Heat flow switch for controlling heat tube conduction

A heat pipe and switch technology, applied in the field of heat flow switches for controlling heat pipe conduction, can solve the problems that the working temperature of the high temperature part fails to meet the working requirements, the normal use of the equipment in the high temperature part is affected, and the heat conduction efficiency of the heat pipe is low. Good control, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

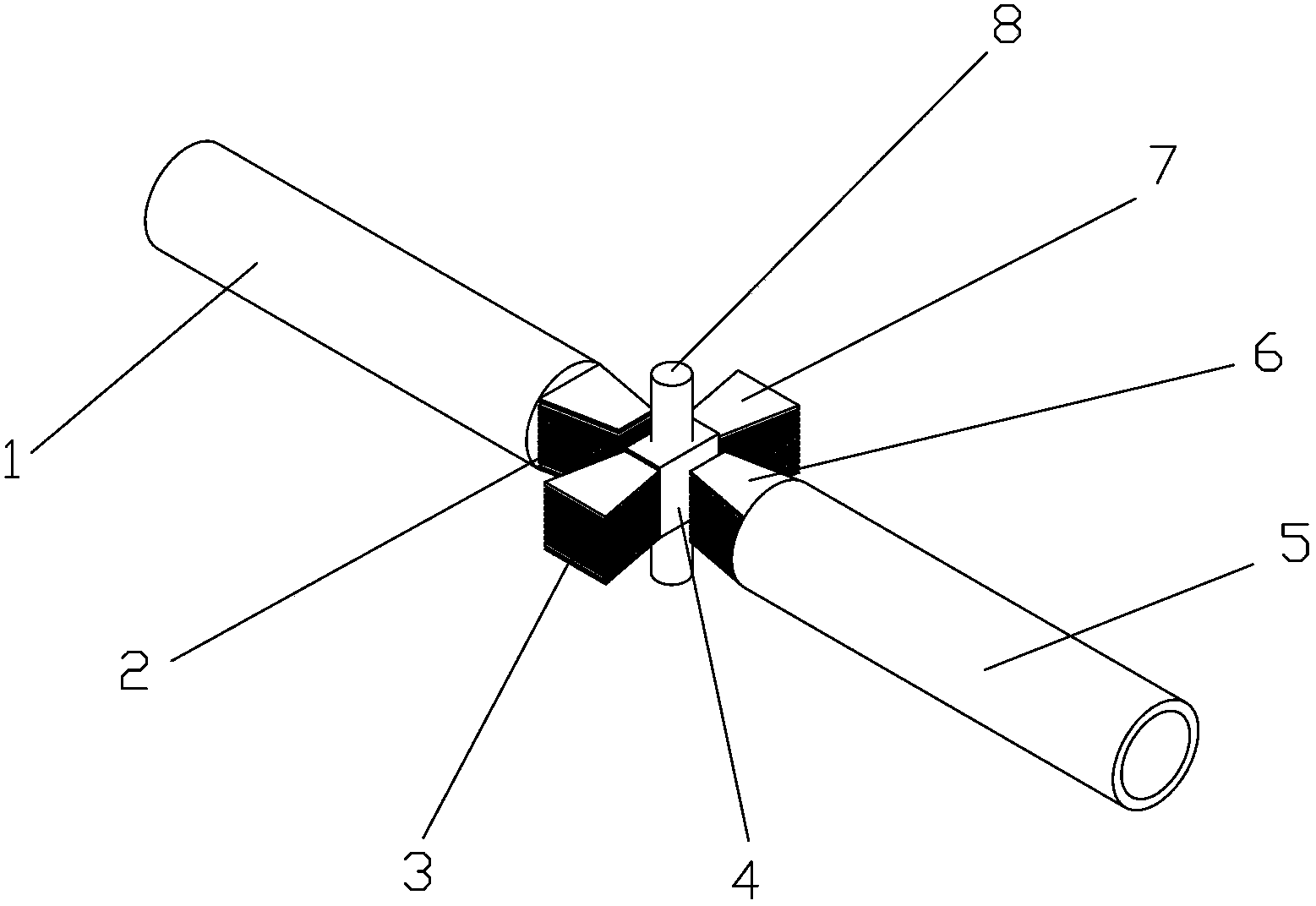

