Power battery thermal management module based on liquid metal

A power battery and liquid metal technology, applied to battery pack parts, secondary batteries, circuits, etc., can solve problems such as uneven heat transfer effects, affecting energy efficiency, and non-uniform structure of a single liquid-cooled heat exchange element, achieving The effect of improving high-efficiency heat transfer performance, ensuring flow uniformity, and excellent thermal flattening performance

Inactive Publication Date: 2020-08-11

HEFEI UNIV OF TECH

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] From the perspective of heat transfer medium, the existing power battery thermal management systems are divided into: air-cooled thermal management (referred to as air-cooled), liquid-cooled thermal management (referred to as liquid-cooled), and phase change heat storage thermal management; from the current industry According to the application situation in the chemical market, liquid cooling is currently the most widely used technology. Its heat transfer efficiency is high and the technology is mature. Mostly due to the irregular layout of the single cells in the battery box, the structure of the single liquid-cooled heat exchange element that directly exchanges heat with the single battery is not uniform, resulting in inconsistent liquid resistance loss flowing through each liquid-cooled heat exchange element. It is easy to cause a disproportionate relationship between the liquid flow and the required heat transfer, and a slightly unreasonable structural design will easily cause uneven heat transfer effects, making the temperature difference of the single battery exceed the target of 5°C;

[0009] For example, for cuboid power batteries, in the paper "Analysis and Optimization of Liquid Cooling and Heat Dissipation Structure of Lithium-ion Battery Packs for Pure Electric Vehicles", Roman adopted a liquid-cooled thermal management technology solution, and designed and arranged replacement parts on the bottom and upper parts of this type of battery pack. It is found that the effect of arranging heat exchange plates on both sides of the upper and lower sides is better than arranging heat exchange plates at the bottom alone; however, the heat transfer at the middle height of the battery is still lagging behind;

[0010] For another example, for the sheet-shaped pouch battery, the more classic design is the battery thermal management system of General Motors Volt, which also adopts liquid-cooled thermal management technology, and metal heat sinks (thickness 1mm), and there is a capillary structure on the heat sink, so that the coolant can flow in the capillary and take away the heat to achieve the purpose of heat dissipation; The power consumption of the flowing pump increases, which affects the improvement of energy efficiency and is prone to blockage of the flow channel; under this background, a new type of room temperature liquid metal cooling technology has emerged and has begun to be applied to the field of thermal management of power batteries; The liquid metal mentioned mainly refers to a kind of safe and non-toxic low melting point metal material with a melting point near room temperature. Its most prominent feature is its inherent high thermal conductivity. The thermal conductivity of common liquid metals is generally 10~40W / (m K), the thermal conductivity of liquid-cooled working medium water is 0.6W / (m K) (20°C), that is, liquid metal is 2 orders of magnitude higher than that of traditional cooling working medium water. This characteristic gives liquid metal Excellent convective heat transfer ability of metal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

