Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Accurate color registration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

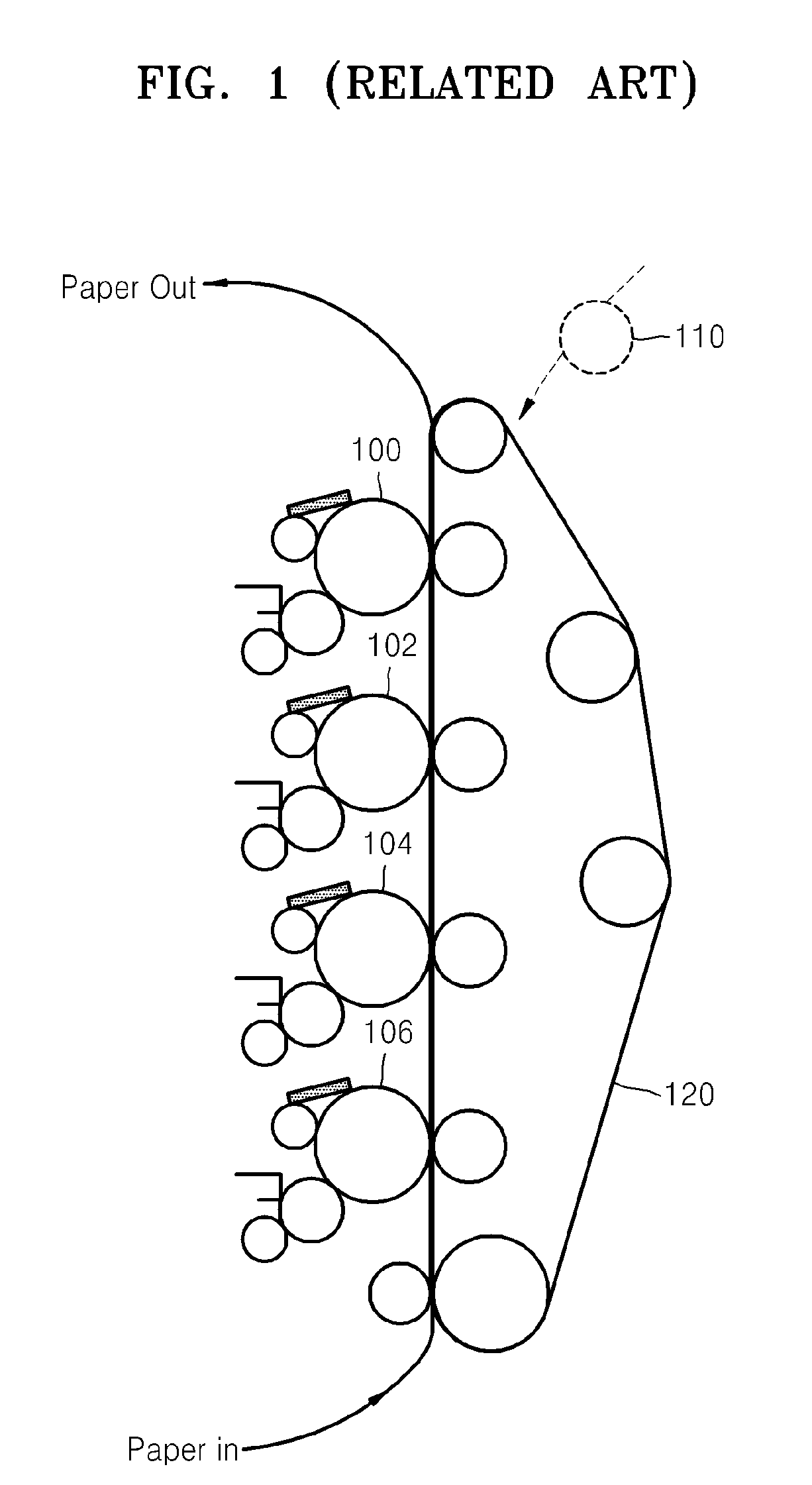

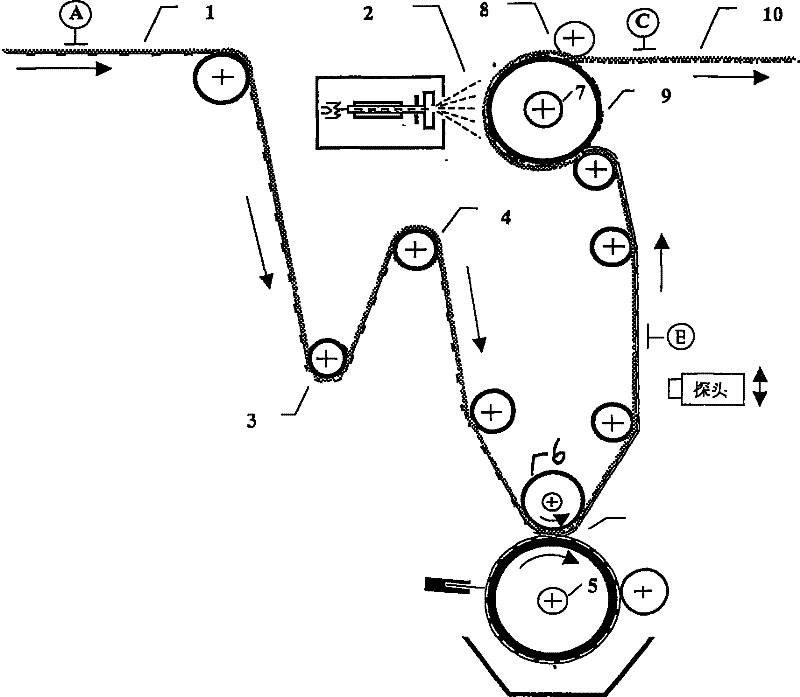

Image position detecting method

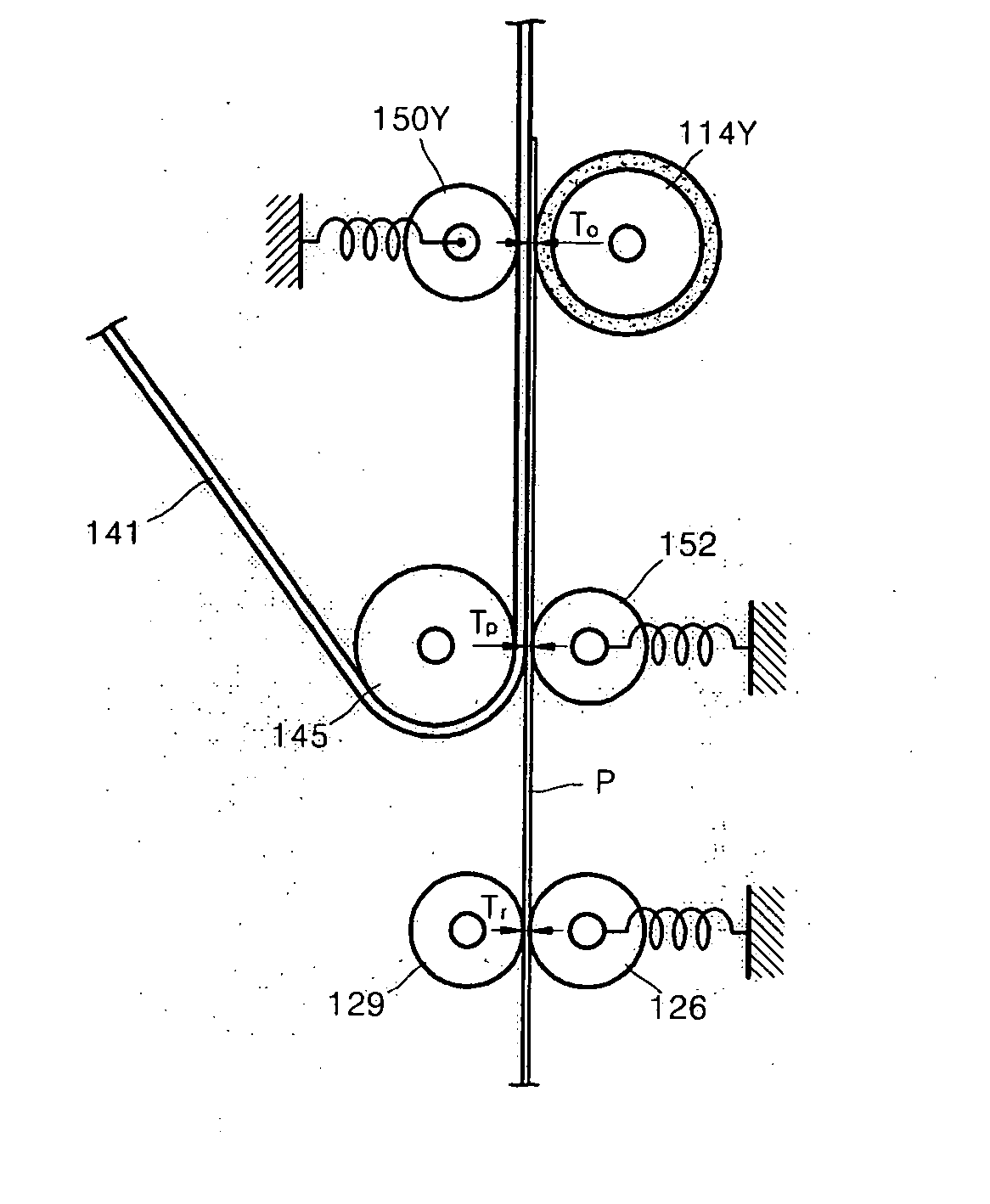

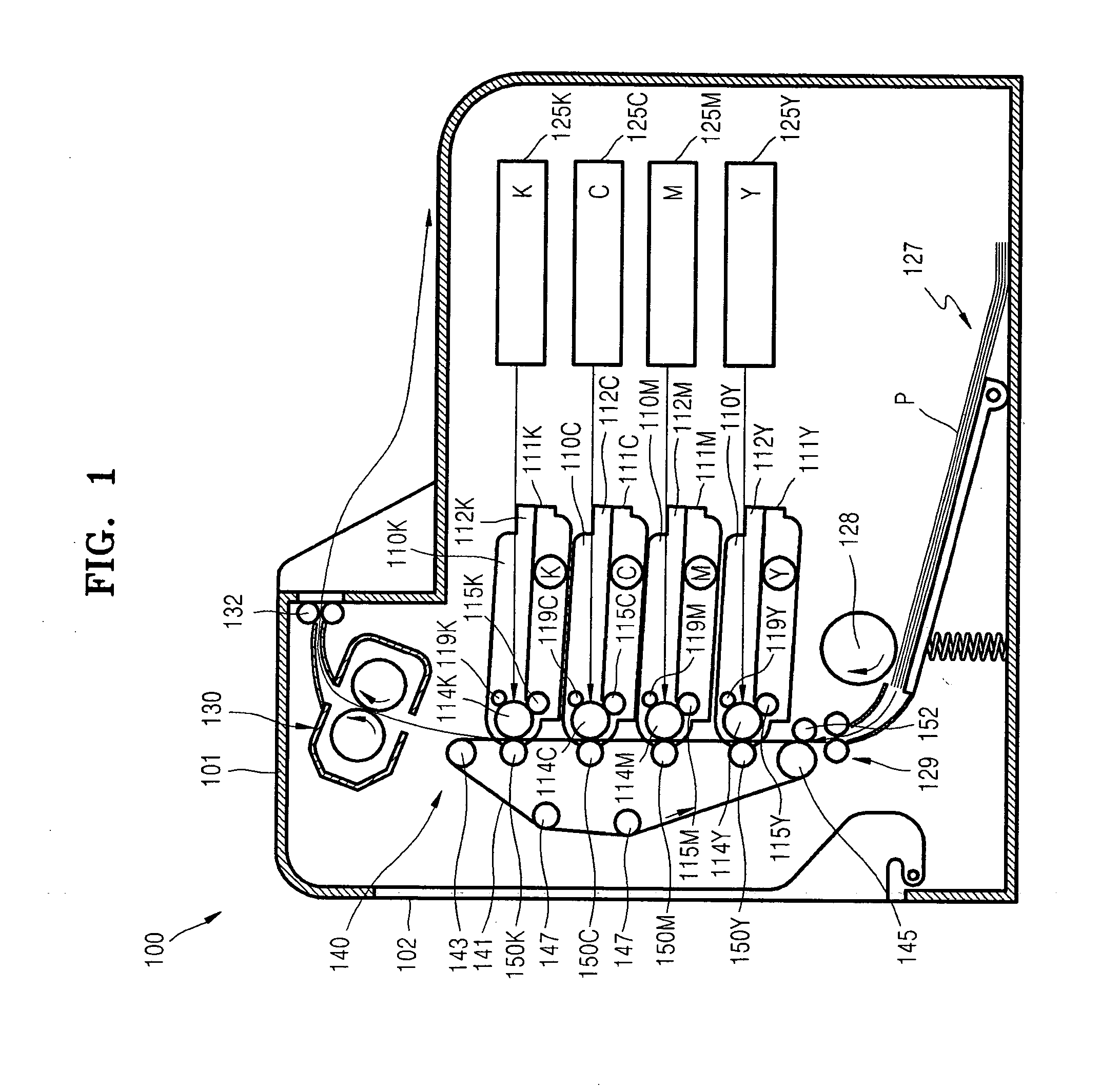

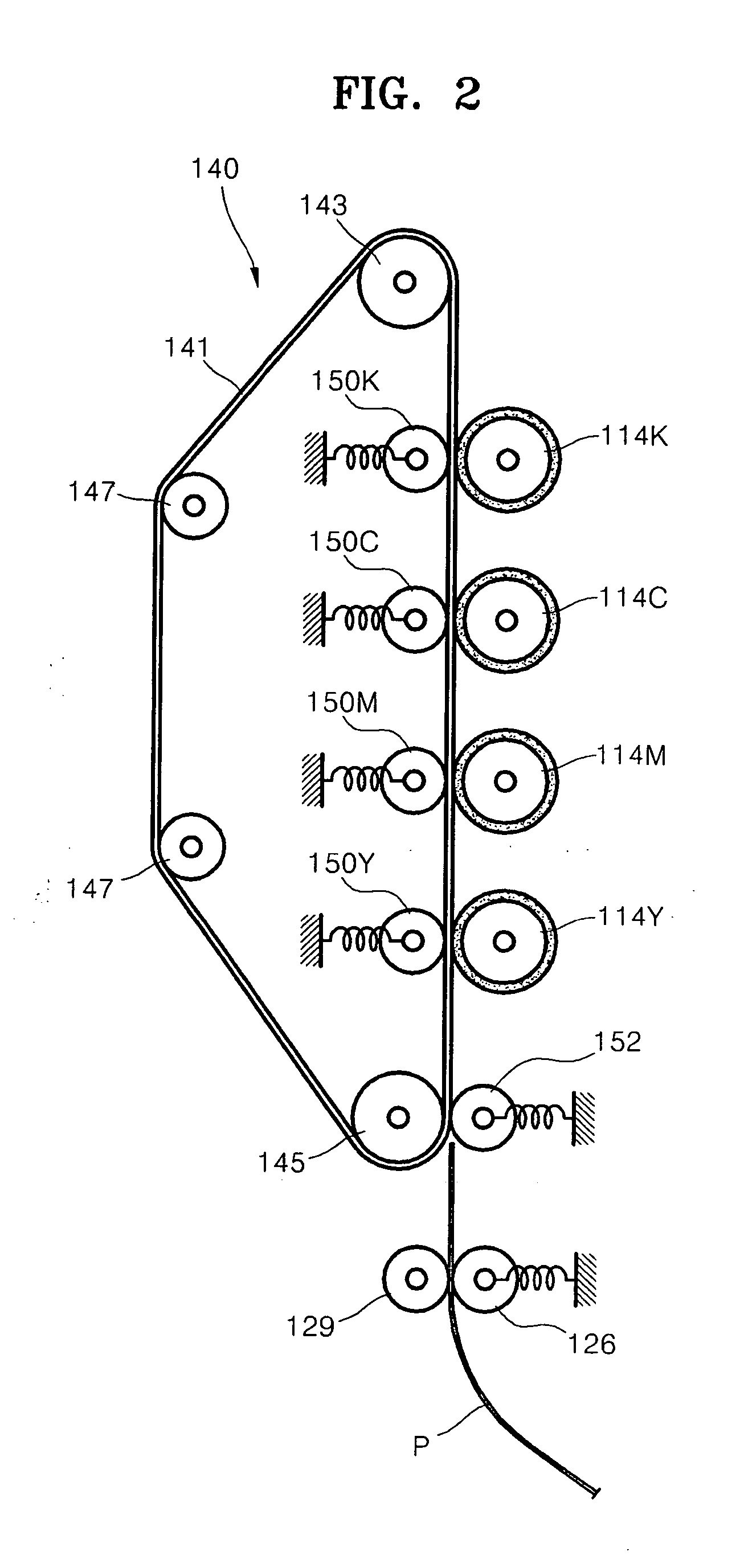

InactiveUS6993275B2Accurate color registrationQuality improvementRecording apparatusElectrographic process apparatusLocation detectionLeading edge

