and a positive electrode collector, respectively, in the overlapping portion. A lyophobic part having no affinity for the electrolytic solution is formed on at least one of the negative electrode collector and the positive electrode collector.

Owner:HONDA MOTOR CO LTD

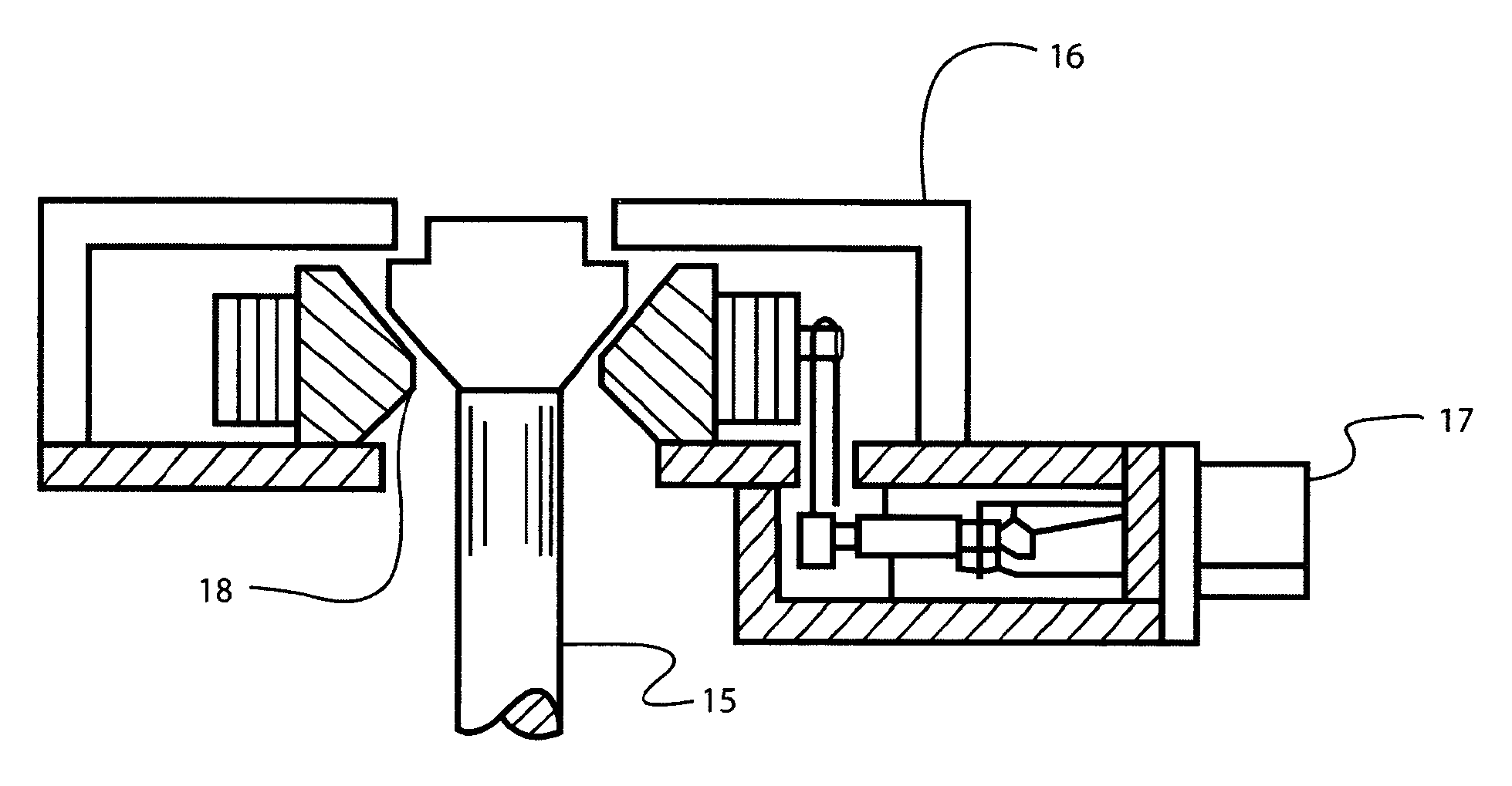

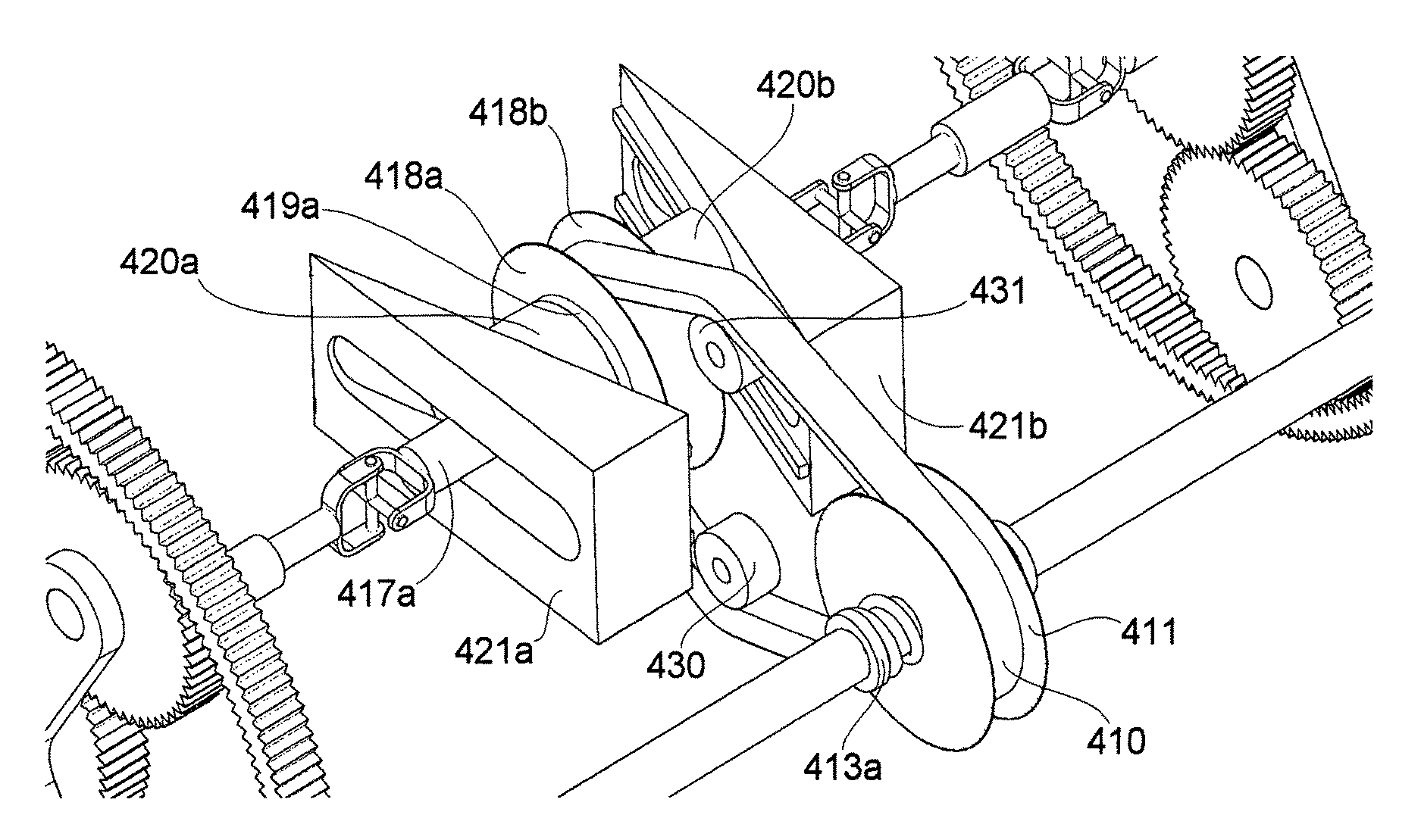

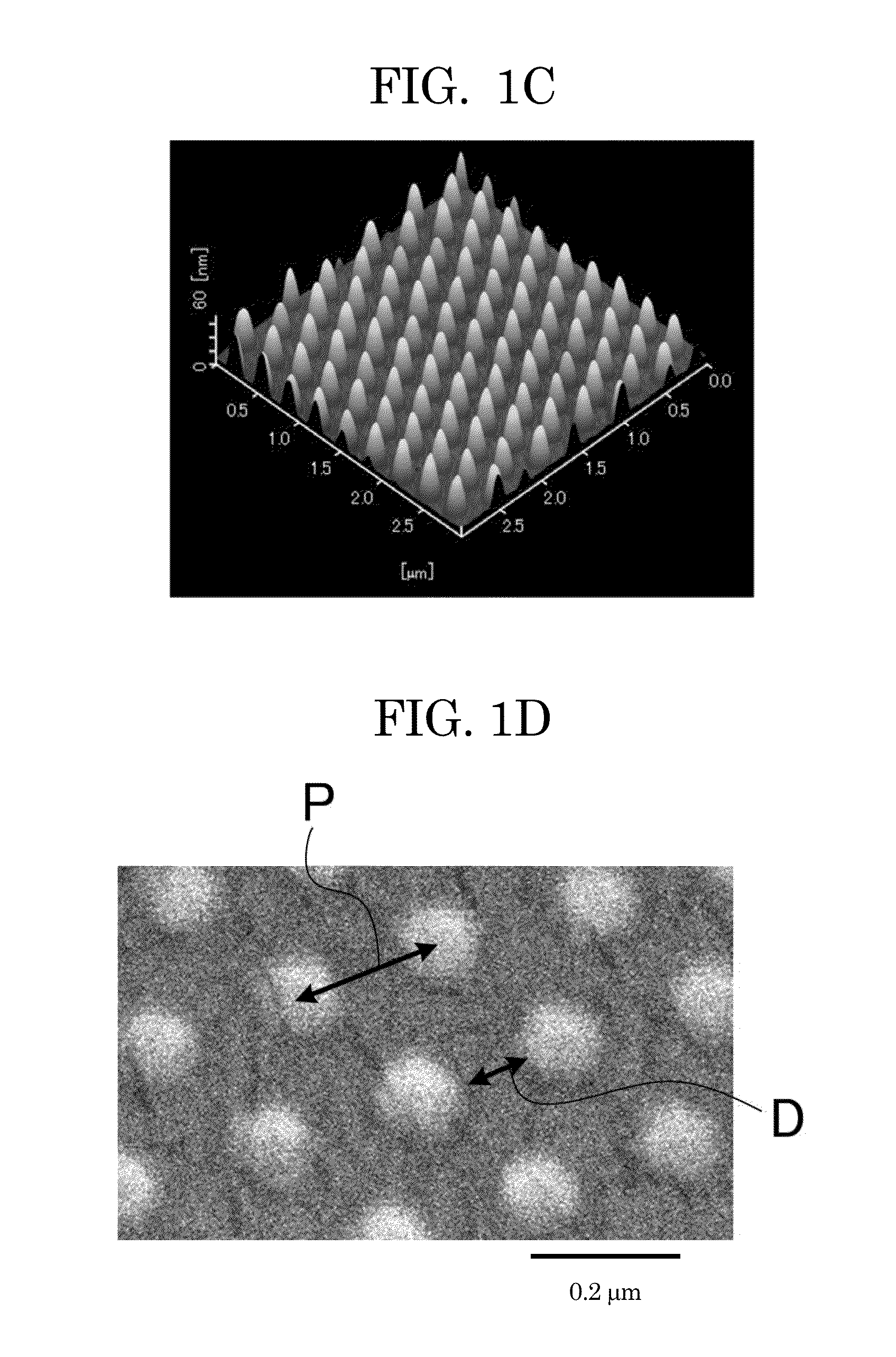

Infinitely variable transmission for differentially steered vehicles

An infinitely variable transmission system for differentially steered vehicles comprises two planetary gearboxes, each coupled to drive, as output, a driving component, such as track or wheel, on either side of a vehicle. The planetary gearboxes are drivingly coupled to a power source, such as an engine or motor, via fixed gear ratio driver and via belt drive system of two or more variable ratio belt drive pulleys. Each of the two outputs of the transmission can independently and simultaneously be controlled to revolve in forward, neutral (stop), and reverse directions in a manner of continuously and infinitesimally variable speed and torque.

Owner:INAL MEHMET KORAY

Lipophilic laminate, method for manufacturing the same, product, and method for manufacturing the same

InactiveUS20140295145A1Excellent fingerprint resistanceAvoid large contactAntifouling/underwater paintsSynthetic resin layered productsChemistryOleic Acid Triglyceride

A lipophilic laminate, including: a substrate made of a resin; and a lipophilic resin layer on the substrate made of a resin, wherein the lipophilic resin layer includes micro convex portions or micro concave portions in a surface thereof, and wherein an oleic acid contact angle of the surface of the lipophilic resin layer is 10° or less.

