A kind of modified graphene and n-octadecane phase change composite material and preparation method

A phase change composite material and n-octadecane technology are applied in the field of modified graphene and n-octadecane phase change composite materials and preparation, can solve the problems of low thermal conductivity of phase change energy storage materials and the like, and achieve a simple preparation method. , The effect of improving thermal conductivity and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

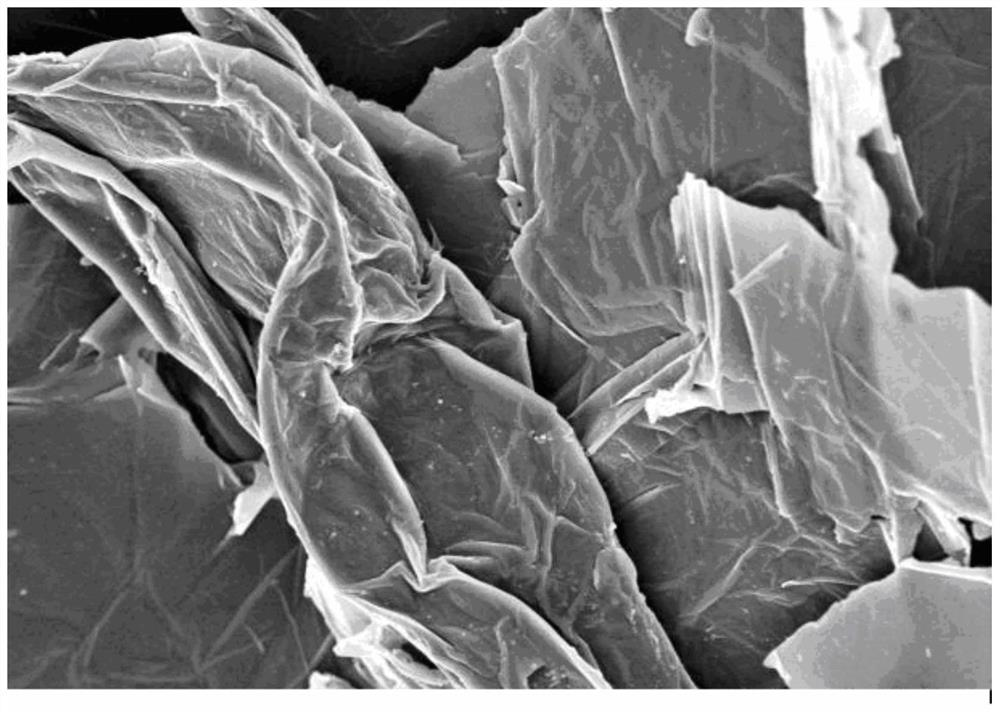

Image

Examples

Embodiment 1

[0034] A preparation method of modified graphene oxide, the method may further comprise the steps:

[0035] Step A. Disperse graphene oxide GO in N,N-dimethylformamide DMF under the condition of condensation and reflux, and add thionyl chloride SOCl 2 , reacted at 80°C for 12 hours, the carboxyl group of graphene oxide and thionyl chloride underwent acyl chloride reaction to generate acyl chloride group to obtain the reaction product; in this step, graphene oxide GO and thionyl chloride SOCl 2 The ratio of the amount added is 1:1~200, N,N-dimethylformamide DMF and thionyl chloride SOCl 2 The ratio of adding amount is 1:1~10.

[0036] Step B, with organic solvent dichloromethane CH 2 Cl 2 The reaction product obtained in step A was washed and dried in a vacuum oven at 60 °C to obtain an intermediate product; it could be observed that the graphene oxide was transformed from a yellow-brown fluffy powder to a black powder, and the intermediate product had covalent functionaliza...

Embodiment 2

[0040] A preparation method of modified graphene oxide, carried out as follows:

[0041] 1. Under the condition of condensation and reflux, disperse 1g of graphene oxide GO in 30g of 99.5% N,N-dimethylformamide DMF, and add 150g of SOCl 2 Treat at 80°C for 12h.

[0042] 2. Use 500g dichloromethane CH 2 Cl 2 The reaction product was washed and dried in a vacuum oven at 60 °C to obtain graphene oxide covalently functionalized with acid chloride groups, labeled as the intermediate GO-COCl.

[0043]3. Add 2g of the intermediate product GO-COCl, 30g of stearyl alcohol, 3g of triethylamine TEA, 15g of toluene and 15g of N,N-dimethylformamide DMF into a round bottom flask equipped with a magnetic stirrer core and a reflux condenser and stirred at 85°C for 1 h to disperse the particles and fully dissolve the stearyl alcohol.

[0044] 4. The mixture obtained in step 3 is condensed and refluxed for a period of time, about 120 hours, then the product obtained by the condensation reac...

Embodiment 3

[0047] A kind of preparation method of modified graphene oxide, this method is different from embodiment 2:

[0048] 1. Under the condition of condensation and reflux, disperse 1g of graphene oxide GO in 10g of N,N-dimethylformamide DMF, and add 40g of SOCl 2 Treat at 80°C for 12h.

[0049] 3. Add 2g graphene oxide GO-COCl, 2g stearyl alcohol, 2g triethylamine TEA, 10g toluene and 10g N,N-dimethylformamide DMF to a round bottom equipped with a magnetic stirrer core and a reflux condenser flask, and stirred at 85°C for 1 h to disperse the particles and fully dissolve the stearyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com