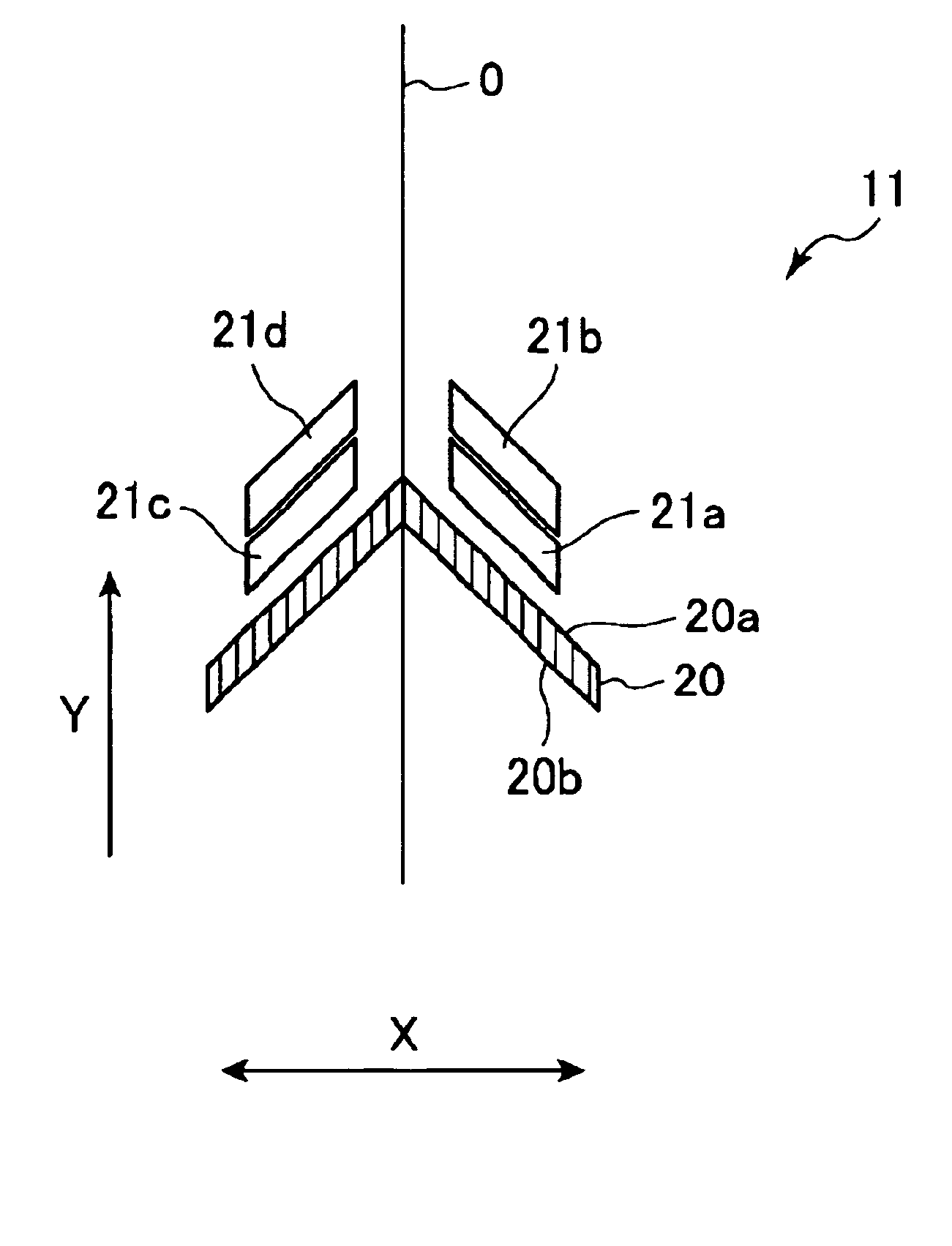

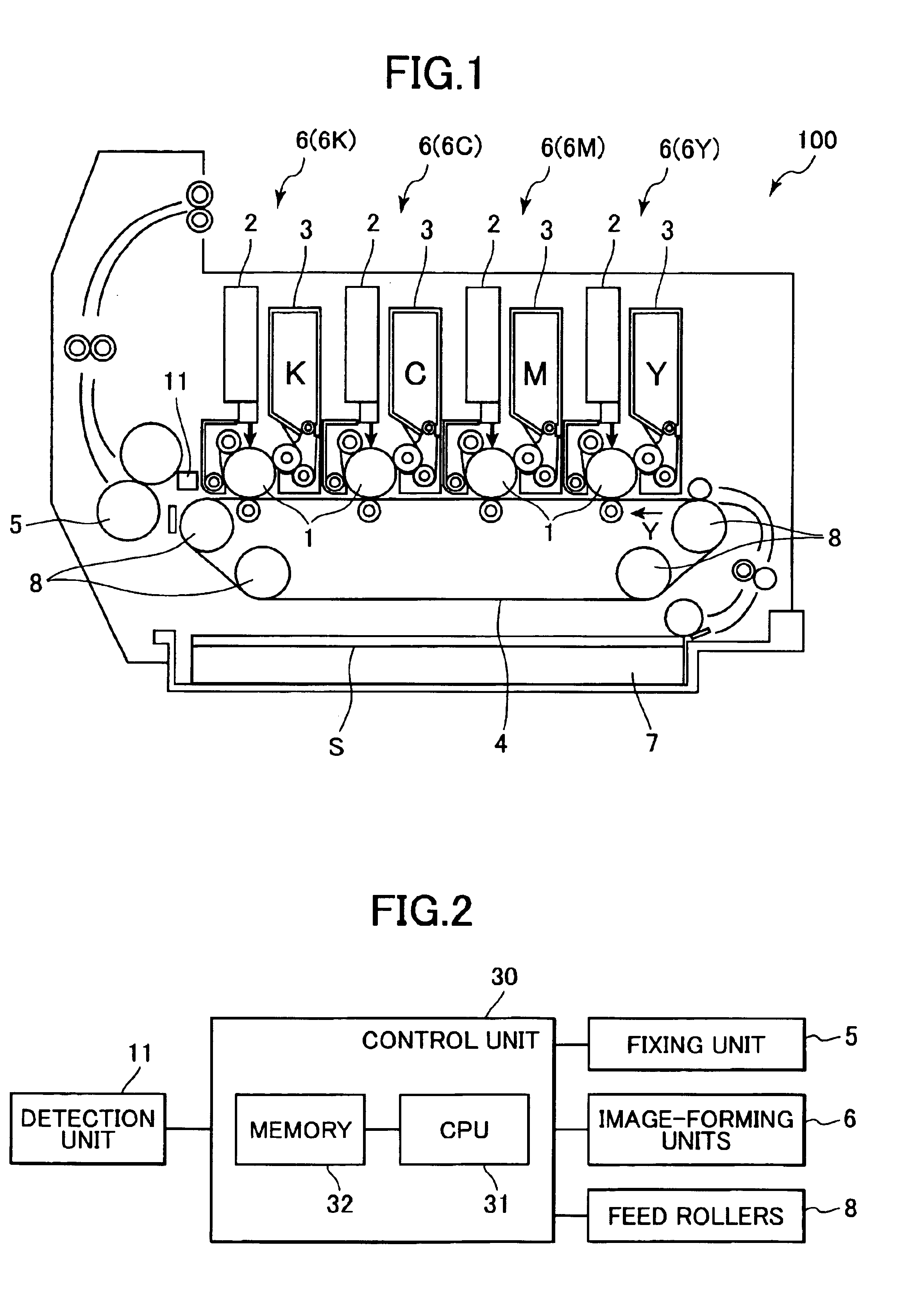

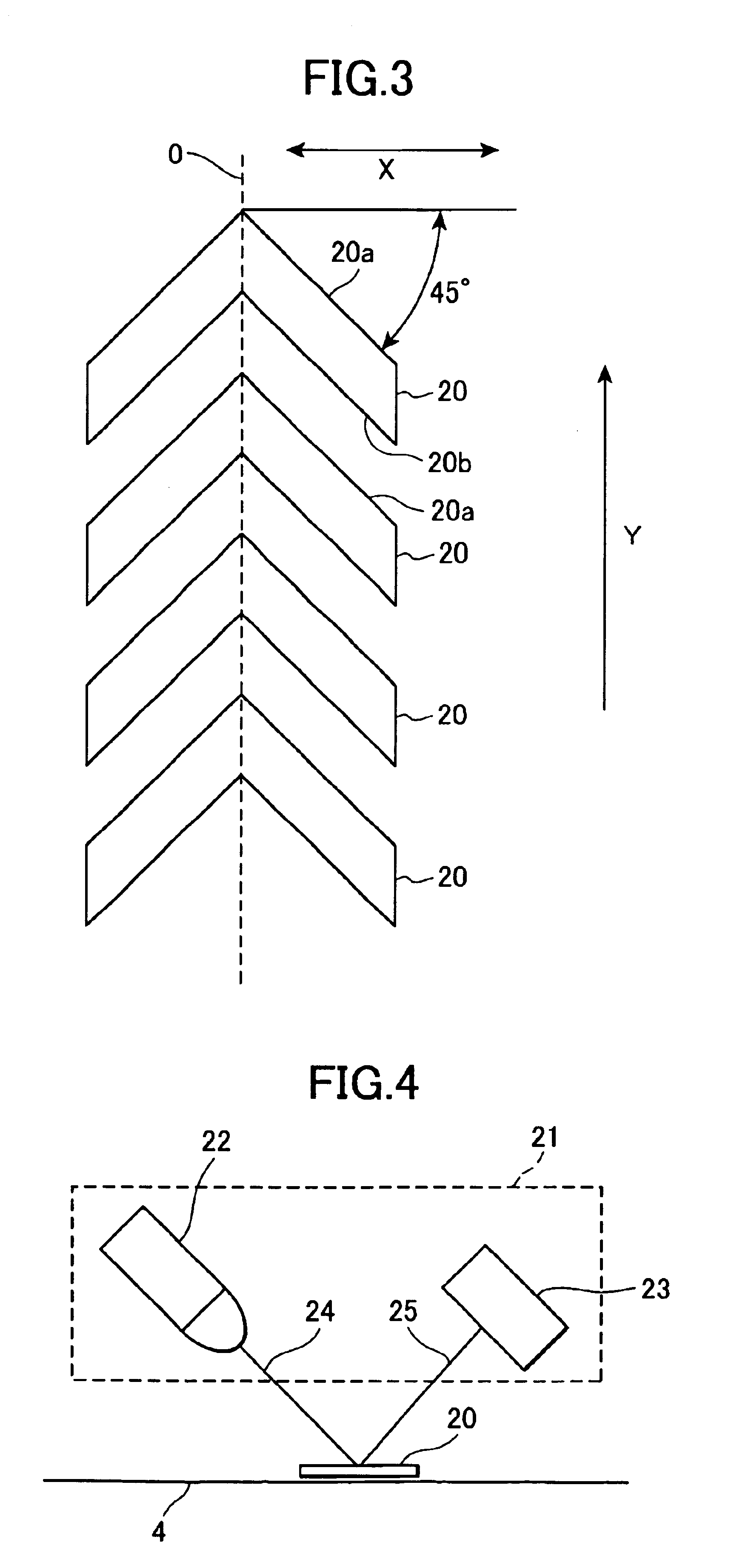

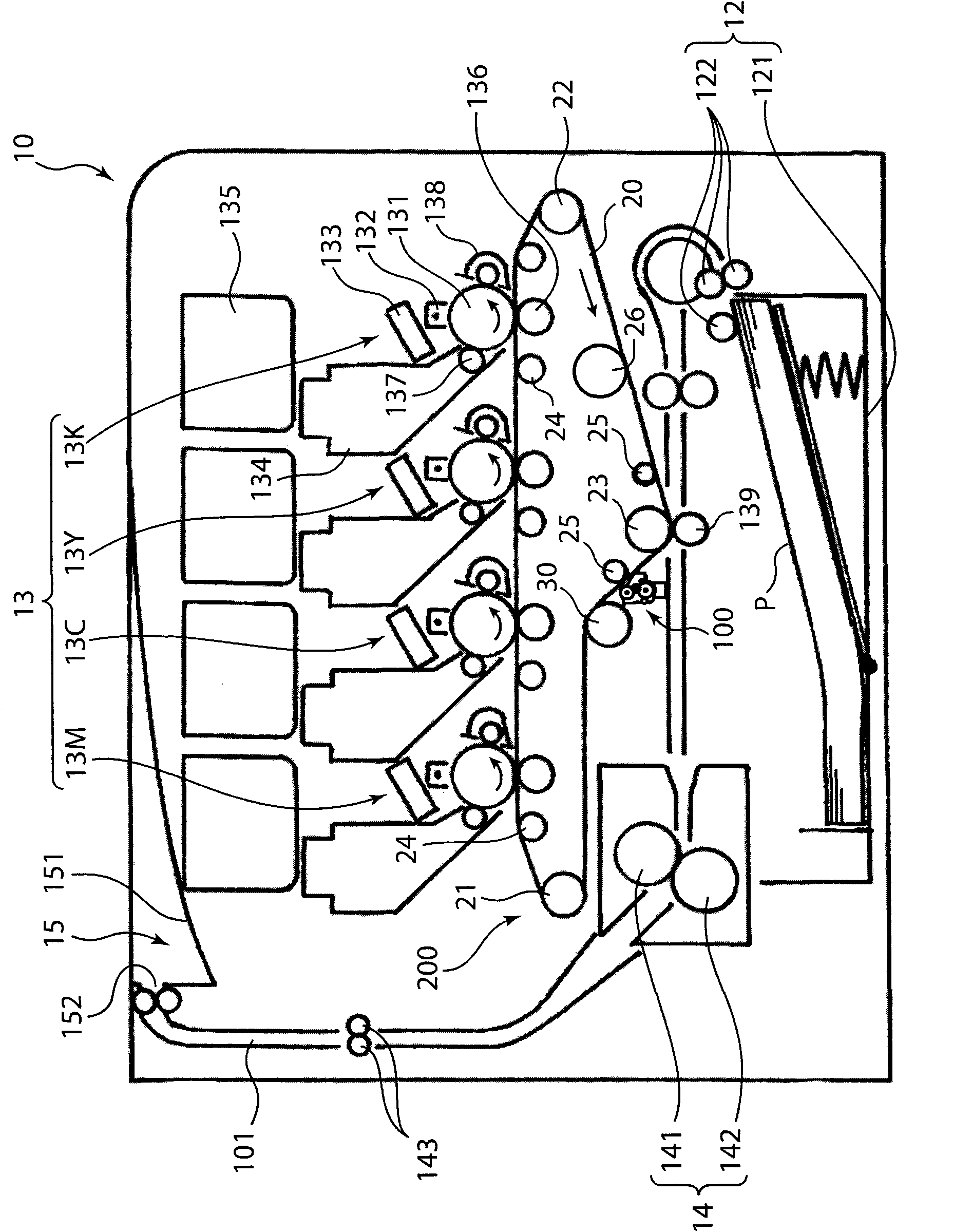

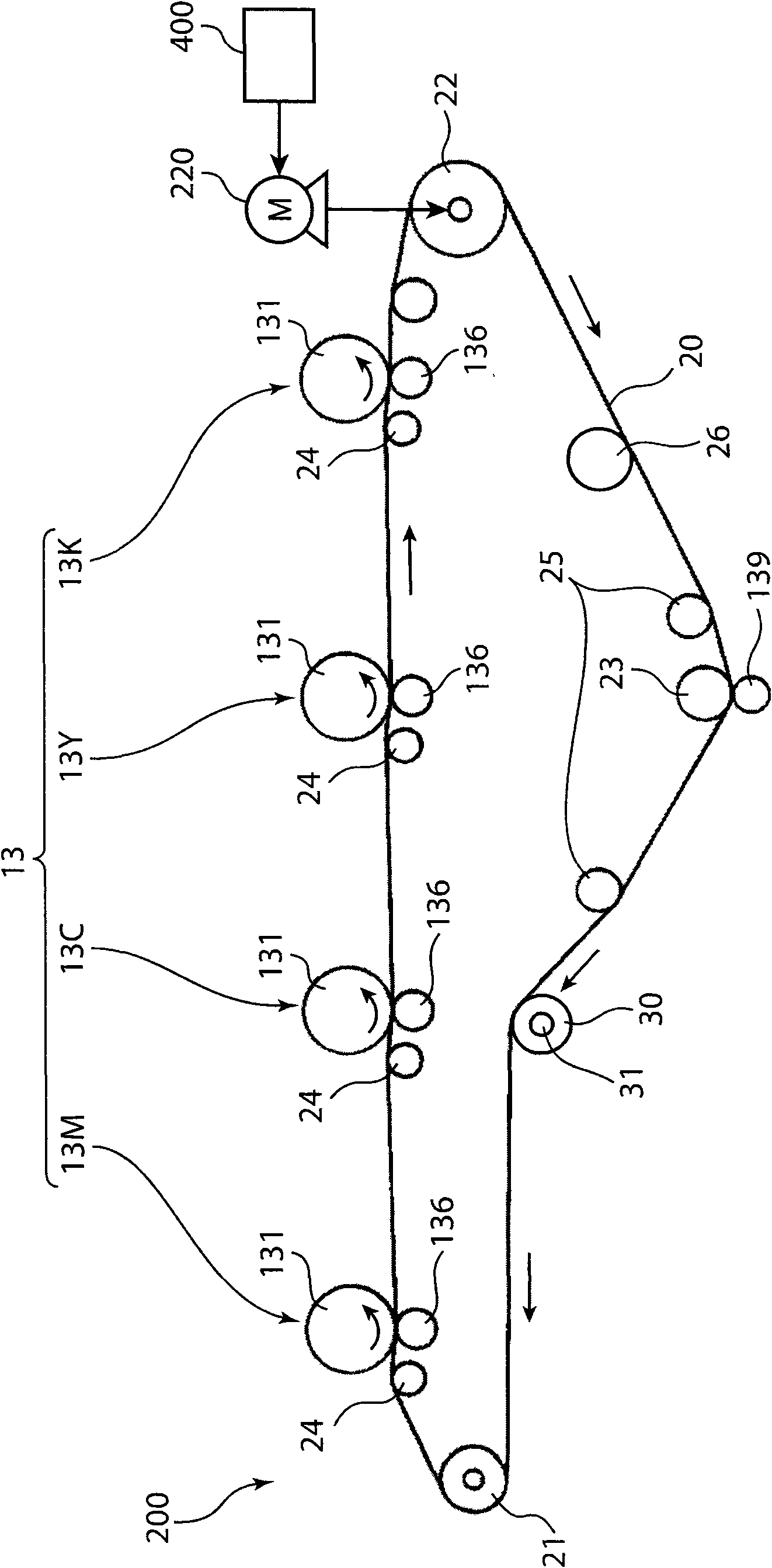

In an electrophotographic recording device, a multicolor toner image is formed by images in each color superimposed on one another. In order to detect image misalignment, image-forming units form a color registration detection pattern, and sensors detect the pattern and output detection signals. A control unit detects the position of the patterns based on only portions of the detection signals corresponding to leading edges of the patterns.

