Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Rotation speed control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

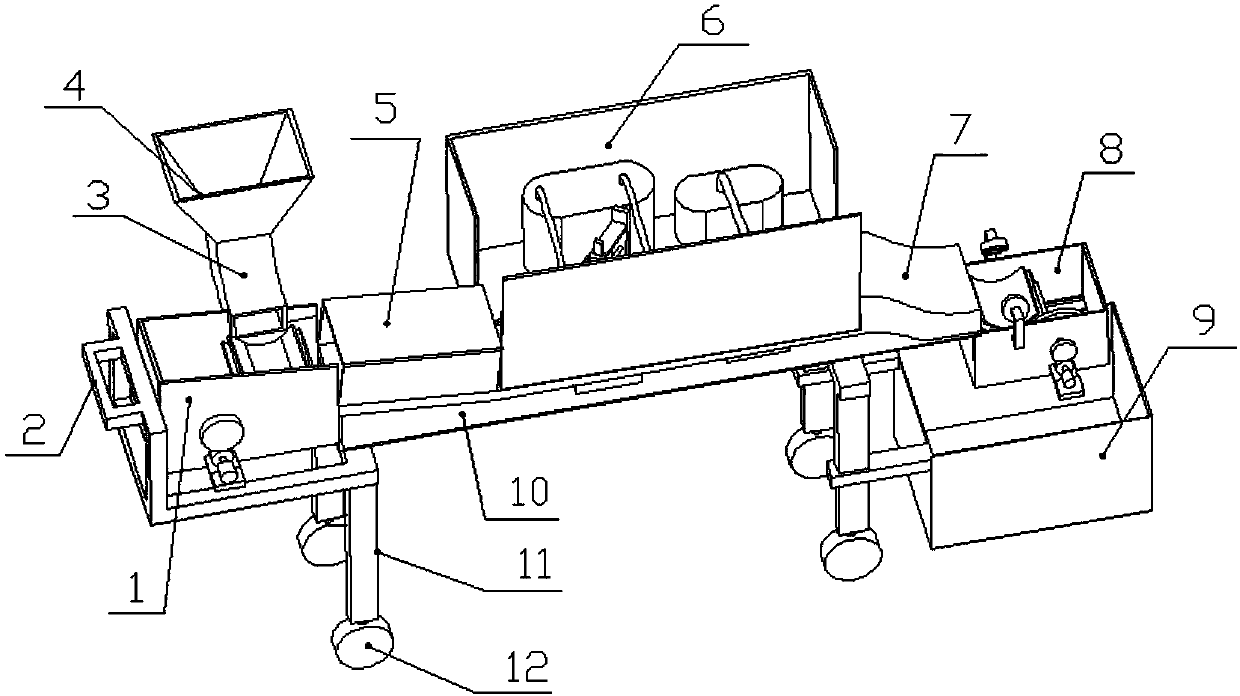

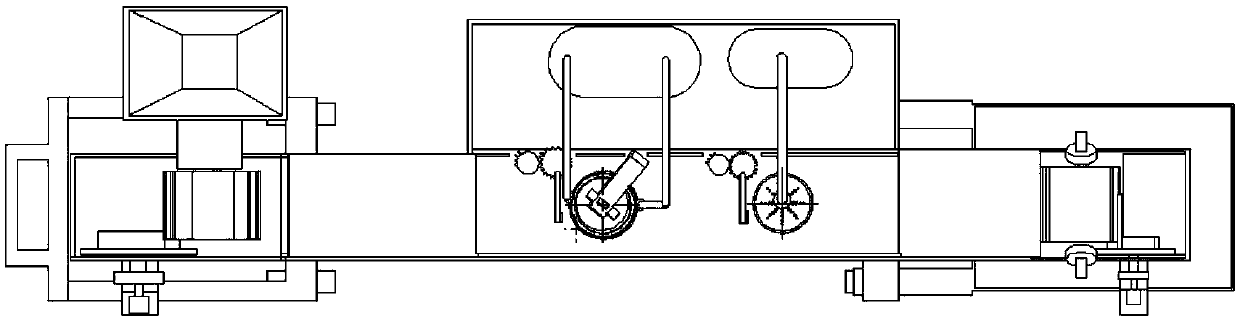

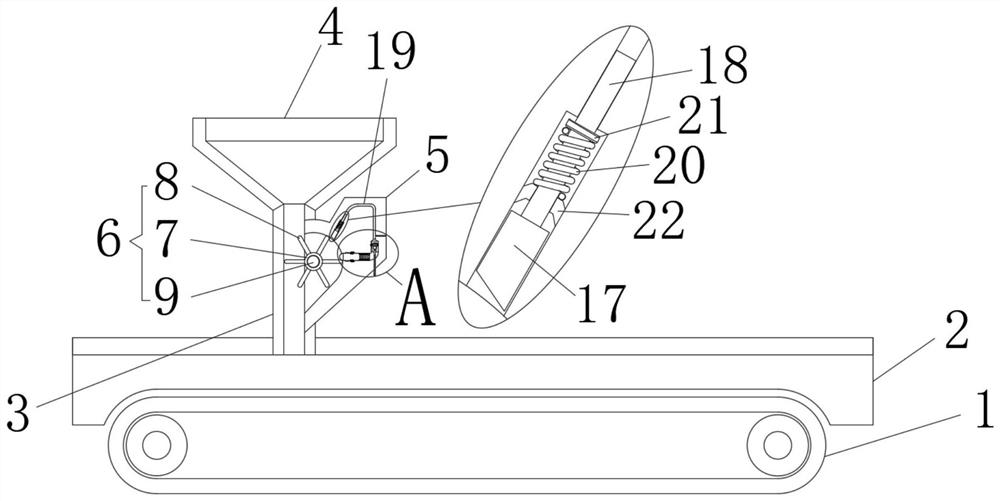

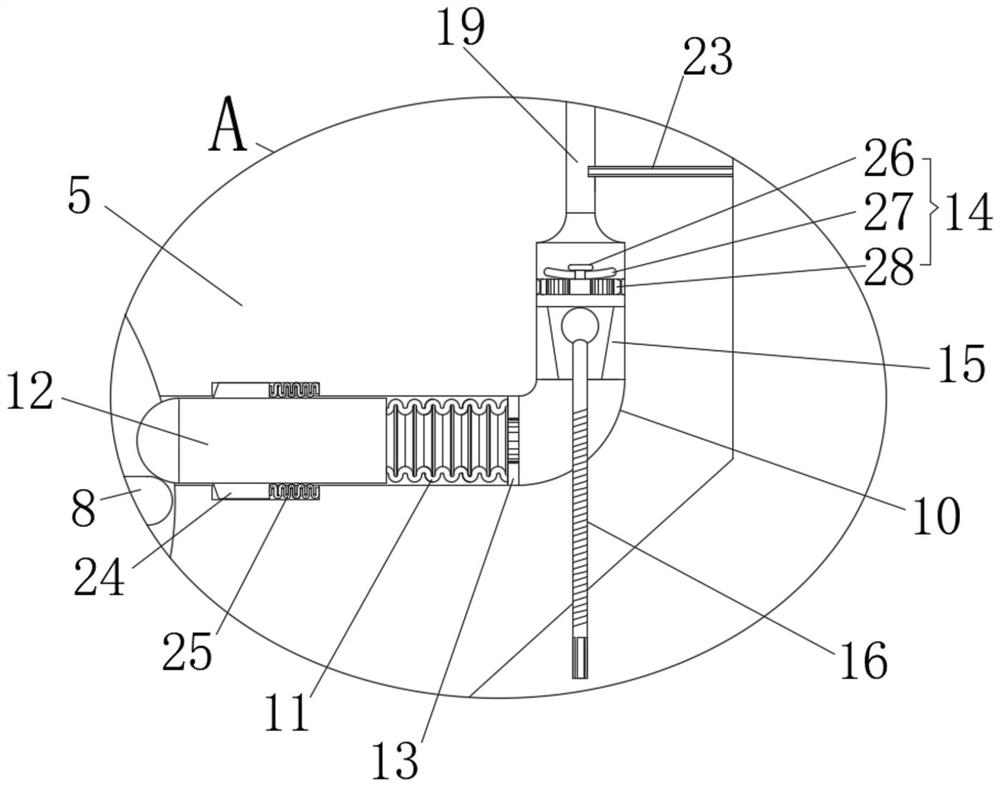

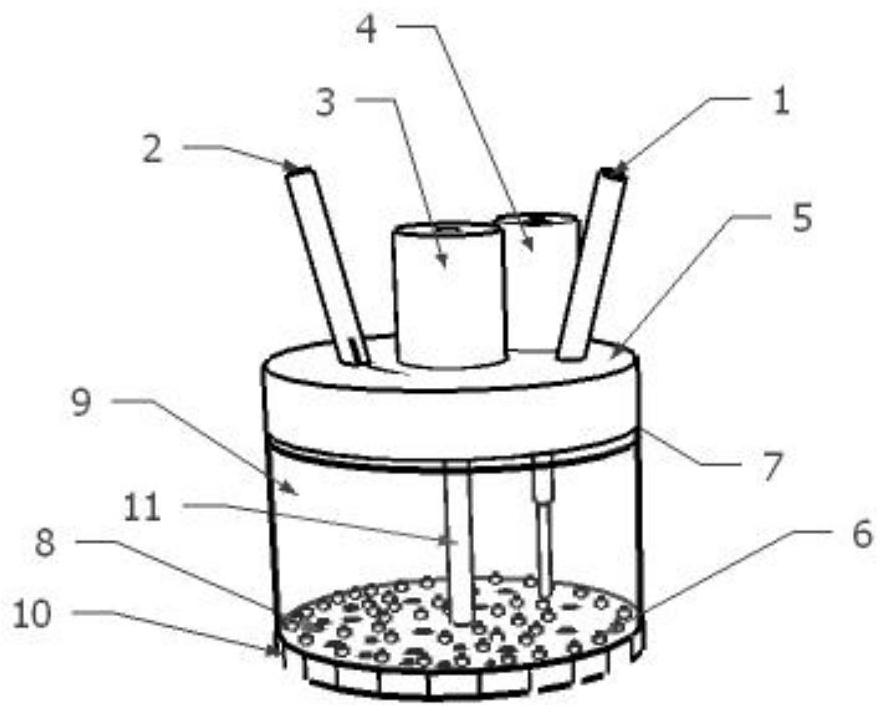

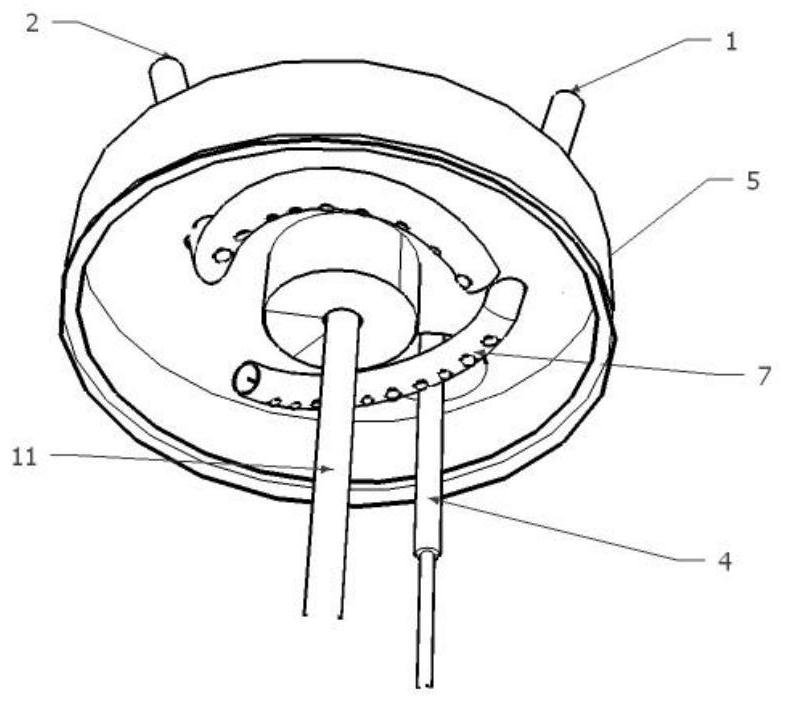

Automatic basketball cleaning device for teaching and training

ActiveCN107899206ARealize automatic washingExtended service lifeBall sportsIntermittent motionGear wheel

An automatic basketball cleaning device for teaching and training is composed of a ball inlet box, a handle, a ball inlet cylinder, a put-in box, an inclined box, a cleaning box, a ball outlet cylinder, a ball outlet box, a storage box, a support plate, a support frame and wheels. In the ball inlet box, a ball inlet grooved wheel intermittent motion mechanism is mainly used for controlling basketball put-in; in the cleaning box, a washing incomplete gear intermittent motion mechanism, a disinfecting incomplete gear intermittent motion mechanism and a double-rack intermittent motion mechanism are mainly used for completing the work of washing and disinfecting basketballs; in the ball outlet box, a ball outlet grooved wheel intermittent motion mechanism is mainly used for controlling basketball drying. The automatic basketball cleaning device for teaching and training has the advantages that the grooved wheel intermittent motion mechanisms, the incomplete gear intermittent motion mechanism and the double-rack intermittent motion mechanism are effectively utilized in the whole device, the work of automatically washing, disinfecting and drying basketballs is completed, the working efficiency is greatly improved, the service life of basketballs is prolonged, and the hidden danger of germ infection on basketballs is reduced.

Owner:宿州速果信息科技有限公司

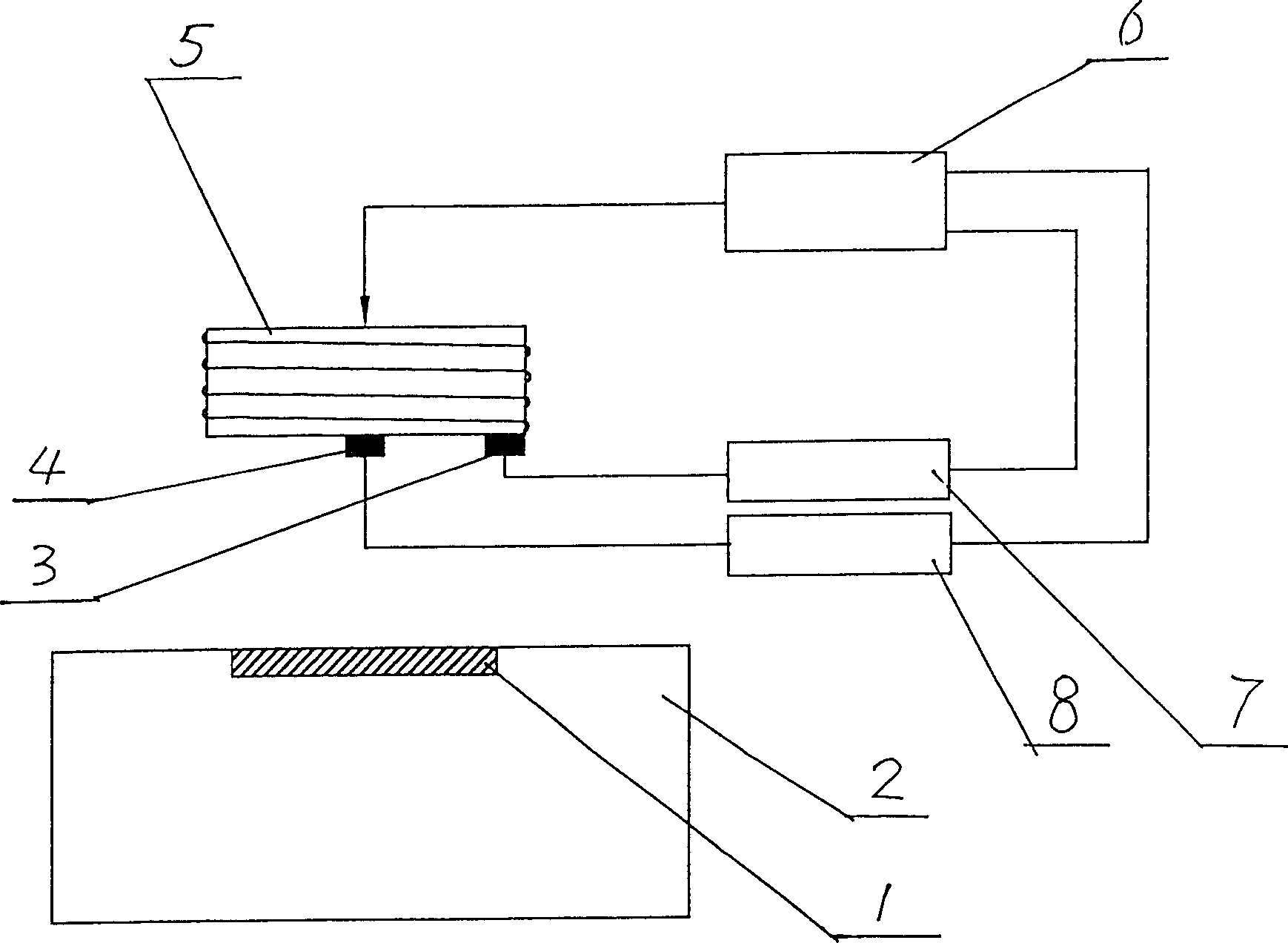

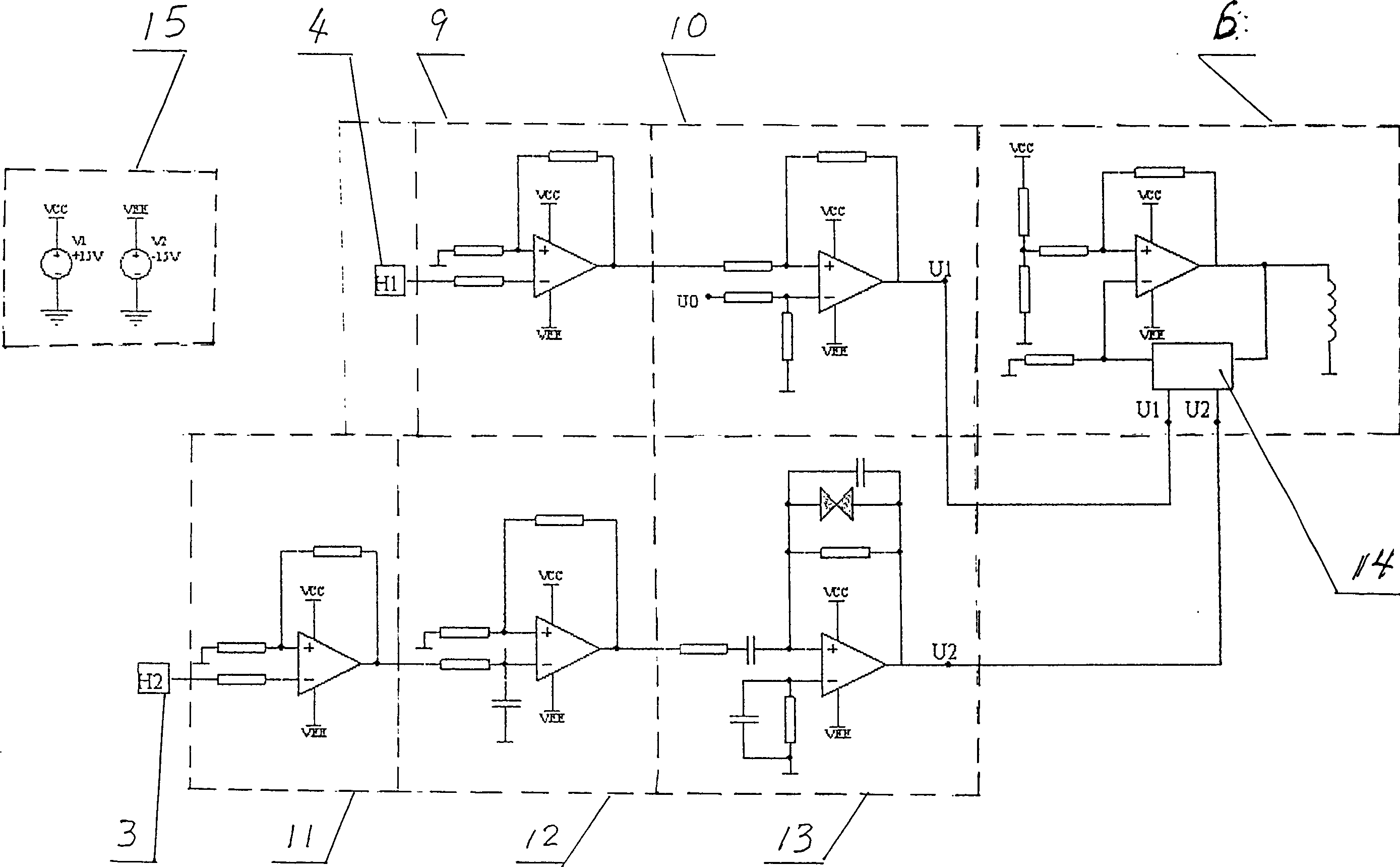

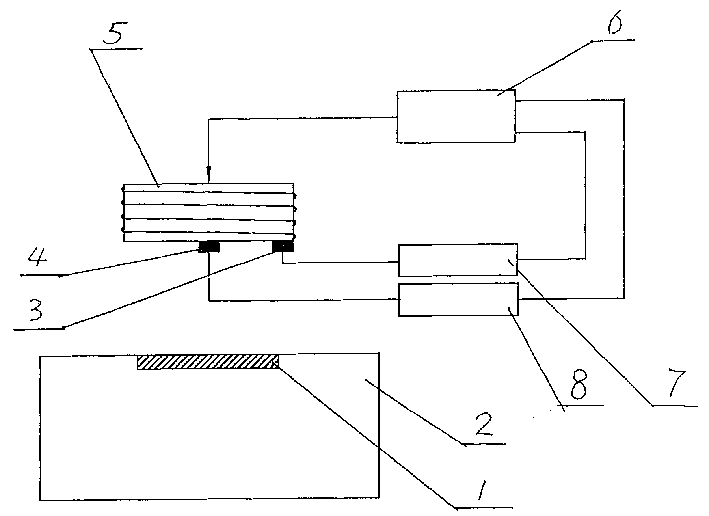

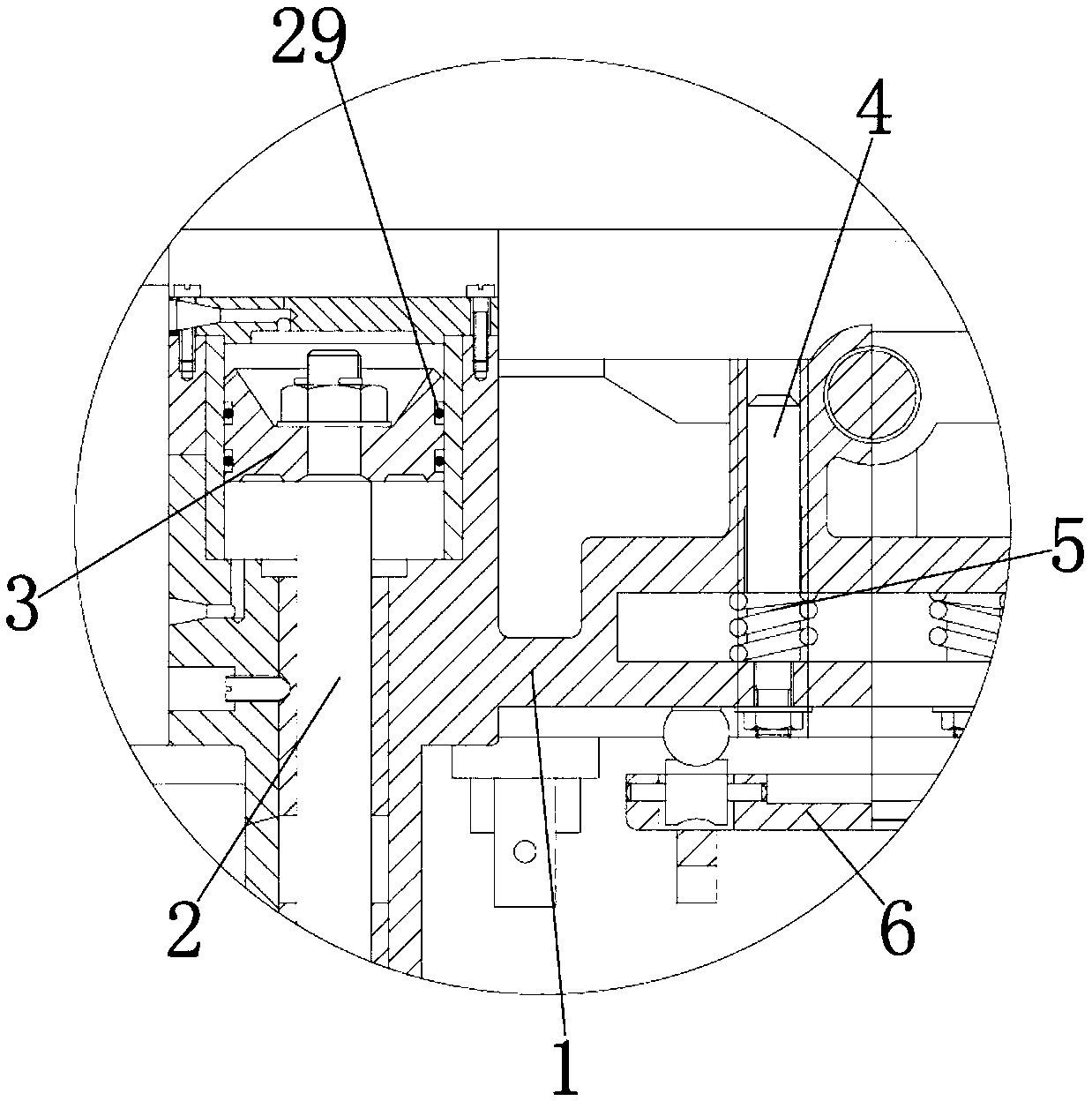

Magnetically suspended rotator with single electromagnetic winding

InactiveCN1156071CAchieve the purpose of rotationRotation speed controlMagnetic holding devicesSignal processing circuitsControl circuit

A magnetically suspended rotator with single electromagnetic coil is composed of suspended body and electromagnetic coil for generating magnetic field. The iron core of said electromagnetic coil has rectangular cross-section. On the suspended body, there are rectangular permanent magnets. On the surface of said electromagnetic coil, there are two sensors for detecting vertical direction and circumferential direction and connected with the control circuit of electromagnetic coil. Said control circuit consists of position sensor, signal processing circuit, and controlling circuit of exciting current. Its advantages are simple structure and high symmetry.

