Energy-saving and environment-friendly steel smelting processing device

A technology for iron and steel smelting and processing equipment, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of uneven heating of hot exhaust gas, reduced processing efficiency of equipment, and unfavorable collection and utilization of hot gas, so as to avoid auxiliary The effect of hole adhesion, improving processing efficiency, avoiding bending or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

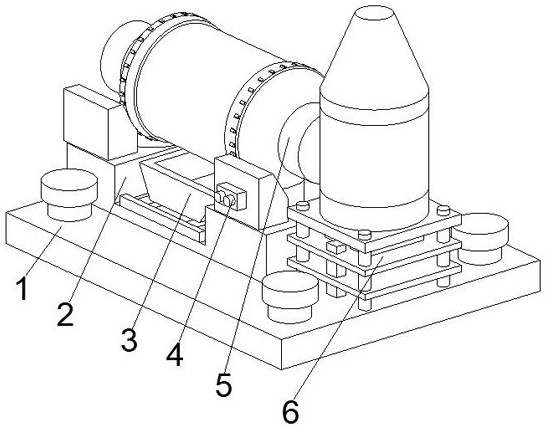

[0043] see Figure 1-6 , the present invention provides a technical solution: an energy-saving and environment-friendly iron and steel smelting processing device, including a stable bottom plate 1, a mounting bracket 2 is fixedly connected to the middle position on the top left side of the stable bottom plate 1, and the middle position of the inner cavity bottom of the mounting bracket 2 slides The material storage box 3 is connected, the middle position on both sides of the top of the mounting bracket 2 is rotatably connected to the processing device 5, the front right top of the mounting bracket 2 is fixedly connected to the controller 4, and the top right middle position of the stable bottom plate 1 is fixedly connected to a support frame 6;

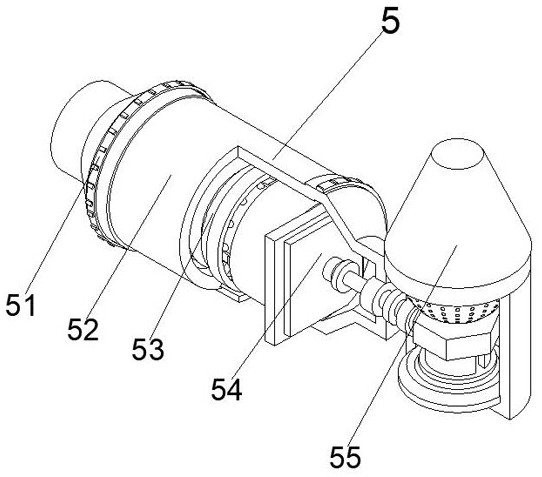

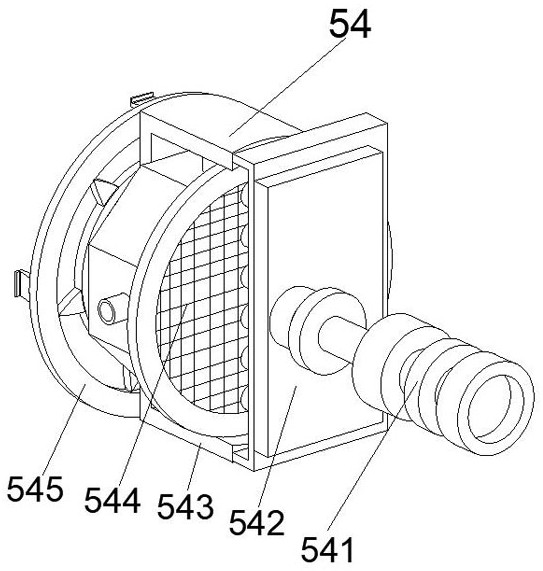

[0044] The processing device 5 includes a smelting main body 52, a transmission ring 51 is fixedly connected to the outer walls on both sides, a separator 53 is fixedly connected to the middle position of the inner cavity bottom of th...

Embodiment 2

[0050] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using an energy-saving and environmentally friendly iron and steel smelting processing device, step 1: install the equipment, and slide the storage box 3 and the installation bracket 2 To connect, the processing device 5 is rotationally connected to the installation bracket 2, and the installation bracket 2 is connected to the energy source, and the stable base 1 is fixed to the ground;

[0051] Step 2: Carry out sundry transport processing through the conveying chamber generated by the separator 53 and the protective device 54, and after the gas is transported and processed inside the protective device 54, it enters the interior of the placement device 55 for secondary treatment, and the transmission ring 51 and the smelting main body 52 is fixedly connected so that the device rotates and rotates for processing;

[0052] Step 3: Use the delivery pipeline 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com