Owner:RICOH PRINTING SYST +1

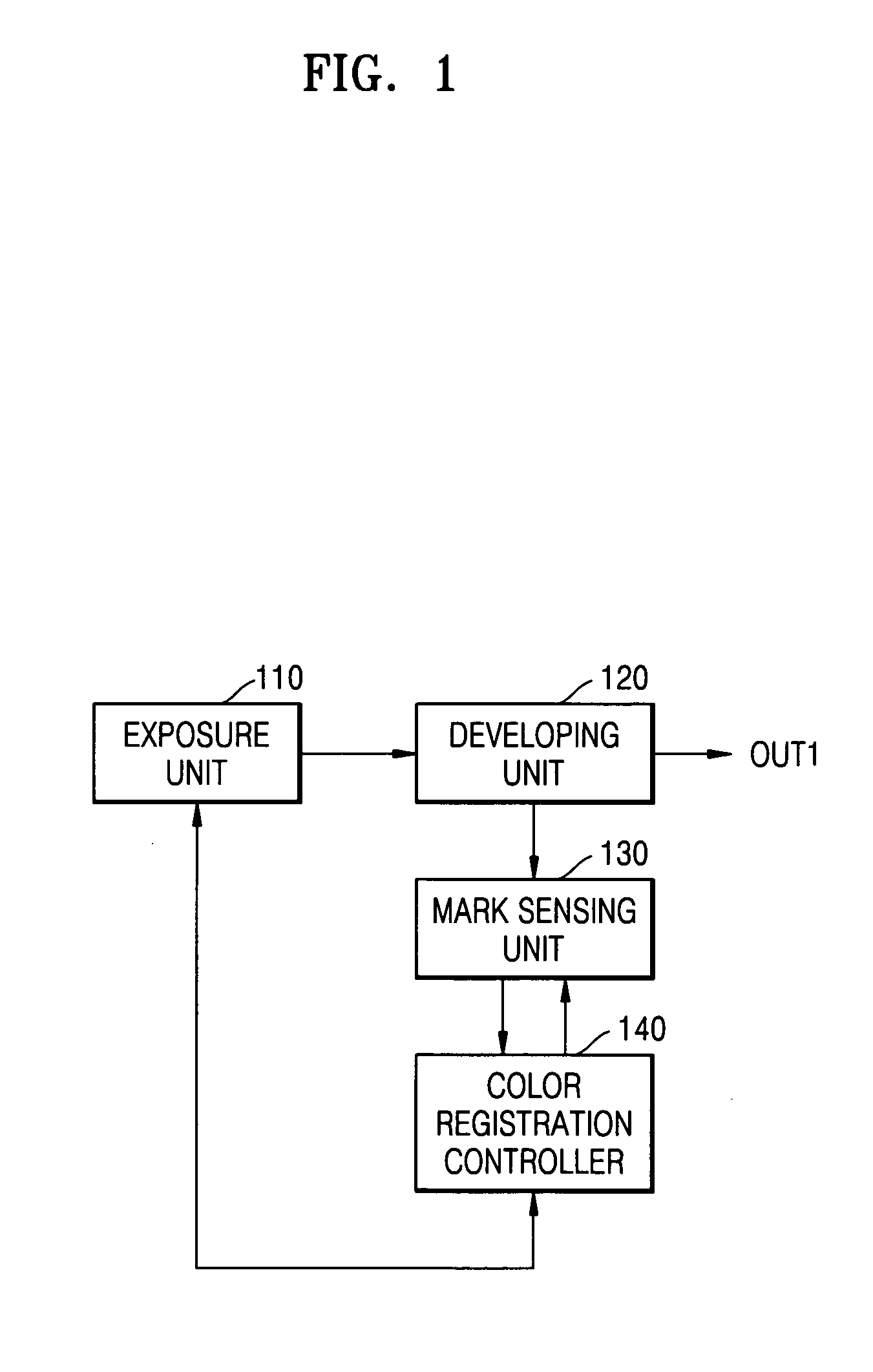

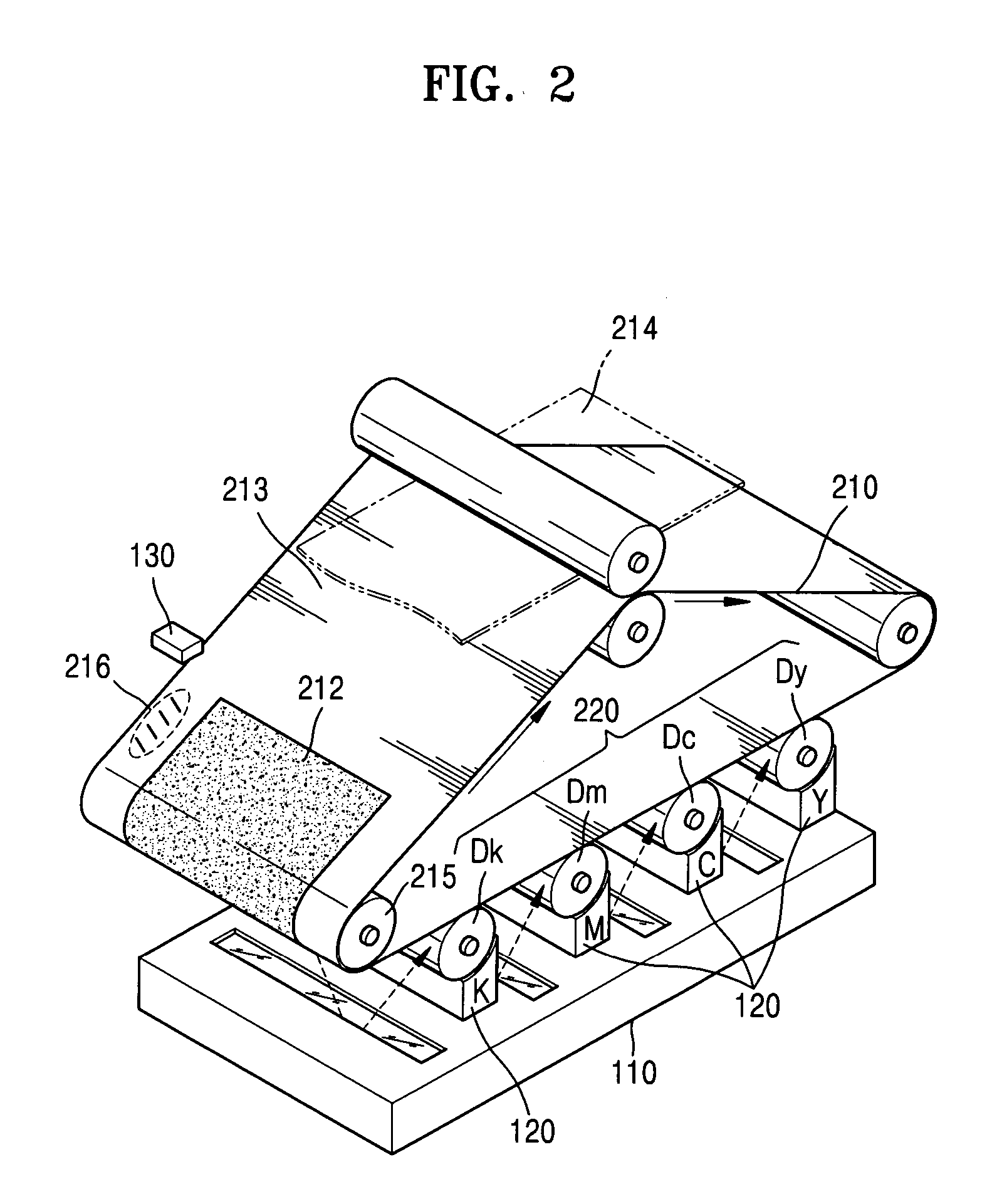

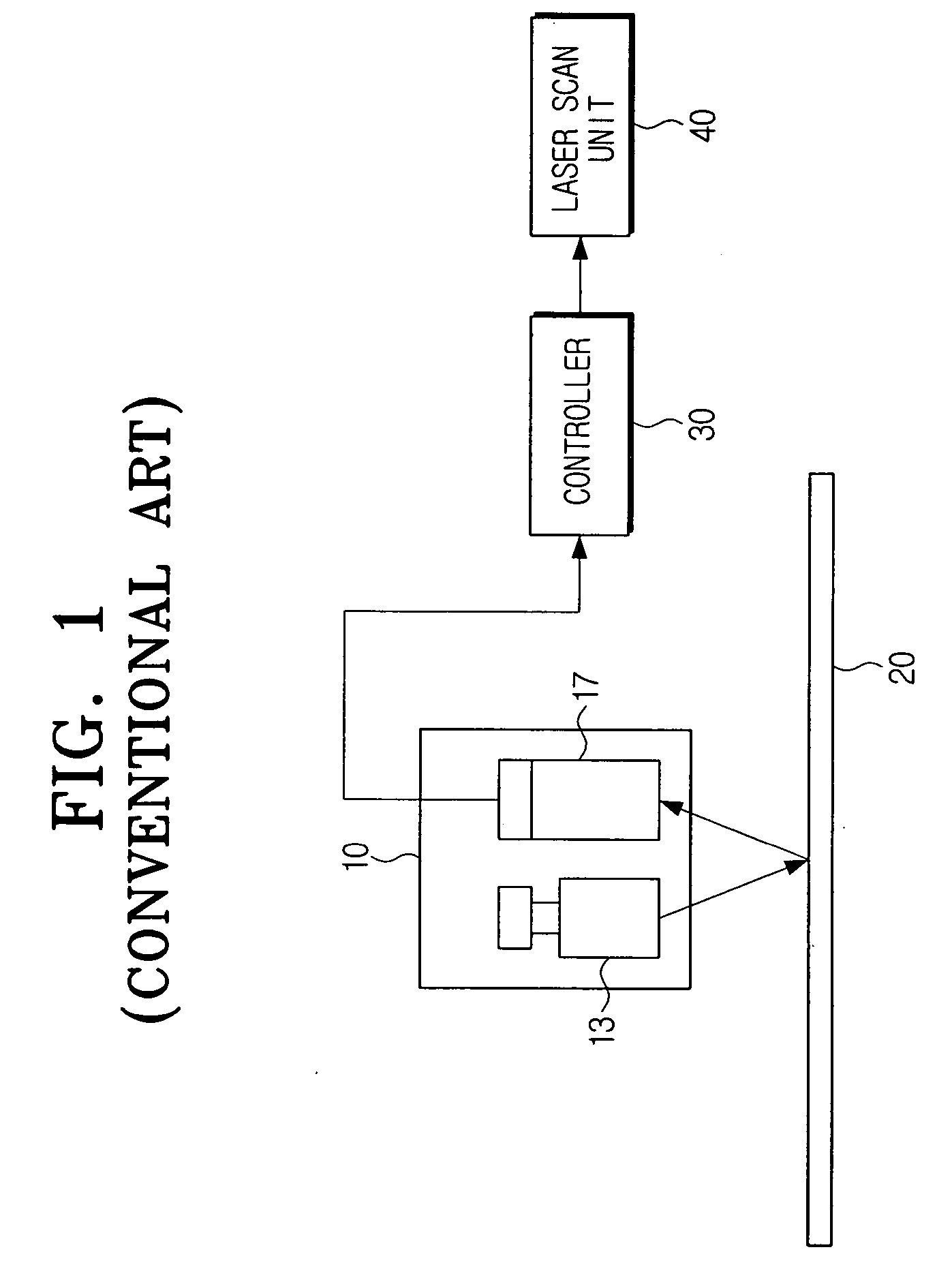

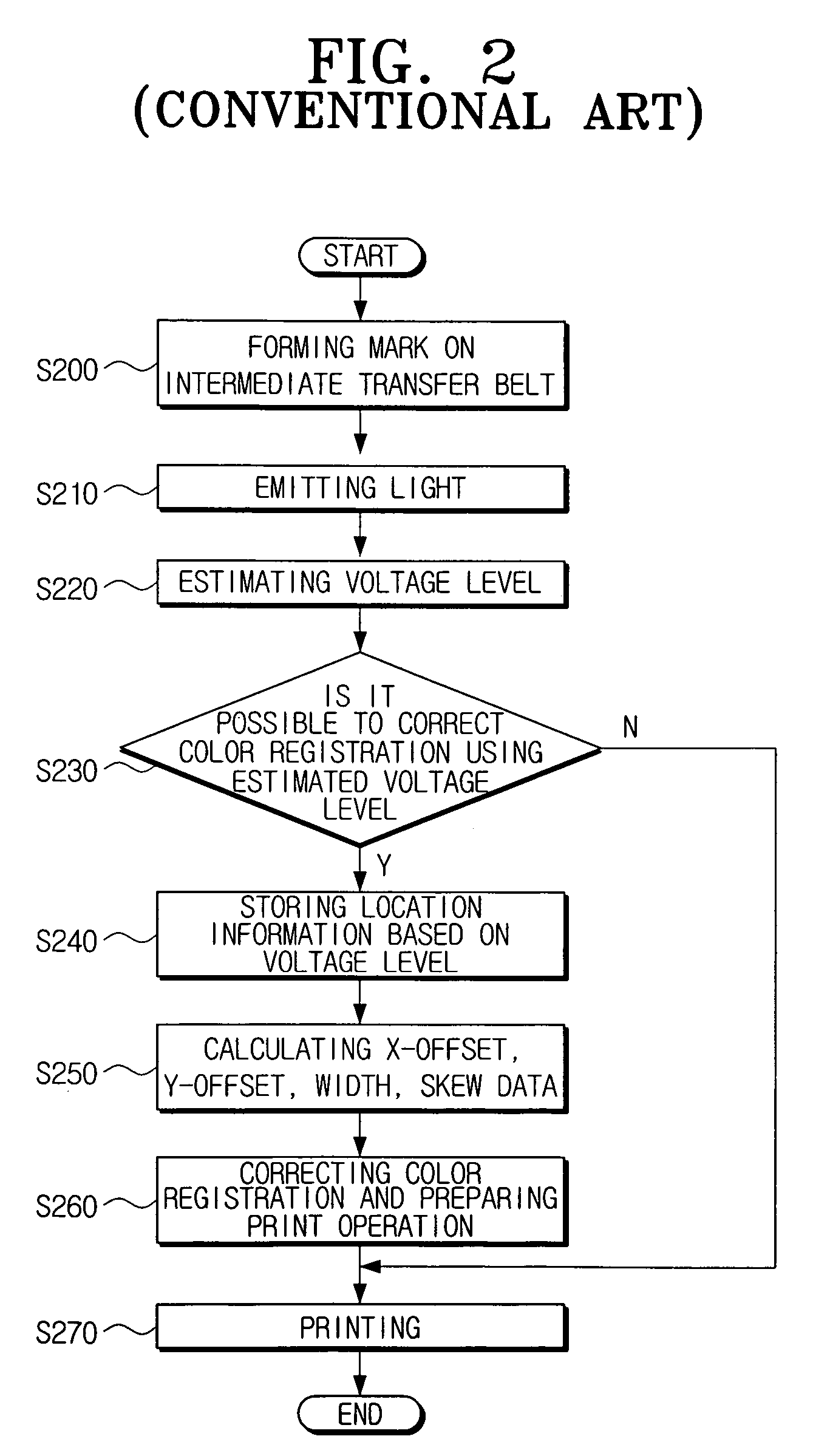

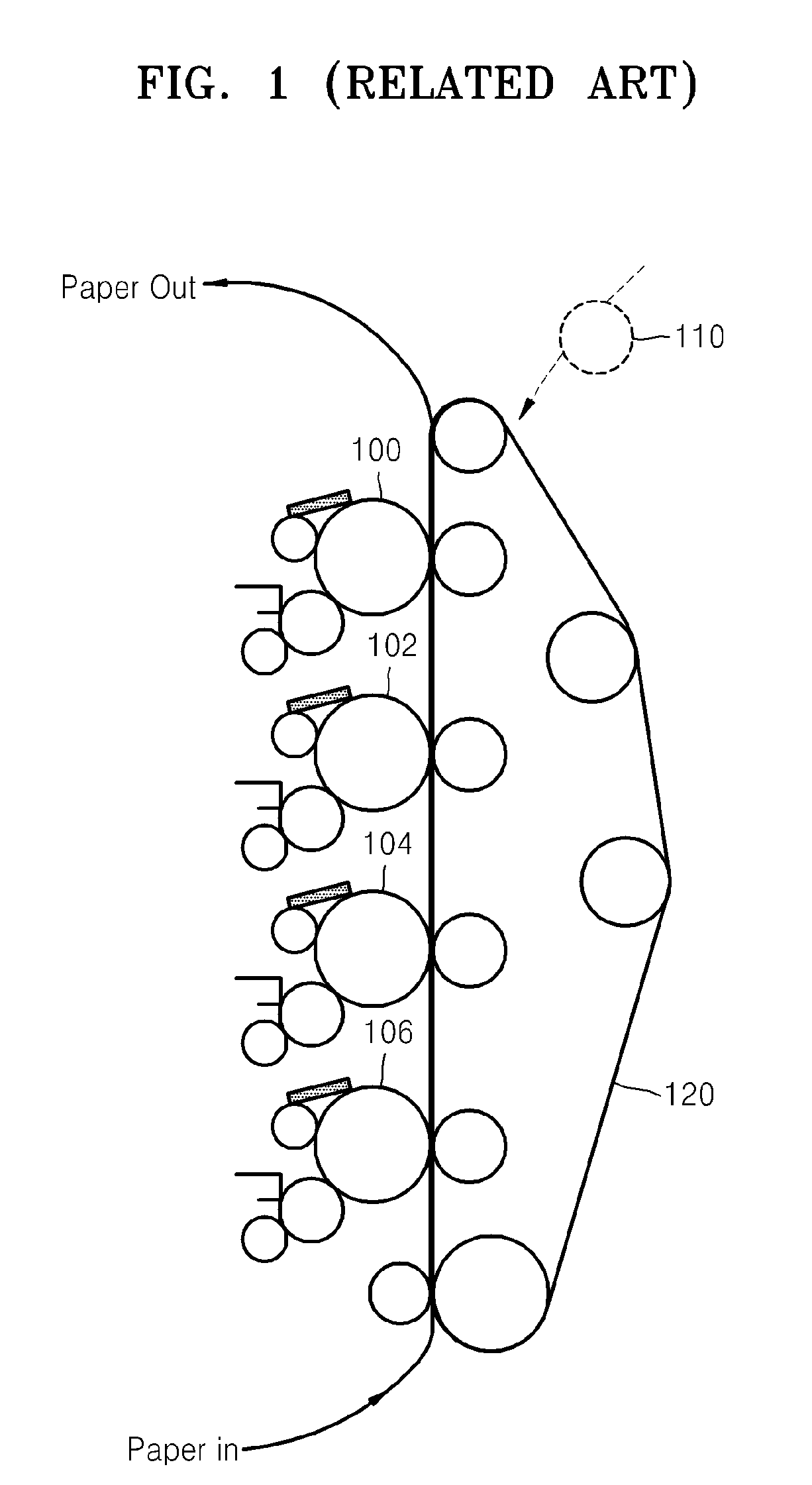

Apparatus and method of correcting color registration in electrophotographic printer

ActiveUS20060119690A1Accurate calculationAccurate color registrationRecording apparatusElectrographic process apparatusComputer visionLight beam

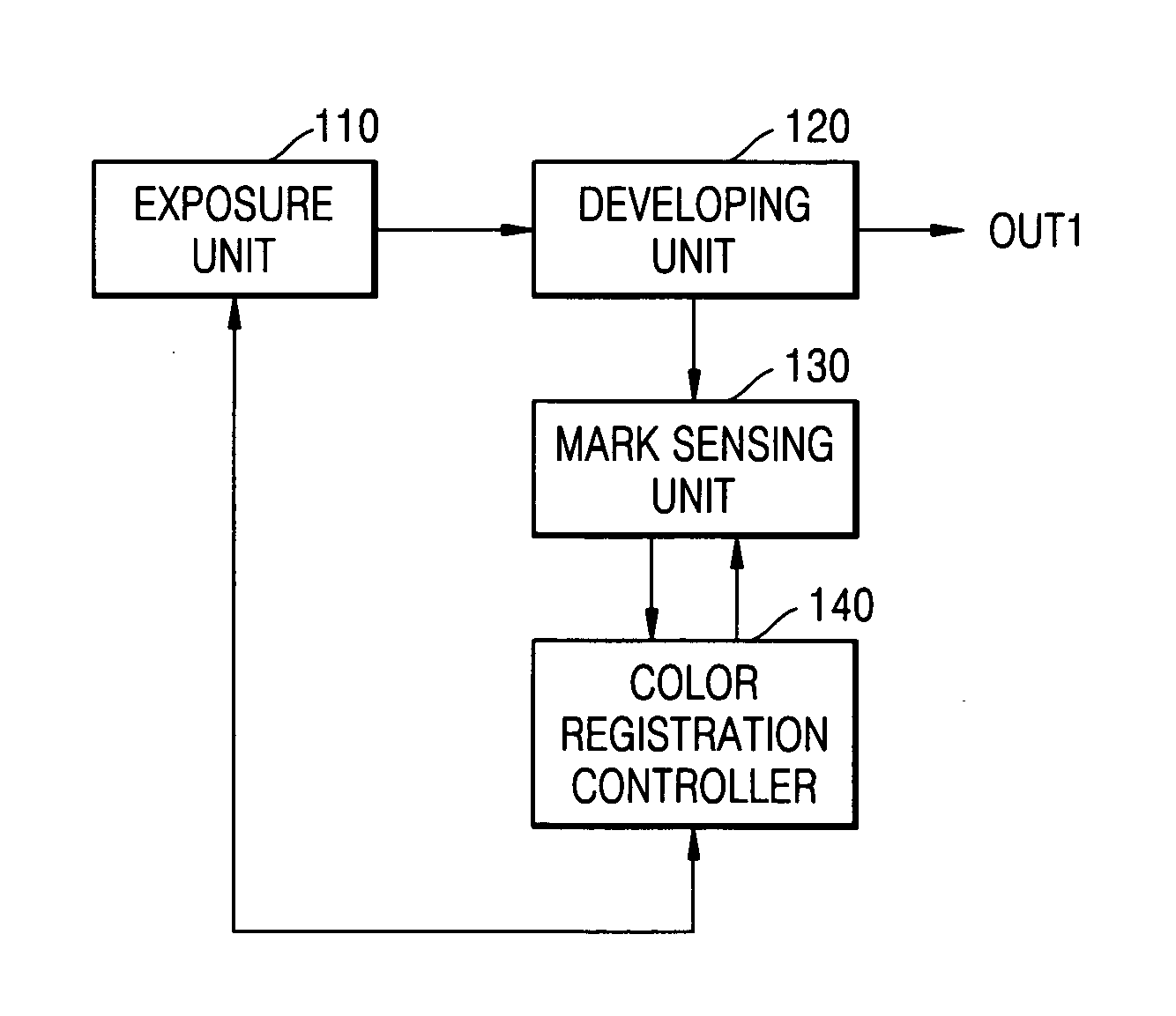

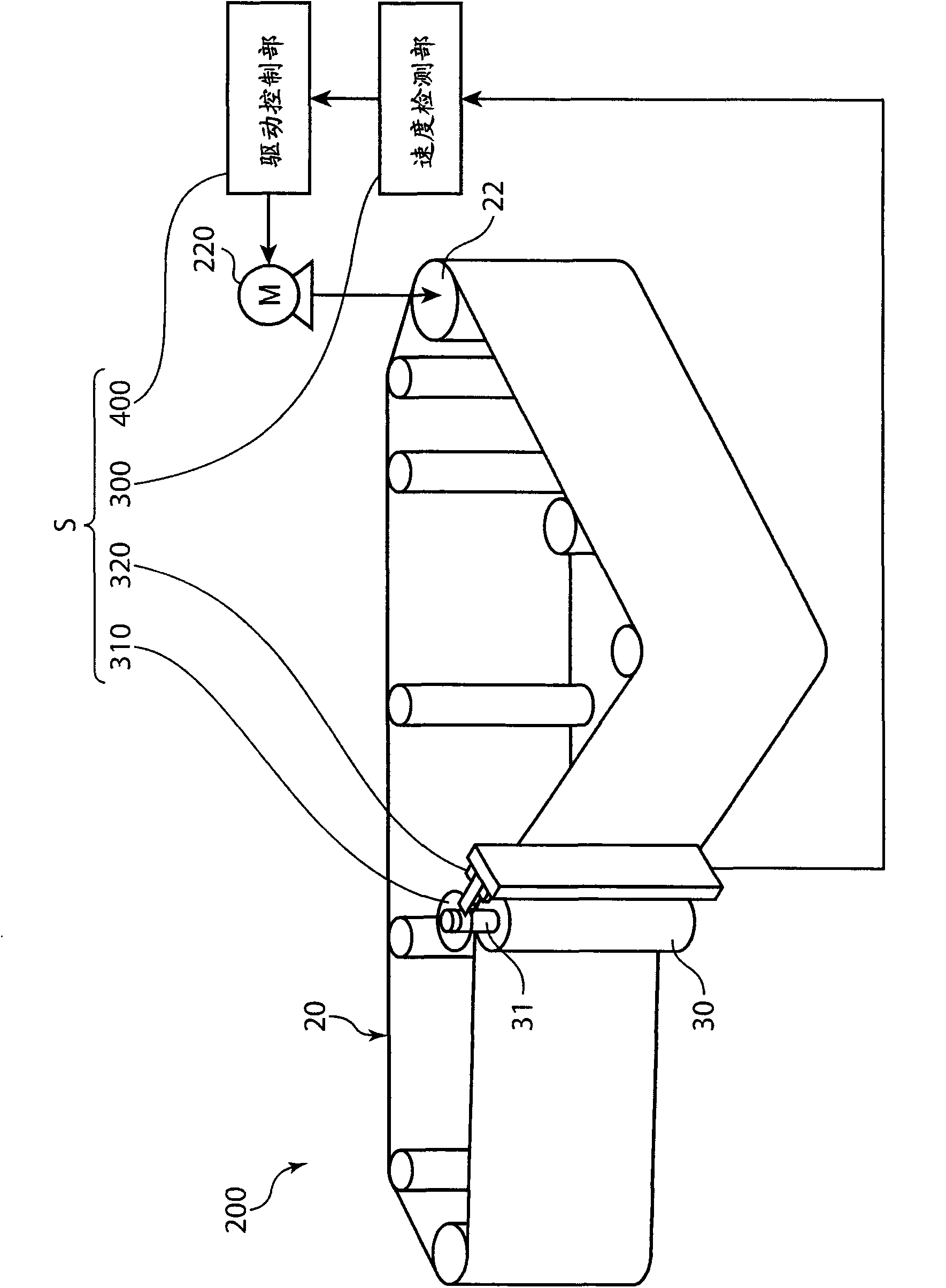

Disclosed are an apparatus for and a method of correction color registration in an electro-photographic printer. An apparatus for correcting color registration in an electro-photographic printer, in which exposure start points of each color unit for a photosensitive drum are adjusted to superpose images developed in a plurality of colors on matching positions of a transfer belt, includes an exposure unit to project light beams on the photosensitive drum to form latent images of one or more marks for each color unit. A developing unit is also disclosed to generate developed images by developing the latent images of the marks and a mark sensing unit is provided to detect the developed images transferred on a surface of the transfer belt for a predetermined time period. A color registration controller stores information on time points at which the developed images are detected and compares the number of the time points with the number of the marks. Thus, the color registration controller controls the exposure start points in response to the compared result.

Owner:HEWLETT PACKARD DEV CO LP

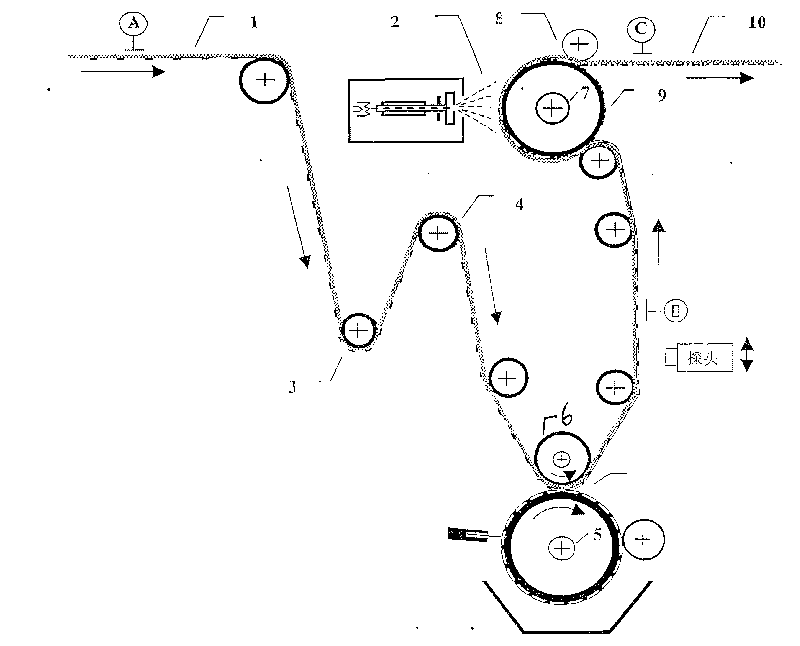

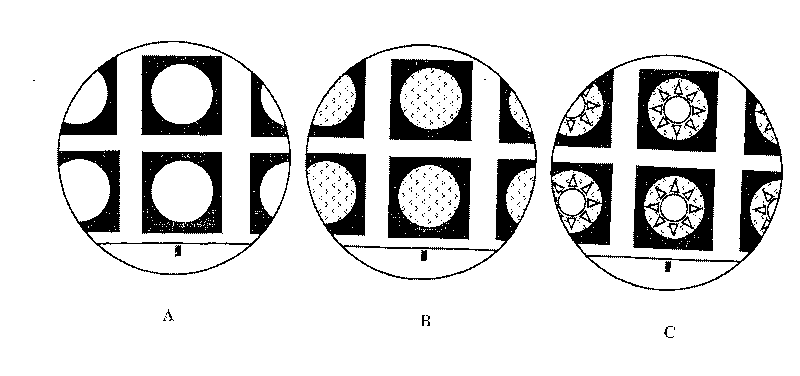

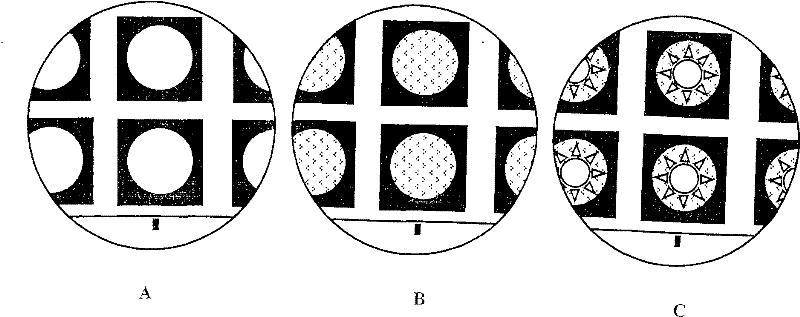

Method for printing embossment microstructure with positioned color register

ActiveCN101691091AOverprint accuracy can be controlledSmall shrinkage deformationPattern printingPlate printingDie castingEngineering

The invention relates to a method for printing an embossment microstructure with a positioned color register, in particular to a method for the integrated online printing of an embossment type optical microstructure layer which is positioned and nested with an ink color. The method comprises the following steps: taking a microstructure area as a special color for printing; printing a molding ink at a specified position; in the state that the ink area is not completely dried and solidified, attaching and die-casting the ink area in a positioning mode by an embossment microstructure mother set roller on a next printing plate roller so that the ink is embedded in an embossment microstructure groove on a mother set; and solidifying and molding a hinge for drying the ink in a coating area of a printing material and a microstructure image, wherein the embossment shaped microstructure on the mother set roller is completely copied to the ink surface of a printing stock in a mirror image mode, and a copying molding area serves as a color register printed at the specified position and can be connected with front and back printing colors to form a + / -0.15 millimeter printing registration accuracy. The method can achieve the positioned color register with a common printing and the accurate positioning of pattern and ink printing on the mother set.

Owner:上海冠众光学科技有限公司

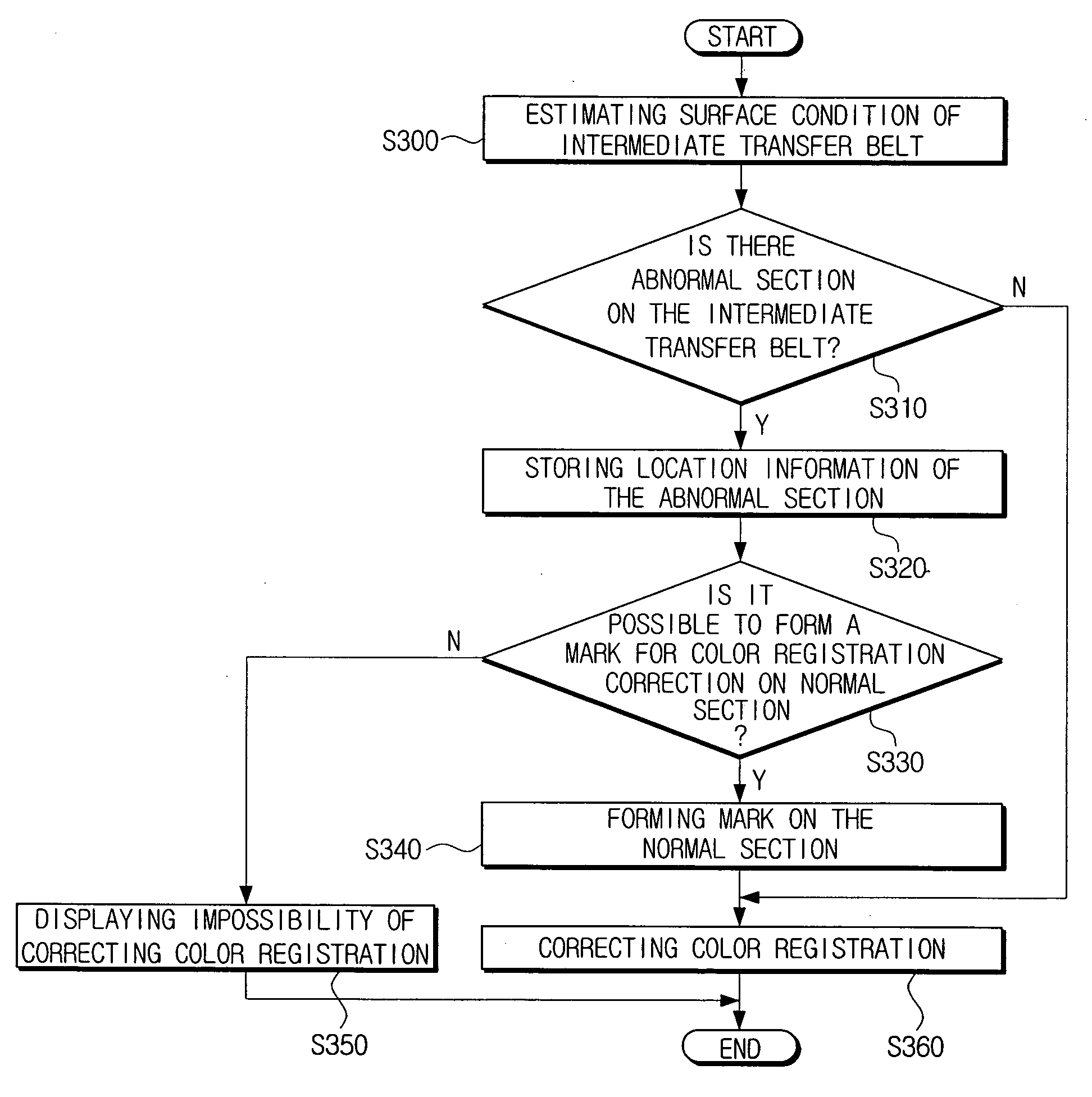

System and method for correcting color registration

ActiveUS20070003332A1Accurate color registrationAccurate locationElectrographic process apparatusSurface conditionsComputer science

Owner:HEWLETT PACKARD DEV CO LP

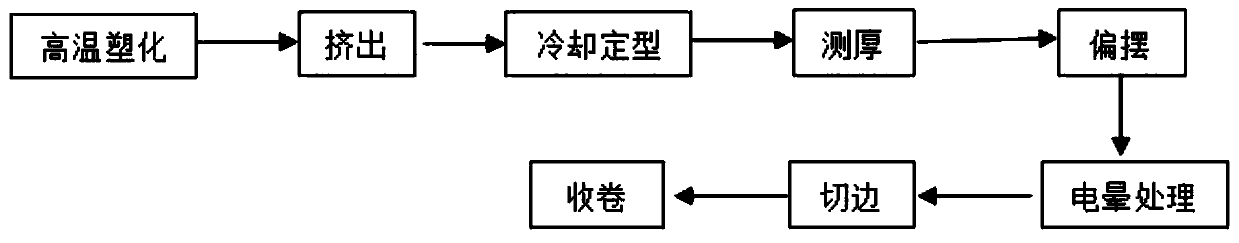

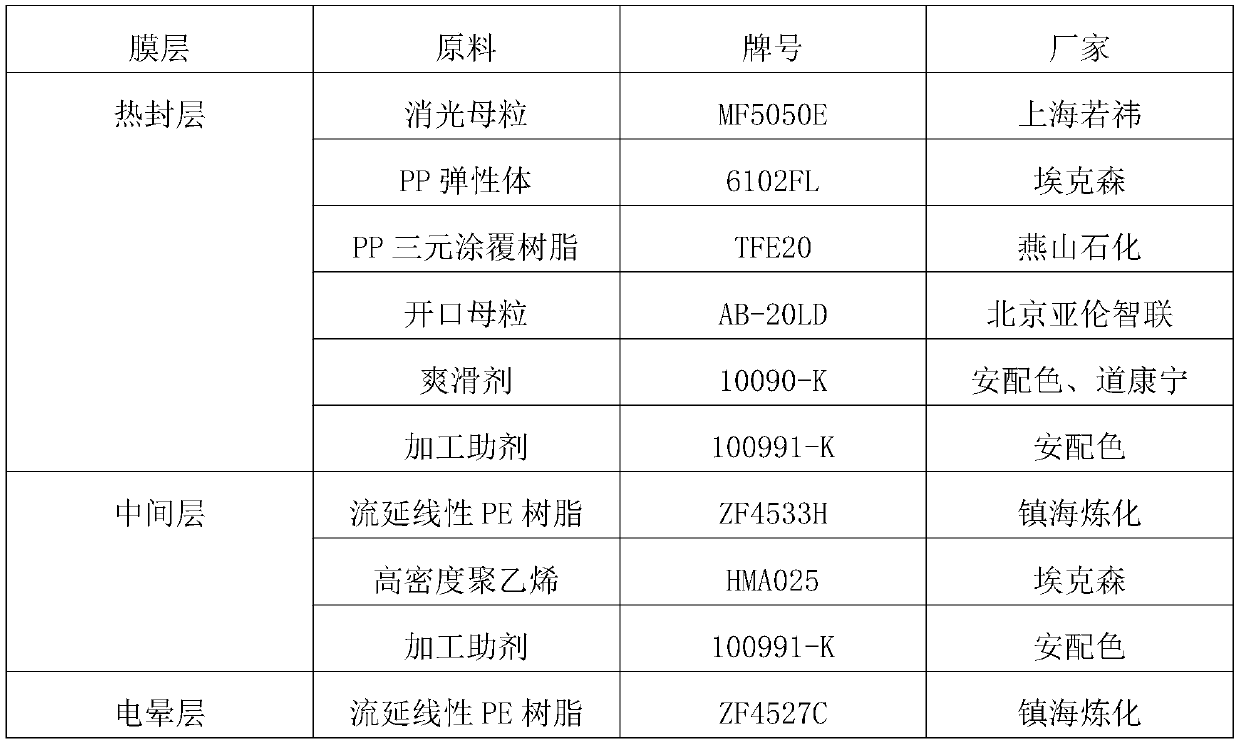

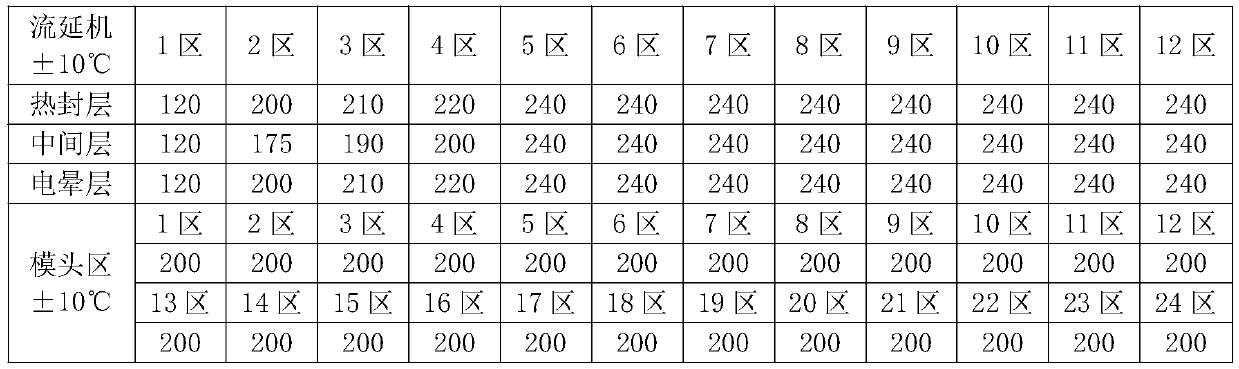

Extinction casting PE film and production process thereof

ActiveCN110305402ASpecular Scatter ScaleGood heat sealing performanceSynthetic resin layered productsFlat articlesMasterbatchElastomer

The invention relates to an extinction casting PE film and a production process thereof. The extinction casting PE film comprises a heat sealing layer, an intermediate layer and a corona layer, wherein the heat sealing layer comprises extinction masterbatch, a PP elastomer, PP ternary coating resin, opening masterbatch, a slipping agent and a processing aid; the intermediate layer comprises cast linear PE resin, high density polyethylene and a processing aid; and the corona layer comprises cast linear PE resin. The extinction cast PE film prepared by the composition is suitable for the requirements of printing equipment: excellent thickness uniformity, stable friction coefficient, 10% high tensile strength, high tensile breaking force, low surface gloss of extinction surface, high overallhaze of the film, fine appearance of the film surface, suitability for high-speed printing of intaglio and flexographic plates, accurate color coating and no deviation during intaglio multi-color printing.

