Rotary ultrasonic-microwave combined microfluid extraction equipment

An ultrasonic and rotary technology, applied in the field of microfluidic extraction equipment, can solve the problems of complex structure, high production process requirements, long extraction time, etc., and achieve the effect of increasing high specific surface area, improving extraction efficiency, and accelerating extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

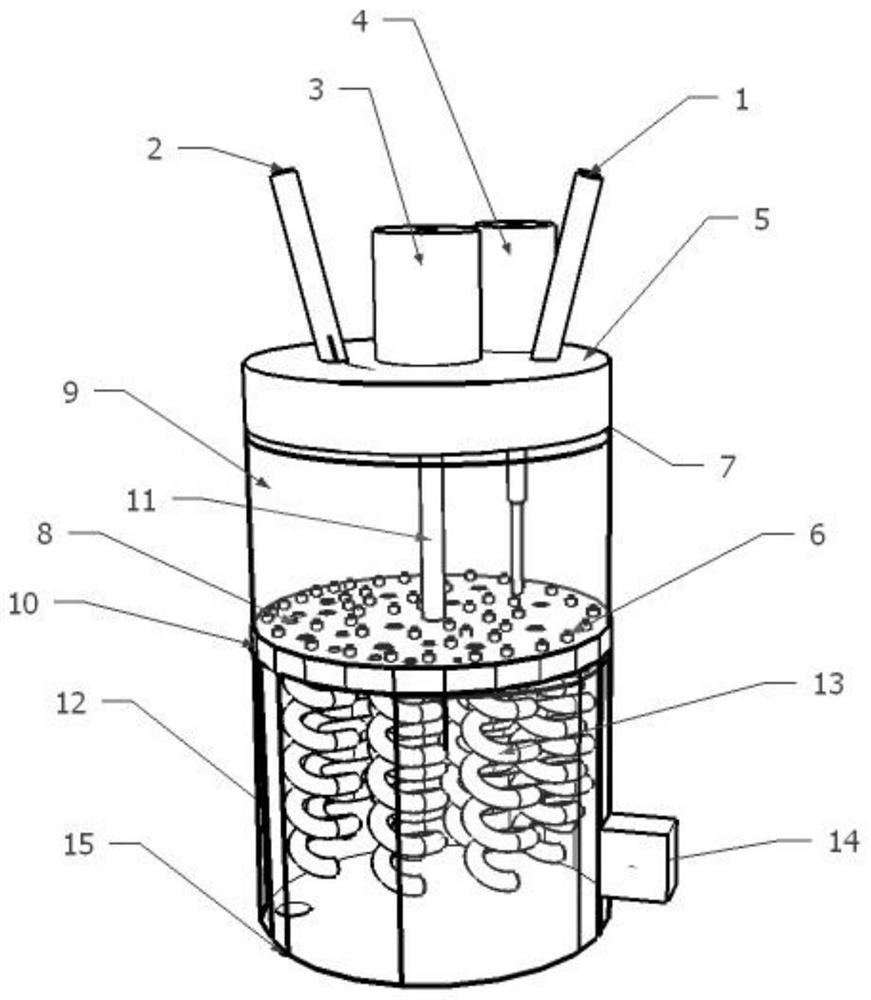

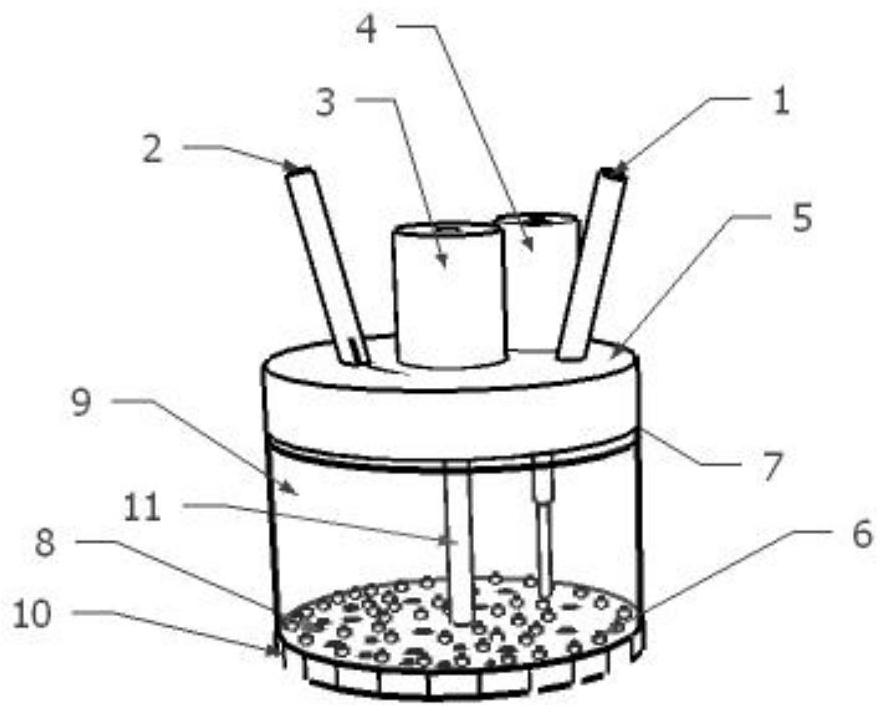

[0028] like figure 1 As shown, the rotary ultrasonic-microwave combined microfluidic extraction device includes a liquid collecting chamber cover 5 , an ultrasonic mixing liquid collecting chamber 9 and a microwave extraction chamber 12 .

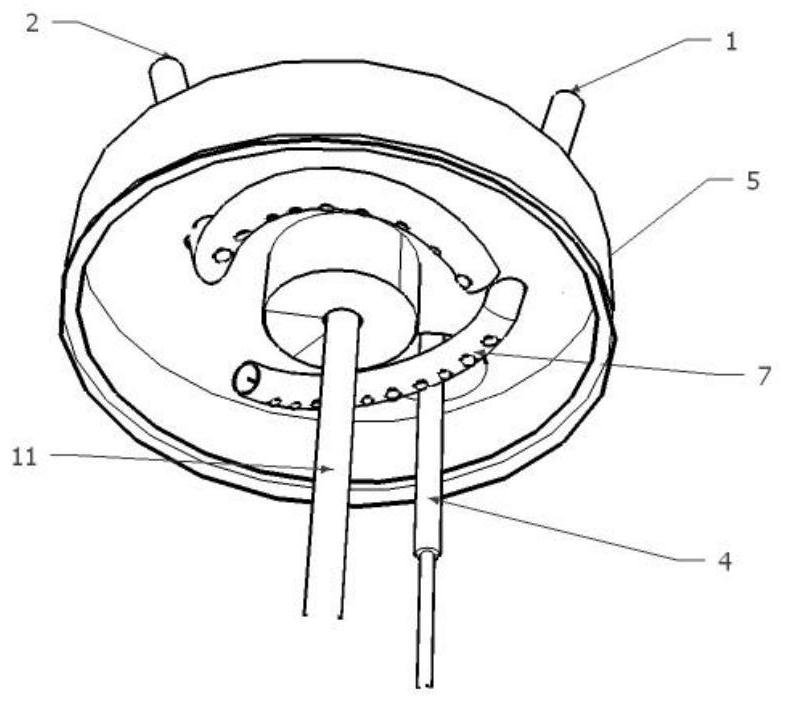

[0029] The lid 5 of the liquid collection chamber is equipped with a water-phase feeding micro-tube 1 and an oil-phase feeding micro-tube 2, and the ends of the water-phase feeding micro-tube 1 and the oil-phase feeding micro-tube 2 are arc-shaped curved horizontal sections, and the curved sections are They are respectively fixed on the bottom end of the lid 5 of the liquid collection chamber, the inner diameter of each microtube is 3 mm, and each microtube is provided with 15 liquid column cutting holes 7, and the diameter of the micropores is 0.7 mm, which can separate the water phase and the oil phase. The liquid column is cut into small diameter liquid columns or droplets. A motor 3 and an ultrasonic exciter 4 are fixed on the cover 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com