Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Achieve heat transfer performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

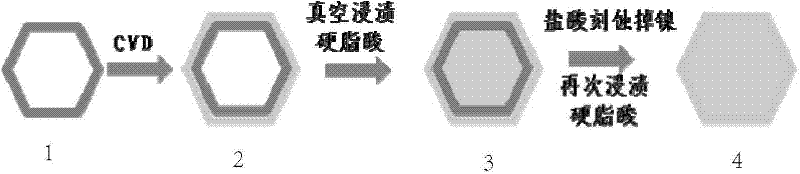

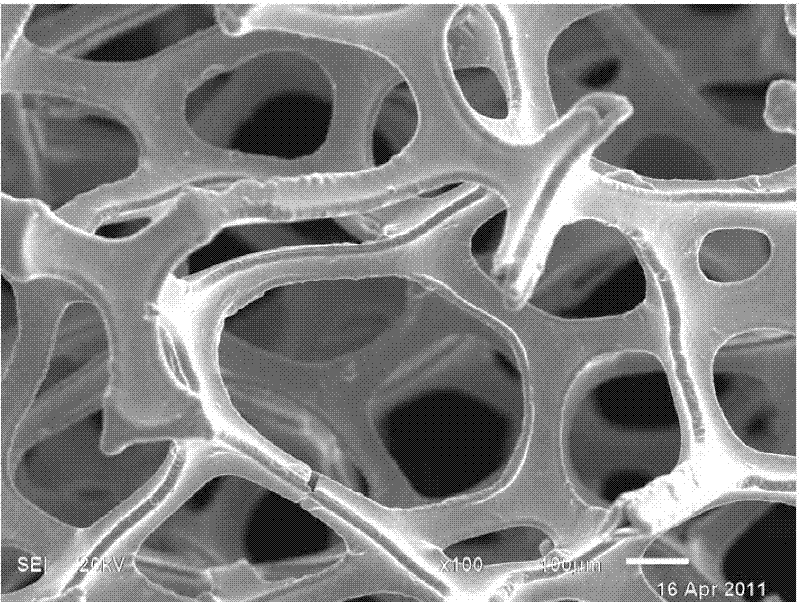

Three-dimensional graphene/phase change energy storage composite material and preparation method thereof

InactiveCN102585776AImprove thermal conductivityLow densityHeat-exchange elementsPorous grapheneLiquid state

The invention provides a three-dimensional graphene / phase change energy storage composite material and a preparation method thereof. The technical scheme is as follows: graphene and a phase change energy storage material are in situ compounded, wherein porous graphene with a three-dimensional structure is used as a heat conductor and a compound die, and a solid-liquid phase change organic material is used as the energy storage material and filler. The three-dimensional porous graphene is compounded with the phase change material, the phase change energy storage material is partitioned in a plurality of pore spaces and is in tight joint with the graphene wall so as to greatly increase the effective heat contact area, and the highly linked graphene three-dimensional heat conduction network channels can realize rapid system heat exchange. In addition, due to the capillary adsorption capacity of porous graphene, the liquid-state phase change energy storage material is localized, so as to effectively prevent seepage. Therefore, the three-dimensional graphene foam has good designability, and becomes a lighter and more effective heat dissipation material for electronic devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

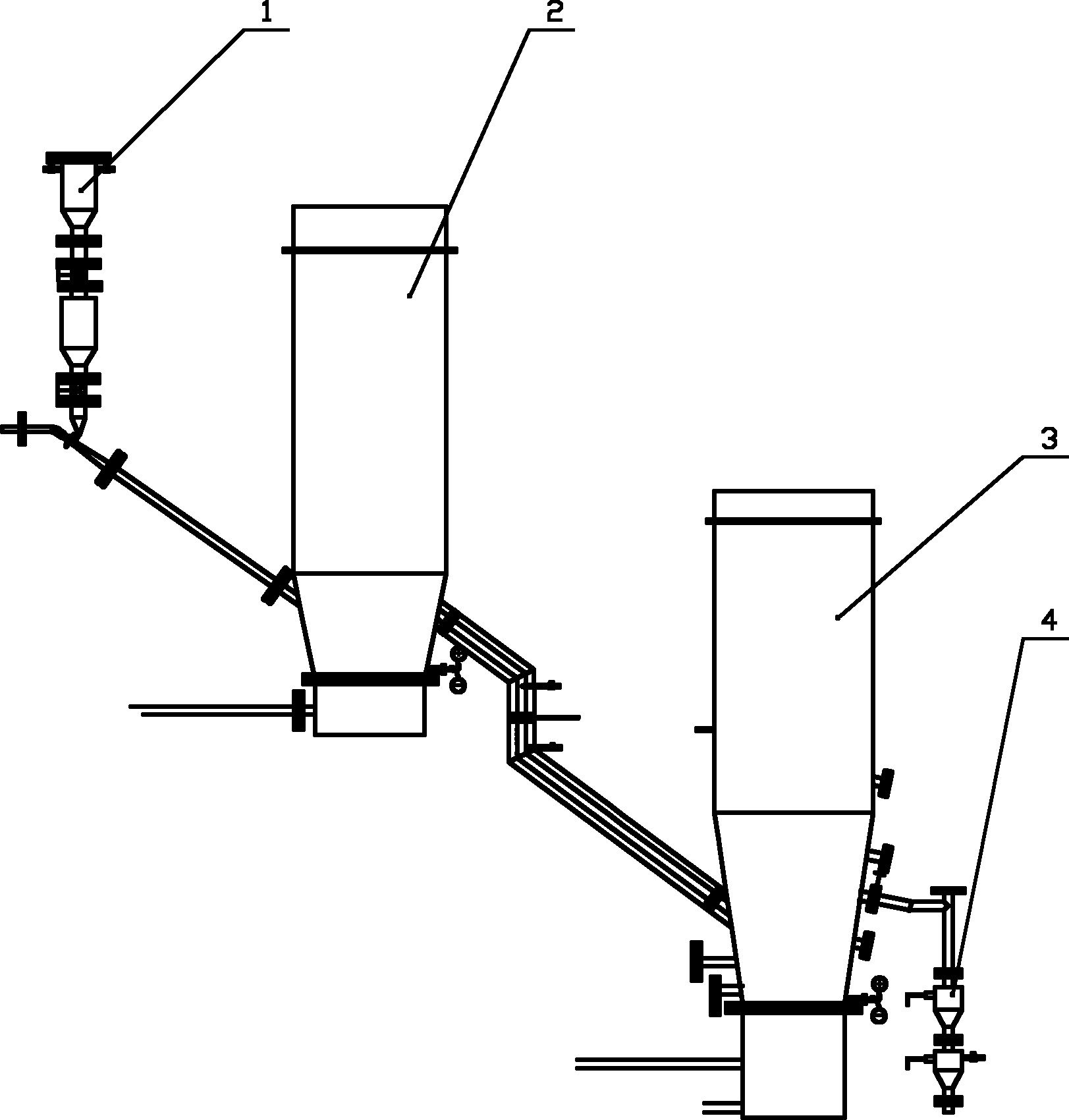

Device and process method for continuously producing carbon nanotubes

ActiveCN102120570ASuitable for productionImprove standardizationNanotechnologyNanoparticleFluidized bed

The invention discloses a device for continuously producing carbon nanotubes, which consists of a feeder, a reduction reactor, a synthesis reactor and a product collector which are connected in series in turn, wherein the reduction reactor is a fluidized bed reactor; and the synthesis reactor is a spouted bed reactor. The invention also discloses a process method for continuously producing carbonnanotubes based on the device. The catalyst reduction and deposition preparation of the carbon nanotubes are respectively realized by the fluidized bed and the spouted bed, so that the process conditions can be regulated in a wider range, the fluidized state of agglomerated nanoparticles in the beds is ensured, and the high-quality carbon nanotubes are continuously produced.

Owner:GUANGZHOU BAIYUN CHEM IND

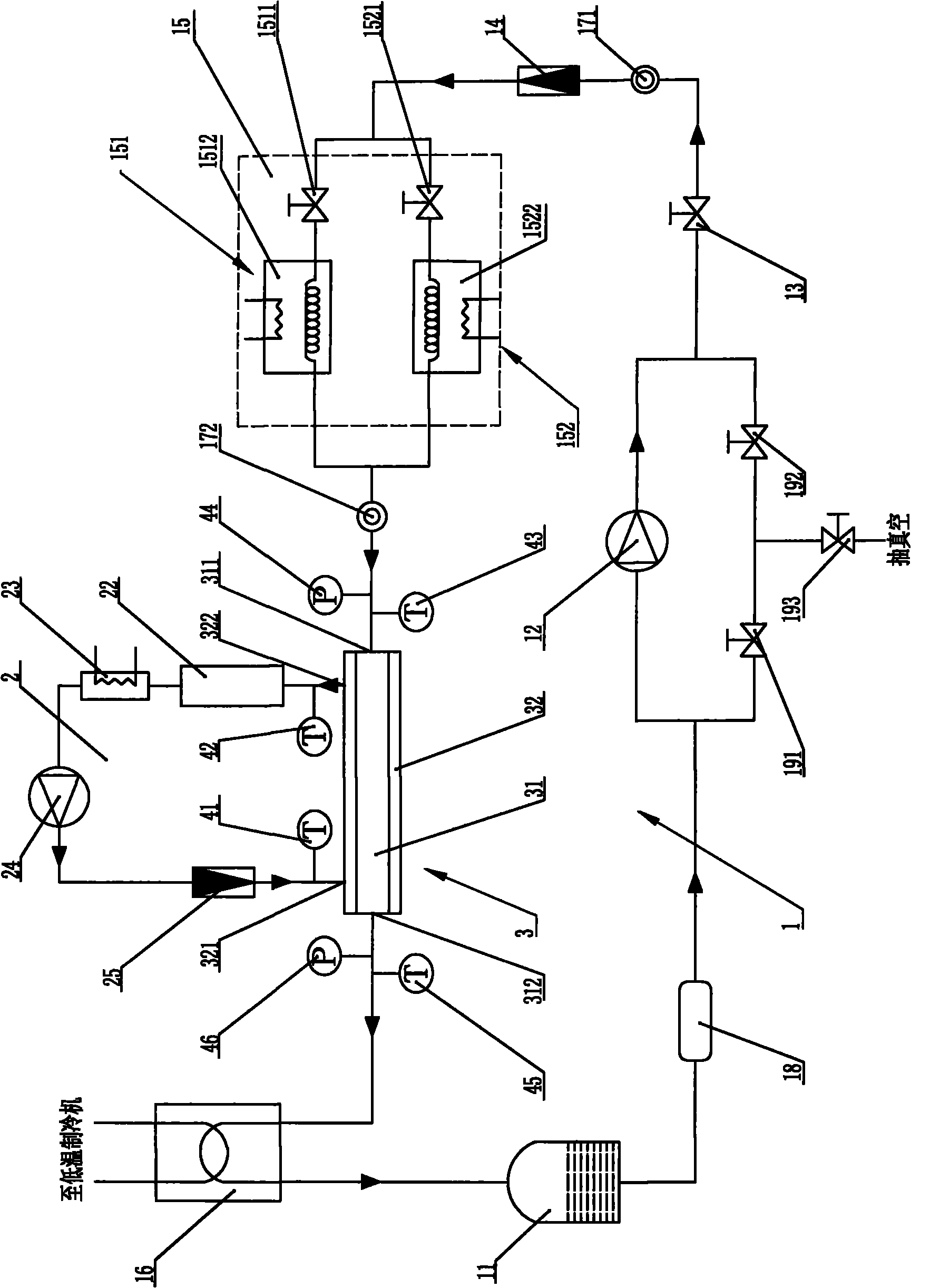

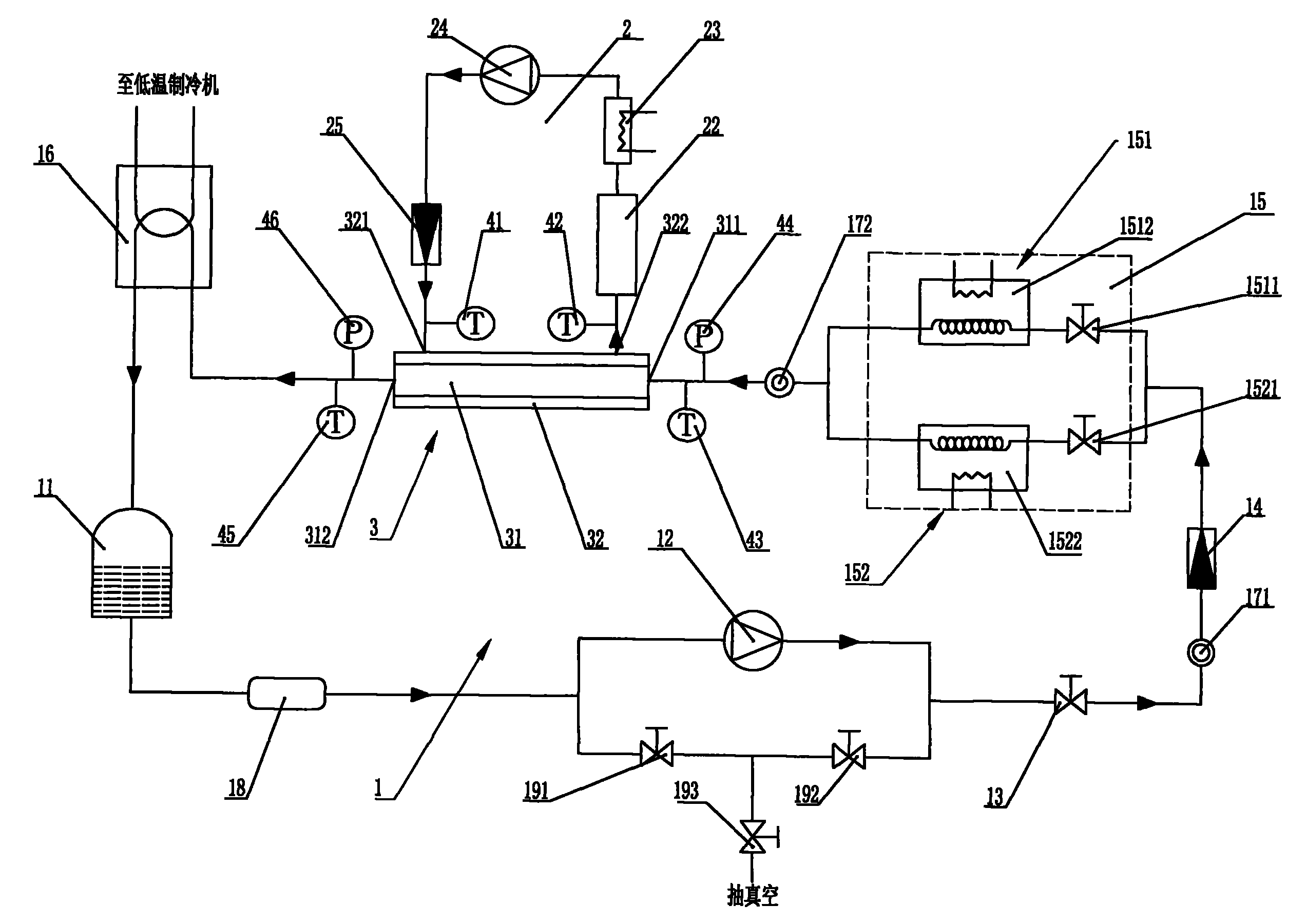

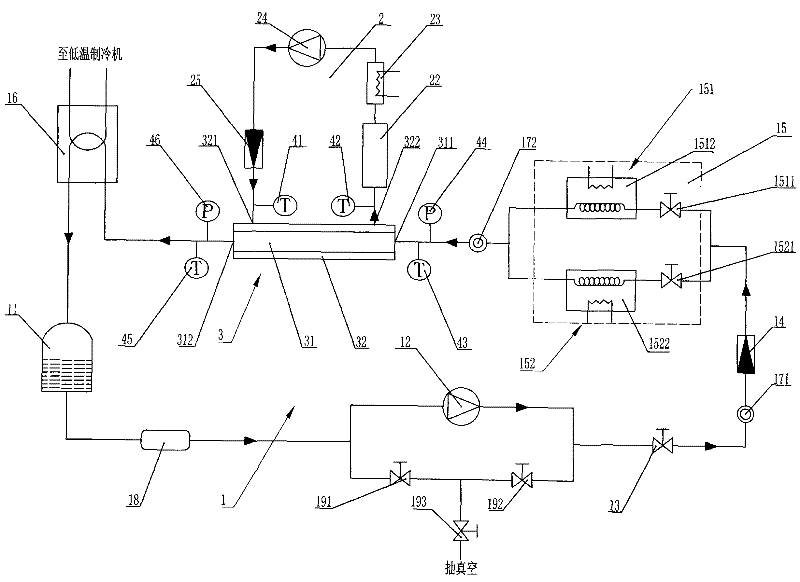

All-in-on device for evaporation/condensation heat transmission testing in micro pipe and testing method thereof

ActiveCN101852749AAchieve evaporationAchieve heat transfer performanceMaterial thermal conductivityStructural/machines measurementRefrigerantWater mass

The invention discloses an all-in-one device for evaporation / condensation heat transmission testing in a micro pipe and a testing method thereof. The device comprises a refrigerant circuit and a heat exchange circuit in testing section, wherein the refrigerant circuit comprises a recovery tank, a power pump, a regulating valve, a refrigerant mass flow meter, a regulating testing circuit in parallel composed of a condensation preheating passage and an evaporation preheating passage, a inner pipe in testing section and a condenser; a inlet of the power pump is connected with the recovery tank; an outlet is connected with the refrigerant mass flow meter; the inlet of the regulating testing circuit in parallel is connected with the refrigerant mass flow meter; the outlet of the regulating testing circuit in parallel is connected with the inner pipe in testing section; a refrigerant outlet of the inner pipe in testing pipe is connected with the condenser; and the heat exchange circuit in testing section comprises a outer pipe in testing section and a heat exchanger, a water heater, a water pump and a water mass flow meter in sequent communication. By using the power pump to control the refrigerant flow and using the evaporation preheater / condensation preheater to control the dryness of the refrigerant and using the heat exchange circuit in testing section to control the heat exchange in the testing section, the invention respectively realizes evaporation and condensation heat transmission testing in a micro pipe.

