Method and apparatus for continuously winding bobbin material in strand form

A winding bobbin and winding technology, applied in the field of winding materials and equipment for continuous winding of strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

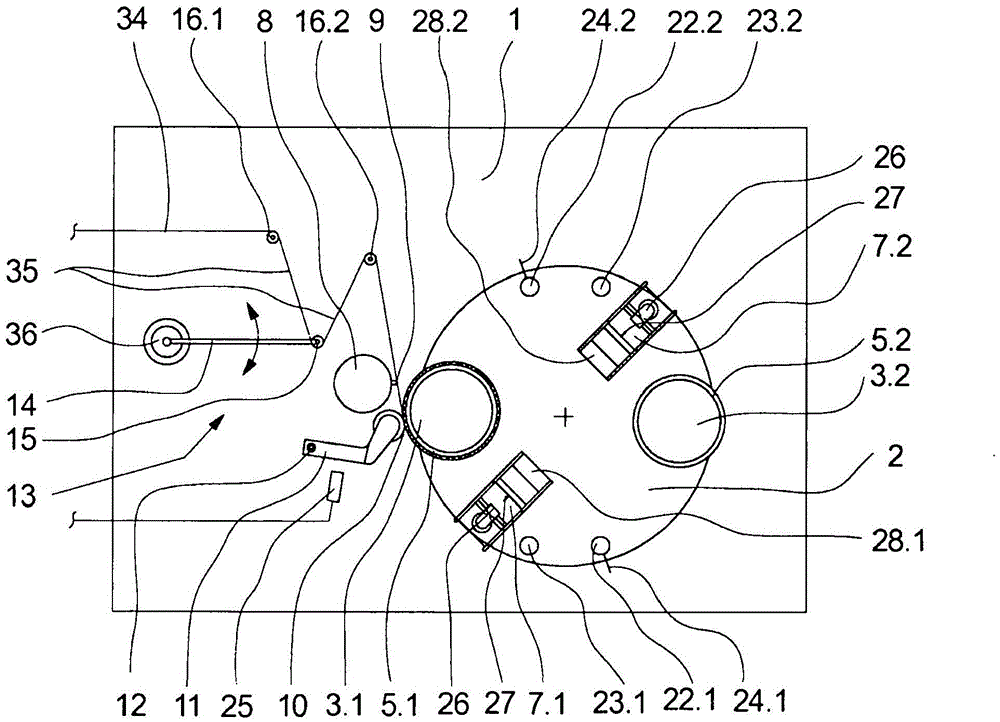

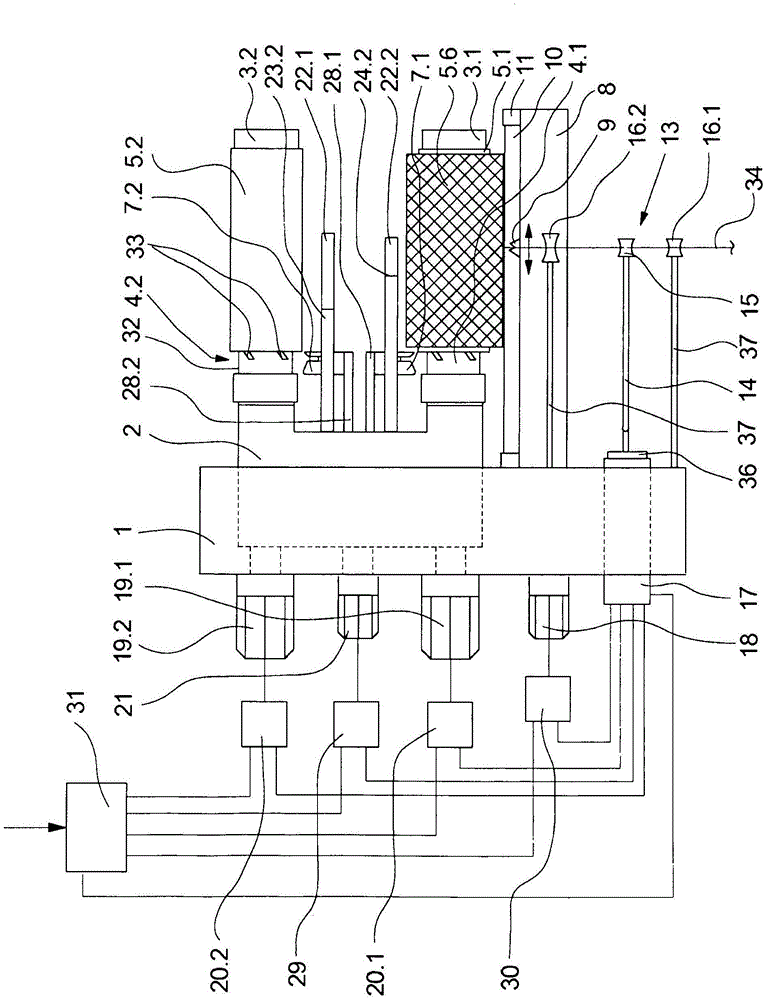

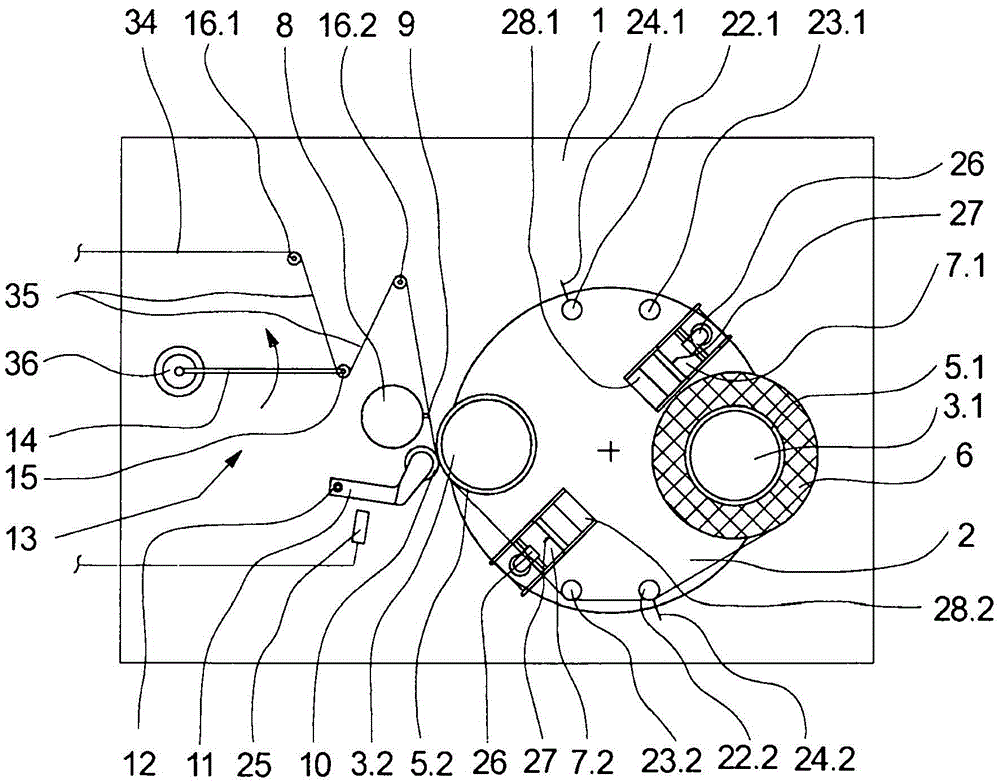

[0022] Figures 1 to 3 An exemplary embodiment of an apparatus according to the invention for continuously winding a bobbin material into a bobbin is shown in several views. figure 1 with image 3 The embodiment is shown in front view under different operating conditions and figure 2 The exemplary embodiment is shown in a plan view. The following description applies to all graphs if nothing is particularly emphasized about one graph.

[0023] The exemplary embodiment of the device for continuous winding according to the invention has a bobbin turret 2 which is rotatably mounted in a machine frame wall 1 and which can be rotated counterclockwise via a turret drive 21 . A turret control device 29 is assigned to the turret drive 21 , by means of which the turret drive 21 can be controlled for carrying out the rotational movement of the bobbin turret 2 .

[0024] The bobbin turret 2 supports two rotatably mounted bobbin spindles 3.1 and 3.2, which are held with a free end ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com