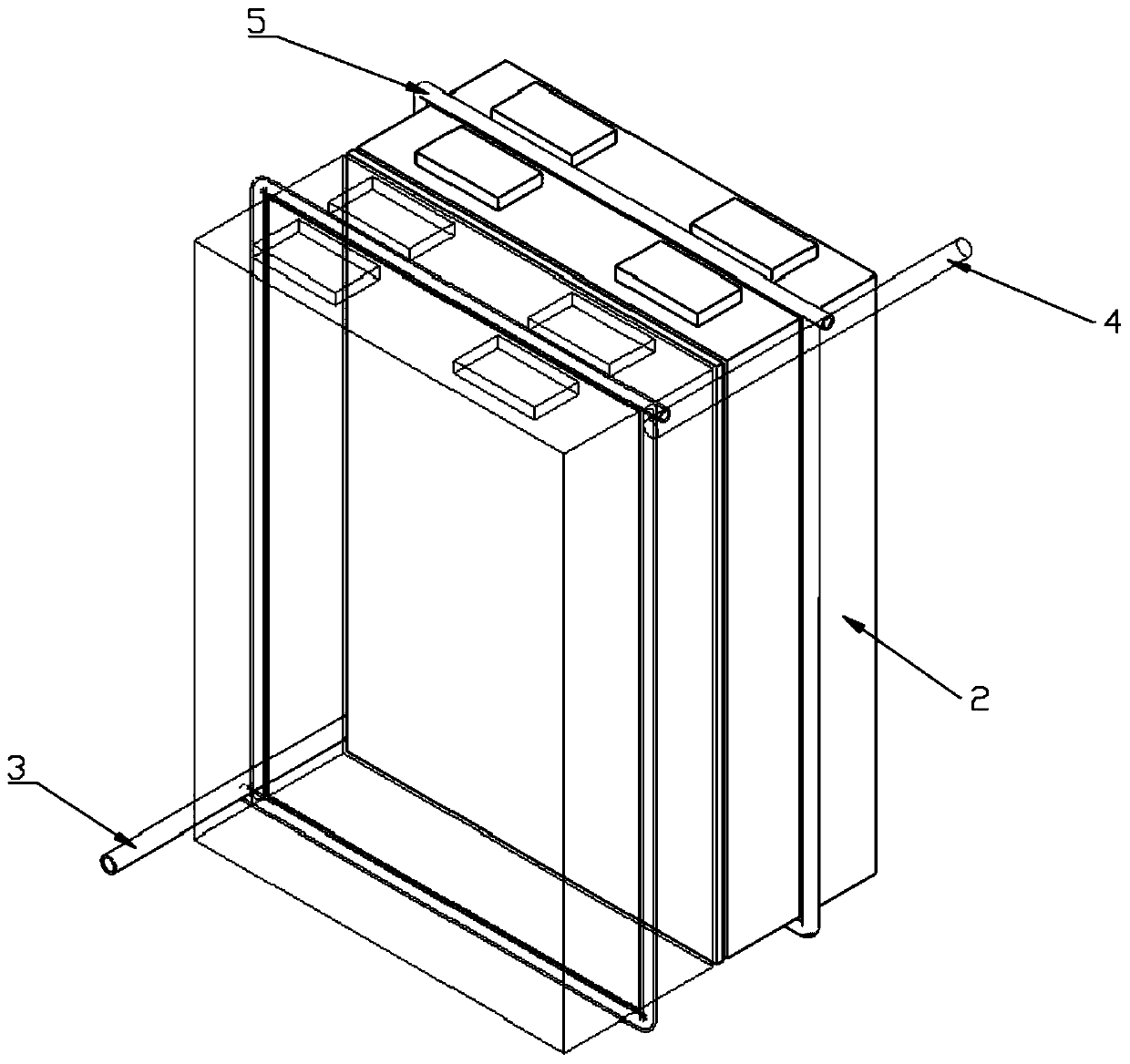

[0044] The difference between this embodiment and Embodiment 1 is that the single battery is a sheet-shaped pouch battery, and its structural design is as follows: Figure 5 , Figure 6 As shown, other structural design schemes are consistent with the technical scheme of embodiment 1, and the working process is also the same as that of the rectangular parallelepiped single battery.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Login to View More