Owner:李蔚

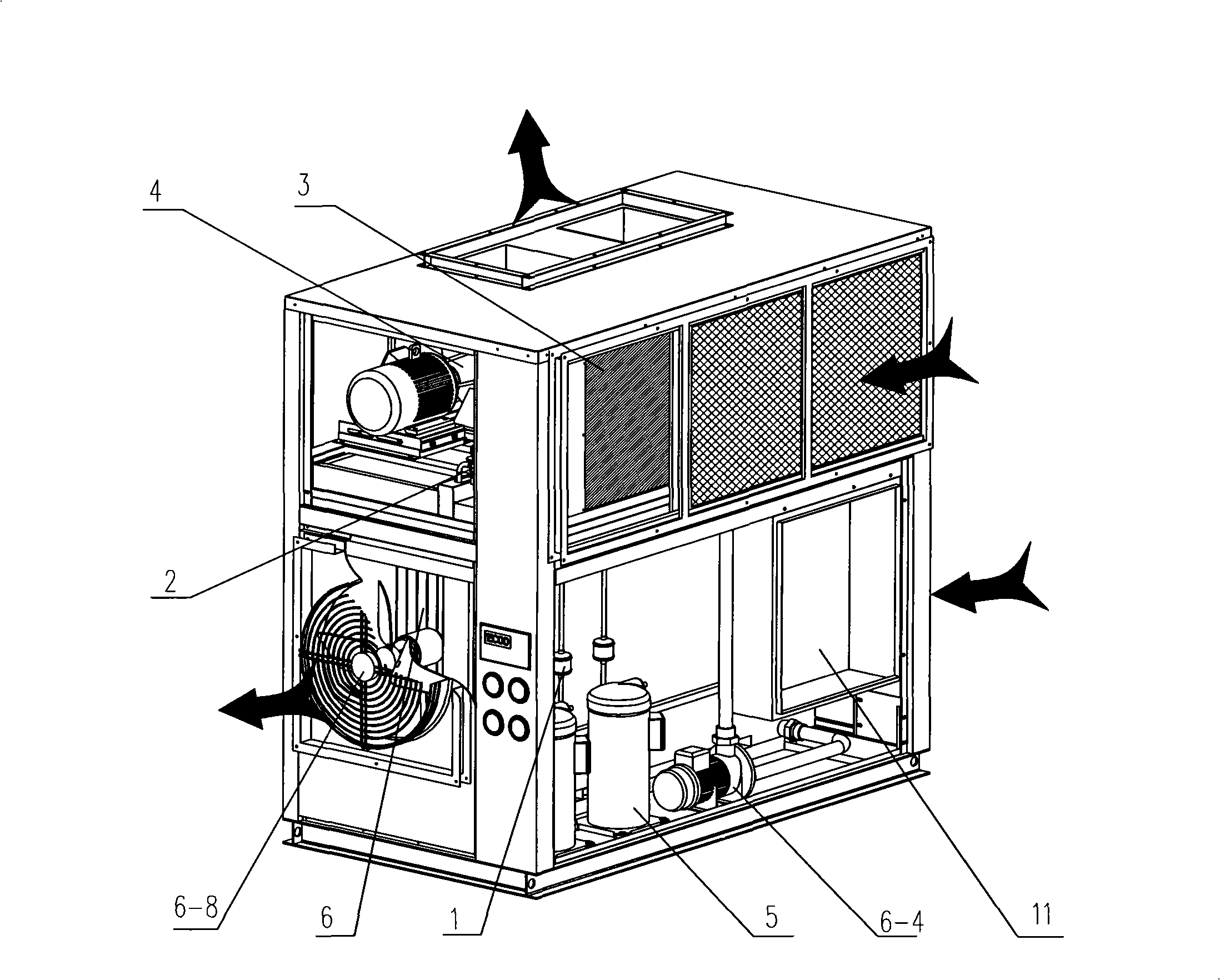

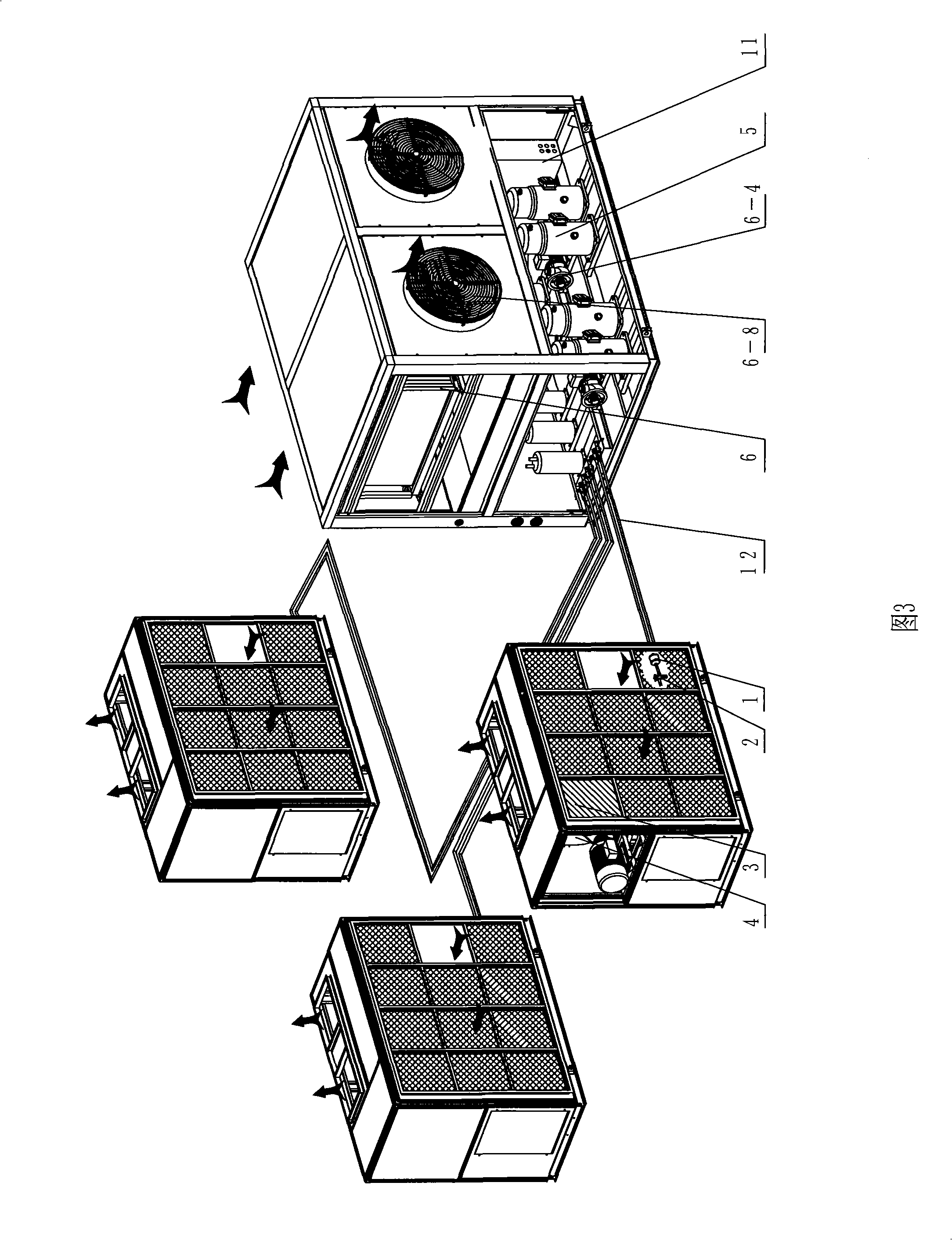

Tube-plate evaporative condensing air-conditioning unit with packing

ActiveCN101514829ARealize heat exchangeAchieve heat transfer performanceEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsFresh airEvaporation

The invention provides a tube-plate evaporative condensing air-conditioning unit with packing. The unit comprises an evaporation and air supply unit and a compression and condensing unit. The evaporation and air supply unit consists of a drying and filtering device, an expansion valve, an evaporator and a centrifugal fan which are sequentially connected, and the compression and condensing unit is formed by connecting a compressor and a condenser; the condenser is connected with the drying and filtering device, and the compressor is connected with the evaporator; the air-conditioning unit is provided with a condensate recovery system which is formed by connecting a condensate recovering collector of the evaporator with the condenser by a tube or a water pump; and an indoor air supply system of the evaporation and air supply unit consists of an outdoor fresh air inlet of the evaporator, a unit air supply outlet and the centrifugal fan, or consists of the outdoor fresh air inlet of the evaporator, a unit return air inlet, the unit air supply outlet and the centrifugal fan. The tube-plate evaporative condensing air-conditioning unit has high heat exchange efficiency, and can realize maximal energy recovery and reduction of energy consumption and water consumption, effectively solves increased energy consumption resulting from increased fresh air volume of an air-conditioning system and realizes double performance of saving energy and water and health care.

Owner:GUANGZHOU WIDE IND

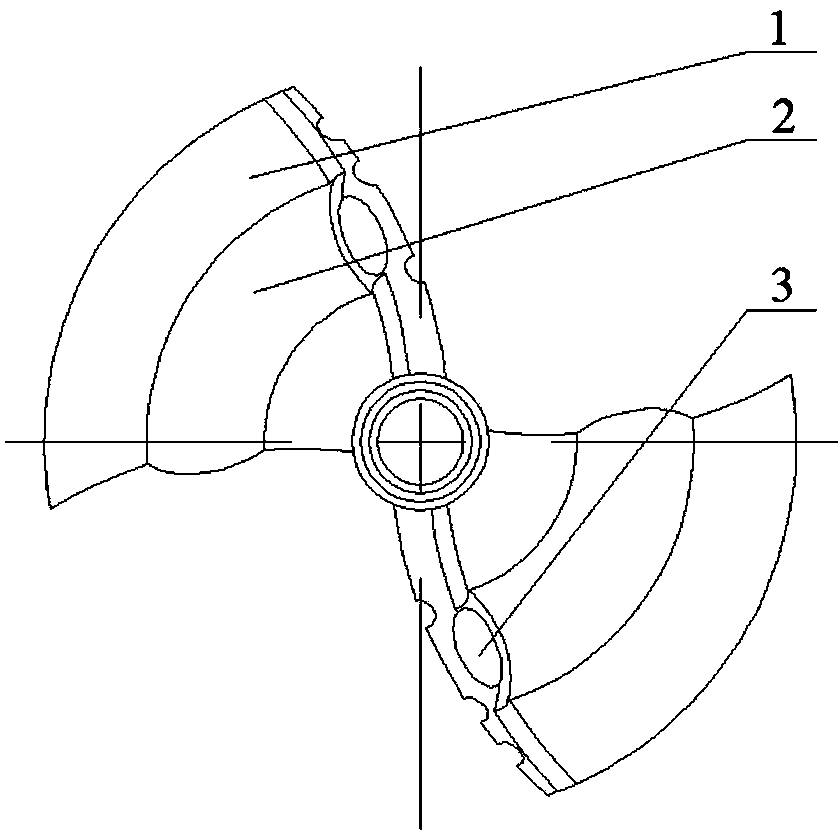

Loop heat pipe

InactiveCN109387104ASpeed up the flowStable flowIndirect heat exchangersHeat transfer modificationNoise levelEvaporation

The invention provides a loop heat pipe comprising an evaporation header, a condensation header, a riser tube and a return tube; the riser tube is in communication with the evaporation header and thecondensation header, the evaporation header is located at a lower portion, and the condensation header is located at an upper portion; the fluid absorbs heat in the evaporation header and evaporates,passes through the riser tube and enters the condensing header, and condenses after heat exchange in the condensing header, and the condensed fluid returns to the evaporation header through the returntube; a flow stabilization device is disposed in the riser tube, and the flow stabilization device comprises a central rod disposed along a central axis of the riser tube and a plurality of radial rods extending radially along the central rod; the radial rod is provided with a plurality of fins extending downward from the radial rod, the fins having a tip with the tip facing downward. The invention provides a loop heat pipe of a new type of flow stabilization device. By providing the radial rod and the downward tip fin, when there is a vapor-liquid two-phase flow in the riser tube, the heat transfer is enhanced, and the vibration of the riser tube is weakened, and the noise level is lowered.

Owner:SHANDONG UNIV

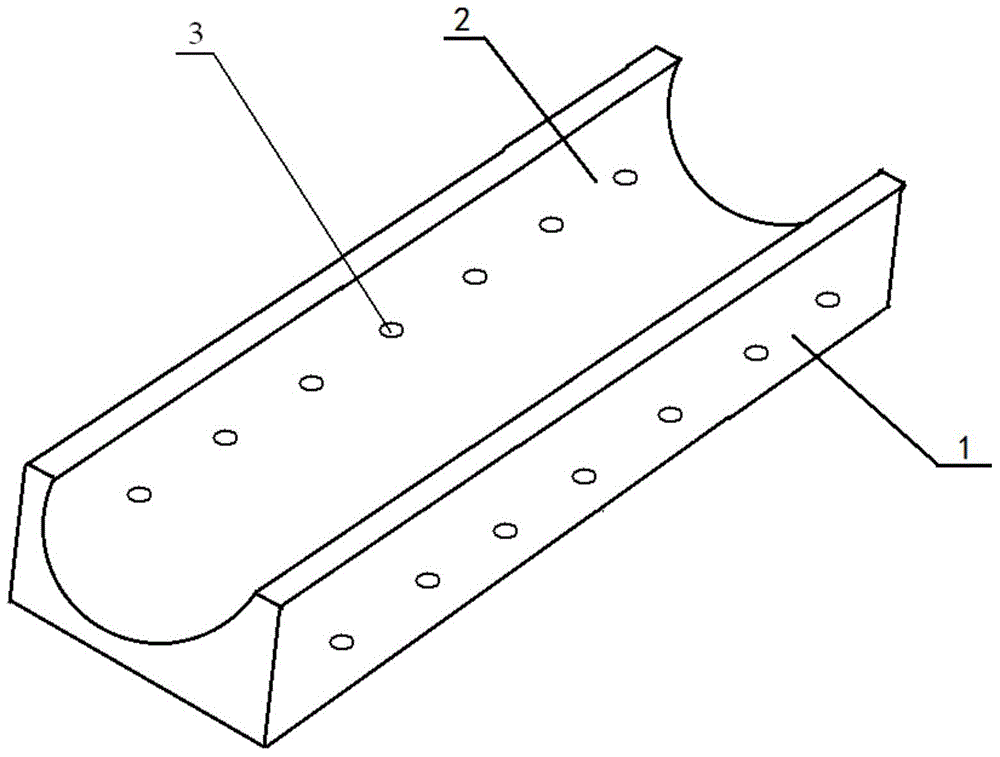

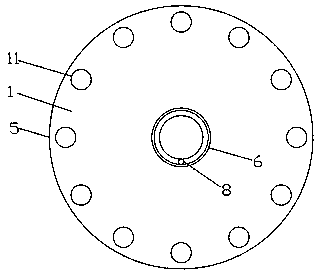

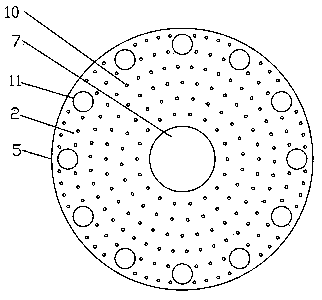

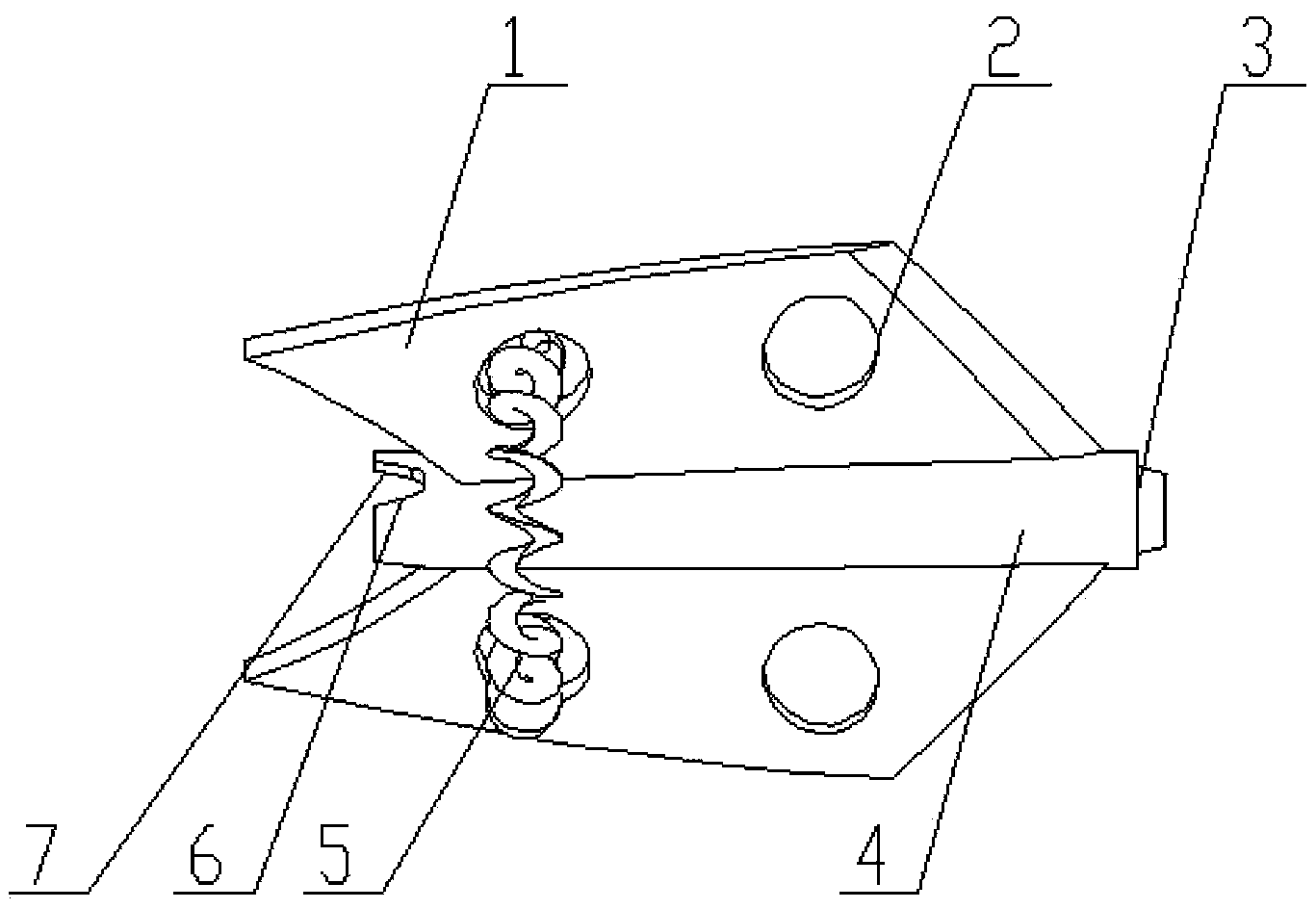

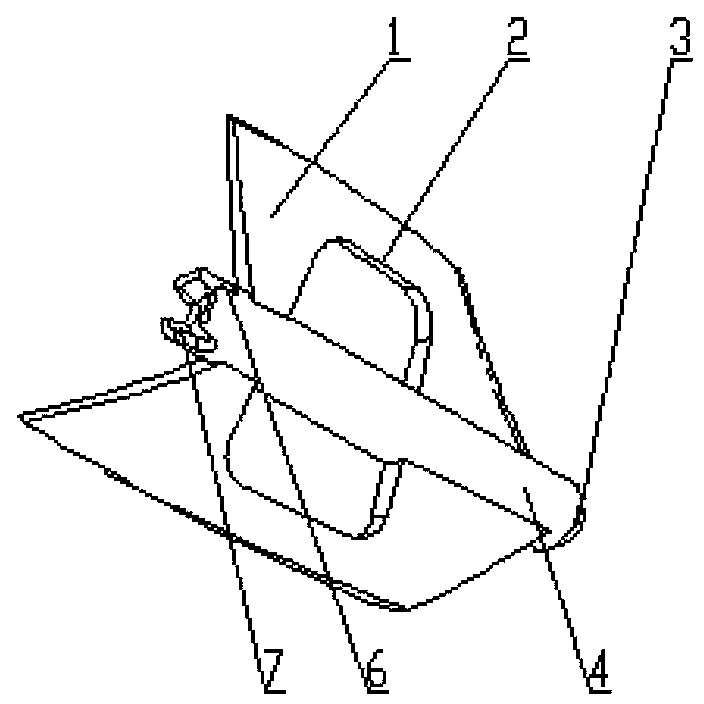

Preparation method for active dendrobium candidum superfine powder

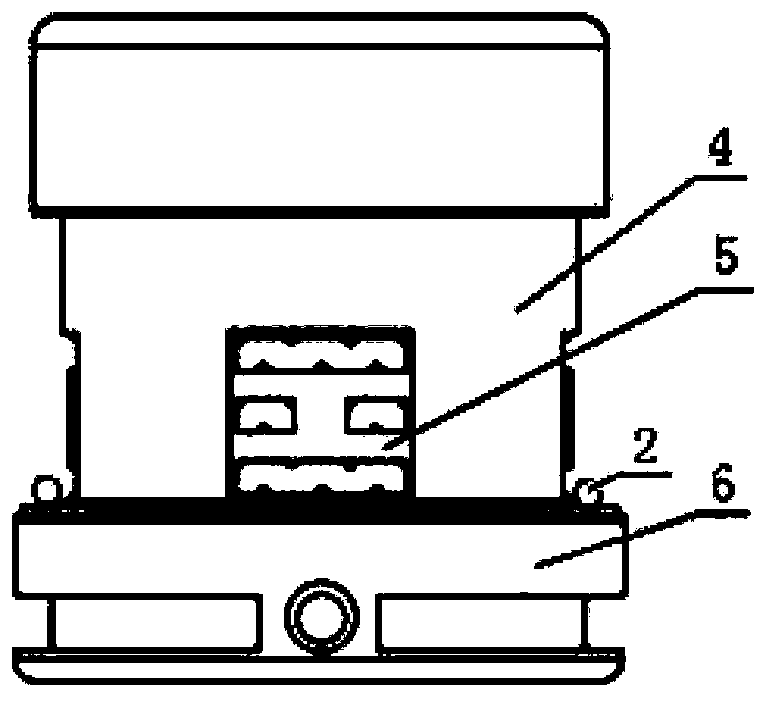

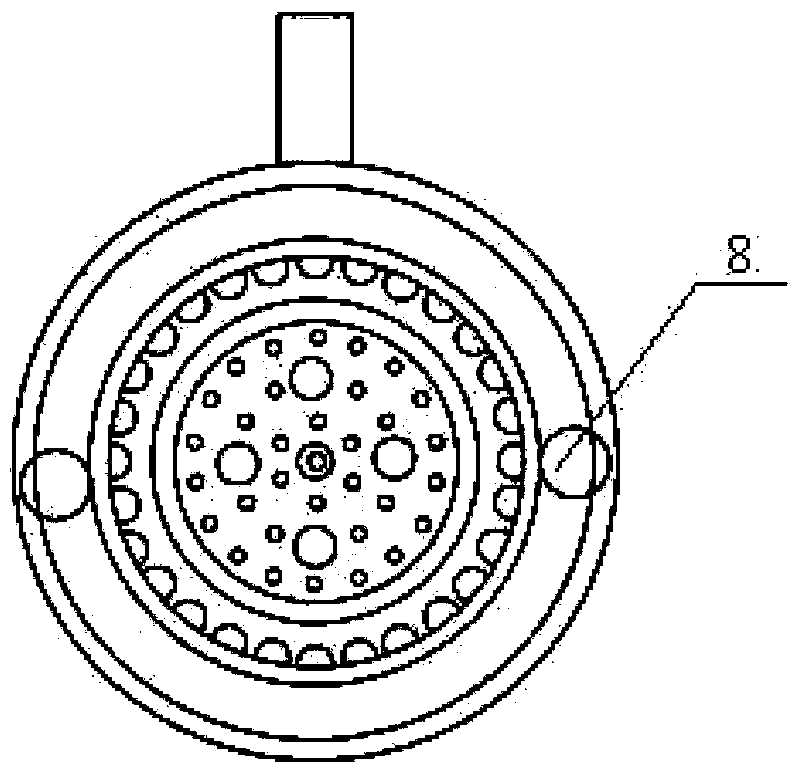

ActiveCN104906384AReduce contact areaIncrease pre-freezing and heat transfer effectPowder deliveryPlant ingredientsMicrometerSmall hole