Owner:UNIV OF SCI & TECH OF CHINA

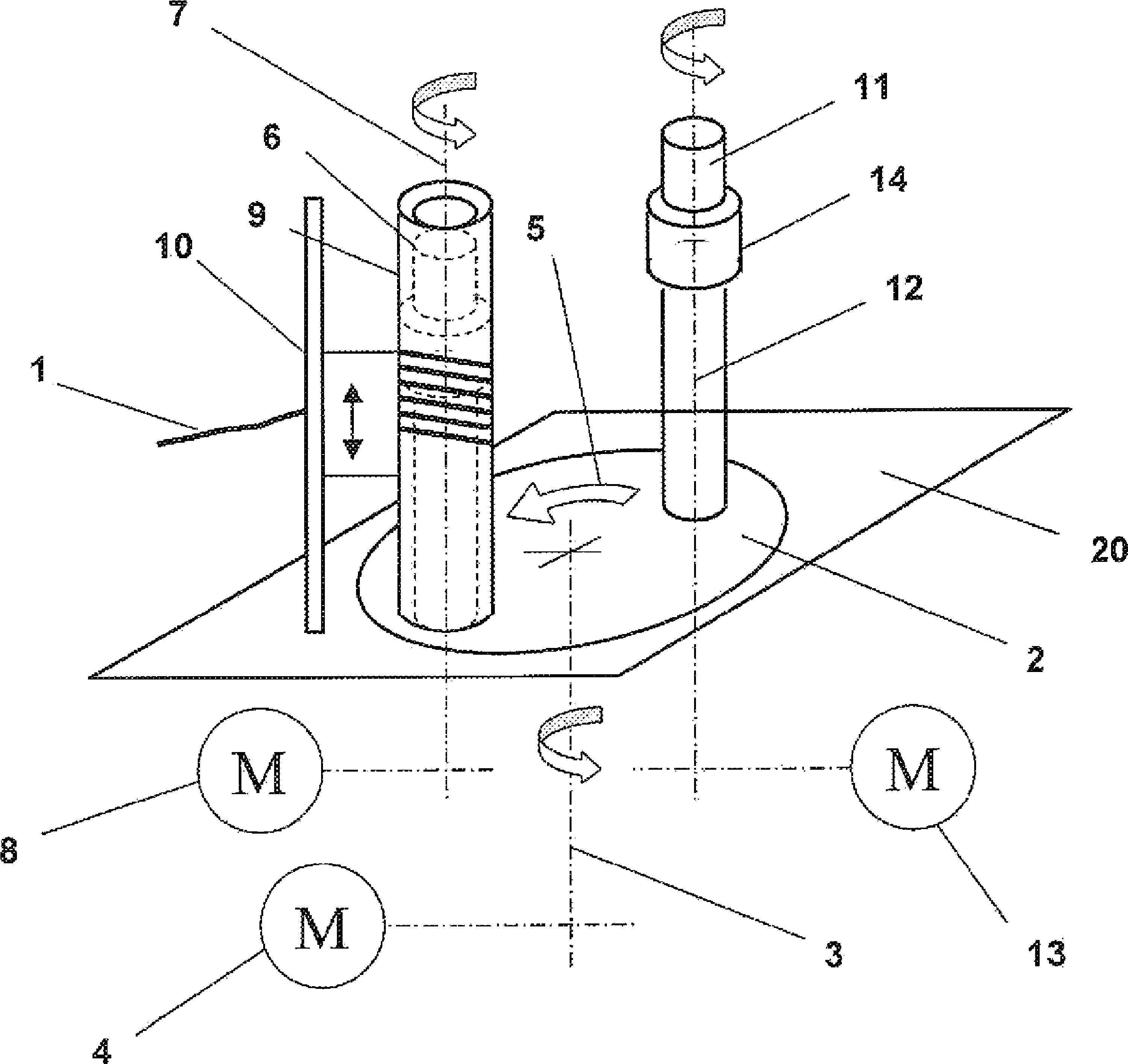

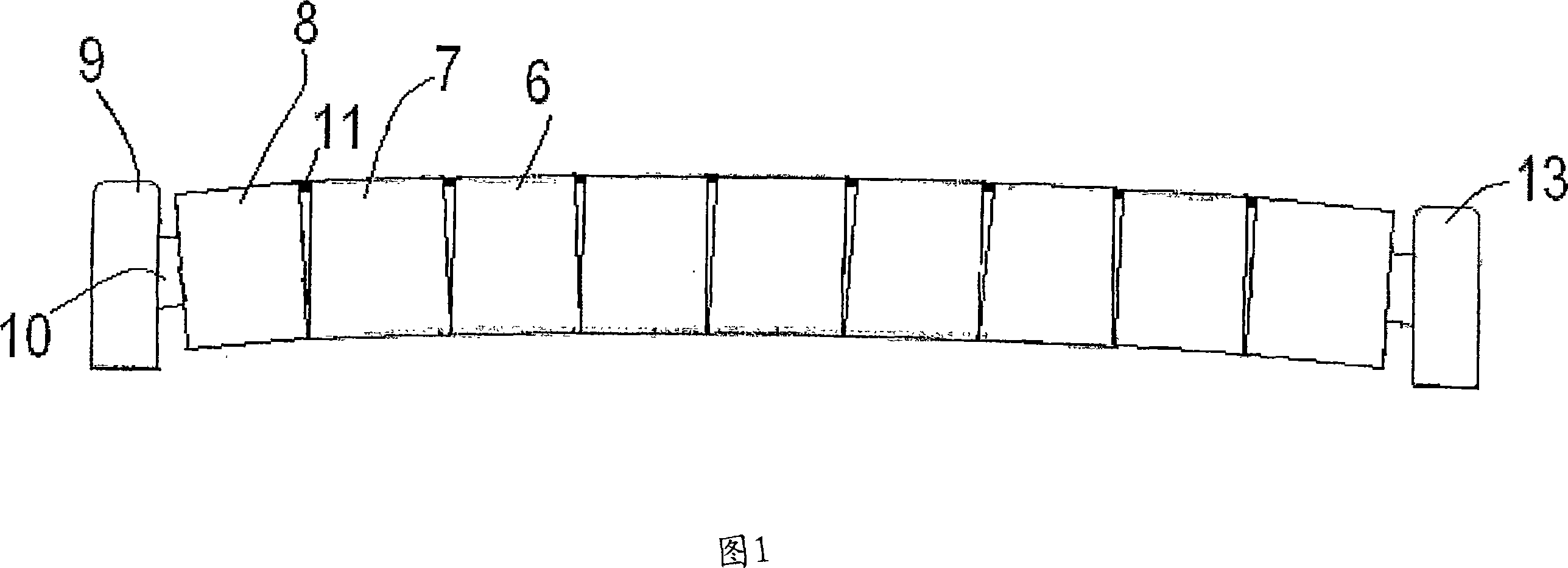

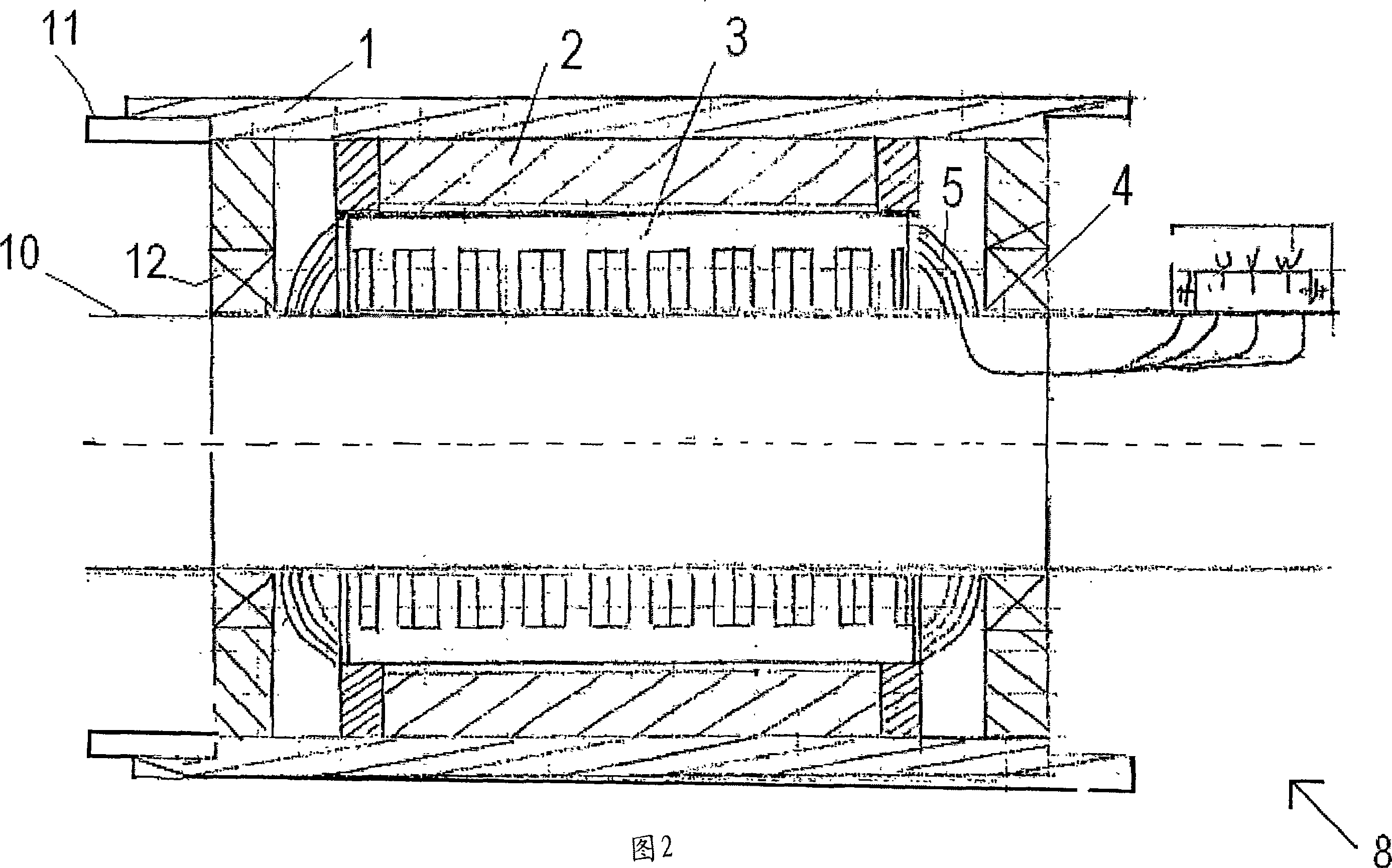

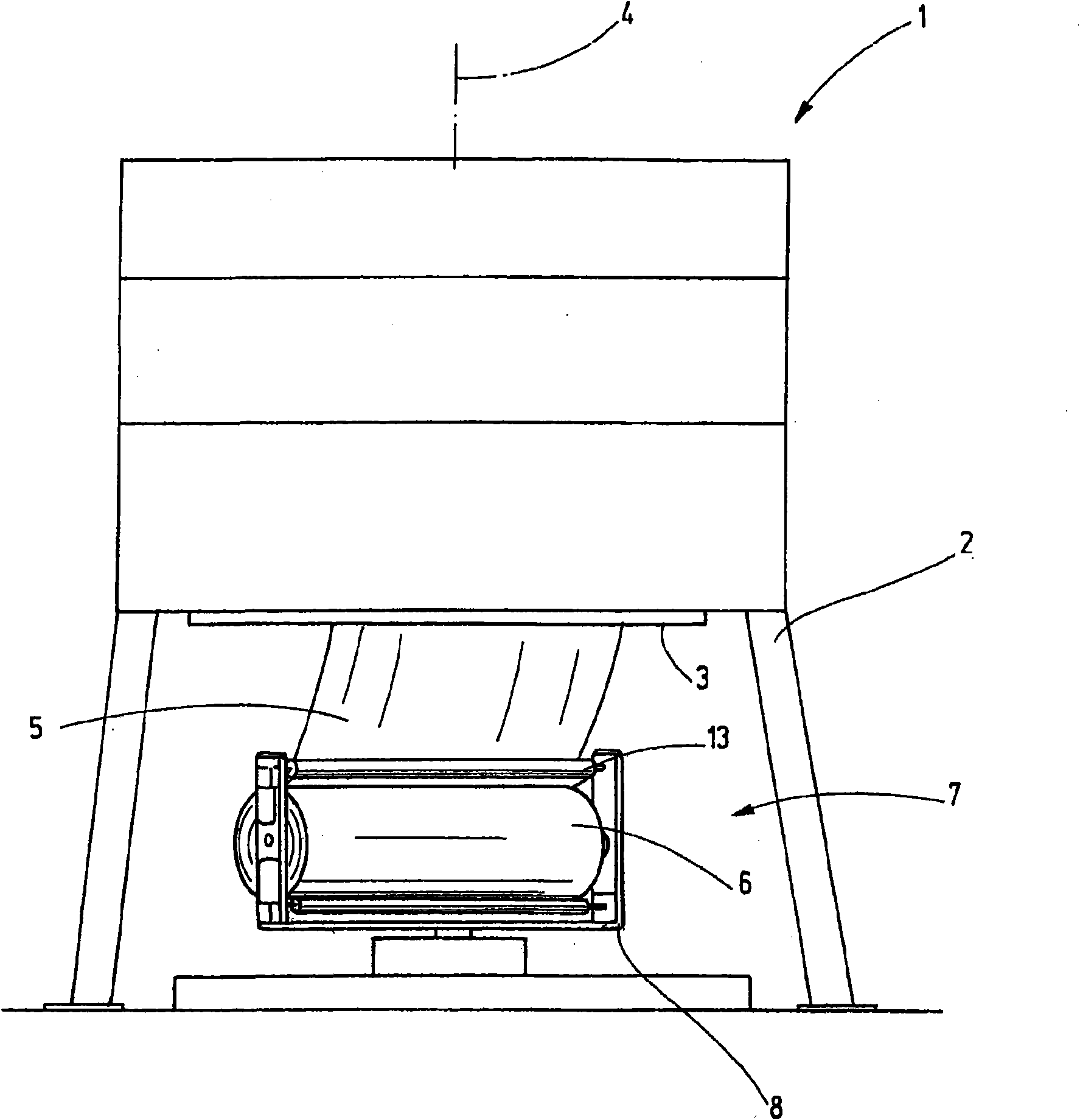

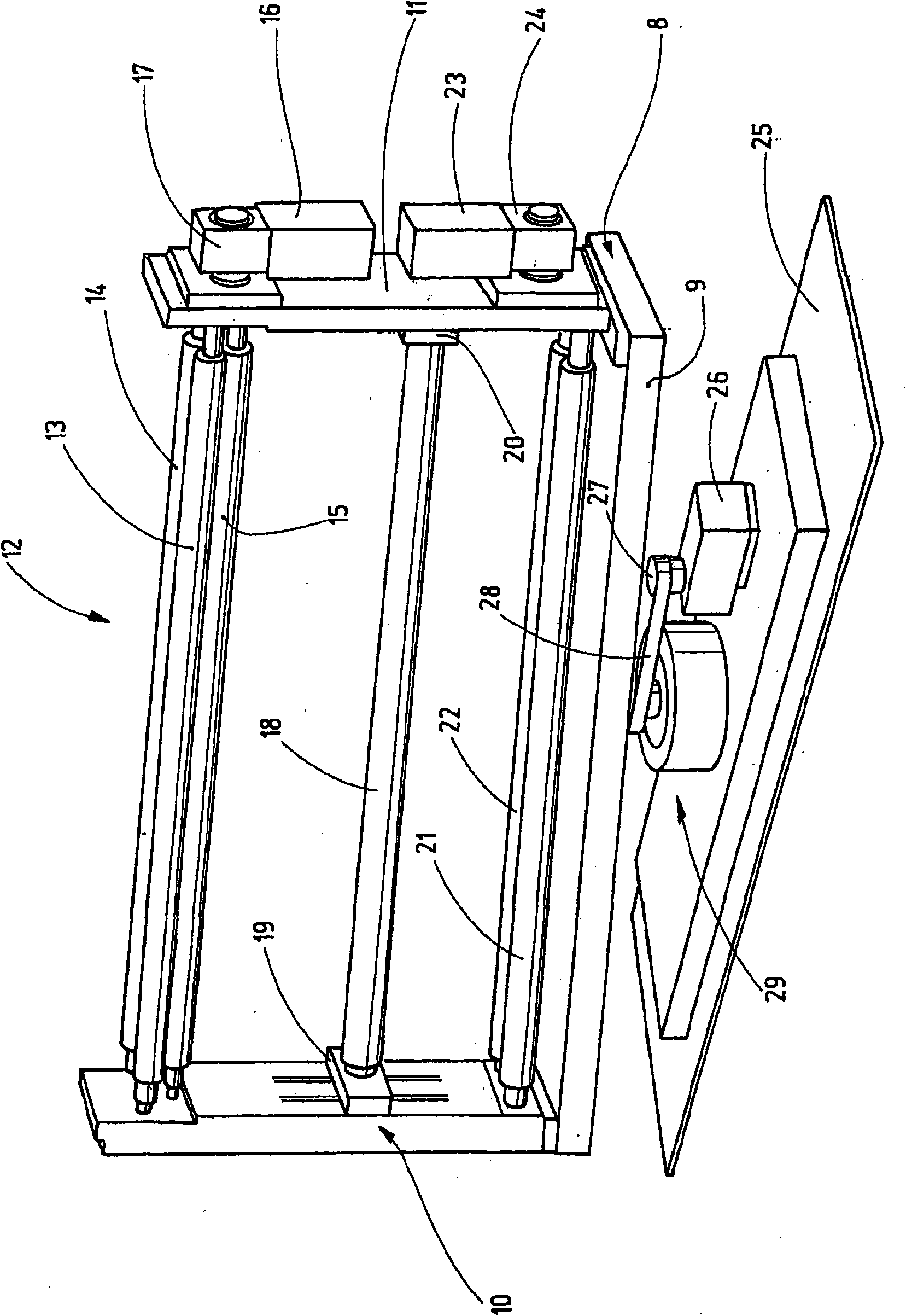

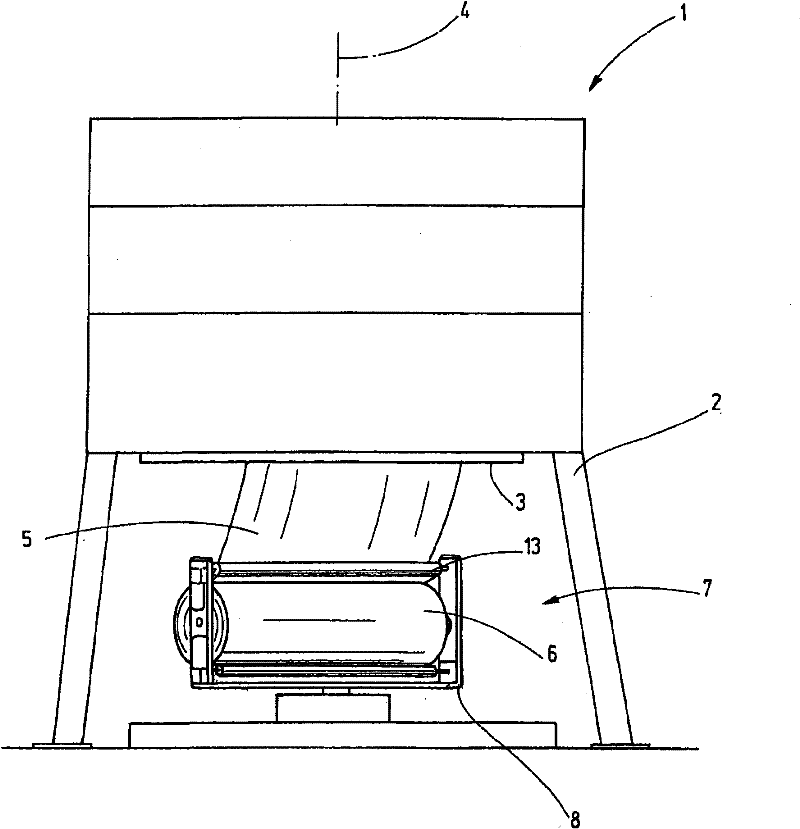

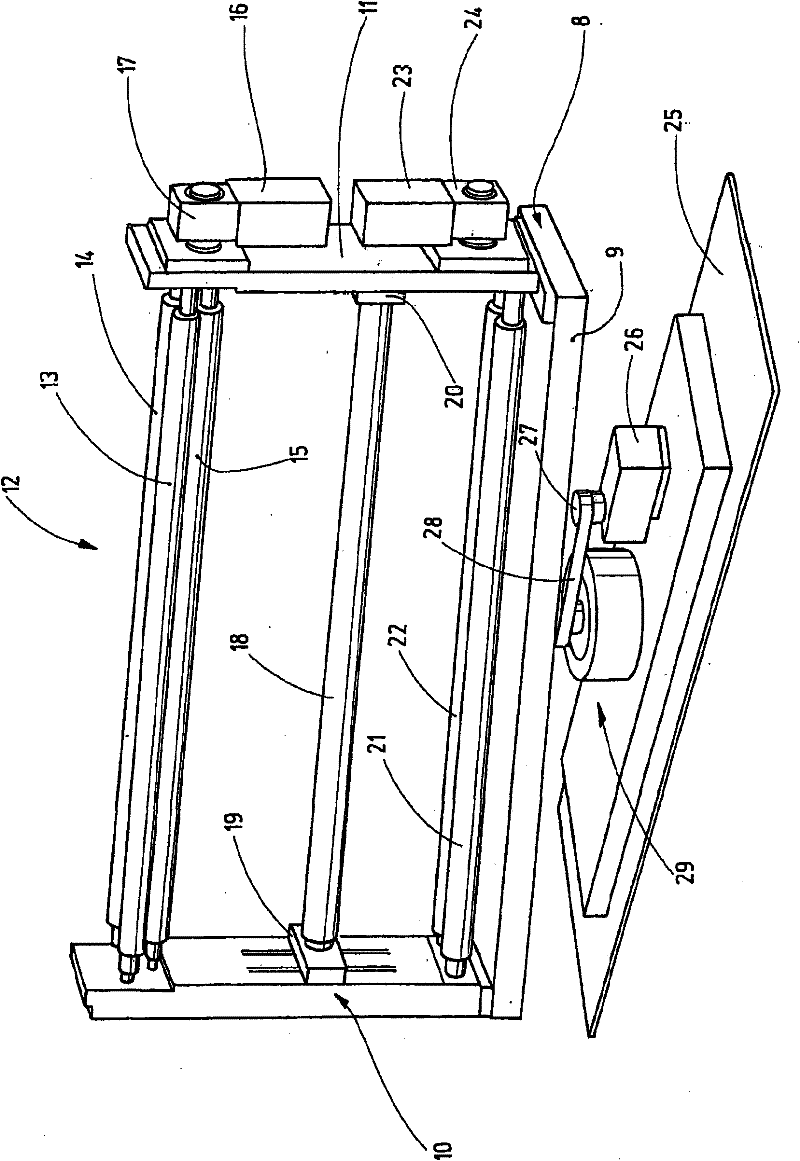

Bobbin-winding machine

InactiveCN103648941ACompatibleFull concentric operationFilament handlingContinuous wound-up machinesWinding machineBobbin

The invention relates to an apparatus and a method for winding roving (1) onto bobbin tubes (9) by way of a turret winding head. The turret winding head comprises a turret base plate (2) having a first spindle (6) and a second spindle (11) for receiving the bobbin tubes, said spindles being held in the turret base plate and having a longitudinal axis (7, 12). The turret base plate (2) and the spindles (6, 11) are each provided with a separate drive (4, 8, 13). The longitudinal axes (7, 12) of the spindles (6, 11) are oriented in the vertical direction.

