Composite loop heat pipe and composite loop heat pipe heat exchange assembly

A technology for heat exchange components and heat pipe heat exchangers, which is applied in the field of heat exchange and heat pipes, can solve the problems of the working position being affected by gravity, the heat transfer capacity is not large enough, the volume heat capacity is small, etc., and achieves compact structure, low cost and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

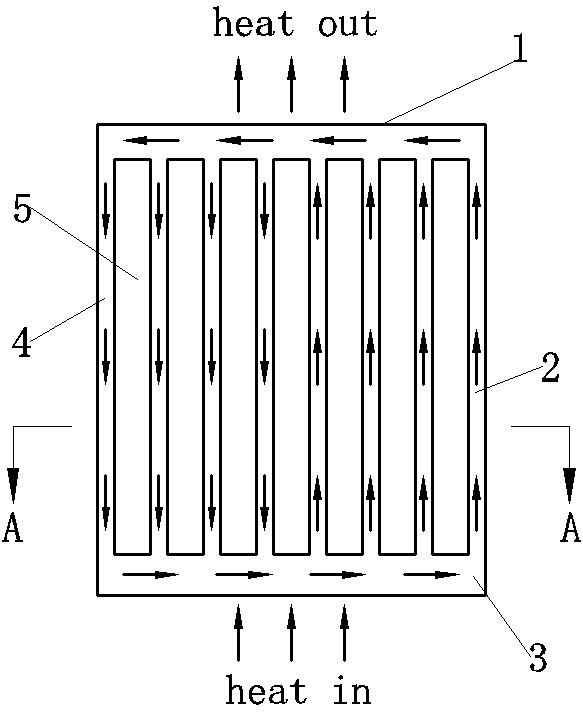

[0047] Embodiment 1: as figure 1 As shown, the composite loop heat pipe is composed of header A1, evaporation channel 2, header B3, and condensation channel 4, and evaporation channel 2 or condensation channel 4 is composed of figure 2 The porous channel composition shown is that the porous channels are arranged side by side with channel gaps 5 in between. The inner wall of the porous channel is smooth or provided with internal teeth, Figure 5 for figure 2 An example of an internal tooth enlargement of a porous channel. When working, heat enters the composite loop heat pipe from the heating section (such as the bottom plate or the lower half of the composite loop heat pipe), and the working fluid is heated and evaporated, and the heat is brought to the cooling section (such as the upper top plate or the composite loop heat pipe) along the evaporation channel 2 The upper part of the heat pipe) and dissipate away from the cooling section. At this time, the working fluid co...

Embodiment 2

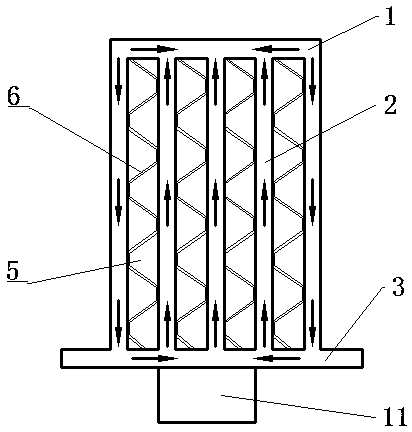

[0048] Embodiment 2: as image 3 and Figure 4 As shown, the porous channel in the composite loop heat pipe is not limited to only one header A described in Embodiment 1, the header A of this embodiment is divided into four, and the header B shares one, and its working principle Same as Example 1. The inner wall of the porous channel is smooth or provided with internal teeth, Figure 5 also for Figure 4 An example of an internal tooth enlargement of a porous channel.

Embodiment 3

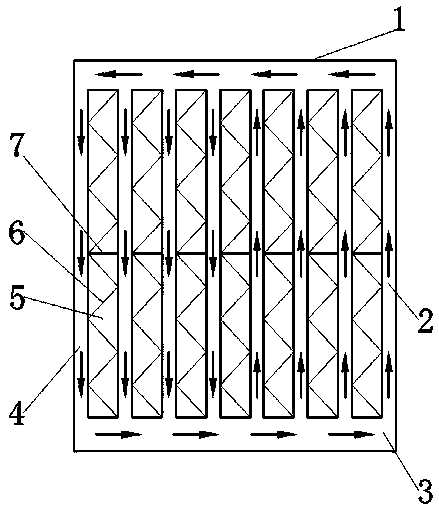

[0049] Embodiment 3: as Figure 6 As shown, the composite loop heat pipe and its heat exchange components are air-air heat exchangers, which are composed of header A1, evaporation channel 2, header B3, condensation channel 4, fins 6, and partitions 7. The channel gap Fins 6 are arranged inside 5, so that the fins 6 fit closely with the porous channel. The partition plate 7 divides the heat exchange area into a heating section and a cooling section. The hot air enters the channel gap 5 from the heating section, and the fins 6 are heated to transfer heat. For the heating section of the porous channel, the working fluid is heated and evaporates to form the evaporation channel 2 along the channel with small resistance, which is transferred to the header A1, the heat is transferred from the cooling section to the fin 6, and then transferred to the cold air, and the working fluid releases heat and condenses into condensation Channel 4 realizes the return flow of working fluid, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com