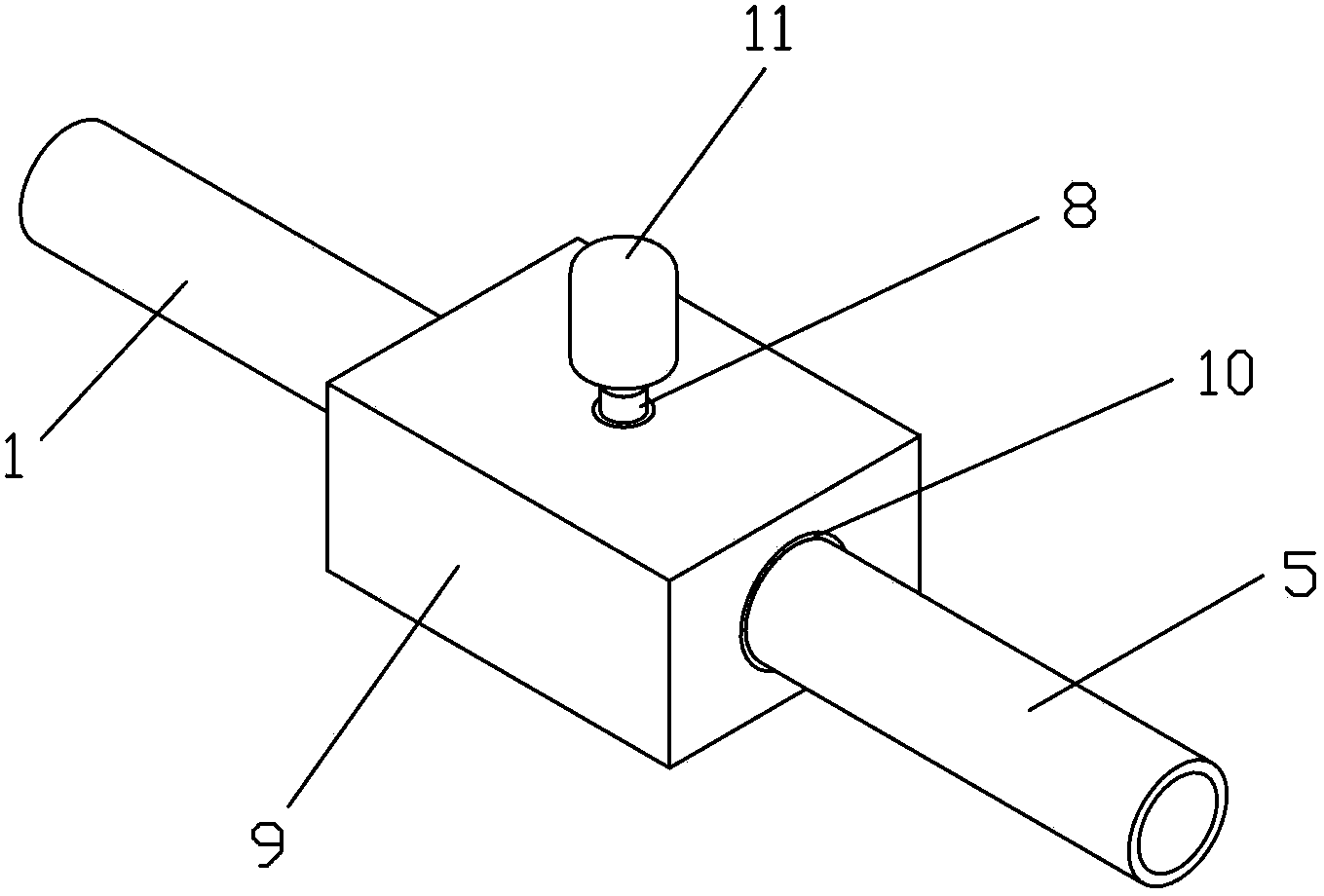

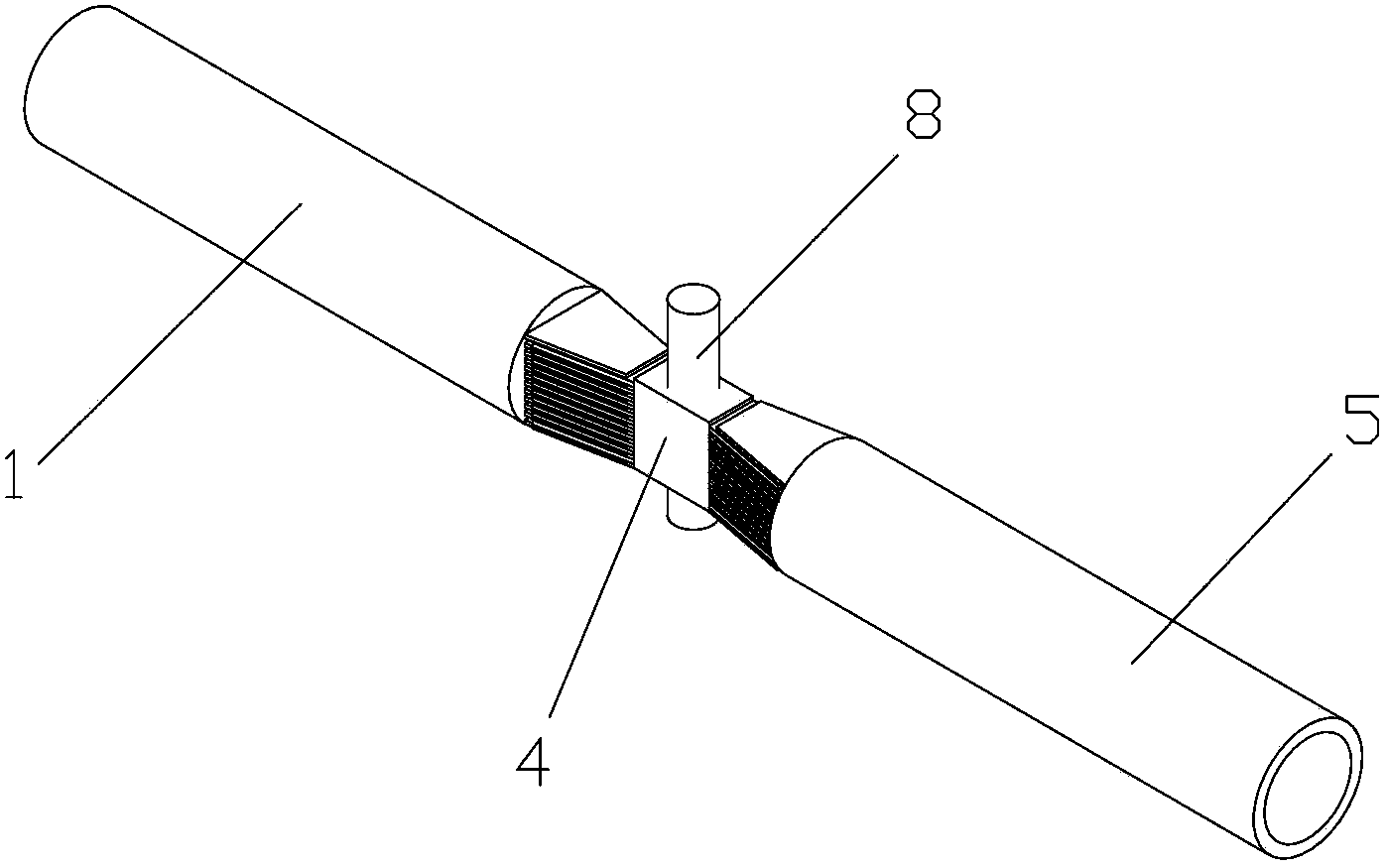

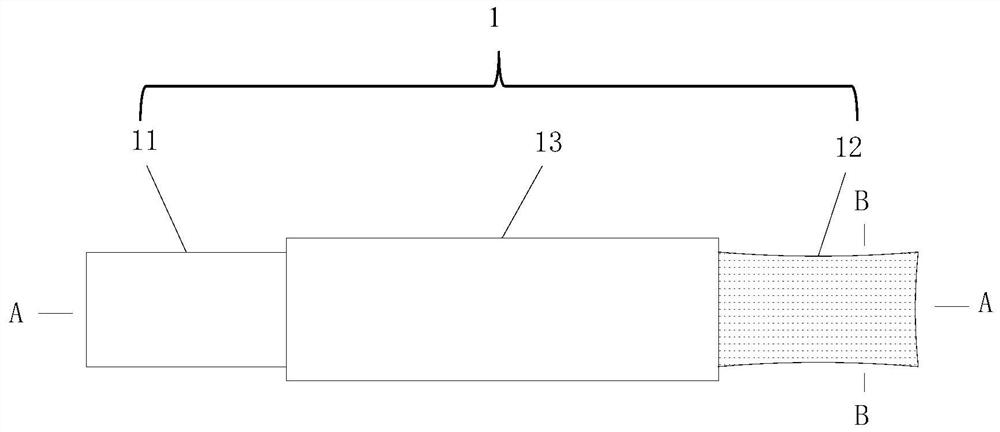

The invention discloses a preparation method for active dendrobium candidum superfine powder. The preparation method comprises steps: first, leaves of harvested fresh dendrobium candidum are removed, and washing and draining are carried out; second, punching is carried out, the dendrobium officinale is fixed on a die, the die is placed on a shelf of a vacuum drying container, cooling is carried out, the die is a cube-shaped metal die body (1) with an upper surface equipped with a half-cylindrical groove (2), and small holes (3) are arranged in the die body; third, vacuum-pumping is carried out; fourth, the shelf is heated, the temperature is risen to 0 DEG C, the pressure intensity is kept at 20-100Pa, drying is carried out, the material temperature is risen from 0 DEG C to 20 DEG C, the pressure intensity is kept at 10-20Pa, drying is carried out, the material temperature is risen from 20 DEG C to 40 DEG C, the pressure intensity is kept within 10Pa, drying is carried out, pressurization to a normal pressure is carried out; fifth, low temperature air-flow crushing is carried out, and active dendrobium candidum superfine powder is obtained and more than 95% of active dendrobium candidum superfine powder has a particle size of being less than 20 micrometers. The freeze-drying rate is high, freeze-drying time is saved, energy consumption is lowered, the product has a small particle size and is easy to dissolve and absorb, and the bioavailability is high.

Owner:ZHEJIANG JIANFENG HEALTH TECH

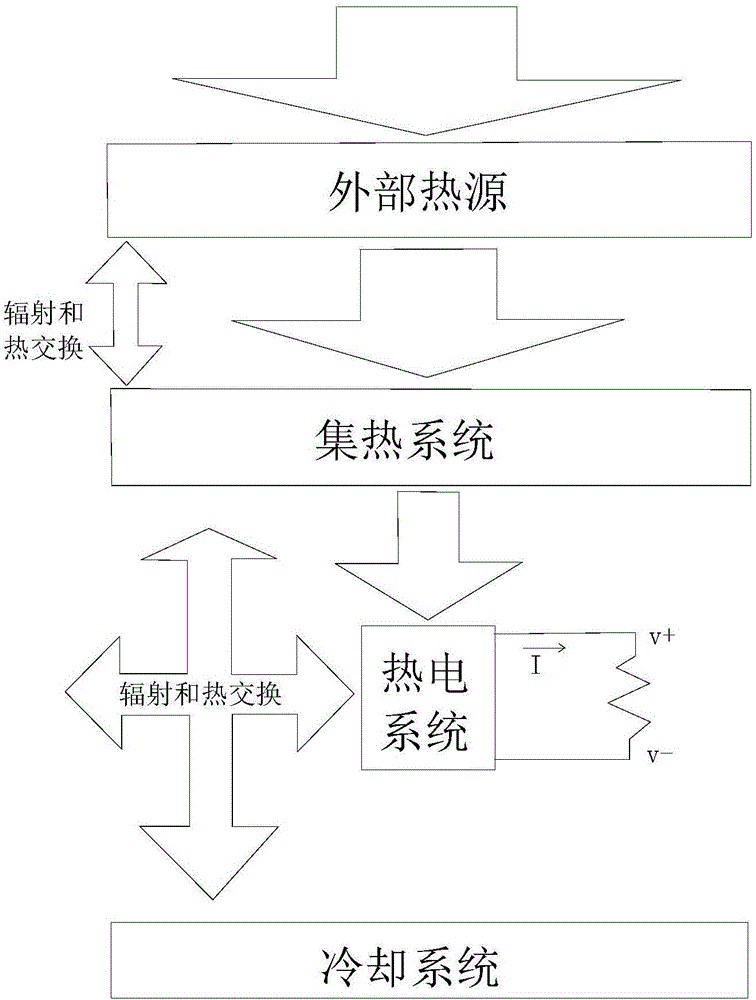

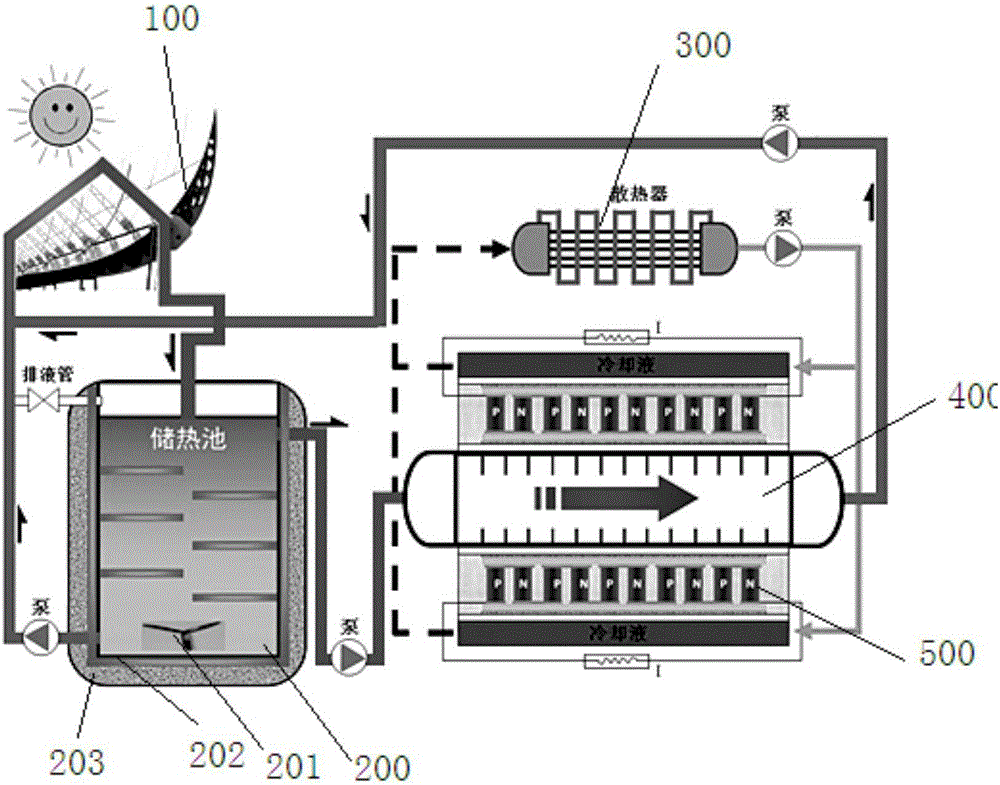

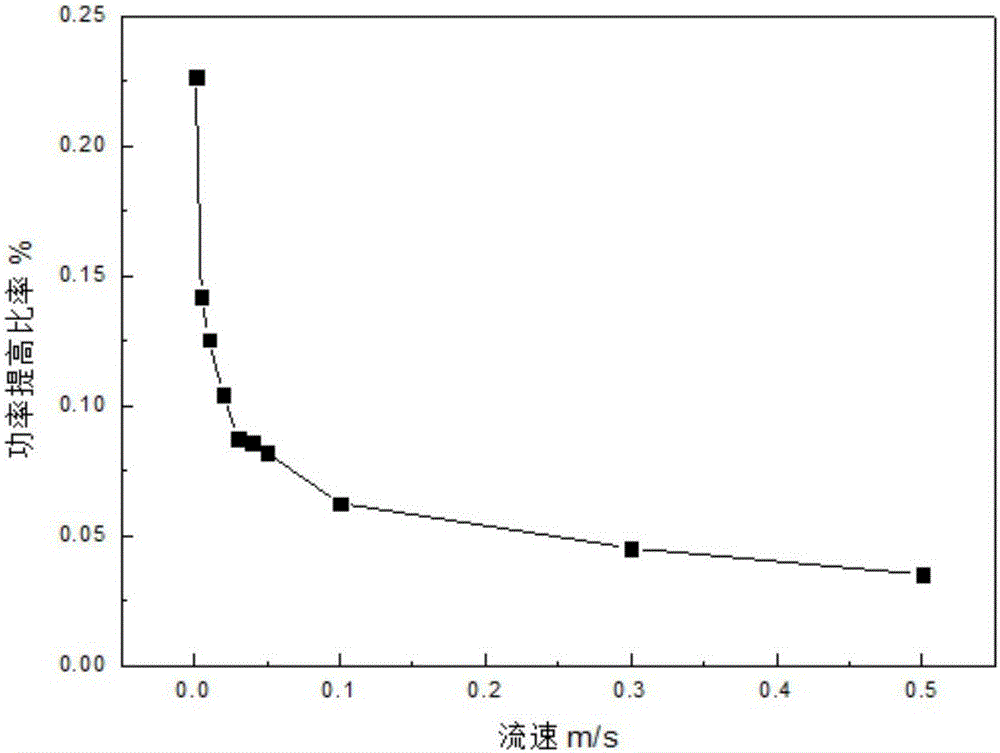

Nanofluid-based system for improving solar thermoelectricity generating efficiency

InactiveCN106123363AReduce surface temperatureReduce thermal resistanceSolar heating energySolar heat devicesThermal energyEngineering

The invention relates to a nanofluid-based system for improving the solar thermoelectricity generating efficiency. The nanofluid-based system comprises a nanofluid-based direct absorption type vacuum pipe heat collecting system, a nanofluid-based heat storage pool, a nanofluid-based cold end radiator, a thermoelectric device heat end heat exchanger and a thermoelectricity generating system; the nanofluid-based direct absorption type vacuum pipe heat collecting system is connected with the nanofluid-based heat storage pool through a pipeline; the nanofluid-based heat storage pool is connected with the thermoelectric device heat end heat exchanger through a pipeline; the thermoelectric device heat end heat exchanger and the thermoelectricity generating system are directly installed together; the nanofluid-based cold end radiator is a radiator of the thermoelectricity generating system; and the nanofluid-based cold end radiator and the thermoelectricity generating system are connected together through a pipeline. By means of the nanofluid-based system for improving the solar thermoelectricity generating efficiency, integration of heat absorption, transfer and storage is achieved, a heat exchanger is omitted in the solar optothermal absorption, storage and conveying processes, the heat exchange link is simplified, and thermal energy losses are decreased.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

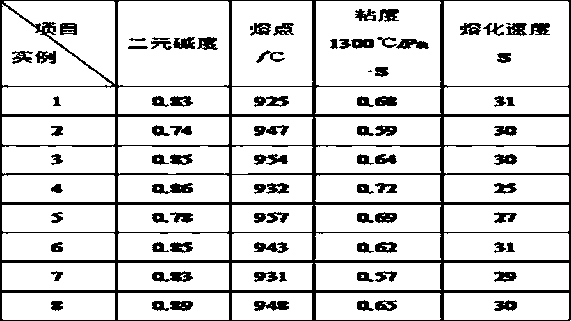

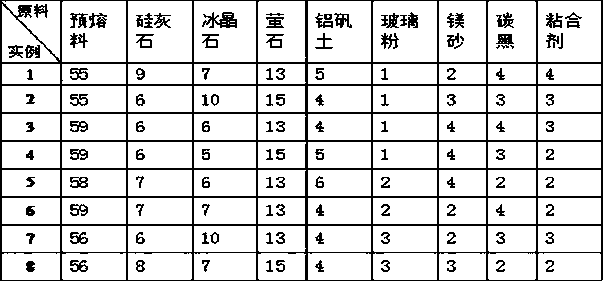

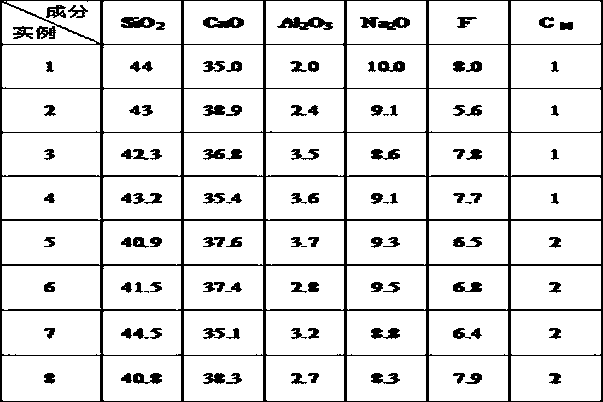

Continuous casting crystallizer casting powder for 400 stainless steel

InactiveCN108160960AEnables lubrication and heat transferAchieve lubricationCarbon steelChemical composition

The invention belongs to the technical field of steel making, and particularly relates to continuous casting crystallizer casting powder for 400 stainless steel. The continuous casting crystallizer casting powder for 400 stainless steel comprises the chemical components of, by weight percentage, 35-40% of CaO, 40-48% of SiO2, 2.0-4.0% of Al2O3, 8-10% of Na2O, 5-8% of F- and 1-2% of solid C. The chemical components of the continuous casting crystallizer casting powder for 400 stainless steel are used cooperatively, a proper smelting speed is kept while the heat preservation function is guaranteed, and an obtained casting blank is smooth in surface, regular in folding mark and free of concaves or other quality problems.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Novel rapid cooling hydrogen tank

ActiveCN103769004AImprove heat transfer efficiencyEliminate hot spotsTransportation and packagingMixing methodsHydrogen tankEngineering

