Extinction casting PE film and production process thereof

A casting and matting technology, applied in the field of film materials, can solve the problems of uneven thickness of matting PE blown film, easy stretching and extension under force, poor color registration accuracy, etc., and achieve excellent matting effect, high surface tension, and improved processing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

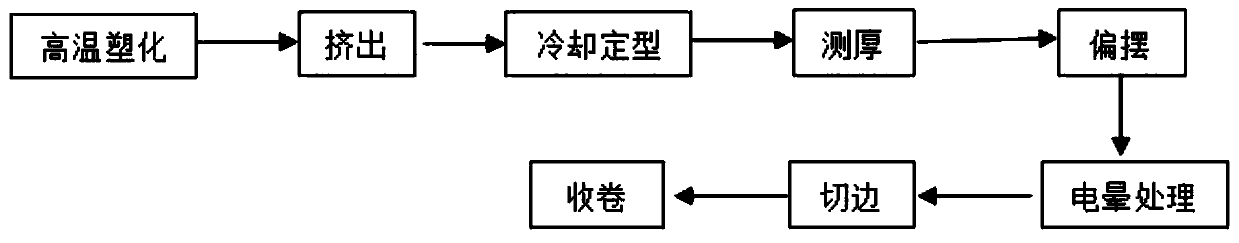

[0029] Step 1, high-temperature plasticization: add the resins and additives of the heat-sealing layer, the intermediate layer and the corona layer into the corresponding hoppers respectively, and enter each section of the German Reifen machine extruder through the automatic feeding system, and then place the Plasticized into melt at high temperature;