Owner:HUANGSHAN NOVEL

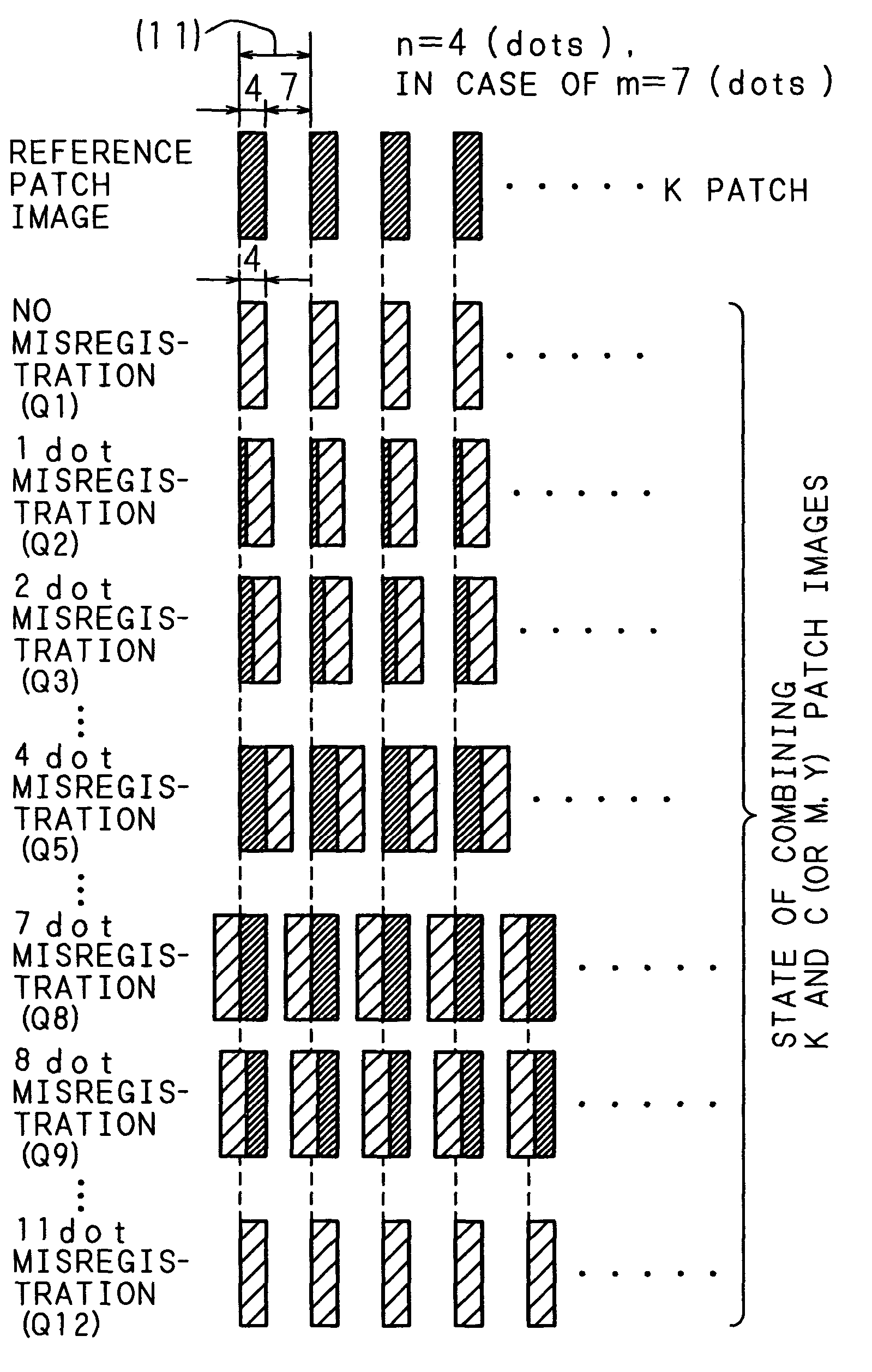

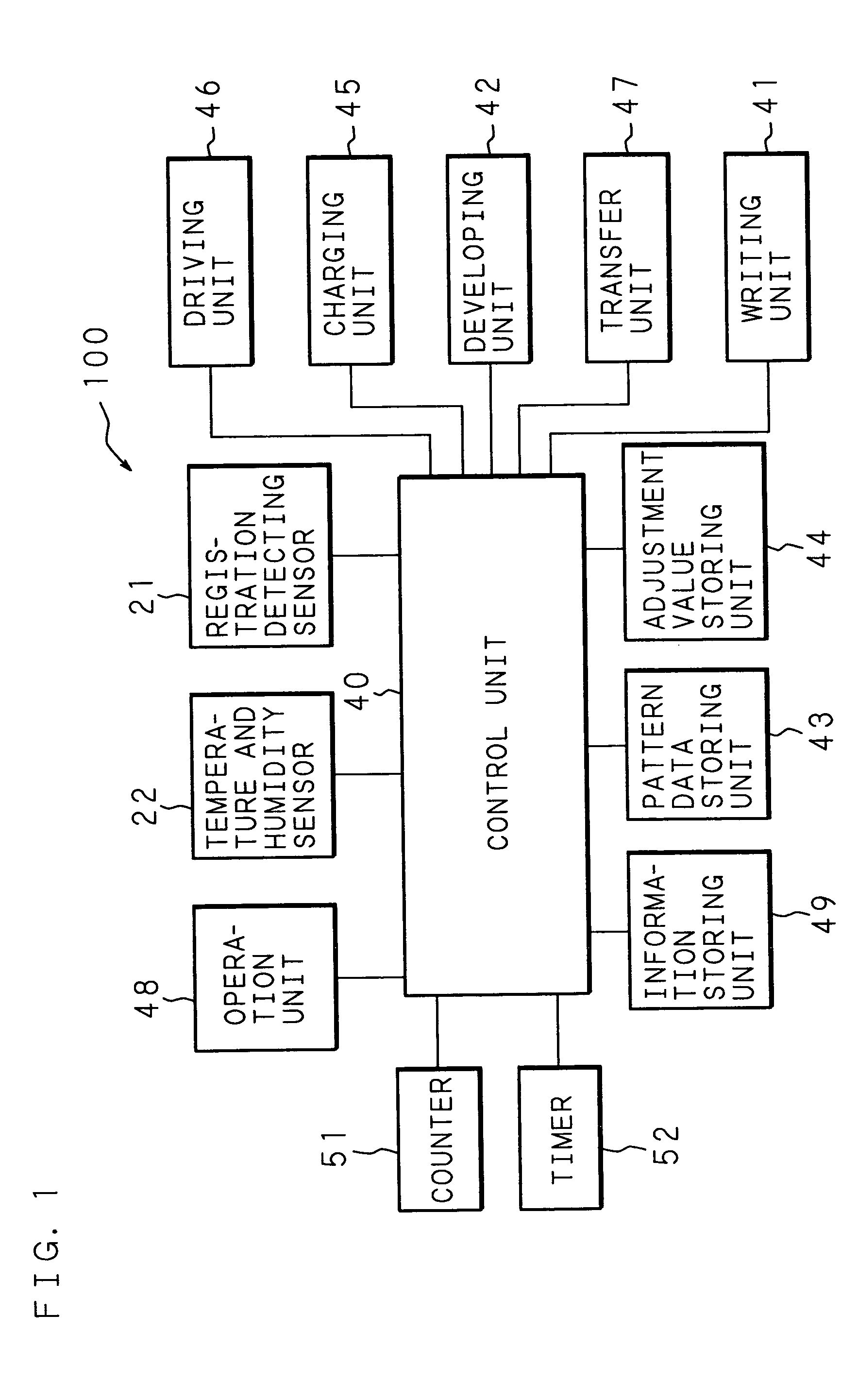

Image adjustment method and image forming apparatus

InactiveUS6970660B2Shorten the timeHighly accurate color registration adjustmentRecording apparatusElectrographic process apparatusReference imageImage formation

Owner:SHARP KK

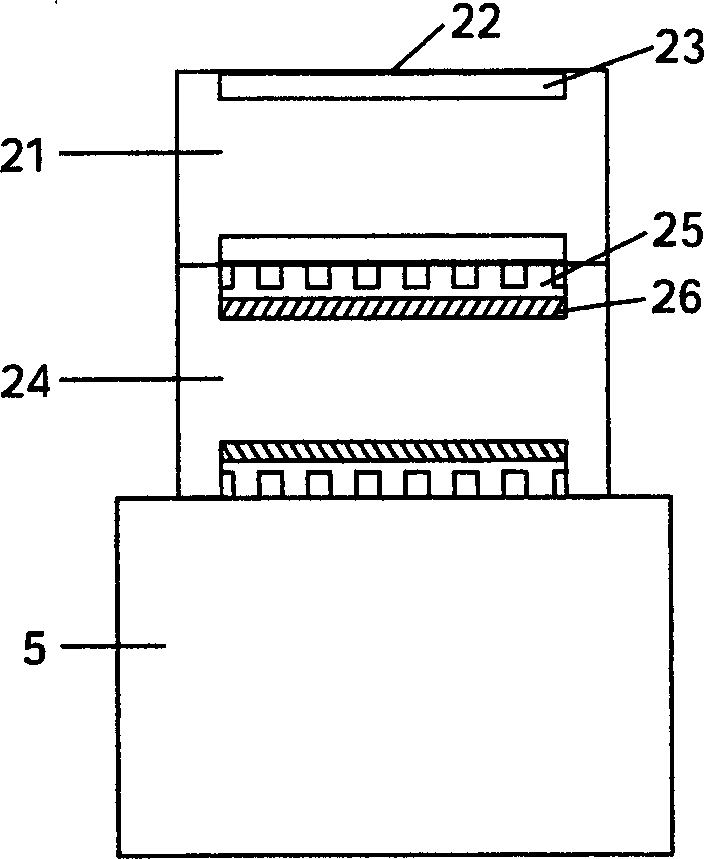

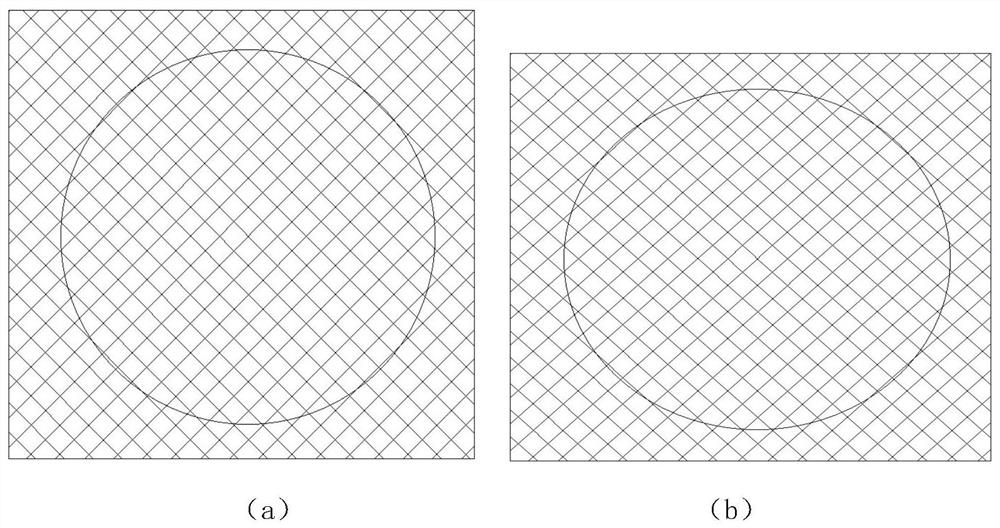

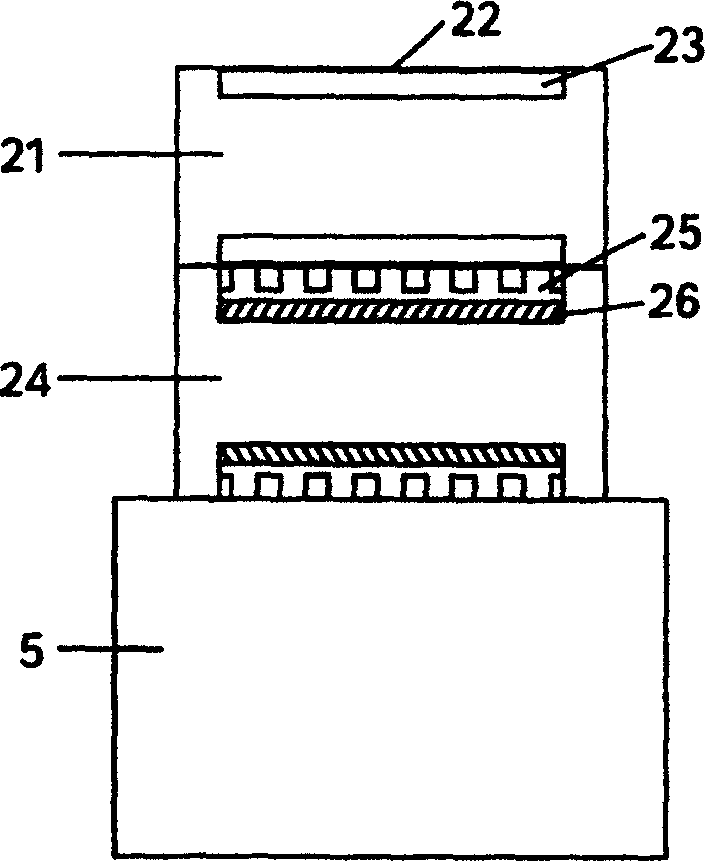

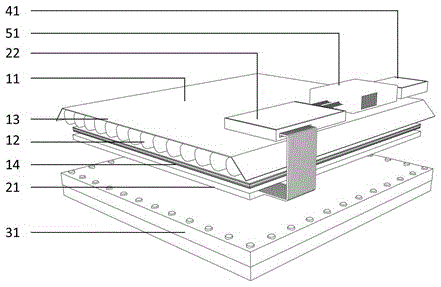

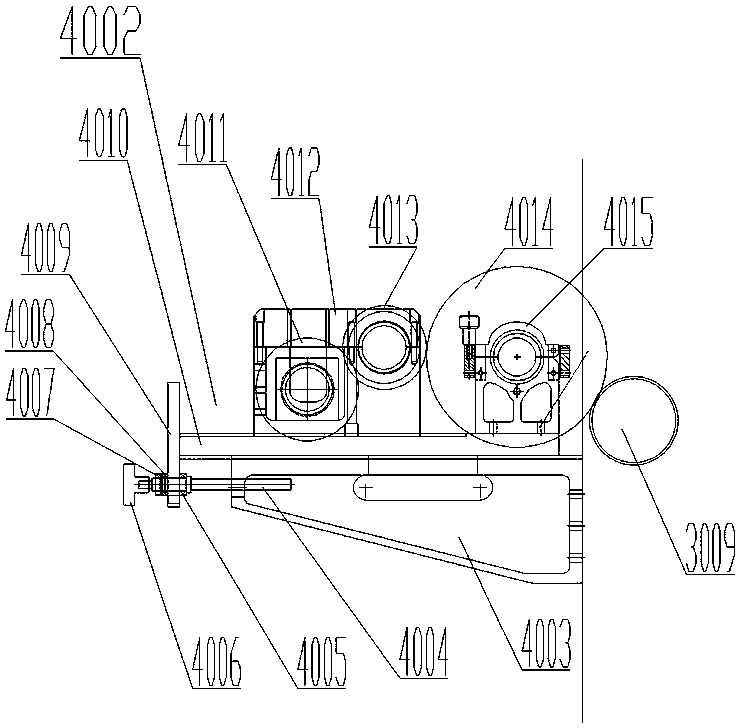

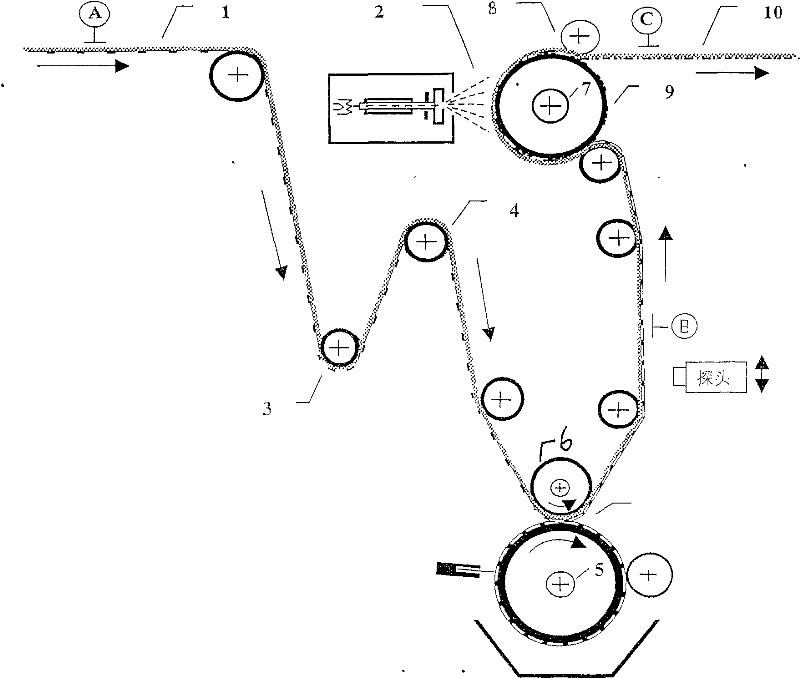

Computer imaging type direct plate making equipment and plate making method

ActiveCN103955112AQuality improvementReduce usagePhotomechanical apparatusForme preparationLight guideSheet film

The invention provides computer imaging type direct plate making equipment and a plate making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, so as to mask the light from the exposure light source, and thus a corresponding exposure image is formed on the printing plate; to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Due to the introduction of a light homogenizing layer, dependence on a light source is further reduced, and in particular, good plate making precision can be obtained by combination of light sources with different specifications, light sources or spot light sources with different surface luminescence uniformity and line light sources. A plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:青岛斯博锐意电子技术有限公司