Owner:MASCHINENFABRIK RIETER AG

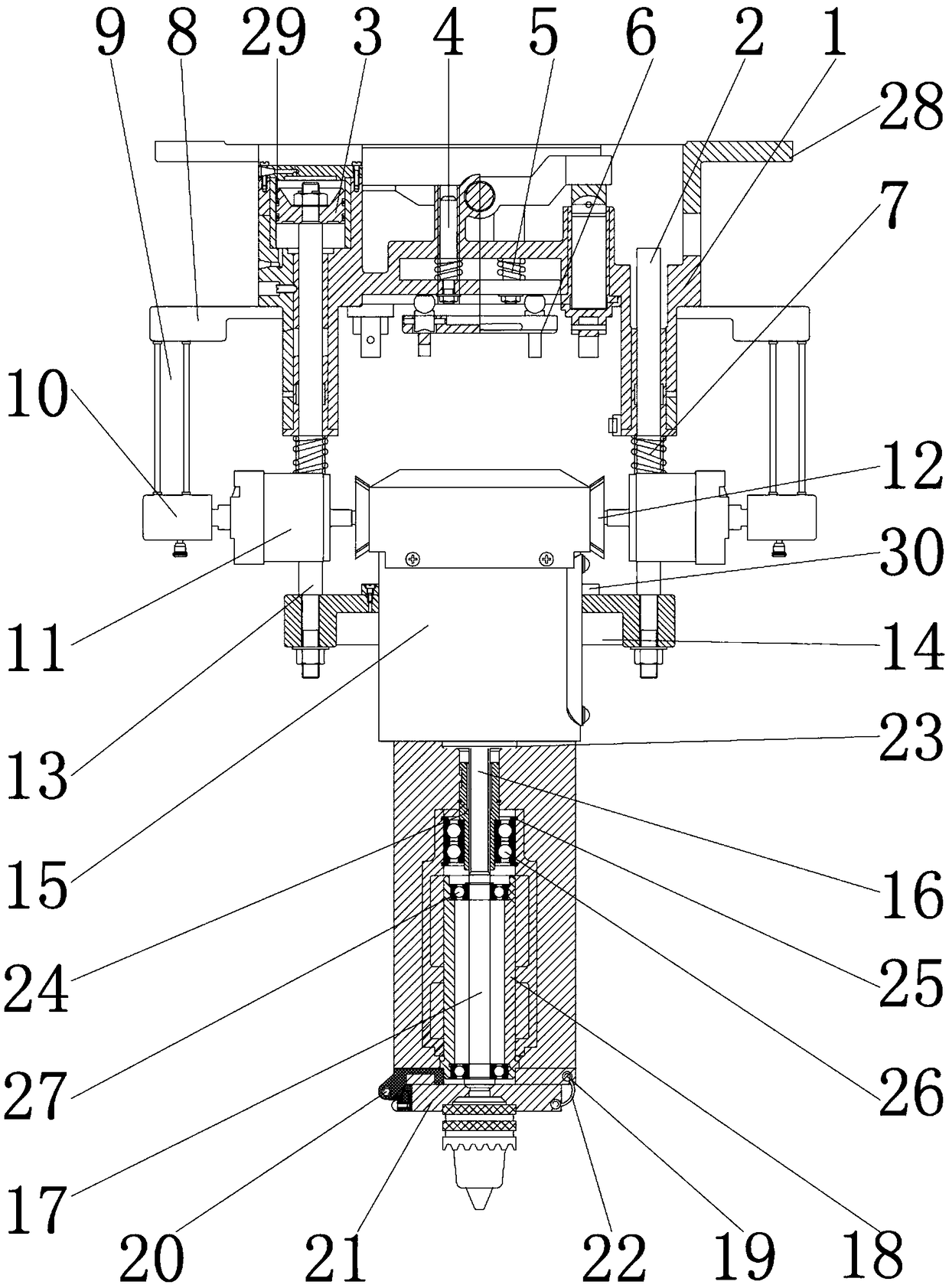

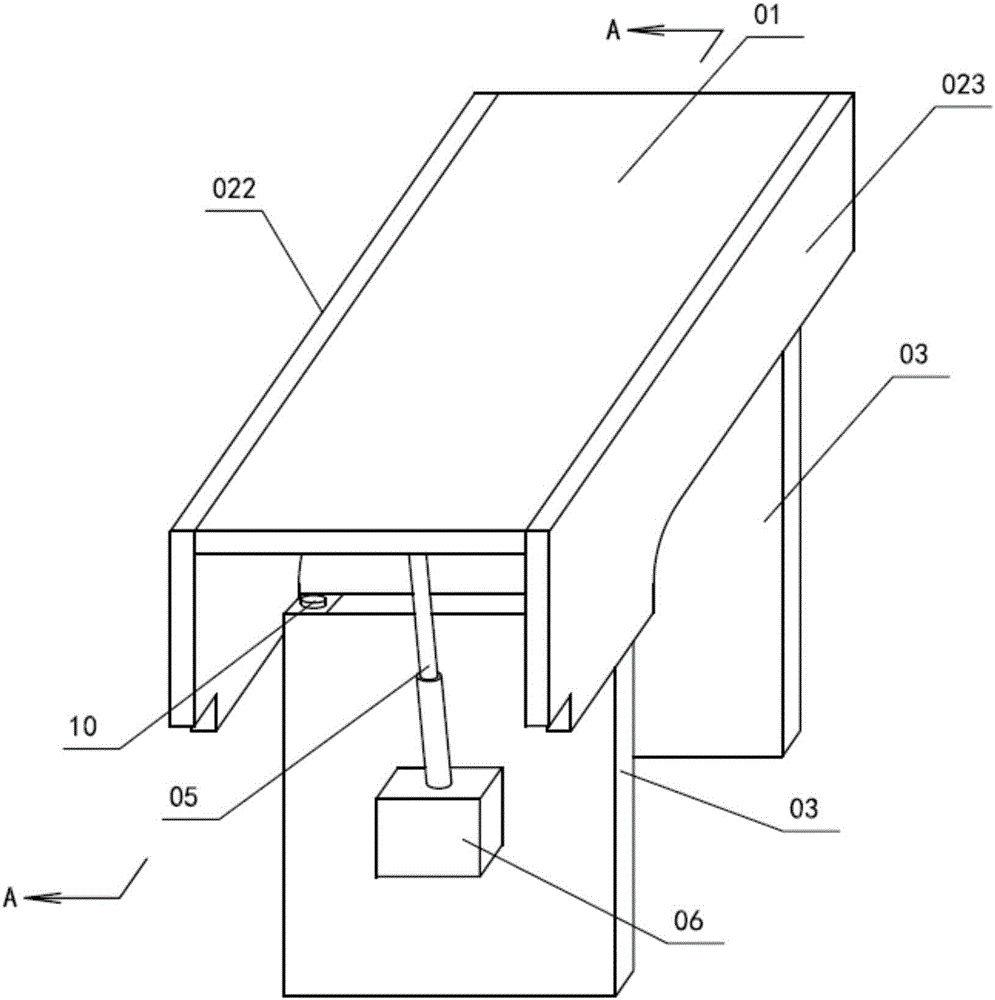

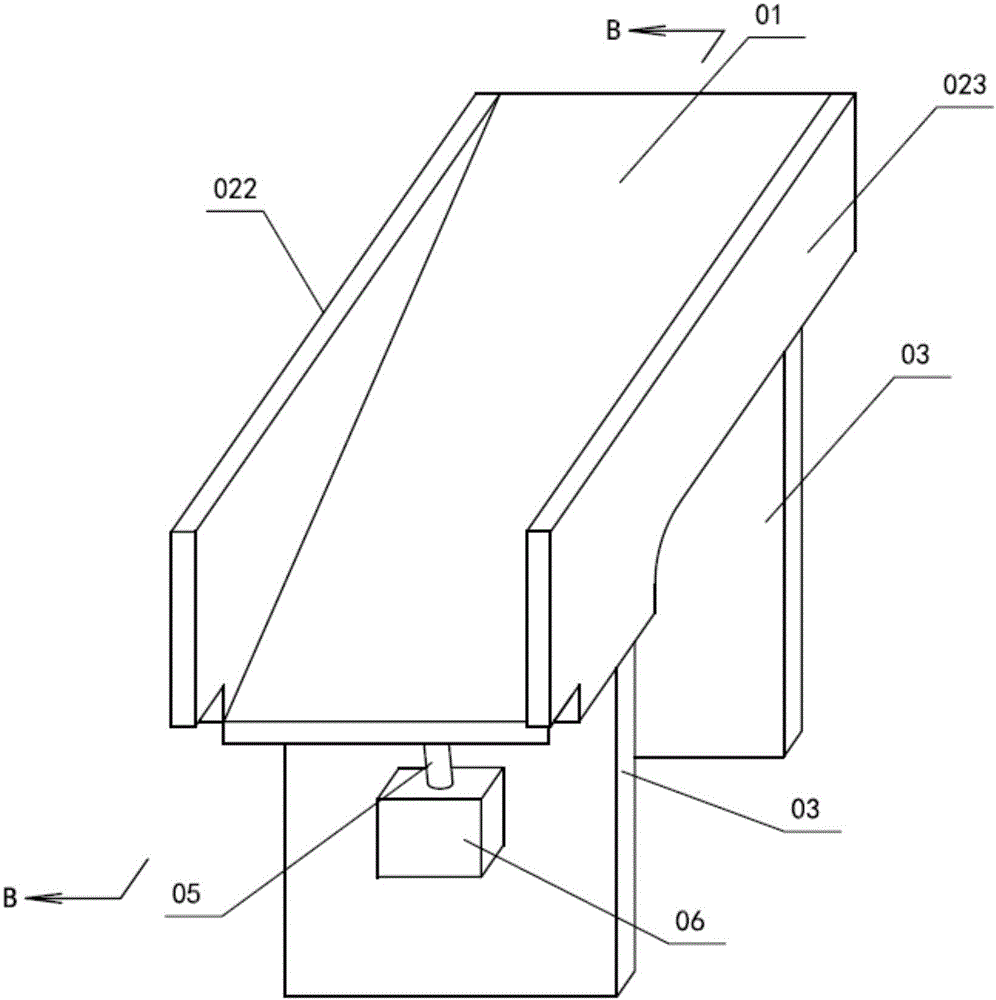

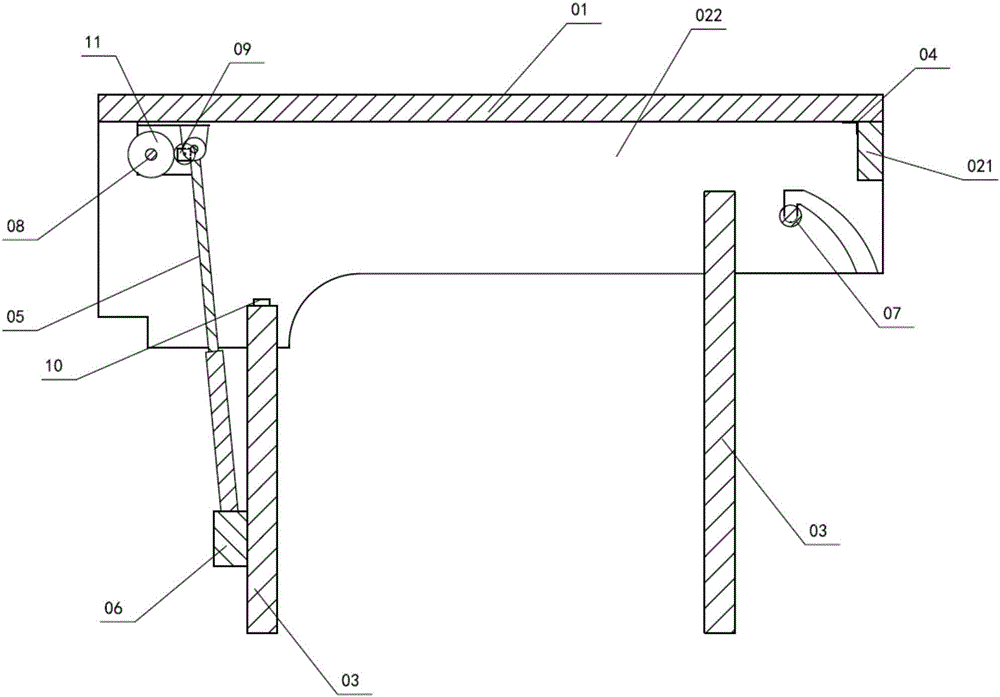

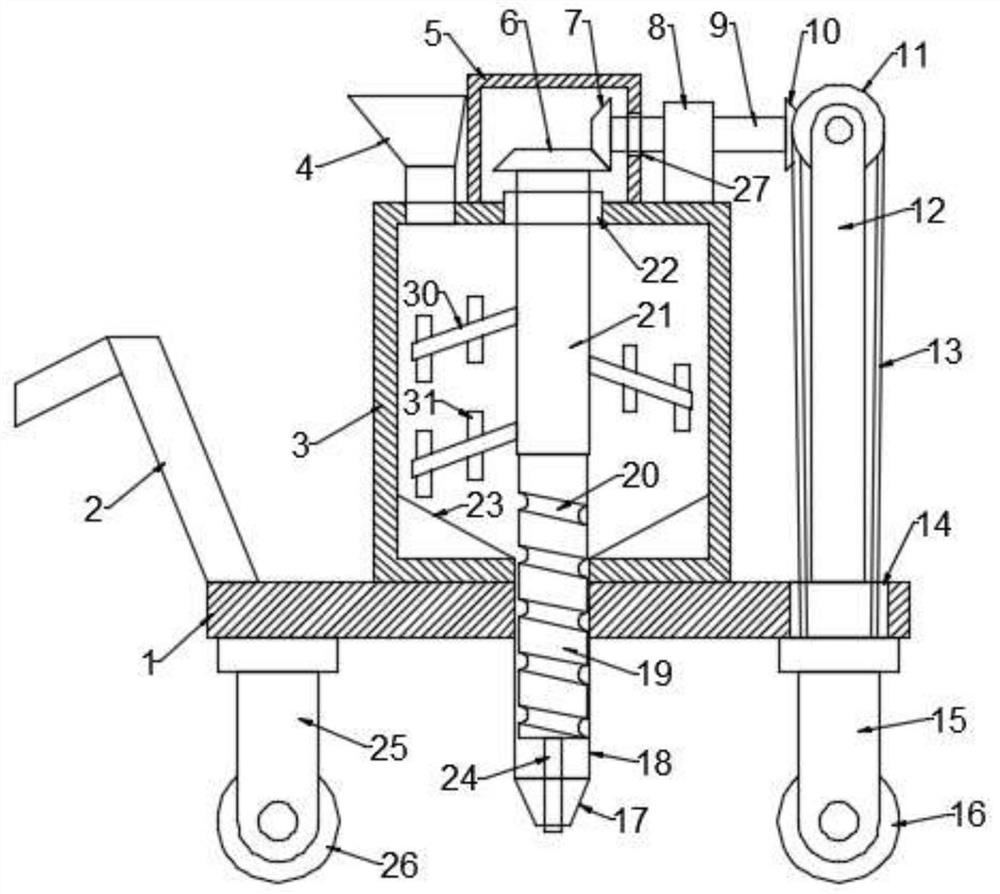

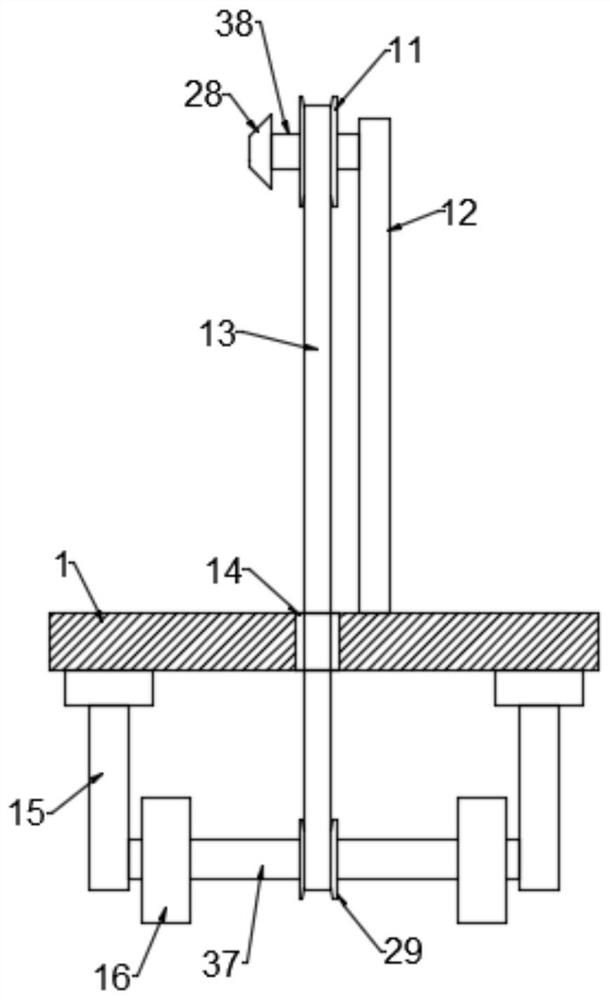

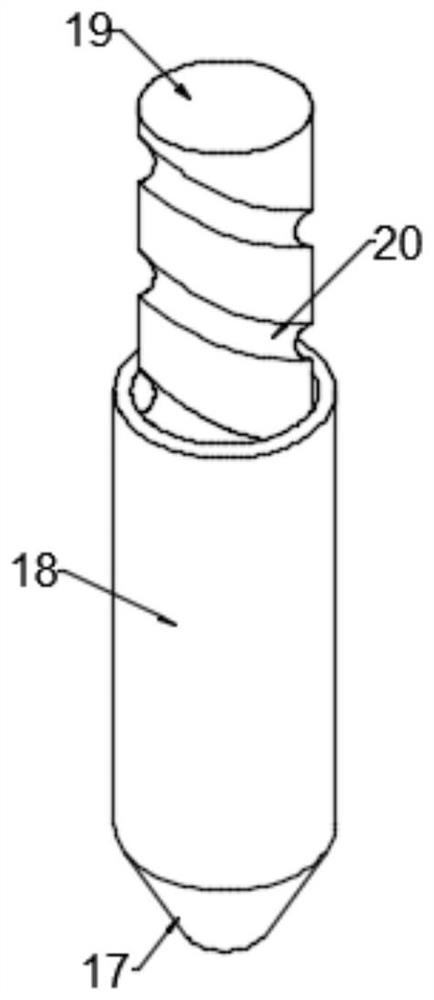

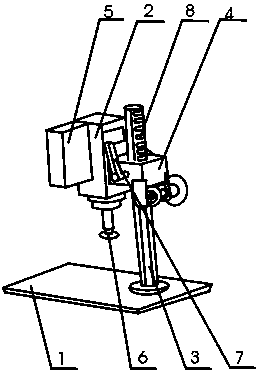

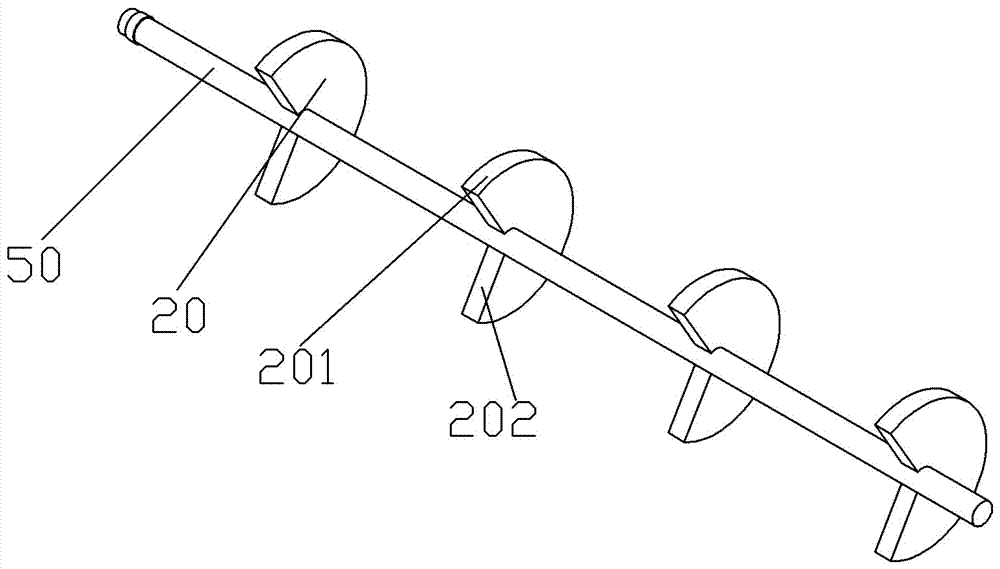

Novel vertical type sampling tool for geological prospecting

InactiveCN108663231AImprove work efficiencyExtended service lifeWithdrawing sample devicesInstabilityGeological exploration

The invention discloses a novel vertical type sampling tool for geological prospecting. The novel vertical type sampling tool comprises a base and is characterized in that a short rod is mounted on the inner wall of the base, the outer wall of the short rod is movably connected with the inner wall of the base, a first compression spring sleeves the outer wall of the short rod, the inner wall of the compression spring is movably connected with the outer wall of the short rod, a retaining plate is mounted on the outer wall of the base, the inner wall of the retaining plate is movably connected with the outer wall of the base, and the inner wall of the retaining plate is connected with the outer wall of the short rod. The novel vertical type sampling tool has the advantages that by the coordination of the short rod, the first compression spring and the retaining plate and by the aid of an alternating-current servo motor, the connecting part instability of the holding rod, connected with aconnecting rod, a rod sleeve and a spring, of a traditional sampling device is overcome, the purchasing cost of a user is saved, the resource waste of the novel vertical type sampling tool is avoided, and the novel vertical type sampling tool is suitable for being popularized and used.

Owner:广西珠委南宁勘测设计院有限公司

Spreader roll

A spreader roll comprising at least one actuator and a stationary and most advantageously curved spreader-roll axle (10) on which there are roll segments (6, 7 and 8) which roll segments are connected to each other with flexible connector members (11) in connection with shell sleeves (1) so that the roll-segment shell sleeves rotate bearing-mountedly around the spreader-roll axle, in which at least one roll segment (8) is an actuator which operates most advantageously as a drum motor rotating the roll-segment shell sleeves (1) around the spreader-roll axle.

Owner:PIKOROLLS

Automatic bowl-collecting table

PendingCN106617674AThe time to collect the bowl is shortRealize automatic resetVariable height tablesFeetComputer science

Owner:伍贤勇 +1

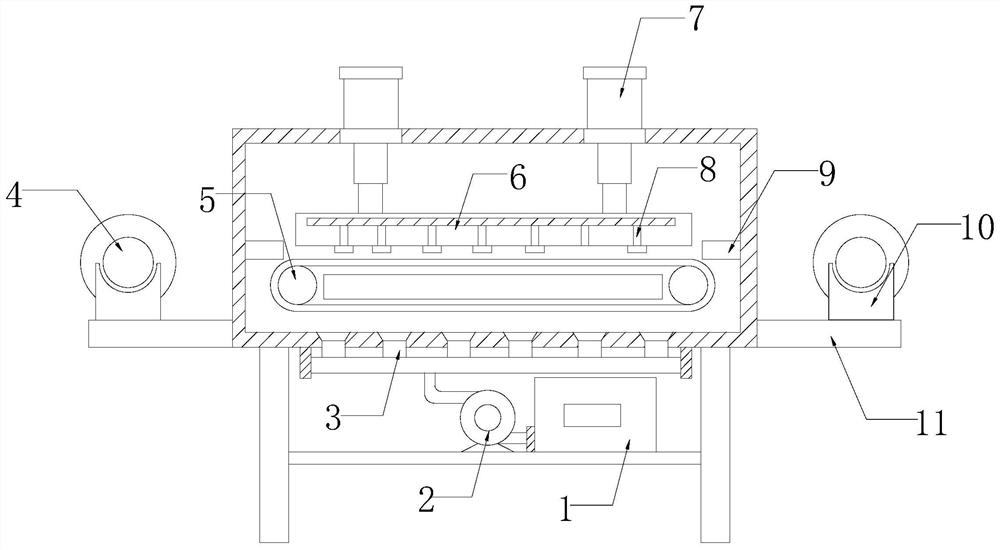

Textile fabric printing machine

InactiveCN112776467ARotation speed controlPrevent retractionRotary pressesOther printing apparatusTextile printerMechanical engineering

The invention discloses a textile fabric printing machine which structurally comprises a drying machine, a fan, an air outlet, a guiding roller, a conveying table, a printing rack, an ink storage cavity, a printing roller, a leveling device, a wind-up roll and a body. When the textile fabric printing machine is used after improvement, a textile fabric is guided node by node by matching a shear supporting part with an arc guide plate, the textile fabric moves to drive a rotating wheel to rotate, a friction pad is in contact with a pressing piece to generate resistance to control the rotating speed of the rotating wheel, the rotating wheel drives the pressing piece to rotate to output the textile fabric at a uniform speed. The textile fabric is stably compressed to the conveying table by a leveling rod, so that displacement due to movement of the equipment is avoided. The leveling rod rotates with the rotating wheel to convey the textile fabric circularly at a uniform speed to ensure uniform stress of the textile fabric to prevent the textile fabric from being pulled excessively, so that the printed textile fabric is protected and the printing efficiency of the textile fabric is improved.

Owner:刘钰婷

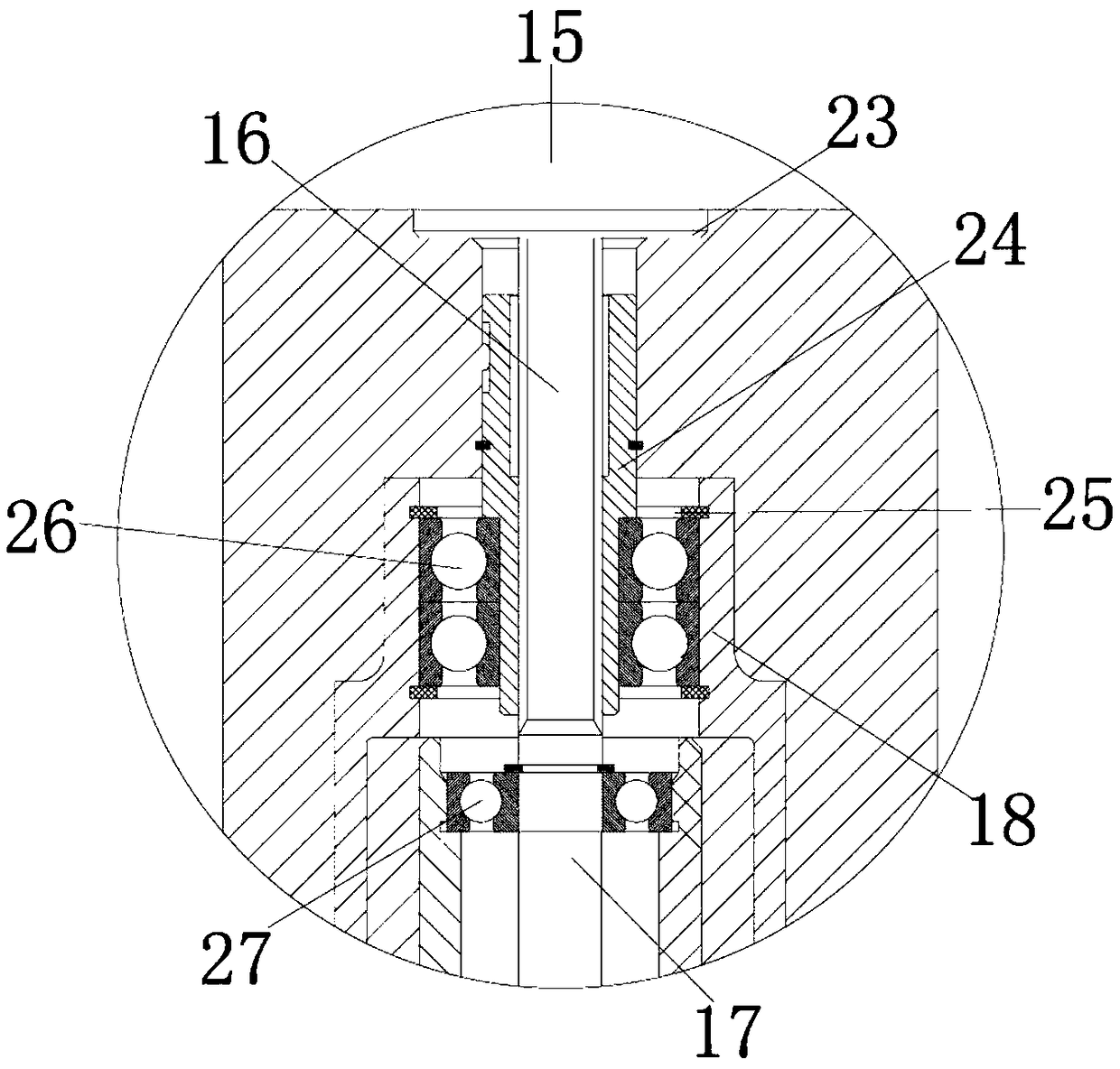

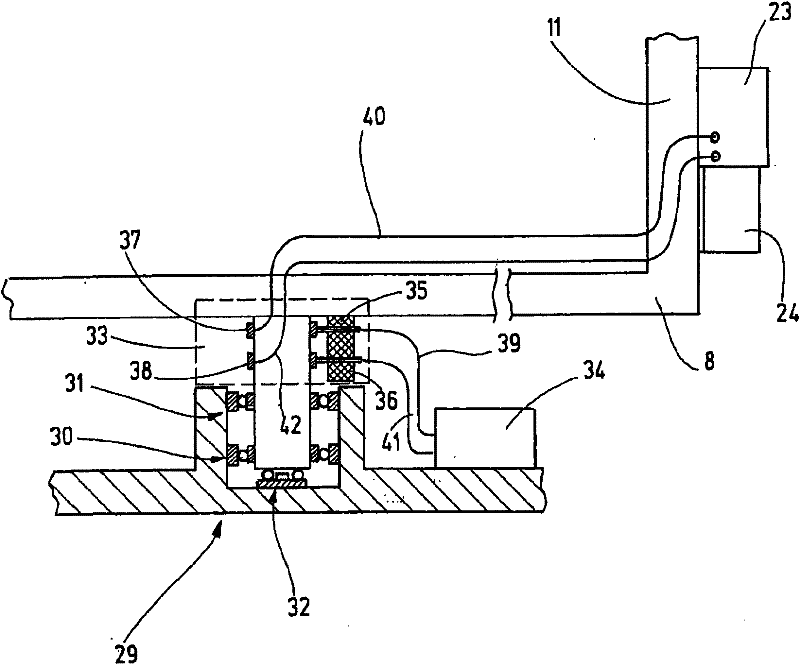

Fabric draw-off device

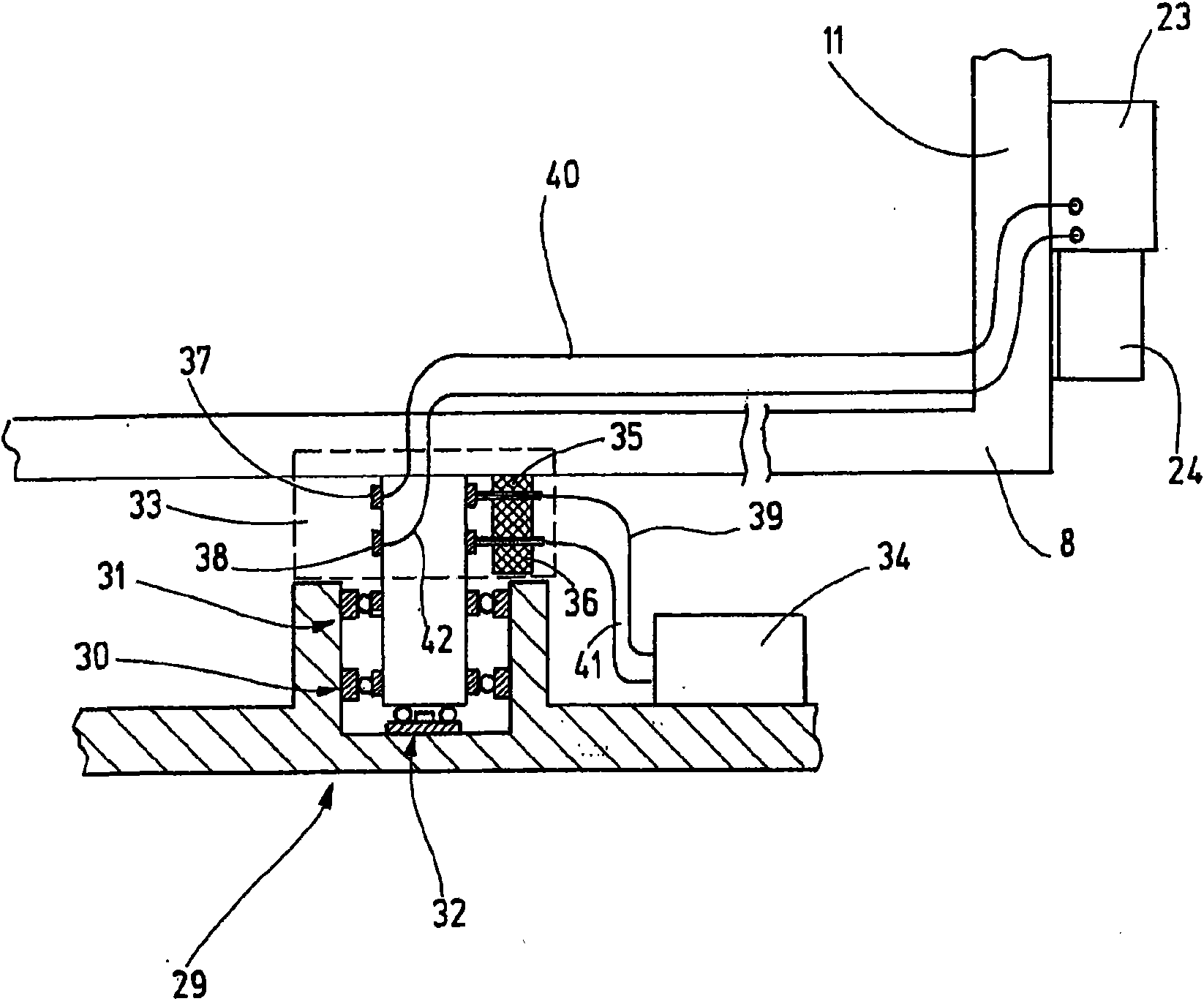

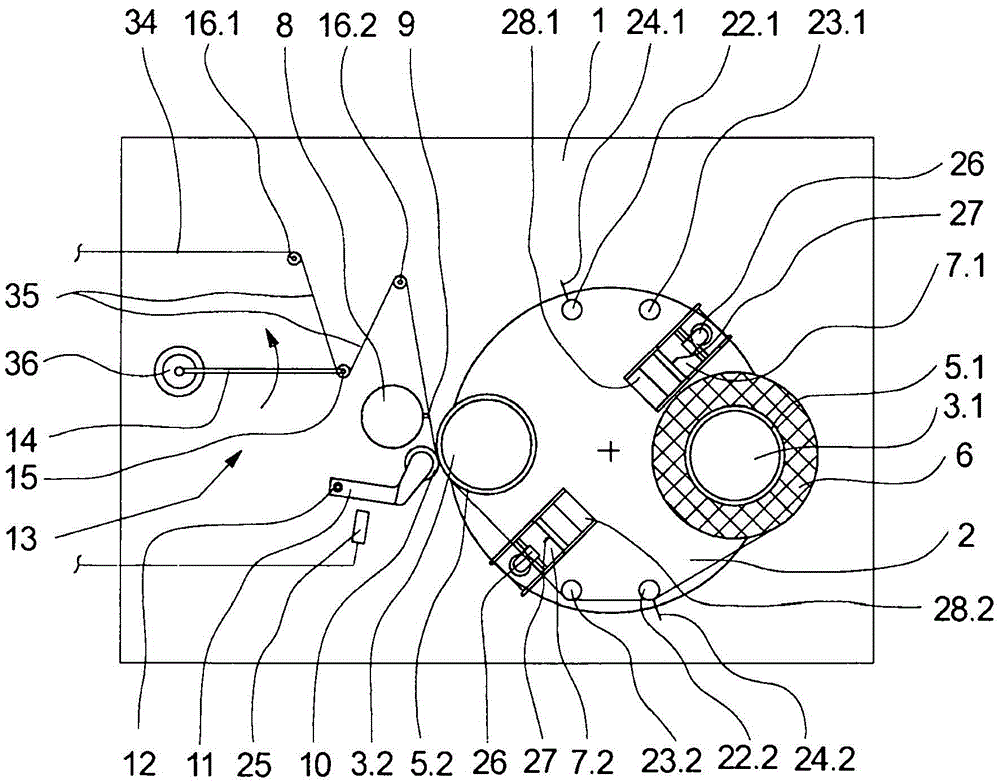

An electrically driven fabric draw-off device (7) is disclosed which uses at least one electric motor (16) for driving at least one draw-off roller (13, 14, 15). The electric power is supplied via a rotary electrical interface which electrically connects the motor (16) on rotating frame (8) to the stationary electric supply (34). The rotational movement of frame (8) is caused by another electric motor (26) which is driven in response to a signal indicating the rotational movement of the cylinder (3) of knitting machine (1).

