High-speed base paper digital pre-printing machine

A pre-printing machine, digital technology, applied in the direction of papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as affecting the economic benefits of producers, expensive printing plates, unable to solve small batch orders, etc., to achieve reasonable design, color registration, etc. Precise, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

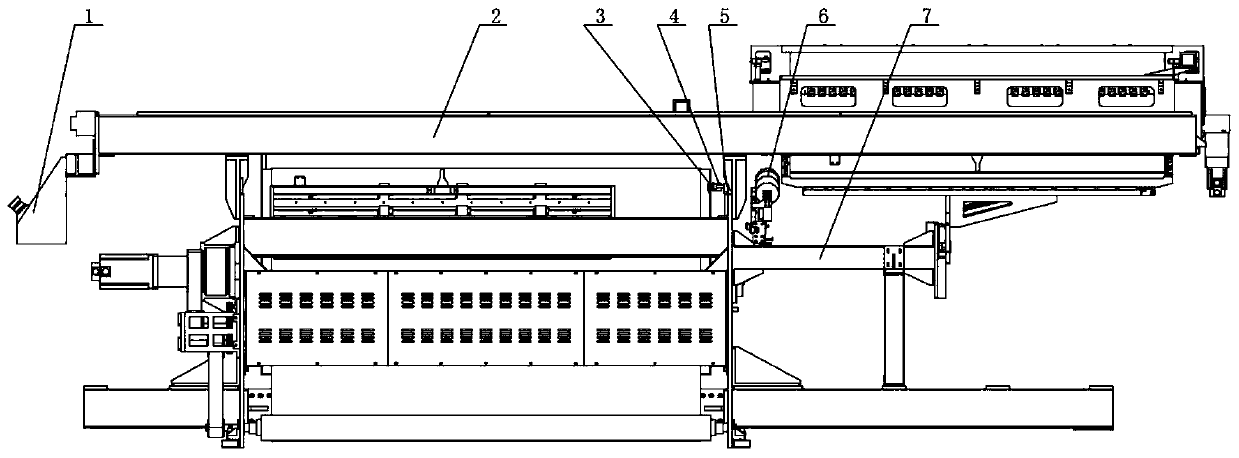

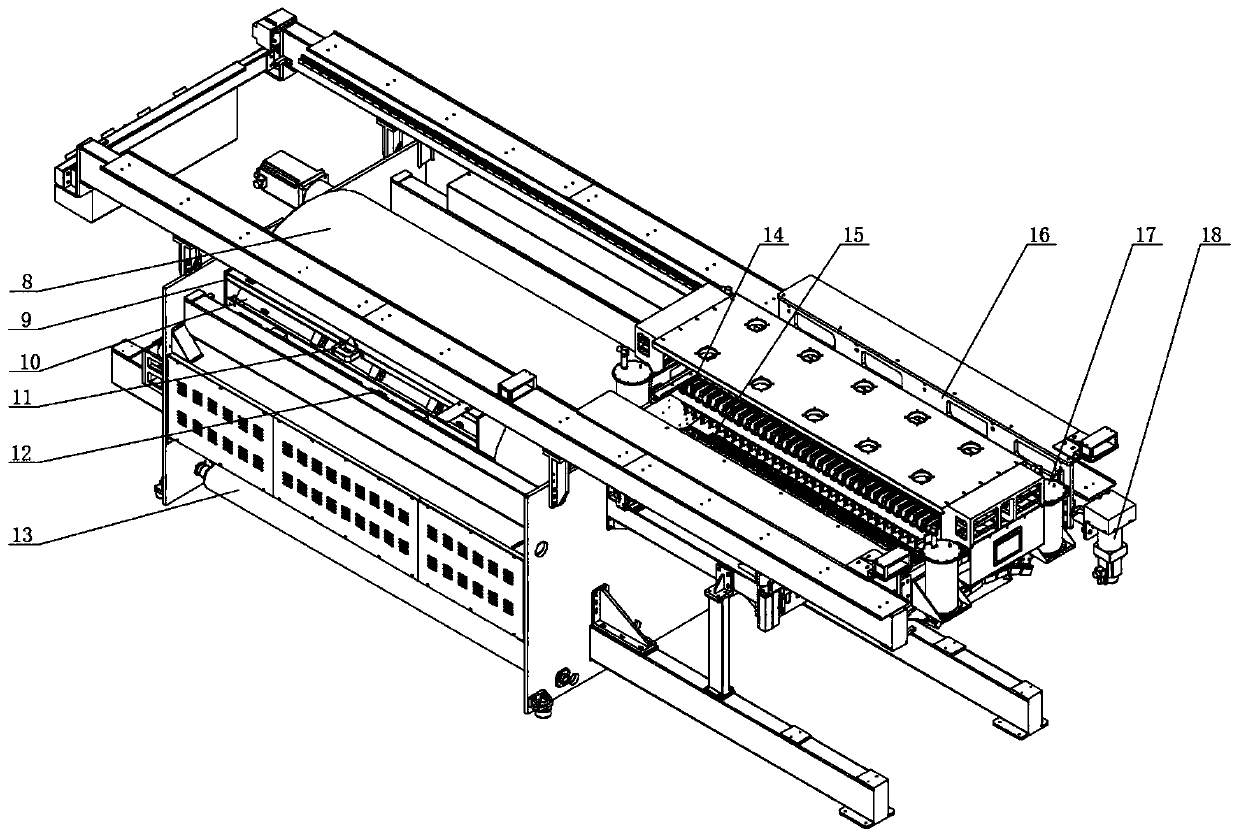

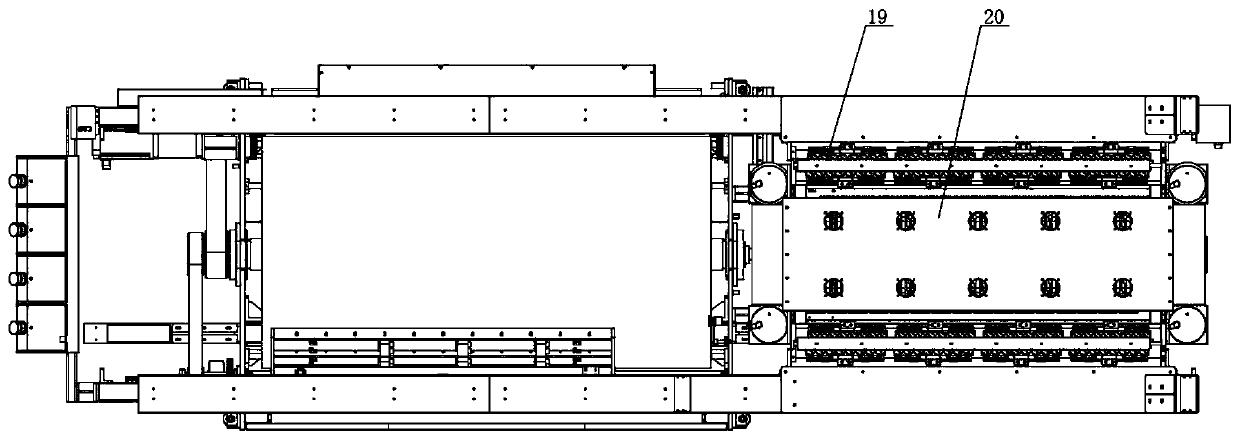

[0031] A high-speed base paper digital preprinting machine, comprising an outer cover 37, an active power mechanism, an ink stack wiping mechanism, a printing mechanism, a position detection mechanism, a drying mechanism and an electric control system, the main power mechanism, the ink stack wiping mechanism, The printing mechanism, the position detection mechanism and the drying mechanism are all installed in the outer cover 37, and the electric control system is electrically connected with the main power mechanism, the ink stack wiping mechanism, the printing mechanism, the position detection mechanism and the drying mechanism respectively. Control box 36, power supply box 39 and main control panel 38, electric control box 36, power supply box 39 and main control panel 38 are all installed on the outside of outer cover 37, and main power mechanism includes main power motor 21, center drum 8 and tension roller 13 , the output end of the main power motor 21 is connected with th...

Embodiment 2

[0039] A high-speed base paper digital preprinting machine, comprising an outer cover 37, an active power mechanism, an ink stack wiping mechanism, a printing mechanism, a position detection mechanism, a drying mechanism and an electric control system, the main power mechanism, the ink stack wiping mechanism, The printing mechanism, the position detection mechanism and the drying mechanism are all installed in the outer cover 37, and the electric control system is electrically connected with the main power mechanism, the ink stack wiping mechanism, the printing mechanism, the position detection mechanism and the drying mechanism respectively. Control box 36, power supply box 39 and main control panel 38, electric control box 36, power supply box 39 and main control panel 38 are all installed on the outside of outer cover 37, and main power mechanism includes main power motor 21, center drum 8 and tension roller 13 , the output end of the main power motor 21 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com