Abstract

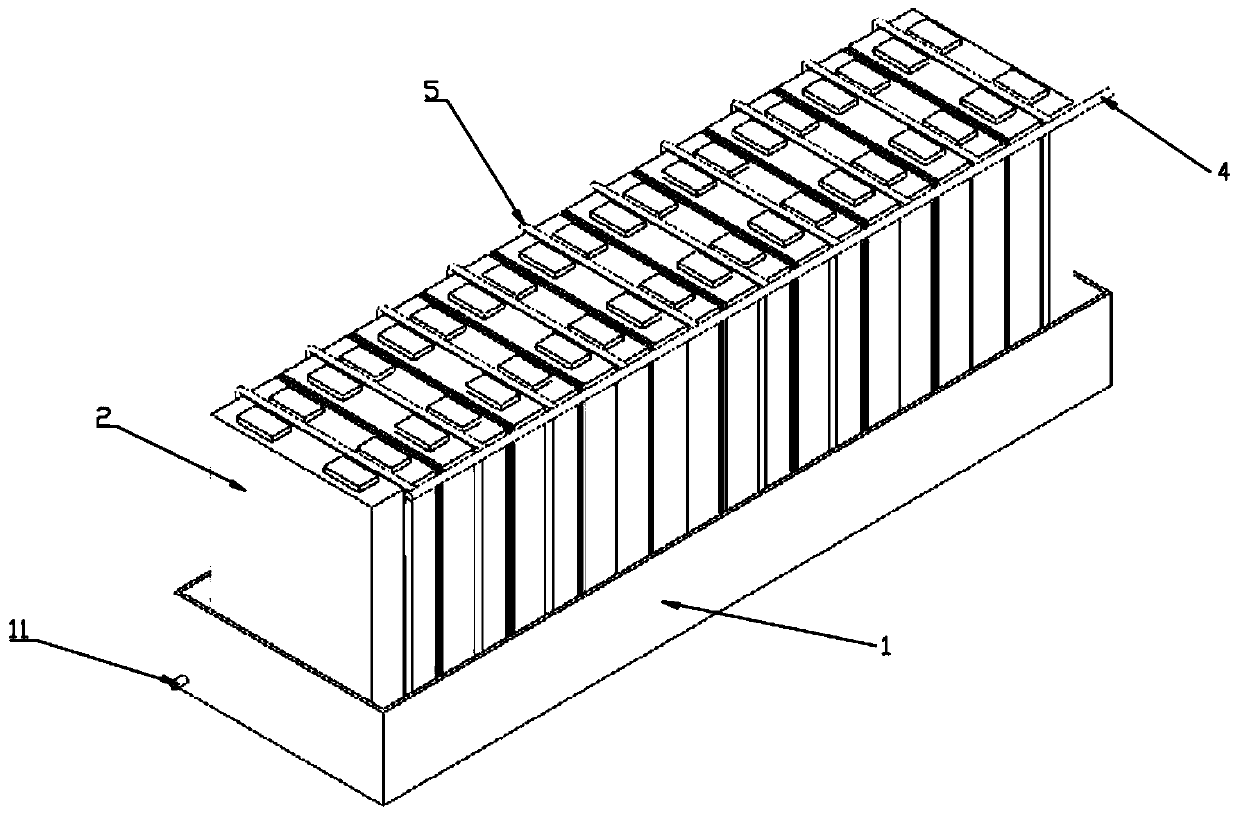

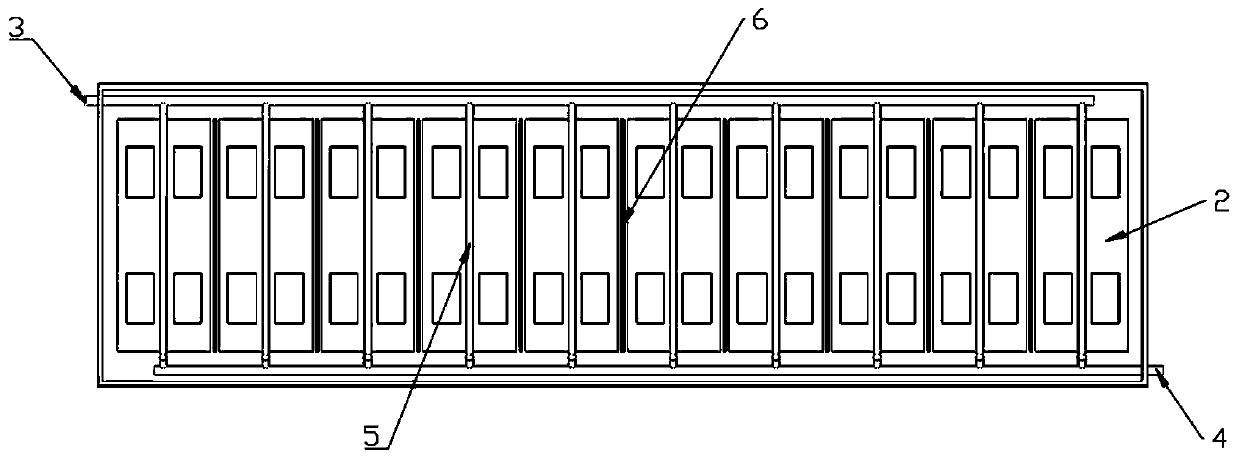

The invention relates to a power battery thermal management module based on liquid metal. The module comprises a box body, single batteries fixed in the box body and adjacently arranged with the largest side face, and a liquid inlet main pipe and a liquid outlet main pipe which are arranged along the opposite angles of the single batteries; and a shunting branch pipe is arranged between the liquidinlet main pipe and the liquid outlet main pipe in a communicating mode, a heat insulation partition plate is tightly arranged on one side of each single battery, and a flexible graphite film is tightly arranged on the other side of each single battery. The periphery of the flexible graphite film is wound and wrapped on the shunting branch pipe; according to the invention, the requirements on high-speed heat transfer and high temperature uniformity of each single battery in the power battery pack can be met, thermal runaway propagation and expansion accidents can be avoided or delayed, and the energy density of the power battery box body is greatly improved.

Description

technical field [0001] The invention belongs to the field of power batteries of electric vehicles, in particular to the field of thermal management modules of power batteries based on liquid metal. Background technique [0002] The technical key of electric vehicles is the power battery. The performance of the power battery directly determines the performance, safety and service life of the electric vehicle. Among the performance parameters of the power battery, temperature is the most important factor affecting the safety, performance and life of the battery. If the key parameter is too low, the performance of the whole vehicle will decrease, and if it is too high, it may cause a thermal safety accident; therefore, it is necessary to design the thermal management of the power battery, and the design requirements mainly include: [0003] (1) Rapid heat exchange requirements to maintain the battery working in a suitable temperature range. In a high-temperature environment, e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M2/10H01M10/613H01M10/625H01M10/647H01M10/653H01M10/6551H01M10/6555H01M10/6568

CPCH01M10/613H01M10/625H01M10/647H01M10/6551H01M10/6555H01M10/6568H01M10/653H01M50/20Y02E60/10

Inventor 唐志国刘志清孔德垚陈雪豹蒋意深朱晨赵军

Owner HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com