Owner:MEMMINGER IRO GMBH

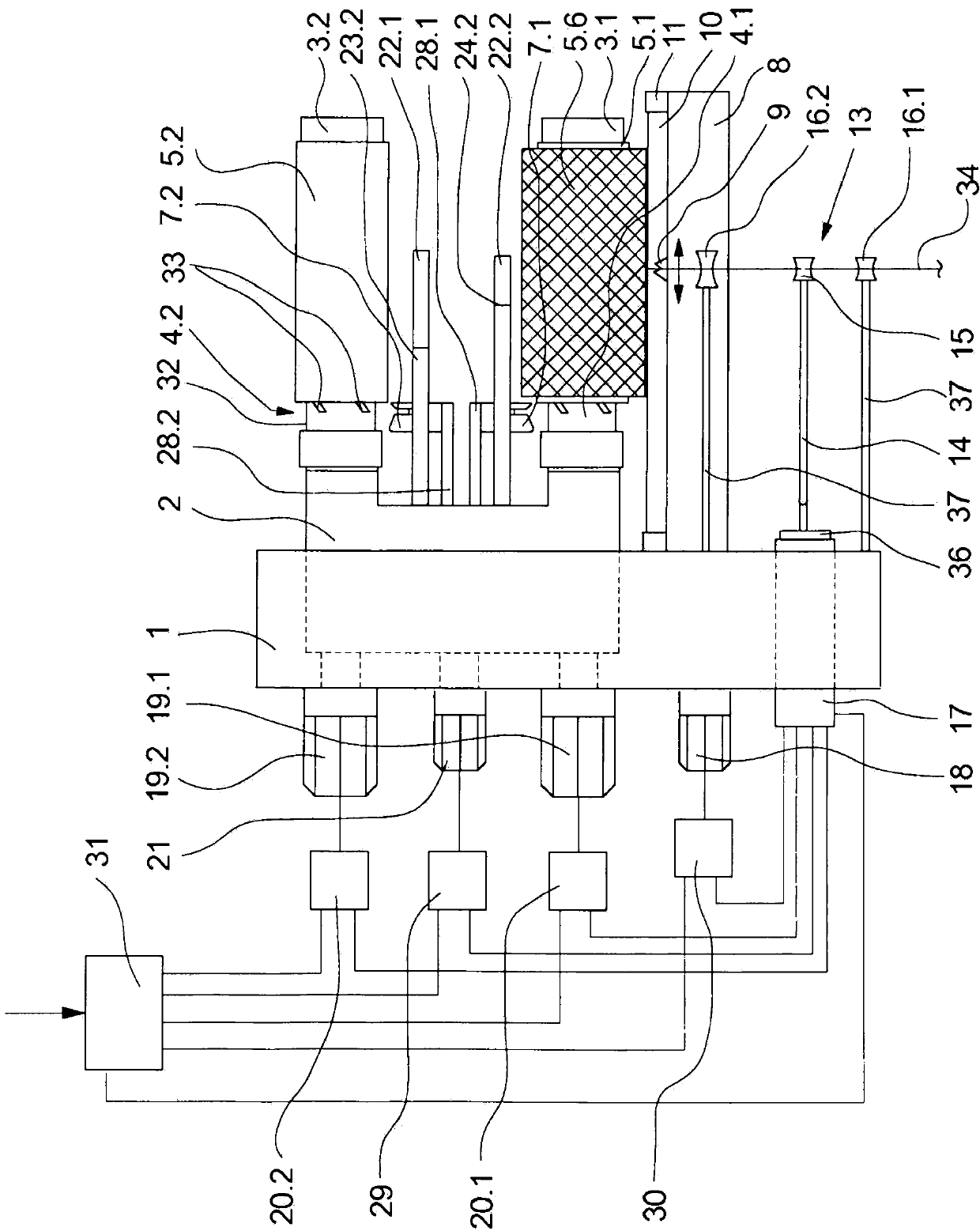

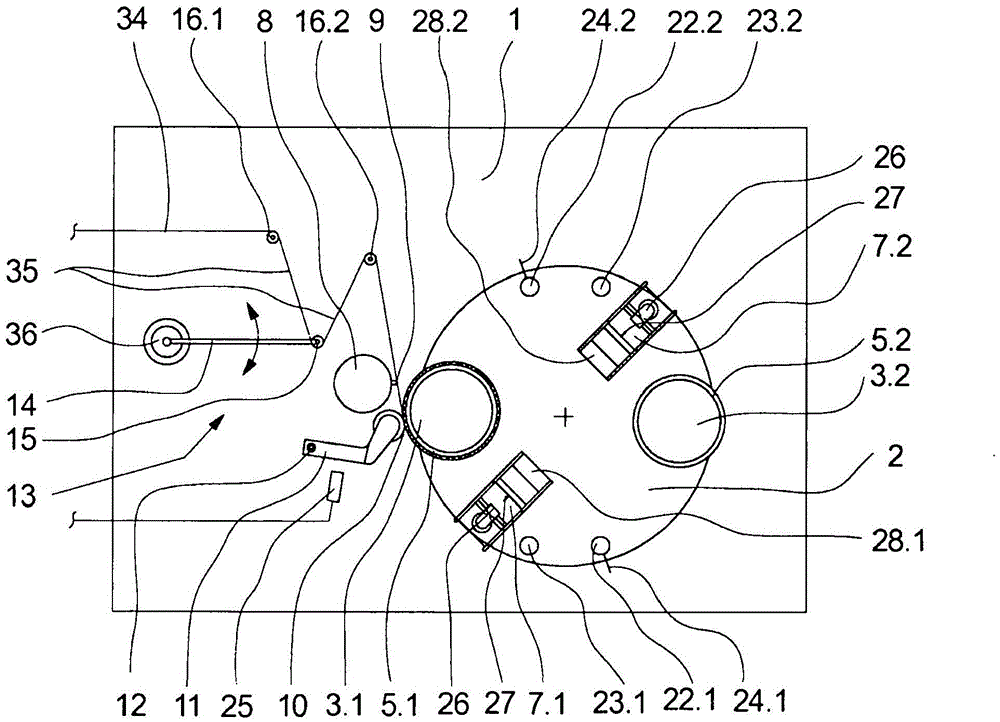

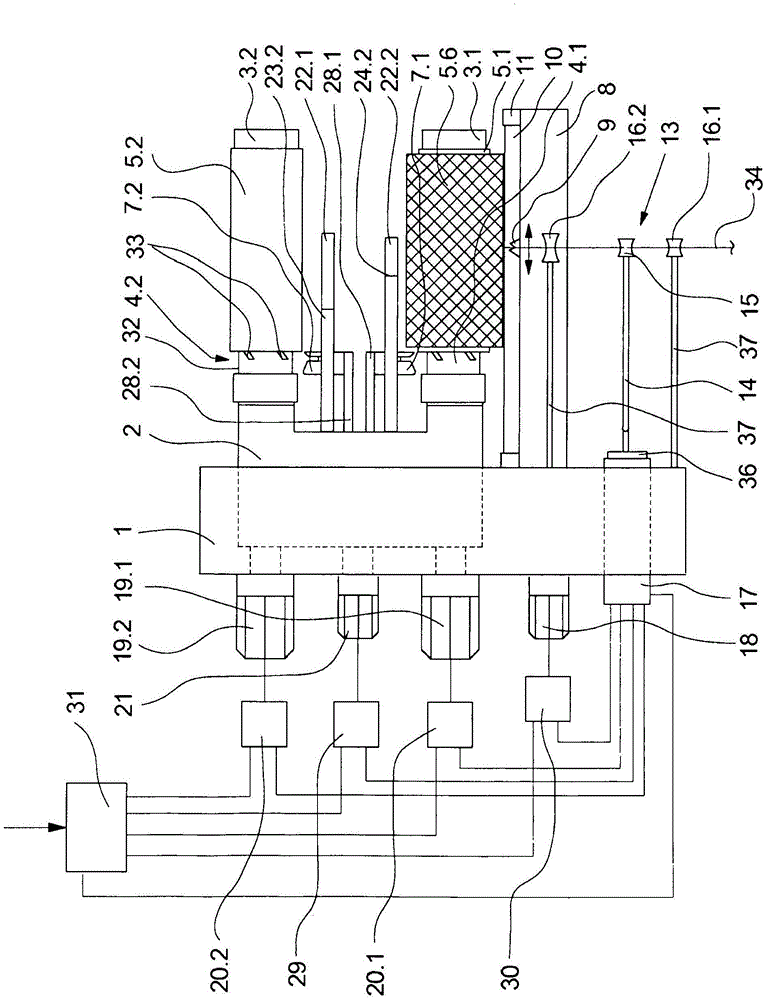

Method and device for continuously winding a strand-shaped winding material

InactiveCN103874644AChange controlChange rotational motionFilament handlingChange positionsConductor Coil

The invention relates to a method and to a device for continuously winding a strand-shaped winding material (34) into spools (6). The spools (6) are alternately wound on two winding spindles (3.1, 3.2) retained on a winding revolver (2), wherein the winding spindles (3.1, 3.2) are driven by two separate spindle drives (19.1, 19.2). In order to maintain a constant winding speed during the winding of the spools, a movable jockey arm (14) of a jockey arm apparatus (13) is provided, which jockey arm produces a loop having a slack (35) on the fed winding material (34). The slack of the loop of the winding material is used to control a spindle rotational speed of one of the winding spindles. The winding spindles are arranged on a winding revolver that, by means of a rotational motion, guides the winding spindles alternately between a changing position and an operating position for transferring the winding material. According to the invention, in order to ensure an even acceptance of the fed winding material during a changing phase, a rotational motion or a rotational speed of the winding revolver is controlled according to the slack of the loop of the winding material. For that purpose, the revolver drive (21) of the winding revolver (2) is coupled to a rotational-speed control unit (17) of the jockey arm apparatus (13).

Owner:STC二捻股份有限公司

Fabric draw-off device

InactiveCN102007241BRotation speed monitoringRotation speed controlWeft knittingEngineeringElectric power

An electrically driven fabric draw-off device (7) is disclosed which uses at least one electric motor (16) for driving at least one draw-off roller (13, 14, 15). The electric power is supplied via a rotary electrical interface which electrically connects the motor (16) on rotating frame (8) to the stationary electric supply (34). The rotational movement of frame (8) is caused by another electric motor (26) which is driven in response to a signal indicating the rotational movement of the cylinder (3) of knitting machine (1).

Owner:MEMMINGER IRO GMBH

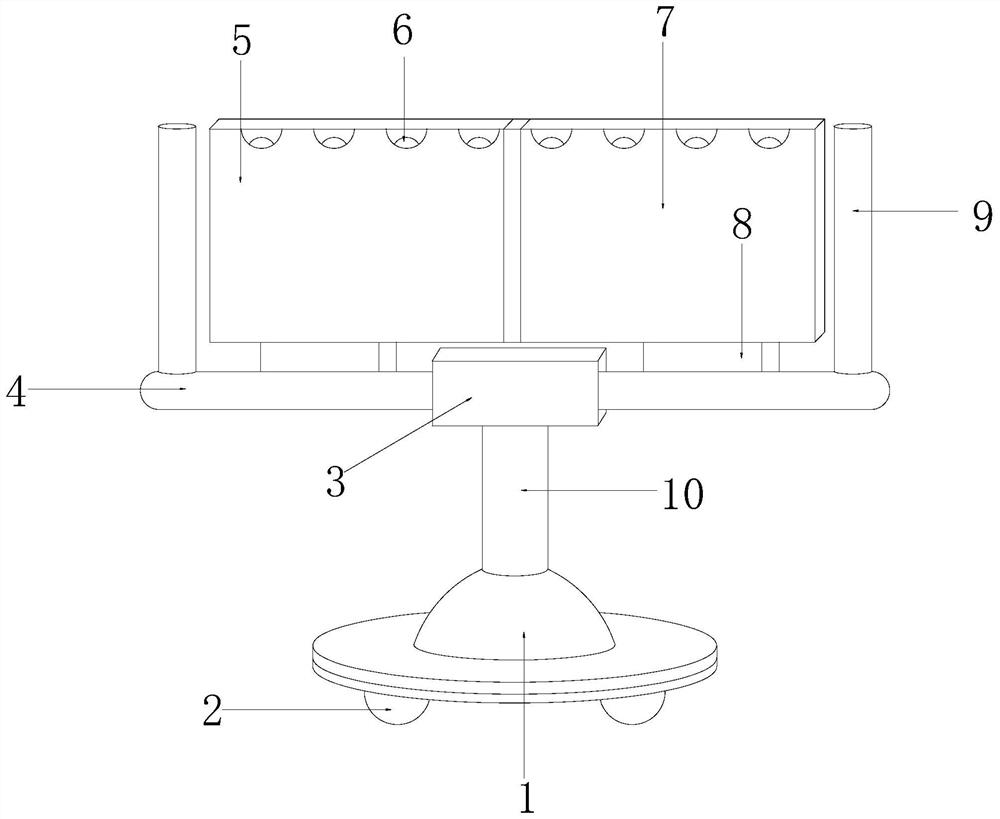

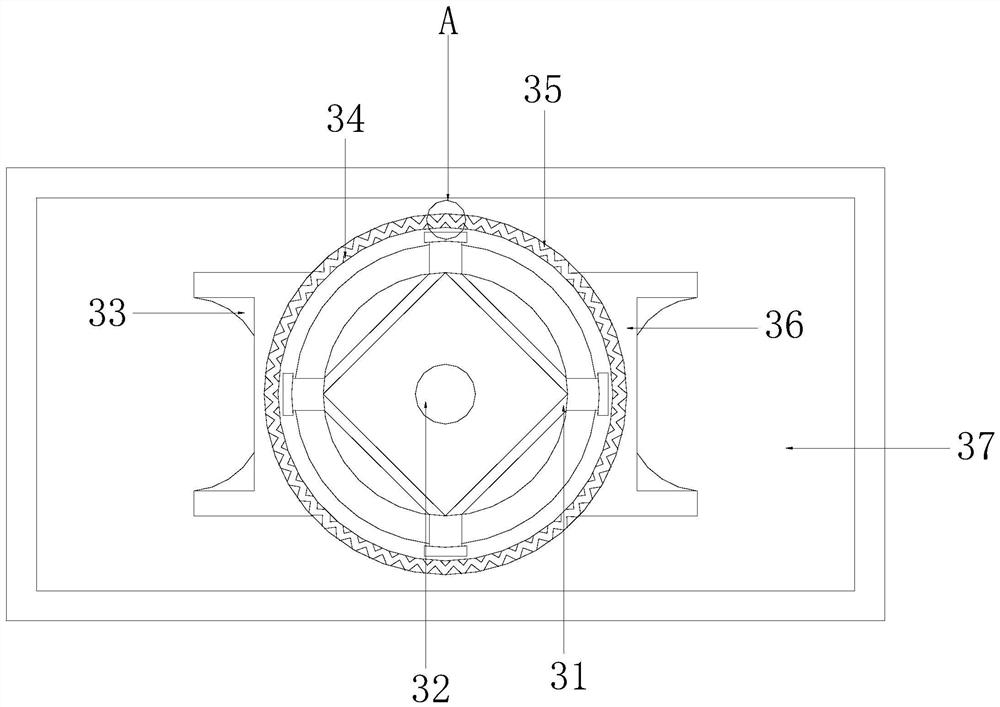

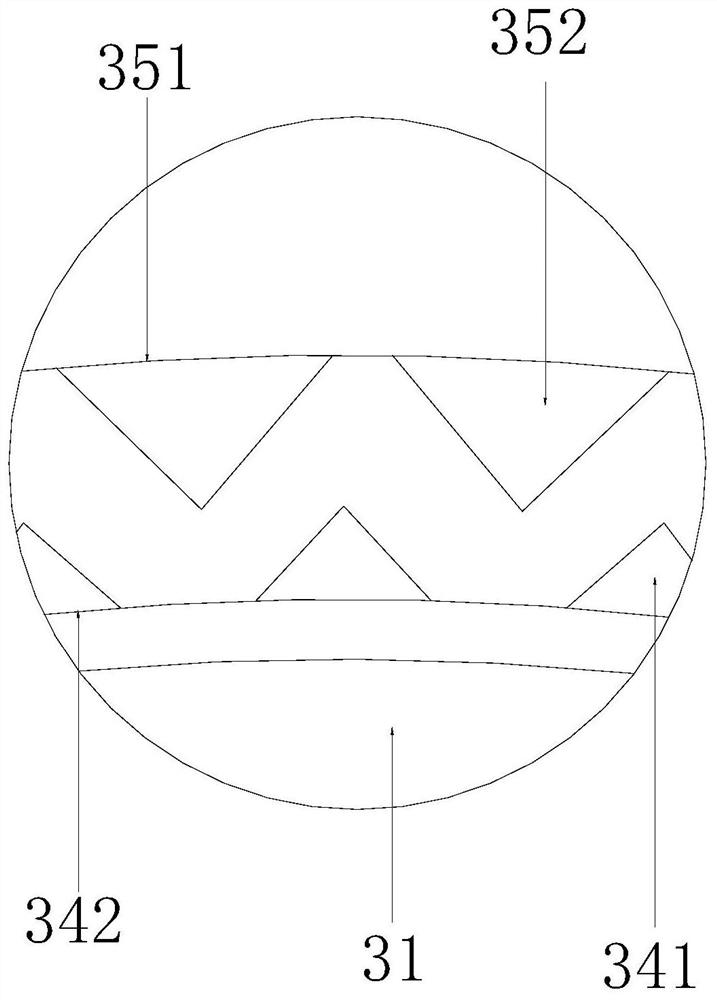

Imaging department film reader

The invention discloses an imaging department film reader which structurally comprises a base, universal wheels, an adjusting device, a fixing frame, a left film reading screen, an illuminating lamp, a right film reading screen, a clamping seat, a blocking rod and a positioning rod; when the imaging department film reader is used after improvement, the left film reading screen and the right film reading screen are spliced together in a matched mode, so a doctor can arrange a plurality of image films on the left film reading screen and the right film reading screen in parallel, the image films can be compared and observed, and the illness state of a patient can be quickly understood; the doctor holds a blocking rod to apply force, the moving angle of a fixing frame is adjusted through cooperation of a receiving disc and an extrusion elastic block, after the moving angle is adjusted to a certain angle, the position of the extrusion elastic block is limited through a triangular supporting plate, and it is guaranteed that the fixing frame can be stably positioned at the adjusted position, so a doctor can quickly point the situation observed by the images to a patient or family members to see, and the usability of the radiograph reading device and the disease diagnosis efficiency of the doctor for the patient are improved.

Owner:刘雪萍

Release film winding and recycling device with deviation rectifying structure

InactiveCN112678583AAvoid offsetSolve the effect of not having the effect of preventing the offset of the release filmCleaning using toolsWebs handlingReduction driveElectric machinery

The invention discloses a release film winding and recycling device with a deviation rectifying structure. The release film winding and recycling device comprises a frame, wherein vertical plates are fixedly connected to the left side and the right side of the frame; winding rods are arranged on the inner sides of the vertical plates, and the left ends and the right ends of the winding rods penetrate through the vertical plates and are movably connected with the vertical plates through bearings; and speed reducers are fixedly connected to the left sides of the vertical plates, the bottoms of the speed reducers are fixedly connected with transmission motors, and the output ends of the speed reducers are fixedly connected with the left ends of the winding rods. According to the release film winding and recycling device with the deviation rectifying structure, a rotating wheel drives a screw rod to rotate, threads on the surface are used for driving an adjusting plate to ascend, the distance between the adjusting plate and the winding rods can be increased, and stretching rollers can tension a release film wound around the surfaces of the winding rods, so that the release film is prevented from deviating due to loosening, and the problem that the percent of pass of the release film is seriously affected due to the fact that the inclined protruding part of the release film can be damaged due to transportation extrusion after the release film is wound at will due to the fact that an existing winding device does not have the effect of preventing the release film from deviating is solved.

Owner:李丽荣

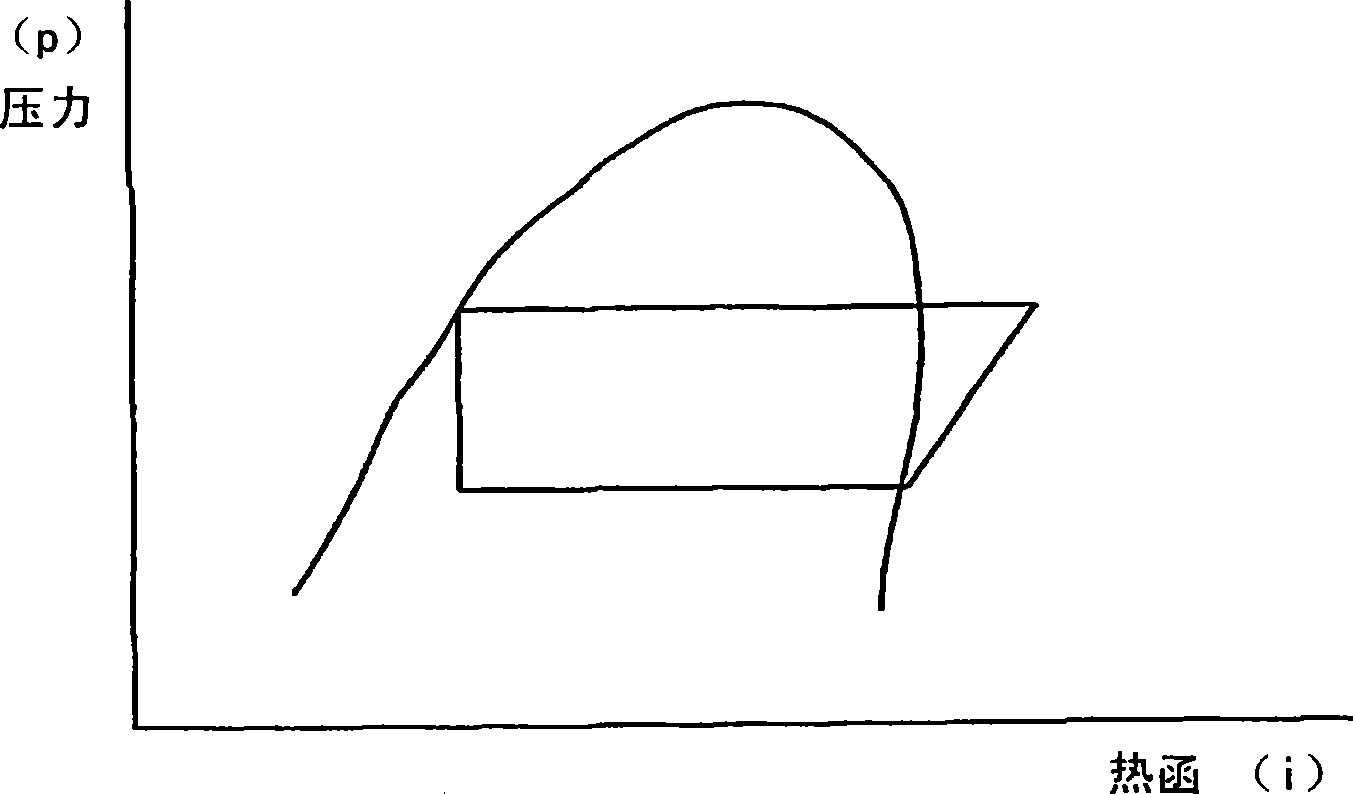

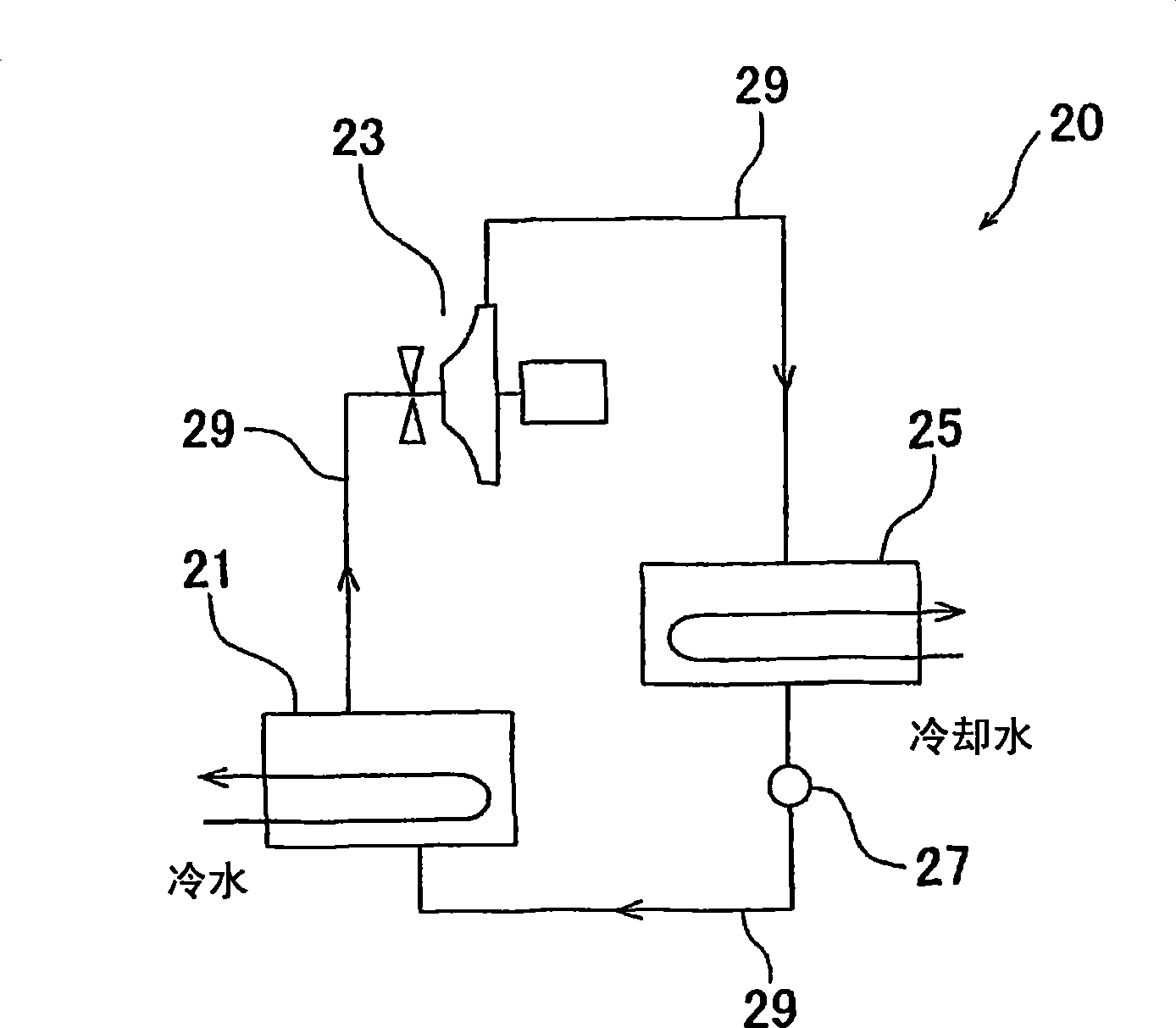

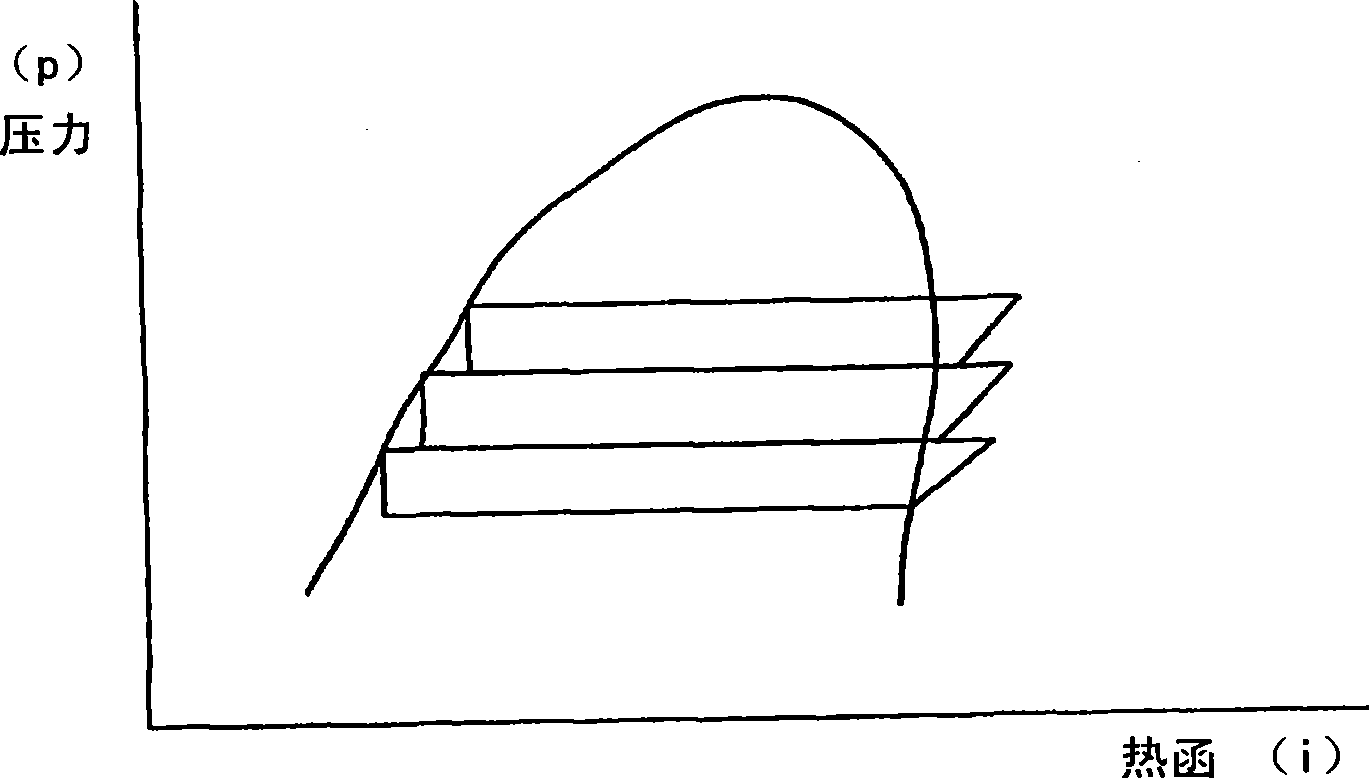

Refrigeration apparatus

InactiveCN101371082AImprove overall efficiencyRealize the compressor structureCompression machines with non-reversible cycleCompression machines using turbinesRefrigerantEvaporator

The invention relates to a cooling apparatus having multiple refrigeration units (20-1, 20-2) each including evaporator (21-1, 21-2) structured to deprive cold water of heat and cause a refrigerant to evaporate, thereby exerting refrigerating effect; compressor (23-1, 23-2) for compressing of refrigerant vapor into high-pressure vapor; and condenser (25-1, 25-2) for cooling of the high-pressure vapor with cooling water to thereby achieve condensation. The cold water is connected in series with the evaporators (21-1,21-2) of the multiple refrigeration units (20-1, 20-2), and is sequentially cooled by the heat of evaporation of the refrigerant of the multiple evaporators (21-1, 21-2). The cooling water is connected in series with the condensers (25-1, 25-2) of the multiple refrigeration units (20-1, 20-2), and sequentially cools the refrigerant of the multiple condensers (25-1, 25-2).