The invention discloses a novel rapid cooling hydrogen tank. The novel rapid cooling hydrogen tank comprises, from the upper part to the lower part, a liquid collecting plate, a liquid dropping plate, a separating plate, and a redistributing sieve plate; a center opening of the liquid collecting plate is provided with a traverse baffle; a center opening of the liquid dropping plate is provided with a liquid collecting groove; a cold hydrogen pipe coiled pipe is arranged in the liquid collecting groove; a center opening of the separating plate is provided with a mixing pipe; the center of the redistributing sieve plate is provided with a diversion cone; and the periphery of the diversion cone is provided with small holes. The novel rapid cooling hydrogen tank is provided with the liquid collecting groove, and the liquid collecting groove is used for collecting liquid phase materials of an upper bed layer; the cold hydrogen pipe is arranged in the liquid phase materials in the liquid collecting groove in a coiled manner, cold hydrogen is sprayed out from the cold hydrogen pipe so as to stir and bubble the liquid phase materials, the relatively high temperature difference of the cold hydrogen and the liquid phase materials is used for enhancing gas-liquid heat transferring, heat is transferred from the liquid phase materials to the cold hydrogen, and then the cold hydrogen is mixed with oil gas for heat transferring, so that heat exchange efficiency of the novel rapid cooling hydrogen tank is increased greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

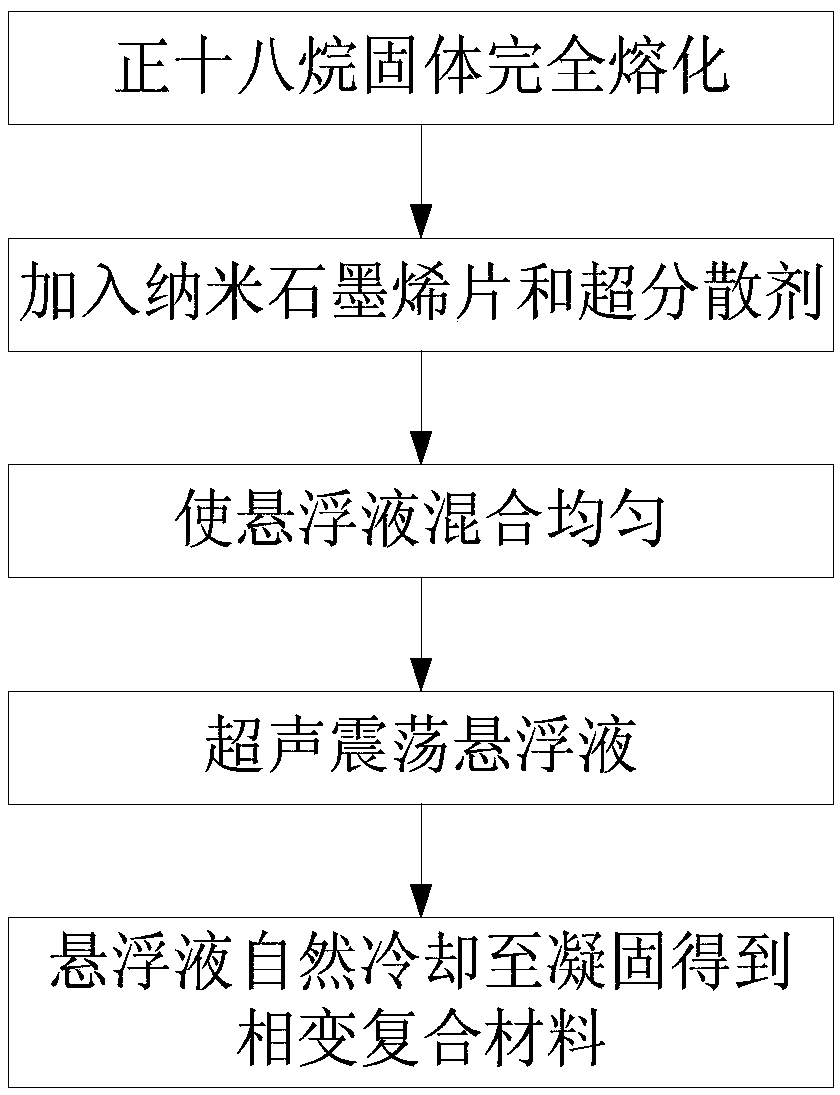

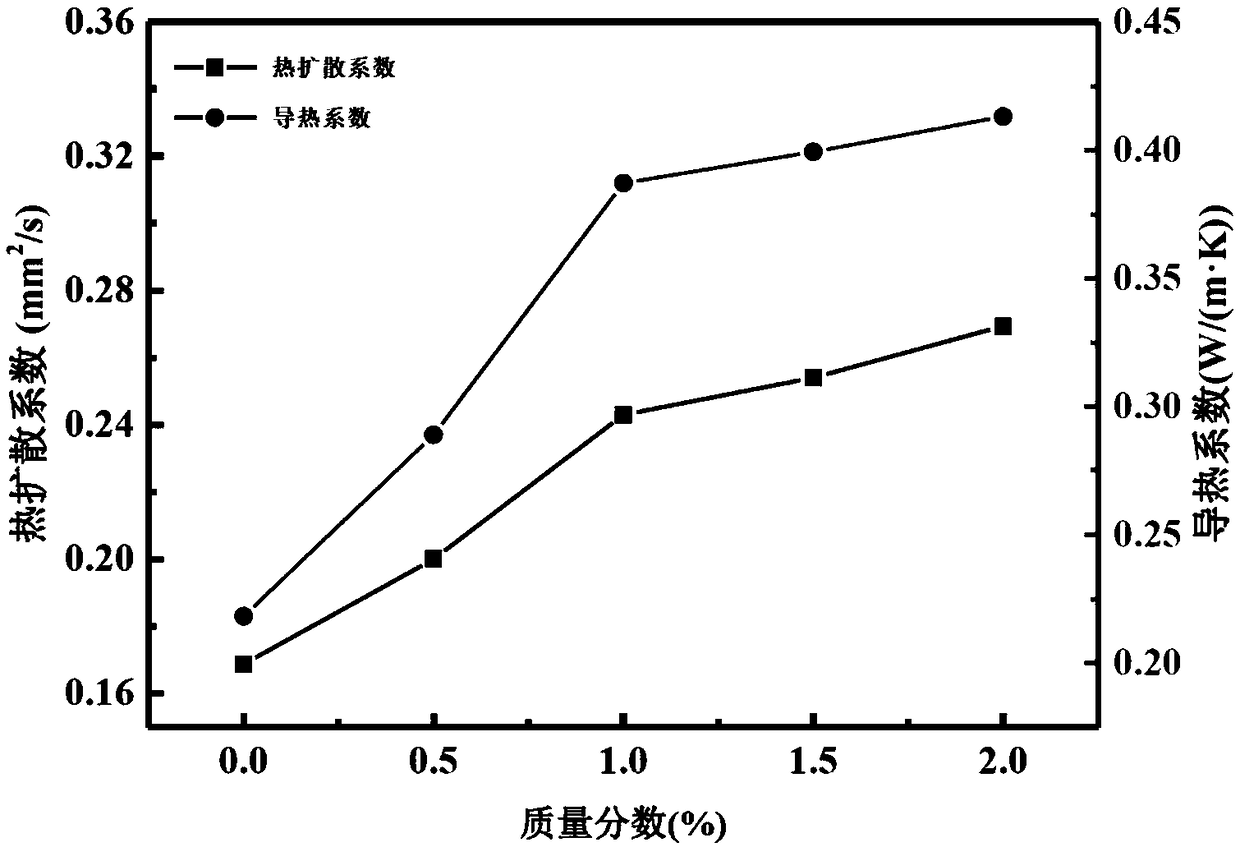

Phase-change composite material filled with graphene nanosheets and preparation method

ActiveCN109054759AStable three-dimensional heat conduction network structureImprove thermal conductivityHeat-exchange elementsMegasonic cleaningPre treatment

The invention discloses a phase-change composite material filled with graphene nanosheets and a preparation method. The preparation method for the phase-change composite material filled with graphenenanosheets is characterized by comprising the following steps: (step 1) n-octadecane solid which already undergoes drying pretreatment is completely melted; (step 2) graphene nanosheets and superdispersant are added into liquid-phase n-octadecane according to a proportion, so that a mixed suspension is obtained; (step 3) an agitator is used for agitation, so that the suspension is uniformly mixed;(step 4) the uniformly mixed suspension is poured into an ultrasonic cleaner and ultrasonically oscillated, so that the graphene nanosheets are formed into a stable three-dimensional heat conductionnetwork structure inside n-octadecane; (step 5) the suspension obtained in step 4 is naturally cooled to be solidified, and thereby the phase-change composite material with n-octadecane as a matrix which is filled with the graphene nanosheets is obtained. The phase-change composite material and the preparation method disclosed by the invention can be widely applied in fields, such as energy.

Owner:CHONGQING UNIV

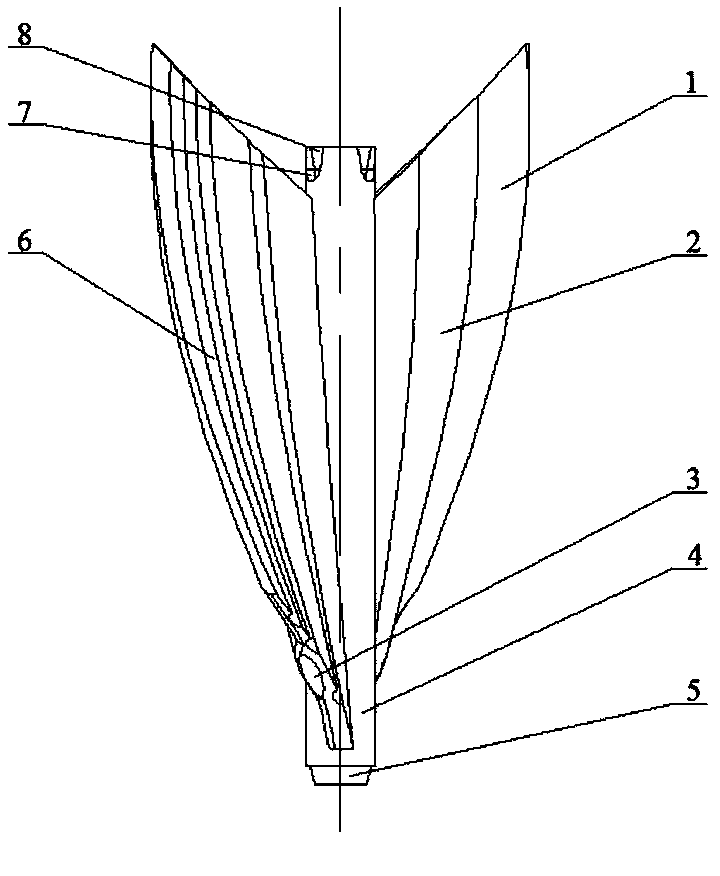

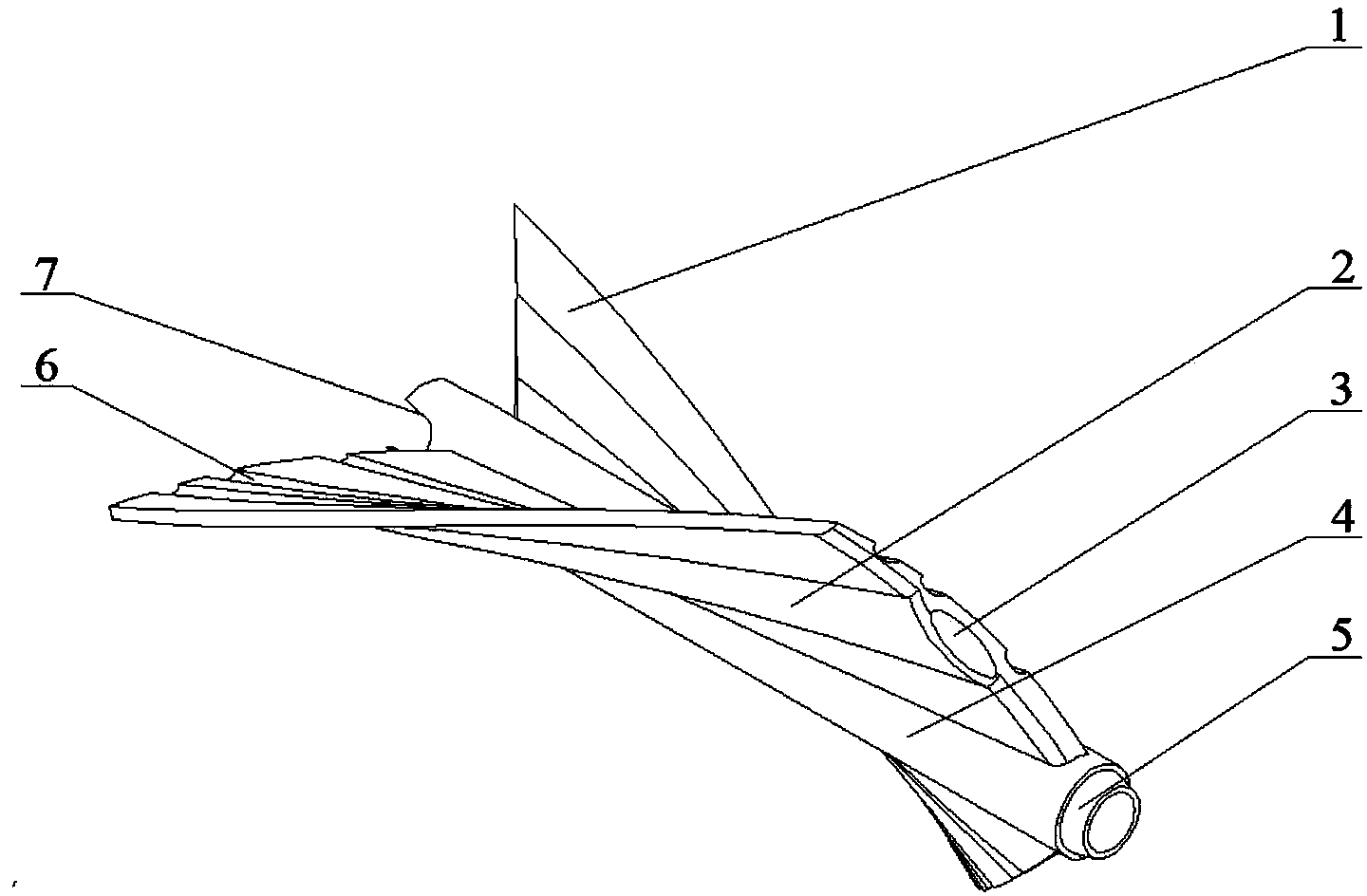

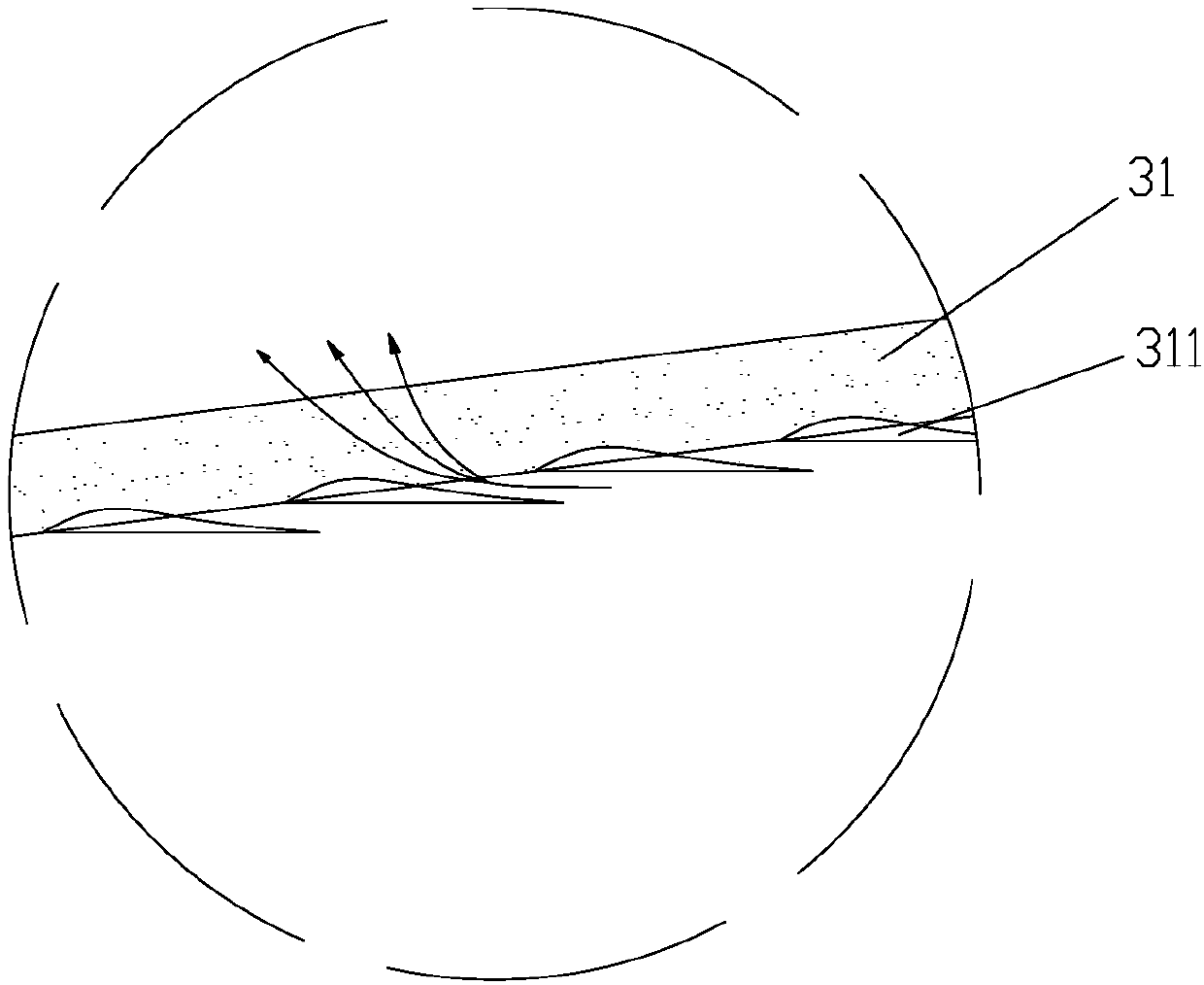

Rod-fin type loop heat pipe with varying sizes

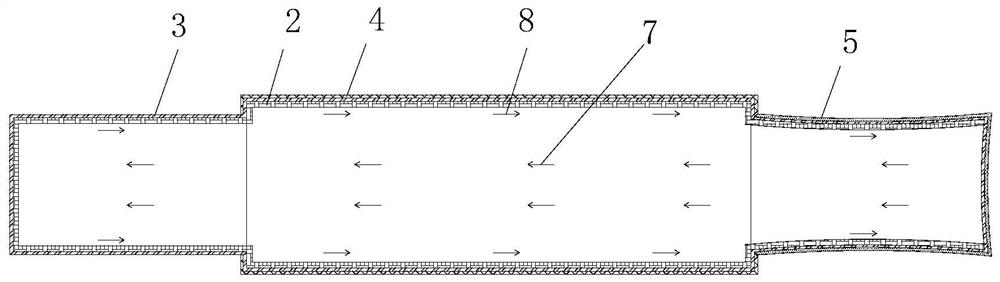

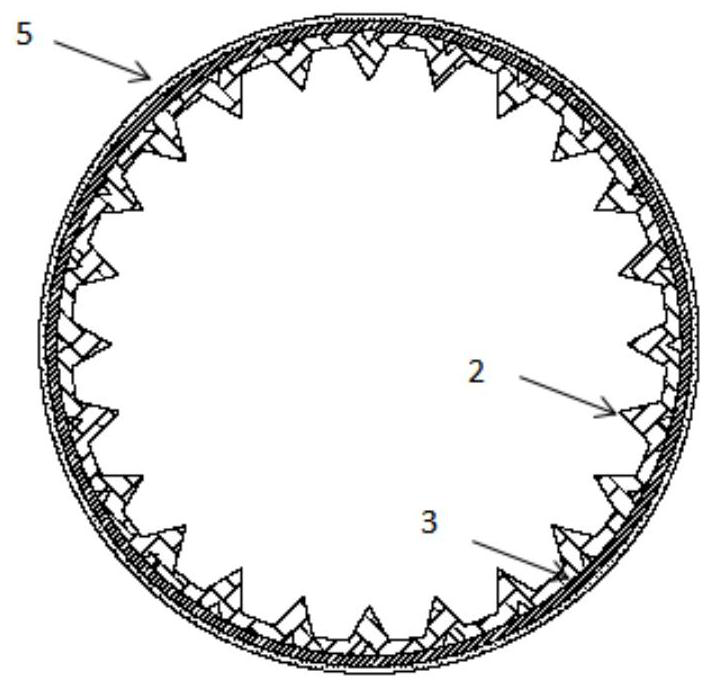

InactiveCN111238274ASpeed up the flowStable flowSafety devices for heat exchange apparatusIndirect heat exchangersFluid phaseEngineering

The invention provides a rod-fin type loop heat pipe with varying sizes. The rod-fin type loop heat pipe includes an evaporation header, a condensation header, rising pipes and return pipes, flow stabilizing devices are arranged in the rising pipes, the flow stabilizing devices each include a core body and an outer shell, the core bodies are arranged in the outer shells, the outer shells are connected and fixed to the inner walls of the rising pipes, the core bodies each include a plurality of radial rods extending from the centers of the core bodies to the radial direction, and a plurality offins extending downwards from the radial rods are arranged on each radial rod; and the core bodies each include a core column arranged at the center of each core body, one ends of the radial rods arefixed into the core columns, and from the core columns of the rising pipes to the radial extension direction, the size of the fins on the same radial rods is getting larger and larger. According to the rod-fin type loop heat pipe with the varying sizes, the size of the fins on the rising pipe walls is increased, so that the ability to cut vapor phases and liquid phases near the pipe walls is enhanced. The ability to cut near the pipe walls is focused to be strengthened, and noise reduction and vibration damping can be targeted for specific situations, so that the effects of noise reduction and vibration damping are further achieved, and meanwhile, heat transfer can be further enhanced.

