Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

355results about "Thin film resistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

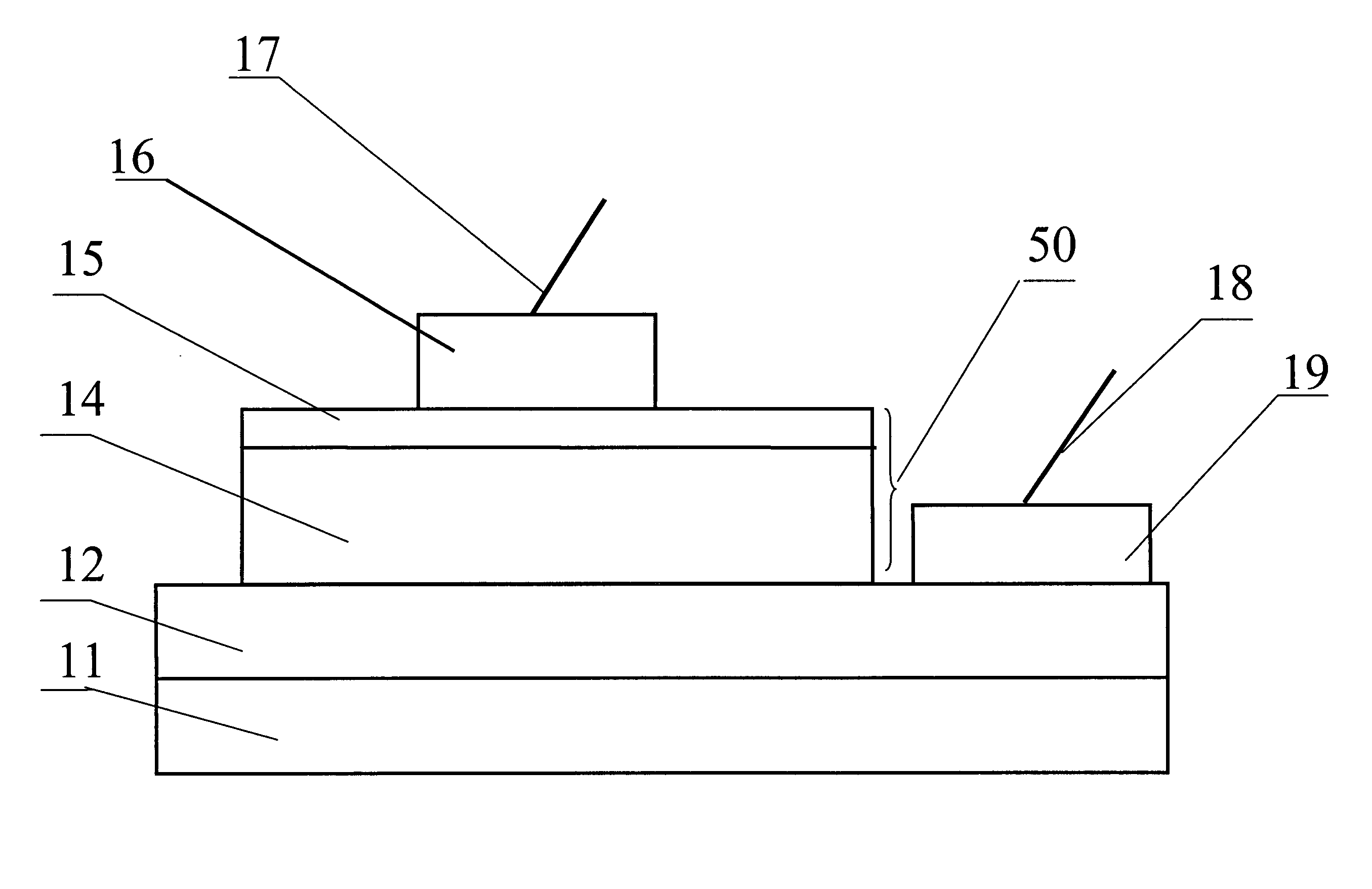

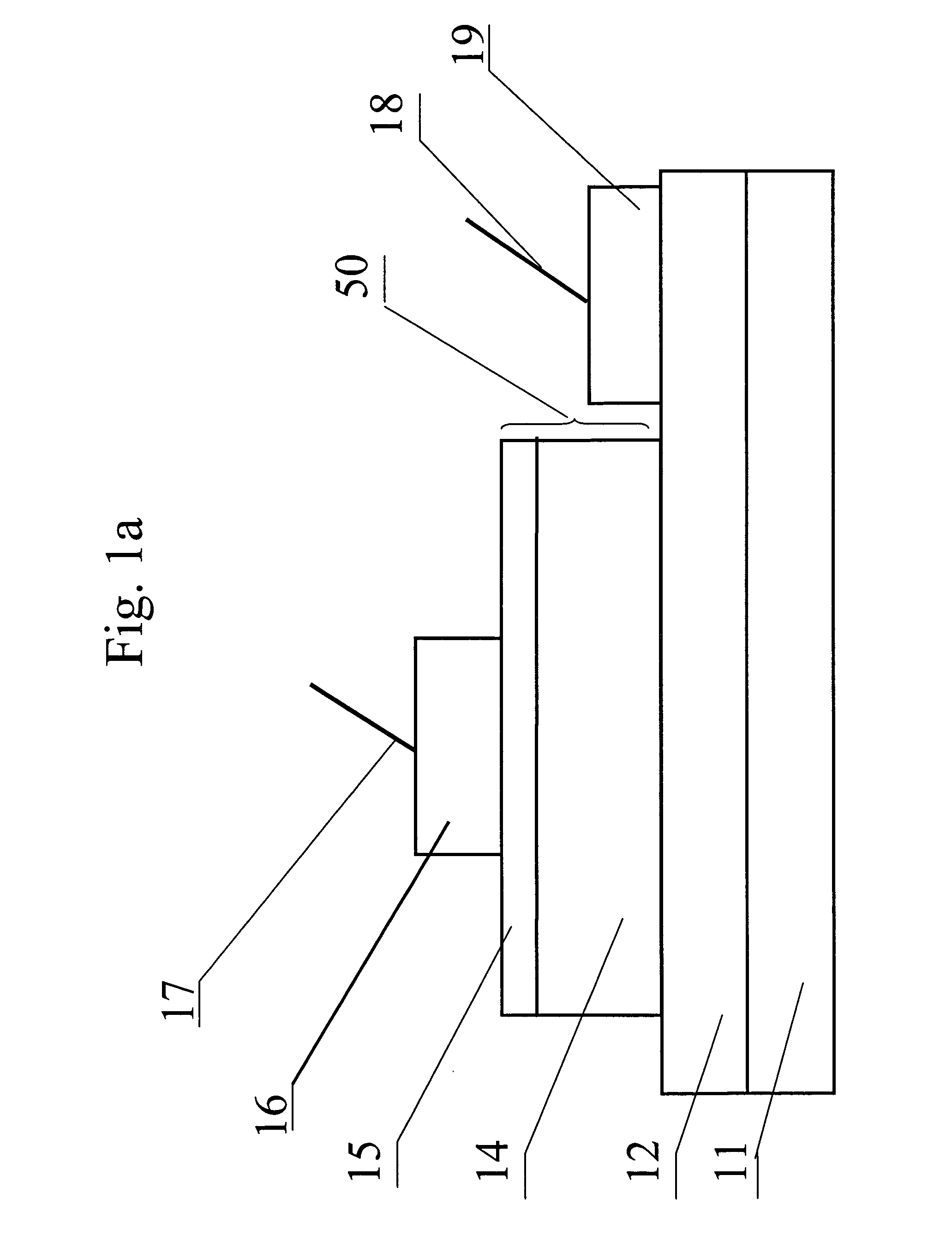

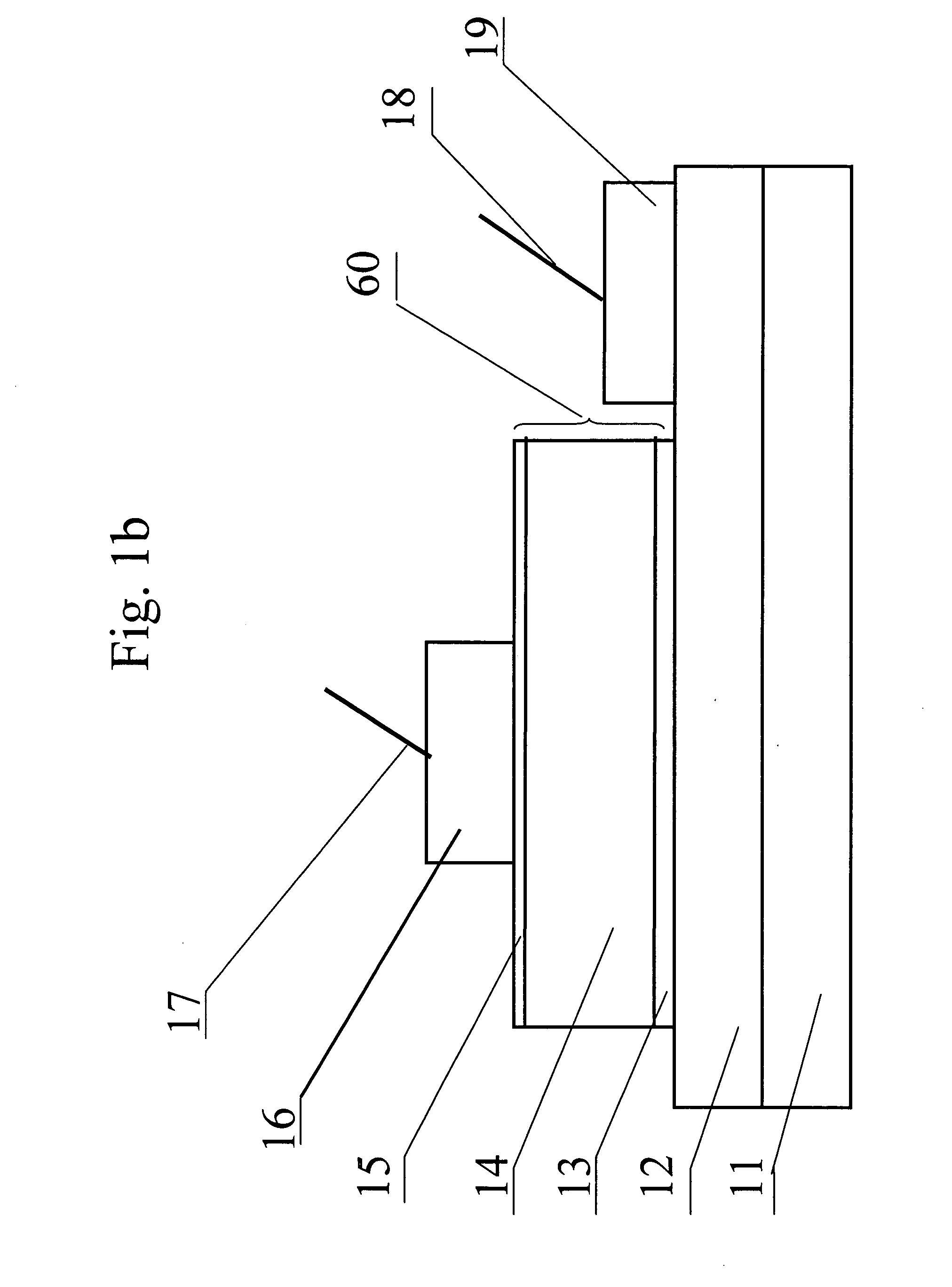

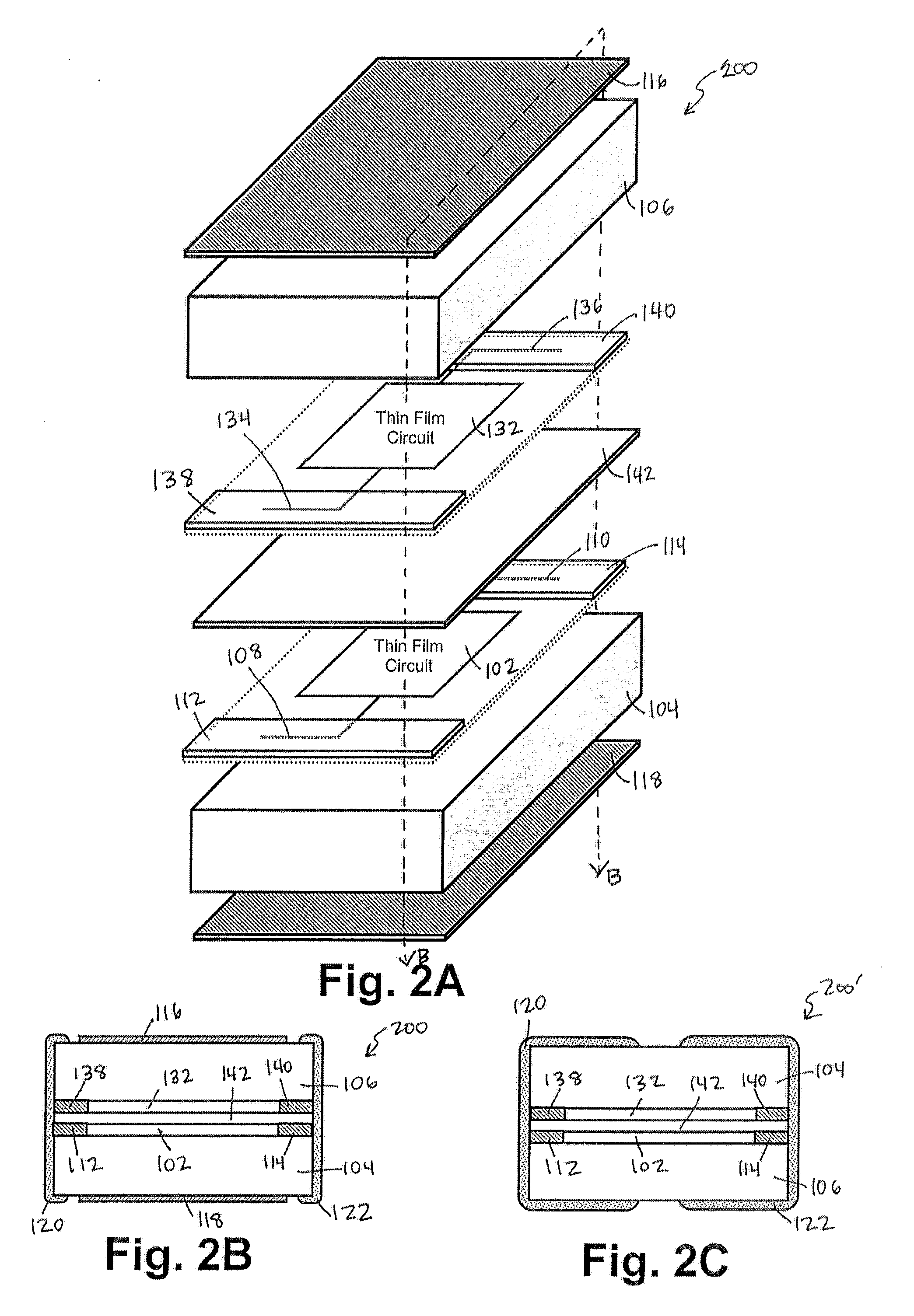