Owner:EBARA CORP

Method and apparatus for continuously winding bobbin material in strand form

The invention relates to a method and to a device for continuously winding a strand-shaped winding material (34) into spools (6). The spools (6) are alternately wound on two winding spindles (3.1, 3.2) retained on a winding revolver (2), wherein the winding spindles (3.1, 3.2) are driven by two separate spindle drives (19.1, 19.2). In order to maintain a constant winding speed during the winding of the spools, a movable jockey arm (14) of a jockey arm apparatus (13) is provided, which jockey arm produces a loop having a slack (35) on the fed winding material (34). The slack of the loop of the winding material is used to control a spindle rotational speed of one of the winding spindles. The winding spindles are arranged on a winding revolver that, by means of a rotational motion, guides the winding spindles alternately between a changing position and an operating position for transferring the winding material. According to the invention, in order to ensure an even acceptance of the fed winding material during a changing phase, a rotational motion or a rotational speed of the winding revolver is controlled according to the slack of the loop of the winding material. For that purpose, the revolver drive (21) of the winding revolver (2) is coupled to a rotational-speed control unit (17) of the jockey arm apparatus (13).

Owner:STC二捻股份有限公司

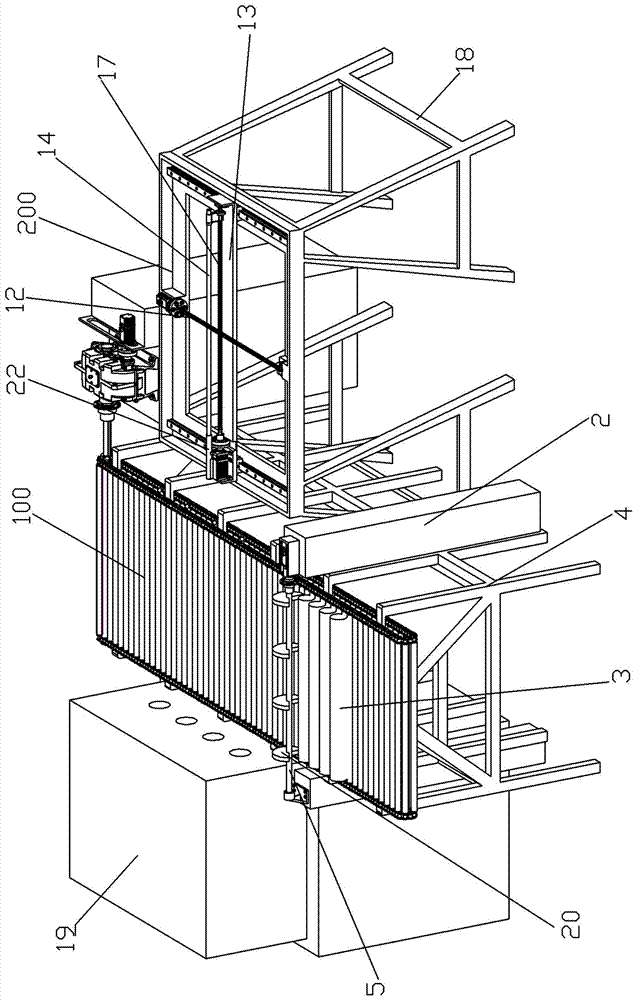

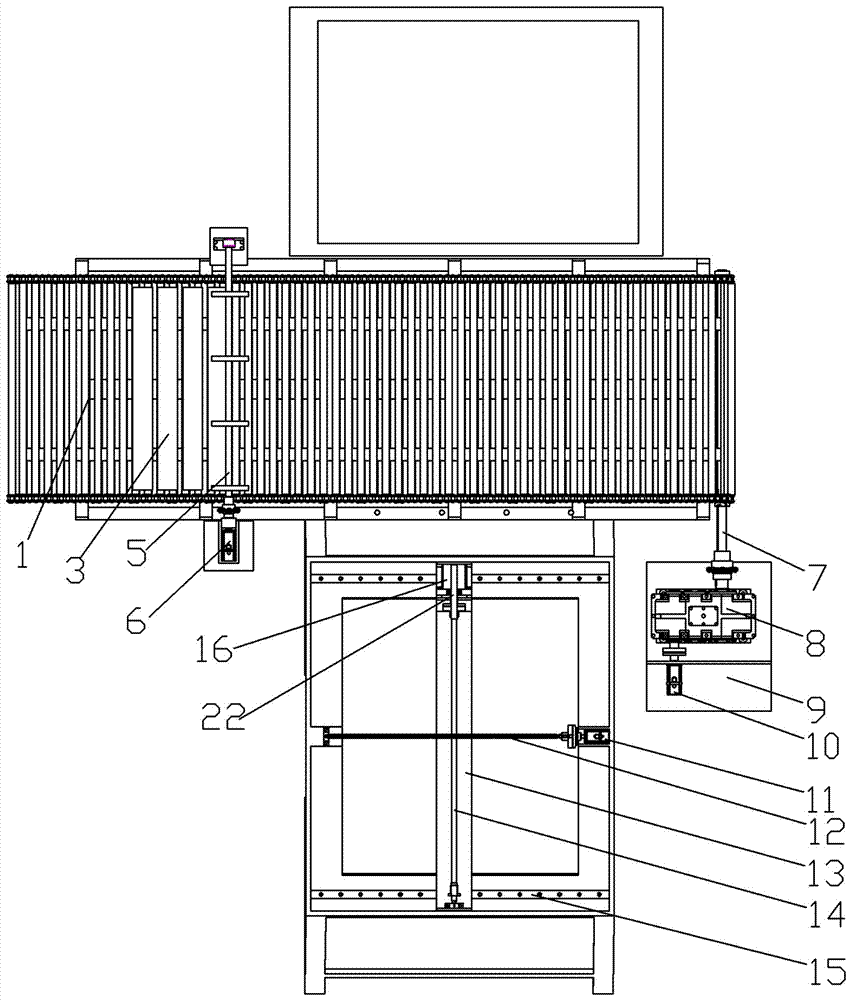

Welding conveying assembly for giant iron tower steel frame machining

ActiveCN113478135ADelivery will not affectAvoid tail liftWelding/cutting auxillary devicesAuxillary welding devicesSteel frameMechanical engineering

The invention relates to the technical field of iron tower steel frame machining equipment, in particular to a welding conveying assembly for giant iron tower steel frame machining, the welding conveying assembly comprises a base, a conveying structure is arranged on the base, a supporting structure is arranged at one end of the base, a fixing structure is arranged on the lifting structure, and a jacking structure is mounted on the base. A pressing structure is mounted on the base, a rotating structure is mounted on the base, a lifting structure is mounted on the rotating structure, and a driving structure is arranged at one end of the lifting structure; and through the arrangement of the jacking structure, when a conveyed steel pipe needs to be rotationally welded, the steel pipe can be jacked up and rotated, rotary welding is facilitated, the jacking structure can synchronously drive the pressing structure to work while carrying out jacking action, and through the work of the pressing structure, the outside of the steel pipe can be laterally pressed while the steel pipe is jacked up.

Owner:徐州金尊机械有限公司

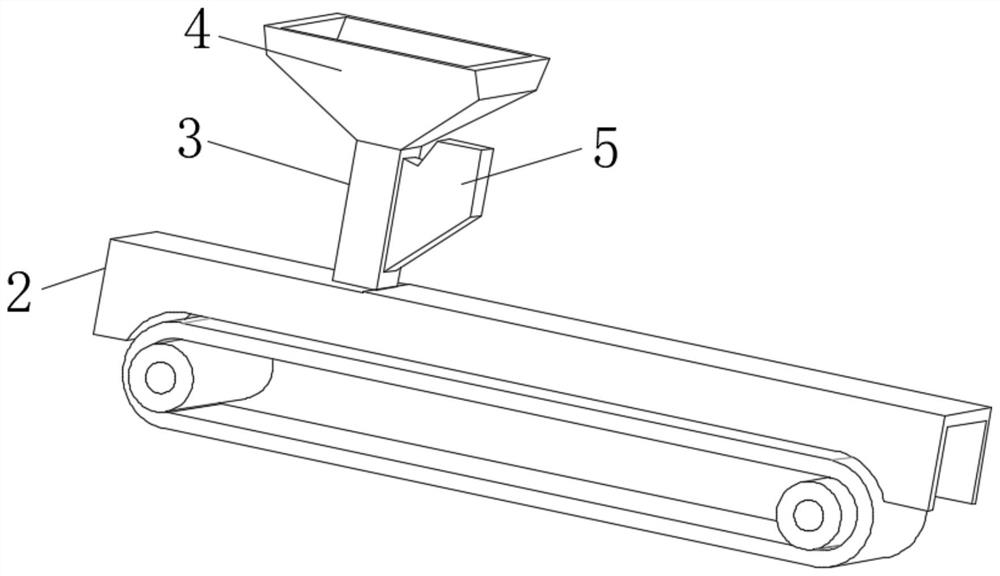

Transport device for cement production

InactiveCN111824793APrevent fallingRotation speed controlLoading/unloadingClassical mechanicsConveyor belt

The invention relates to the technical field of cement production, in particular to a transport device for cement production. The device comprises a conveyor belt, an outer cover, a square cylindricalslide rail, a funnel housing and a control board, the gate-shaped outer cover in a bent plate shape is arranged at the upper end of the conveyor belt, the upper end of the outer cover is fixedly connected with the slide rail, the slide rail penetrates through a shell of the outer cover, the upper end of the slide rail is fixedly connected with the funnel housing, one side of the slide rail is fixedly connected with the control board, and the control board penetrates through a shell of the slide rail. The structural design of the device achieves that falling materials in the slide rail drive asquare plate to rotate, the square plate is intercepted by a clamping block, and the rotation speed of the square plate can be controlled, so that excessive materials are prevented from falling on the conveyor belt, the stable conveying work of the conveyor belt is ensured, wrench tools can be used to turn a control rod to directly adjust the expansion frequency of a telescopic column and the clamping block, and the rotation speed of the square plate is directly changed.

Owner:沈辉

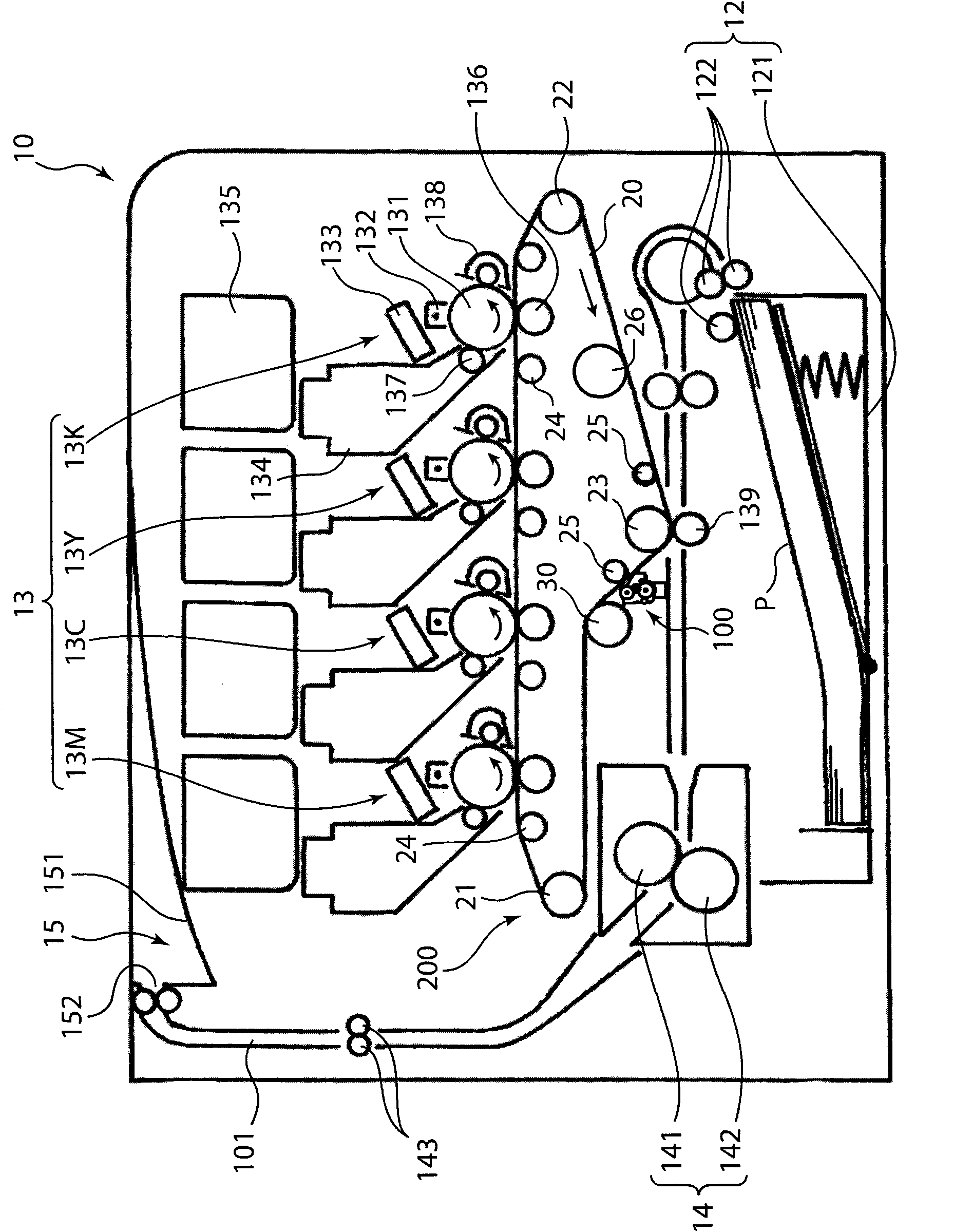

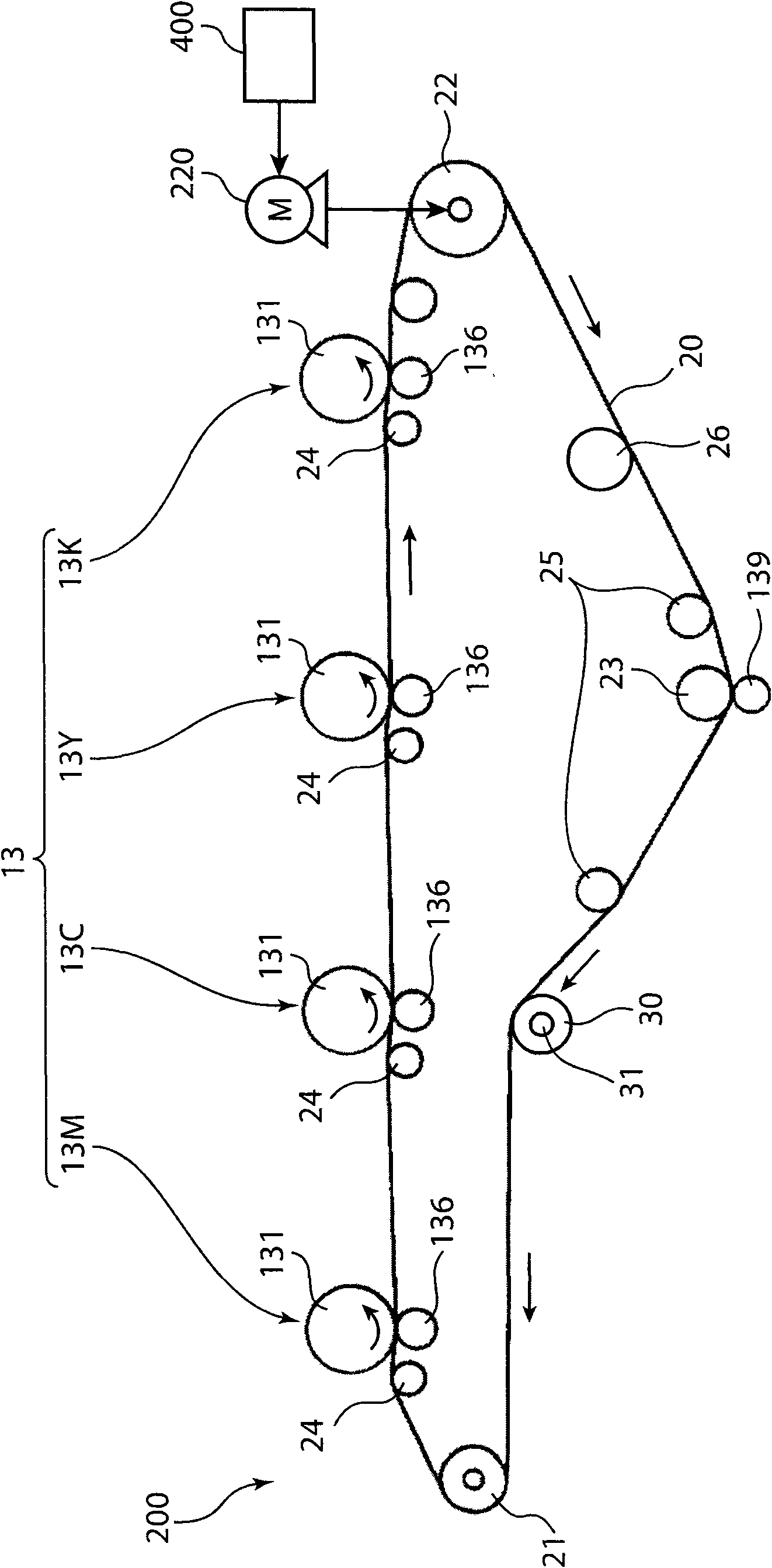

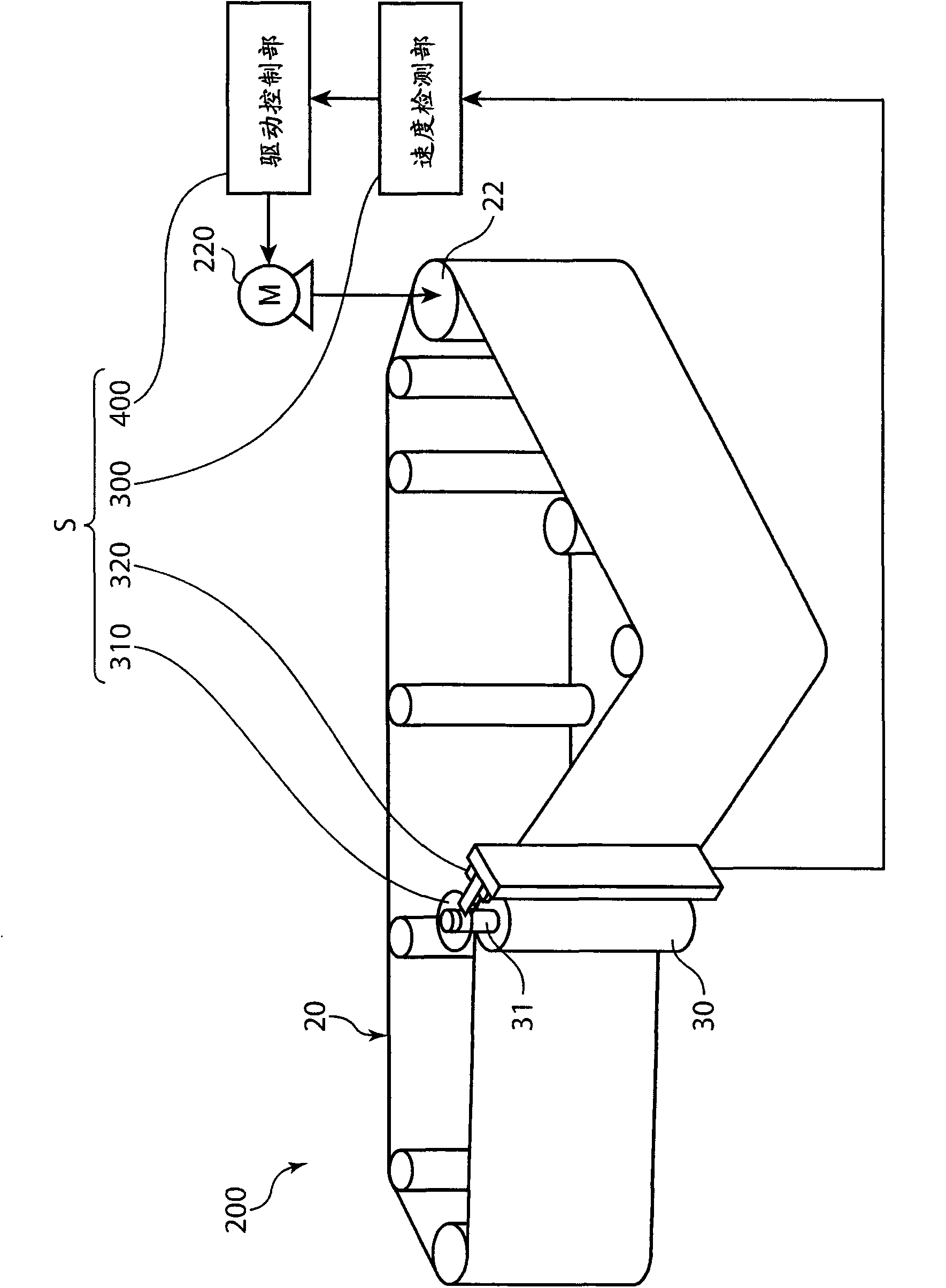

Image forming apparatus

InactiveCN101598914ARotation speed controlAccurate transferElectrographic process apparatusImage formationEngineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

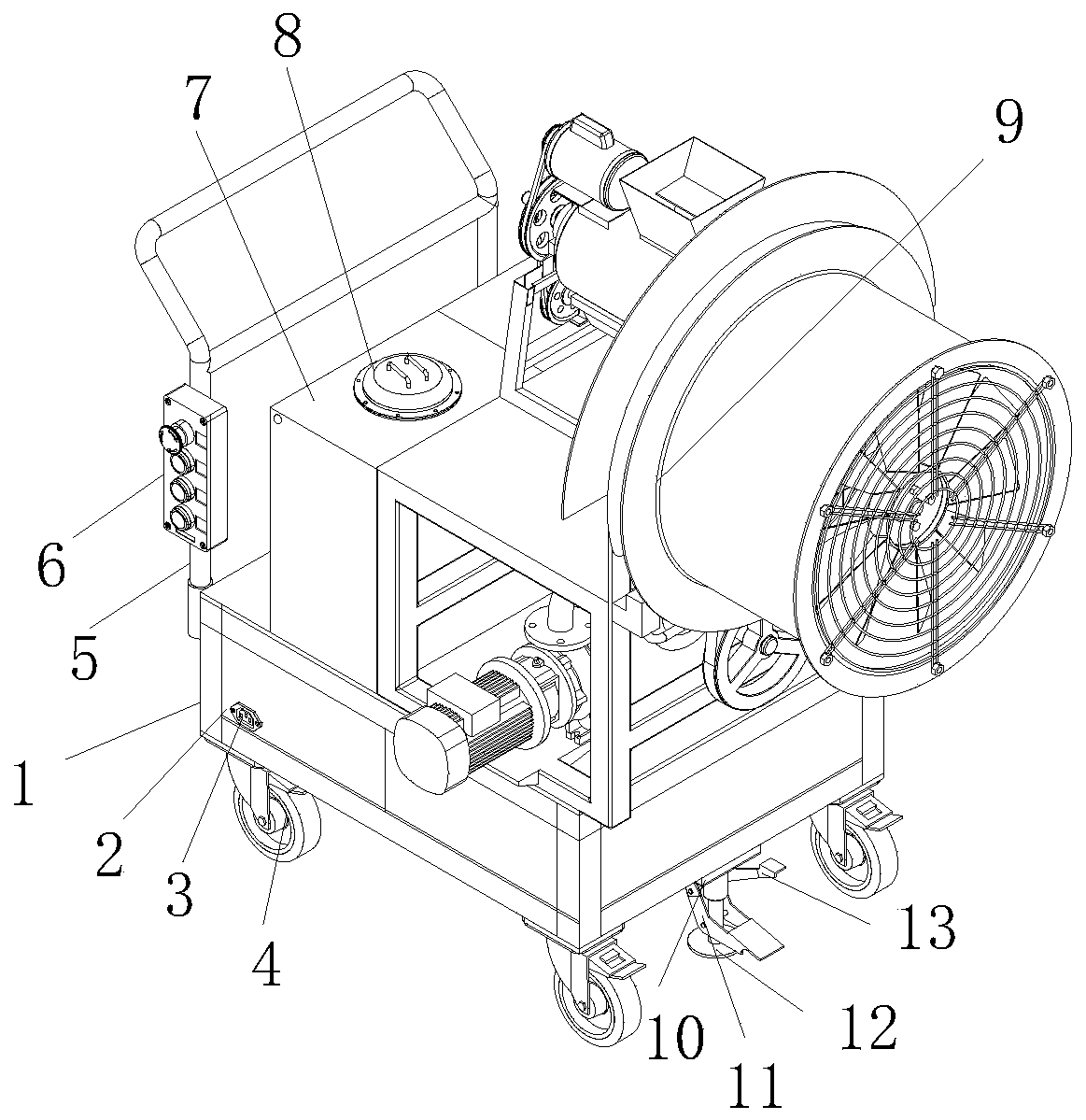

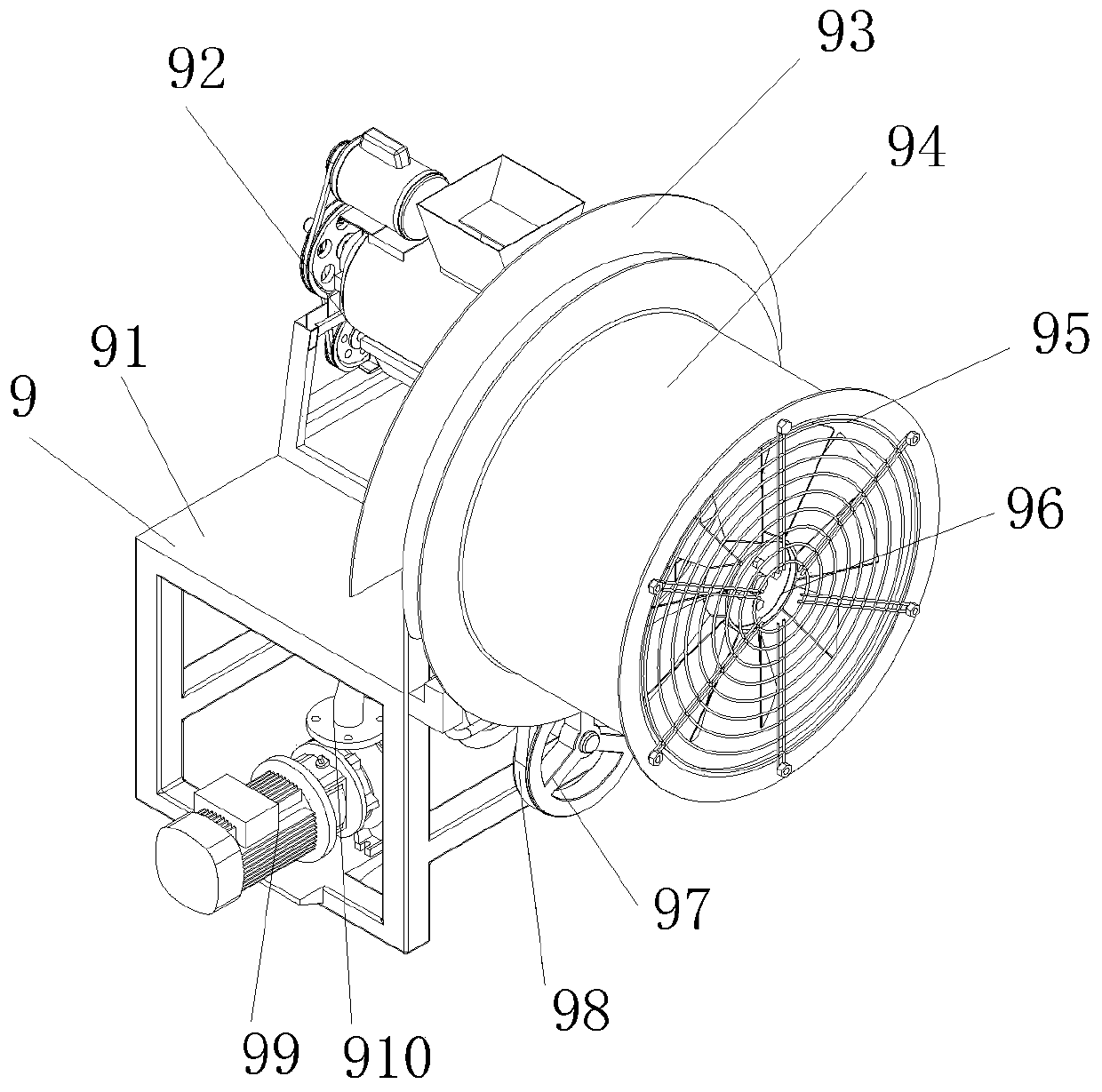

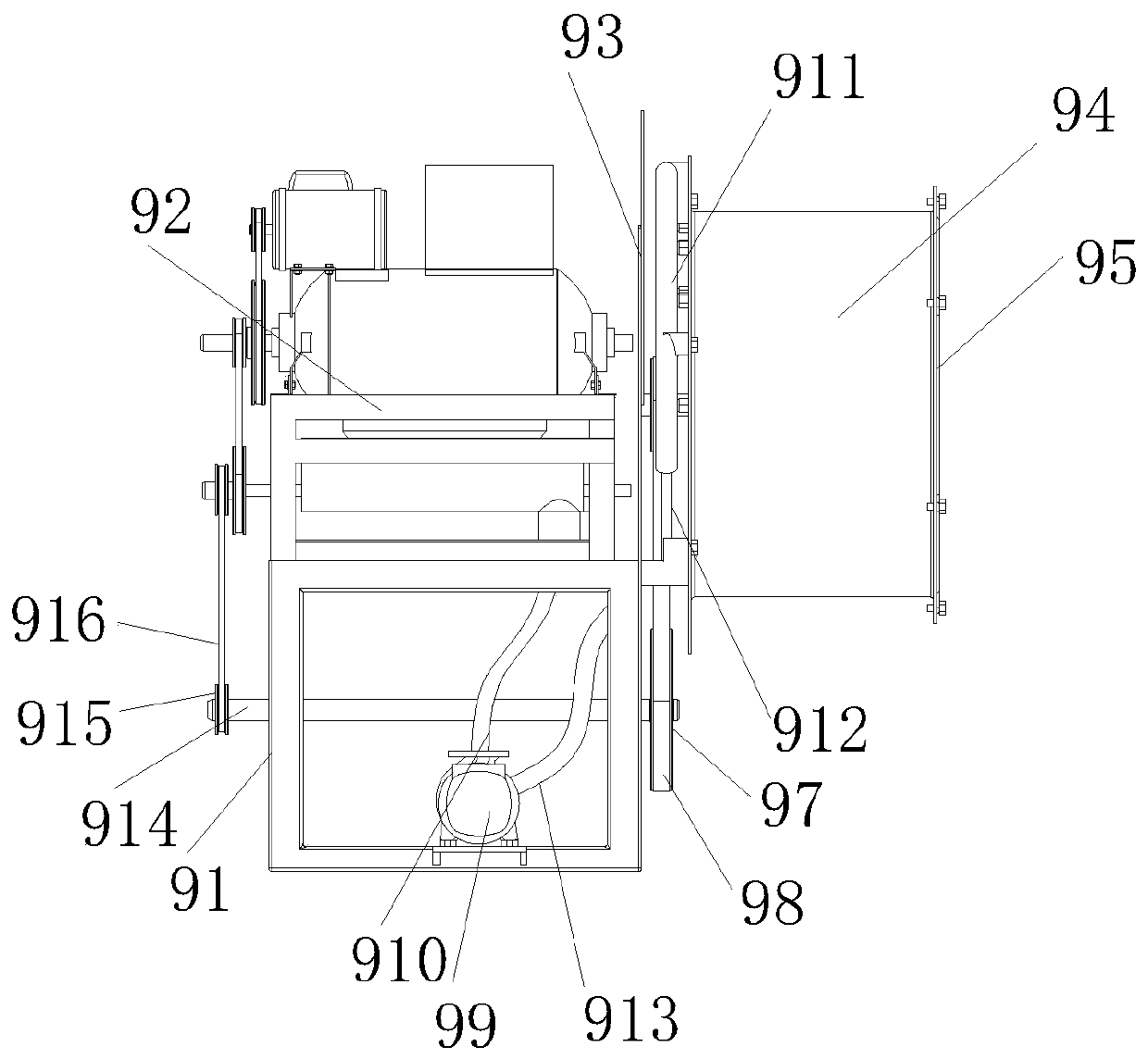

Mobile atomizing machine for forestry seedling protection

InactiveCN110771334AReduce manual operationsImprove work efficiencyRotary stirring mixersTransportation and packagingForest industryAgricultural science

