Textile fabric printing machine

A technology of textile fabrics and printing machines, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of fabric wrinkling, printing dislocation of textile fabrics, and inability to print fabrics completely, so as to reduce frictional resistance and stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

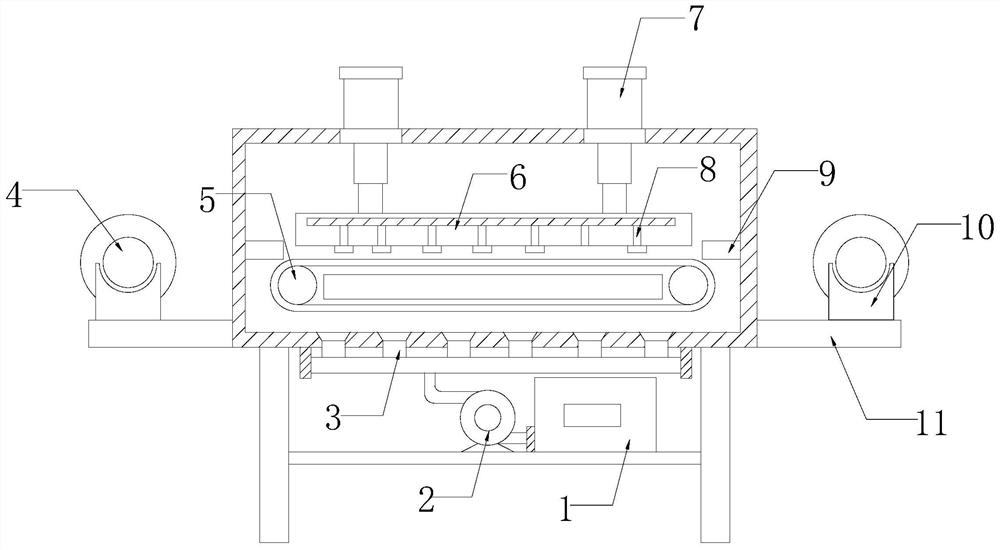

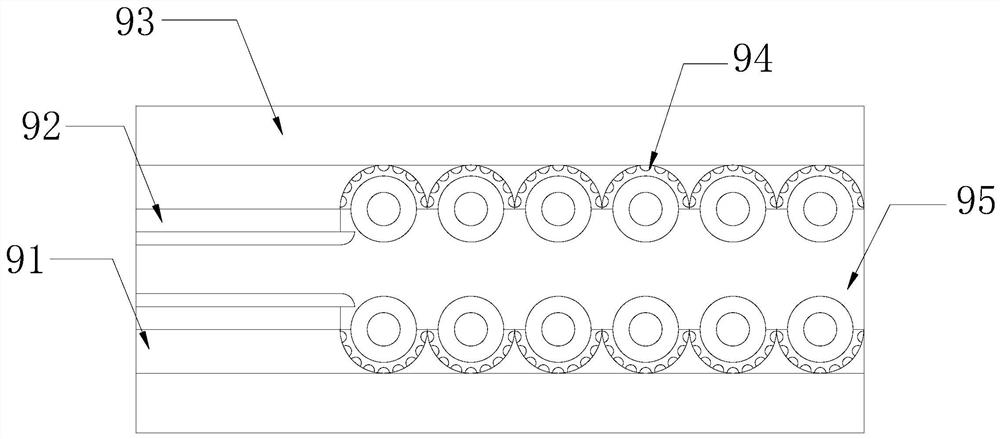

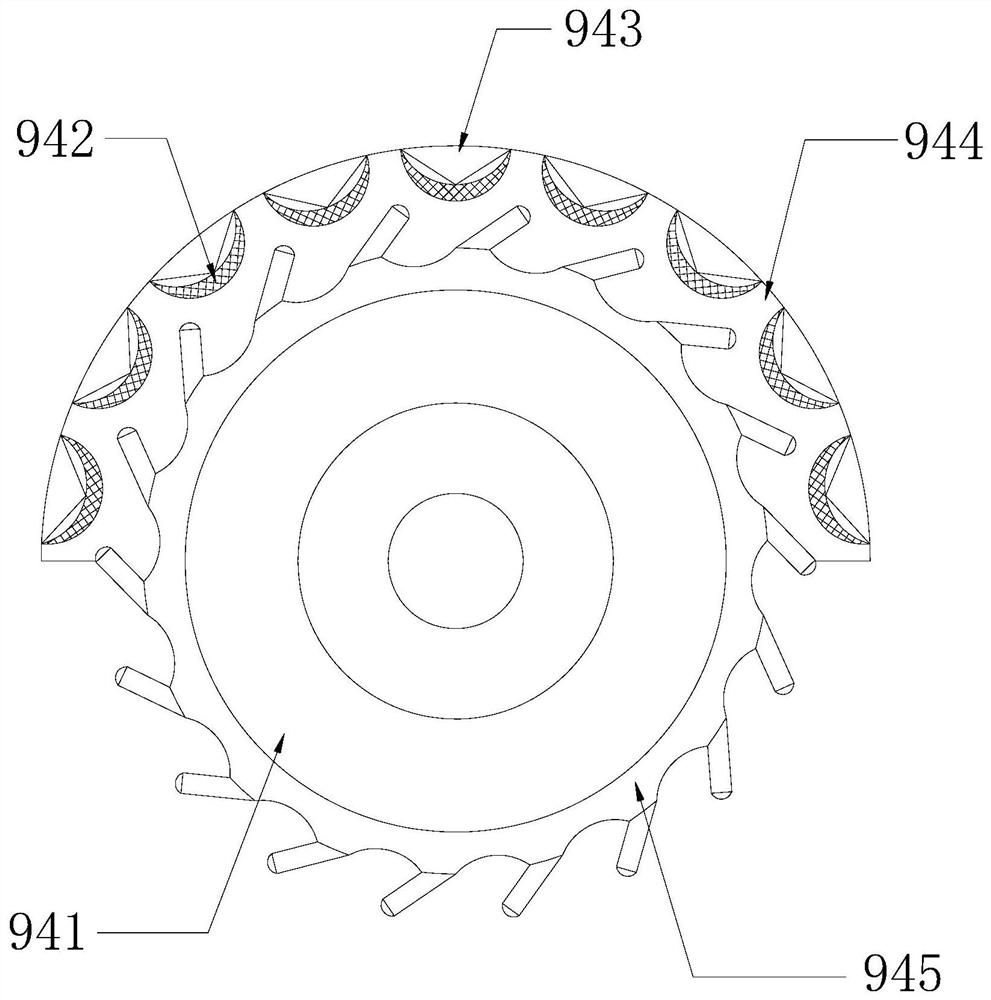

[0034] see figure 1, the present invention provides a technical solution: a textile fabric printing machine, the structure of which includes a dryer 1, a fan 2, an air outlet 3, a guide roller 4, a transfer table 5, a printing stand 6, an ink storage chamber 7, a printing Drum 8, leveling device 9, winding roller 10, body 11, the dryer 1 is connected with the fan 2, the fan 2 is provided with six air outlets 3 and the two are connected, the air outlet 3 runs through the bottom of the machine body 11, and the body 11 is provided with a transmission platform 5 embedded therein. The top of the transmission platform 5 is in contact with the bottom of the printing frame 6, and the printing cylinder 8 is connected to the transmission platform 5 through the printing frame 6. connected, two ink storage chambers 7 are installed on the top of the printing frame 6 and the two are connected, and the two ink storage chambers 7 run through the body 11, and both sides of the body 11 are prov...

Embodiment 2

[0045] see figure 1 , the present invention provides a technical solution: a textile fabric printing machine, the structure of which includes a dryer 1, a fan 2, an air outlet 3, a guide roller 4, a transfer table 5, a printing stand 6, an ink storage chamber 7, a printing Drum 8, leveling device 9, winding roller 10, body 11, the dryer 1 is connected with the fan 2, the fan 2 is provided with six air outlets 3 and the two are connected, the air outlet 3 runs through the bottom of the machine body 11, and the body 11 is provided with a transmission platform 5 embedded therein. The top of the transmission platform 5 is in contact with the bottom of the printing frame 6, and the printing cylinder 8 is connected to the transmission platform 5 through the printing frame 6. connected, two ink storage chambers 7 are installed on the top of the printing frame 6 and the two are connected, and the two ink storage chambers 7 run through the body 11, and both sides of the body 11 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com