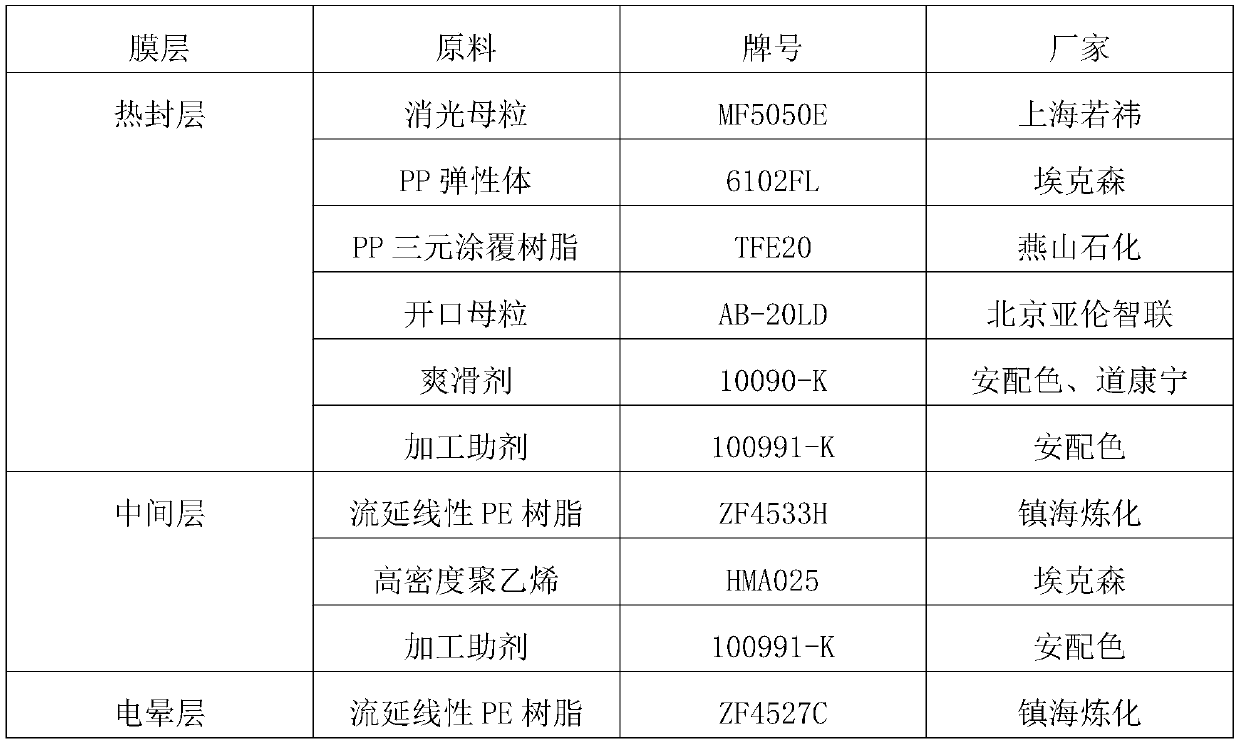

[0030] The heat-sealing layer includes a mass ratio of 25:25:35:0.5:0.4:0.3 for cast PE matting masterbatch, PP elastomer, PP ternary coating resin, opening masterbatch, slip agent and processing aid. The intermediate layer includes cast linear PE resin, high-density polyethylene and processing aids in a mass ratio of 25:50:0.3; the corona layer is all cast linear PE resin.

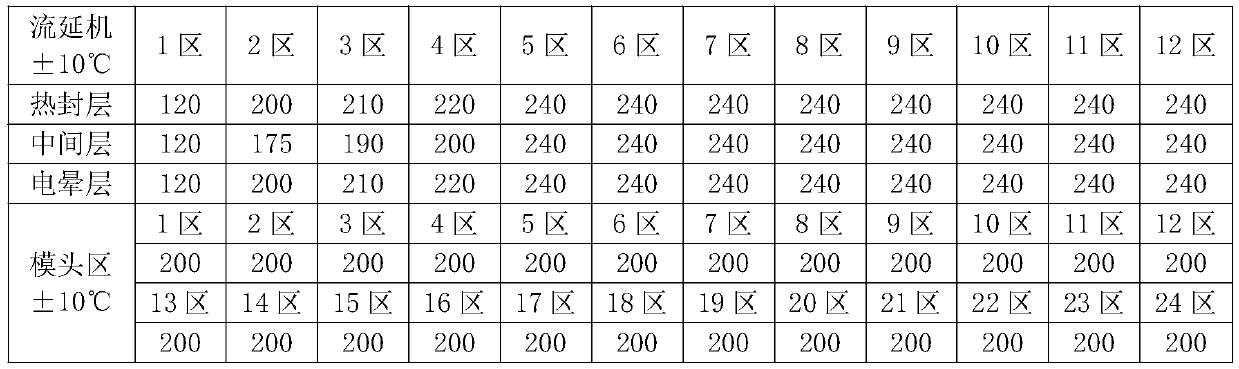

[0031] The temperature settings of the German Reifen casting machine are as follows:

[0032]

[0033] Step 2, extrusion: through the action of the driving force generated by the thread when the extruder screw rotates, the molten material is extruded f...

Embodiment 2

[0047] Step 1, high-temperature plasticization: add the resins and additives of the heat-sealing layer, the intermediate layer and the corona layer into the corresponding hoppers respectively, and enter each section of the German Reifen machine extruder through the automatic feeding system, and then place the Plasticized into melt at high temperature;

[0048] The heat-sealing layer includes a mass ratio of 24:24:33:0.4:0.3:0.2 for cast PE matting masterbatch, PP elastomer, PP ternary coating resin, opening masterbatch, slip agent and processing aid. The intermediate layer includes cast linear PE resin, high-density polyethylene and processing aids in a mass ratio of 24:48:0.2; the corona layer is all cast linear PE resin.

[0049] The temperature settings of the German Reifen casting machine are as follows:

[0050]

[0051] Step 2, extrusion: through the action of the driving force generated by the thread when the extruder screw rotates, the molten material is extruded f...

Embodiment 3

[0062] Step 1, high-temperature plasticization: add the resins and additives of the heat-sealing layer, the intermediate layer and the corona layer into the corresponding hoppers respectively, and enter each section of the German Reifen machine extruder through the automatic feeding system, and then place the Plasticized into melt at high temperature;

[0063] The heat-sealing layer includes a mass ratio of 26:26:37:0.6:0.5:0.4 for cast PE matting masterbatch, PP elastomer, PP ternary coating resin, opening masterbatch, slip agent and processing aid. The intermediate layer includes cast linear PE resin, high-density polyethylene and processing aids in a mass ratio of 26:52:0.4; the corona layer includes cast linear PE resin.

[0064] The temperature settings of the German Reifen casting machine are as follows:

[0065]

[0066] Step 2, extrusion: through the action of the driving force generated by the thread when the extruder screw rotates, the molten material is extruded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com