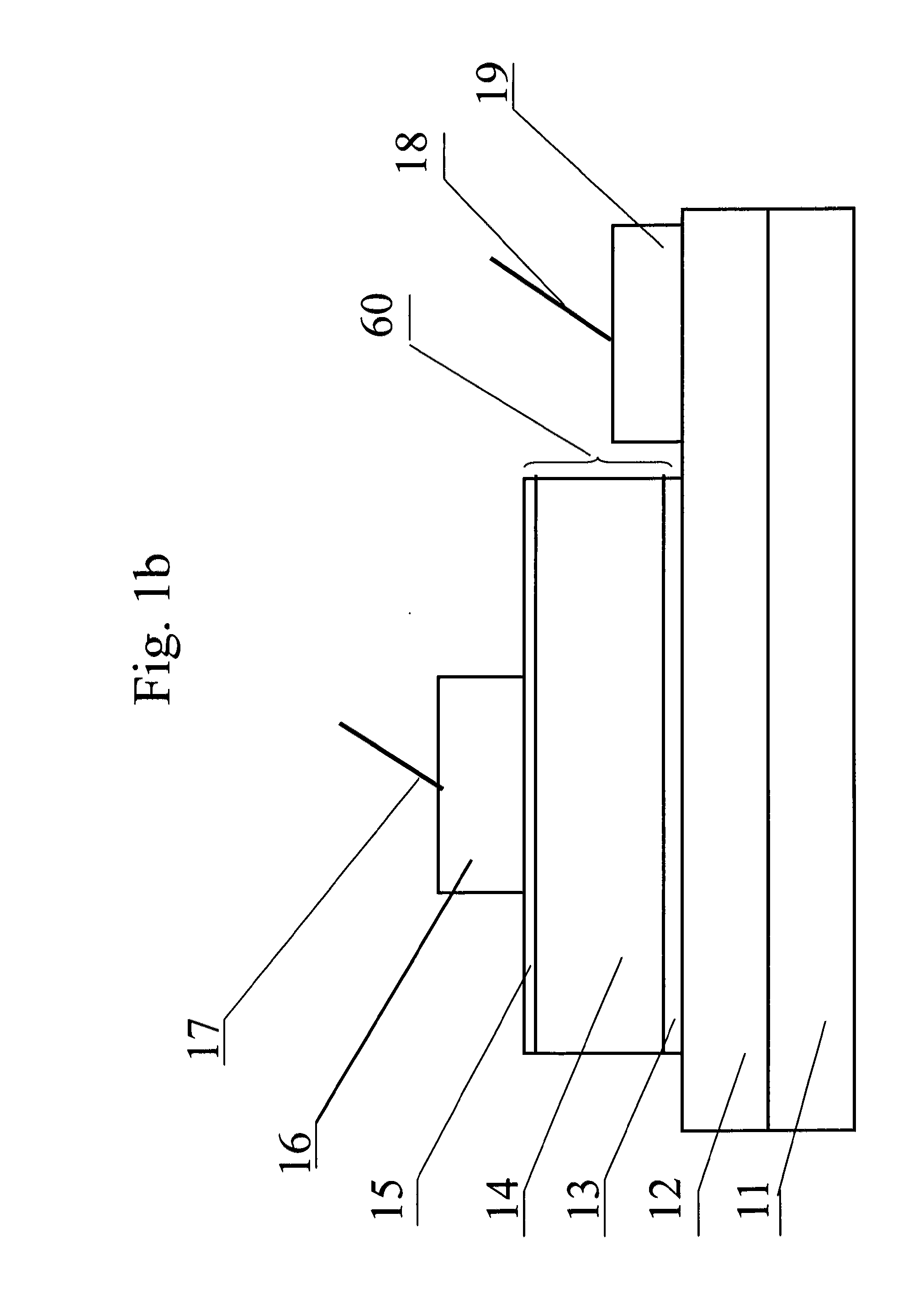

Switchable resistive perovskite microelectronic device with multi-layer thin film structure