The invention discloses a mobile atomizing machine for forestry seedling protection. The mobile atomizing machine comprises bottom frame, a storage battery, a power port, rolling wheels, a push frame,a controller, a storage tank, a top cover, a supporting column, a linkage part, a base plate and a pressure part. By mounting of a spraying device at the top right end of the bottom frame, water andneeded fertilizers are injected at the same time to realize quick blending, and then fertilizer water is pressurized and atomized prior to being quickly sprayed by fan blades in high-speed rotation. By integration of multiple steps, manual operations can be reduced effectively, operating efficiency is improved, and problems of operating efficiency reduction and labor cost increase caused by the fact that fertilizers or some pesticides need to be dispersed by manual stirring prior to being injected into an atomizing device and atomized semi-automatically or manually are solved.

Owner:泉州泉港聚业工业设计有限公司

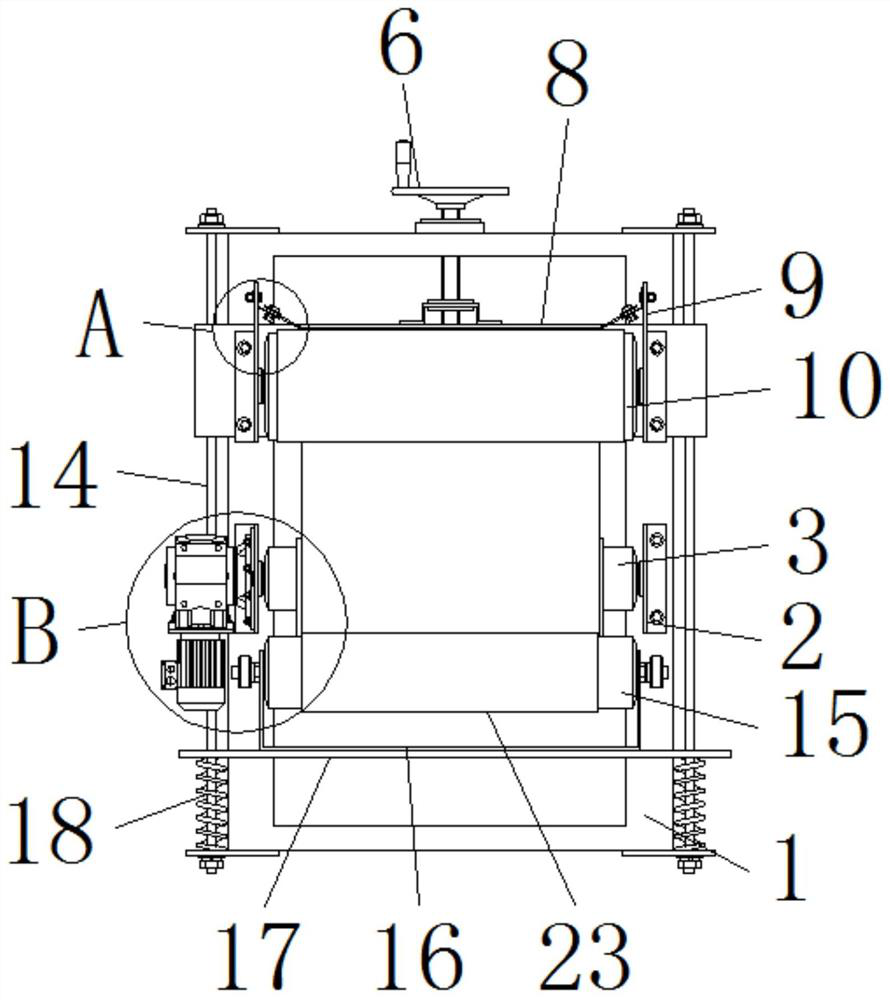

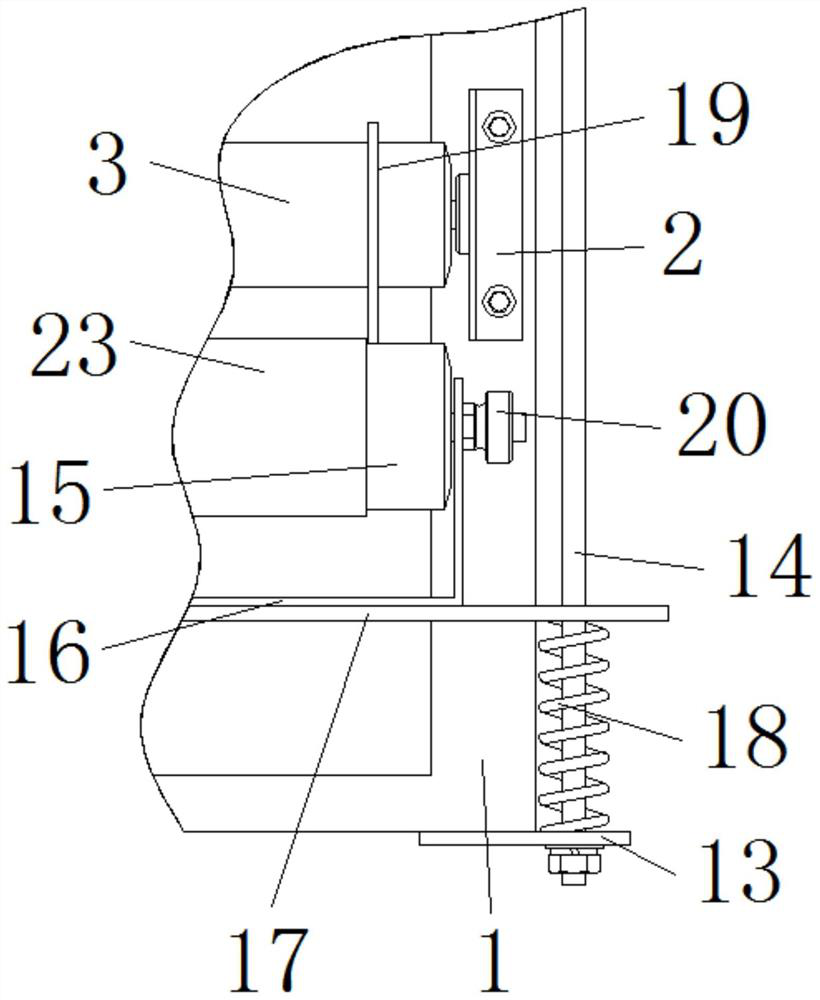

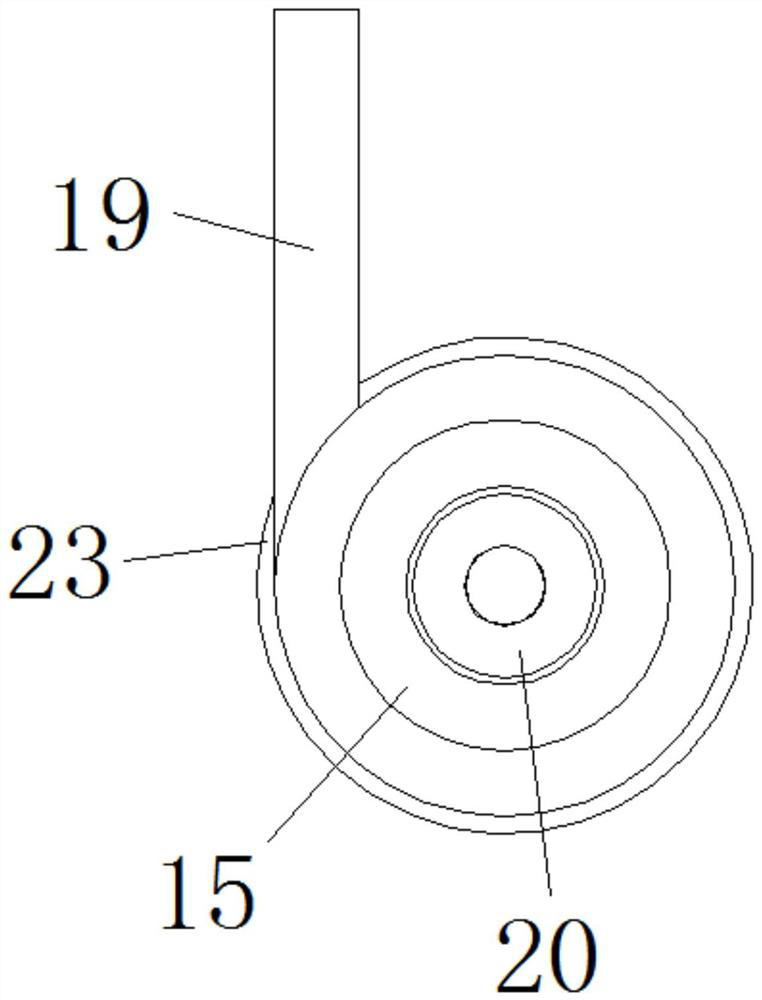

Energy-saving and environment-friendly steel smelting processing device

InactiveCN113731044AEasy to solveAvoid bendingDispersed particle filtrationProcess engineeringWaste management

The invention discloses an energy-saving and environment-friendly steel smelting processing device which comprises a stable bottom plate, a mounting bracket is fixedly connected to the middle position of the left side of the top of the stable bottom plate, a storage box is slidably connected to the middle position of the bottom of an inner cavity of the mounting bracket, and processing devices are rotatably connected to the middle positions of the two sides of the top of the mounting bracket; a controller is fixedly connected to the top of the right side of the front face of the mounting bracket, and a supporting frame is fixedly connected to the middle position of the right side of the top of the stable bottom plate. The invention belongs to the technical field of steel smelting. According to the energy-saving and environment-friendly steel smelting processing device, the situation that steel and iron are scattered during collection is not prone to occurring, residues and hot air are separated through a separator, the residues and the hot air are prevented from entering the device together, and the rotating speed of a smelting main body is conveniently controlled; and the situation that residues are increased due to uneven heating during internal smelting caused by the situation that the device rotates fast and slowly is avoided, and the machining efficiency of the device can be improved.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

Building construction pay-off liming device

InactiveCN111648610ARotation speed controlConvenient whereaboutsRoads maintainenceBuilding material handlingDrive wheelArchitectural engineering

The invention is suitable for the technical field of building devices and provides a building construction pay-off liming device. The building construction pay-off liming device comprises a vehicle board; a first supporting plate and a second supporting plate are arranged at the bottom of the vehicle board; a driving wheel and a driven wheel are correspondingly mounted on the first supporting plate and the second supporting plate; a first bearing is embedded in the top wall of a lime filling box; a rotating shaft is mounted on the first bearing; a rotating rod is connected to the bottom end ofthe rotating shaft; a threaded groove is formed in the side surface of the rotating rod; and a driving component used for driving the rotating shaft to operate is arranged on the vehicle board. According to the building construction pay-off liming device, by using a push handle to push the device and using rotation of the driving wheel as power, the rotating shaft and the rotating rod are drivento rotate, limes in the lime filling box enter into the threaded groove in the side surface of the rotating rod, and the limes are enabled to move down with continuous rotating of the rotating rod andfinally fall off from a lime dropping pipe; and by using a rotation speed of the driving wheel, a rotation speed of the rotating rod is controlled to control a material dropping speed so that the limes are uniformly spread.

Owner:刘少荣

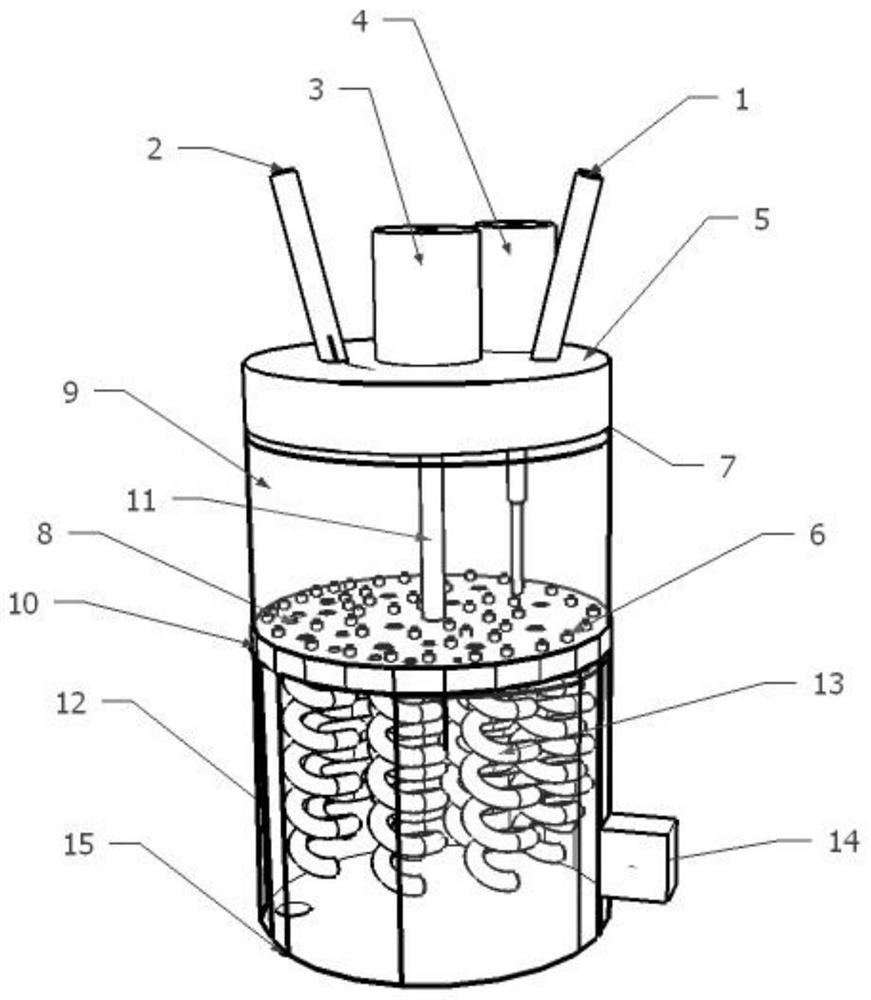

Rotary ultrasonic-microwave combined microfluid extraction equipment

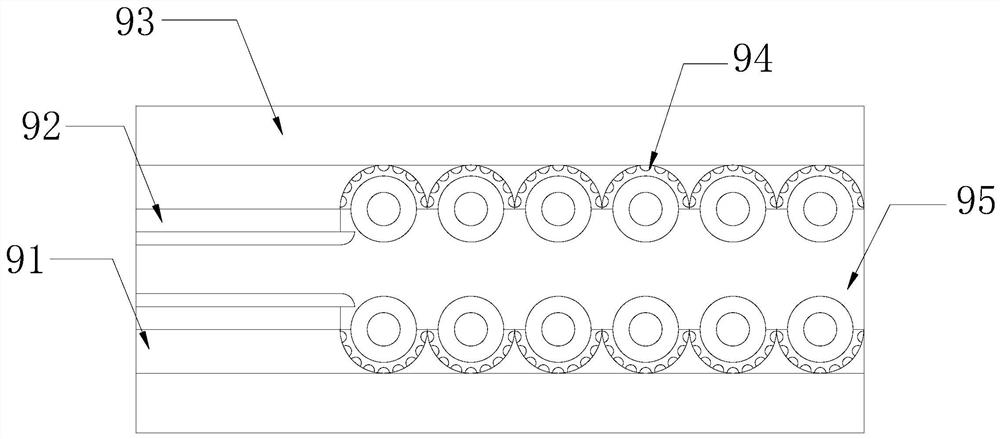

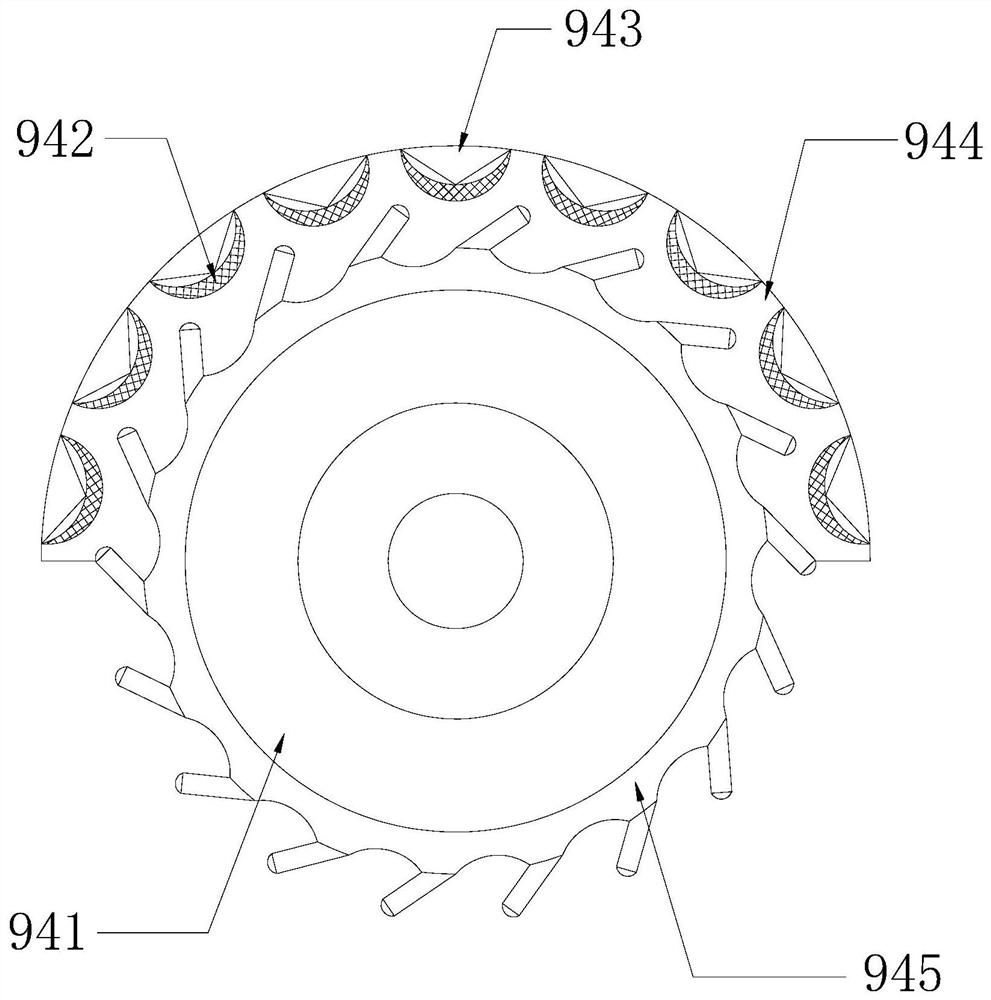

PendingCN111991845AIncrease the high specific surface areaShorten the timeLiquid solutions solvent extractionEnergy based chemical/physical/physico-chemical processesPhysicsMicro fluidic

The invention discloses rotary ultrasonic-microwave combined microfluid extraction equipment. The equipment comprises a water-phase feeding micropipe, an oil-phase feeding micropipe, an engine, a contact mixing rotary table and an ultrasonic exciter, an ultrasonic mixing liquid collecting chamber, a microwave extraction chamber, a microwave generator and a microwave extraction micro-channel; tailends of the water-phase feeding micropipe and the oil-phase feeding micropipe are arc-shaped bent horizontal sections and are respectively fixed at the bottom end of the liquid collecting chamber cover; liquid column cutting holes are formed in the micropipe; the engine is connected with the contact mixing rotary table through a rotary shaft; micropores are formed in the contact mixing rotary table and connected with the microwave extraction micro-channel through an extraction chamber inlet hole; and the microwave generator is arranged on the outer wall of the microwave extraction chamber. According to the invention, a sample solution and an extraction agent can be continuously and stably conveyed into the equipment, the combination speed of the sample solution and the extraction agent isaccelerated, and the fluid contact area and extraction rate are improved.