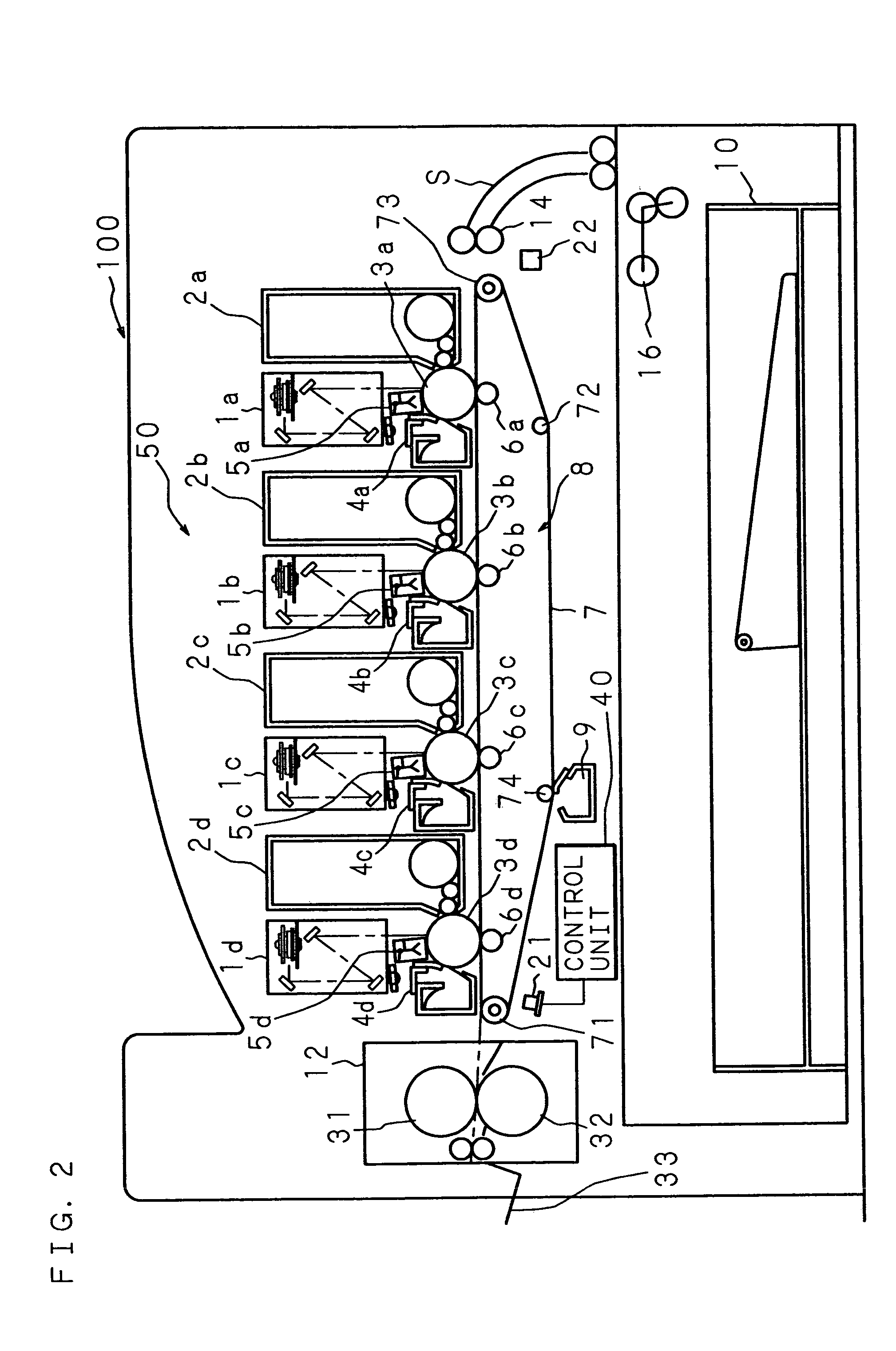

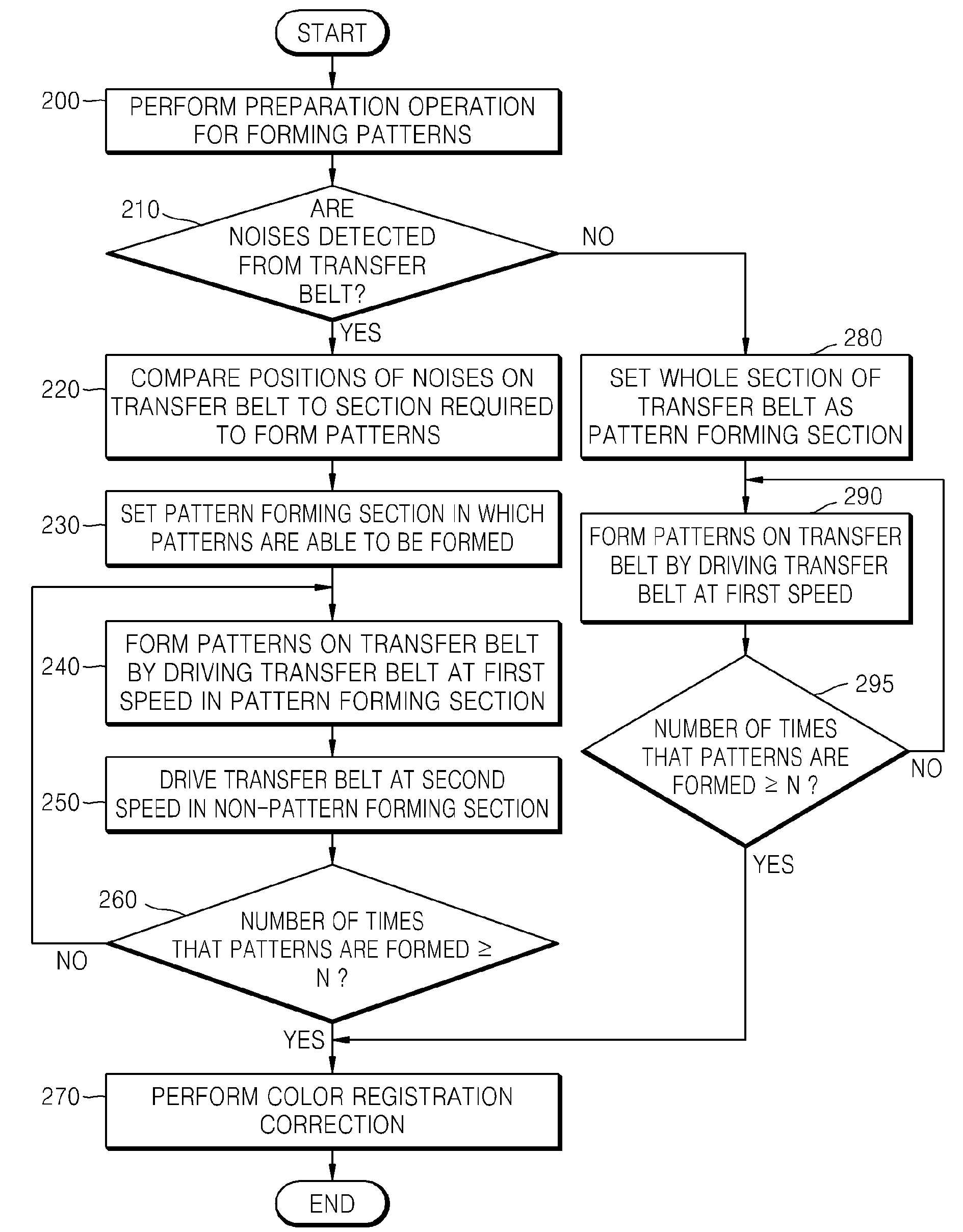

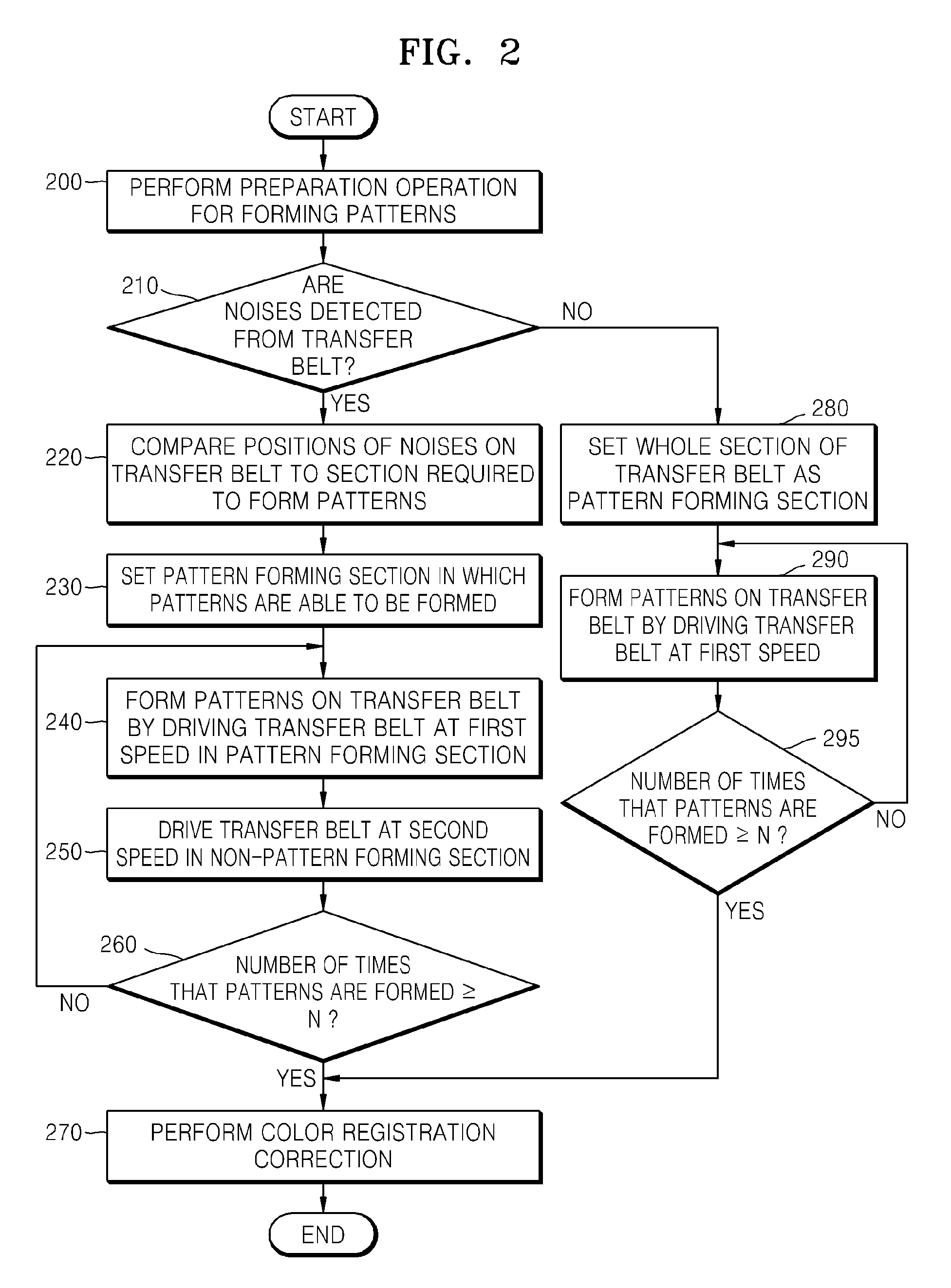

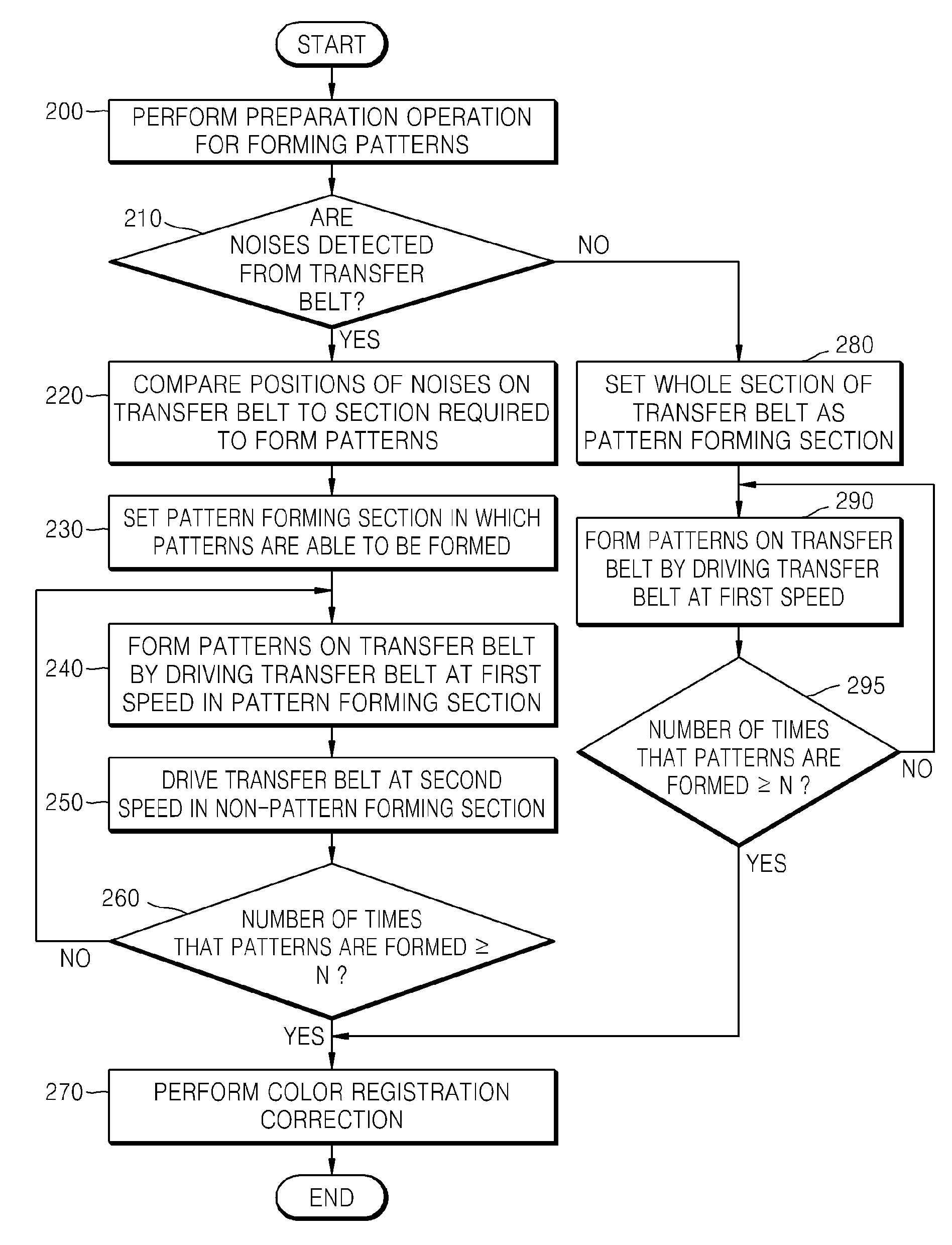

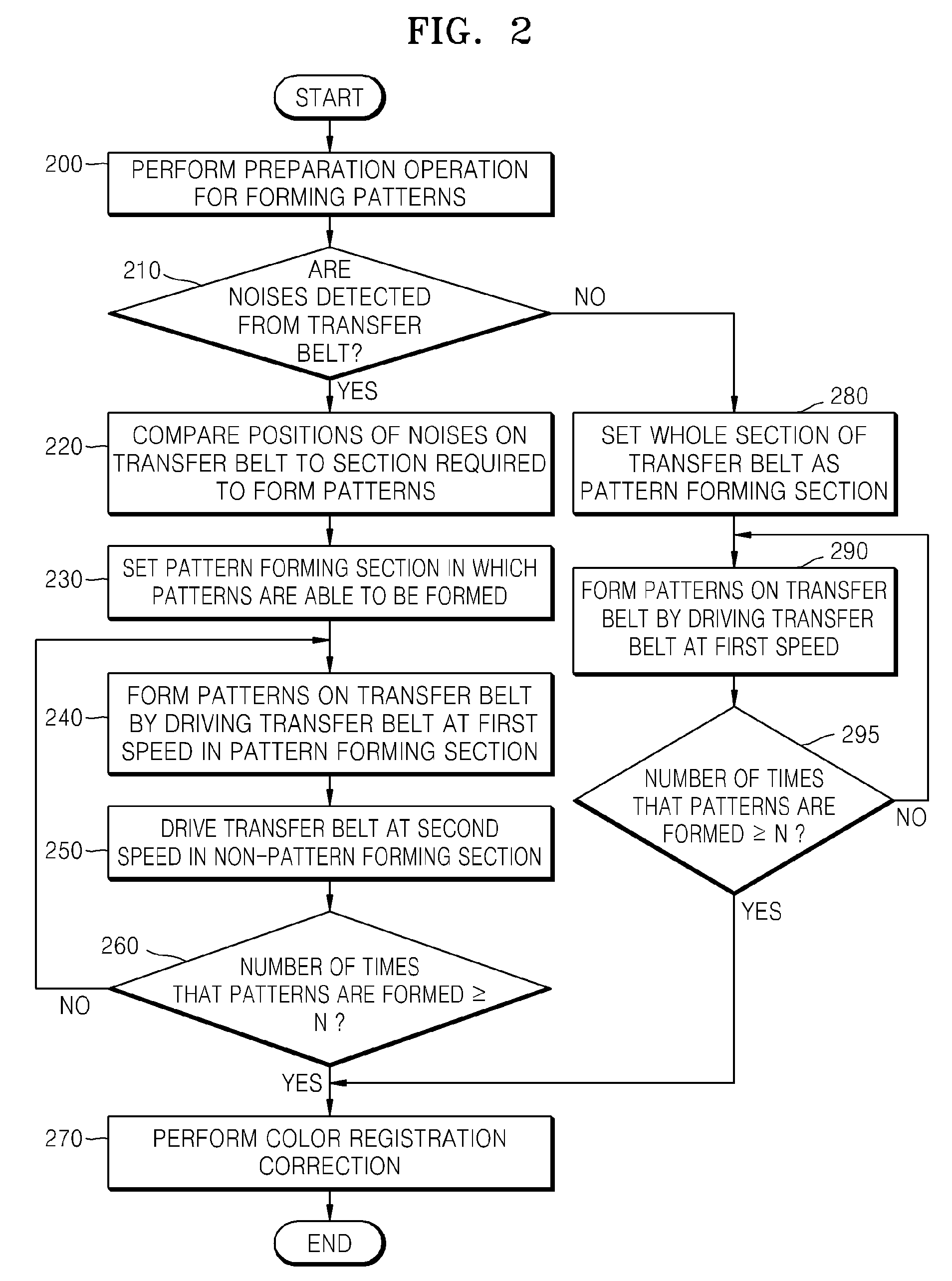

Transfer belt driving control method and transfer belt driving control apparatus for color registration correction

ActiveUS20090290914A1Accurate color registration correctionShort timeRecording apparatusElectrographic process apparatusMechanical engineeringCorrection method

A transfer belt driving control method and transfer belt driving control apparatus for color registration correction. The color registration correction method and apparatus performs the color registration correction by setting a pattern forming section, in which patterns for the color registration correction are able to be formed, and a non-pattern forming section, in which the patterns are not able to be formed, on a transfer belt in which the patterns are formed, performing the color registration correction by driving the transfer belt at a first speed in the pattern forming section, and driving the transfer belt at a second speed, which is faster than the first speed, in the non-pattern forming section.

Owner:HEWLETT PACKARD DEV CO LP

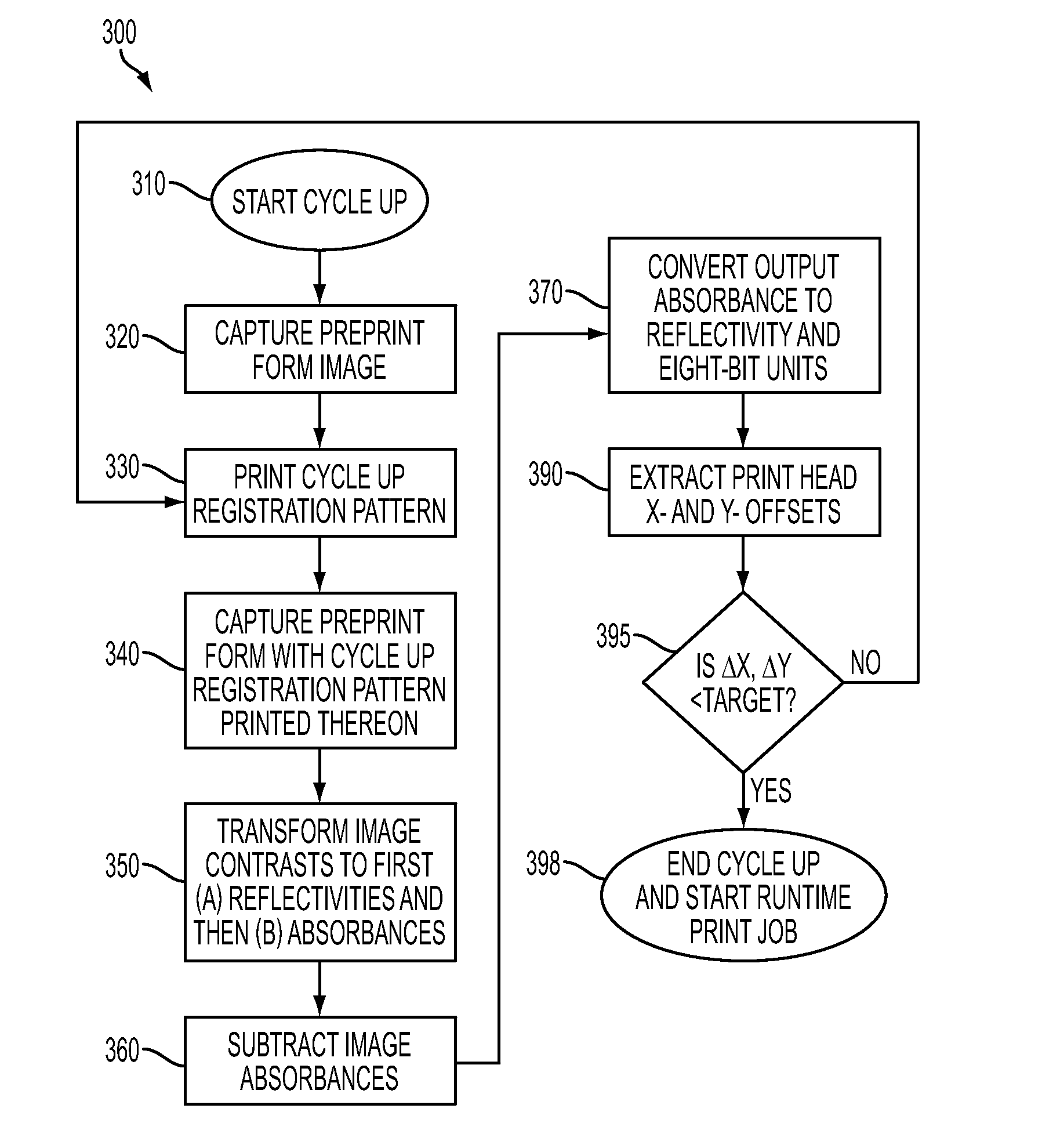

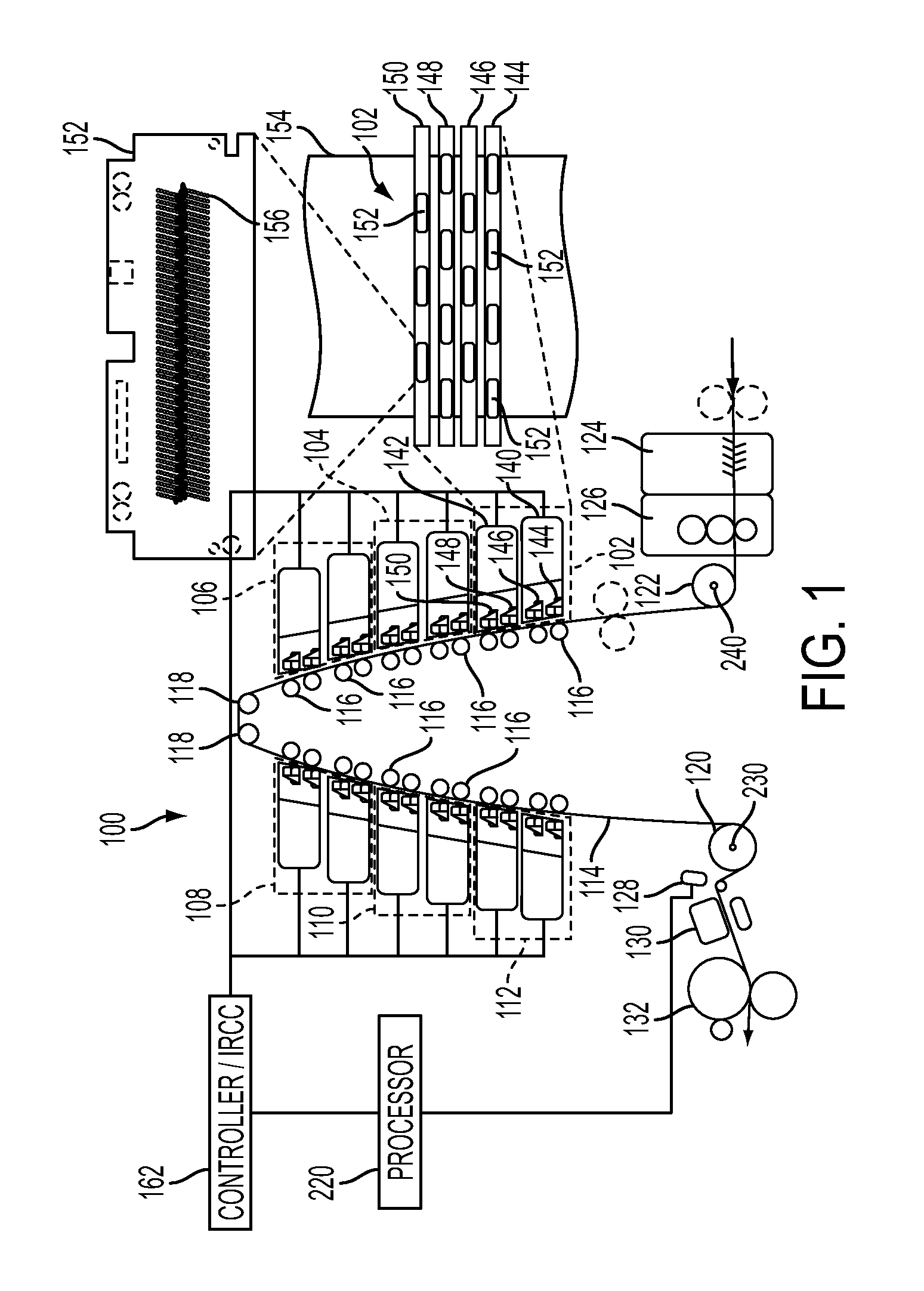

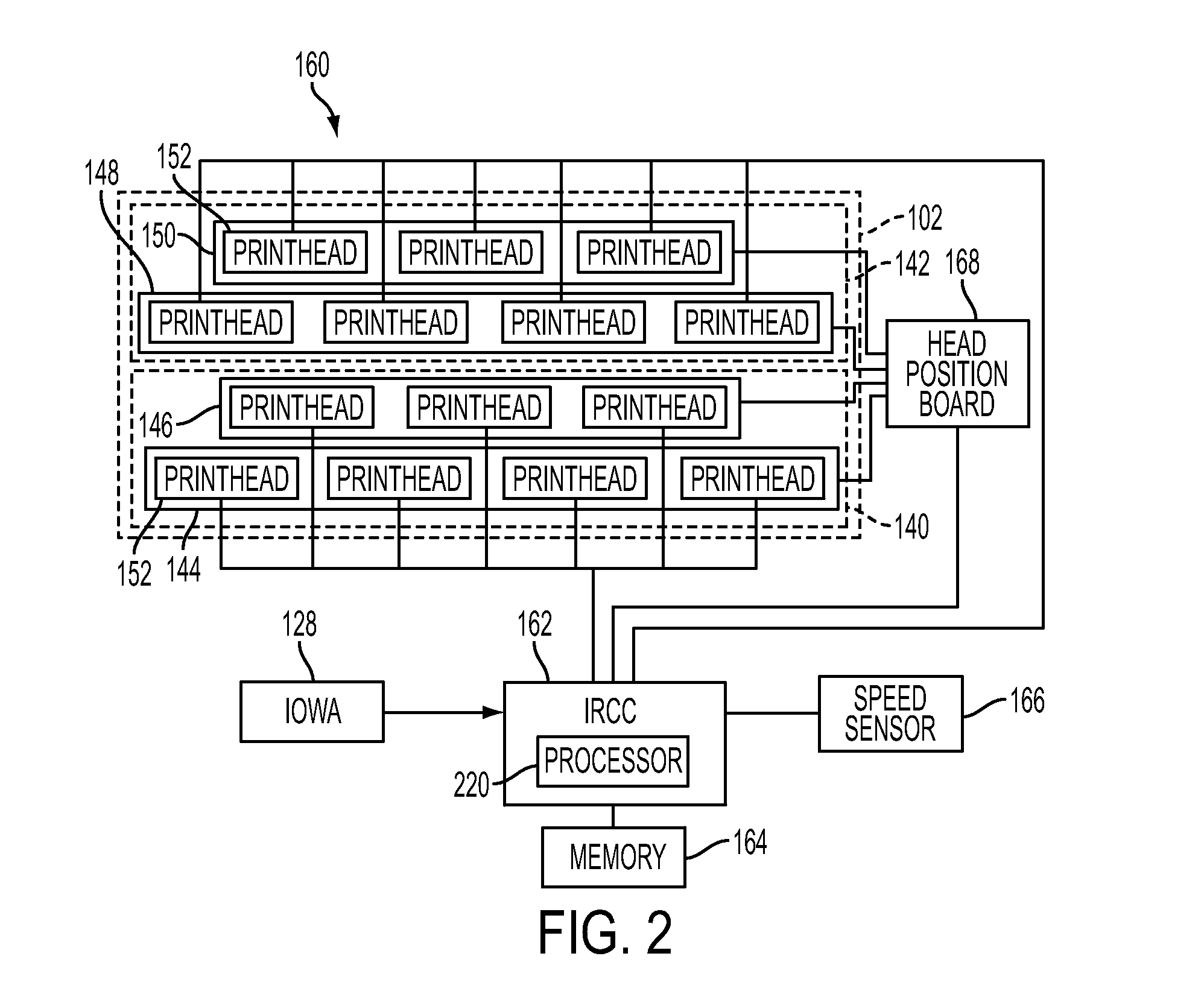

Color registration strategy for preprinted forms

InactiveUS8319202B2Accurate color registrationInvestigating moving sheetsVisual presentationPattern recognitionAbsorbance

A computer-implemented method for performing color registration on template media having template markings thereon. The method comprising sensing the template media using a linear array sensor to obtain first image data; printing a test pattern on the template media; sensing the template media along with the test pattern printed thereon to obtain second image data; transforming the first image data and the second image data into an absorbance space to obtain a first absorbance and a second absorbance, respectively; calculating a difference between the first and the second absorbances to obtain an output absorbance; transforming the output absorbance into a reflectivity space to obtain an output data; determining a process direction misregistration and a cross-process direction misregistration from the output data; and adjusting a cross-process position and a process position of print heads based on the process and cross-process direction misregistration to provide accurate color registration on subsequent template media.

