Monchromatic lustering printing machine

A printing press, monochrome technology, applied in printing presses, printing, general parts of printing machinery, etc., can solve problems such as single function, multiple printing process requirements cannot be completed uniformly, etc., achieve accurate color registration, shorten production cycle, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

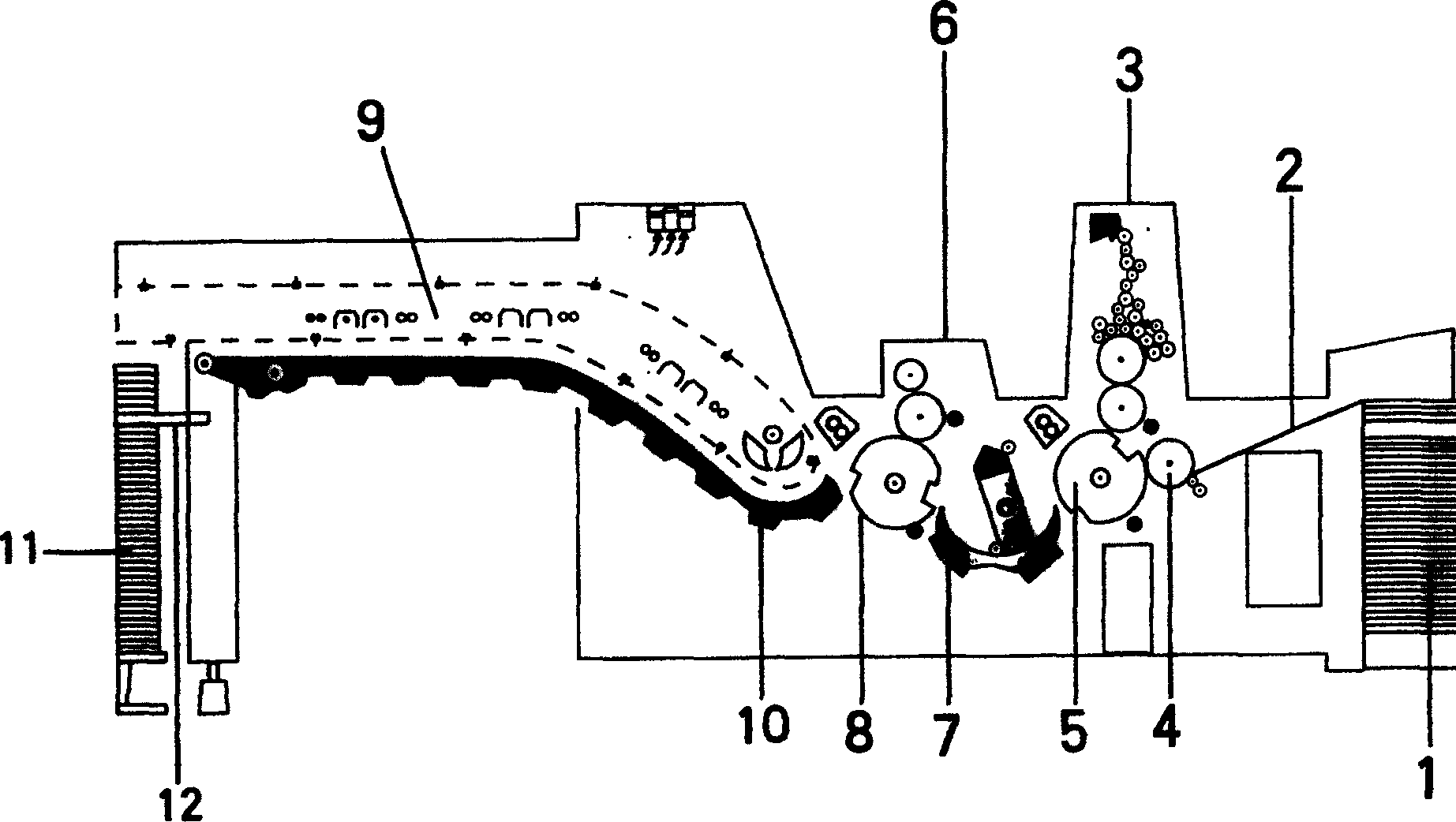

[0013] Further description will be made below in conjunction with accompanying drawings. specify figure 1 Attached is the abstract.

