A multi-station automatic distance-divided bar conveying device

A conveying device and multi-station technology, which is applied to conveyer objects, transportation and packaging, etc., to achieve the effect of improving conveying accuracy, improving conveying efficiency and simple design structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

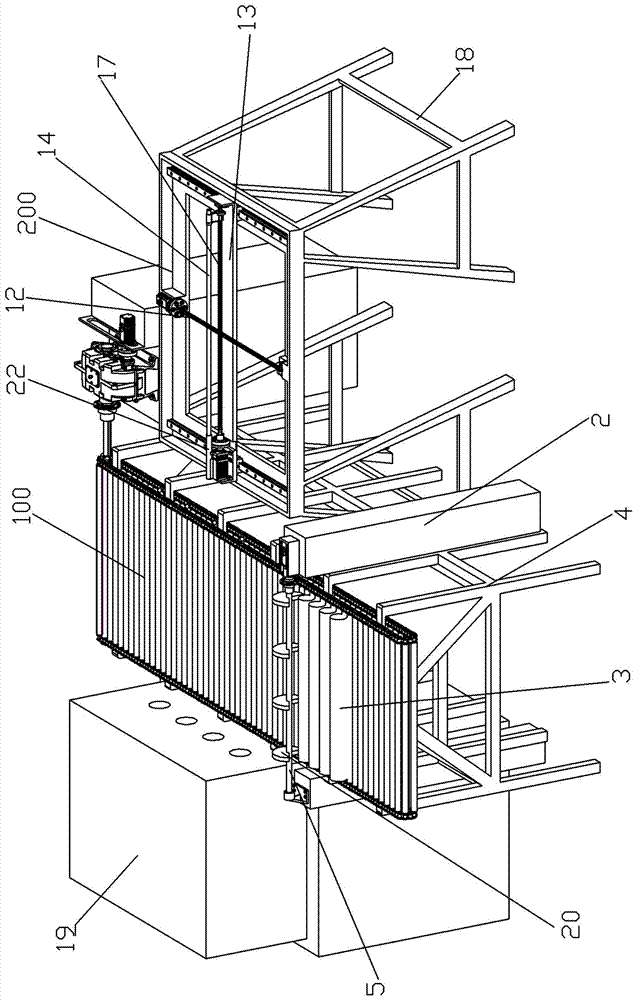

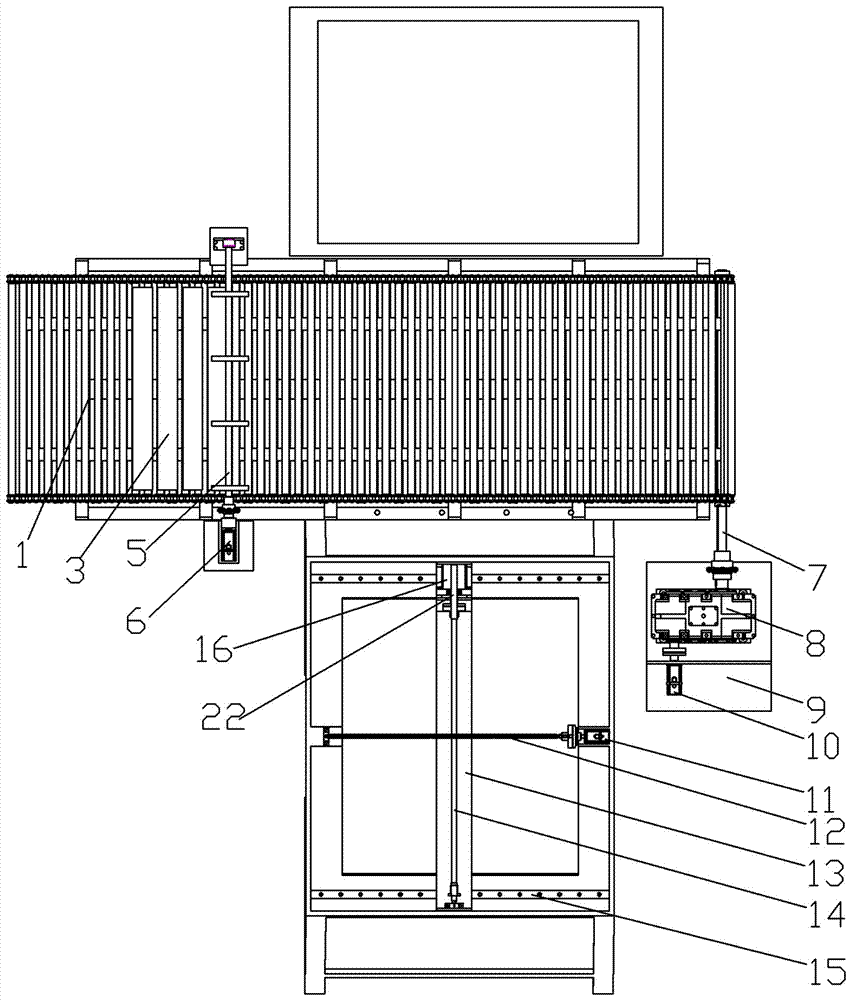

[0020] Such as Figure 1 to Figure 3 As shown, an embodiment of a multi-station automatic distance-divided bar material conveying device, the conveying device in this embodiment includes a conveying line 100 and a bar arranged on the side of the conveying line 1 for transferring the bar on the conveying line 1 3. Push it into the direct motion pushing mechanism 200 at the furnace mouth station of the heating furnace 19.