Owner:XEROX CORP

Transfer belt driving control method and transfer belt driving control apparatus for color registration correction

ActiveUS7983606B2Short timeAccurate color registrationRecording apparatusElectrographic process apparatusEngineeringMechanical engineering

A transfer belt driving control method and transfer belt driving control apparatus for color registration correction. The color registration correction method and apparatus performs the color registration correction by setting a pattern forming section, in which patterns for the color registration correction are able to be formed, and a non-pattern forming section, in which the patterns are not able to be formed, on a transfer belt in which the patterns are formed, performing the color registration correction by driving the transfer belt at a first speed in the pattern forming section, and driving the transfer belt at a second speed, which is faster than the first speed, in the non-pattern forming section.

Owner:HEWLETT PACKARD DEV CO LP

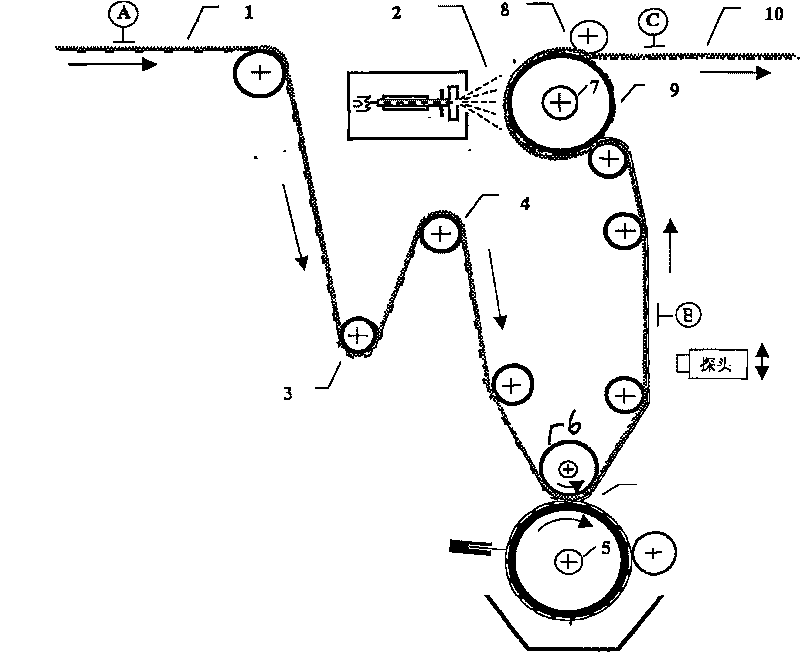

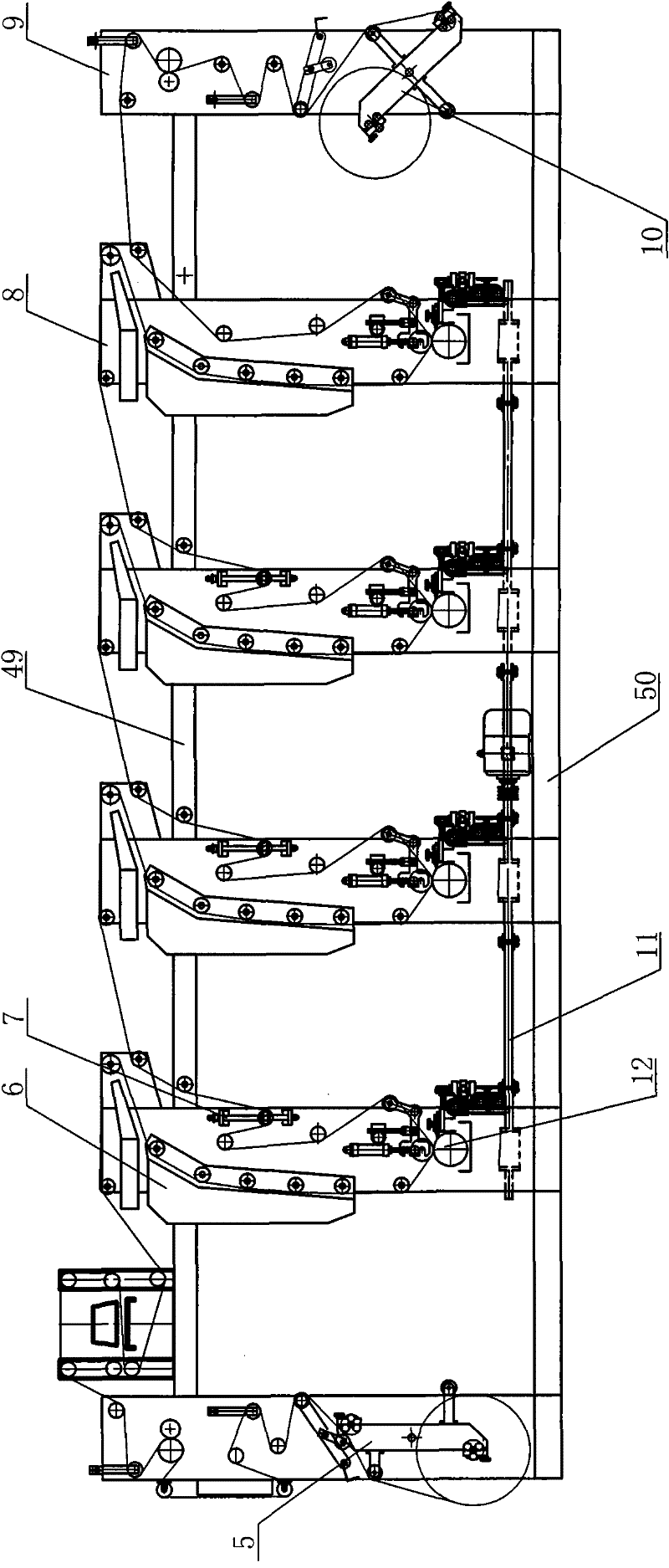

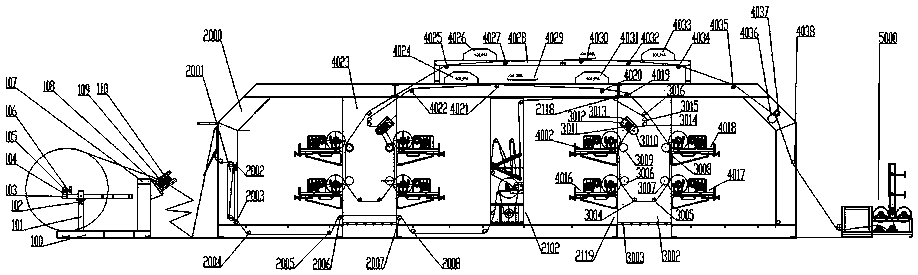

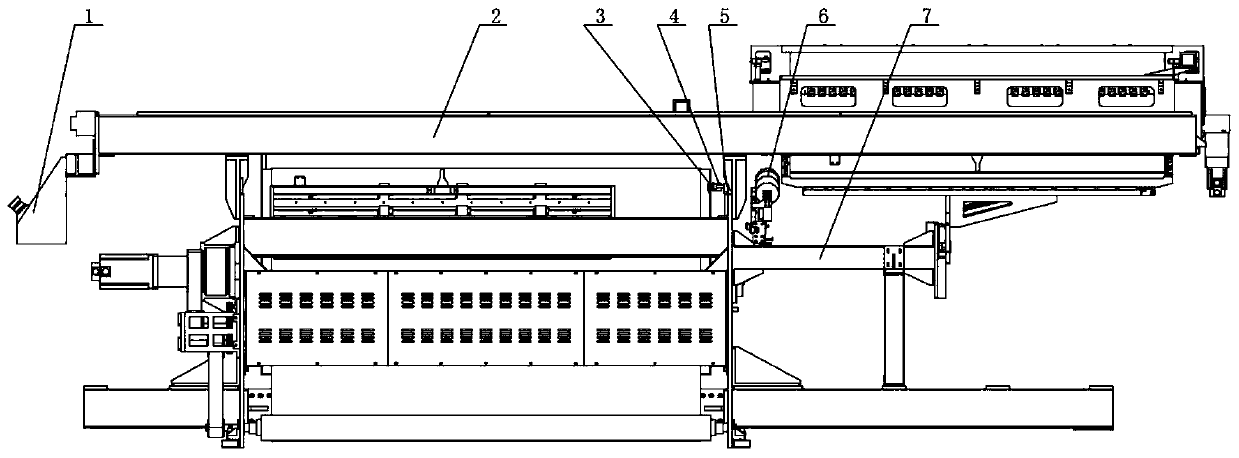

Gravure printing machine

InactiveCN101698369BImprove appearance qualityImprove overprint accuracyRotary intaglio printing pressPrinting press partsDrive shaftThrough transmission

The invention discloses a gravure printing machine. The gravure printing machine comprises a winding group, a unwinding group and a middle color group, wherein the groups are connected together though cross beams and based which are fixed on wall boards of the groups, an operating corridor is arranged outside the wall boards, the winding group and the unwinding group are separately provided with a winding device and an unwinding device, the middle color group owns a plurality of groups, each color group is provided with a coining device and an oven heating device, and the coining devices of the color groups are connected together through transmission shafts in a synchronous manner. The gravure printing machine has good appearance and quality, compact structure and high installation precision, can ensure continuous roll-changing without stopping the machine, and is characterized by energy saving, high efficiency and low consumption.

Owner:WENZHOU GUOWEI PRINTING MACHINERY

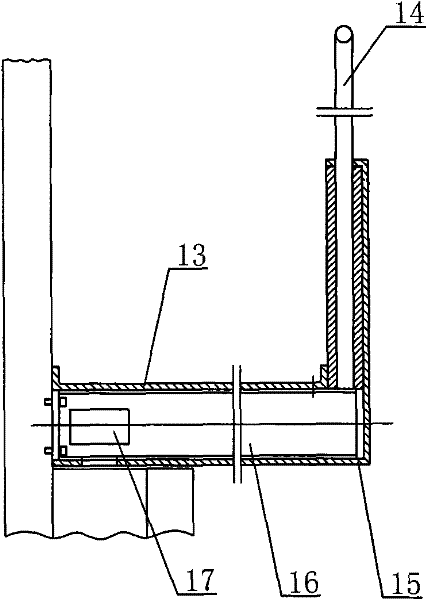

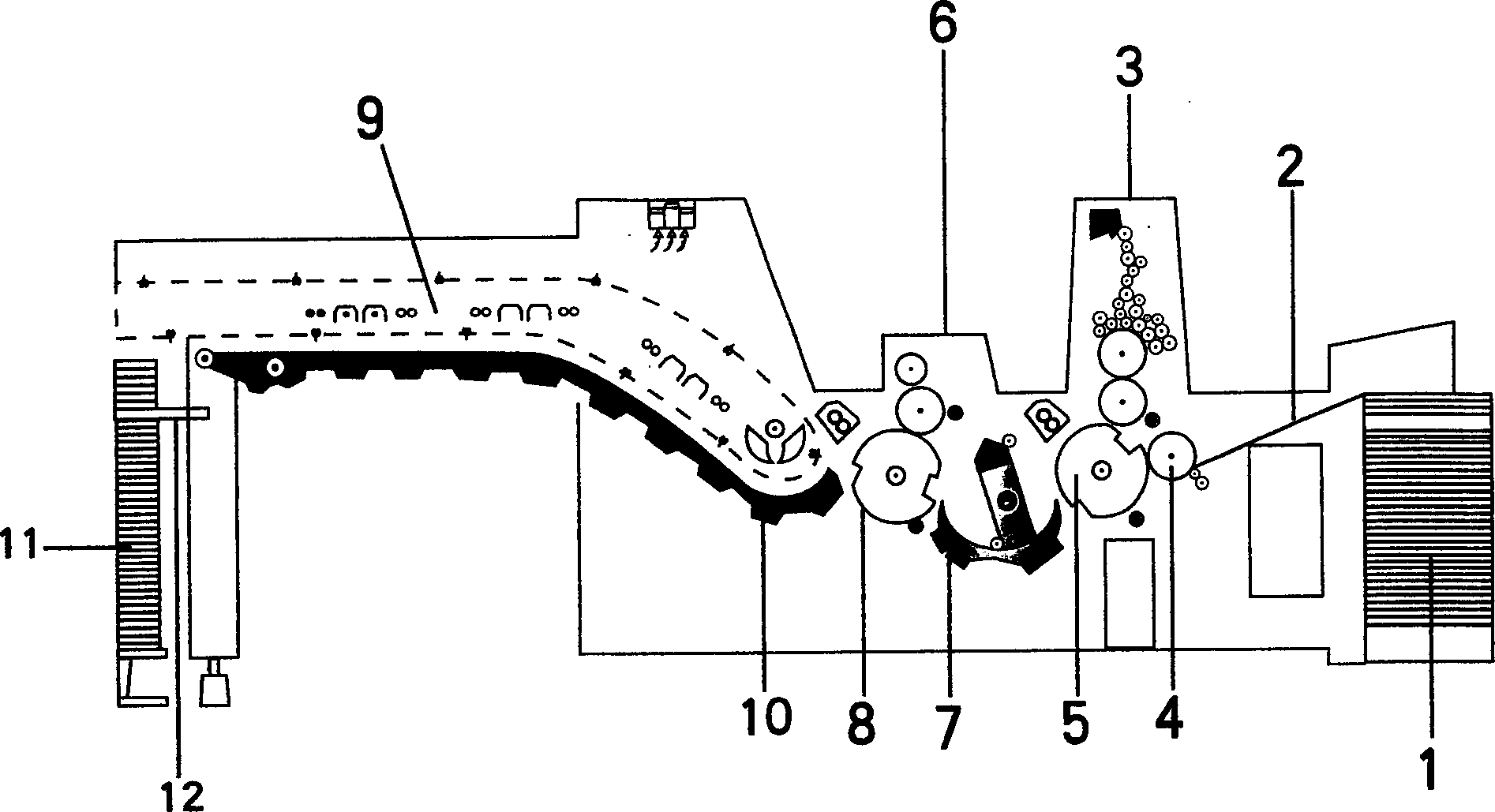

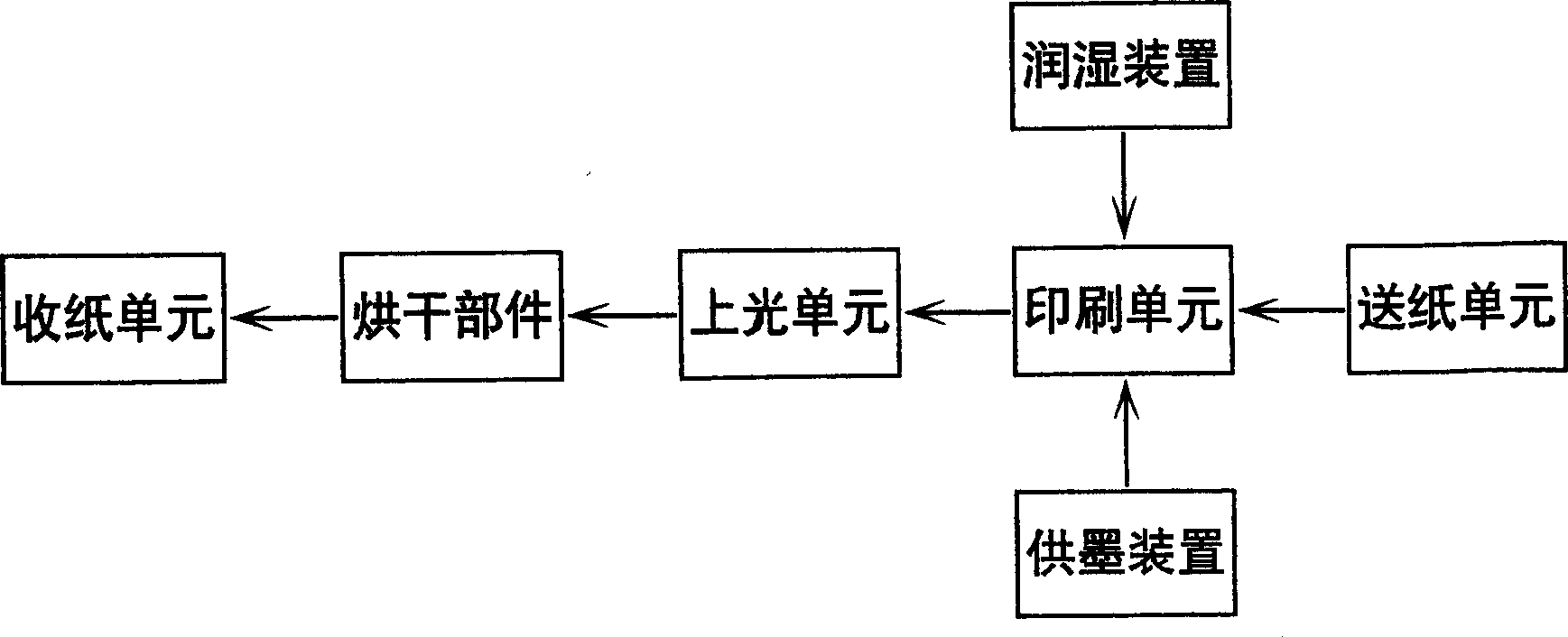

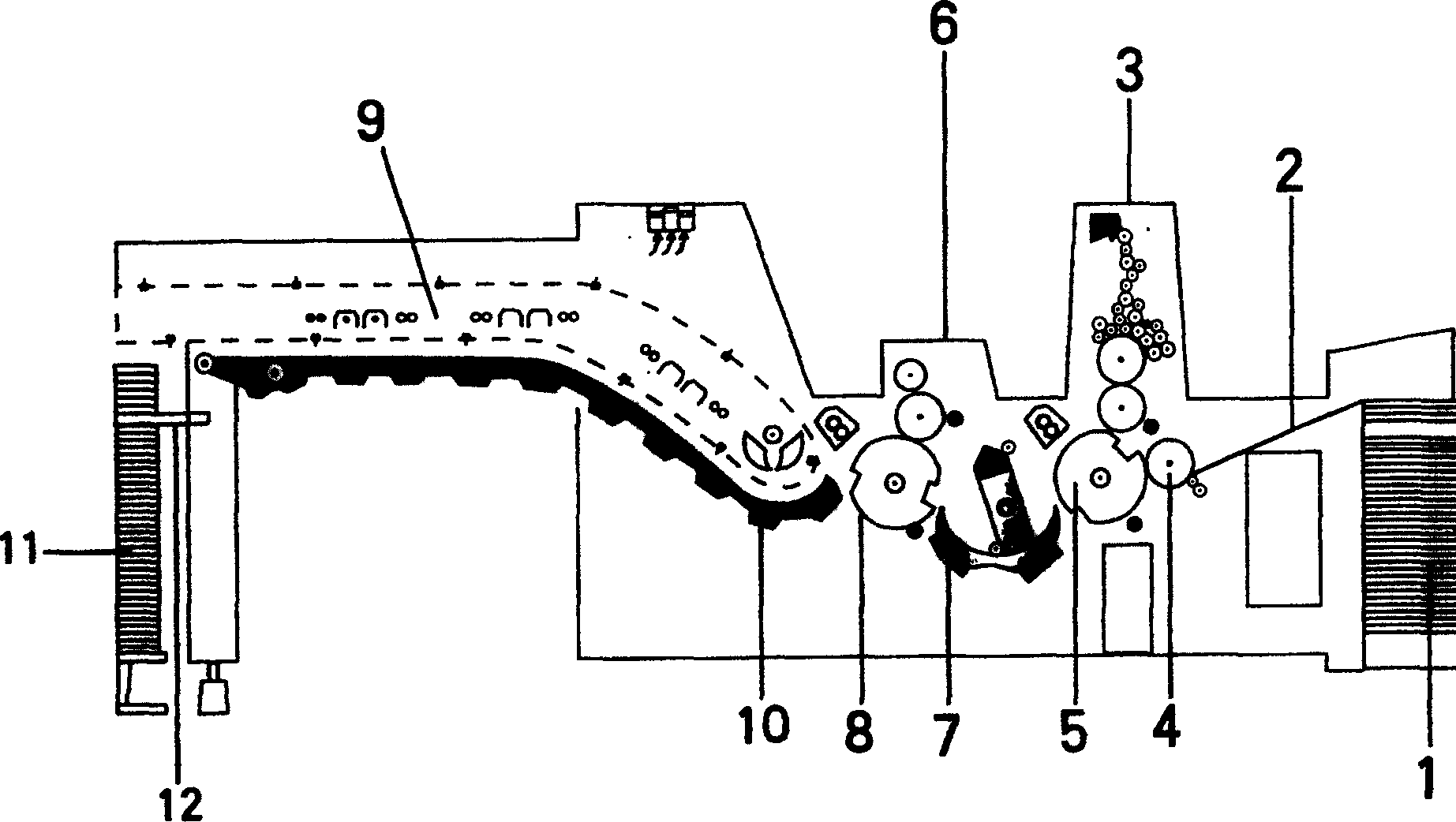

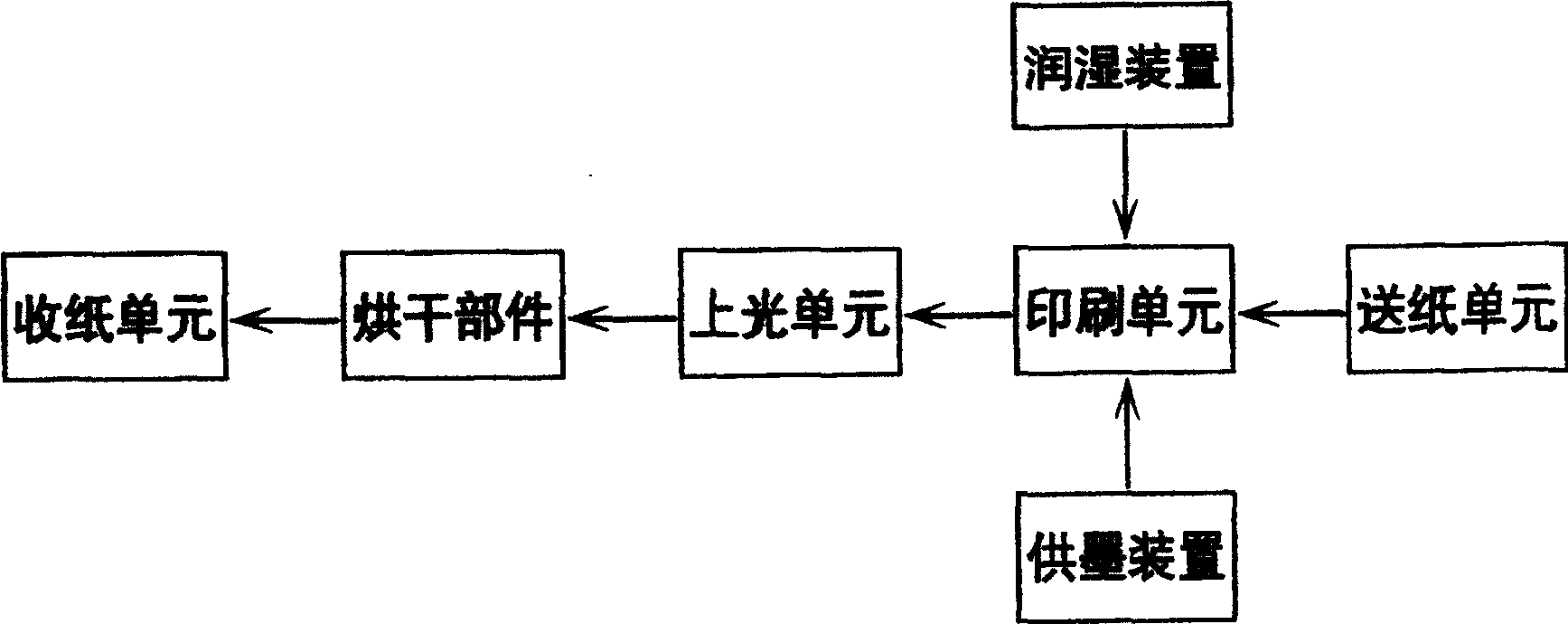

Monochromatic lustering printing machine

InactiveCN1486844AOffset printing speed is fastQuality improvementOffice printingPrinting press partsPrinting inkPulp and paper industry

The present invention relates to printing machinery, and is especially one kind of monochromatic lustering printing machine. The monochromatic lustering printing machine includes paper feeding unit, printing unit, lustering unit, stoving unit, paper withdrawing unit. The paper feeding stage of the paper feeding unit is connected to the paper transferring cylinder, the impression cylinder in the printing unit has one end connected to one end of paper transferring cylinder in the lustering unit, one end of the impression cylinder in the lustering unit and the paper guide air cushion in the infrared drying and ultraviolet curing system are connected to the paper withdrawing toothed bar in the paper withdrawing unit. Compared with available technology, the printing machine of the present invention has comprehensive functions of offset printing, lustering printing and flexible printing.