Owner:DEXERIALS CORP

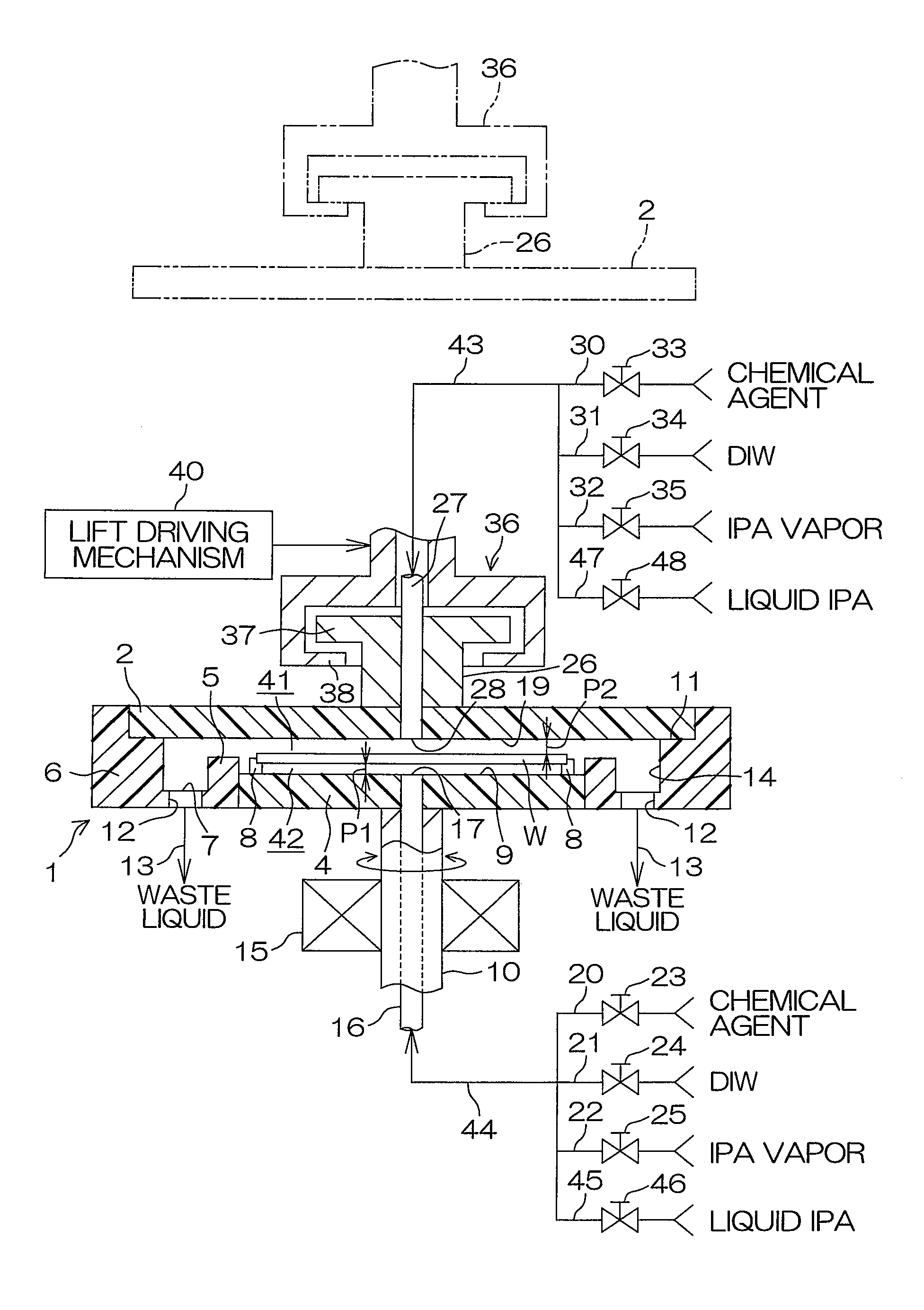

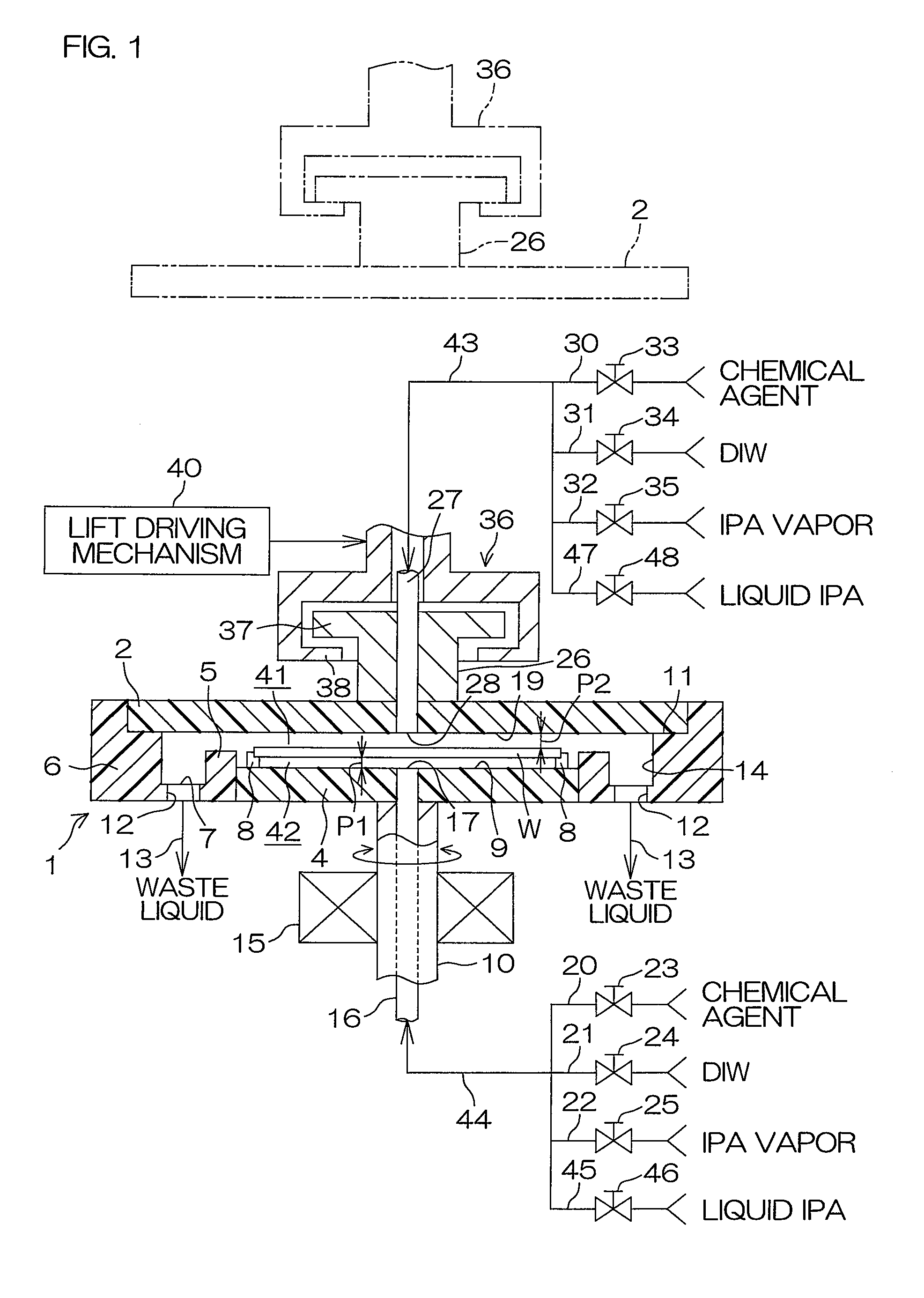

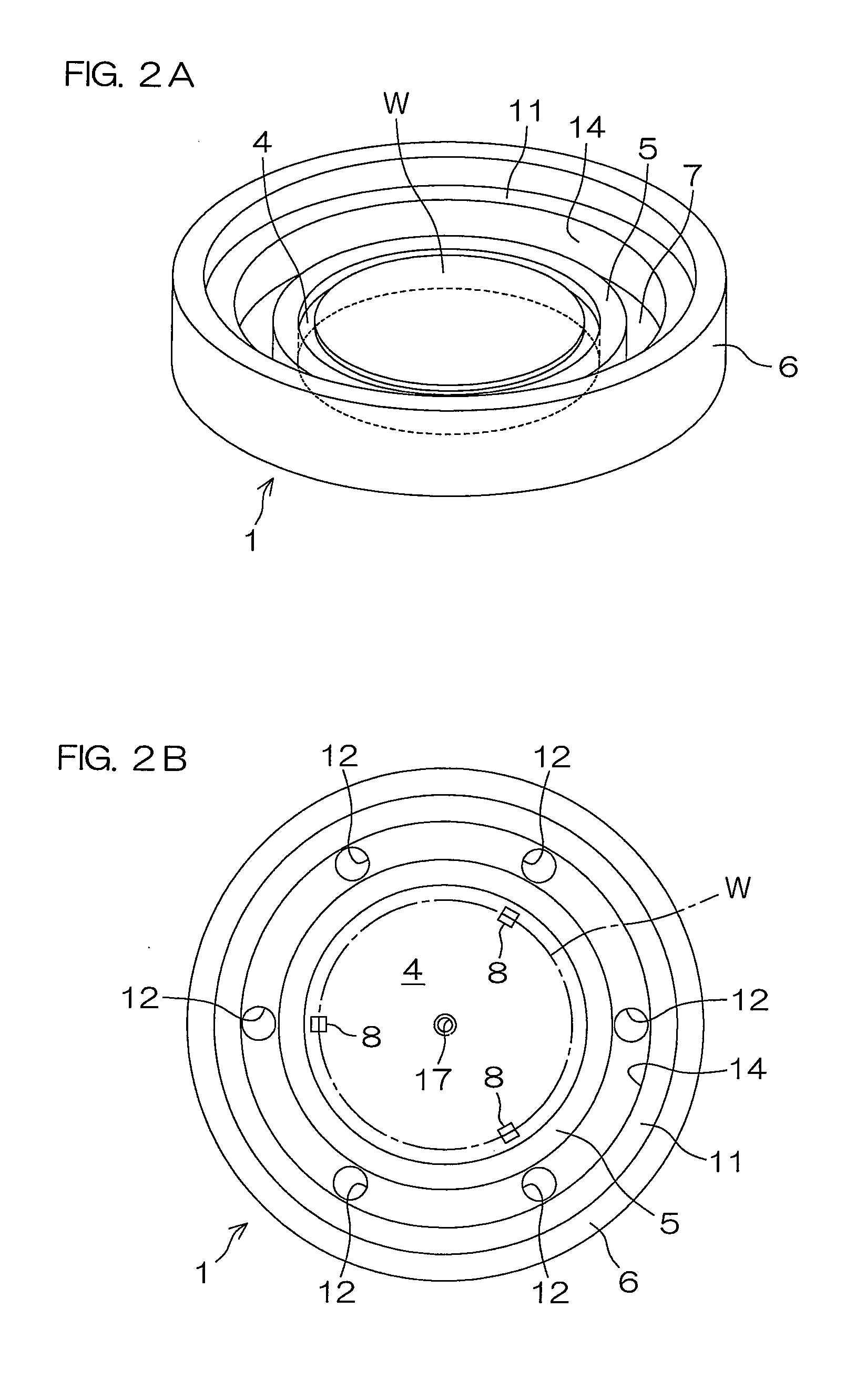

Substrate treatment method and substrate treatment apparatus

InactiveUS20090107522A1Avoid pollutionReliable removalLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringContact angle

An inventive substrate treatment method is performed by a substrate treatment apparatus including a plate having an opposed surface to be kept in opposed spaced relation to one surface of a substrate for treating the substrate with a treatment liquid, and includes: a pre-supply liquid filling step of supplying a pre-supply liquid into a space defined between the one surface of the substrate and the plate through a spout which is provided in the opposed surface in opposed relation to the center of the substrate, and filling the space with the pre-supply liquid, the pre-supply liquid having a smaller contact angle with respect to the substrate and the plate than the treatment liquid; a treatment liquid replacing step of, after a liquid-filled state is established in the space filled with the pre-supply liquid, supplying the treatment liquid into the space to replace the pre-supply liquid present in the space with the treatment liquid while keeping the space in the liquid-filled state; and a treatment liquid contacting step of, after the replacement of the pre-supply liquid, filling the space with the treatment liquid to cause the treatment liquid to contact the one surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