Owner:SHANDONG UNIV

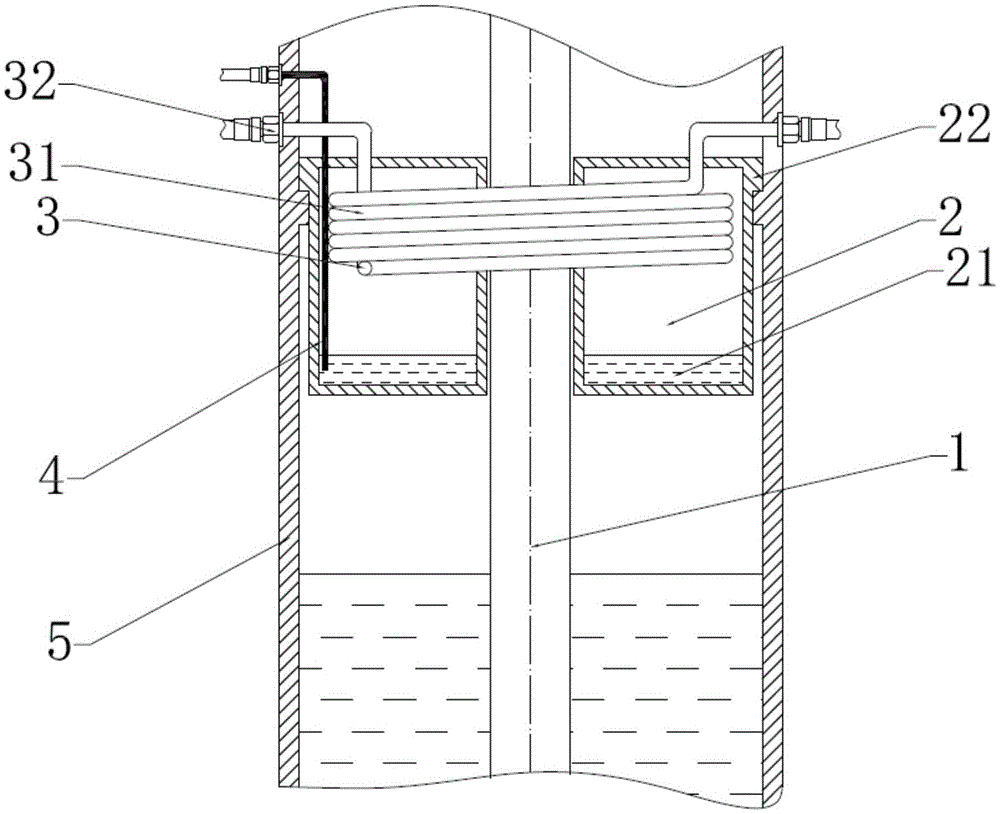

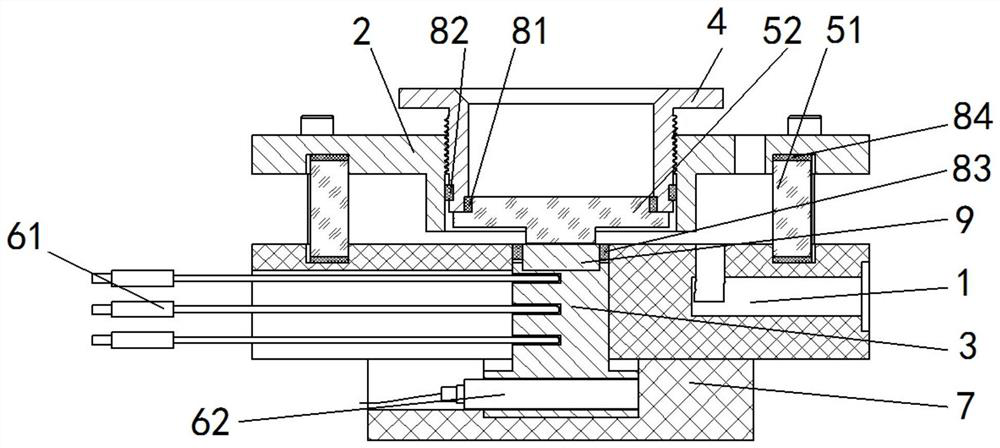

Combined thermal shielding structure for vertical pump for conveying high-temperature medium

ActiveCN105545819AAchieve heat transfer performanceCapable of natural circulationSpecific fluid pumpsPump componentsEngineeringCooling medium

The invention discloses a combined thermal shielding structure for a vertical pump of conveying a high-temperature medium. The structure comprises a low-pressure heat pipe, a forced heat exchange pipe and a liquid level meter. A thermal shielding device is a combined structure of the forced heat exchange pipe and the low-pressure heat pipe. The forced heat exchange pipe is installed in the low-pressure heat pipe. A medium in the heat pipe is subjected to phase change after being heated, is condensed when ascending to the top end of a low-pressure cavity and meeting the heat exchange pipe, and falls to the bottom of the low-pressure cavity under the effect of gravity. When the heat exchange pipe is broken, the internal medium is leaked into the heat pipe, so that the medium in the heat exchange pipe is prevented from leaking into the pumped medium to cause pollution. The liquid level meter is mounted in the low-pressure cavity; and when the heat exchange pipe is broken, the liquid level rises, and the liquid level meter detects an ultrahigh liquid level signal and monitors if the heat exchange pipe is broken. When the temperature of the pumped medium is changed, the flow of a cooling medium in the heat exchange pipe is adjusted to realize adjustment of heat exchange quantity so as to guarantee such installed parts as a shaft seal after thermal shielding to be located at a relatively stable temperature.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

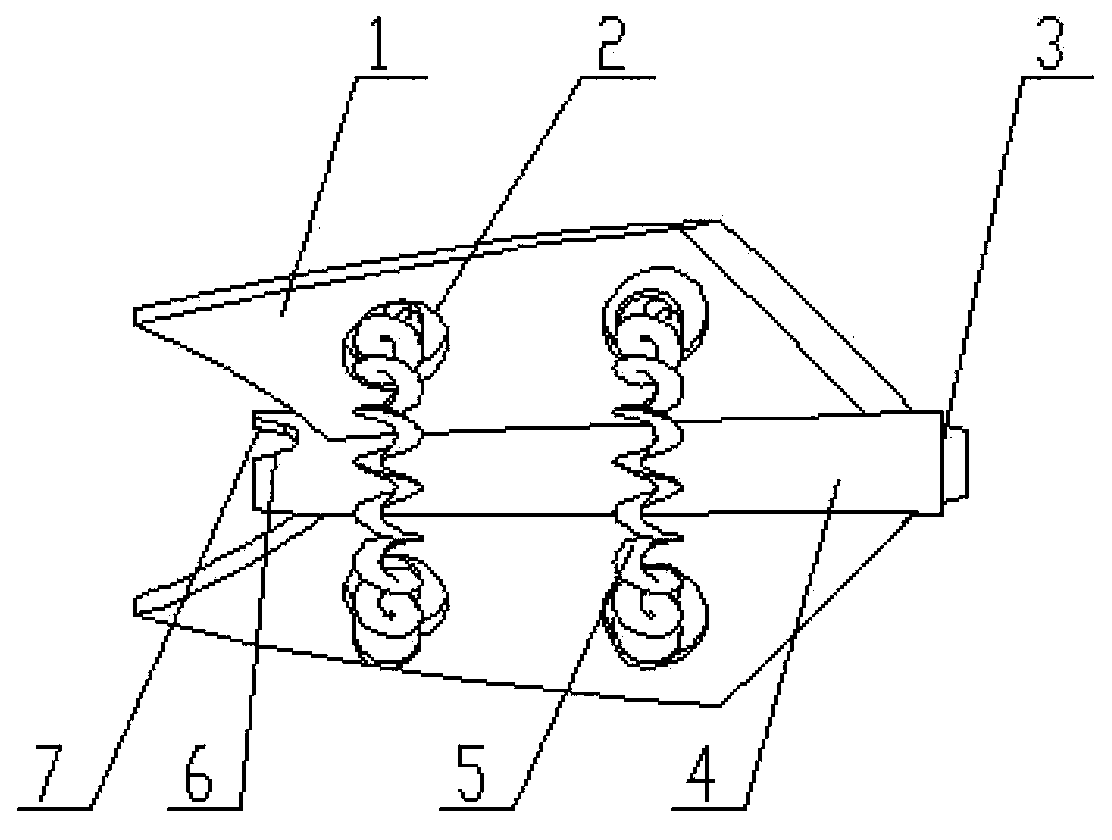

Penetration type concave-convex blade rotor inside heat exchange pipe

InactiveCN103411465AAvoid depositionSave materialHeat exchanger casingsRotary device cleaningHeat transmissionSpiral blade

The invention relates to a penetration type concave-convex blade rotor inside a heat exchange pipe. The penetration type concave-convex blade rotor inside the heat exchange pipe is formed by hollow shafts and spiral blades; groove structures are formed in back water sides of the spiral blades along the spiral directions of the blades; holes are formed in cross sections of the blades; the holes extend along the spiral directions of the blades to penetrate the whole blades to form into penetration holes; flow disturbance shafts namely projections are formed by the wall thickness of the penetration holes on the blades. The perturbance of the flow disturbance shafts and the concave-convex fluctuation functions of the grooves which are formed in the back water sides of the blades continuously act on the heat transmission fluid along the facing water sides, so that the radial speed and the tangential speed of the fluid on two sides of the blades are increased and the flow disturbance effect is increased. According to the penetration type concave-convex blade rotor inside the heat exchange pipe, the rotor can play a good self-centering role during rotating in the fluid due to the fact that the fluid has a suspension force function on the penetration holes when flowing through the penetration holes, scrapping between the blade tops and the pipe walls is avoided, the service life of the rotor is prolonged, mass and energy exchange between fluids inside the pipe is greatly enforced due to the separation effect of the penetration holes, and antiscale, descaling and heat transmission reinforcement functions are achieved.

Owner:BEIJING UNIV OF CHEM TECH

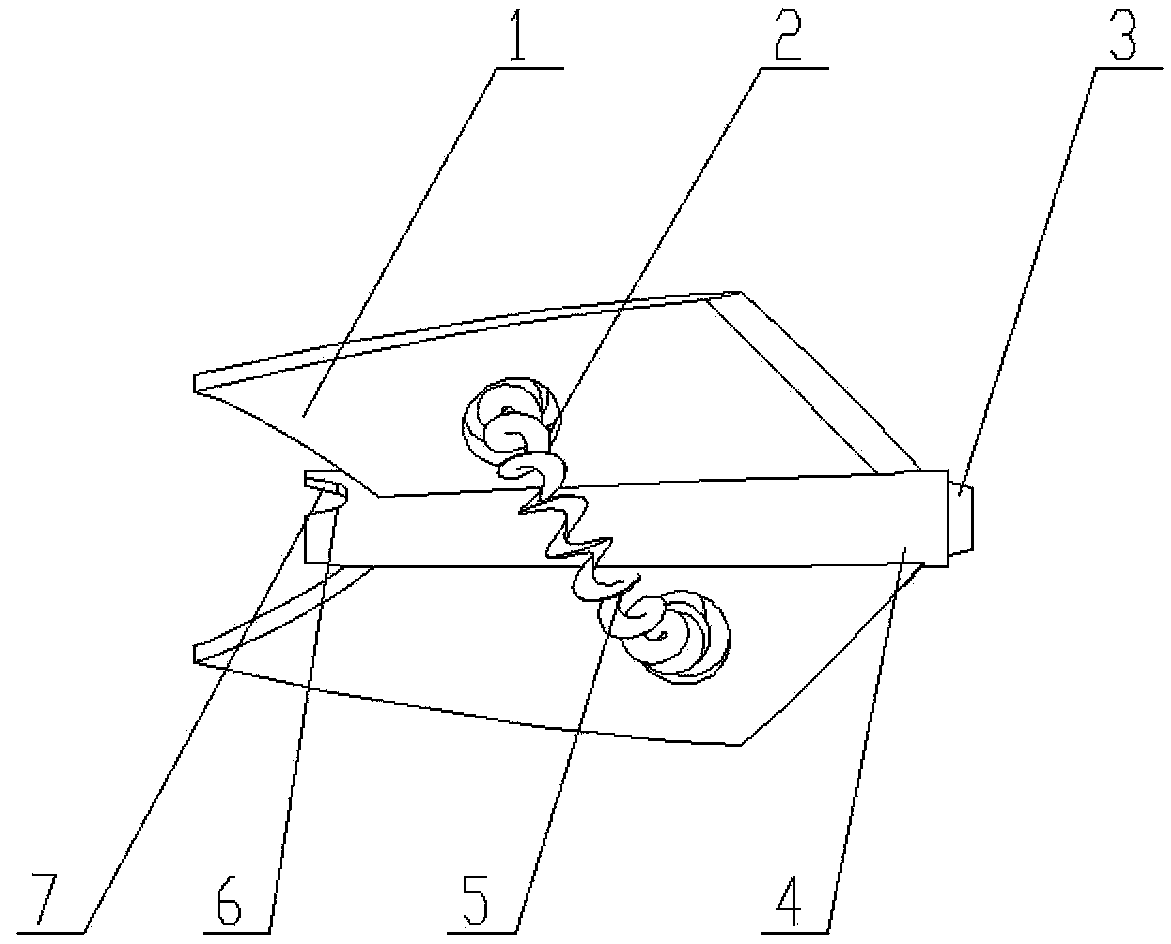

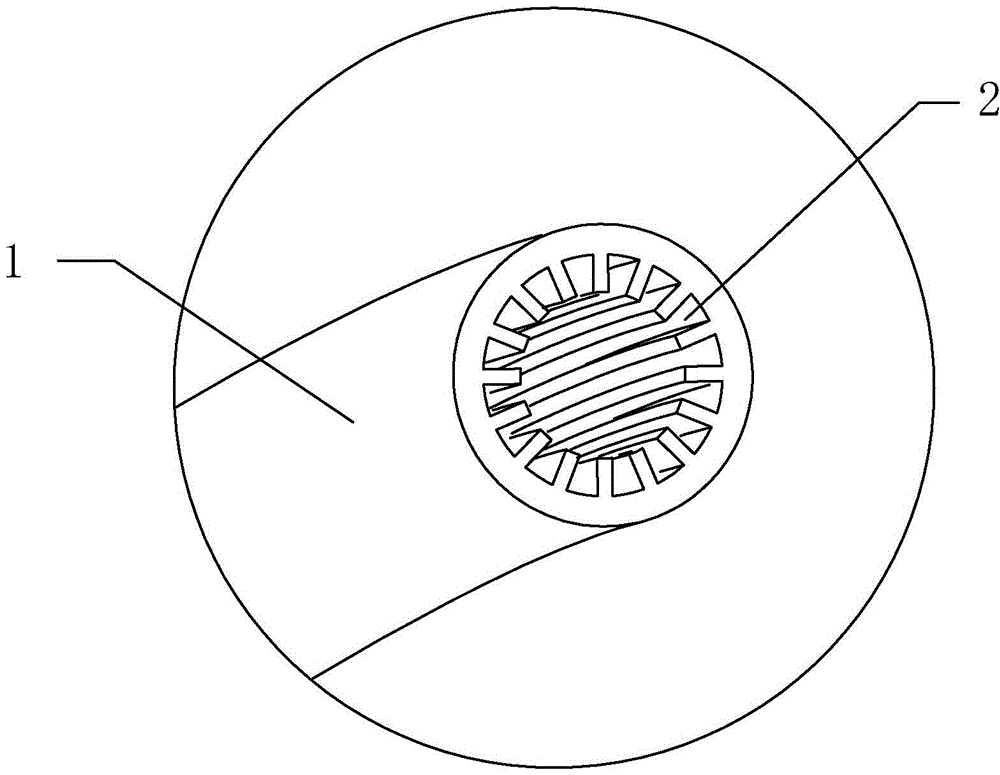

Through hole spring and helical blade rotor in heat exchange tube

ActiveCN103411464AReduce manufacturing costSave materialHeat exchanger casingsRotary device cleaningSpiral bladeCoil spring

The invention relates to a through hole spring and helical blade rotor in a heat exchange tube. The rotor mainly consists of a hollow shaft, perforated blades and coil springs, the perforated blades are positioned on the surface of the hollow shaft, the outer diameter of each perforated blade is smaller than the inner diameter of the heat exchange tube, the perforated blades are smooth in surface and helically shaped around the hollow shaft, and through hole structures are arranged on the surface of each perforated blade so as to reduce contact area of fluid and the rotor blades and reduce pressure loss when the fluid flows through the rotor. The edge, firstly contacting with the fluid, of the perforated blades is chamfered or filleted, and holes communicating with an inner hole of the hollow shaft are evenly and circumferentially formed in the end, away from a water inlet, of the hollow shaft. The coil springs penetrate the through holes in the surfaces of the blades, in the process that the coil springs rotate with the rotor, radial movement of a fluid region between the blades is strengthened, and a turbulence effect of through hole regions is further improved; and impacts on a laminar boundary layer of heat transfer fluid nearby the tube wall are generated, so that effects of scale prevention, descaling and strengthened heat transfer are further realized.

Owner:BEIJING UNIV OF CHEM TECH

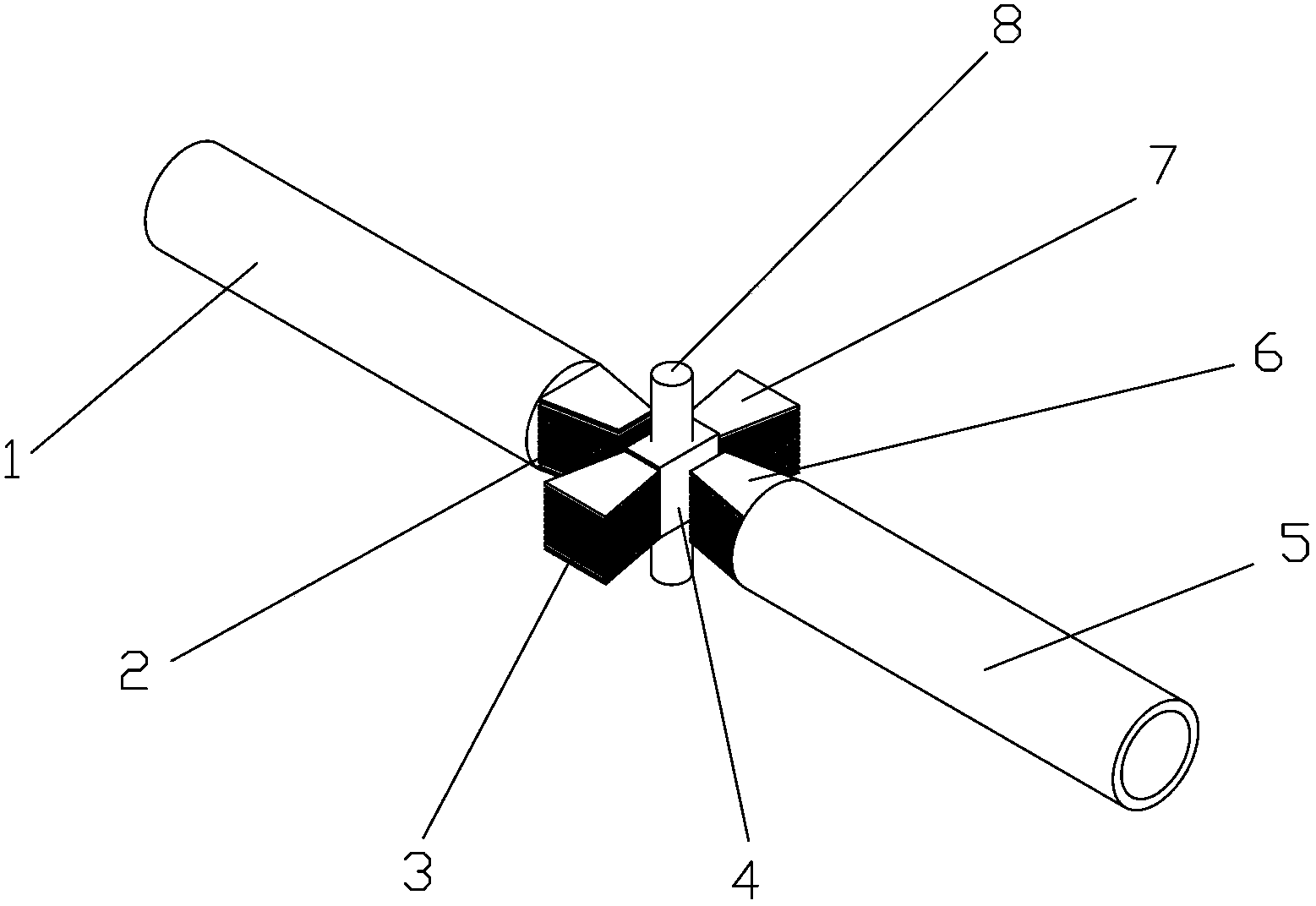

Heat flow switch for controlling heat tube conduction

The invention discloses a heat flow switch for controlling heat tube conduction. The heat flow switch comprises a switch shell, a switch motor, a first heat conduction fin set installed at the tail end of a first heat tube, a second heat conduction fin set installed at the tail end of a second heat tube, a connecting body arranged between the first heat tube fin set and the second heat conduction fin set and a switch shaft installed on the connecting body. The tail end of the first heat tube and the tail end of the second heat tube stretch into the switch shell respectively, the tail end of the first heat tube and the tail end of the second heat tube are arranged oppositely, a third heat conduction fin set meshed with the first heat conduction fin set is installed on one side of the connecting body, a fourth heat conduction fin set meshed with the second heat conduction fin set is installed on the other side of the connecting body, the first heat conduction fin set, the second heat conduction fin set, the connecting body, the third heat conduction fin set and the fourth heat conduction fin set are all located inside the switch shell, the switch shaft is installed on the switch shell, and the upper end of the switch shaft is connected with the switch motor. The heat flow switch can well control heat tube conduction and cannot affect the heat tube transmission efficiency.

