A kind of printing plate-making equipment and plate-making method

A technology of equipment and printing plates, which is applied in the field of printing plate making equipment and plate making, can solve problems such as LED light-emitting units not being able to emit light normally, LED arrays not being used normally, blurred exposure graphic edges, etc., to achieve large-area one-time exposure and improve long-term Effect of plate cycle and ablation instability, reduced number of image transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

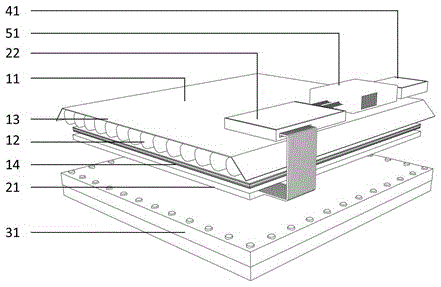

[0032] In order to make the technical scheme of the present invention and its technical effect clearer and clearer, the following is combined figure 1 —4 The specific implementation of the present invention will be further detailed. It should be understood that the following specific embodiments are only used to explain the present invention, but not to limit the present invention.

[0033] Such as figure 1 As shown, it is a perspective view of a printing plate making device in a specific embodiment. The printing plate-making equipment includes: an exposure device 11, a printing image imaging device 21, a printing plate bearing device 31, and a timing control device 41. Conventional components such as a power supply box 51 are well known in the art and will not be repeated.

[0034] In terms of overall structure, the exposure light source 11, the printing image imaging device 21, and the printing plate bearing device 31 are arranged coaxially in sequence to ensure the efficiency an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com