Owner:KUNMING UNIV OF SCI & TECH

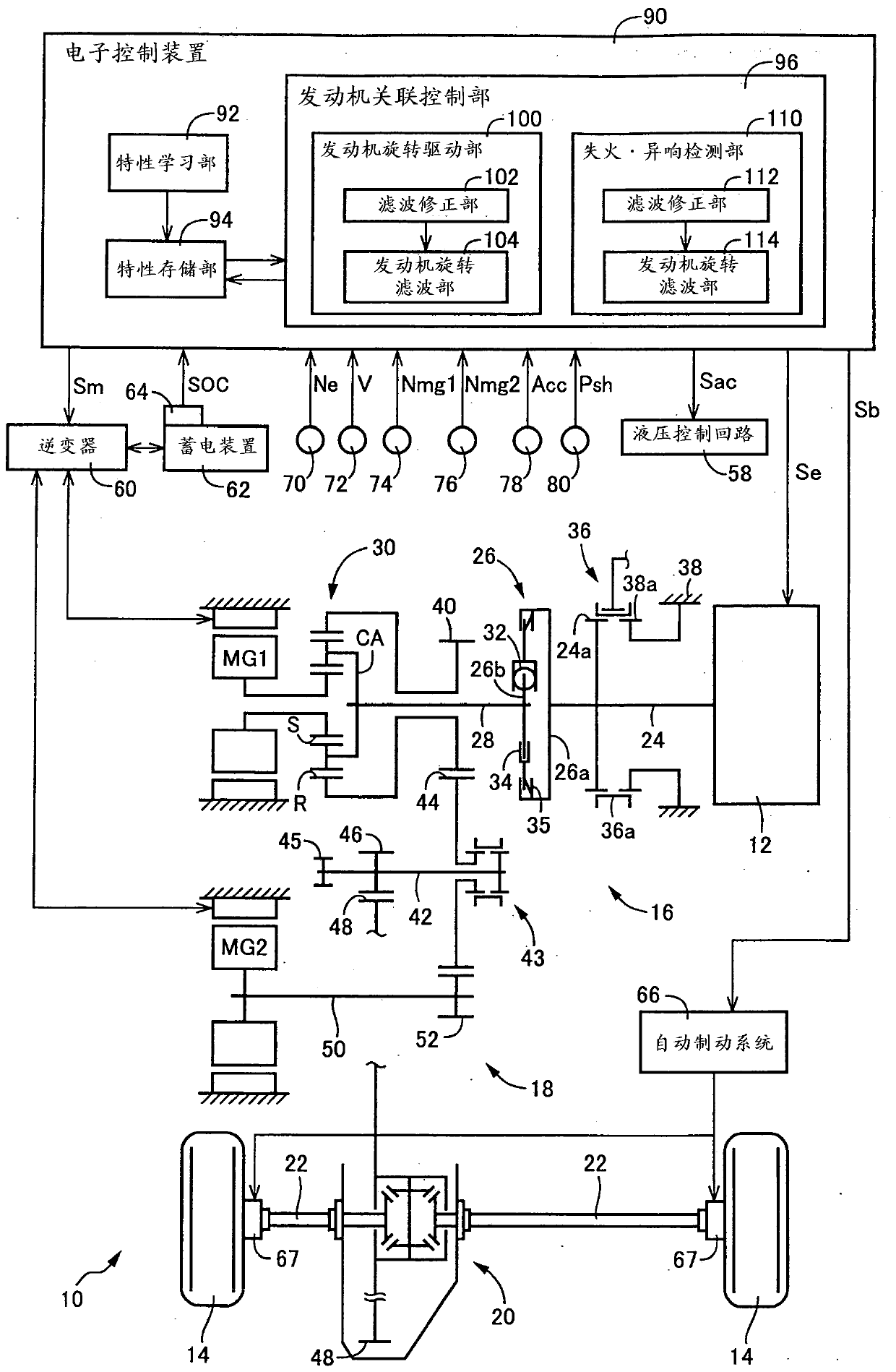

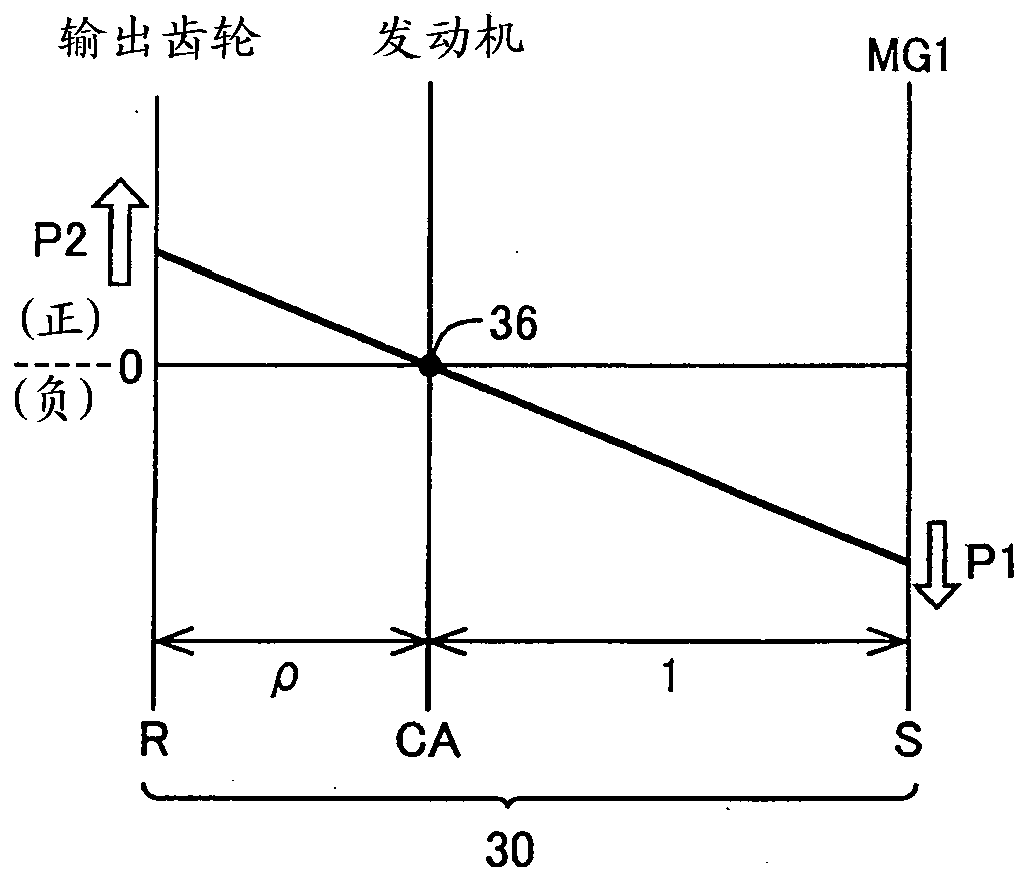

Vehicle control device

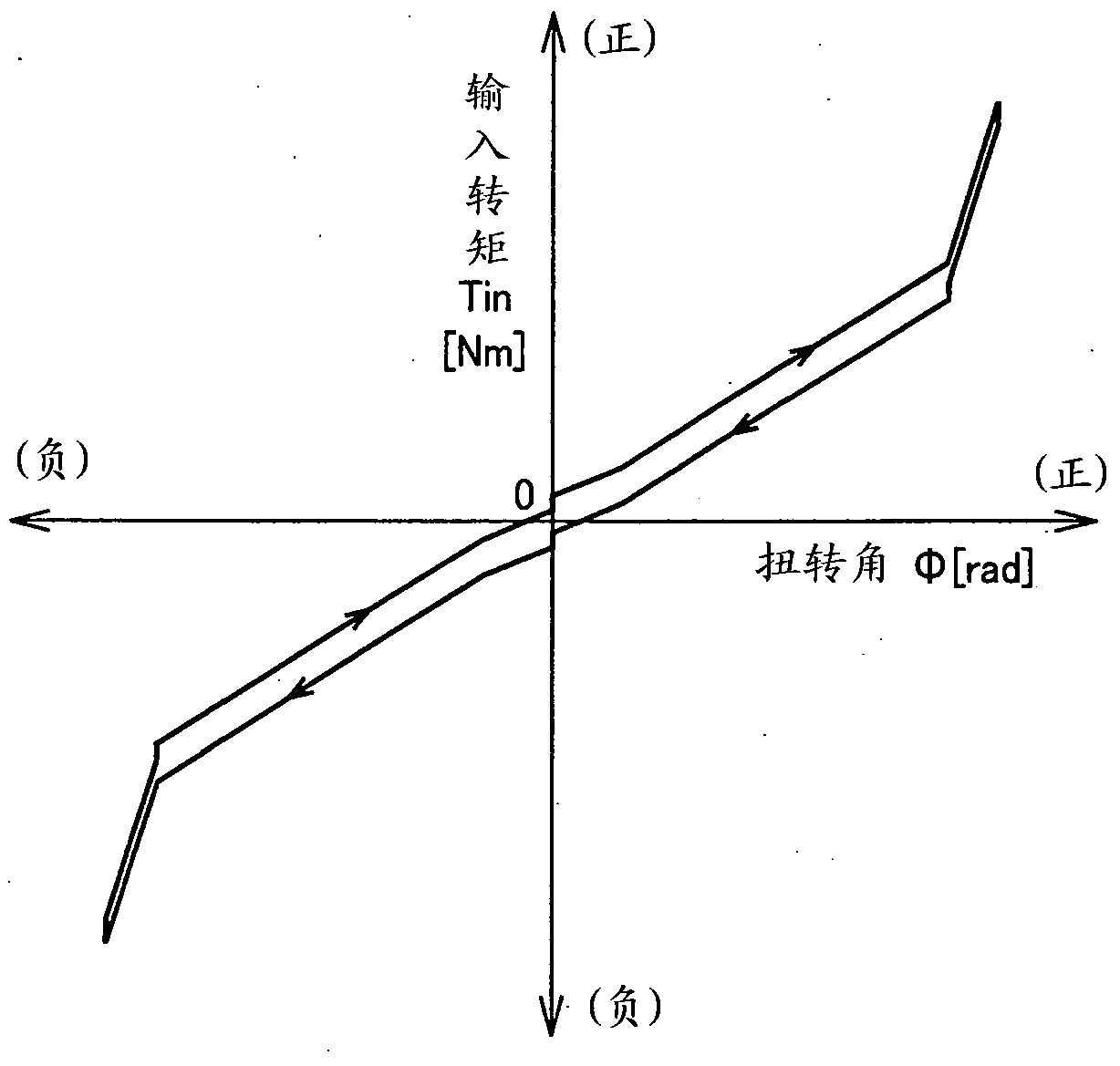

ActiveCN110040121AVibration component reductionIncrease attenuation gainHybrid vehiclesInternal-combustion engine testingResonanceRotation velocity

The present invention relates to a vehicle control device capable of obtaining an engine rotational speed signal in which a vibration component having a resonance frequency determined on the basis ofthe torsional rigidity of a rotating member is appropriately reduced regardless of fluctuations in the torsional rigidity caused by individual differences in the rotating member or the like. The actual resonant frequency (fr) is calculated by applying a torque (Tin) to a vibration damping device (a rotating member) and measuring a torsional angle (phi), detecting torsional rigidity (a rigidity value (K1) or the like). Then, the vibration component of the actual resonant frequency (fr) in the engine rotation speed signal (SNe) provided by the engine rotation speed sensor is attenuated, and theengine rotation driving control, misfire determination, abnormal sound determination, and the like are performed by using the engine rotation speed signal (SNe). The vibration component of the enginerotation speed signal (SNe) is appropriately reduced on the basis of the actual resonance frequency (fr) regardless of fluctuations in torsional rigidity caused by individual differences in the damping device or the like. Thus, it is possible to appropriately control the engine rotation speed signal (SNe) used later.

Owner:TOYOTA JIDOSHA KK

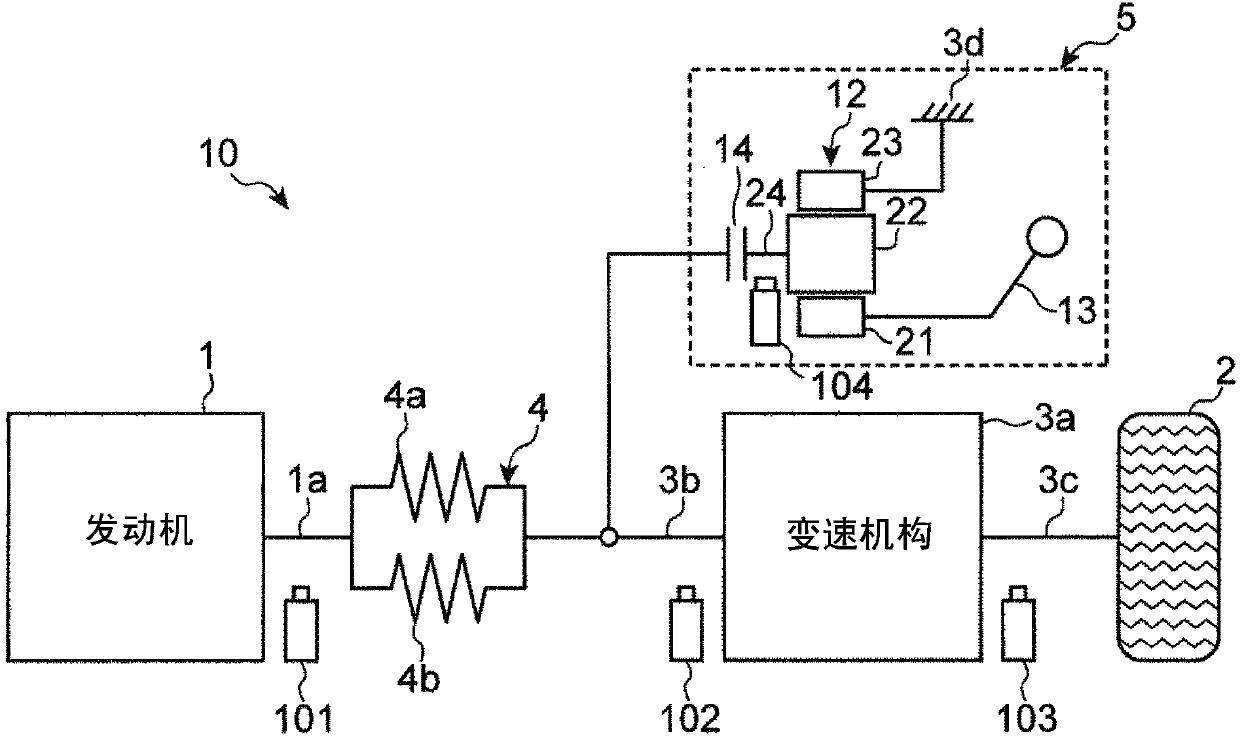

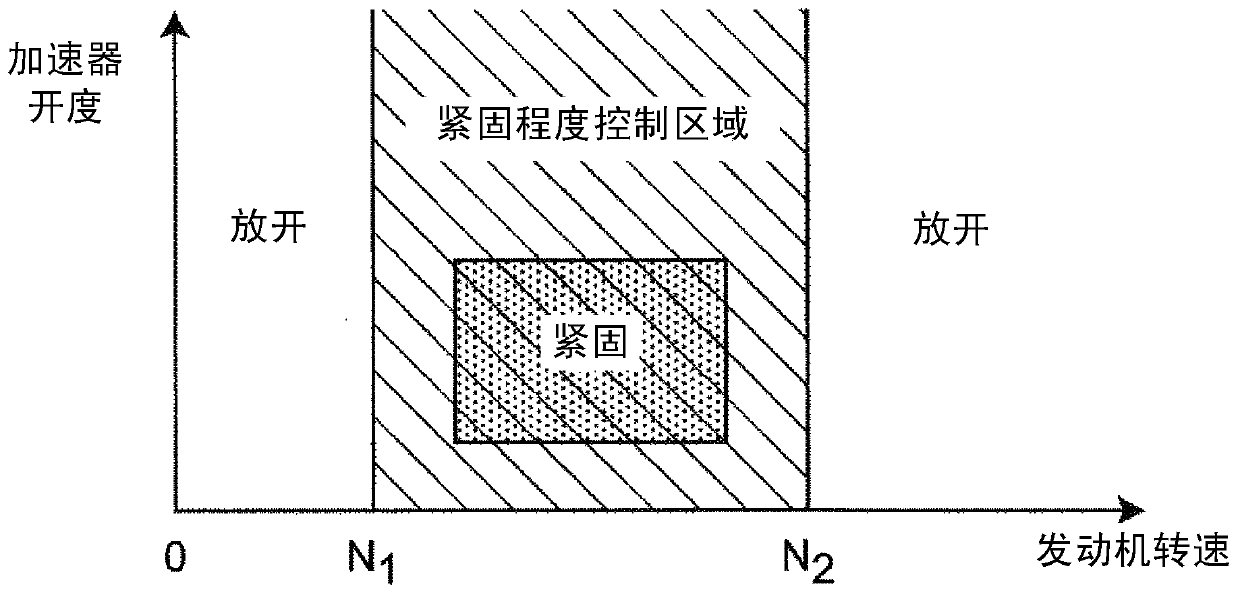

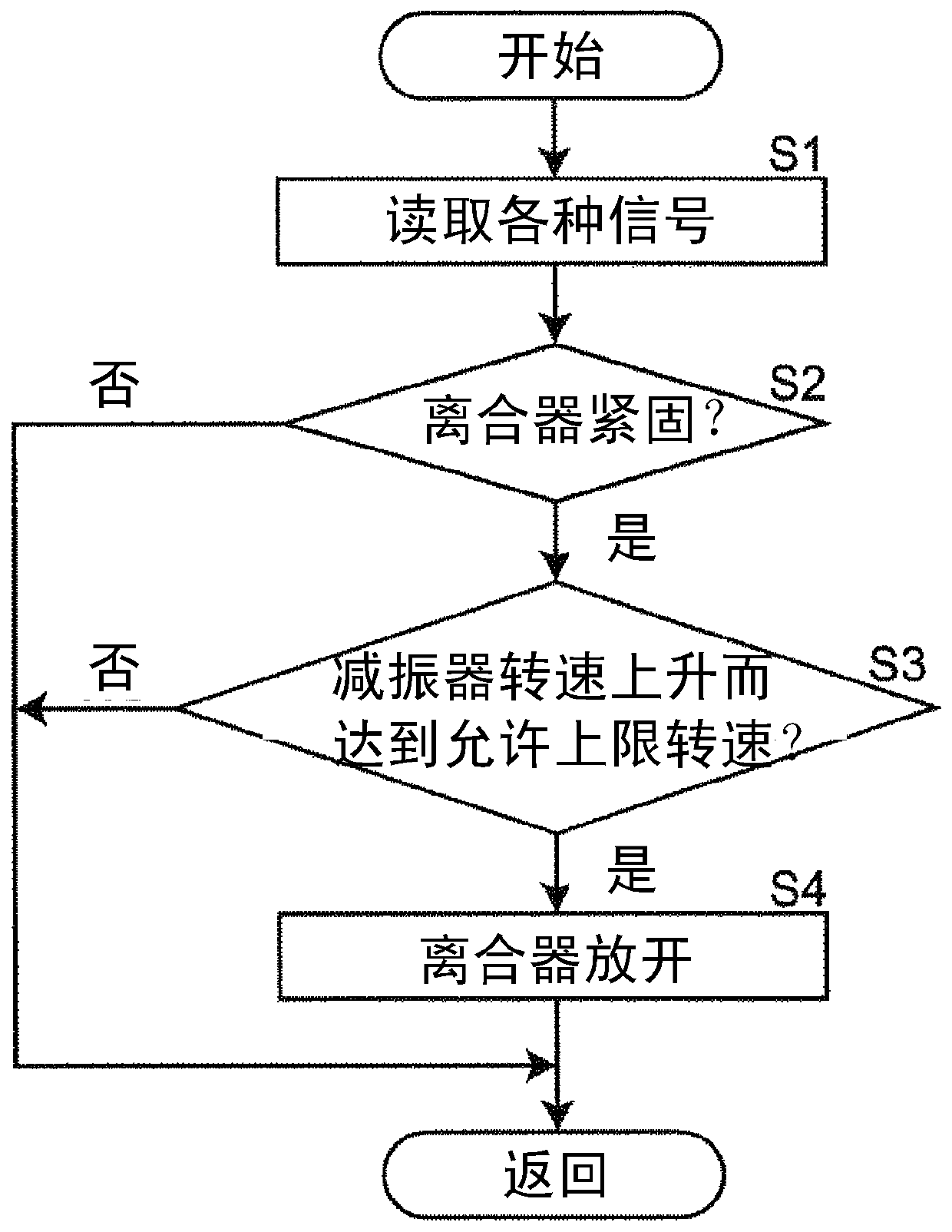

Control device of a powertrain with a centrifugal pendulum damper

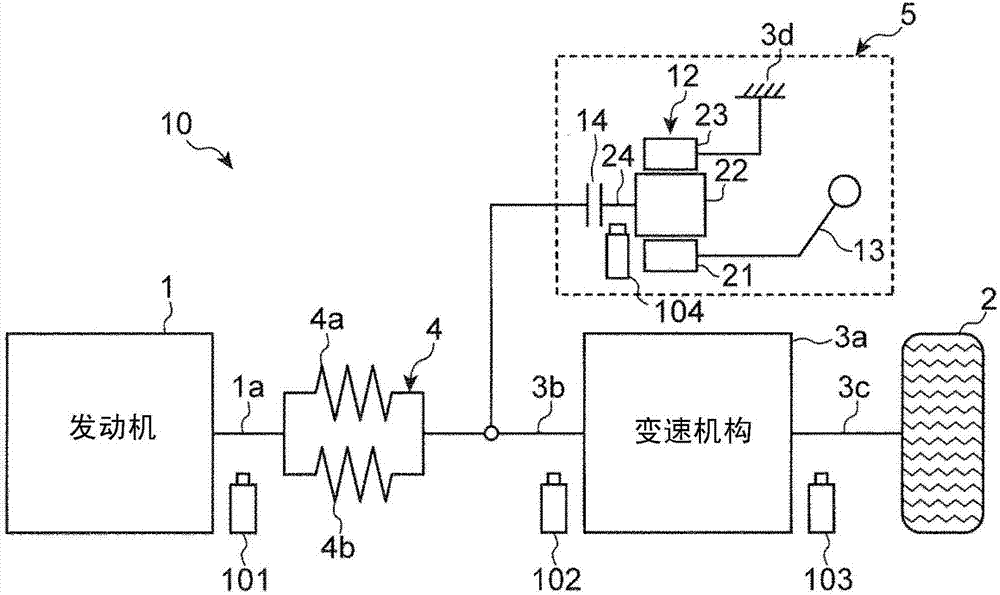

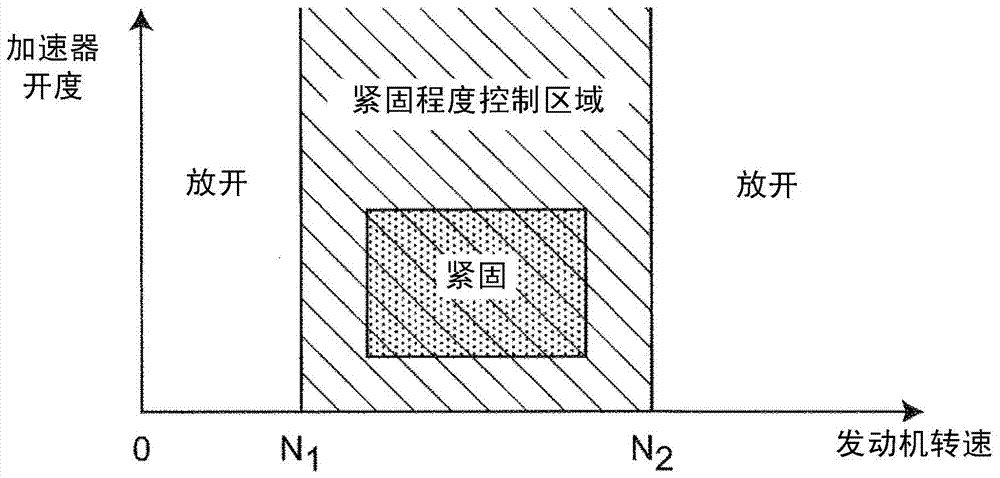

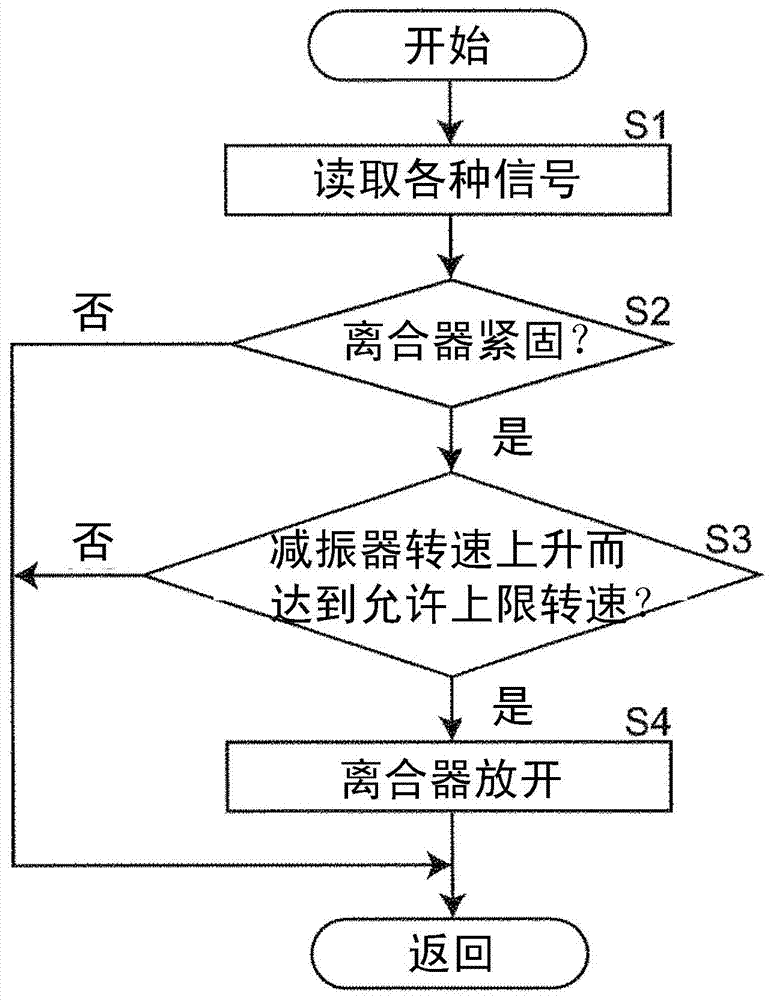

InactiveCN106949191ALow reliabilityReduce weightRotating vibration suppressionClutchesDrivetrainControl theory

The invention relates to a control device of a powertrain with a centrifugal pendulum damper, and the control device can avoid reliability reduction caused by high-speed revolution of the centrifugal pendulum damper. The control device (100) of the powertrain (10) with a centrifugal pendulum damper is provided in which the centrifugal pendulum damper (13) and a power transmission shaft (3b) are operatively coupled via a clutch mechanism (14), and the control device of the powertrain with the centrifugal pendulum damper includes a connection / disconnection control portion (130) for controlling an engagement degree of the clutch mechanism (14) by controlling the engagement degree of the clutch mechanism (14) such that the centrifugal pendulum damper (13) rotates at or below an predetermined upper rotational speed limit.

Owner:MAZDA MOTOR CORP

Control unit for drivetrain with centrifugal vibrator damper

InactiveCN106949191BRotation speed controlLow reliabilityRotating vibration suppressionClutchesElectric power transmissionDrivetrain

An object of the present invention is to realize a control device for a power transmission system with a centrifugal vibrator damper capable of avoiding a decrease in reliability due to high-speed rotation of the centrifugal vibrator damper. It is a control device (100) of a power transmission system (10) with a centrifugal vibrator damper connected to an input shaft (3b) and a centrifugal vibrator damper (13) through a clutch mechanism (14), and is characterized in that it has A disconnection control part (130) that controls the tightening degree of the clutch mechanism (14); the disconnection control part (130) rotates the centrifugal vibrator damper (13) at a rotational speed below a specified allowable upper limit rotational speed Form controls how tight the clutch mechanism (14) is.

Owner:MAZDA MOTOR CORP

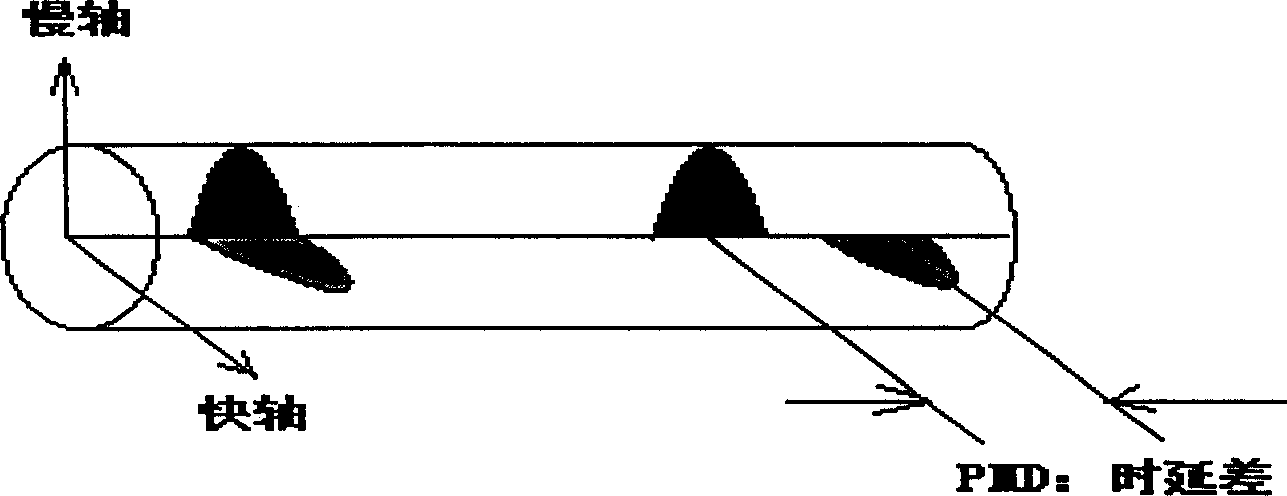

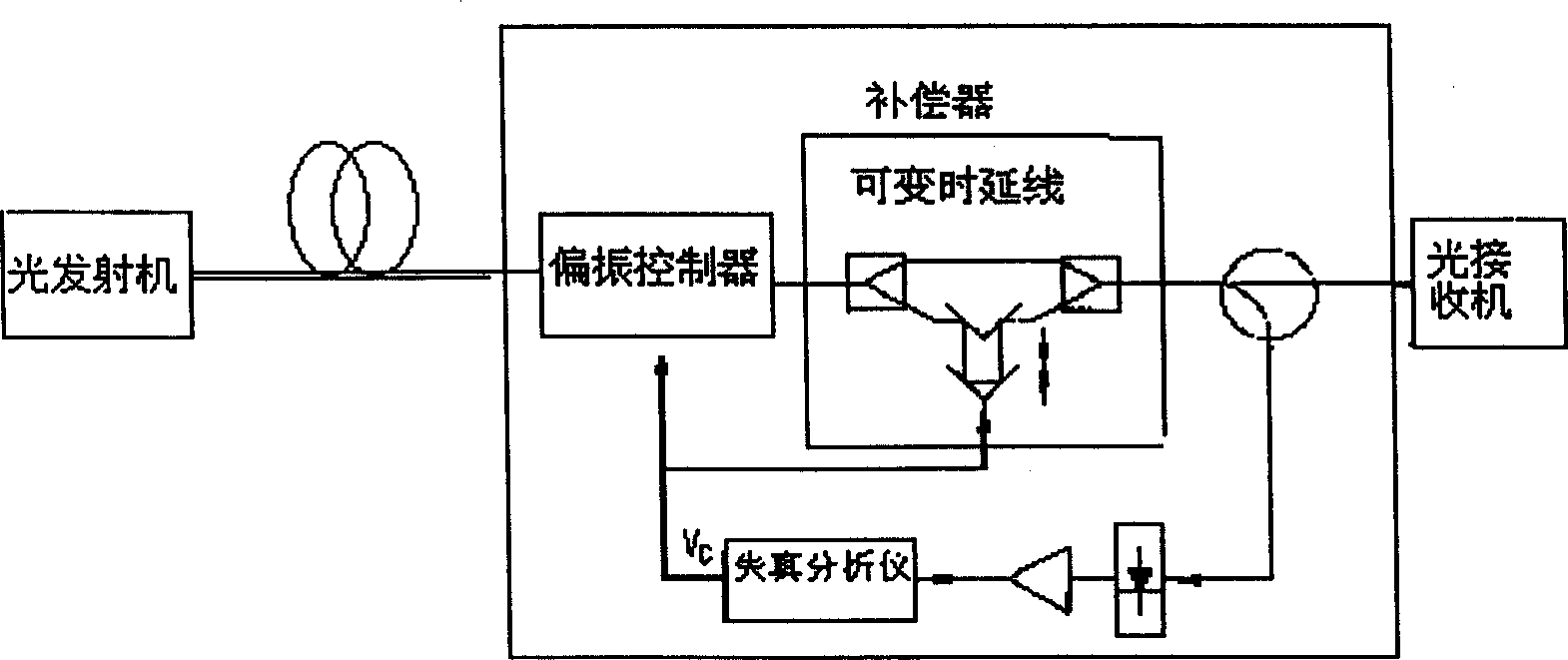

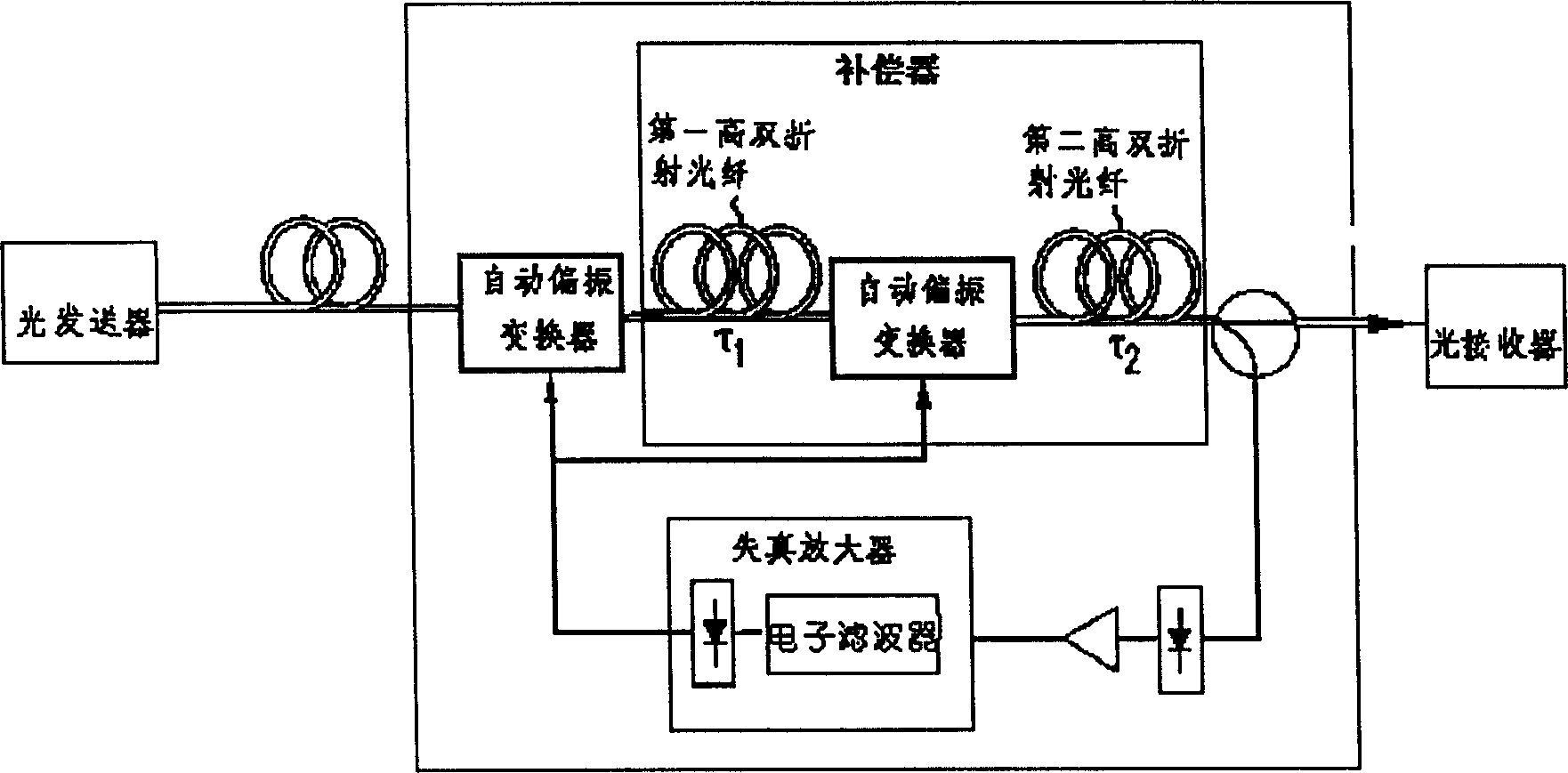

Polarization mould chromatic dispersion simulator, compensator and compensating system

InactiveCN1214263CReduce and eliminate impactThe rotation speed is effectively controlledCoupling light guidesElectromagnetic transmissionOptical circulatorPolarization beam splitter

A polarizing mode dispersion simulator, compensator and compensation system are disclosed. Said system is composed of polarizing controller, optical circulator with three ports for receiving the optical signal from polarizing controller, outputting it to polarizing splitter and outputting the compensated optical signal, polarizing splitter for splitting to optical signal into two orthogonal polarized components, optical fibre ring, and rotating device for rotating the optical ring to generate a delay difference between said two orthogonal polarized components. Its advantages are simple structure, high response speed, and low cost.

