Hydrophilic composition for use with a lubricating system as well as an apparatus and method for using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

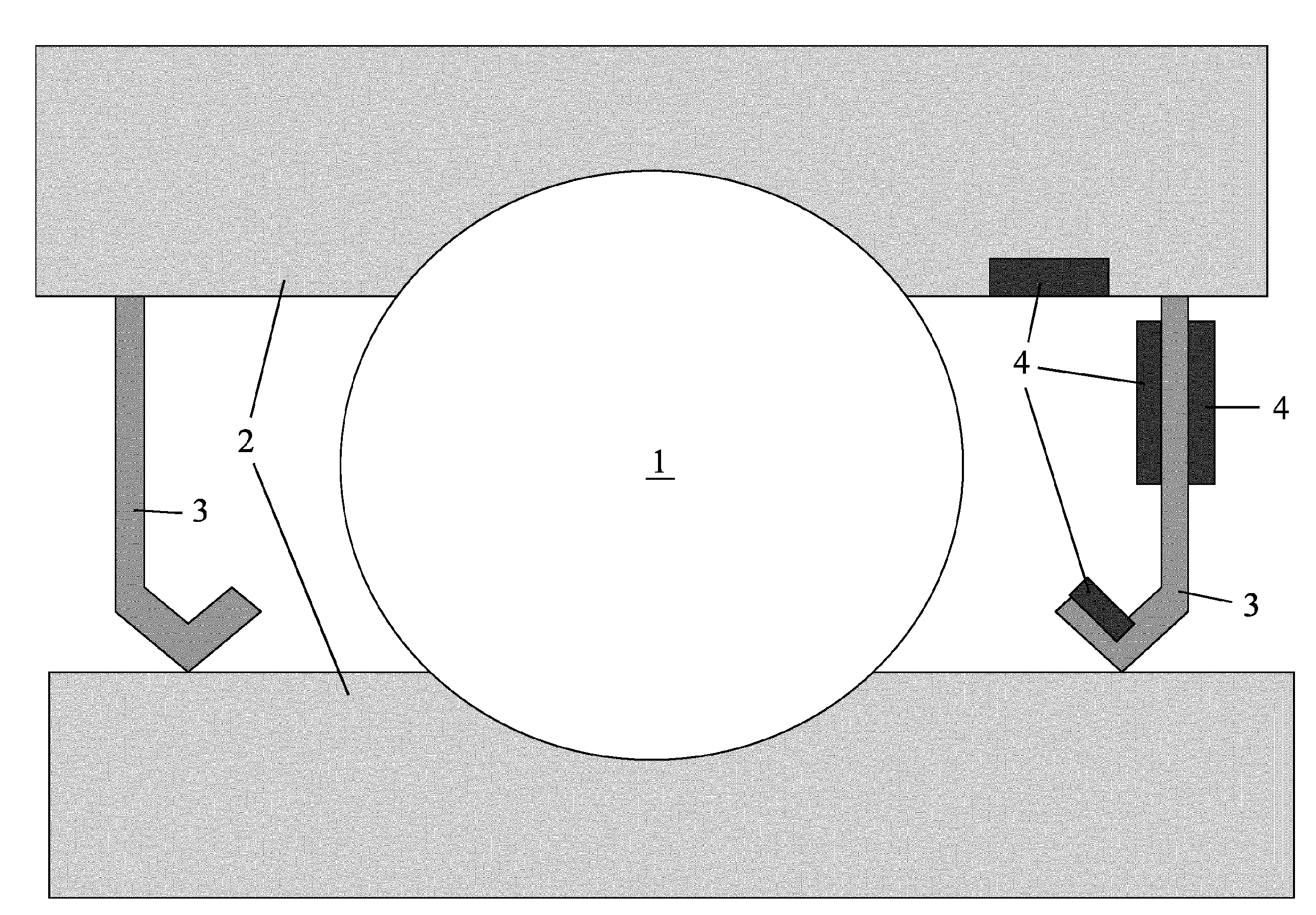

Image

Examples

embodiment 1

[0108]2. A grease , wherein the fibers comprise at least two portions having different physical and / or chemical properties.

embodiment 2

[0109]3. A grease , wherein at least one of the portions has a higher affinity to a like portion than to the oil and / or lubricating fluid, thereby imparting a self-assembly property to the thickening fibers.

[0110]4. A grease according to any preceding embodiment, wherein the fibers have a length of 100-500 microns.

embodiment 4

[0111]5. A grease , further comprising oleophilic thickening fibers having a length of 1-100 microns.

[0112]6. A grease according to any one of embodiments 1-3, wherein the fibers have a length of 1-100 microns.

[0113]7. A grease according to any preceding embodiment, wherein the fibers have a length that is at least about 5-10 times the diameter thereof.

[0114]8. A grease according to any preceding embodiment, wherein the thickening fibers are a mixture of organic fibers, e.g., polypropylene, and inorganic, e.g., ceramics, e.g., aluminum oxide and / or silicon dioxide.

[0115]9. A grease according to any preceding embodiment, wherein the fibers also have oleophobic and / or hydrophilic properties.

[0116]10. A grease according to any preceding embodiment, further comprising non-oleophilic fibers having oleophobic and / or hydrophilic and / or hygroscopic properties.

[0117]11. A grease according to any preceding embodiment, wherein the fibers are biodegradable.

[0118]12. A grease according to any pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com