Visual experiment device for researching critical heat flux density of ultra-thin vapor chamber

A technology of critical heat flux and experimental equipment, applied in the field of visual experimental equipment, can solve the problems of inability to adjust the gap between thermal insulation plates, the inability to study the influence of gap effect flow, and poor adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below.

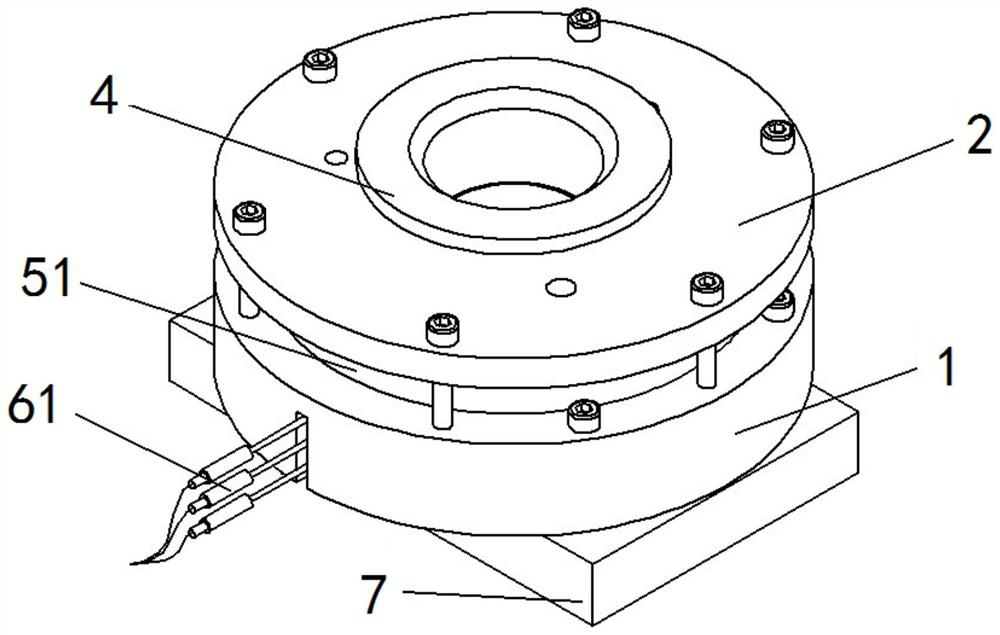

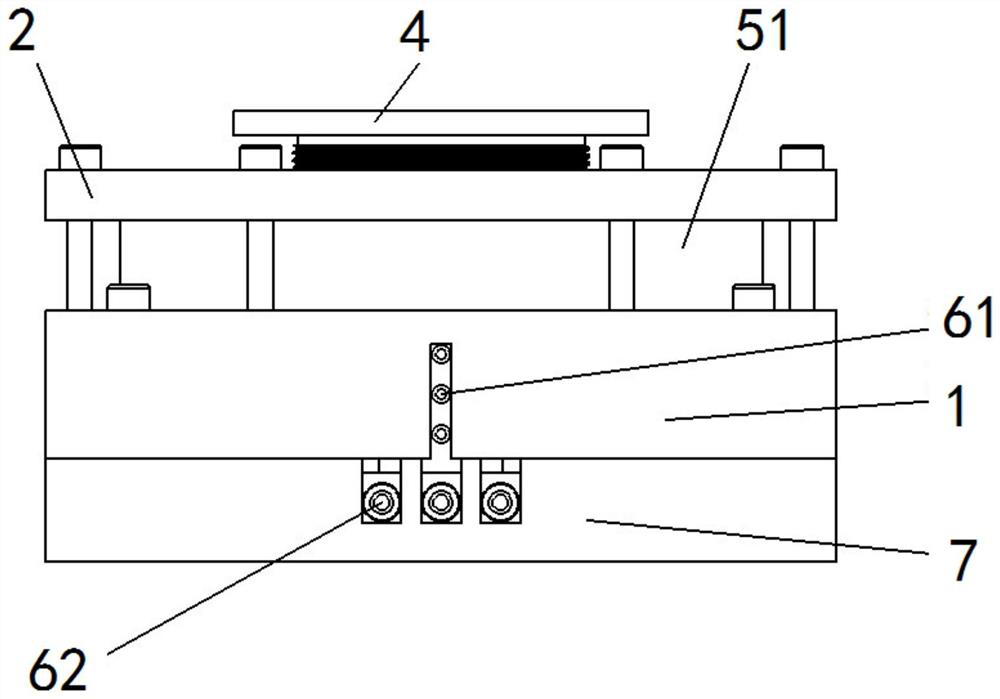

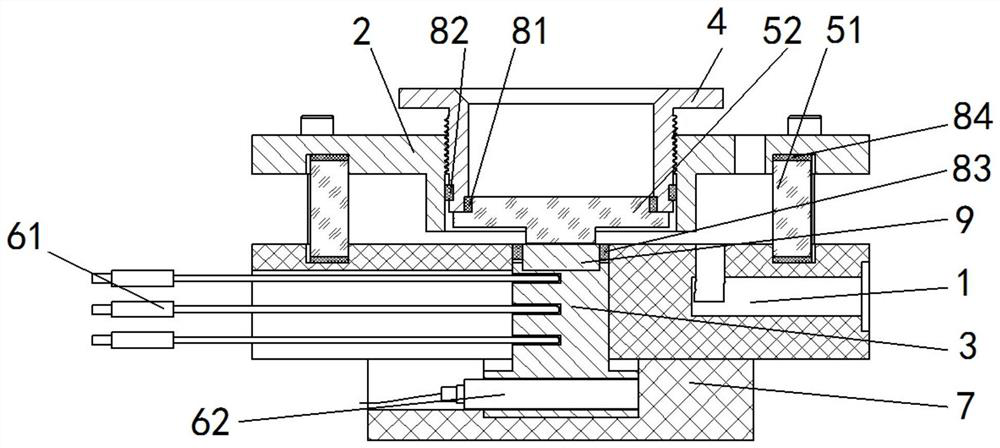

[0036] like Figure 1 ~ Figure 3 , Image 6 As shown, a visual experimental device for the study of the critical heat flux of an ultra-thin vapor chamber, including a ring-shaped side plate, the lower end of which is connected to a sample 9, and the sample 9 and the side plate are semi-enclosed to form a working medium cavity, and the side plate The upper part is detachably connected with a first transparent heat-insulating plate, the upper end of the first transparent heat-insulating plate is provided with a liquid filling hole 21 communicating with the working medium cavity, the lower end of the first transparent heat-insulating plate abuts against the upper end of the sample 9, and the first transparent heat-insulating plate The gap between the sample 9 and the sample 9 forms a working medium flow channel, the distance between the first transparent heat insulating plate and the sample 9 can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com