Vehicle control device

A technology for control devices and vehicles, applied in the direction of control devices, electrical devices, power devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

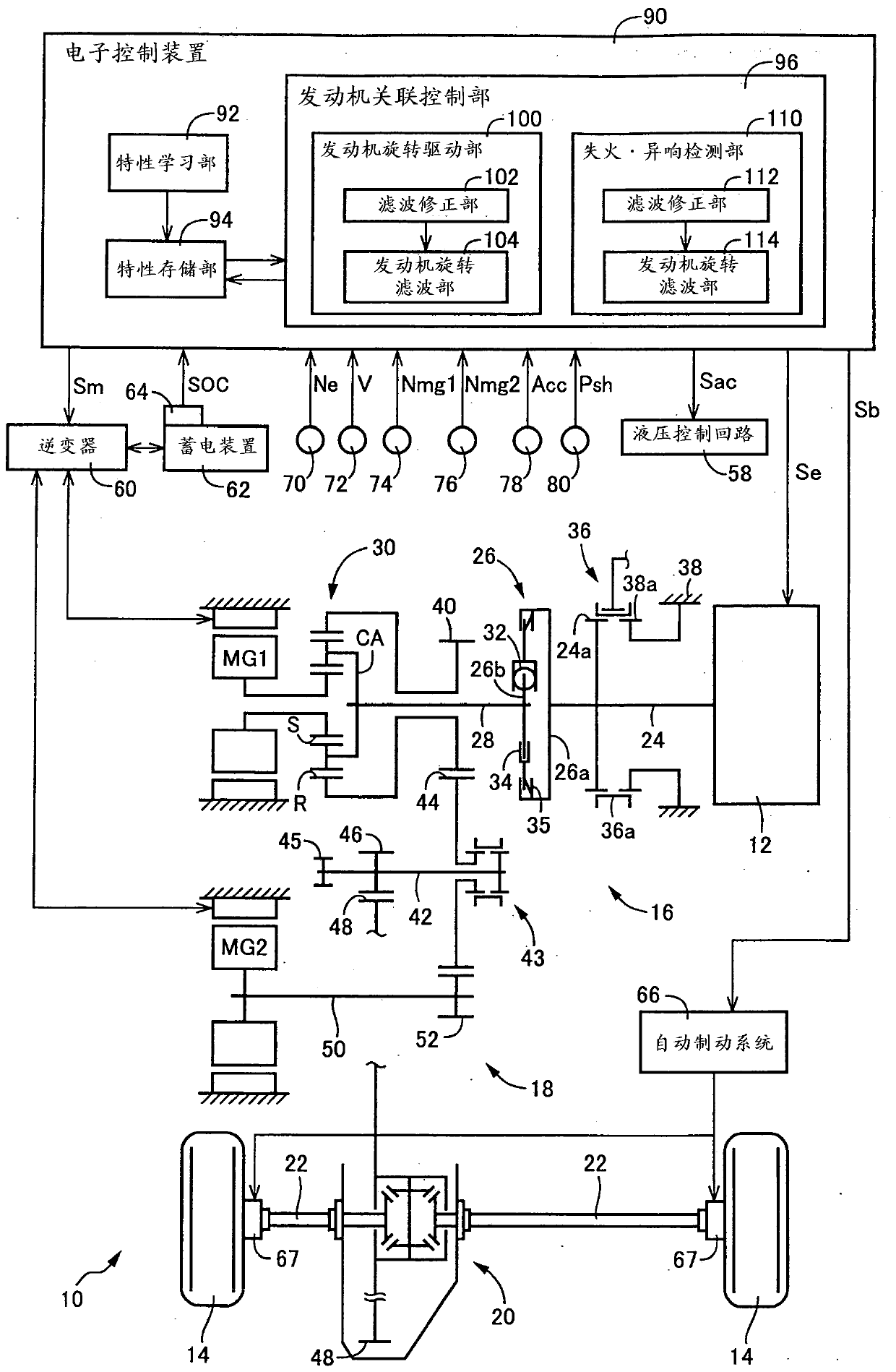

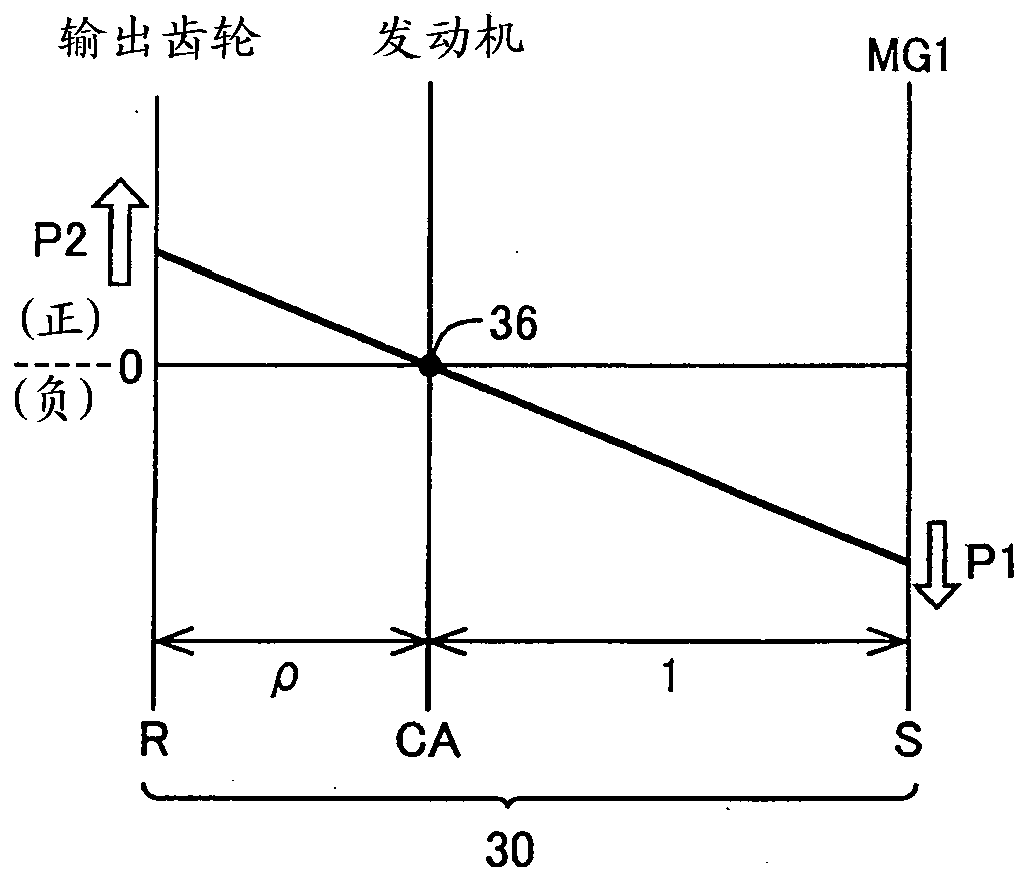

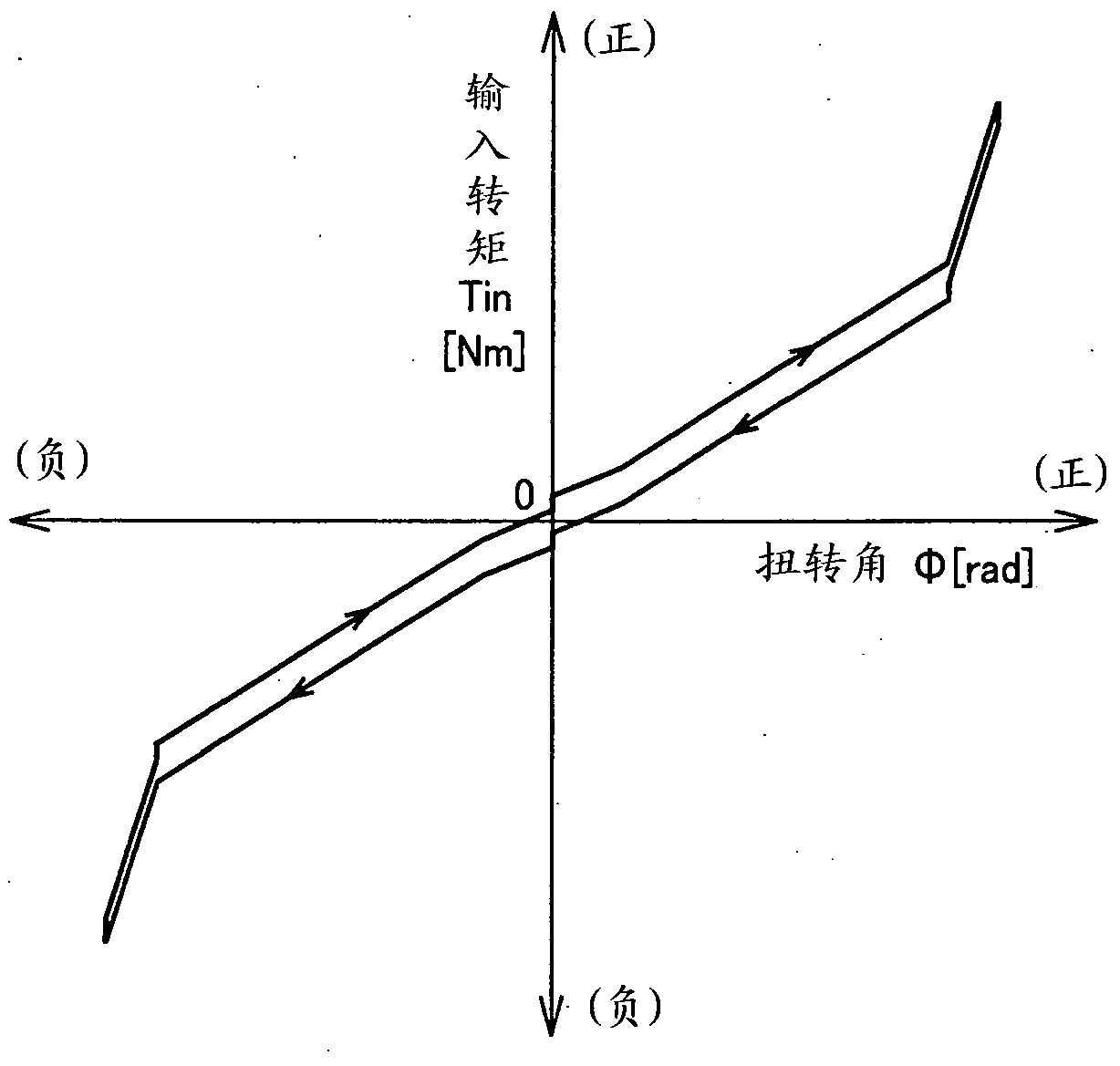

[0050] The engine is an internal combustion engine that generates power by combustion of fuel, such as a gasoline engine or a diesel engine, and rotational vibration is generated by knocking or the like, and the rotational vibration may be amplified by resonance of a torsionally rigid rotating member such as a vibration damper. As the electric motor, it is preferable to use a motor generator that can also function as a generator. A rotating member having rotational characteristics with respect to input torque is, for example, a damper device that absorbs rotational vibration of an engine, a power transmission shaft having predetermined torsional rigidity, and the like. The vibration damper is configured to include, for example, an elastic body such as a spring and a friction mechanism, but may only include an elastic body. As the rotation characteristics of the rotating member with respect to the input torque, there are the rigidity value of the torsional rigidity correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com