[0021] In this embodiment, the conveying line 100 is arranged on the side of the heating furnace 19, and the four furnace mouth stations on the heating furnace 19 are separated from each other along the front and rear horizontal directions.

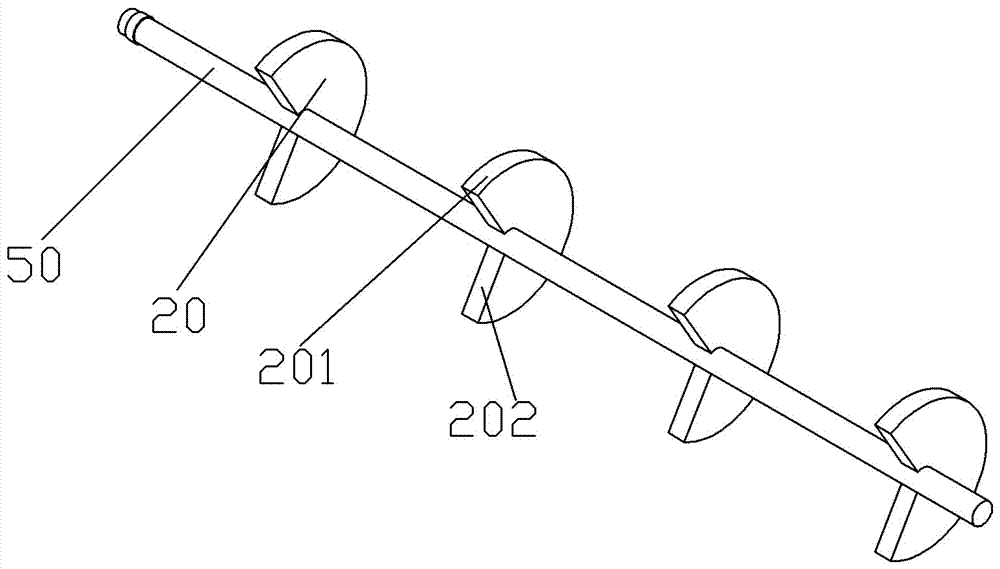

[0022] The conveyor line 100 in this embodiment is a chain-type conveyor line extending along the front-to-back direction. The chain-type conveyor line is arranged on the conveyor line support frame 4. The conveyor line 100 includes a conveyor chain and is fixed on the conveyor chain and moves with the conveyor chain. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com