Owner:HUAWEI TECH CO LTD

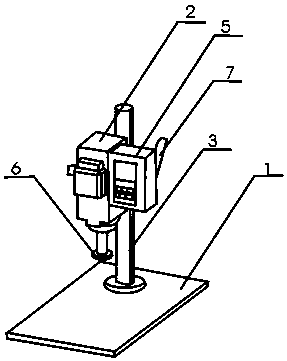

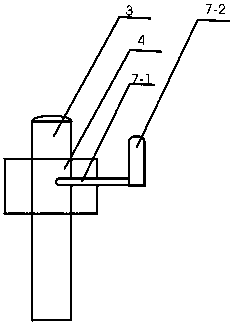

High-speed motor rotation tester

InactiveCN107733169APrevent fallingAvoid scratchesLinear/angular speed measurementManufacturing dynamo-electric machinesMagnetic effectRotation test

The invention provides a high-speed motor rotation tester, which is characterized in that it includes a base, a motor frame, a support column, a fixed frame, a controller, a speed measuring magnetic ring, a fixed handle, and a fixing hole, and a support column is installed on the upper side of the base. A fixing hole is provided on the supporting column, a fixing frame is installed on the upper side of the supporting column, and the fixing handle is connected through the fixing frame and the supporting column. The present invention is a high-speed motor rotation tester. The motor is installed on the Inside the motor frame, the setting of the motor frame facilitates the placement of the motor, prevents the motor from falling or being scratched during the test, and protects the motor. In the present invention, the speed-measuring magnetic ring is installed on the lower side of the motor frame, which facilitates the speed-measuring function of the speed-measuring magnetic ring.

Owner:丰源昭和(天津)科技发展有限公司

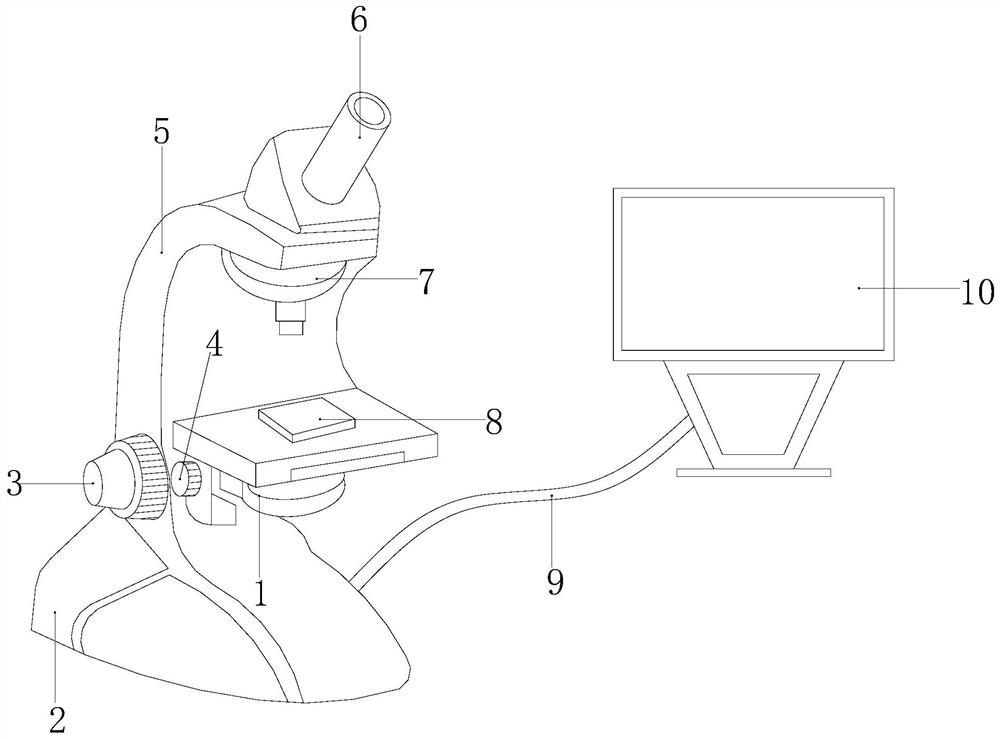

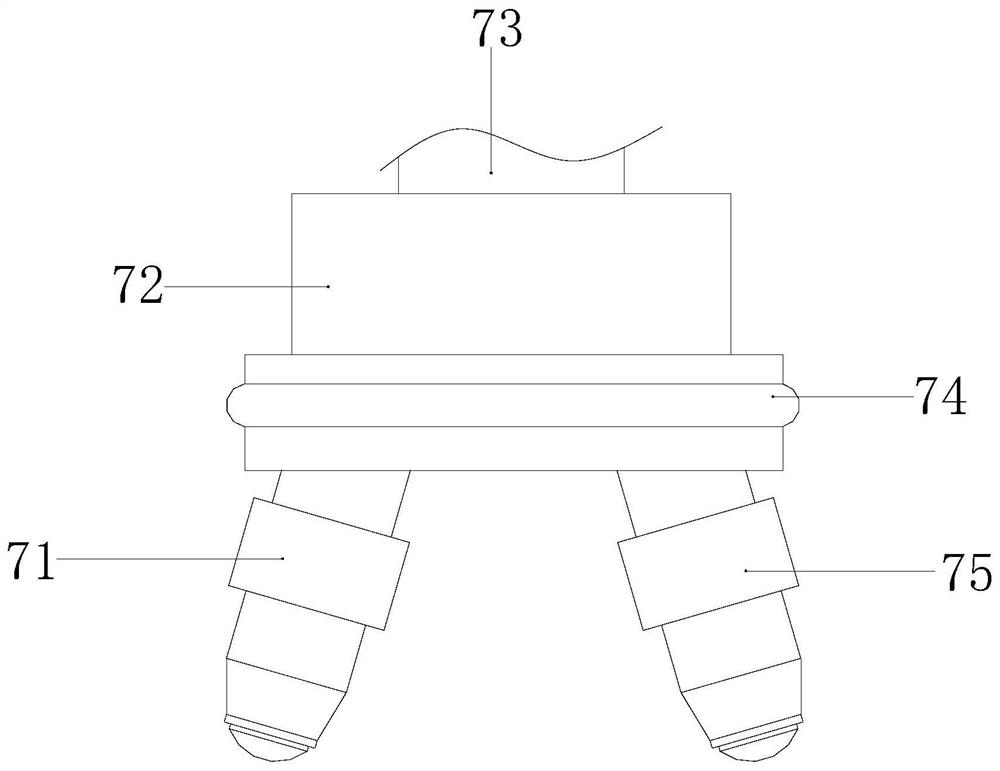

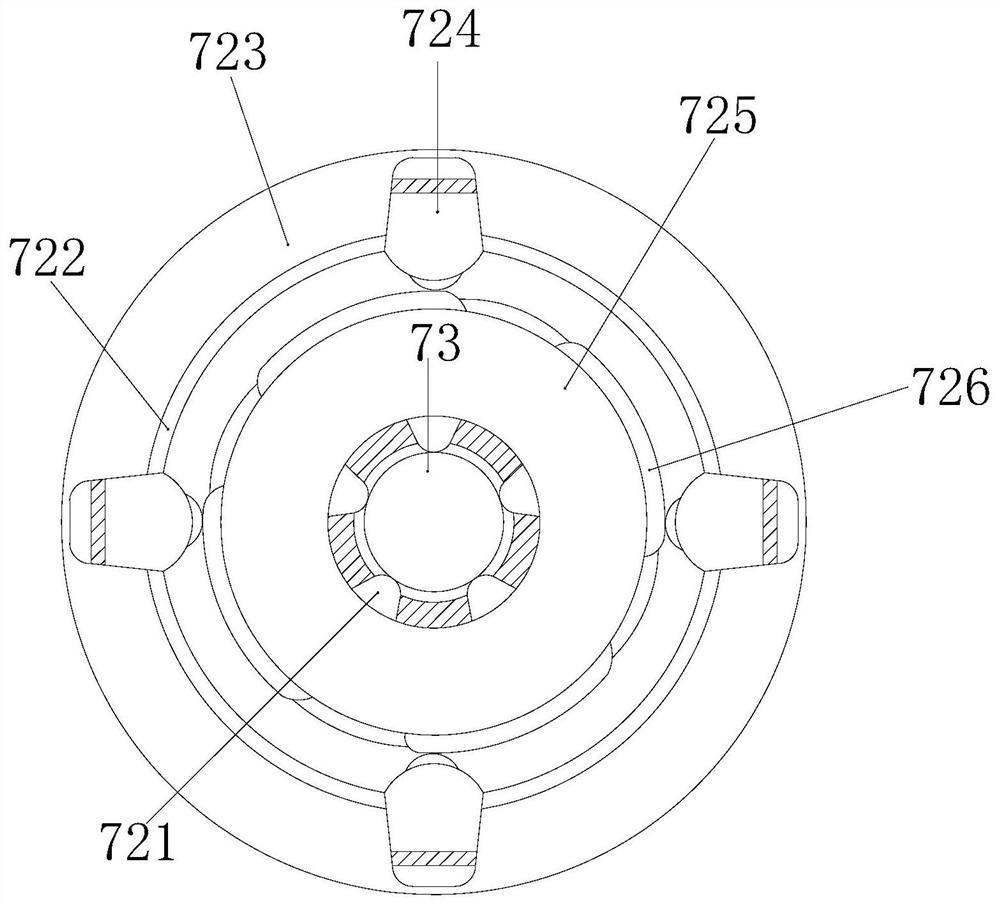

Optical tweezer device for treating cancer

InactiveCN112345456AIncrease elasticityIncrease frictionMaterial analysis by optical meansCancer cellEyepiece

The invention discloses an optical tweezer device for treating cancer, which structurally comprises a collecting lens, a main body, a focusing wheel, a lifting adjusting wheel, an optical tweezer reflector, an ocular lens, an adjusting device, an objective table, a wire and a display screen. When the device is used after improvement, a worker adjusts the high-magnification lens and the low-magnification lens, a pushing and pressing piece makes contact with a friction pad to generate certain extrusion resistance, the shell is pulled inwards through mutual cooperation of an elastic pull rope anda tension bar, the friction pad can be tightly attached to the pushing and pressing piece through mutual cooperation of the abutting block and the pushing block and resistance to force borne by the friction pad, and an experimenter can accurately adjust the optical tweezers reflector. Laser optical tweezers are formed through the optical tweezer reflector to capture cancer cells of peripheral blood of cancer cells of a patient, the captured cancer cells and cancer drugs for treating the patient are fully mixed and cultured, and proliferation of the cancer cells in the body of the patient canbe effectively inhibited.

Owner:刘以南

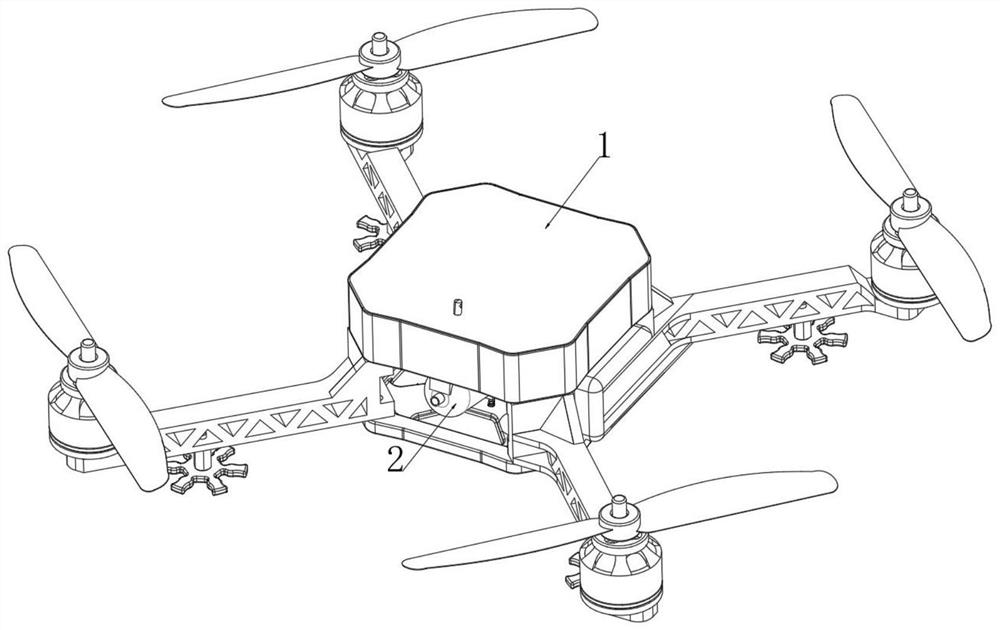

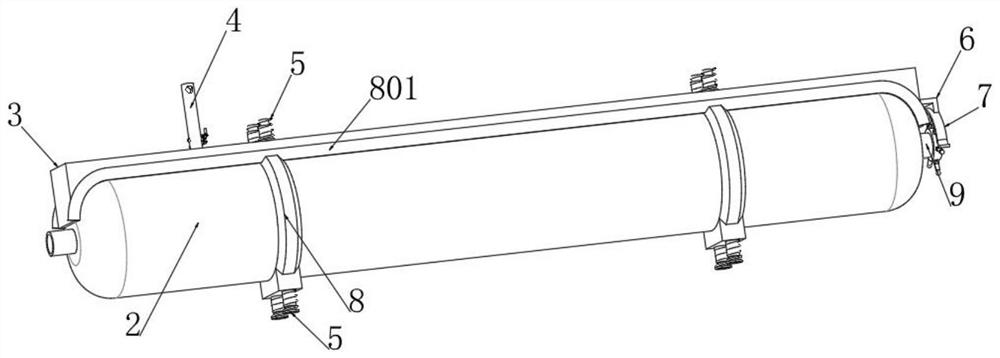

Hydrogen storage device based on hydrogen kinetic energy unmanned aerial vehicle

InactiveCN114084356AAvoid high concentrationsGuaranteed tightnessFuel tank safety measuresFuel systems for specific fuelsAerospace engineeringStructural engineering

The invention discloses a hydrogen storage device based on a hydrogen kinetic energy unmanned aerial vehicle, an unmanned aerial vehicle body and a hydrogen storage bottle arranged below the unmanned aerial vehicle body are included, a fixing and sealing mechanism is arranged on the unmanned aerial vehicle body and used for fixedly installing the hydrogen storage bottle, and the fixing and sealing mechanism comprises a fixing strip; the periphery of the fixing strip extends downwards and is attached to the upper surface of the hydrogen storage bottle to form a closed cavity, hoops are fixedly connected to the unmanned aerial vehicle body through two sets of symmetrical telescopic rod pieces, the number of each set of telescopic rod pieces is two, the hoops are in a C shape, and the two free ends of each hoop are fixedly connected with C-shaped baffles; a mounting pipe is fixedly inserted into the upper end of the fixing strip, and a through hole is formed in one side of the mounting pipe. According to the technical field of new energy automobiles, the hydrogen storage device can automatically block the hydrogen storage cylinder when the unmanned aerial vehicle encounters an emergency situation and the hydrogen storage cylinder leaks, and explosion caused by the fact that hydrogen in the hydrogen storage cylinder leaks to the outside is avoided.

Owner:WEST ANHUI UNIV

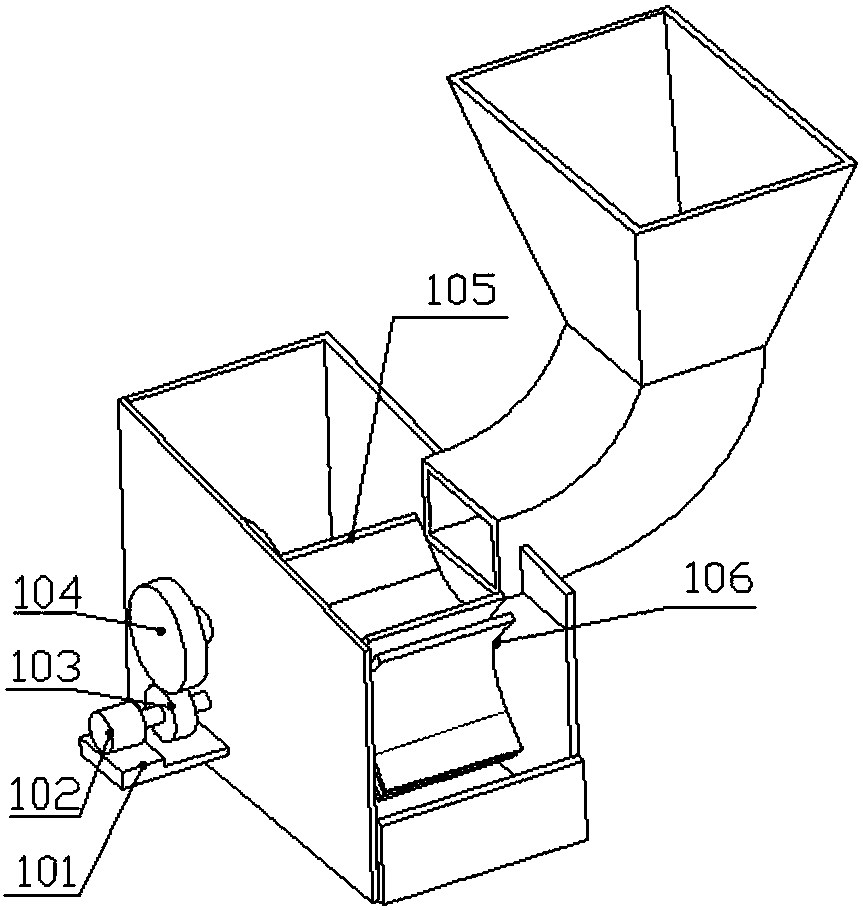

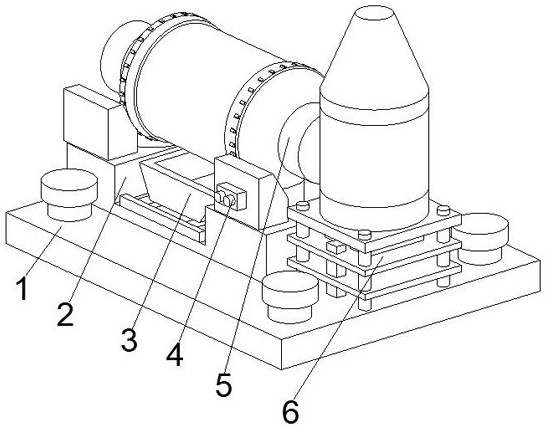

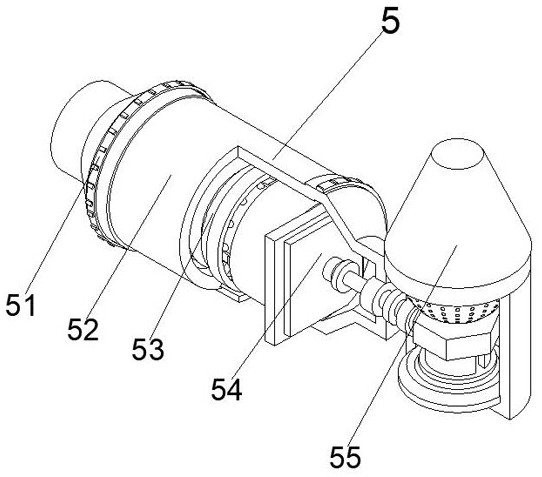

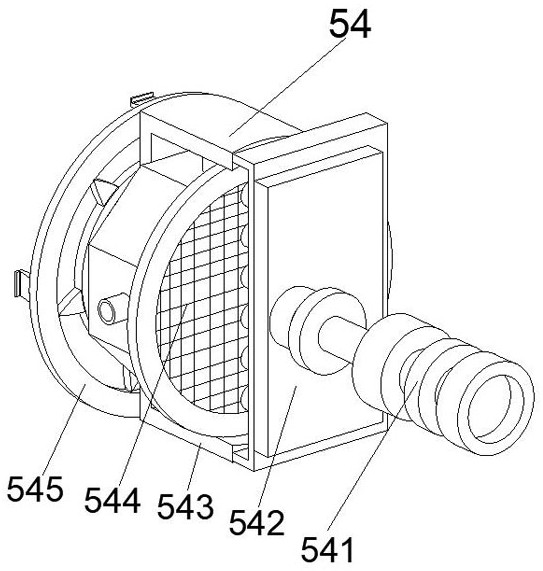

Device and method used for continuous material thermal treatment

ActiveCN111895779AAvoid deflectionGuaranteed free expansionRotary drum furnacesLoading/unloadingTube furnaceLap joint

The invention relates to a device used for continuous material thermal treatment. The device comprises a rotary device, a charge device and a tubular type furnace body, wherein the rotary device comprises supporting frames, a supporting barrel and a corundum furnace tube; the supporting frames are positioned at the two sides of the tubular type furnace body; a rotary left supporting barrel and a rotary right supporting barrel are mounted on the supporting frames; the corundum furnace tube is arranged between the supporting barrels; joints of the supporting barrels and the corundum furnace tubeare equipped with aluminum oxide cotton; a charge hole is formed in the left supporting barrel; an inclined guide block is arranged in the left supporting barrel on the lower part of the charge hole;a discharge hole is formed in the right supporting barrel; the charge device comprises a bracket, a collecting barrel, an unloading adjusting template and a guide plate; the collecting barrel is mounted on the supporting frames through the bracket; a loading hole and an unloading hole are formed in the collecting barrel; one end of the unloading adjusting module is inserted into the unloading hole, and the other end of the unloading adjusting module is hinged with the guide plate, and a hinged part is equipped with an elastic element; and one end of the guide plate is inserted into the side wall of the bracket, and the other end of the guide plate is in lap joint on the left supporting barrel. The invention further relates to a method for material continuous thermal treatment.

Owner:YANTAI UNIV

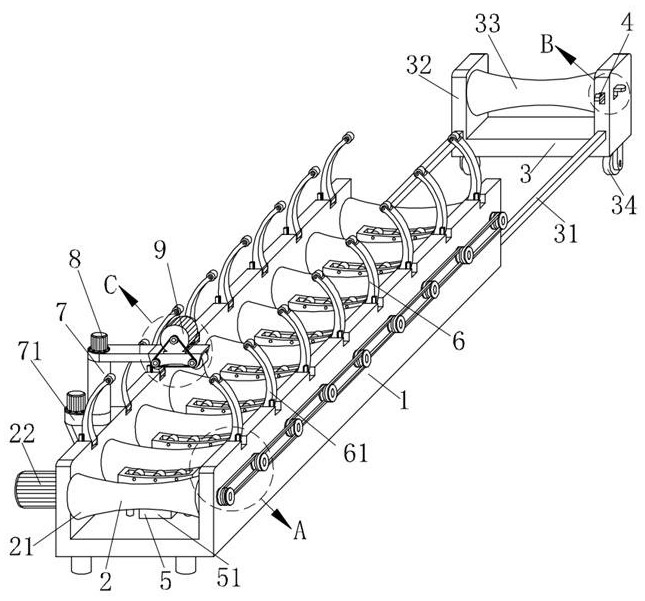

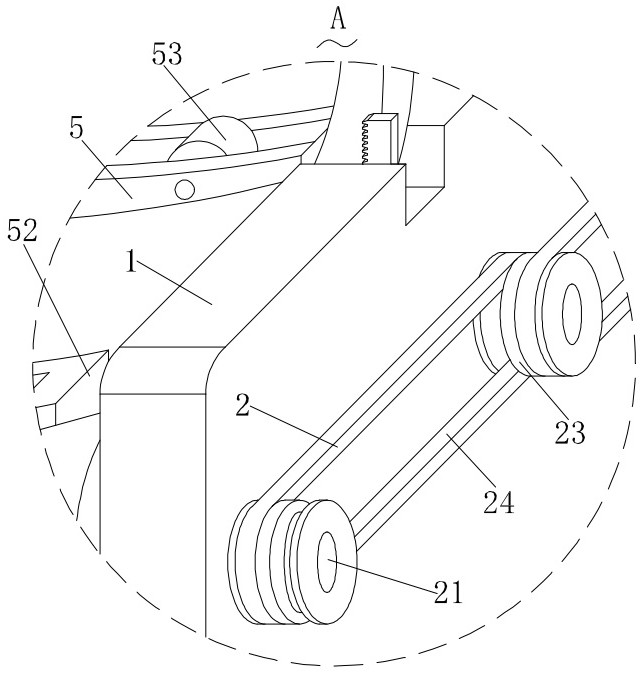

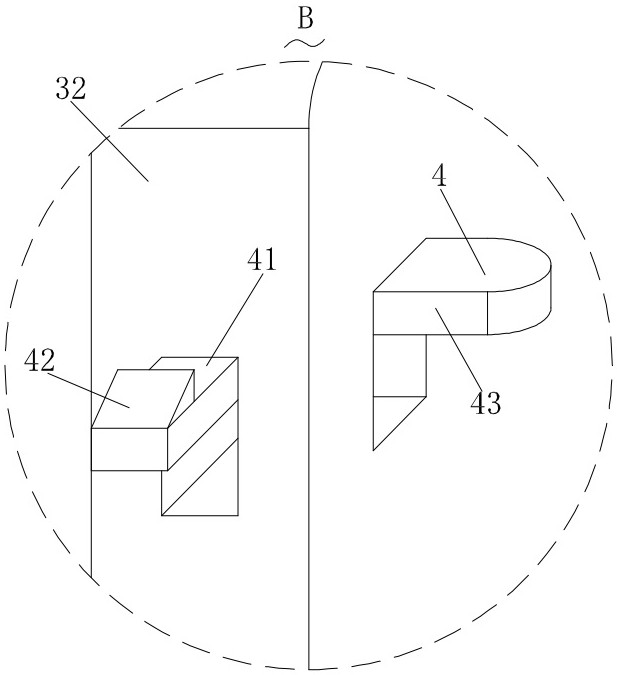

A multi-station automatic distance-divided bar conveying device

InactiveCN105217290BReduce labor intensityImprove delivery efficiencyConveyor partsHorizontal barTransfer line

The invention relates to a multi-station automatic distance-divided bar material conveying device, which includes a conveying line extending along the front and rear horizontal directions for carrying the bar material and transporting it backward, and also including a conveyor line for being arranged on the bar material conveying stroke The intermittent stopper mechanism located in front of the plurality of stations, the intermittent stopper mechanism includes a movable intermittent stopper, and the intermittent stopper has a function on its movable stroke for when the bar moves to the intermittent stopper mechanism. The blocking position that prevents the bar from moving backwards with the conveying line and the avoidance position that allows the bar that moves to the intermittent stopper mechanism to follow the conveying line to move backwards. The intermittent stopper passes through the blocking position when the conveying line moves backward. Reciprocate between the position and the avoidance position to automatically divide a plurality of bars corresponding to the plurality of stations on the conveying line. Multiple bars can be automatically divided and transported by this automatic distance-divided bar material conveying device, and there is no need to completely rely on manual transportation of multiple bars to multiple stations.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com