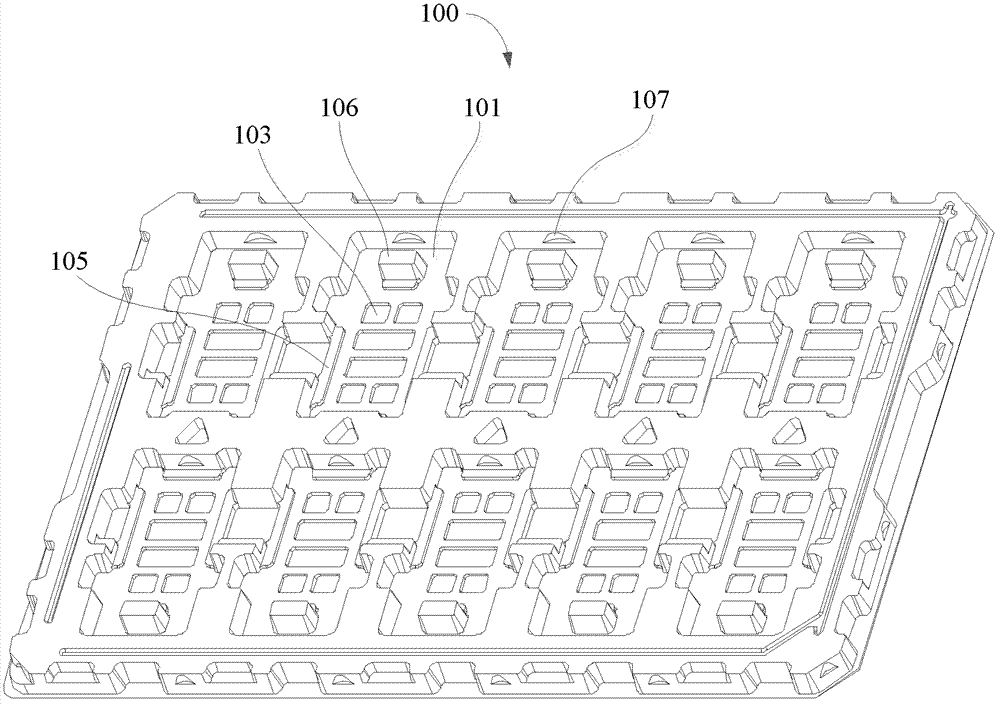

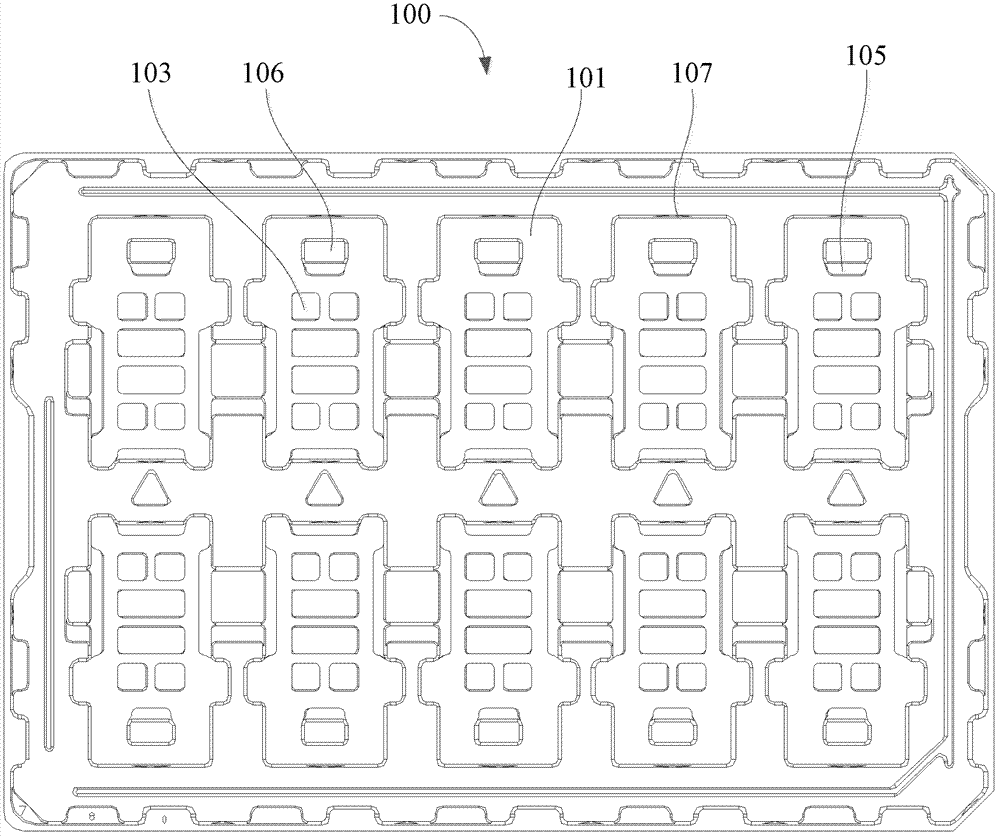

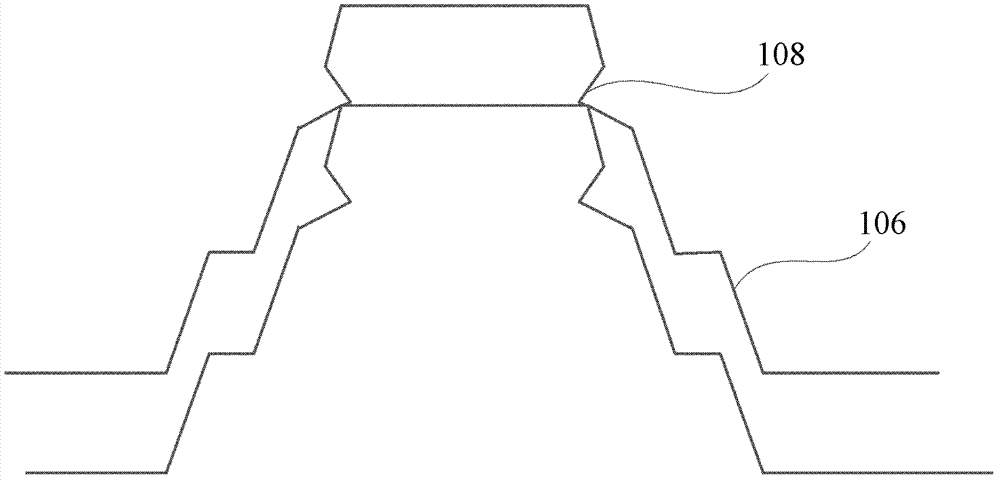

Touch screen package box and production method thereof

InactiveCN103359386AAvoid large contactReduce frictionRigid containersContainers with multiple articlesEngineeringElectrical and Electronics engineering