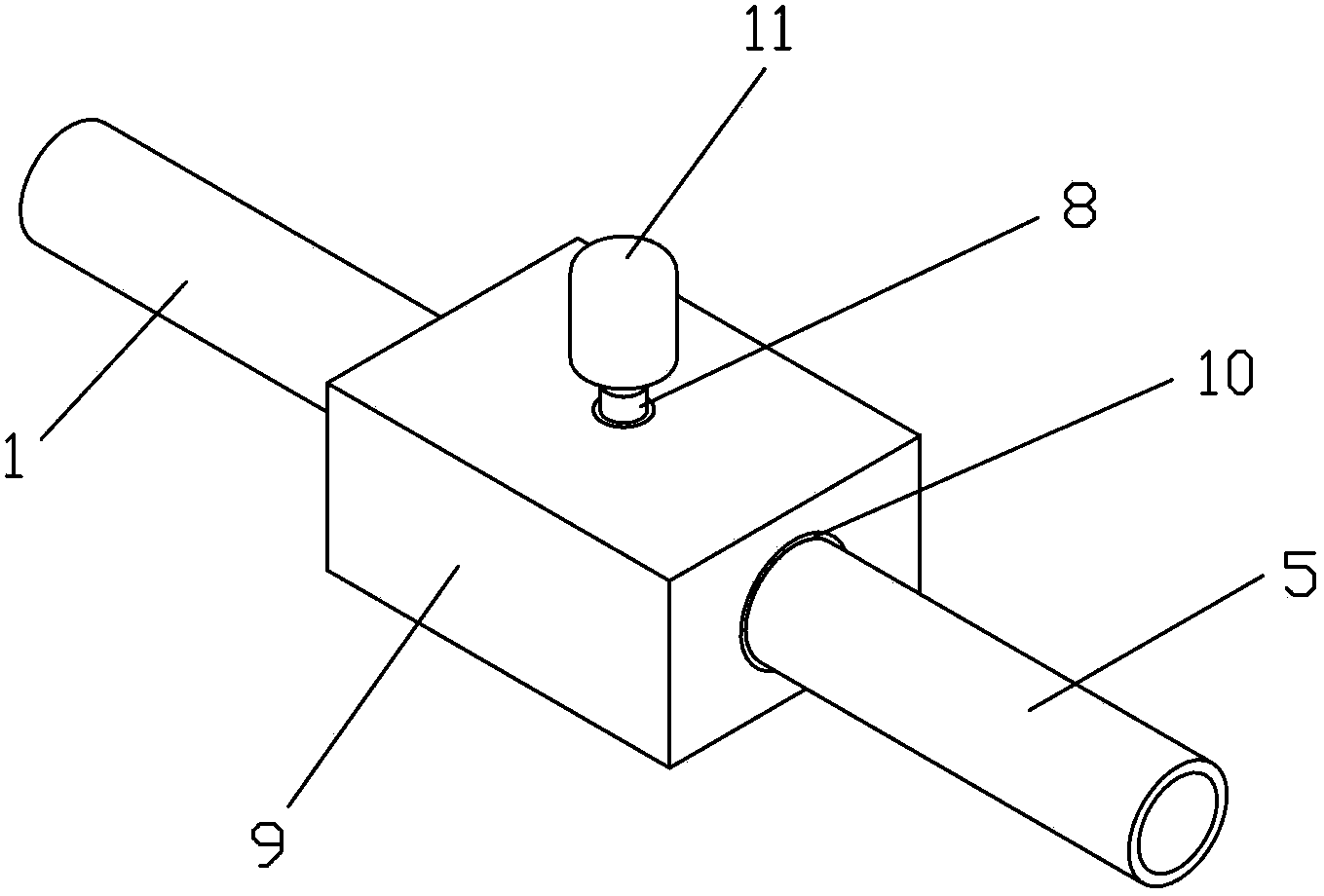

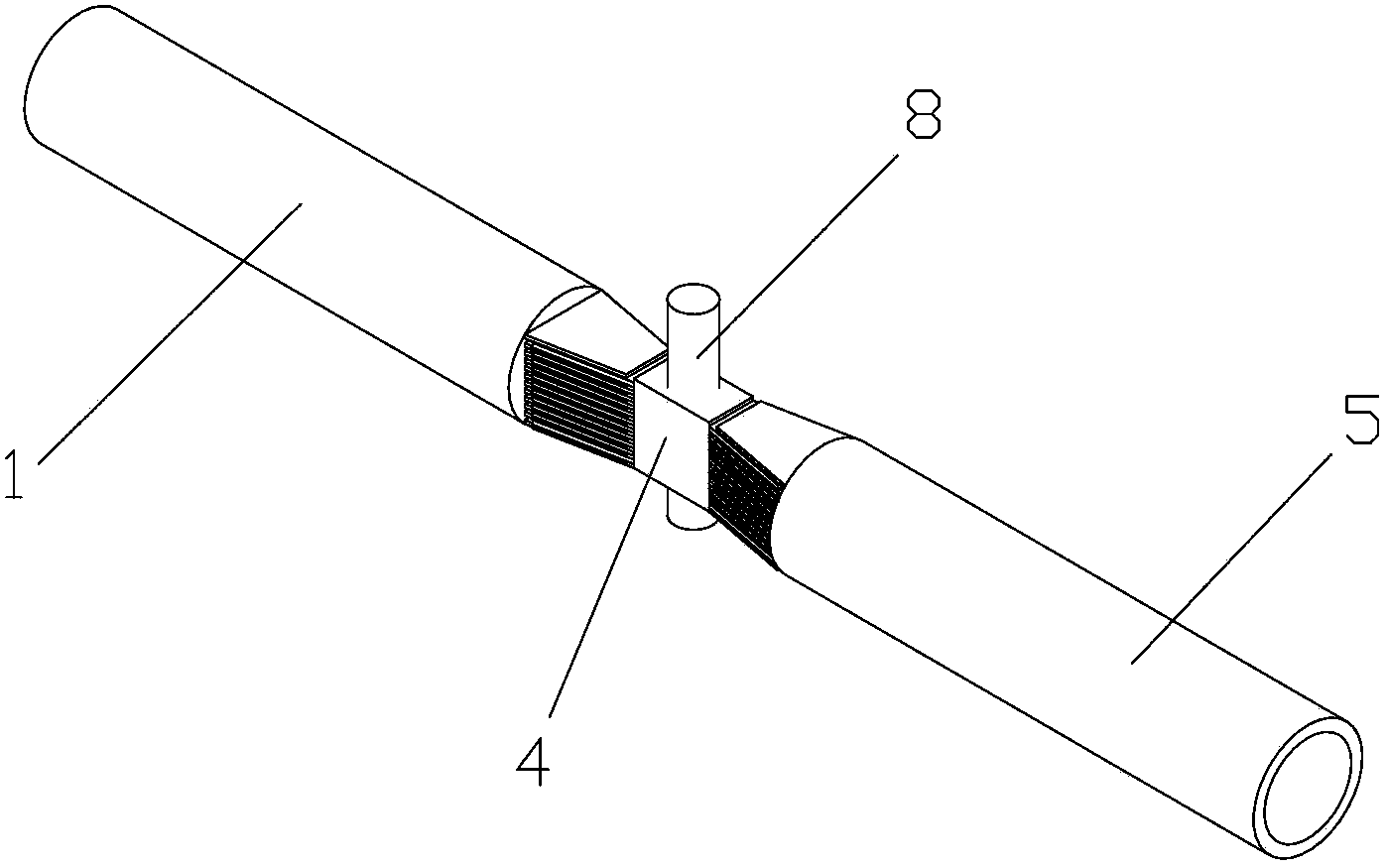

[0023] Such as Figure 1 to Figure 3 As shown, the present invention includes a switch housing 9, a switch motor 11, a first heat transfer fin group 2 installed at the end of the first heat pipe 1 and a second heat transfer fin group 6 installed at the end of the second heat pipe 5, and The connection body 4 arranged between the first heat transfer fin group 2 and the second heat transfer fin group 6 and the switch shaft 8 fixedly installed on the connection body 4, the first heat pipe 1 and the second heat pipe 5 The ends all extend into the inside of the switch housing 9, the ends of the first heat pipe 1 and the second heat pipe 5 are arranged oppositely, and the first heat transfer fin group 2 and the second heat transfer fin group 6 are composed of a plurality of Sheets with a certain thickness are arranged at intervals, one side of the connecting body 4 is equipped with a third heat transfer fin group 3 engaged with the first heat transfer fin group 2, and the other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com