Owner:陕西科林能源发展股份有限公司

Visual experiment device for researching critical heat flux density of ultra-thin vapor chamber

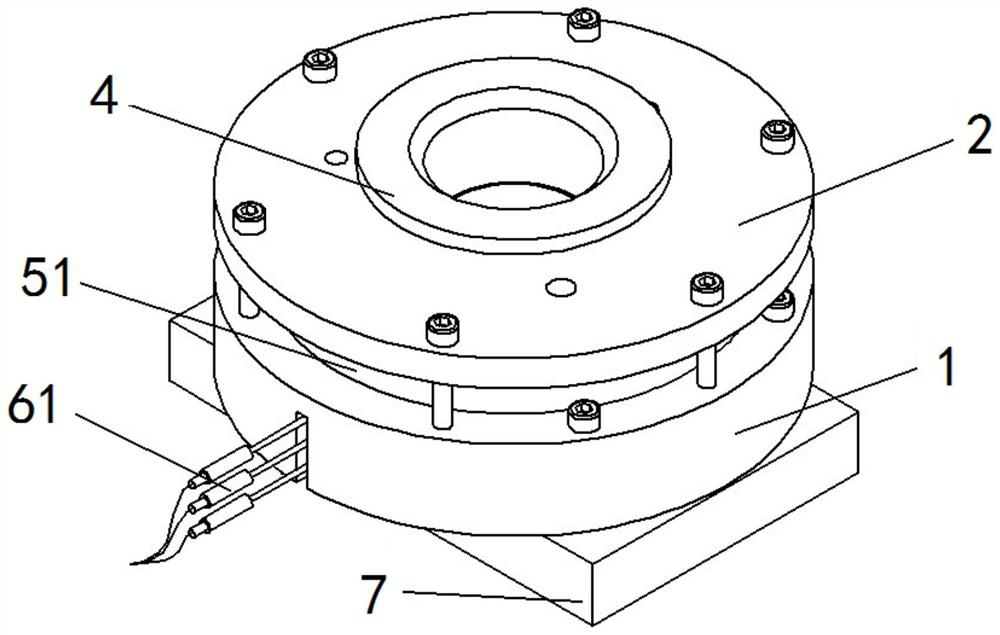

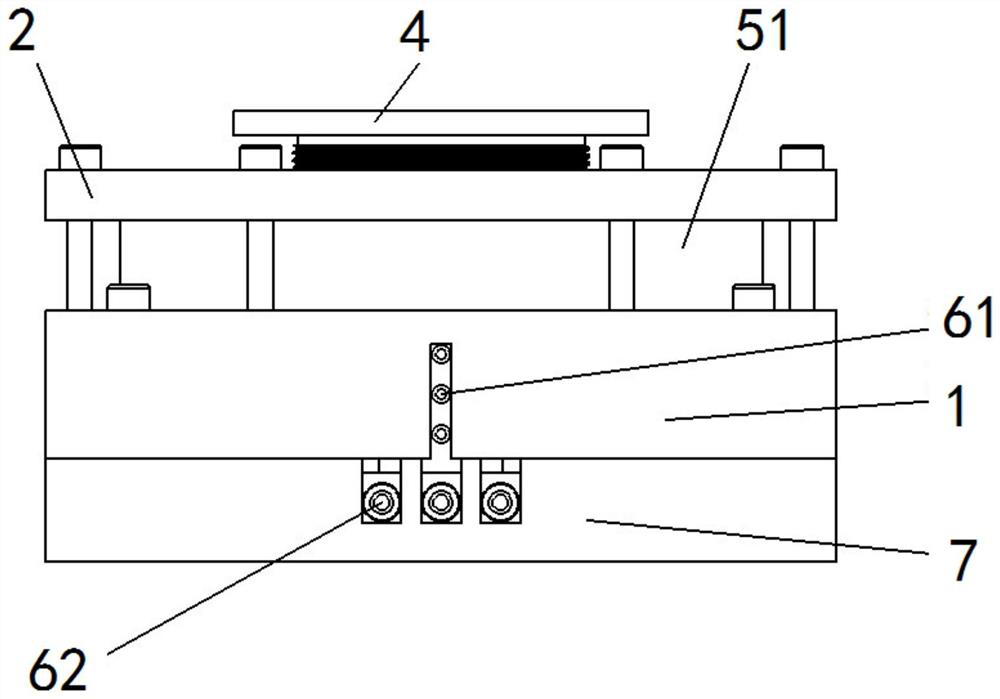

PendingCN112394081AMeet the experimental needsAchieve heat transfer performanceHydrodynamic testingMaterial thermal analysisHeat flowEngineering

The invention relates to a visual experiment device for researching critical heat flux density of an ultra-thin vapor chamber. The device comprises an annular side plate, a sample is connected to thelower end of the side plate, the sample and the side plate are semi-enclosed to form a working medium accommodating cavity, a first transparent heat insulation plate is detachably connected to the upper part of the side plate, a liquid adding hole communicated with the working medium accommodating cavity is formed in the upper end of the first transparent heat insulation plate, the lower end of the first transparent heat insulation plate abuts against the upper end of the sample, a gap between the first transparent heat insulation plate and the sample forms a working medium flow channel, the distance between the first transparent heat insulation plate and the sample can be adjusted, and the sample is provided with a heating device and a temperature sensing device. The gas-liquid change condition of the working medium in working medium flow channels with different sizes can be observed, and more experiment requirements are met. By controlling parameters such as working medium temperature, heating heat flow and a working medium flow channel, research on convective heat transfer and bubble dynamic characteristics of supercritical pressure fluid in the working medium flow channel underthe multi-boundary condition coupling effect is achieved.

Owner:SOUTH CHINA UNIV OF TECH

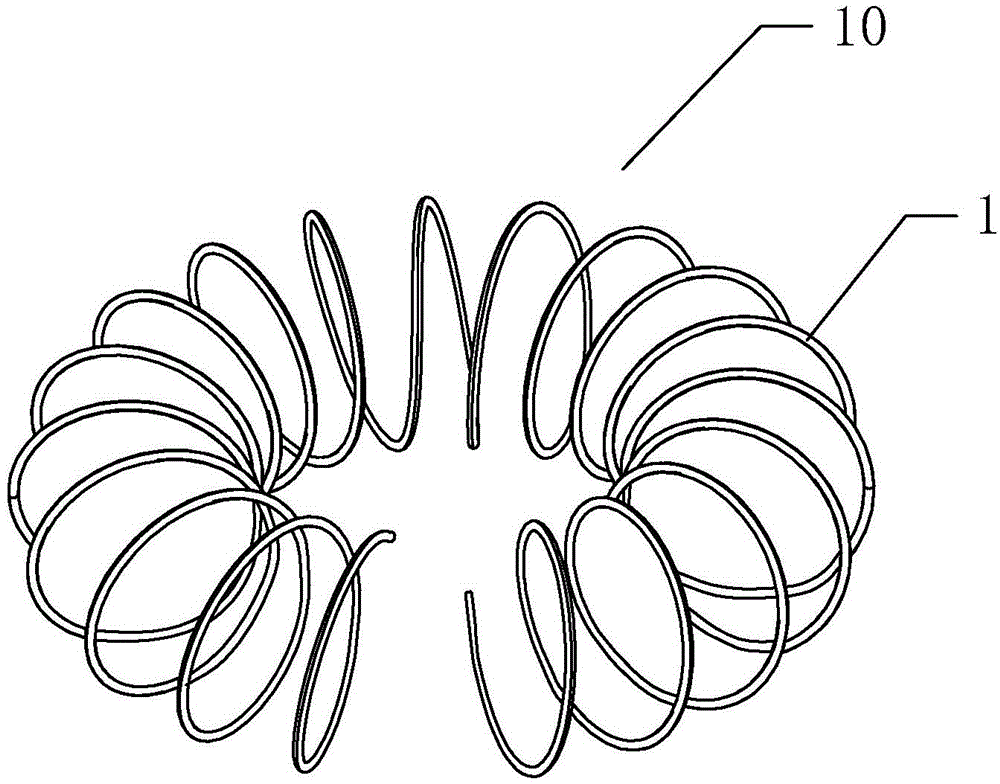

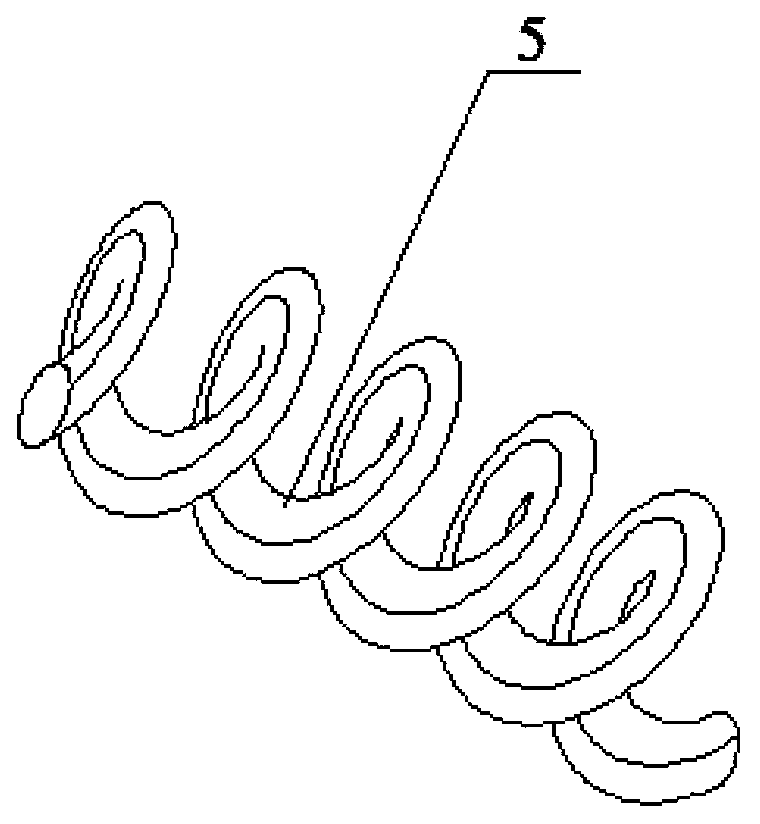

Heat pipe radiator integrated with heat transmission and heat radiation and manufacturing technology thereof

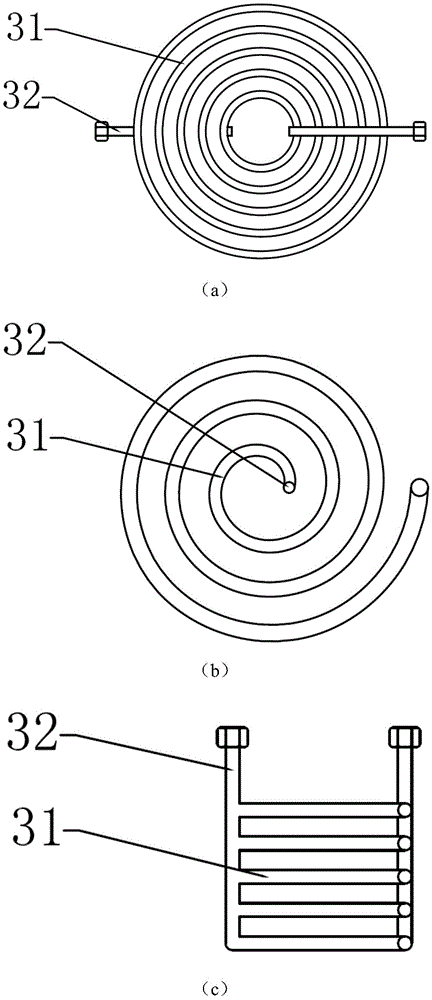

ActiveCN104061811AUniform temperatureAchieve heat transfer performanceIndirect heat exchangersEngineeringHeat transmission

The invention discloses a heat pipe radiator integrated with heat transmission and heat radiation and a manufacturing technology thereof. The heat pipe radiator adopts a long thin heat pipe with the pipe diameter of 2mm to 5mm; the long thin heat pipe is coiled in a spiral form; when the heat pipe radiator is in use, a part of each annular part of the heat pipe contacts with a heat source to form a heat absorbing section; other parts which do not contact with the heat source are used as heat-transmission heat-radiation sections; the heat transmission of heat pipe internal circulation of evaporation, condensation and backflow is formed in the annular heat pipe; the whole parts, which do not contact with the heat source, of the outer wall of the heat pipe directly radiate heat to air; therefore the heat transmission and the heat radiation are simultaneously realized; the whole heat pipe radiator is uniform in temperature, and can be bent into various shapes according to demands of the heat source, thereby being strong in adaptability; by the adoption of the long thin heat pipe which has the pipe diameter of 2mm to 5mm, and has better heat transmission and heat radiation effects than those of a heat pipe with a larger pipe diameter, the overall heat radiation efficiency of the heat pipe radiator is improved; the size and the weight of the radiator are decreased greatly.

Owner:TENON HEAT TRANSFER TECH ZHONGSHANCO LTD

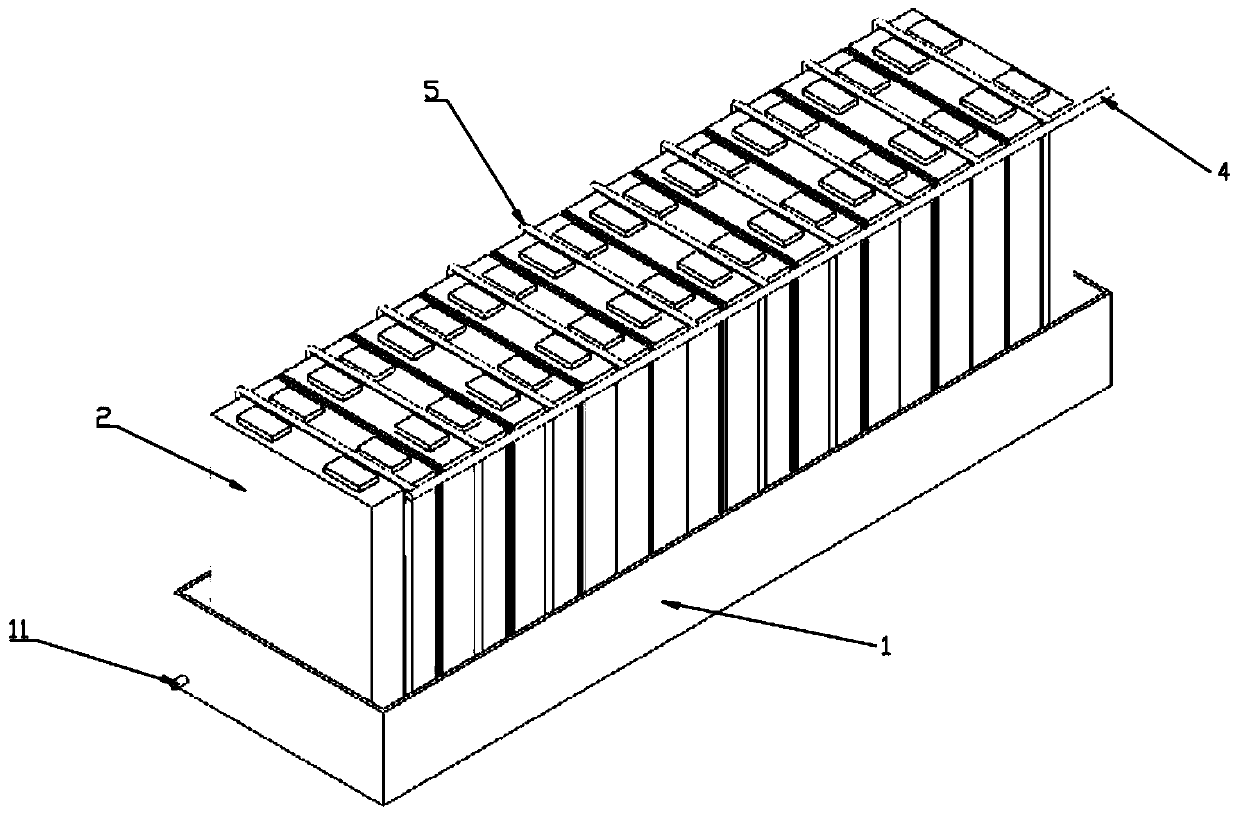

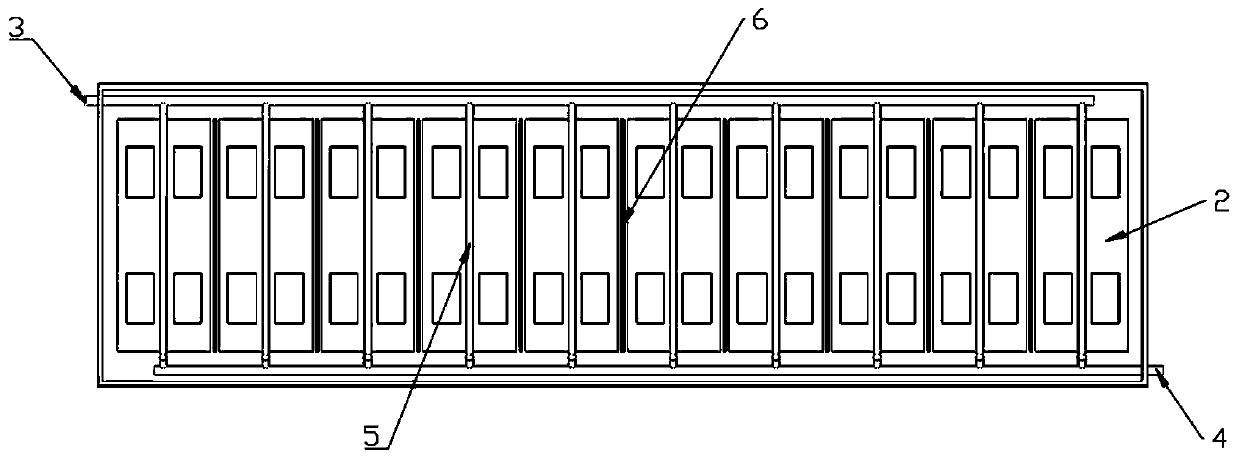

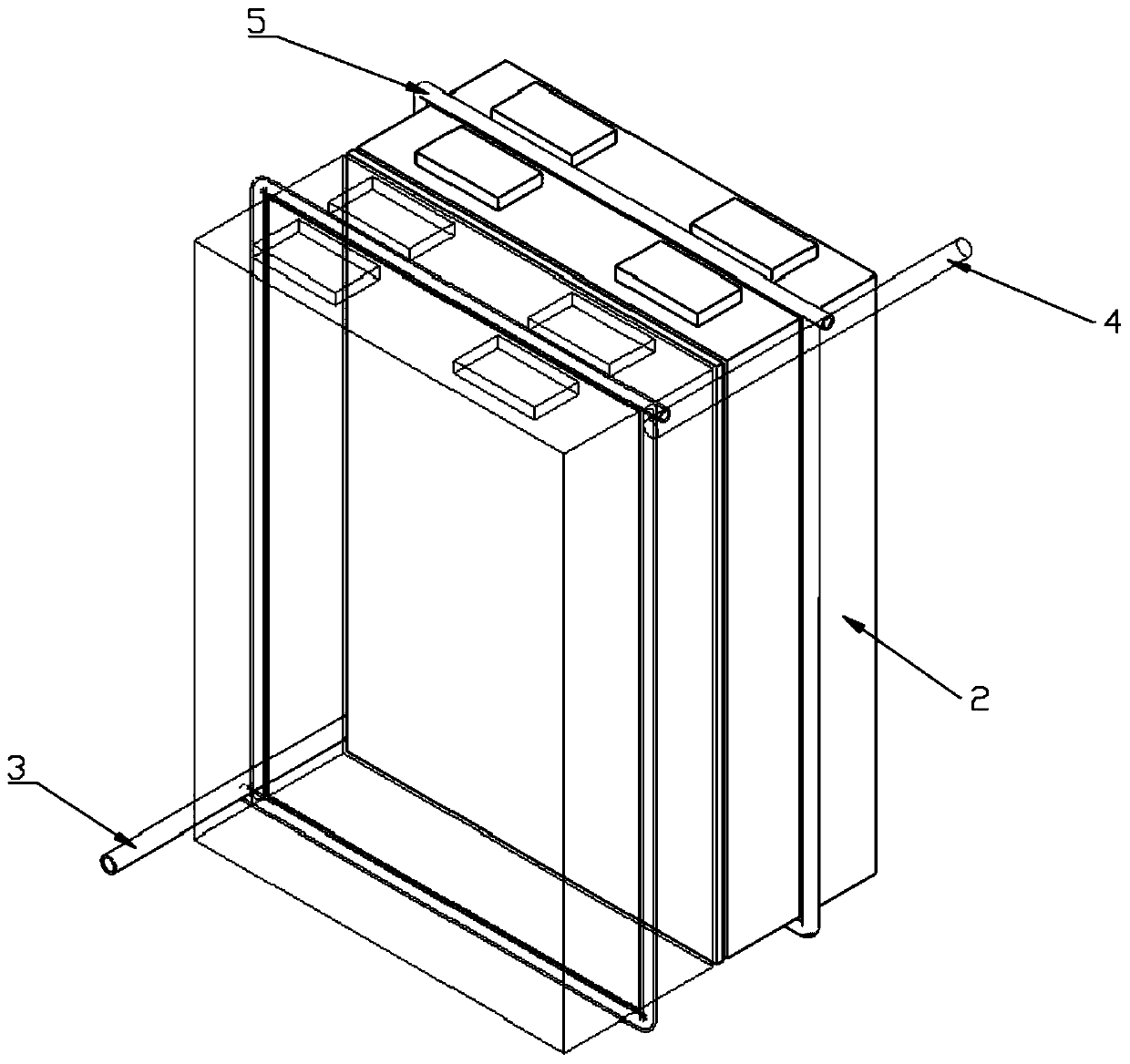

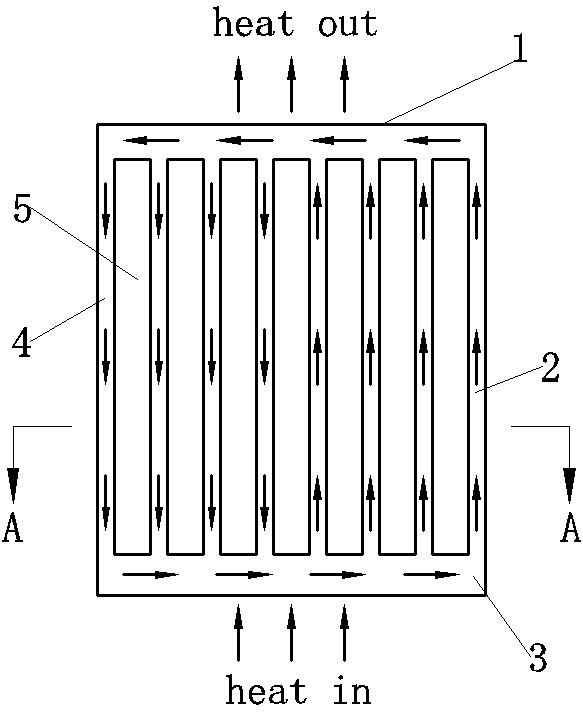

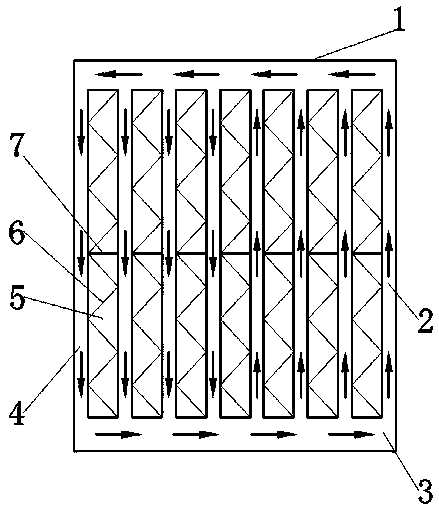

Power battery thermal management module based on liquid metal

InactiveCN111525062AImprove efficient heat transfer performanceImprove heat transfer effectSecondary cellsCell component detailsPower batteryThermodynamics

