Phase-change composite material filled with graphene nanosheets and preparation method

A technology of phase-change composite materials and nano-graphene, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problem of low thermal conductivity of phase-change energy storage materials, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

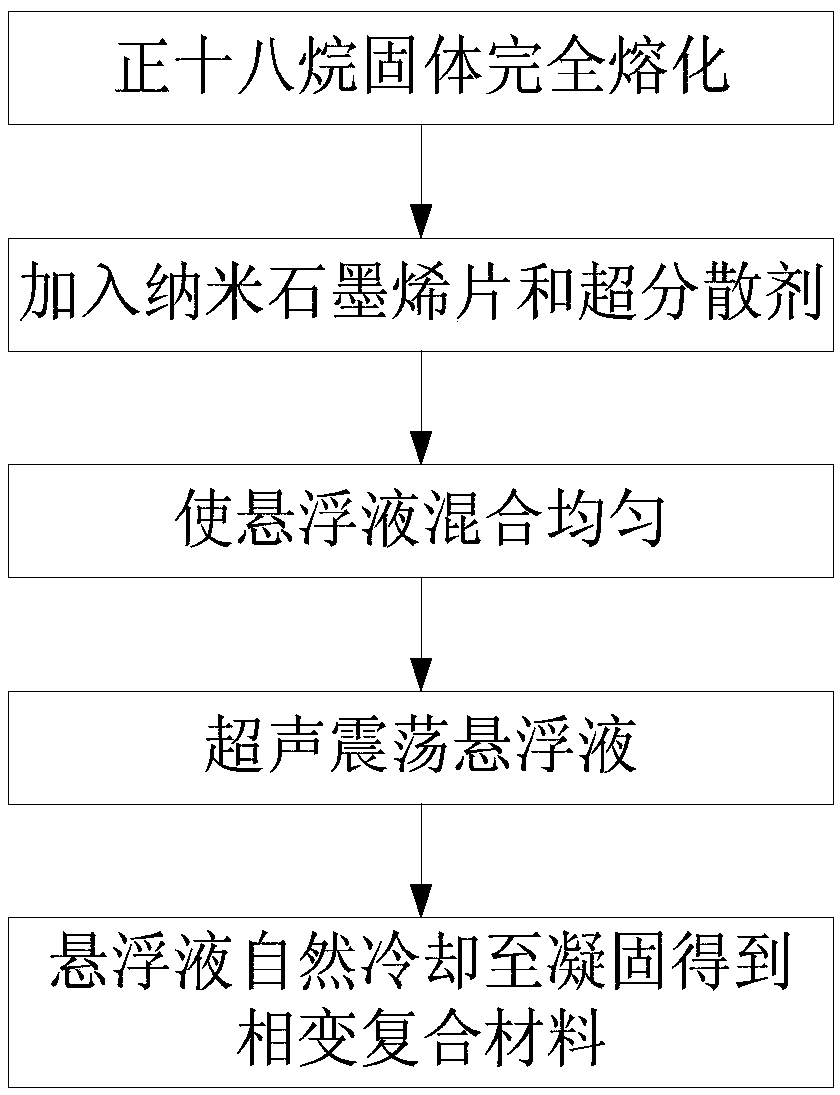

[0026] see figure 1 , the preparation method of the phase-change composite material that fills nano-graphene sheet, comprises the steps:

[0027] The first step: completely melt the n-octadecane solid that has been dried and pretreated;

[0028] The second step: adding the nano-graphene sheet and the hyperdispersant to the liquid phase n-octadecane in proportion to obtain a mixed suspension; the ratio of the nano-graphene sheet to n-octadecane is: 1:15~1: 200; the graphene nano sheet is a multi-layer structure with less than 20 layers. The hyperdispersant accounts for 0.1% of the total mass of the entire composite phase change material.

[0029] Step 3: Stir with a stirrer to mix the suspension evenly;

[0030] Step 4: Put the uniformly mixed suspension into an ultrasonic cleaning machine and oscillate ultrasonically to make the nano-graphene sheets form a stable three-dimensional heat-conducting network structure inside n-octadecane;

[0031] The fifth step: the suspensio...

Embodiment 1

[0034] The preparation method of the phase-change composite material filled with nano-graphene sheet, comprises the steps:

[0035] Step 1: Weigh 49.7g of dried and pretreated n-octadecane solid with an electronic balance and place it in a reagent bottle, move it to a constant temperature magnetic stirrer panel and heat until completely melted, and set the temperature to 65°C.

[0036] Step 2: After keeping the n-octadecane in a molten state for 30 minutes, add 0.25 g of graphene nanosheets and 0.05 g of hyperdispersant Disper S35 into the n-octadecane in liquid phase.

[0037] Step 3: first put the magnetic core into the reagent bottle, adjust the constant temperature magnetic stirrer to 450r / min, keep the temperature constant, and stir the composite phase change material suspension for 3 hours.

[0038] Step 4: Then take out the magnetic core, and place the reagent bottle in an ultrasonic cleaning machine for 30 minutes of ultrasonic vibration.

[0039] Step 5: Allow the su...

Embodiment 2

[0041] The preparation method of the phase-change composite material filled with nano-graphene sheet, comprises the steps:

[0042] Step 1: Weigh 49.2 g of dried and pretreated n-octadecane solid with an electronic balance and place it in a reagent bottle, move it to a constant temperature magnetic stirrer panel and heat until completely melted, and set the temperature to 65°C.

[0043] Step 2: After keeping the n-octadecane in a molten state for 30 minutes, add 0.75 g of nano-graphene sheets into the n-octadecane in liquid phase.

[0044] Step 3: first put the magnetic core into the reagent bottle, adjust the constant temperature magnetic stirrer to 450r / min, keep the temperature constant, and stir the composite phase change material suspension for 3 hours.

[0045] Step 4: Then take out the magnetic core, and place the reagent bottle in an ultrasonic cleaning machine for 30 minutes of ultrasonic vibration.

[0046]Step 5: Allow the suspension of the composite phase-change m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| solidification point | aaaaa | aaaaa |

| solidification point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com