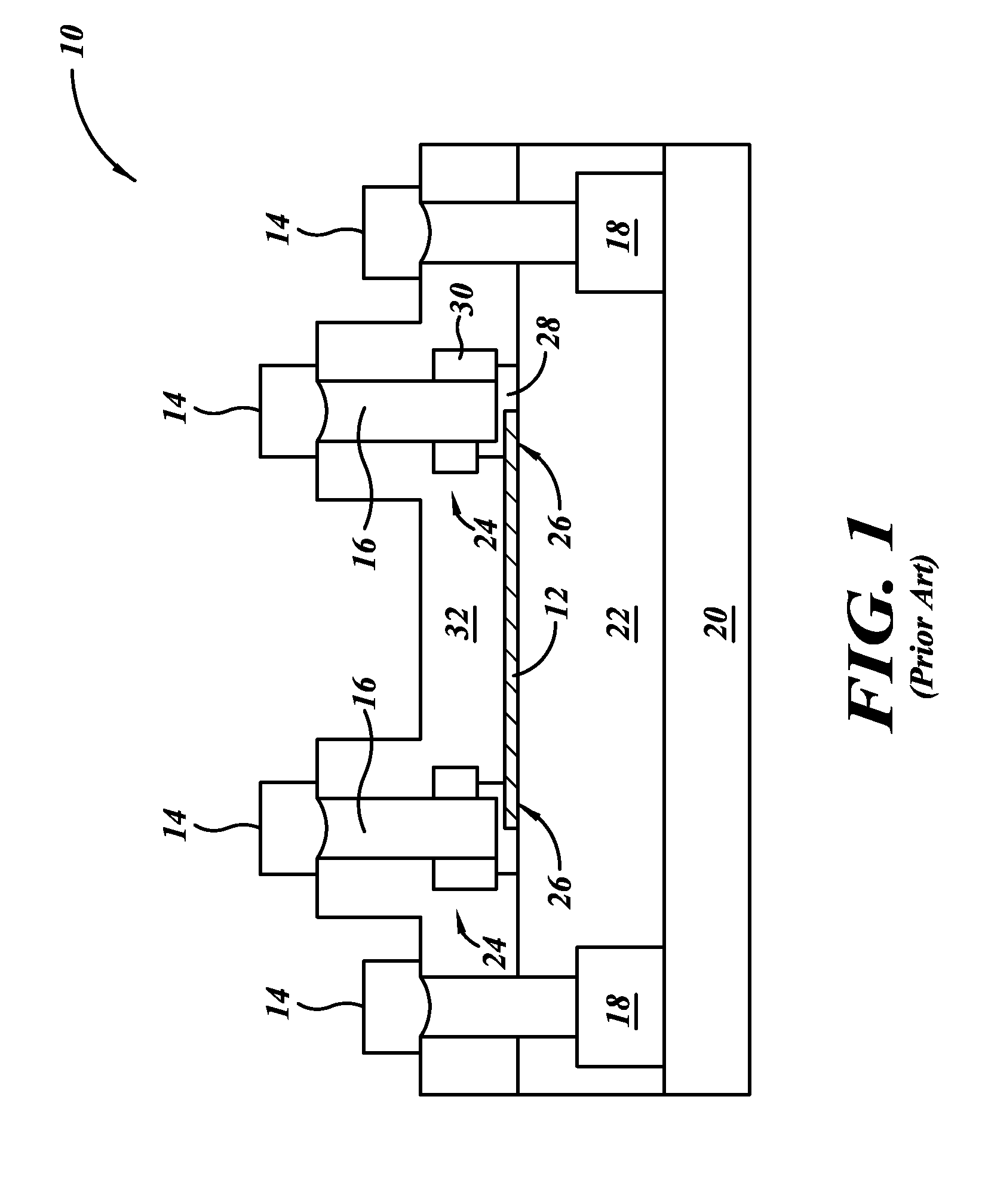

ActiveUS20050151156A1Lowered pulse voltageProtection of device being damagedThyristorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceMagnification

