Spreader roll

A technology of spreading rollers and roller sections, applied in the field of spreading rollers, can solve problems such as damage and complex structure, and achieve the effect of not being easily soiled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

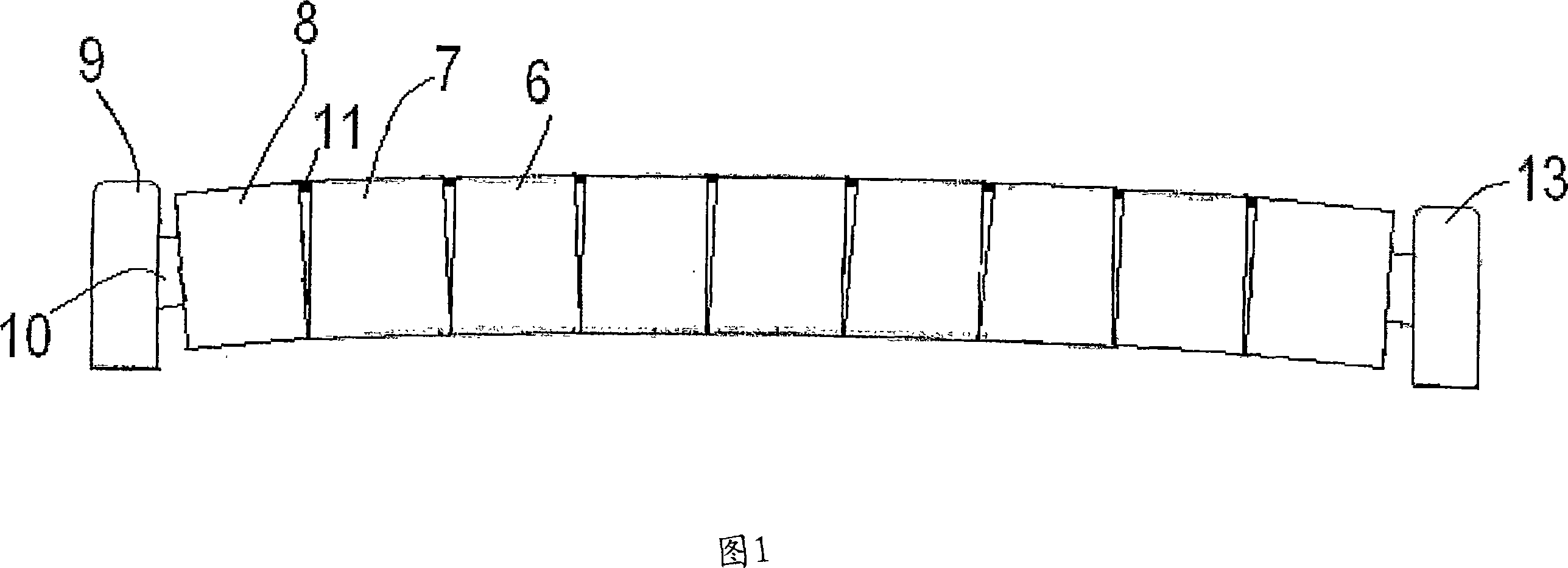

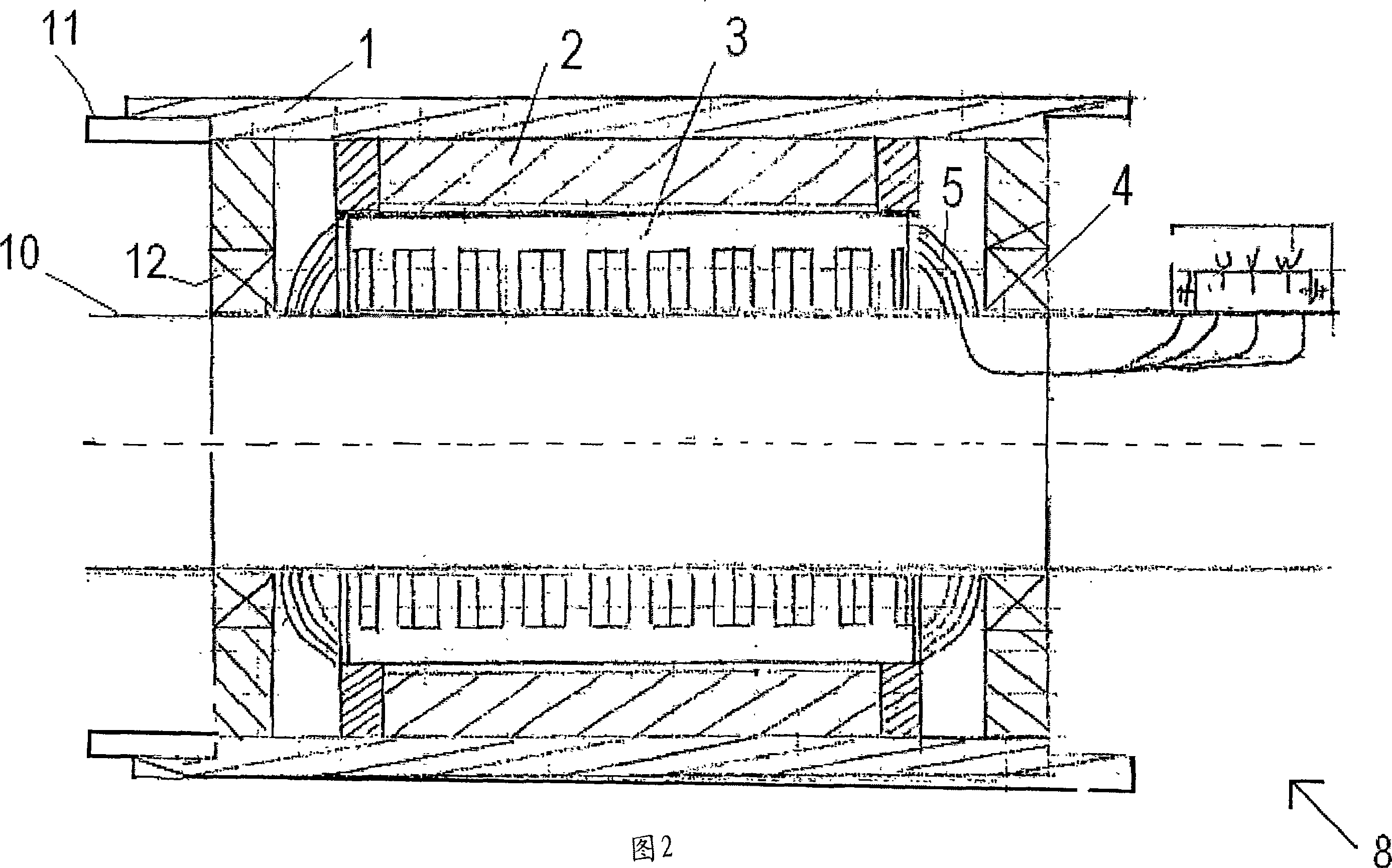

[0016] According to Fig. 1 and shown in Fig. 2, spreader roller comprises at least one actuator (actuator) and fixed stretcher roller shaft 10 that is most conducive to bending, there are roller sections 6, 7 and 8 on stretcher roller shaft 10, described The roll sections are connected to each other by flexible connector parts 11 connected to the shells 1, so that the roll section shells are fixedly supported (bearing-mounted) to rotate around the spreader roll axis, and at least one roll section 8 is an actuator, so The actuator described above is most advantageously operated as a drum motor which rotates the roll section shell 1 about the spreader roll axis.

[0017] When the roll sections 7, 8, etc. are connected to each other by flexible connector parts 11 connected to each roll section, the flexible connector parts transmit the force from each roll section to the next roll section, thus enabling all roll sections to Set 1 is able to rotate. Due to their flexibility, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com