Owner:吴德明

Image forming apparatus

InactiveCN101598914ARotation speed controlAccurate transferElectrographic process apparatusImage formationEngineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

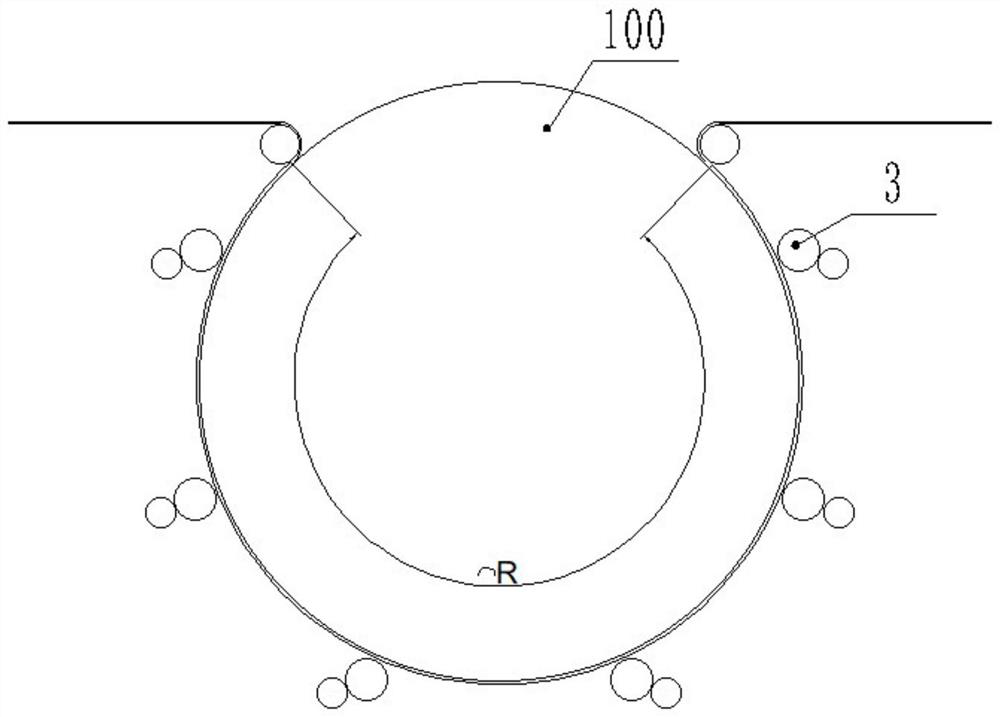

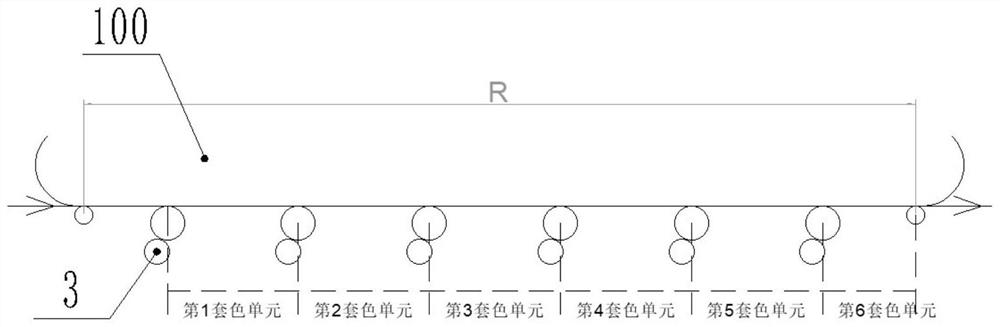

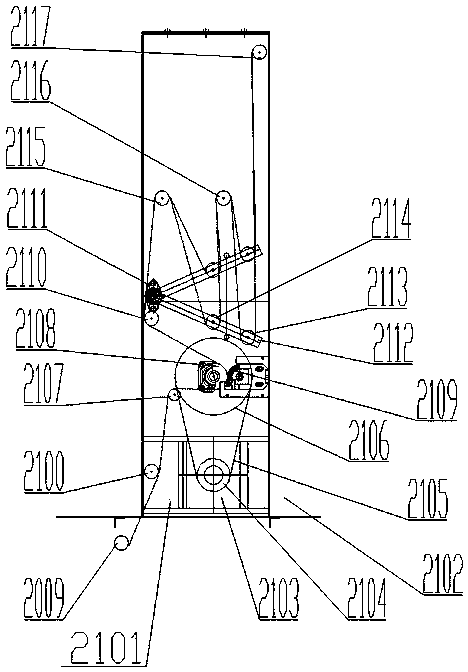

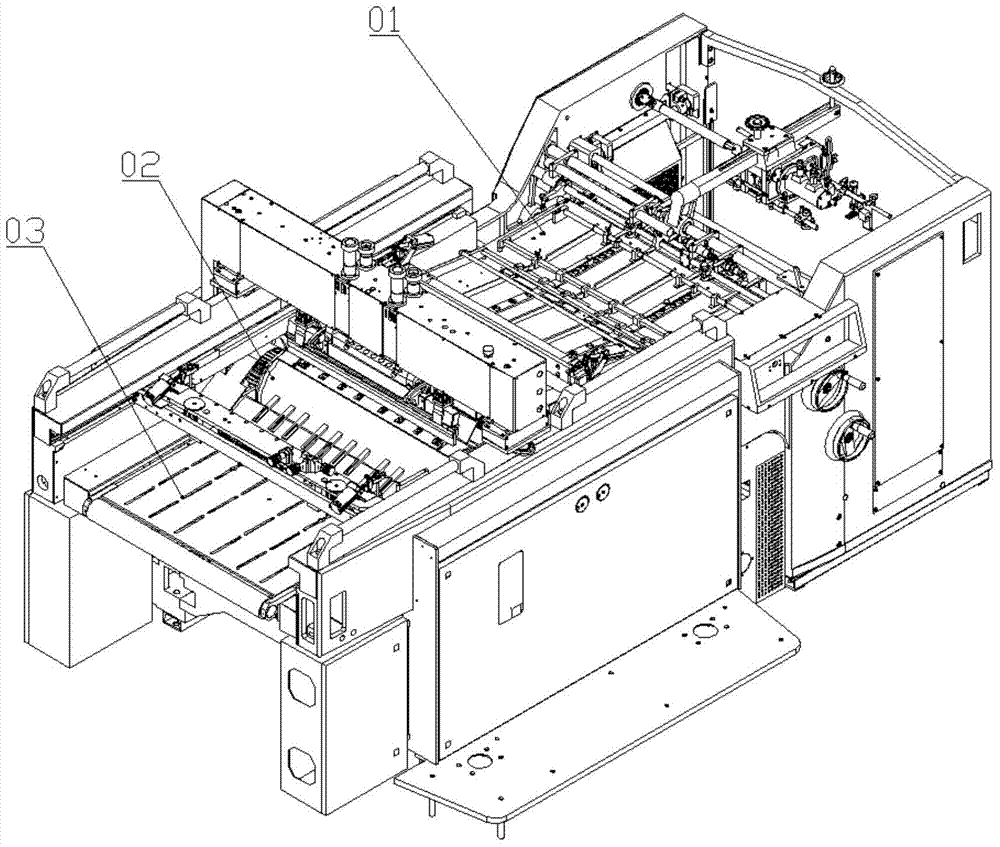

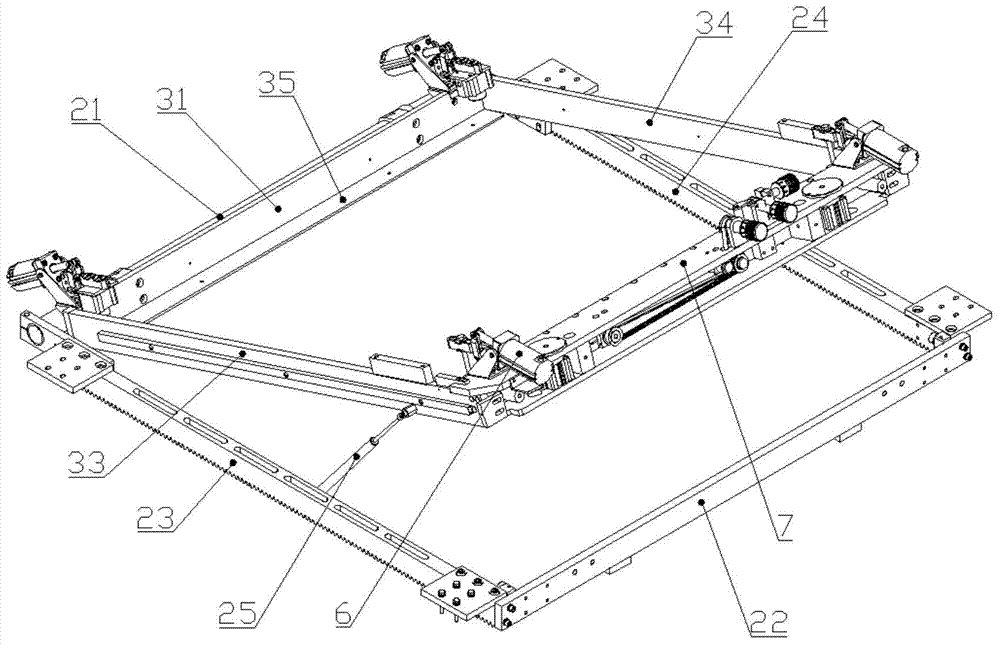

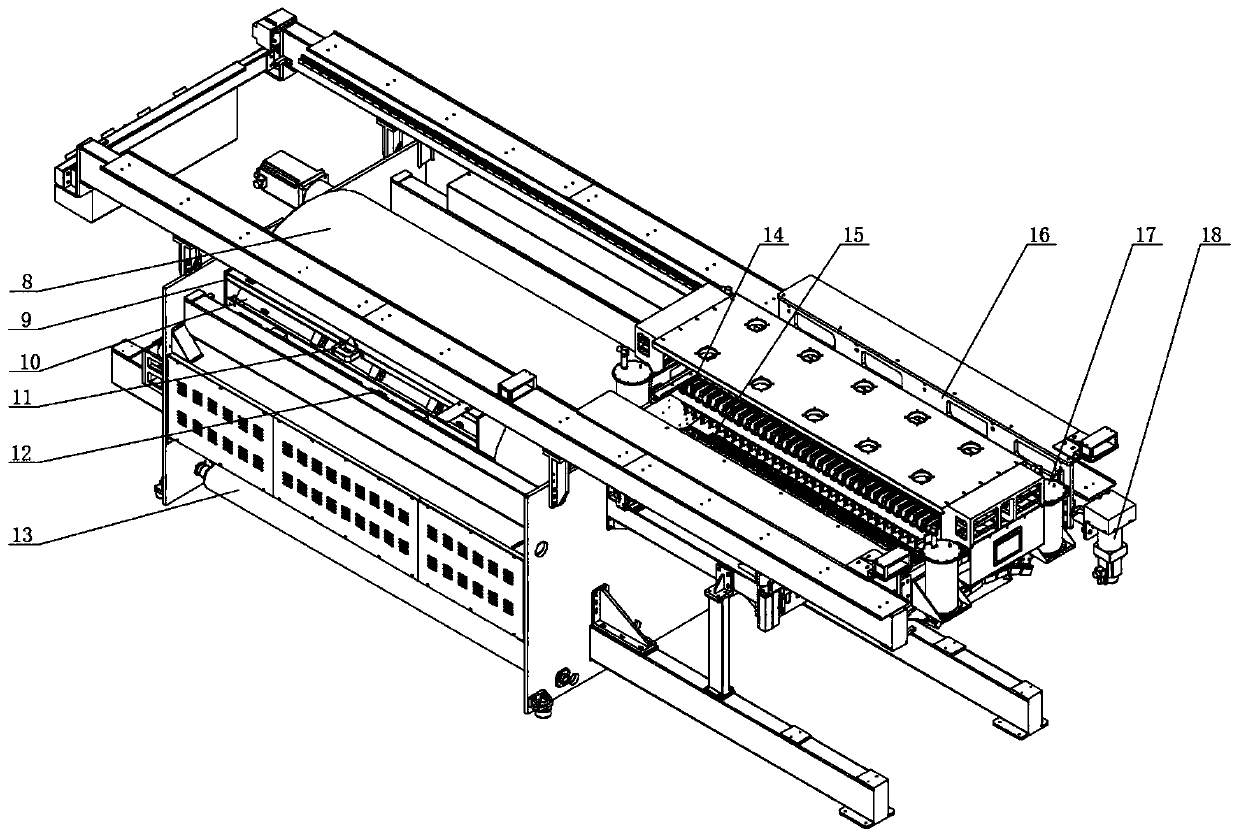

Flexible plate printing machine with accurate color register and control method

ActiveCN113442555AAccurate color registrationAdjust delivery speedRotary letterpress machinesPrinting press partsProcess engineeringPrinting ink

The invention relates to the technical field of flexible package printing, in particular to a flexible plate printing machine with accurate color register. The flexible plate printing machine comprises an unwinding component used for feeding a to-be-printed coiled material; a printing component used for printing ink on a printing material supplied by the unwinding component; a winding component used for winding the printing material printed by the printing component; and a controller, wherein the printing component comprises at least two printing units which are linearly arranged in spatial distribution. The printing units are arranged in a distributed mode, tension isolation roller sets are arranged to limit the change of the tension of the printing materials in the printing units, the output ends of the printing units are connected with tension monitoring components, and the conveying speed of the tension isolation roller sets to the printing materials is adjusted in real time through tension feedback; and the printing materials in each printing unit are controlled to be subjected to transfer printing and color register with the same tension, so that the materials do not deform during color register, and accurate color register in each printing unit is ensured.

Owner:南京邦诚科技有限公司

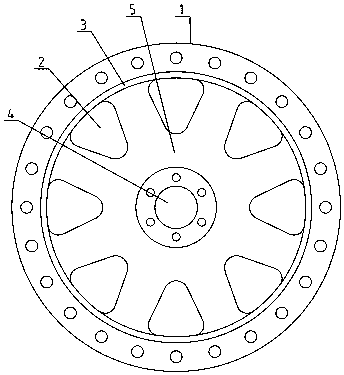

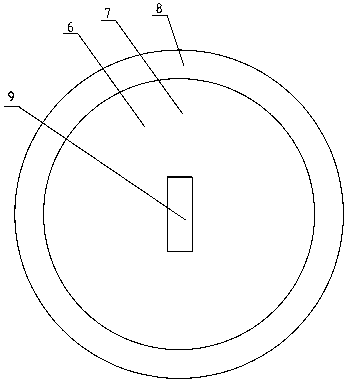

Topping protection tool and manufacturing method thereof

PendingCN108067379ASatisfy the requirements of color registration protectionAccurate color registrationSpraying apparatusEngineeringProtection ring

The invention provides a topping protection tool. The topping protection tool comprises a hub and hub window protection plates matched with hub windows of the hub in shape, and the hub window protection plates can be tightly attached to the hub windows of the hub through extrusion. The topping protection tool further comprises a rim protection ring, a center hole protection plug and a spoke protection plate, wherein the rim protection ring is matched with the hub side vertical plate of the hub in shape, the center hole protection plug is matched with a center hole of the hub, the spoke protection plate is matched with spokes of the hub in shape, the rim protection ring can be tightly attached to the rim side vertical plate of the hub through extrusion, the center hole protection plug is inserted into the center hole of the hub, and the spoke protection plate can be tightly attached to spokes of the hub through extrusion. The topping protection tool can meet topping protection requirements of different shapes, and is accurate in topping, easy and convenient to use, capable of being used repeatedly and low in cost.

Owner:DARE WHEEL MFG

Monchromatic lustering printing machine

InactiveCN1201931COffset printing speed is fastQuality improvementOffice printingPrinting press partsUV curingPulp and paper industry

The invention relates to the technical field of printing machinery, in particular to a single-color glazing printing machine. It is characterized in that it is composed of a paper feeding unit, a printing unit, a glazing unit, a drying unit, and a paper delivery unit. The printing unit includes an ink supply device, a wetting device and a cylinder body; the paper feeding table on the paper feeding unit (1) (2) Connect the transfer cylinder (4) of the printing unit (3), the impression cylinder (5) on the printing unit (3) is connected with the transfer cylinder (7) of the glazing unit (6), and the glazing unit ( 6) The embossing cylinder (8) is connected to the paper guide air cushion (10) of the infrared drying and ultraviolet curing system (9), and the paper guide air cushion (10) of the infrared drying and ultraviolet curing system (9) is connected to the delivery unit (11 ) of the delivery tooth row (12). Compared with the prior art, the present invention has continuously perfected machine structure and integrated multiple functions, and can complete offset printing plus light printing, dry offset printing plus light printing, flexo printing plus light printing.