The invention relates to a power battery thermal management module based on liquid metal. The module comprises a box body, single batteries fixed in the box body and adjacently arranged with the largest side face, and a liquid inlet main pipe and a liquid outlet main pipe which are arranged along the opposite angles of the single batteries; and a shunting branch pipe is arranged between the liquidinlet main pipe and the liquid outlet main pipe in a communicating mode, a heat insulation partition plate is tightly arranged on one side of each single battery, and a flexible graphite film is tightly arranged on the other side of each single battery. The periphery of the flexible graphite film is wound and wrapped on the shunting branch pipe; according to the invention, the requirements on high-speed heat transfer and high temperature uniformity of each single battery in the power battery pack can be met, thermal runaway propagation and expansion accidents can be avoided or delayed, and the energy density of the power battery box body is greatly improved.

Owner:HEFEI UNIV OF TECH

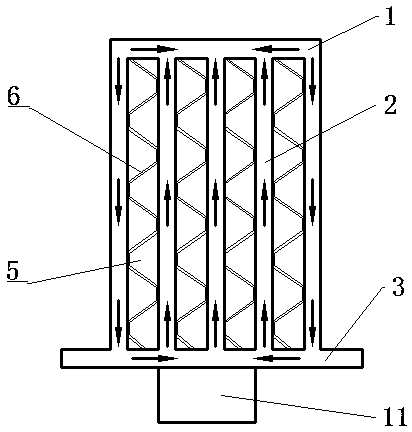

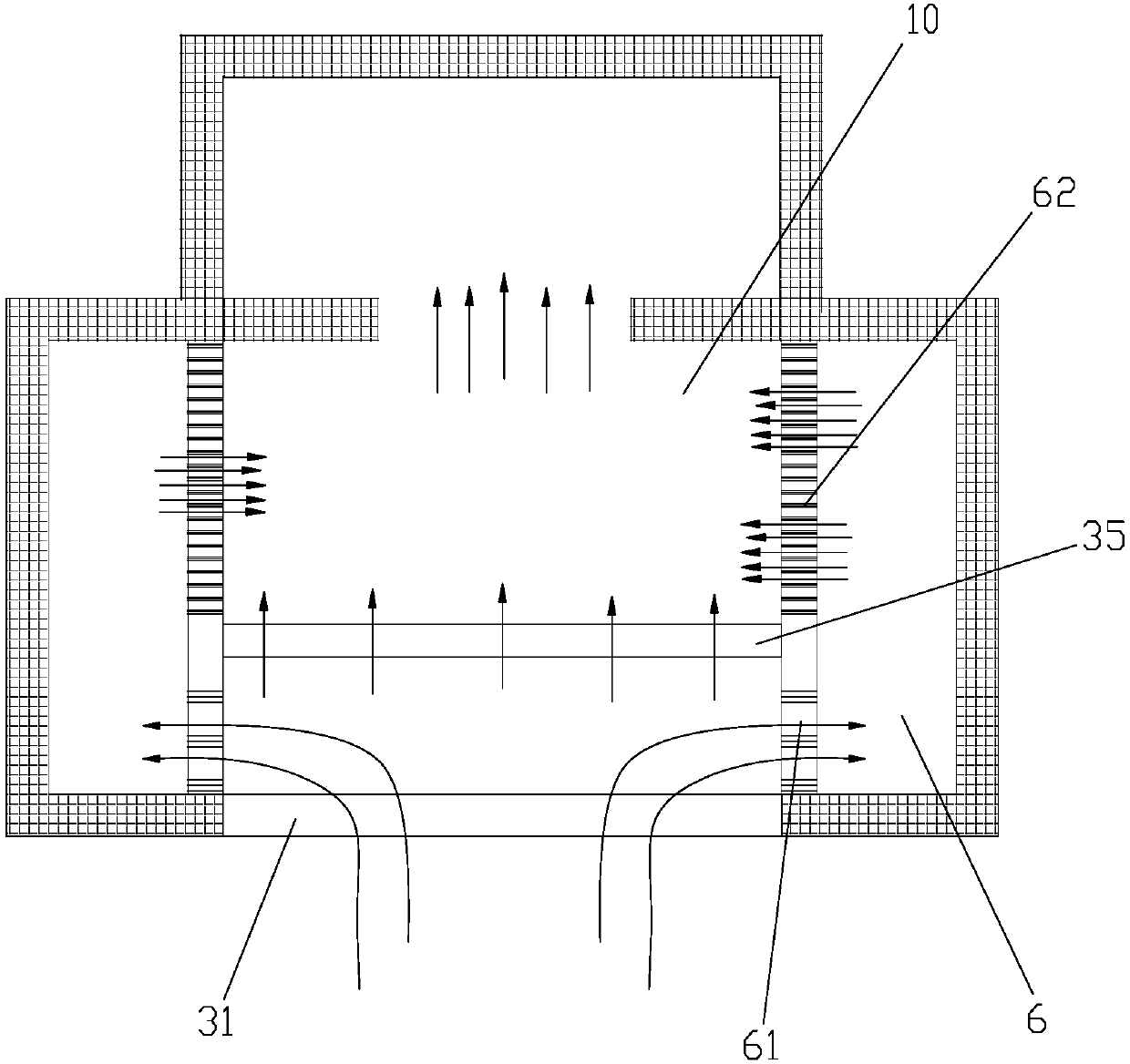

Composite loop heat pipe and composite loop heat pipe heat exchange assembly

PendingCN111207612AImprove heat transfer performanceImprove heat transfer effectIndirect heat exchangersHeat flowHeat flux

The invention relates to a composite loop heat pipe and a composite loop heat pipe heat exchange assembly. The composite loop heat pipe comprises a header box A, a header box B, evaporation channels and condensation channels. One ends of the evaporation channels and one ends of the condensation channels are connected with the header box A, and the other ends of the evaporation channels and the other ends of the condensation channels are connected with the header box B. The header box A, the header box B, the evaporation channels and the condensation channels form a loop, and a composite loop heat pipe structure is formed. The internal channels of the composite loop heat pipe are in a vacuum or negative-pressure state, and a working medium playing a role of phase-change heat transfer is sealed in the internal channels of the composite loop heat pipe. Fins or heat source channels or cold source channels are attached between the adjacent evaporation channels or the adjacent condensation channels of the composite loop heat pipe to form the heat exchange assembly. The heat exchange assembly automatically achieves the gas-gas heat exchange or gas-liquid heat exchange effect. The composite loop heat pipe and the composite loop heat pipe heat exchange assembly have the advantages of high heat exchange efficiency, large heat flux density, high heat exchange speed, high pressure bearingcapacity, light weight, stable structure, good frost resistance, safe operation and the like and belong to novel heat exchange elements.

Owner:长沙馨麓能源科技有限公司

Furnace slag heat exchange device and high-temperature afterheat recycling device containing furnace slag heat exchange device

PendingCN107816898ATo achieve the purpose of waste heat recoveryImprove waste heat utilization efficiencyIncreasing energy efficiencyWaste heat treatmentSlagHot Temperature

The application belongs to the field of energy conservation, and particularly relates to a furnace slag heat exchange device and a high-temperature afterheat recycling device containing the furnace slag heat exchange device. The furnace slag heat exchange device comprises a furnace slag heat exchange mechanism which is used for conveying and distributing furnace slag; the furnace slag heat exchange mechanism comprises a first-stage heat exchange material bed which is arranged in an inclined manner and comprises a high feeding end and a low discharging end; and ventilating holes which can introduce cooling air flow to blow furnace slag to float and move to the discharging end are formed in the bottom of the first-stage heat exchange material bed. According to the furnace slag heat exchangedevice provided by the application, the cooling air flow can blow the furnace slag to float and move to a material bed of the next stage through the ventilating holes in the bottom of the material bed; conveying, heat transferring and heat exchanging of furnace slag particles are realized through collecting, distributing, performing heat exchange and recollecting repeatedly and distributing of thefurnace slag particles; meanwhile, low-pressure cooling air can be subjected to heat exchange stage by stage uniformly to achieve a purpose of recycling afterheat of the furnace slag; and the furnaceslag afterheat utilization efficiency is high.

Owner:中山蓝冰节能环保科技有限公司

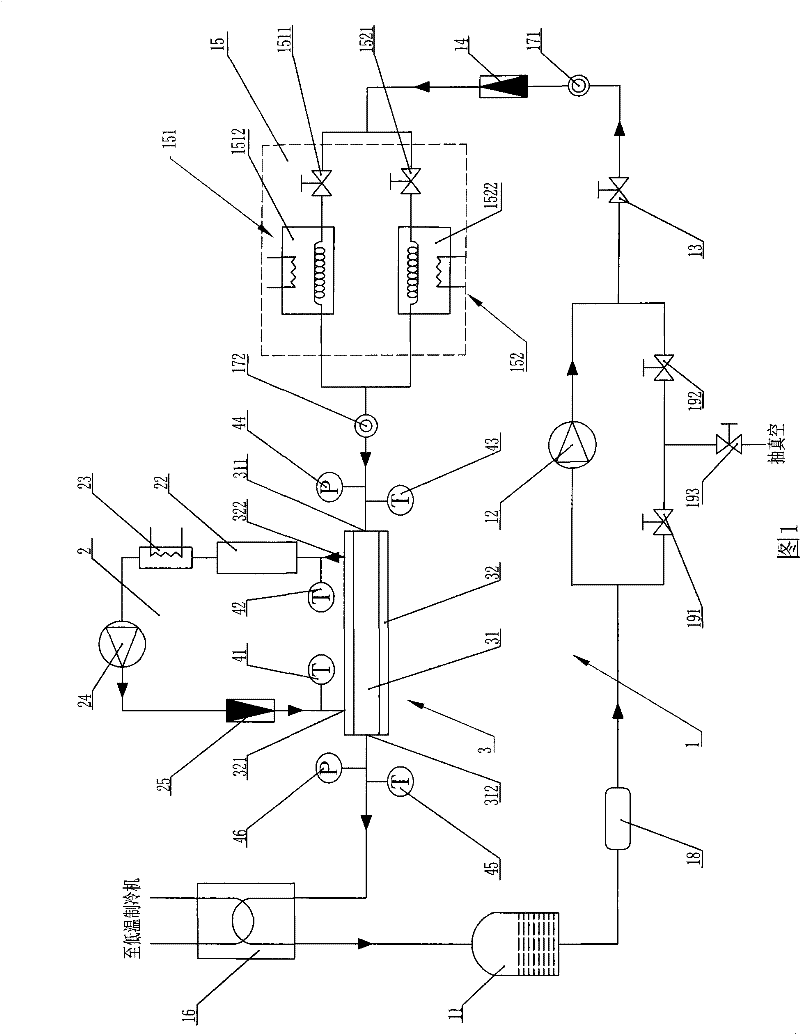

Evaporation/condensation heat transfer test integrated device and test method in micro-diameter tube

ActiveCN101852749BAchieve evaporationAchieve heat transfer performanceMaterial thermal conductivityStructural/machines measurementEvaporationCondensation heat transfer

The invention discloses an integrated device for testing evaporation / condensation heat transfer in a micro-diameter tube and a testing method thereof. The device includes a refrigerant circuit and a test section heat exchange circuit; the refrigerant circuit includes a recovery tank, a power pump, a regulating valve, a refrigerant mass flow meter, a parallel regulation test circuit composed of a condensation preheating path and an evaporation preheating path, and a test section Inner pipe and condenser; the inlet of the power pump is connected to the recovery tank, and its outlet is connected to the refrigerant mass flowmeter; the inlet of the parallel regulation test circuit is connected to the refrigerant mass flowmeter, and its outlet is connected to the inner pipe of the test section; The refrigerant outlet of the tube is connected to the condenser; the test section heat exchange circuit includes the test section outer tube and sequentially connected heat exchanger, water heater, water pump, and water mass flowmeter. Control the flow of refrigerant through the power pump, control the dryness of the refrigerant through the evaporation preheater / condensation preheater, and control the heat transfer amount of the test section through the heat exchange circuit of the test section to realize evaporation and condensation in small pipe diameters respectively. Heat transfer test.

Owner:李蔚

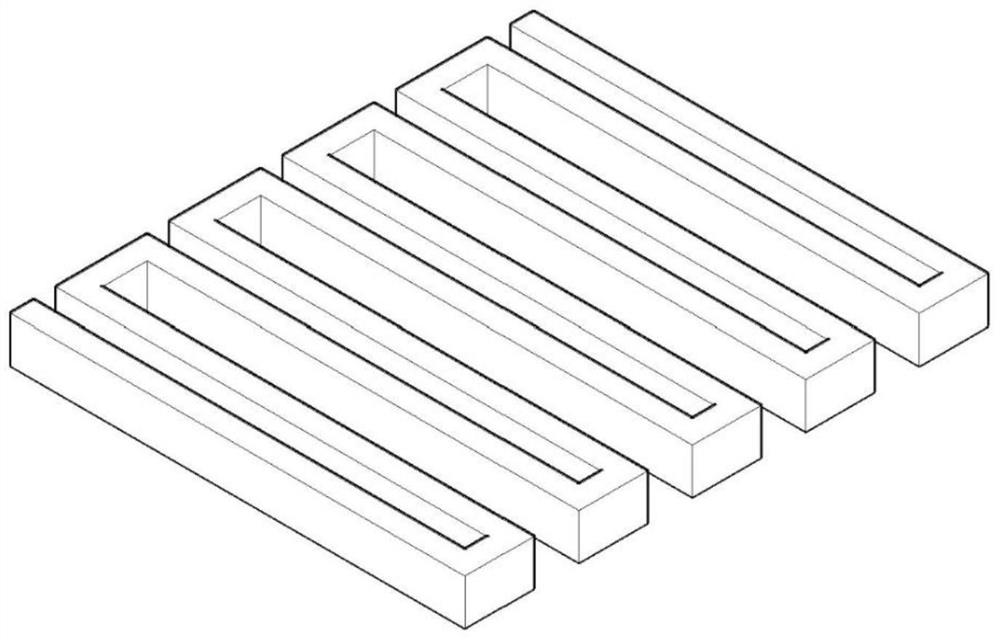

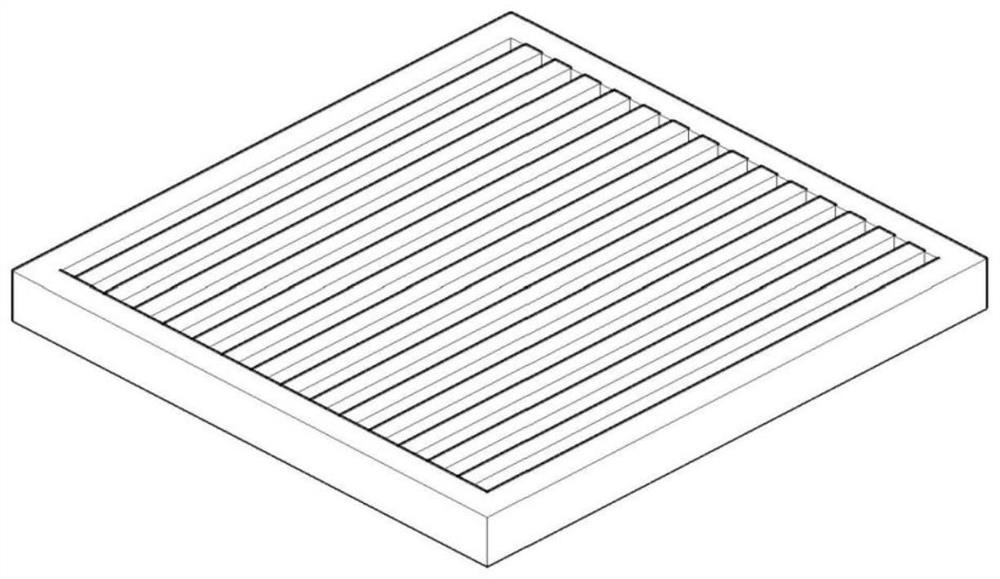

Preparation method of manifold type all-diamond micro-channel radiator

The invention discloses a preparation method of an all-diamond micro-channel radiator with a manifold type fluid path, and belongs to the field of heat dissipation of high-power devices. The manifold type all-diamond microchannel is composed of a packaging cover plate, a shunting substrate, a microchannel substrate and a packaging bottom plate. The preparation method comprises the following steps: firstly, a high-quality crack-free diamond self-supporting thick film is prepared through a CVD preparation process of secondary nucleation and dynamic adjustment of a deposition surface; the surface is flattened through mechanical grinding and polishing; then, the size of a rectangular micro-channel in diamond plates is shaped by adopting a special laser processing technology; at the same time, a welding surface is metalized to improve the welding performance;and finally, the diamond plates are welded together in sequence through a vacuum brazing technology, a manifold type all-diamond micro-channel heat exchanger with the qualified size and groove type is obtained, and the manifold type all-diamond micro-channel heat exchanger meets the heat dissipation design requirement of a high-heat-flux heat exchanger. The micro-channel heat exchanger can be used for effective heat management of high-power advanced equipment such as high-power communication and navigation satellites, directional high-energy weapons and wide bandgap semiconductor radars.

Owner:UNIV OF SCI & TECH BEIJING +1

Gallium heat pipe for reactor and heat exchange device

PendingCN113670101AEnsure safetyImprove cooling effectNuclear energy generationIndirect heat exchangersThermodynamicsNuclear reactor

The invention discloses a gallium heat pipe for a reactor and a heat exchange device. The gallium heat pipe comprises a pipe body; one end of the pipe body is a condensation section, the other end of the pipe body is an evaporation section, and a heat insulation section is arranged between the condensation section and the evaporation section; and the gallium heat pipe is characterized in that a liquid absorbing core, gallium and related working media are arranged in the pipe body, and the interior of the pipe body is filled with gallium and the related working media, the gallium and the related working media circularly flow in the pipe body. According to the gallium heat pipe, the liquid metal gallium serves as a basic working medium, the gallium is in a liquid state at the temperature of 29.76 DEG C, and the liquid gallium has a wide temperature range and good heat stability; the gallium heat pipe can be applied to medium and low temperature systems and high temperature systems; the gallium heat pipe is wide in implementation range, simple, convenient and efficient; and the gallium heat pipe is particularly suitable for a movable small reactor and can be applied to the wide fields of comprehensive energy systems, space nuclear reactors, cooling, deep sea, military and civil integration and the like.