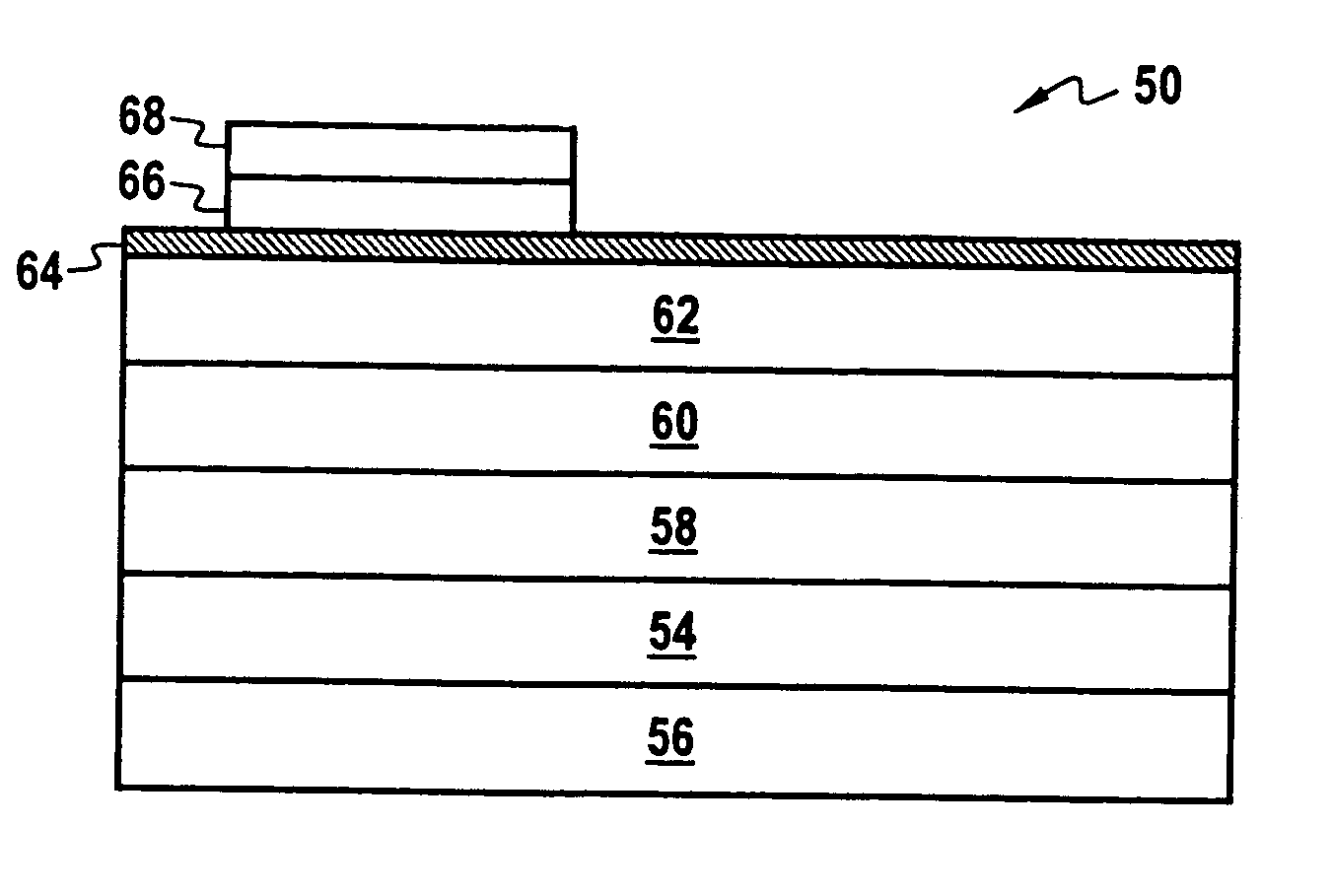

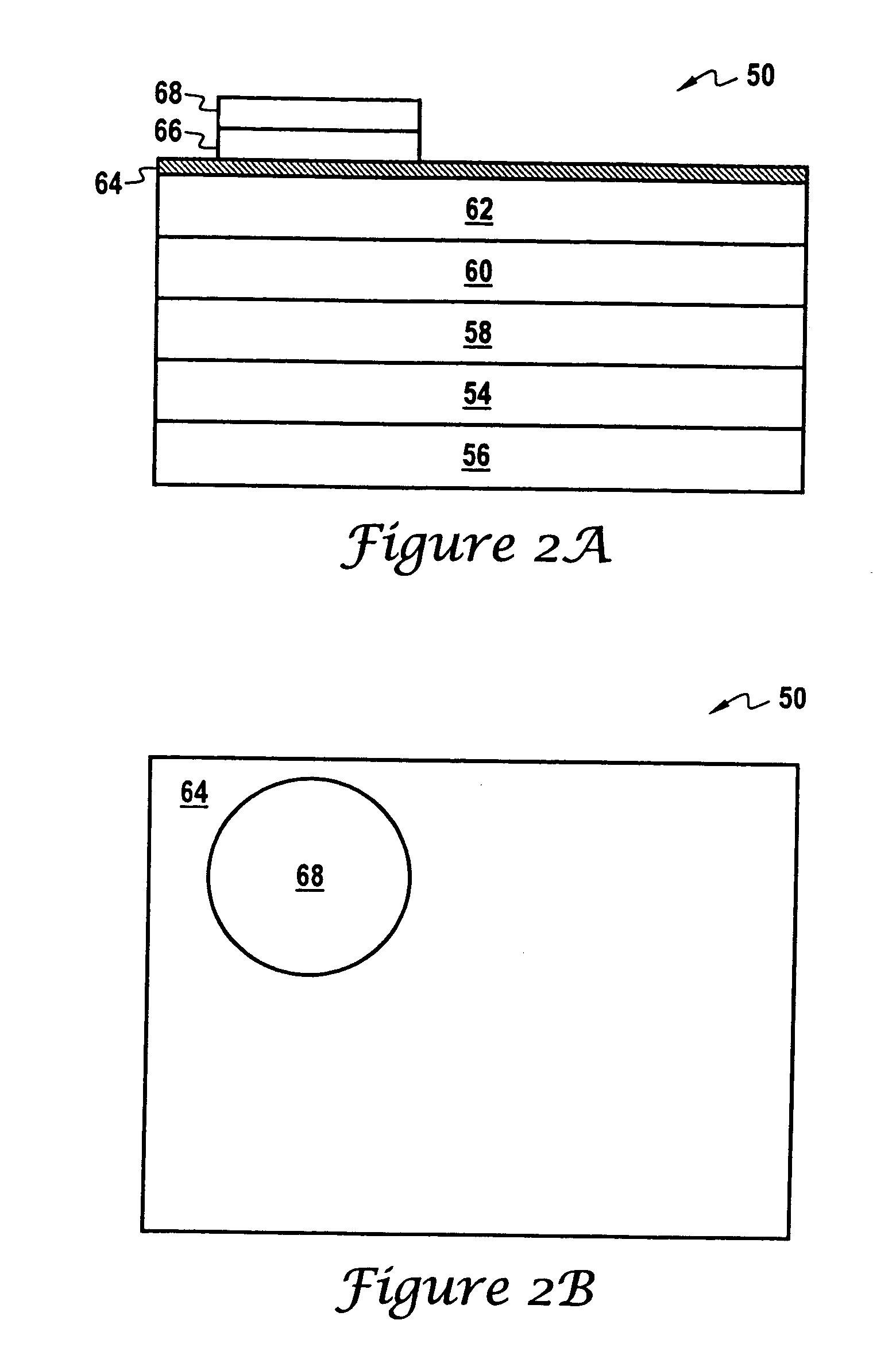

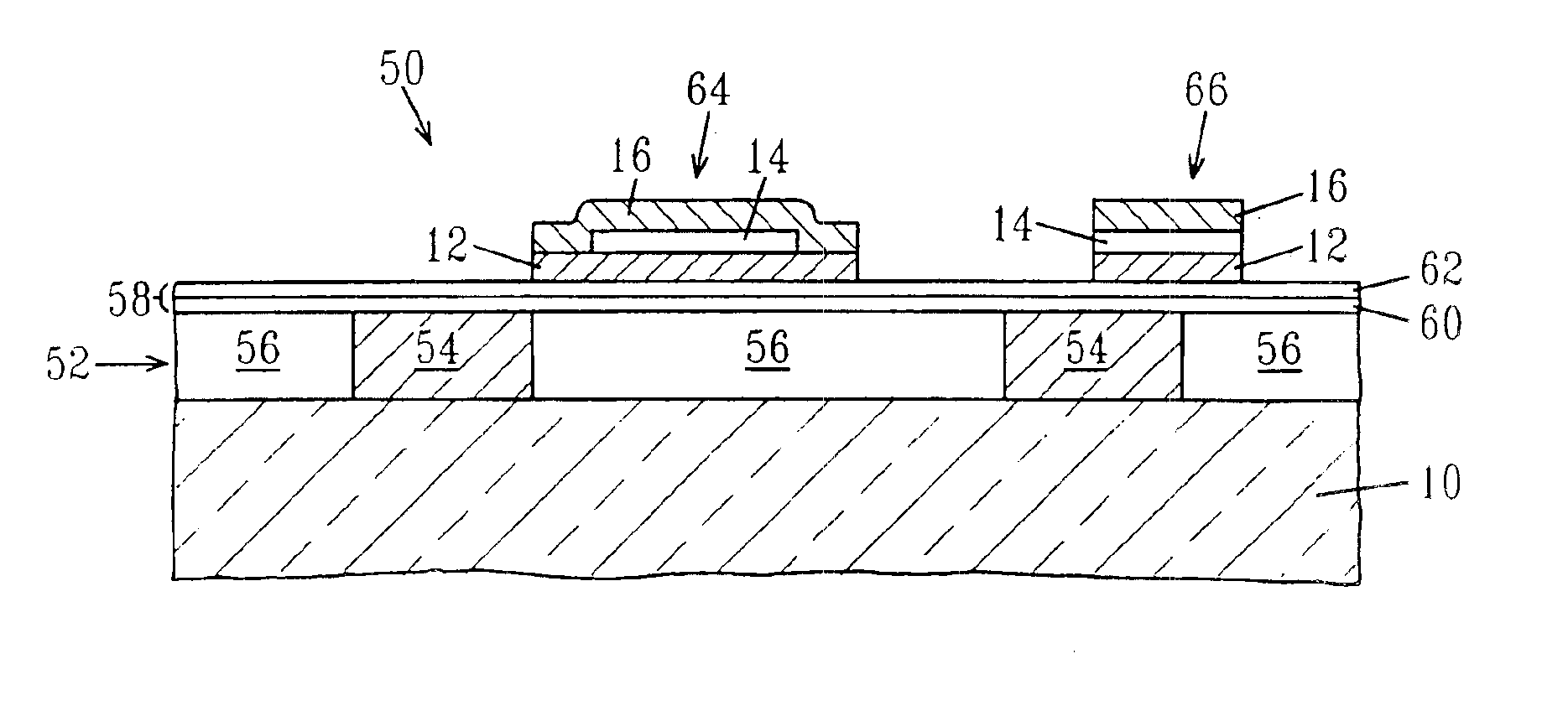

A switchable resistive device has a multi-layer thin film structure interposed between an upper conductive electrode and a lower conductive electrode. The multi-layer thin film structure comprises a perovskite layer with one buffer layer on one side of the perovskite layer, or a perovskite layer with buffer layers on both sides of the perovskite layer. Reversible resistance changes are induced in the device under applied electrical pulses. The resistance changes of the device are retained after applied electric pulses. The functions of the buffer layer(s) added to the device include magnification of the resistance switching region, reduction of the pulse voltage needed to switch the device, protection of the device from being damaged by a large pulse shock, improvement of the temperature and radiation properties, and increased stability of the device allowing for multivalued memory applications.