A touch screen package box comprises accommodating grooves for accommodating touch screens. Pits are formed in the middles of the bottoms of the accommodating grooves to enable reinforcing rib structures to be formed around the pits. Abutting bosses are arranged on the peripheries of the bottoms of the accommodating grooves, and protrude out of the bottoms of the accommodating grooves to enable the touch screens to be accommodated in the accommodating grooves and to enable gaps to be formed between the touch screens and the bottoms of accommodating grooves. The abutting bosses for supporting the touch screens are arranged at the bottoms of the accommodating grooves of the touch screen package box to avoid large-area contact between the touch screens and the bottoms of the accommodating grooves, so that possibility of friction is reduced; the abutting bosses are arranged on the peripheries of the bottoms of the accommodating grooves to enable window areas of the touch screens to be spaced, so that the window areas of the touch screens are prevented against friction and damages. The invention further provides a production method of the touch screen package box.

Owner:SHENZHEN O FILM TECH

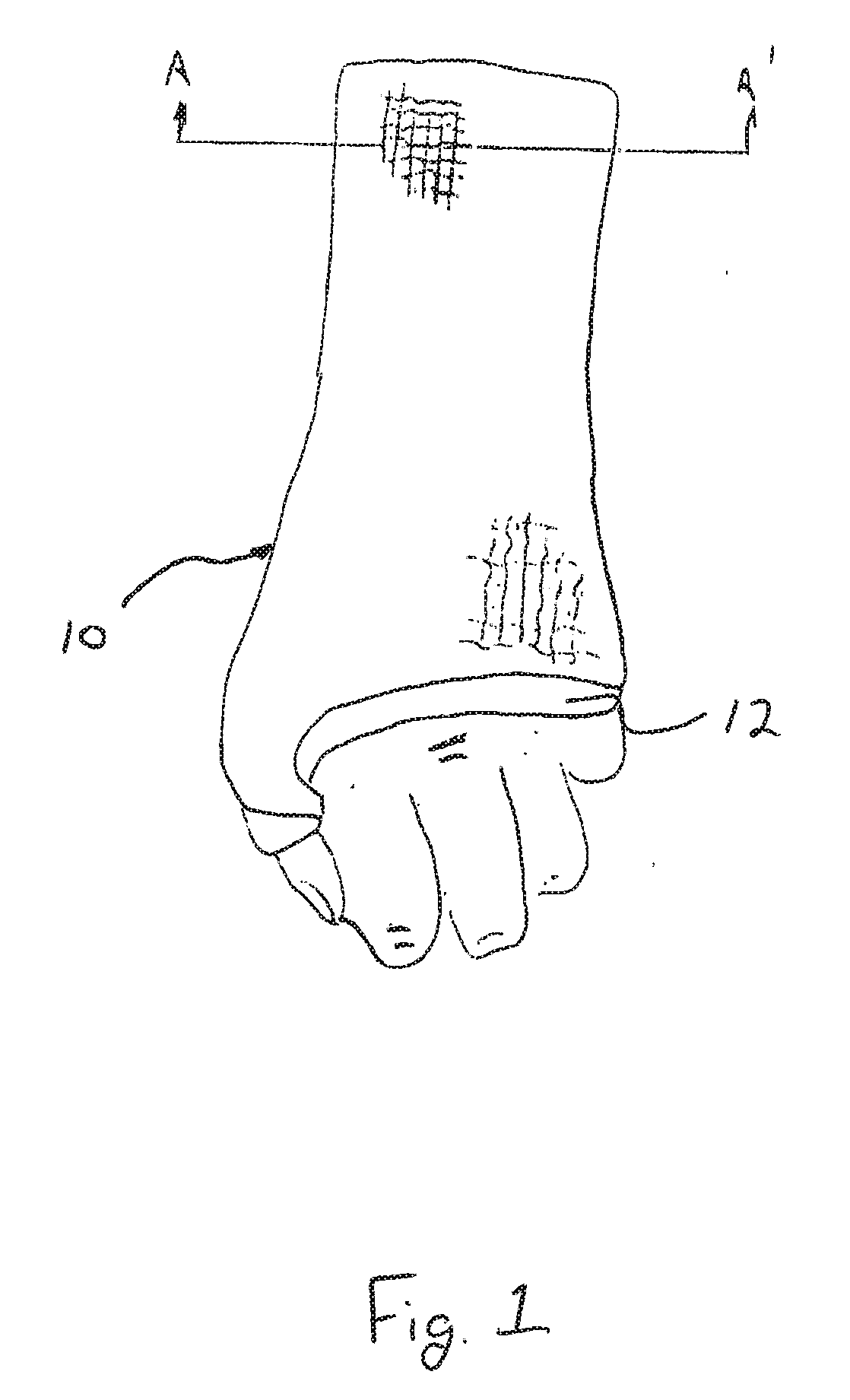

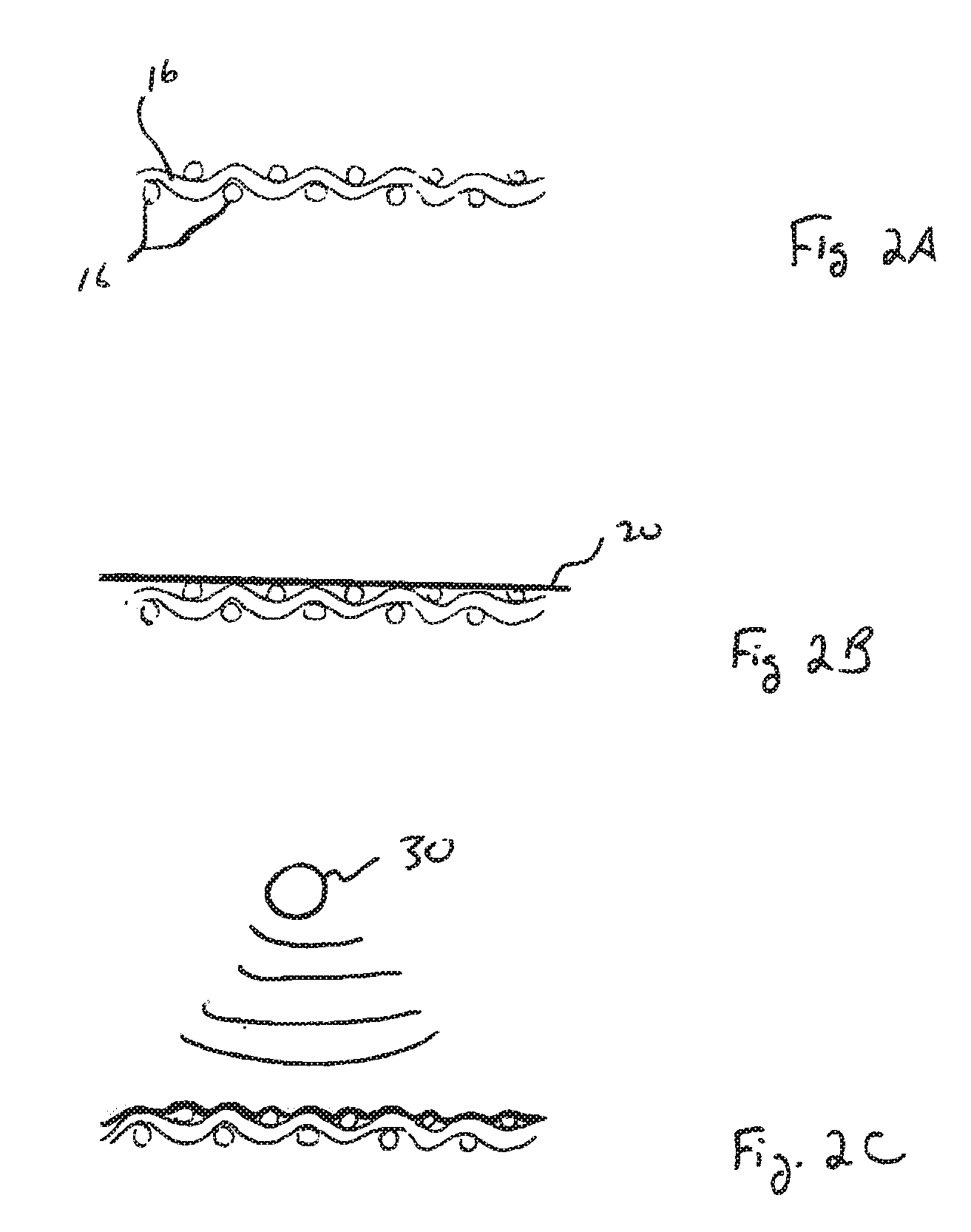

Decorative coverings for orthopedic support

InactiveUS20090053451A1Avoid large contactSmooth connectionLamination ancillary operationsDecorative surface effectsPlastic surgeryPolyresin

A decorative covering is provided for application to an exterior portion of an orthopedic support, Such an orthopedic support may be a cast made out of a curable resin impregnated fabric or any other orthopedic support known in the art. In one embodiment, the decorative covering may be formed on an at least partially translucent thermally deformable sheet member. In this embodiment a design layer may be printed on the sheet member such that the design layer makes up a decorative design. The sheet member may be applied to the orthopedic support using an adhesive applied to a side of