Control device of a powertrain with a centrifugal pendulum damper

A technology of power transmission system and control device, applied in vibration suppression adjustment, rotational vibration suppression, clutch, etc., can solve the problems of reducing the reliability of centrifugal vibrator shock absorbers, and achieve the effect of improving fuel consumption performance and avoiding reliability reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be described below.

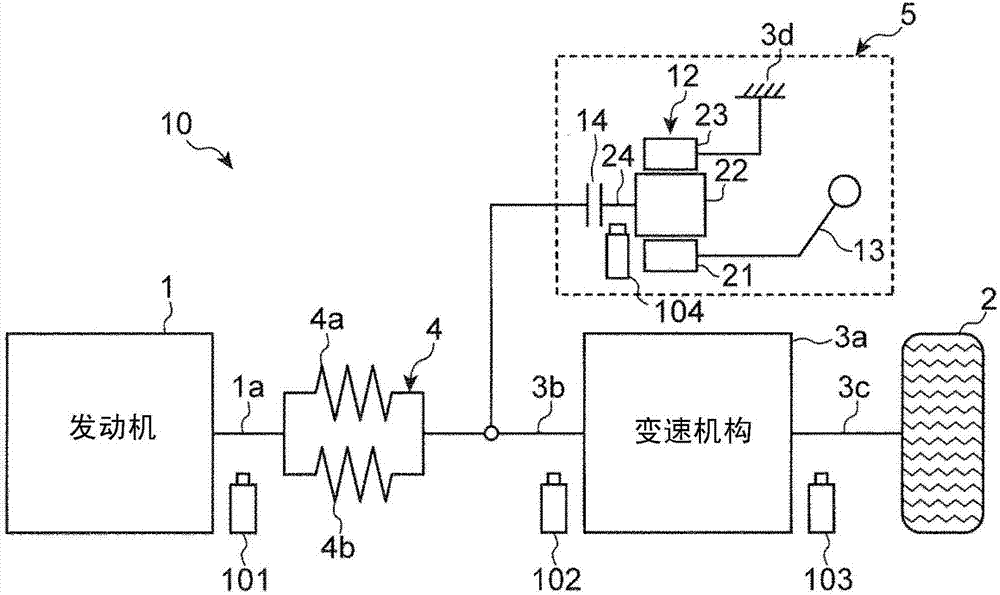

[0056] figure 1 It is a schematic diagram showing the configuration of a powertrain 10 with a centrifugal vibrator damper (hereinafter, simply referred to as “powertrain 10 ”) according to an embodiment of the present invention. Such as figure 1 As shown, the power transmission system 10 includes: an engine 1, a transmission mechanism 3a of an automatic transmission 3 that transmits the driving force of the engine 1 to the drive wheels 2, and an output shaft 1a of the engine 1 and an input shaft 3b of the transmission mechanism 3a. The torsional damper mechanism 4 connected therebetween, and the centrifugal vibrator damper mechanism 5 connected to the input shaft 3b of the transmission mechanism 3a.

[0057] The automatic transmission 3 is a stepped transmission including a transmission mechanism 3 a that selectively tightens a plurality of friction fastening elements to switch gear ratios in steps. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com