Mobile atomizing machine for forestry seedling protection

A kind of movable and sapling technology, applied in application, agriculture, mixer, etc., can solve the problems of increased labor cost and reduced work efficiency, and achieve the effect of reducing manual operation, efficient processing, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

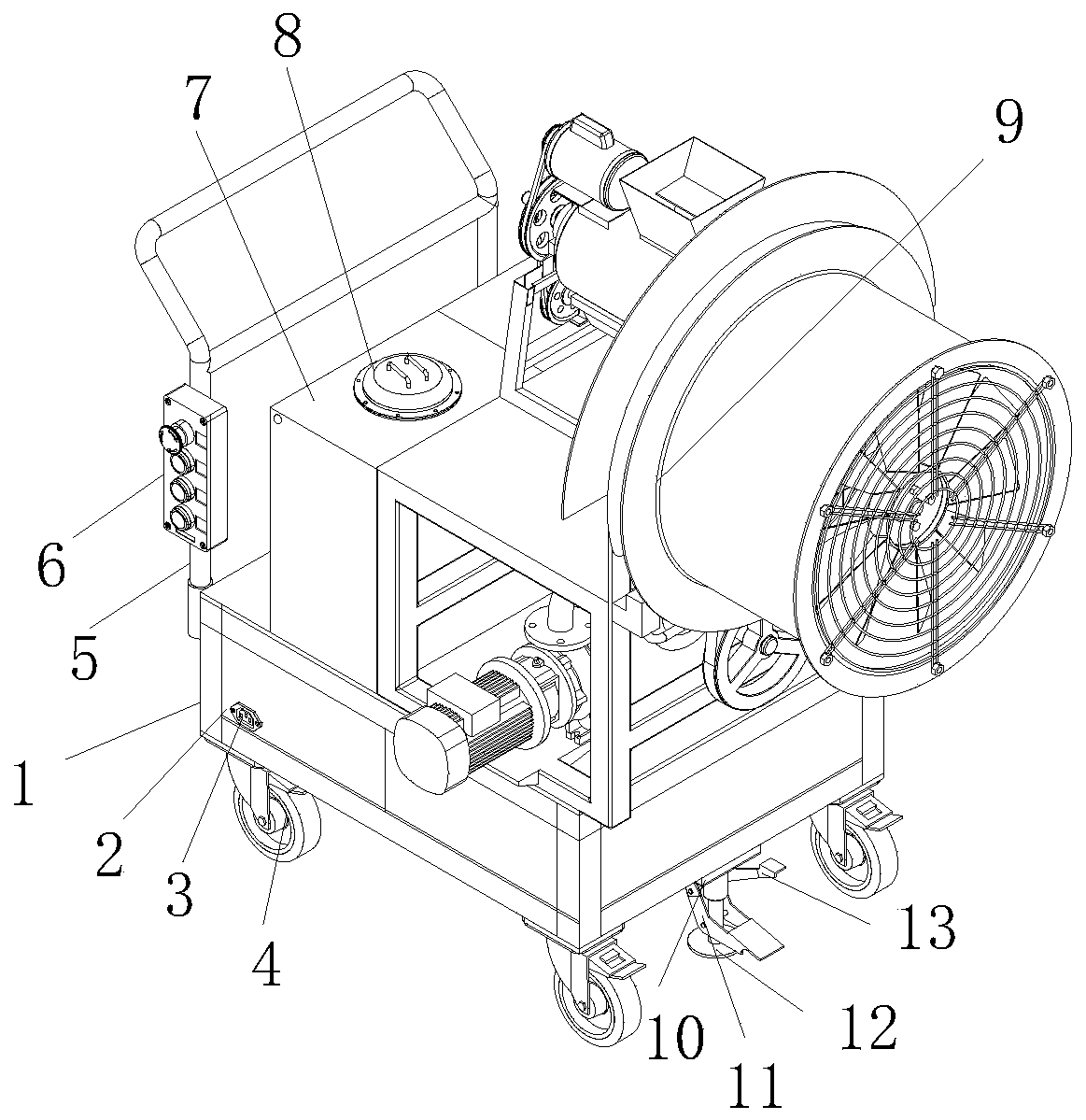

[0034]The present invention provides a kind of movable spraying machine for the protection of forestry saplings through improvement, including underframe 1, battery 2, power supply interface 3, roller 4, push frame 5, controller 6, storage box 7, top cover 8, pillar 10. Linkage piece 11, chassis 12 and pressure piece 13. Battery 2 is embedded in the left end of chassis 1. Power interface 3 is installed at the left end of the front face of battery 2. Power interface 3 is electrically connected to battery 2. The bottom four ends of chassis 1 pass through Bolts are fixed with rollers 4, and a push frame 5 is vertically welded on the upper left side of the bottom frame 1. A controller 6 is installed in the middle of the front end of the push frame 5. A storage box 7 is placed at the left end of the top of the bottom frame 1. A storage box 7 is installed on the top front end of the storage box 7. The top cover 8 and the middle part of the bottom right end of the bottom frame 1 are v...

