Gallium heat pipe for reactor and heat exchange device

A reactor and heat pipe technology, applied in the direction of reactors, cooling devices, indirect heat exchangers, etc., can solve the problems of few industrial applications, complex, unsuitable for reactor neutron physics and chemical environment, etc., to ensure safety, reduce pipeline links, The effect of improving cooling capacity and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

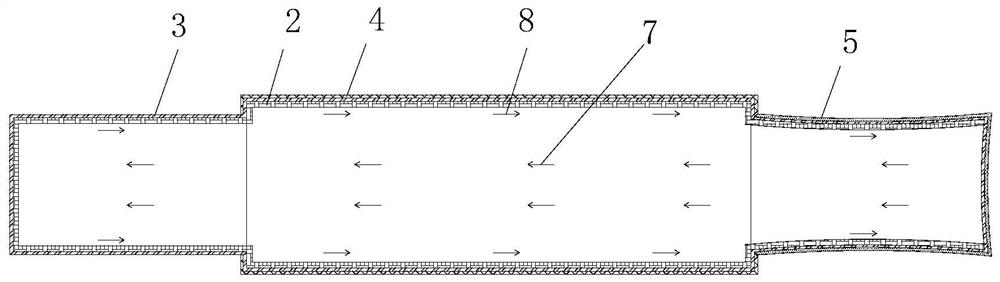

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

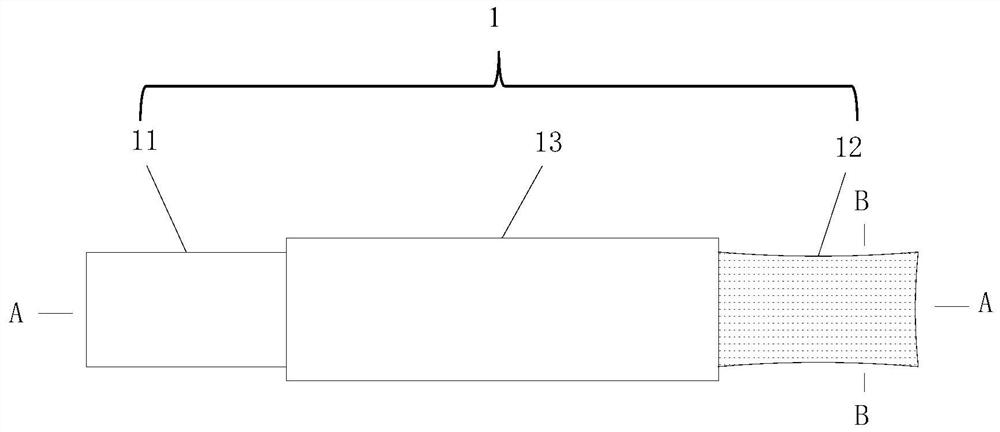

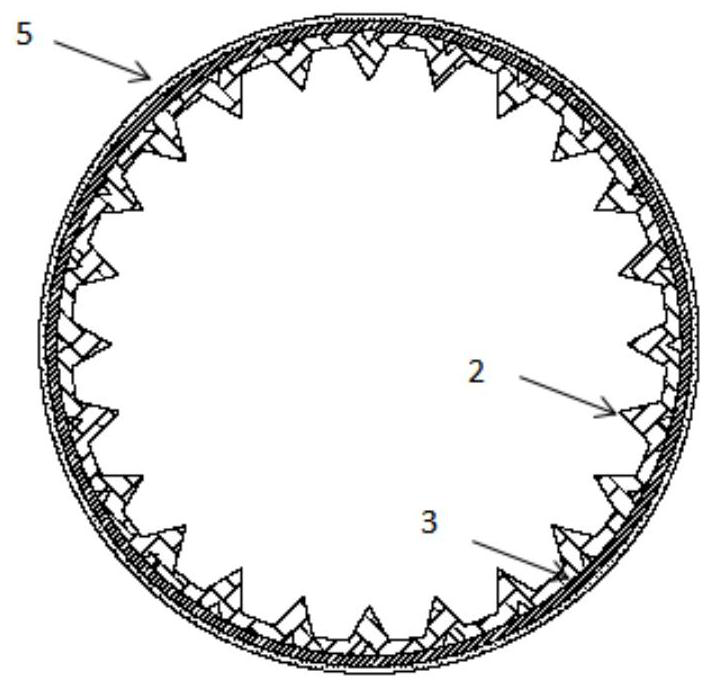

[0038] Gallium heat pipe structure of the present invention such as figure 1 shown. It includes a tube body 1, a liquid-absorbing core 2 set in the tube body, and a working fluid filled in the tube body and circulated in the tube body. The high-temperature working fluid is metal gallium, and the normal temperature and medium temperature are metal gallium and the boiling point meets the relevant temperature range. Working medium, such as water or freon, etc. Add 50%-70% of R600a, R600, R-123 and other refrigerants at room temperature; add 40%-60% of sodium, potassium, zinc, mercury and other boiling point metals at medium temperature. The specific ratio is determined according to actual needs.

[0039] Gallium, the working medium of the heat pipe of the present invention, is liquid at 29.76°C. According to the type and state of the working f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com