High-speed motor rotation tester

A high-speed motor and tester technology, applied in the field of testing, can solve problems such as production problems and cost waste, and achieve the effect of avoiding dropping or scratching, avoiding waste, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

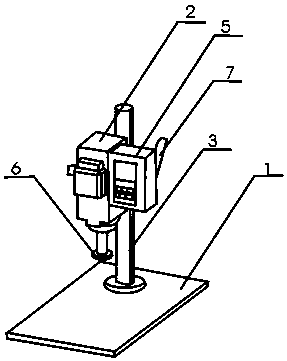

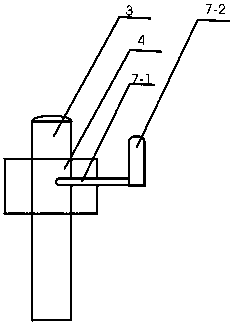

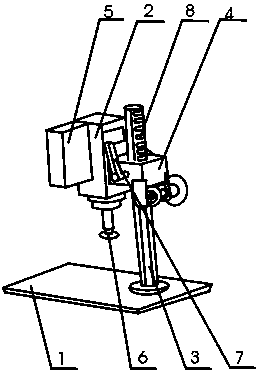

[0016] The invention provides a high-speed motor rotation tester, which includes a base 1, a motor frame 2, a support column 3, a fixed frame 4, a controller 5, a speed measuring magnetic ring 6, a fixed handle 7, and a fixed hole 8. The upper side of the base 1 is equipped with The support column 3 is provided with a fixing hole 8 on the support column 3, and a fixed frame 4 is installed on the upper side of the support column 3. The fixed handle 7 passes through the fixed frame 4 and is connected to the support column 3. The fixed frame 4 is connected to the motor frame 2, and the motor frame 2. A motor is installed inside, and a speed-measuring magnetic ring 6 is installed on the lower side of the motor frame 2. The side of the motor frame 2 is connected to the controller 5, and the controller 5 is connected to the motor and the speed-measuring magnetic ring 6 respectively. The fixed handle 7 includes a fixed head 7-1, a control handle 7-2, and the control handle 7-2 is conn...

Embodiment 2

[0018] When in use, place the motor in the motor frame 2, and then adjust the position of the motor frame 2 according to the motor model. When adjusting, move the fixed handle 7, and then move the fixed frame 4. When moving to a suitable position, fix the fixed handle 7 The head 7-1 is placed in the fixing hole 8 of the support column 3, the fixing frame 4 is fixed, and then the motor in the motor frame 2 is fixed, and then the controller 5 is opened, and the motor is tested through the speed measuring magnetic ring 6 and The data is transmitted to the controller 5, and the controller 5 records and controls it. When the rotation speed exceeds the range of use, it is convenient for the staff to find out in time, ensuring the normal production, avoiding waste of costs, and saving costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com