Embodiment 2

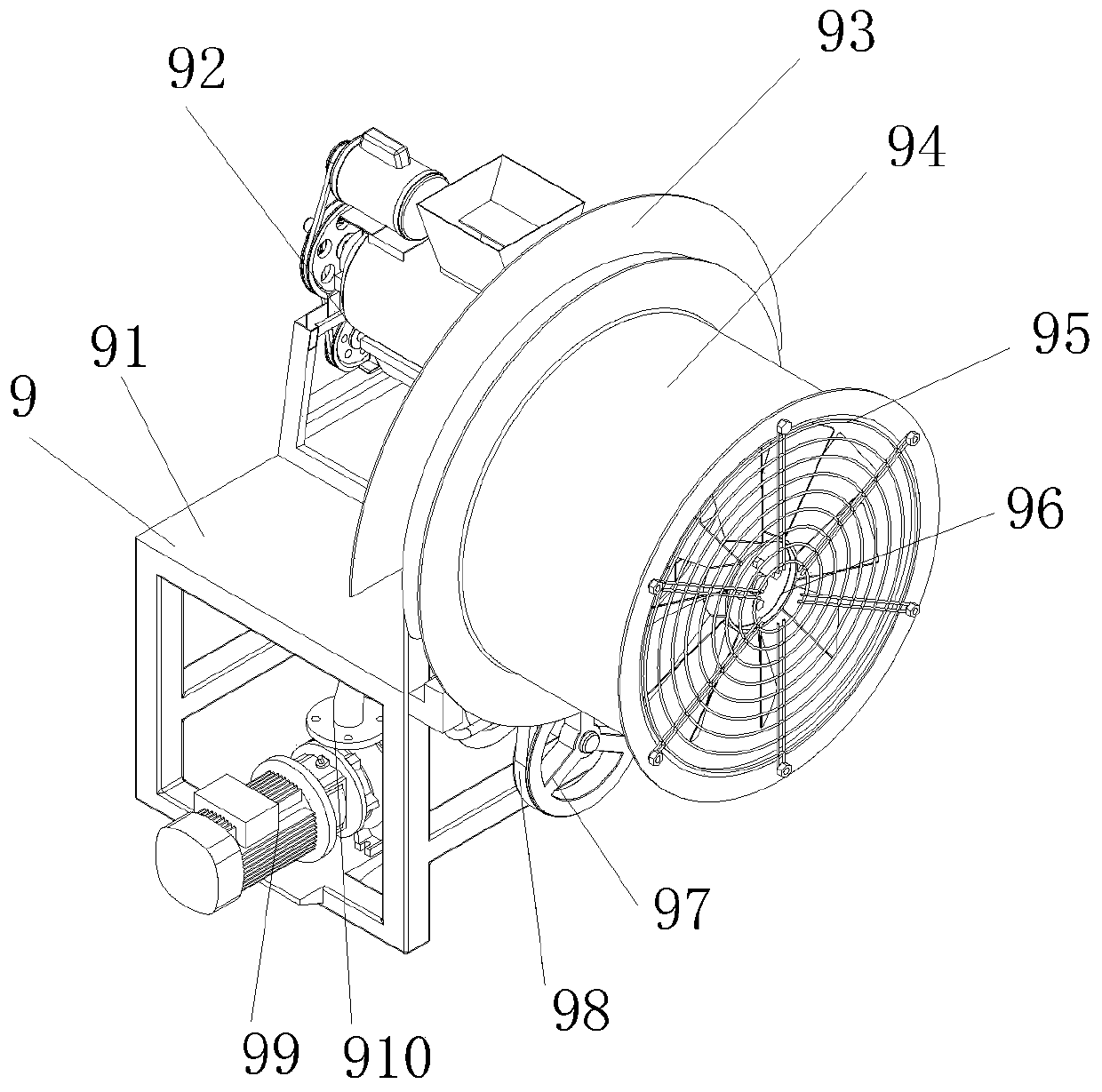

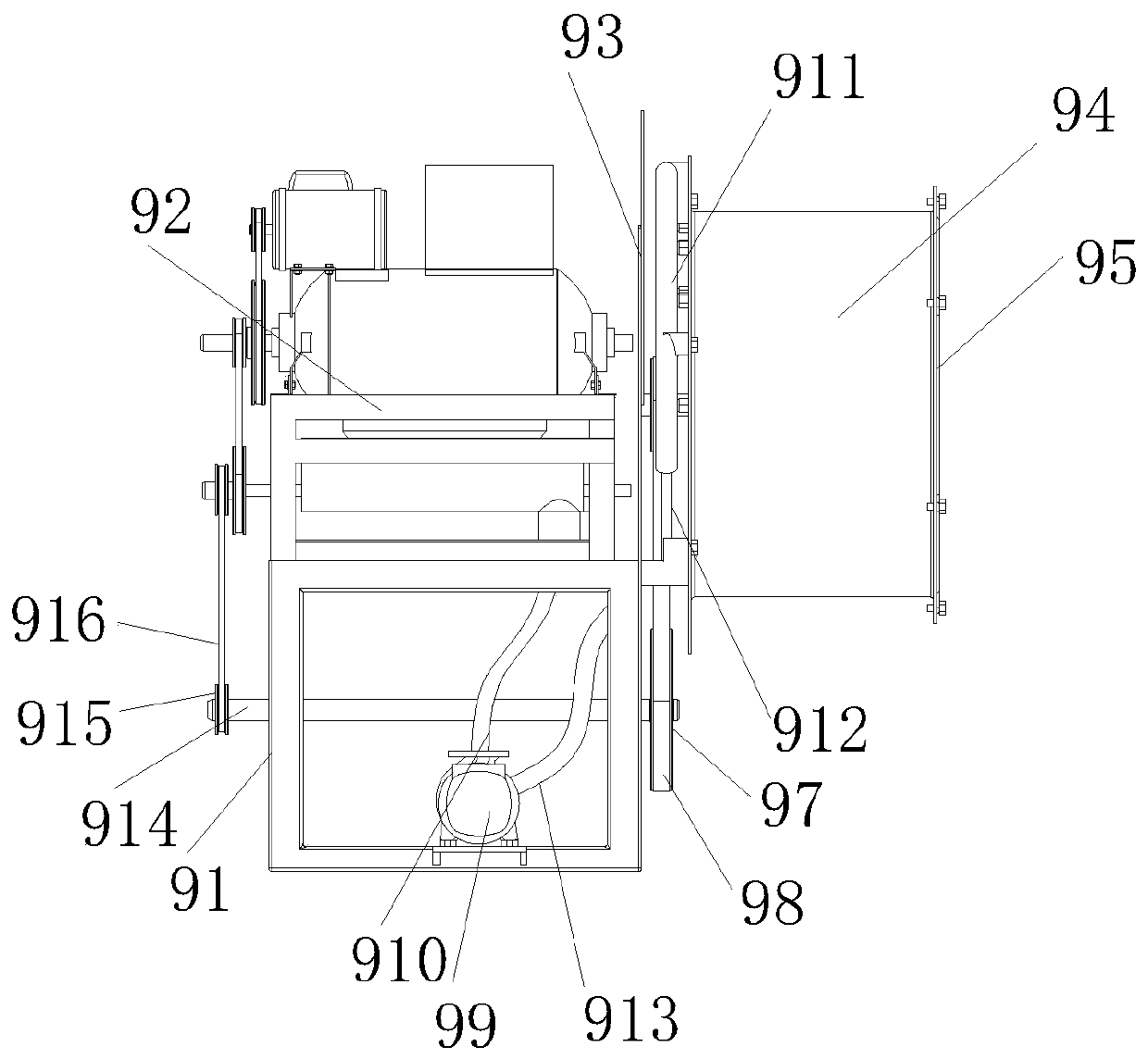

[0048] The present invention provides a kind of forestry sapling protection movable spraying machine here by improvement,

[0049] The left side of the spraying device 9 is attached to the storage box 7, and solid fertilizers and water can be placed separately in the storage box 7, and the water source is stored backwards, which is close to the processing warehouse 923, which is convenient for feeding and feeding; the cylinder 94 An arc-shaped pull plate is installed at the lower end of the inner side, and the water mist on the inner wall of the cylinder 94 can slide down to the bottom along with the side, and the internal residue can be discharged by pulling out the arc-shaped pull plate to prevent excessive residue from overflowing; inside the base 91 The front and rear ends of the bottom are cross bars, and the top of the cross bar is connected to the connecting shaft 914 through a fixed shaft seat, which helps the connecting shaft 914 to be stable during rotation and is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com