Owner:吴德明

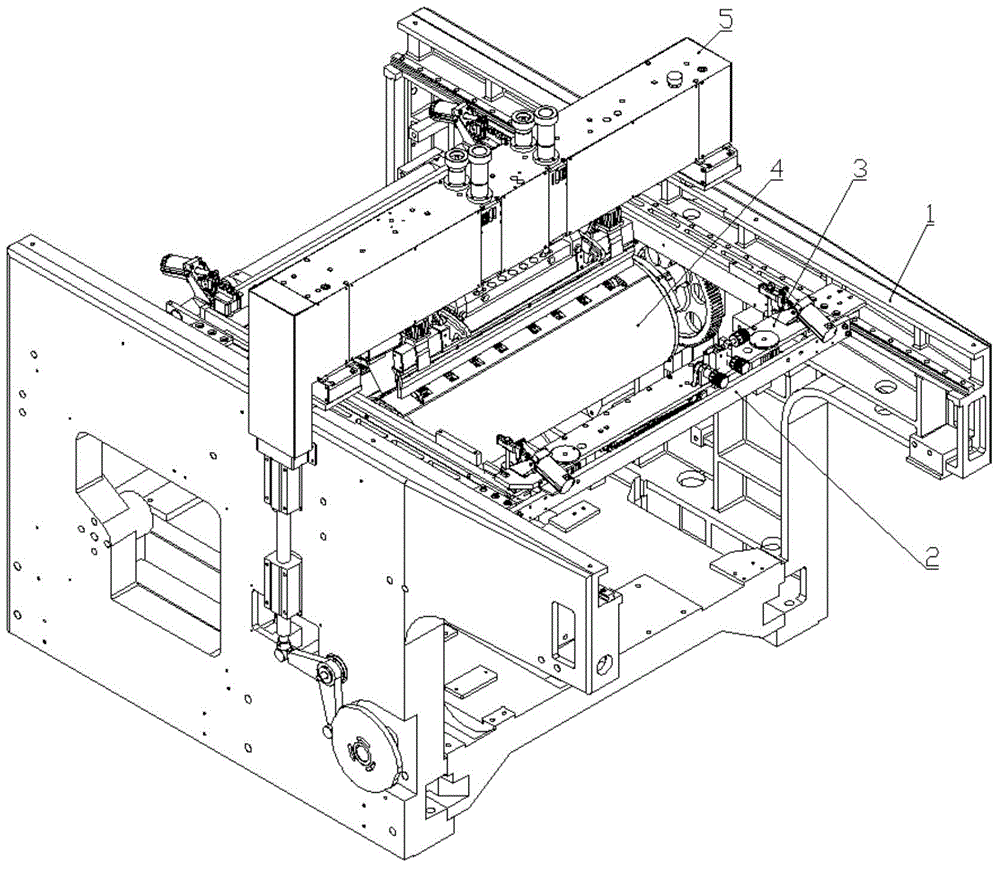

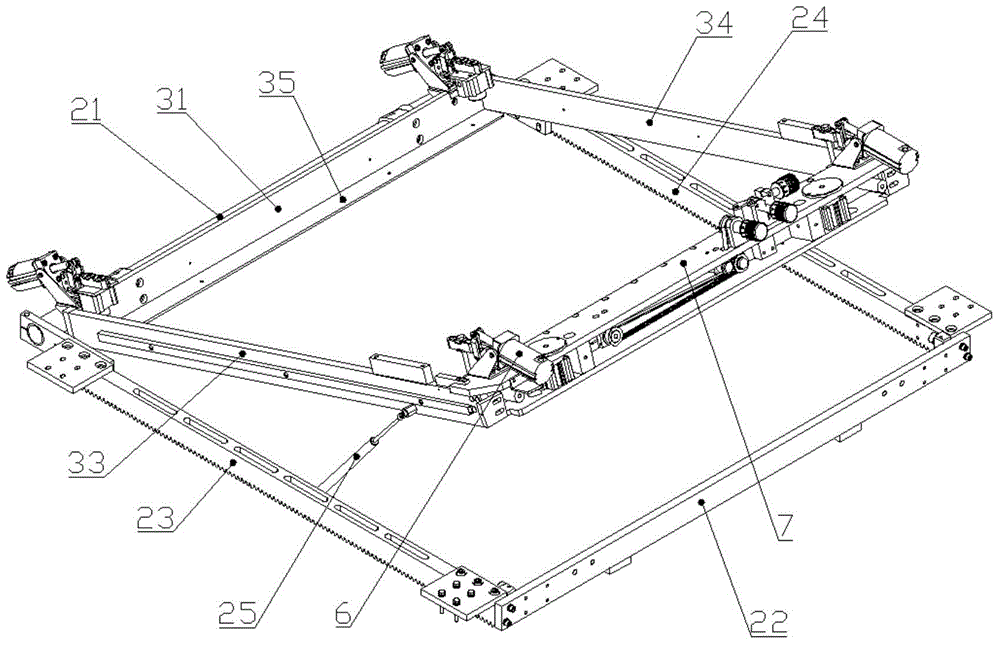

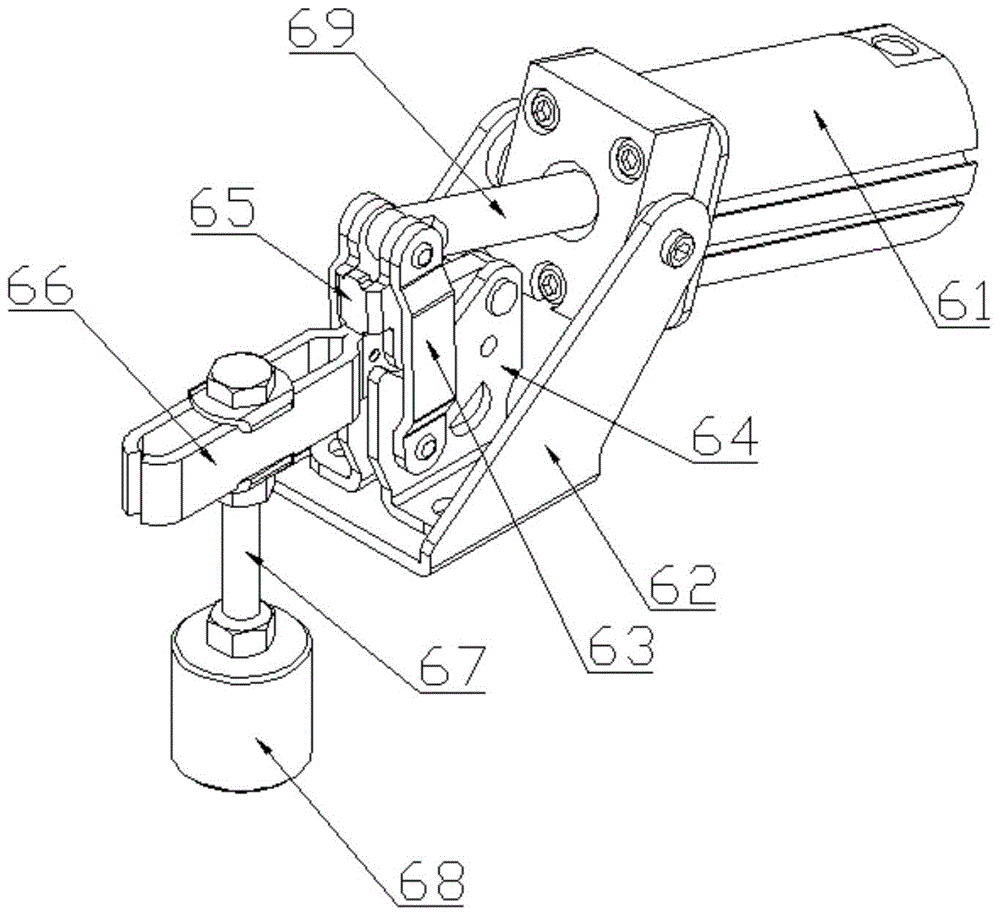

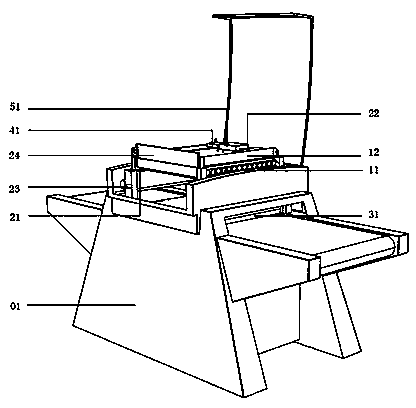

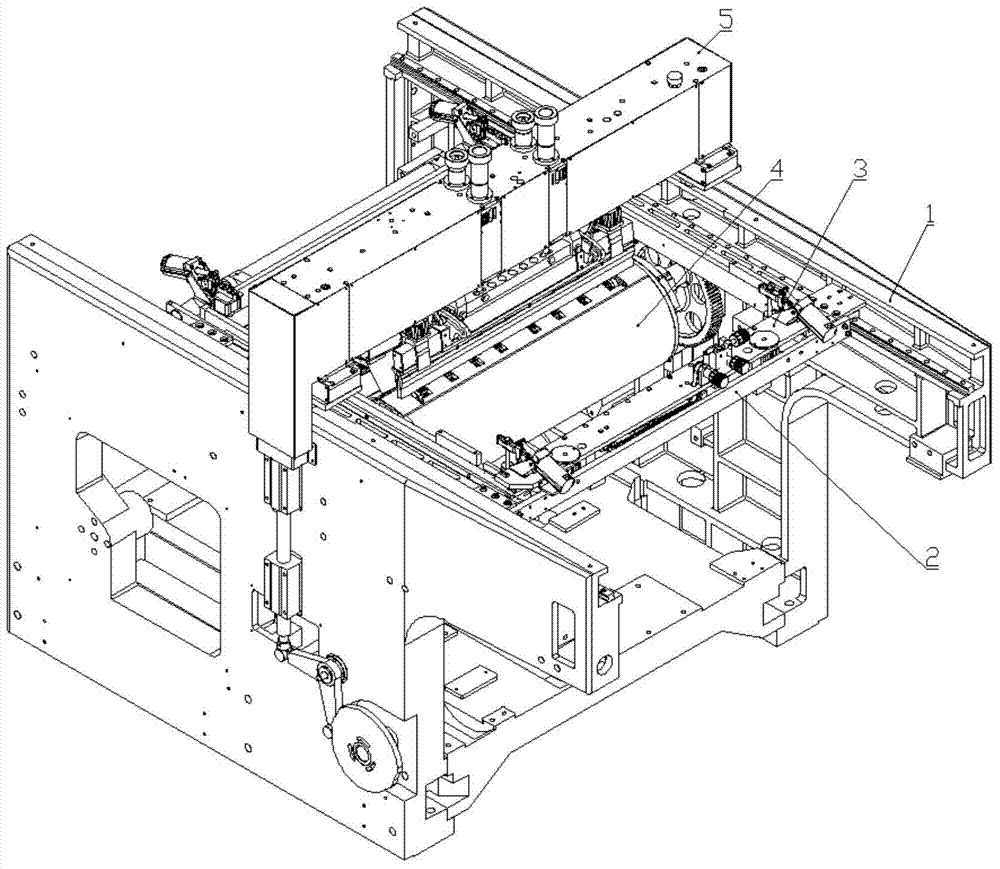

Printing unit of screen printing machine

The invention provides a printing unit of a screen printing machine. The printing unit comprise a rack, a screen frame, a screen bracket, a roller and a printing cutter bit, wherein a rear supporting plate of the screen bracket is provided with a screen adjusting and locking device; four corners of the screen bracket are respectively provided with a screen clamping device; the printing cutter bit comprises a scraping and printing cutter, a cutter frame arranged on the scraping and printing cutter, a cutter bit box arranged on the cutter frame, a scraping and printing cutter pressurizing device, a scraping and printing cutter angle adjusting and locking device, a scraping and printing cutter position adjusting device and a scraping and printing cutter switching device. According to the printing unit provided by the invention, by adopting an oblique table type screen frame, the screen bracket only needs to be obliquely lifted by hands when screen cloth needs to be cleaned, the screen bracket can be supported by an air spring, and thus the screen cloth can be more simply and conveniently cleaned; meanwhile, a closed oil way is formed by a decompression valve, an oil storage seat, an oil cylinder, an oil valve seat and the like, a control air way is formed by an external air source and the decompression valve, thus the cutter frame is controlled, and the stability of the cutter frame is greatly increased.

Owner:ZHEJIANG JINBAO MACHINERY

A computer imaging direct plate-making equipment and plate-making method

ActiveCN103955112BQuality improvementReduce usagePhotomechanical apparatusForme preparationEngineeringComputer image

The invention provides computer imaging type direct plate making equipment and a plate making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, so as to mask the light from the exposure light source, and thus a corresponding exposure image is formed on the printing plate; to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Due to the introduction of a light homogenizing layer, dependence on a light source is further reduced, and in particular, good plate making precision can be obtained by combination of light sources with different specifications, light sources or spot light sources with different surface luminescence uniformity and line light sources. A plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:十二秒融媒体(山东)有限公司

A kind of printing plate-making equipment and plate-making method

ActiveCN103955113BQuality improvementReduce usagePhotomechanical apparatusOriginals for photomechanical treatmentEngineeringEnvironmentally friendly

Owner:十二秒融媒体(山东)有限公司

Film-free computer direct plate making equipment and making method

ActiveCN103955118AQuality improvementReduce usagePhotomechanical exposure apparatusMicrolithography exposure apparatusLight guideEngineering

The invention provides film-free computer direct plate making equipment and a making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, and the target image masks the light from the exposure light source so that a corresponding exposure image is formed on the printing plate; and in order to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Meanwhile, a plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:青岛斯博锐意电子技术有限公司

A plastic woven fabric printing machine

ActiveCN105500916BReasonable structureAccurate color registrationRotary pressesPrinting press partsEngineeringPrinting press

Owner:温州海多堡机械科技有限公司

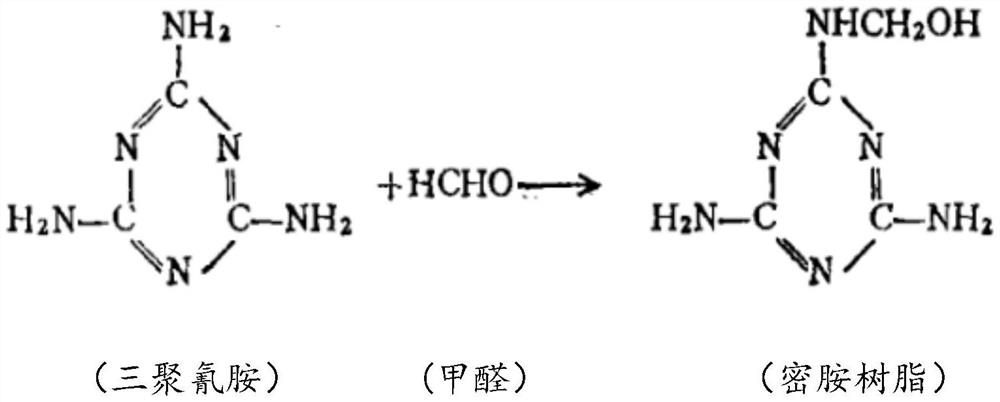

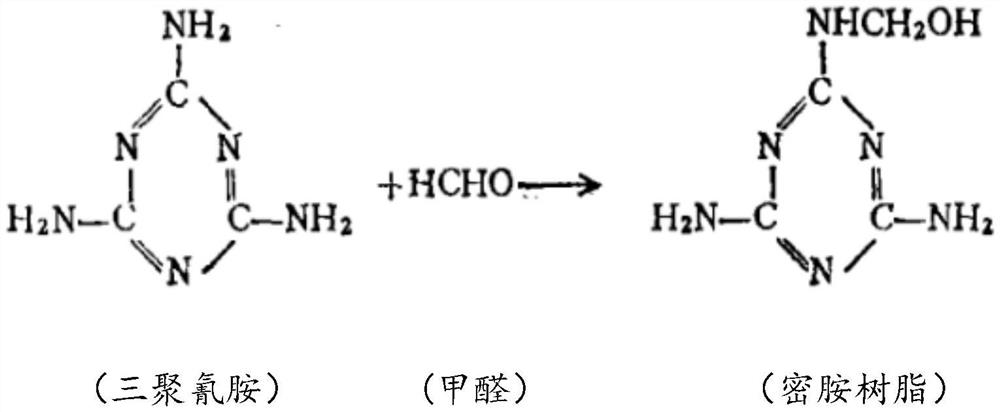

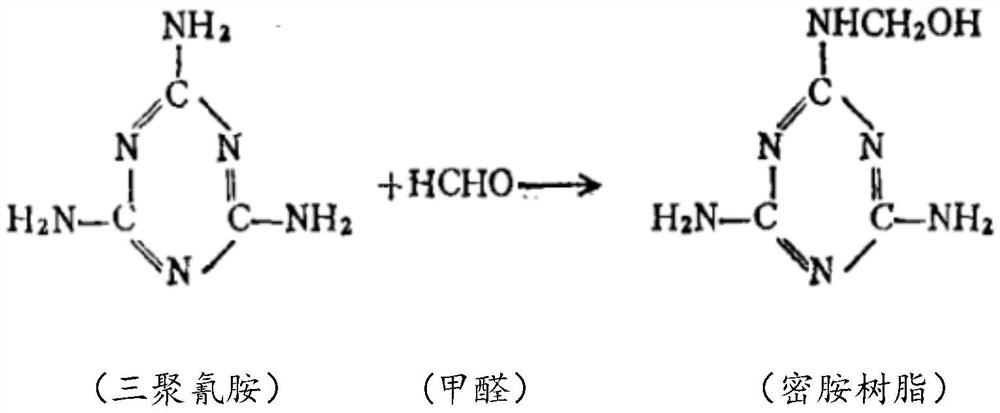

Printing method of melamine resin product and melamine container

PendingCN112693055AWith destructionAvoid deformationDecorative surface effectsDomestic articlesCompression moldingTextile printer

The invention discloses a printing method of a melamine resin product. The printing method comprises the following steps of baking, preparation of melamine-formaldehyde resin slurry water, slurry brushing, baking, cutting, preheating, compression molding, stained paper pasting, gold adding, polishing, inspection and packaging. According to the printing method, the melamine tableware product is manufactured through three times of compression molding, the melamine tableware product with a plain surface is manufactured through the first time of compression molding, stained paper is printed on the outer surface of the melamine tableware product through the second time of compression molding, stained paper is pasted to the inner surface of the melamine tableware product through the third time of compression molding, so that colors and patterns on the melamine tableware product are not prone to being destroyed, and the melamine tableware product has bright colors and luster as porcelains and is exquisite in appearance, high in hardness, resistant to collision and corrosion and good in stability.

Owner:HUIZHOU MOREWARE INDAL

Film-free computer-to-plate-making equipment and plate-making method

ActiveCN103955118BQuality improvementReduce usagePhotomechanical exposure apparatusMicrolithography exposure apparatusComputer to plateLight guide

The invention provides film-free computer direct plate making equipment and a making method. The equipment comprises an exposure light source, a print image imaging device and a printing plate carrying device, which are arranged coaxially; the exposure light source is used for irradiating light to cure a photosensitive material loaded on a printing plate; the print image imaging device is used for forming a target image to replace a film, and the target image masks the light from the exposure light source so that a corresponding exposure image is formed on the printing plate; and in order to improve the exposure efficiency and the plate making efficiency, the print image imaging device is provided with a light guide layer for trimming non-uniform exposure light to uniform parallel light. Meanwhile, a plate making process formed by the plate making equipment can adapt to the plate making requirements of high precision and low cost.

Owner:十二秒融媒体(山东)有限公司

Drum type automatic screen printing machine

The invention provides a drum type automatic screen printing machine, comprising a conveying unit, a printing unit and a paper delivering unit; the printing unit comprises a rack, as well as a screen frame, a screen bracket, a drum and a printing head arranged on the rack; the rear support plate of the screen bracket is provided with a screen adjusting and locking device; a screen tightening device is arranged at each of the four corners of the screen bracket; the printing head comprises a scraper, a scraper holder, a scraper head box, a scraper pressurizer, a scraper angle adjusting and locking device, a scraper position adjusting device and a scraper changing device. The screen bracket of the drum type automatic screen printing machine is of a ramp type, so that the screen cloth can be washed just by aslant uplifting the screen bracket with hands as the screen bracket is supported by an air spring, and thus the screen cloth is simpler and more convenient to wash. Meanwhile, in the drum type automatic screen printing machine, a sealed oil line is composed of a reducing valve, an oil storage seat, an oil cylinder, an oil valve seat and the like, and a control gas circuit consisting of an external gas source and the reducing valve is used for controlling the scraper holder, so that the stability of the scraper holder is greatly improved.

Owner:ZHEJIANG JINBAO MACHINERY

Method for printing embossment microstructure with positioned color register

ActiveCN101691091BEliminate accumulationAccurate color registrationPattern printingPlate printingDie castingEngineering

The invention relates to a method for printing an embossment microstructure with a positioned color register, in particular to a method for the integrated online printing of an embossment type optical microstructure layer which is positioned and nested with an ink color. The method comprises the following steps: taking a microstructure area as a special color for printing; printing a molding ink at a specified position; in the state that the ink area is not completely dried and solidified, attaching and die-casting the ink area in a positioning mode by an embossment microstructure mother set roller on a next printing plate roller so that the ink is embedded in an embossment microstructure groove on a mother set; and solidifying and molding a hinge for drying the ink in a coating area of aprinting material and a microstructure image, wherein the embossment shaped microstructure on the mother set roller is completely copied to the ink surface of a printing stock in a mirror image mode,and a copying molding area serves as a color register printed at the specified position and can be connected with front and back printing colors to form a + / -0.15 millimeter printing registration accuracy. The method can achieve the positioned color register with a common printing and the accurate positioning of pattern and ink printing on the mother set.

Owner:上海冠众光学科技有限公司

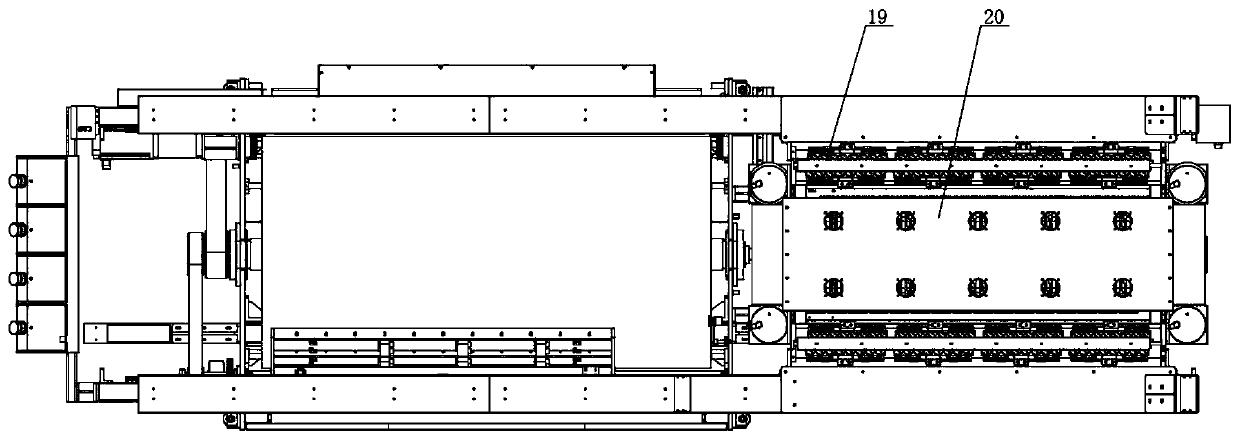

High-speed base paper digital pre-printing machine

PendingCN111421890AReasonable designSolve the problem of small batch ordersBox making operationsPaper-makingComputer printingElectric machinery

The invention discloses a high-speed base paper digital pre-printing machine and aims to solve the problem that an existing pre-printing machine is not suitable for small-batch orders. The high-speedbase paper digital pre-printing machine comprises an outer cover, an active force mechanism, an ink stack ink wiping mechanism, a printing mechanism, a position detection mechanism, a drying mechanismand an electric control system, wherein the active force mechanism comprises an active force motor, a central roller and a tensioning roller, and the printing mechanism comprises a spray head, a trolley plate, a negative pressure cylinder, a primary ink box, a secondary ink box and a trolley motor. The high-speed base paper digital pre-printing machine is reasonable in design, the problem of small-batch orders can be solved through cooperation of components such as the active force mechanism, the ink stack ink wiping mechanism, the printing mechanism and the like, so that the high-speed basepaper digital pre-printing machine is suitable for both large-batch orders and small-batch orders; the high-speed base paper digital pre-printing machine integrates multiple colors to the trolley plate, the printing width is not limited, and the application range is wide; the high-speed base paper digital pre-printing machine adopts the design of the central roller, the base paper clings to the central roller, wrinkles and deformation are avoided, the color matching is more accurate, printed patterns are more delicate, and the high-speed base paper digital pre-printing machine is suitable forhigh-end customers.

Owner:深圳市万德数字科技有限公司

Electrophotographic image forming apparatus

InactiveUS20070071509A1Improve color registrationEasy to controlElectrographic process apparatusImage transferEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Lead-free glass container produced though thermal transfer printing process

The present invention discloses a lead-free glass container produced though a thermal transfer printing process, and belongs to the field of glass manufacturing. According to the present invention, lead-free white broken glass, white quartz sand, soda ash, sodium feldspar, calcite, sodium sulfate, cobalt powder, and a heat-resistant substrate film with color pattern are adopted as raw materials, and lead-free glass container manufacturing and thermal transfer printing are performed to obtain the finished product. According to the present invention, the method has characteristics of simple production, less production steps, high efficiency, no pollution, small occupation area and less investment, the pattern printed on the glass container surface has characteristics of good adhesion, high gloss, clear pattern, accurate chromatic printing, bright color, safety and no toxicity, and after lettering is performed, oil spraying sand blasting, secondary injection molding and other post-treatments can be performed.

Owner:XUZHOU HENGRUN GLASSWARE CO LTD

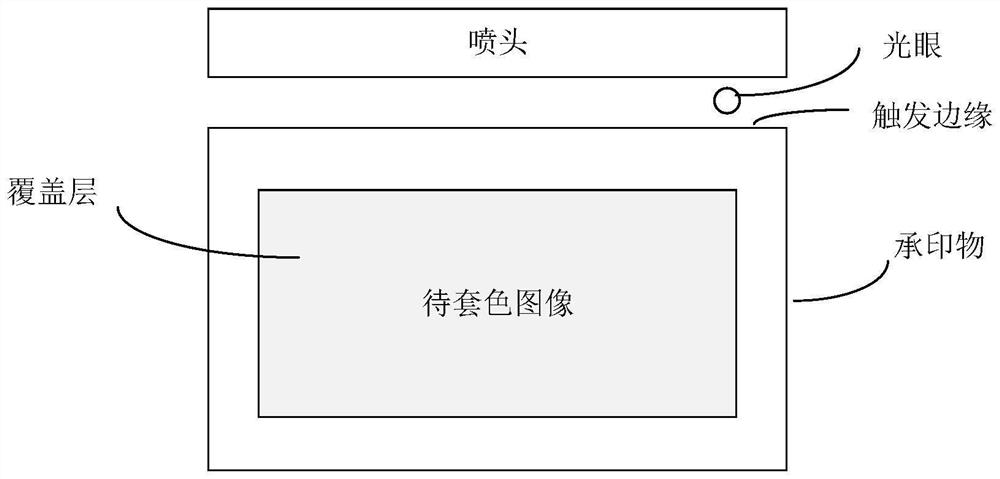

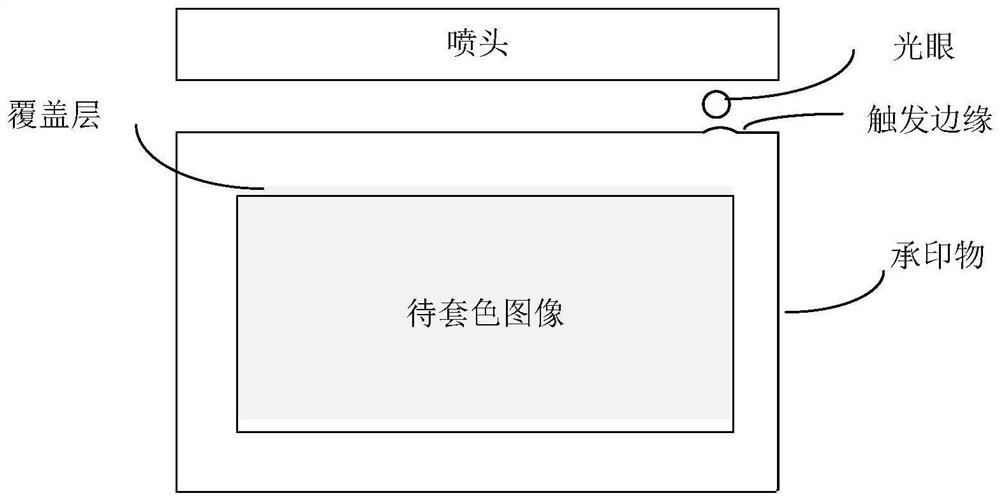

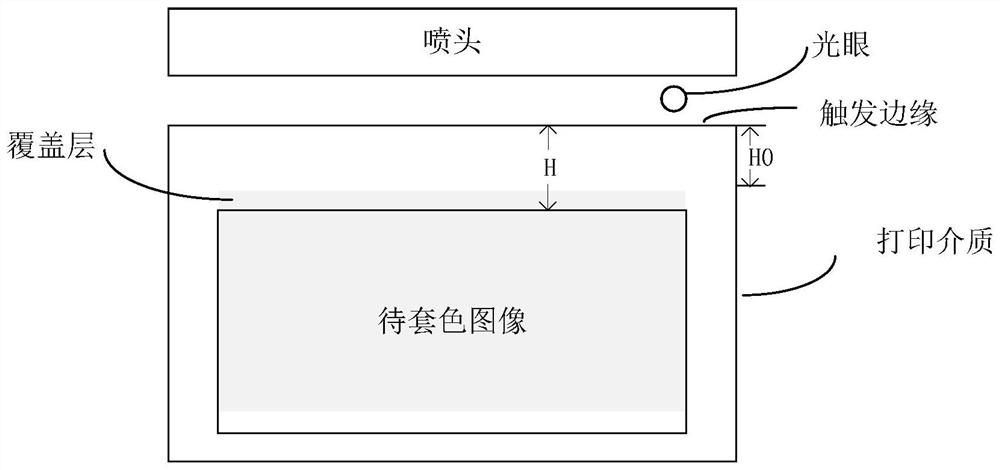

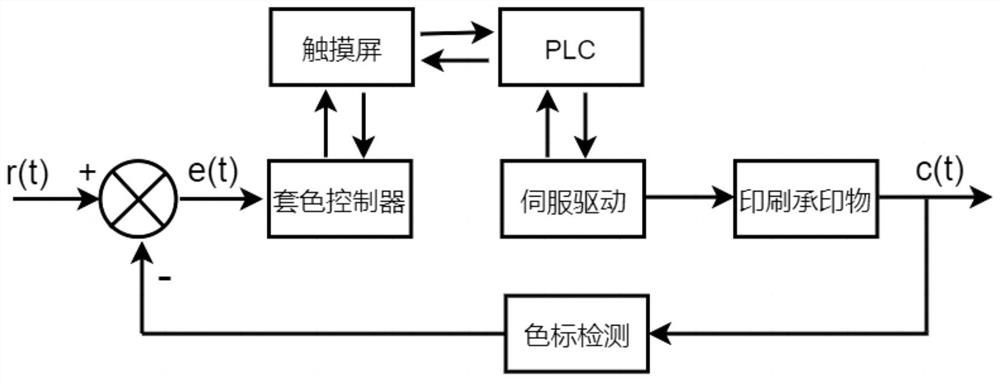

Image chromatography printing control method and device, equipment and storage medium

ActiveCN114454637AAccurate color registrationImprove image print qualityDuplicating/marking methodsOther printing apparatusImage edgeMechanical engineering

The invention discloses an image chromatography printing control method, device and equipment and a storage medium, and relates to the technical field of ink-jet printing. According to the method, the triggering edge of a printing stock is obtained, pixel point sampling is conducted on the edge of a to-be-colored image, the actual distance between the triggering edge of the printing stock and the edge of the to-be-colored image is obtained according to sampling points, and therefore the triggering distance is automatically adjusted to control a sprayer to spray gloss oil, gold stamping ink and other ink to cover the to-be-colored image. Accurate color register of the covering layer and the image is achieved when ink covering printing is conducted on the image to be subjected to color register, and the image printing quality is improved.

Owner:SHENZHEN HOSONSOFT CO LTD

A method for automatic printing color registration by using non-automatic color registration marking plate roller

ActiveCN110978777BReduce labor intensityAccurate color registrationRotary pressesPrinting press partsColor ScaleColor printing

The invention relates to the technical field of printing color registration. The purpose is to provide a method for automatic printing and color registration by using non-automatic color registration marking plate rollers. The method can use non-registering color marking plate rollers to perform automatic color registration, and has high degree of automation, accurate color registration and simple operation. The technical solution is: a method for automatic printing and color registration using non-automatic color registration marking rollers, including the following steps: 1) Engraving a short line at one end of the first color group roller as the color mark line; each color group roller Servo motors are installed Encoder; starting from the second color group version roller, each color group version roller is equipped with a photoelectric eye; 2) The printing machine is started to adjust the printing material; 3) The color mark line prints the first color on the printing material 4) Starting from the plate roller of the second color group, each color group prints its own color registration, and each encoder rotates synchronously; the operator presses the "confirm" button to confirm the standard Set value; 5) The printing material completes color printing.

Owner:ZHEJIANG MEIGE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com