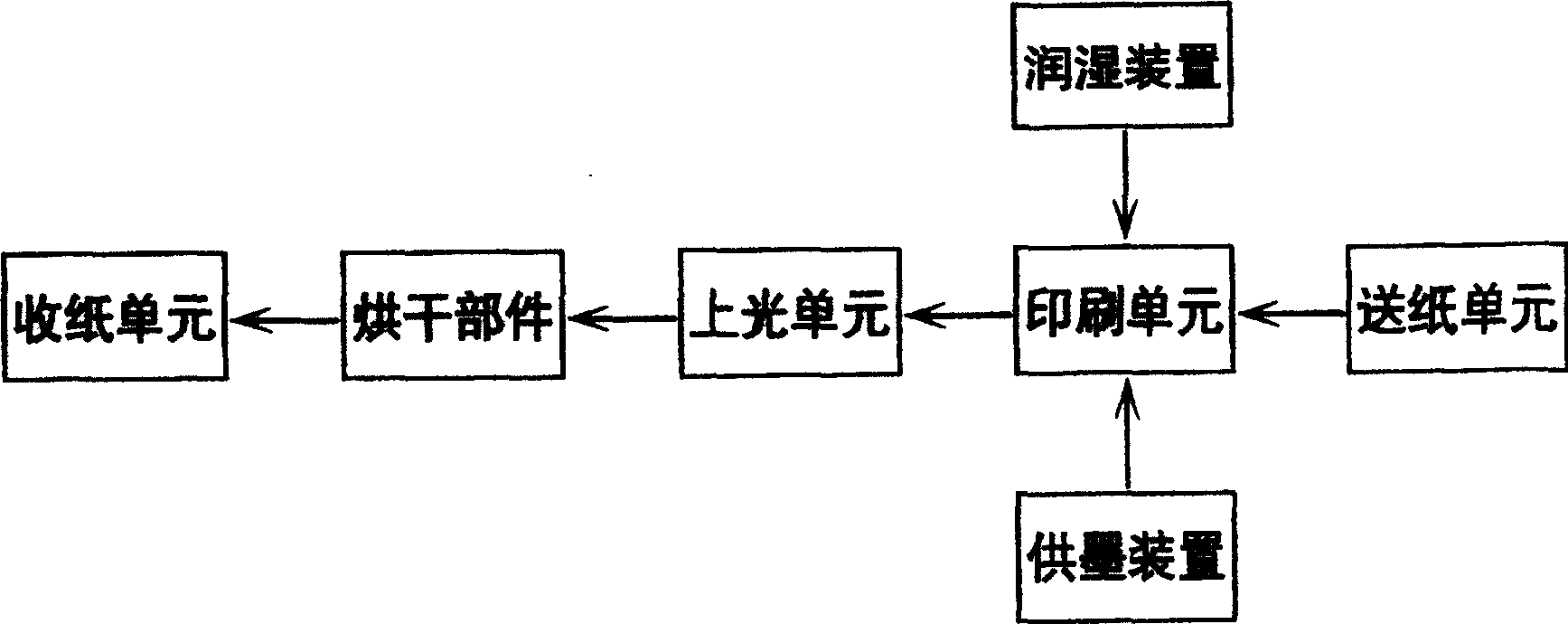

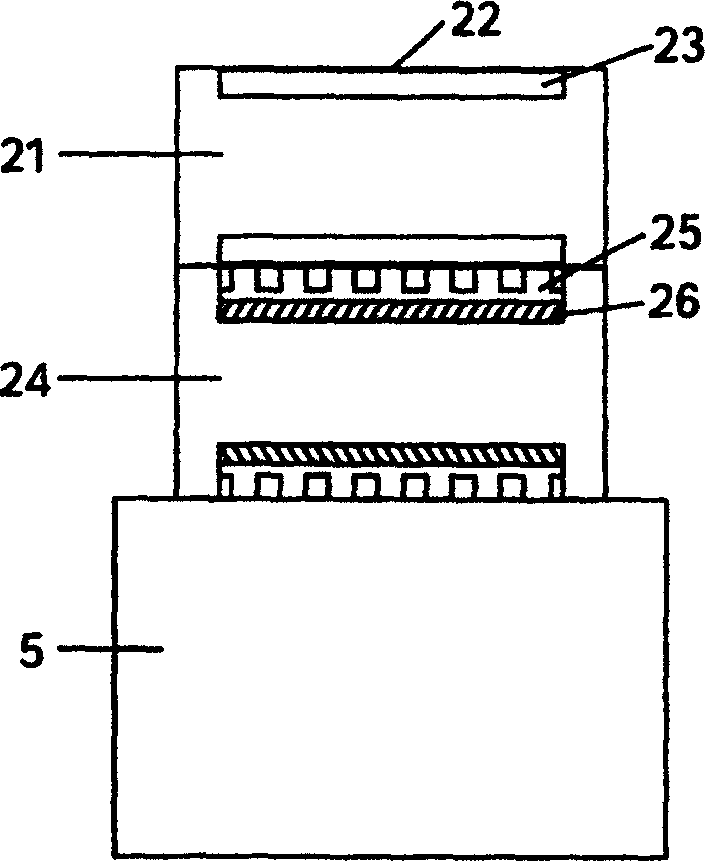

[0014] see figure 1 and figure 2 : The key point of the present invention is that the glazing unit and the printing unit are combined ingeniously, and are connected by a paper feeding unit, a printing unit, a drying unit, and a delivery unit, and the printing unit is composed of an ink supply device, a wetting device, The drum body is connected. The paper feeding table (2) on the paper feeding unit (1) is connected to the paper transfer cylinder (4) of the printing unit (3), and the transfer cylinder (5) on the printing unit (3) and the glazing unit (6) are connected. The paper cylinder (7) is connected, the impression cylinder (8) of the glazing unit (6) is connected with the paper guide air cushion (10) of the infrared drying and ultraviolet curing system (9), and the guide air cushion (10) of the infrared drying and ultraviolet curing sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com