Owner:SOUTHEAST UNIV

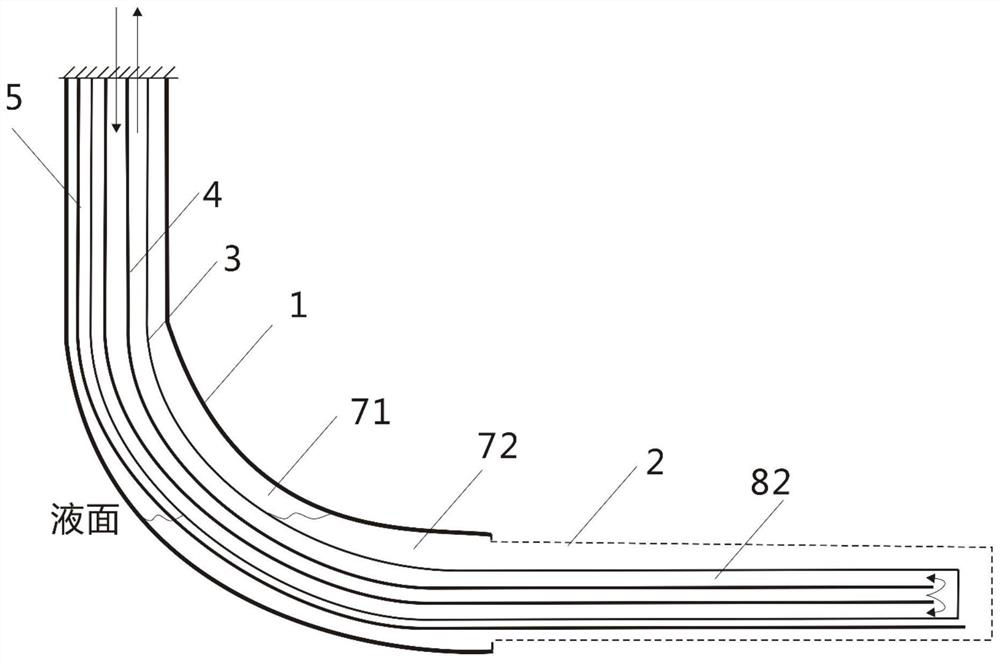

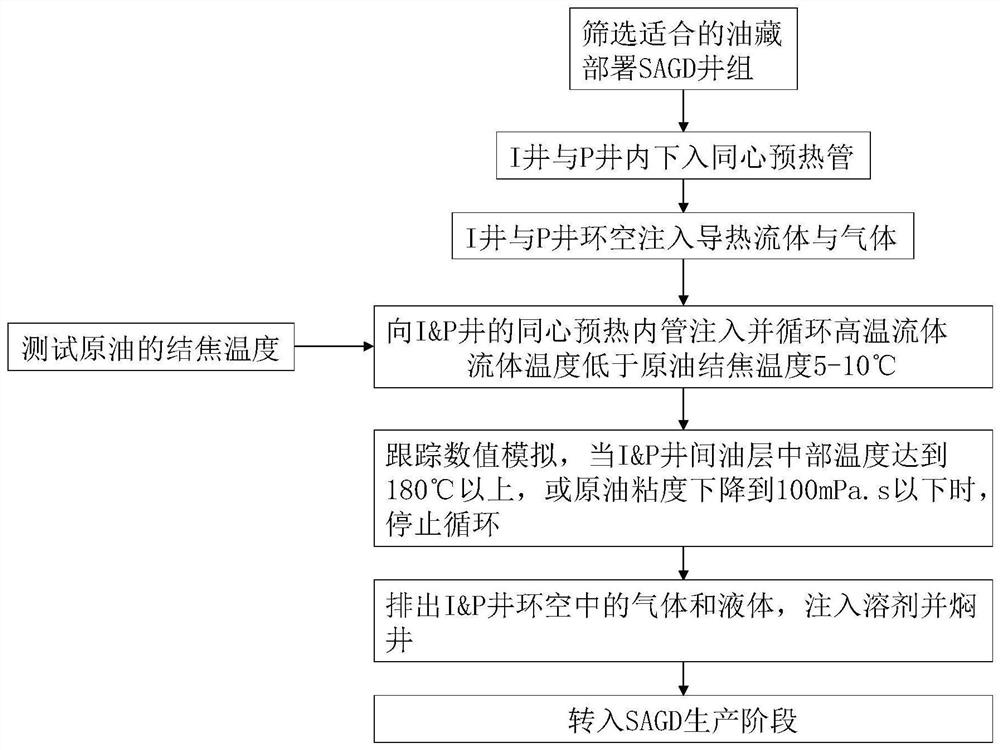

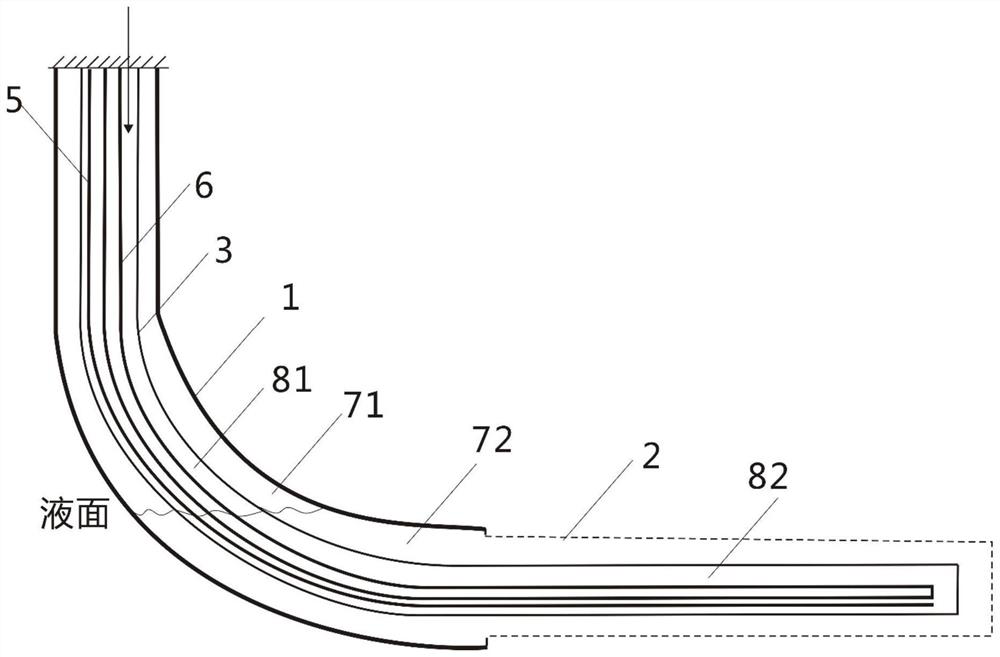

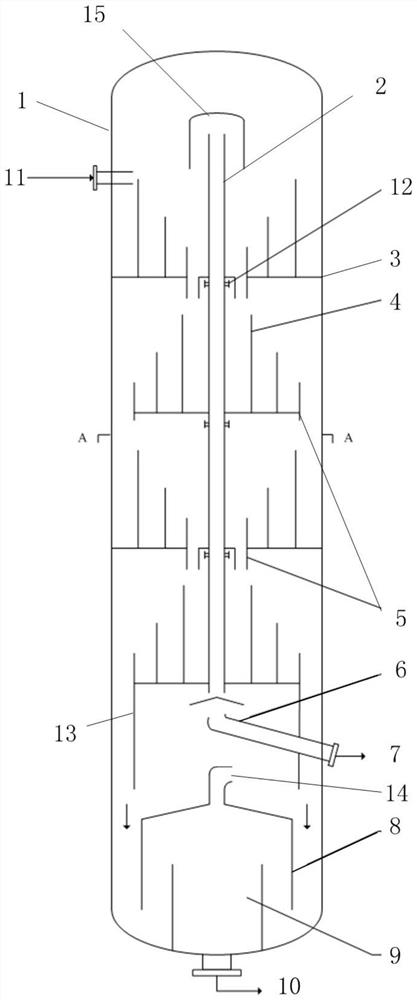

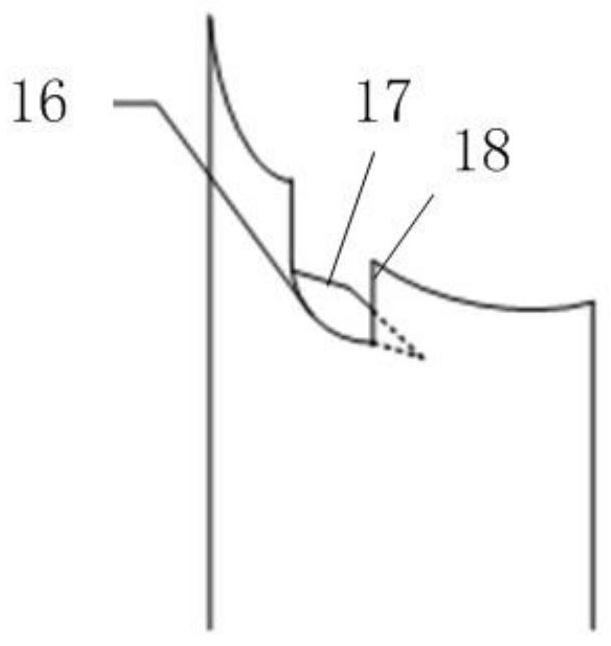

A downhole preheating and start-up method for super heavy oil reservoirs developed by dual horizontal well sagd

ActiveCN113250665BWell-developedUniform heating startInsulationFluid removalThermodynamicsHorizontal wells

The invention provides a method for downhole preheating and start-up of super heavy oil reservoirs developed by SAGD of double horizontal wells. The method includes: running concentric double oil pipes into well I and P well; injecting high-temperature fluid from the inner pipe of the concentric double oil pipe at the initial stage, and producing from the outer pipe of the concentric double oil pipe; Wells I and P are run into concentric pipes and resistance heating cables, and the surface temperature of the heating cables is set below the coking temperature of crude oil and continues to preheat; after tracking digital and analog monitoring, the fluid in the wellbore annulus is discharged when the interwell oil layer reaches the end of preheating conditions, and Inject solvent into the well; transfer to SAGD production stage. This method can realize the balanced preheating start of the SAGD horizontal section, promote the uniform development of the steam chamber in the horizontal section of the SAGD production stage, and effectively improve the oil production and recovery factor.

Owner:PETROCHINA CO LTD

Tower type pre-polycondensation reactor

PendingCN114534624AIncrease contact areaIncrease the number of updatesProductsReagentsEngineeringTower

The tower type pre-polycondensation reactor comprises a tower body, a material inlet and a material outlet are formed in the top and the bottom of the tower body respectively, a vacuum pipe with a plurality of first vacuum ports is arranged at the central axis in the tower body, and a vacuum pipe outlet is formed in the side wall of the tower body; a plurality of tower trays are arranged between the vacuum pipe and the tower body, baffle plates are arranged on the tower trays, the heights of the baffle plates are gradually increased or decreased from the position close to the tower body to the position far away from the tower body, and the height change directions of the adjacent upper and lower baffle plates are opposite; and each layer of tower tray is provided with a downcomer, and the downcomer is positioned at the lowest baffle plate in each layer. According to the invention, materials are baffled / overflowed back and forth on each layer of tower tray, and liquid film flow can be realized at the overflow port, so that the gas-liquid contact area is increased, and mass transfer evaporation of EG is facilitated; and the materials flow downwards in an annular waterfall manner on the inner sides of odd-numbered layers / the outer sides of even-numbered layers, so that the contact area between the materials and vacuum is quickly updated, the mass transfer efficiency is greatly improved, and the polymerization degree is greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

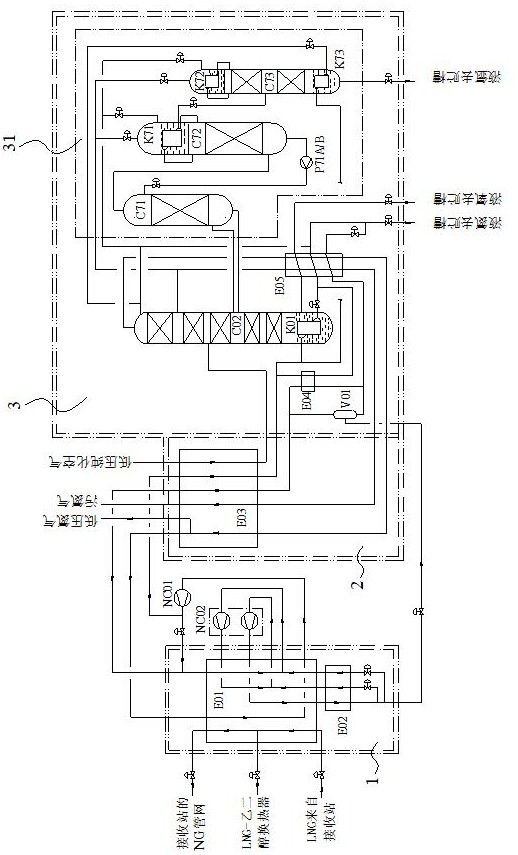

Air separation system utilizing LNG cold energy and air separation method

ActiveCN113587552AAchieve heat transfer performanceAchieve separationSolidificationLiquefactionLiquid argonAir separation

The invention provides an air separation system utilizing LNG cold energy and an air separation method. An LNG cold box unit provides the LNG cold energy for a main heat exchanger cold box unit and a main tower cold box unit, and cooling liquefaction on air and nitrogen is achieved; the main heat exchanger cold box unit cools low-pressure purified air and pressure nitrogen, the low-pressure purified air is sent to a main tower for rectification and purification, liquid oxygen is obtained at the bottom of the tower, nitrogen is obtained at the top of the tower, an argon fraction is obtained in the tower, and the argon fraction is sent to an argon extraction part; the argon extraction part is used for deoxidizing, denitrifying and rectifying the argon fraction to obtain liquid argon; and circulating nitrogen and liquid nitrogen are circularly transmitted among the LNG cold box unit, the main heat exchanger cold box unit and the main tower cold box unit, so that the cold energy of LNG is transmitted, and meanwhile, part of liquid nitrogen products are obtained. According to the system and the method, single-tower rectification is adopted, the LNG cold energy is fully utilized to produce oxygen, nitrogen and argon products, a conventional lower rectification tower is omitted, investment is more saved, operation and maintenance are simpler, energy consumption is low, and safety is high.

Owner:四川空分设备(集团)有限责任公司

Center spring and helical blade rotor in heat exchange tube

ActiveCN103411468BReduce manufacturing costSave materialHeat transfer modificationRotary device cleaningHelical bladeCoil spring

Owner:BEIJING UNIV OF CHEM TECH

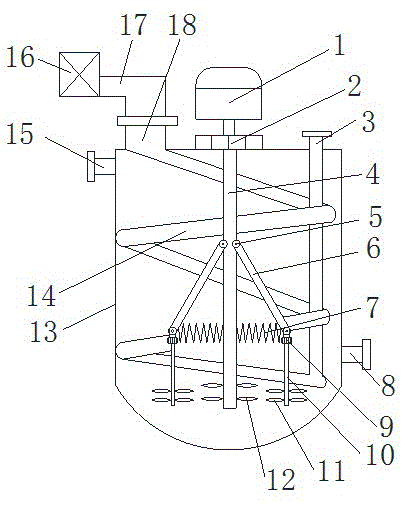

Reaction kettle

InactiveCN106311112ARealize coolingAchieve heat transfer performanceChemical/physical/physico-chemical stationary reactorsReduction driveHeat transmission

A reaction kettle includes a kettle body. A variable frequency motor is arranged above the kettle body. A main rotary shaft is connected to the variable frequency motor through a speed reducer and is arranged in the kettle body. Two connection rods are connected to the upper part of the main rotary shaft through hinges. Two ends of the two connection rods are both connected to the main rotary shaft through reset springs. A hydraulic pump is connected to the end of each connection rod. An auxiliary rotary shaft is connected to the lower parts of each hydraulic pump. A plurality of primary stirring blades are disposed on each auxiliary rotary shaft. A plurality of secondary stirring blades are disposed on the main rotary shaft. A coil pipe inlet and a coil pipe outlet are formed in the top of the kettle body. The reaction kettle has the following advantages: when the variable frequency motor works, turning radiuses of the reset springs are changed through centrifugal force, so that a larger stirring range is reached. In addition, by means of a coil pipe, cold transmission or heat transmission in the kettle body is achieved better and quicker. The reaction kettle has simple structure, is convenient to use and has good stirring effect.

Owner:汪超

Temperature regulating type medicine gas ventilating and combining moxibustion device

ActiveCN102846468BRealize multi-point moxibustionAchieve heat transfer performanceDevices for heating/cooling reflex pointsMedical devicesReflexCombustion

The invention discloses a temperature regulating type medicine gas ventilating and combining moxibustion device, which is characterized by comprising a moxibustion box, a moxibustion rack and a smoke discharging device, wherein the moxibustion box comprises a heat-concentration reflex housing, a chamber, a radiating base and a combustion medicine slot; the heat-concentration reflex housing is reversely buckled on the chamber and is tightly connected with the radiating base; and the circumstance of the upper end of the radiating base is symmetrically provided with two round connection holes. The connection relationship of the temperature regulating type medicine gas ventilating and combining moxibustion device is as follows: the moxibustion box is connected to the moxibustion rack by the round connection holes, and the smoke discharging device is connected with a through hole of the moxibustion box to discharge smoke generated in the moxibustion treatment process. According to the temperature regulating type medicine gas ventilating and combining moxibustion device disclosed by the invention, multipoint moxibustion treatment can be carried out, the generated heat can be directly act on the skin to carry out radiation or heat transfer, the smoke and the volatile matters of moxibustion grass can be gathered on the position which needs to be subjected to the moxibustion treatment at a proper temperature, and the temperature is regulated at any time according to the requirement.

Owner:李三川 +1

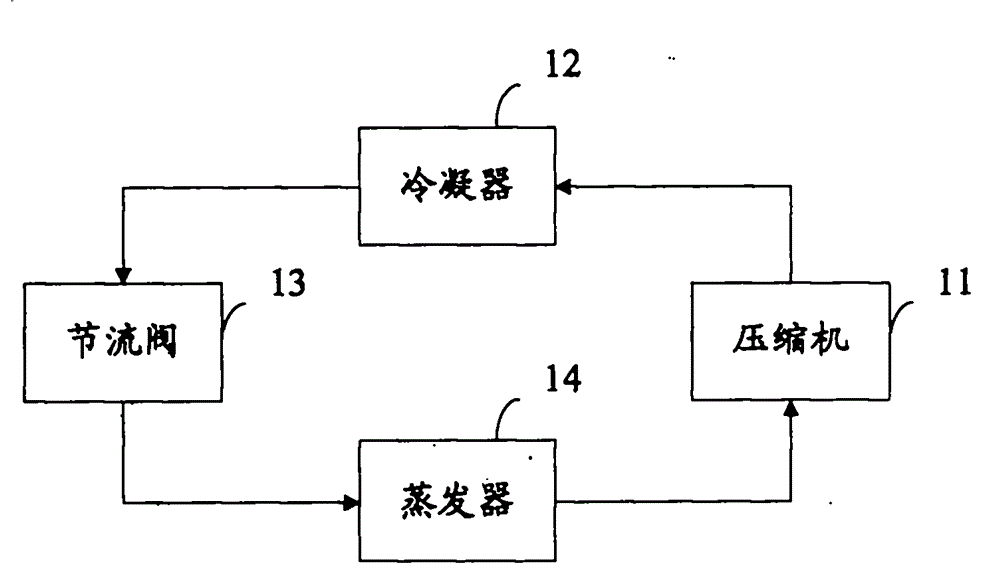

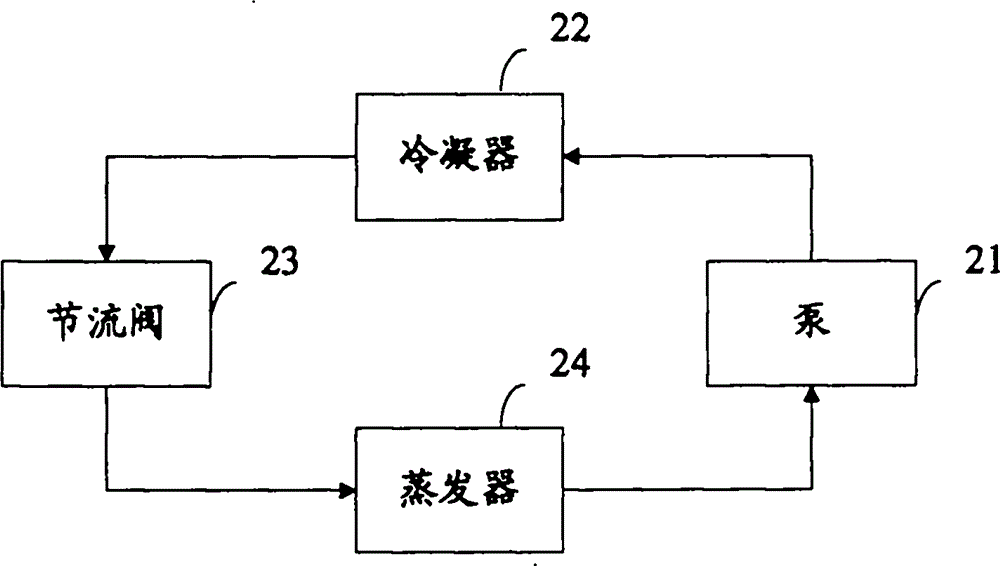

Equipment with heat-transferring and refrigerating functions and refrigerating method

InactiveCN104101123AIncrease pressureHigh boiling pointCompression machines with non-reversible cycleEngineeringOutdoor temperature

The invention relates to equipment with heat-transferring and refrigerating functions and a refrigerating method. The equipment comprises a pump, a condenser, a throttling valve and an evaporator which are arranged in sequence, wherein the components which are arranged in sequence are communicated through a pipeline, thereby constructing an annular channel for a cold medium to flow; the resistance of the throttling valve is variable, and the pressure of the pump is in direct proportion to the resistance of the throttling valve; when the temperature of the condenser end is higher than the temperature of the evaporator end, the pump is used for boosting the cold medium from the evaporator, and feeding the boosted cold medium into the condenser; when the temperature of the condenser end is lower than the temperature of the evaporator end, the pump does not work, and the cold medium pressures at the two ends of the pump are kept constant. According to the equipment with heat-transferring and refrigerating functions and the refrigerating method, the heat-transferring function of indoor equipment is realized without boosting the cold medium through the pump when the outdoor temperature is lower than the indoor temperature, so that energy resource is saved.

Owner:SUGON DATAENERGYBEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com