the sheet member opposite the side on which the design layer is printed. Once initially adhered, the sheet member may be thermally deformed to at least partially conform to the contours of the underlying orthopedic support. In one embodiment, the sheet member has a pre-applied adhesive along with a release liner that covers the adhesive.

Owner:SMITH JESSICA

Novel haze resisting mask with filling air bag

InactiveCN109452703AFree to adjust the pressureRealize flexible constant pressure sealGarment beltsProtective garmentGray levelRespirator

The invention discloses a novel haze resisting mask with a filling air bag. The mask comprises a mask body, the filling air bag and fastening belts; each of the left and right of the mask body is provided with a static-force adjustable dual-purpose fastening belt; the filling air bag is arranged on the part, opposite to the nose bridge, of the interior of the mask body, a respiratory valve, a replaceable filter core or a standardized member is installed on the mask body, a gray level detector is installed on the filter core, the standardized member is screwed on the side, close to the face, ofthe filter core or fixedly clamped to the side, close to the face, of the filter core, the filling air bag is provided with an inflation port and an air discharging port which can be opened and closed, and the filling air bag can be connected with the air bag supporting frame in the mask. The mask has the advantages that the design is reasonable, air tightness and comfort can be taken into consideration by the filling air bag, the mask is light and can be repeatedly used, and the fastening belts are comfortable and can provide more wearing manners. The novel haze resisting mask is provided with the gray level detector so that a user can be reminded to replace the filter core, and the mask surface is well supported by the air bag supporting frame on the inner side of the mask surface to prevent the fitting of the mask surface and the face.

Owner:南晋龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com