Owner:UNIV HOUSTON SYST

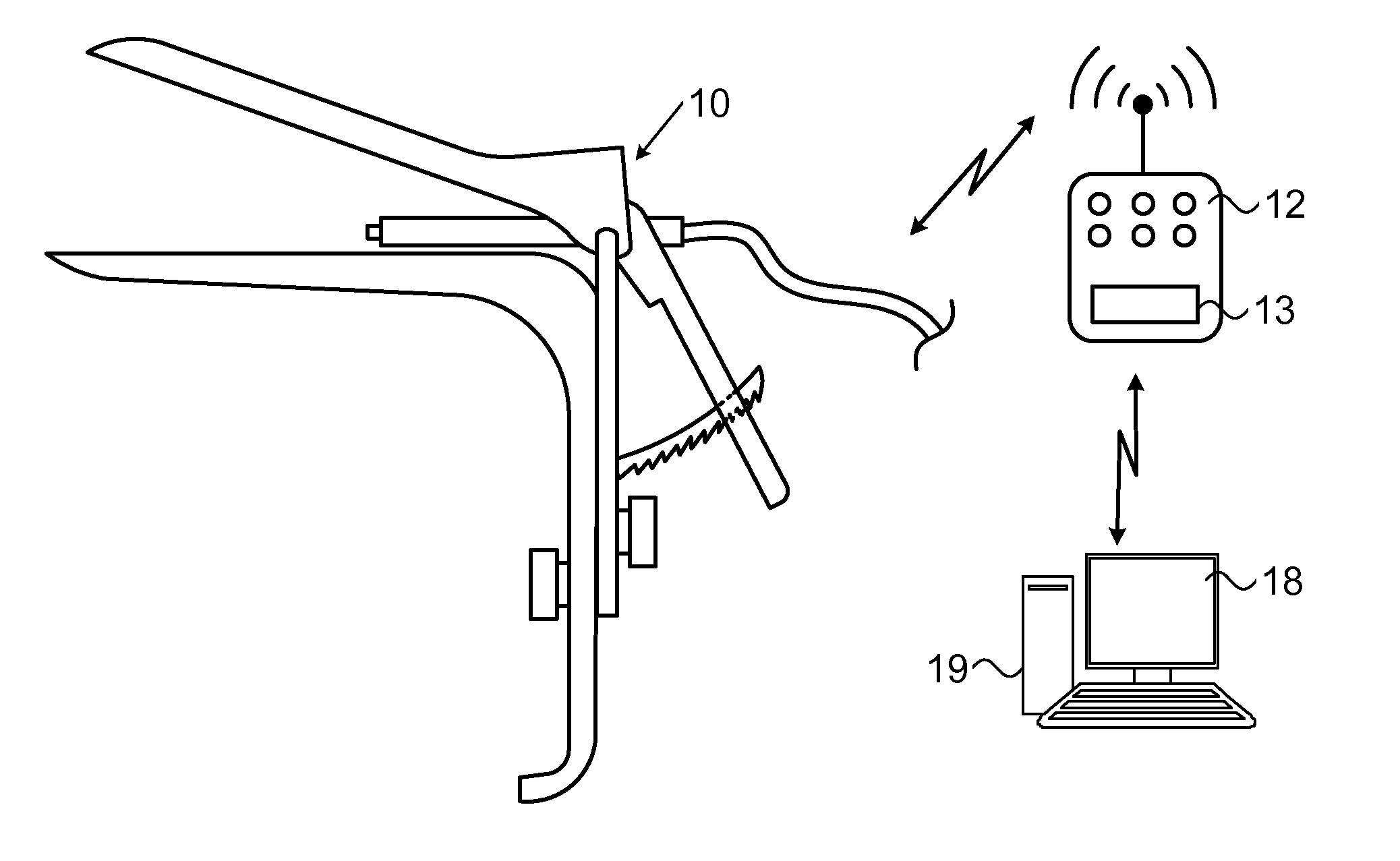

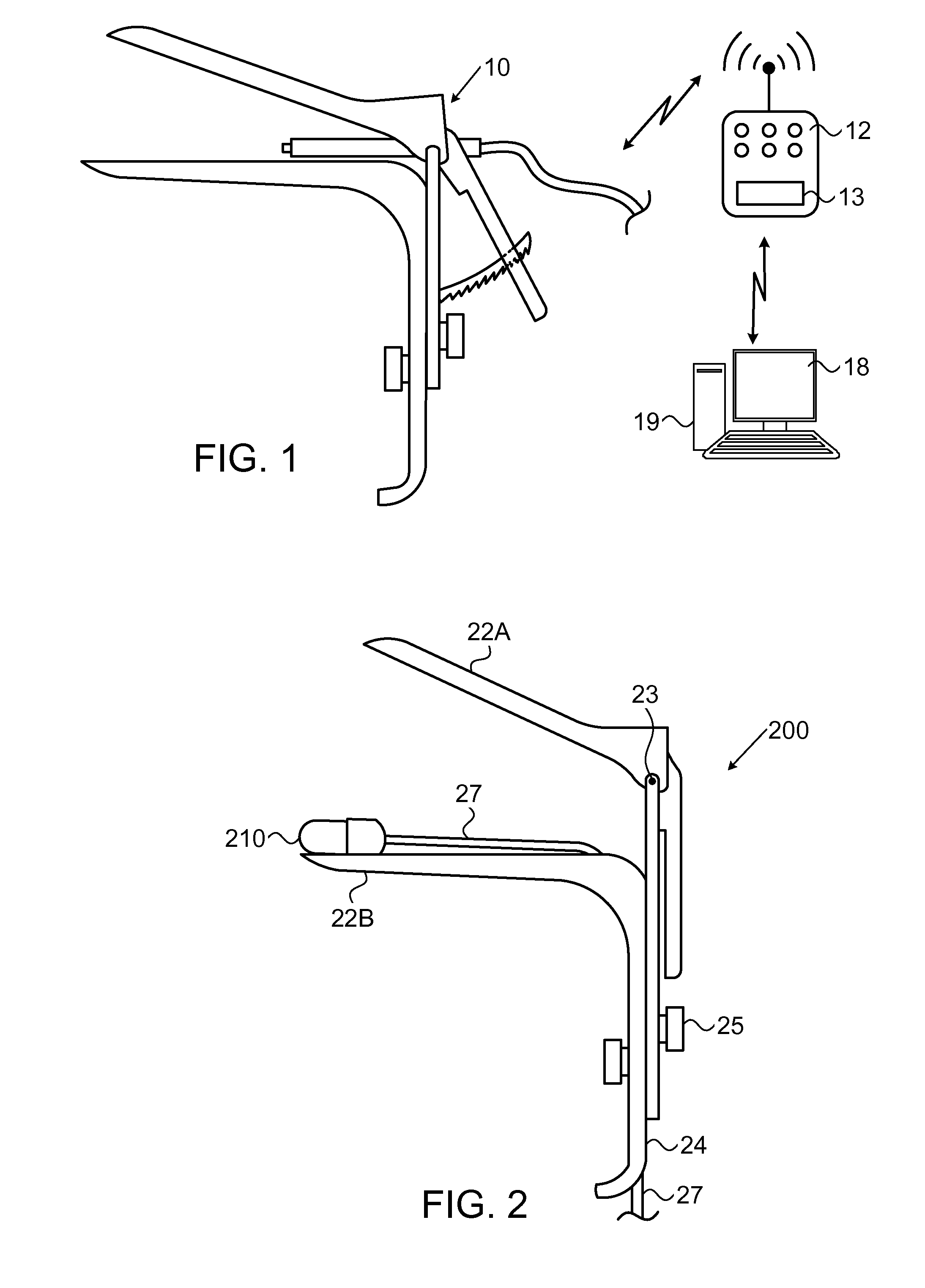

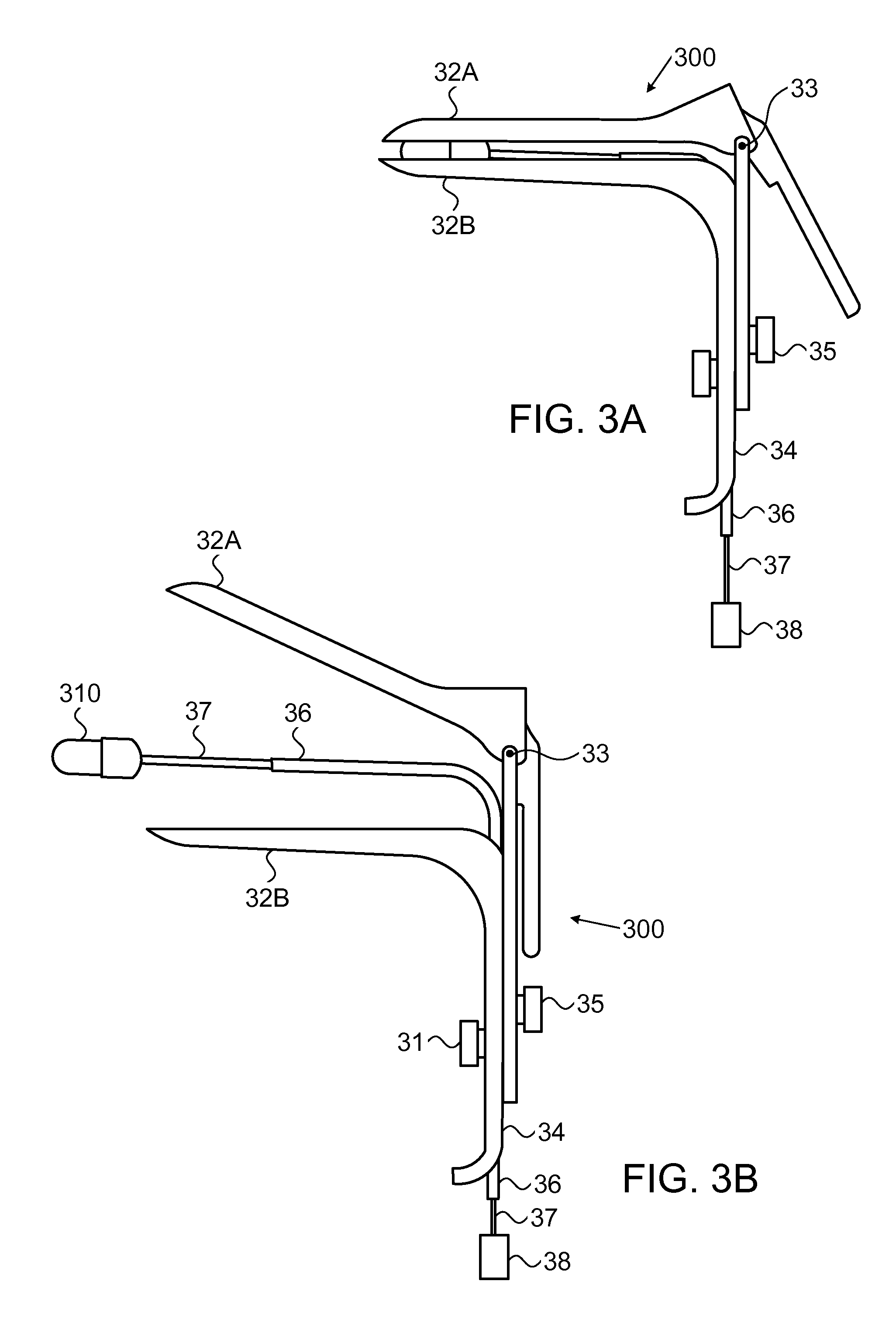

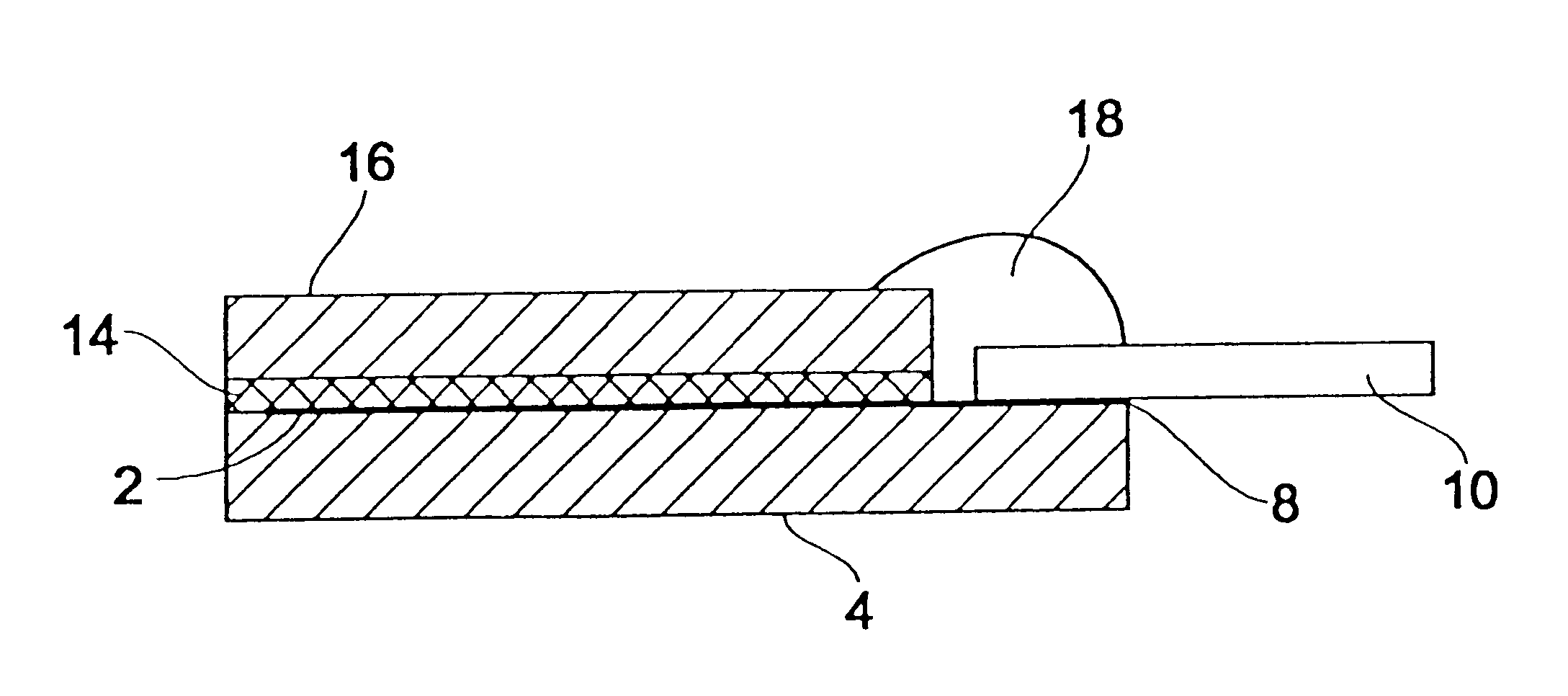

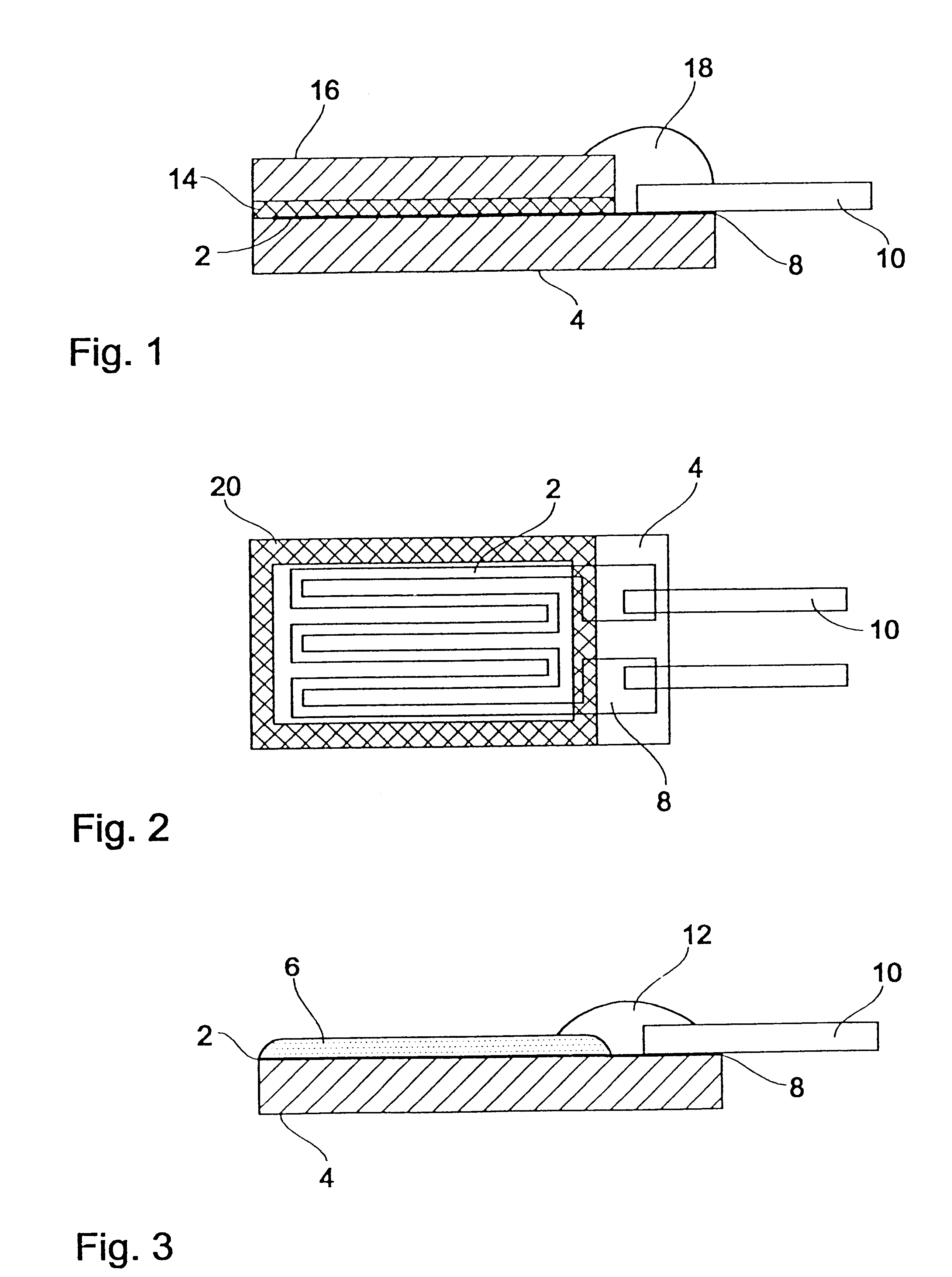

System, device and method for gynecological use

InactiveUS20100305406A1Less cumbersomeLess cumbersome and safer to useObstetrical instrumentsVaginoscopesSensing dataCatheter

A device for gynecological examination has an imaging unit, which may include an illumination source, an imaging unit and an optical system, positioned within a speculum type device, typically between the blades thereof. The imaging unit is positioned at the end of an elongated rod that is positioned within a guide tube, both of which pass from between the blades down through the speculum handle, where they can be manipulated by a user to push the unit upward and forward for better viewing. A transmitter for transmitting sensed data to an external or remote receiver may be part of or may be separate from the device. The device may have non-imaging sensors, such as a pH sensor, a sensor to sense electrical impedance of tissues, a temperature sensor, etc., either by itself or in addition to an imager. A system may further include a remote receiver, a processor for processing data and a monitor for presenting images to the user in real time.

Owner:GIVEN IMAGING LTD

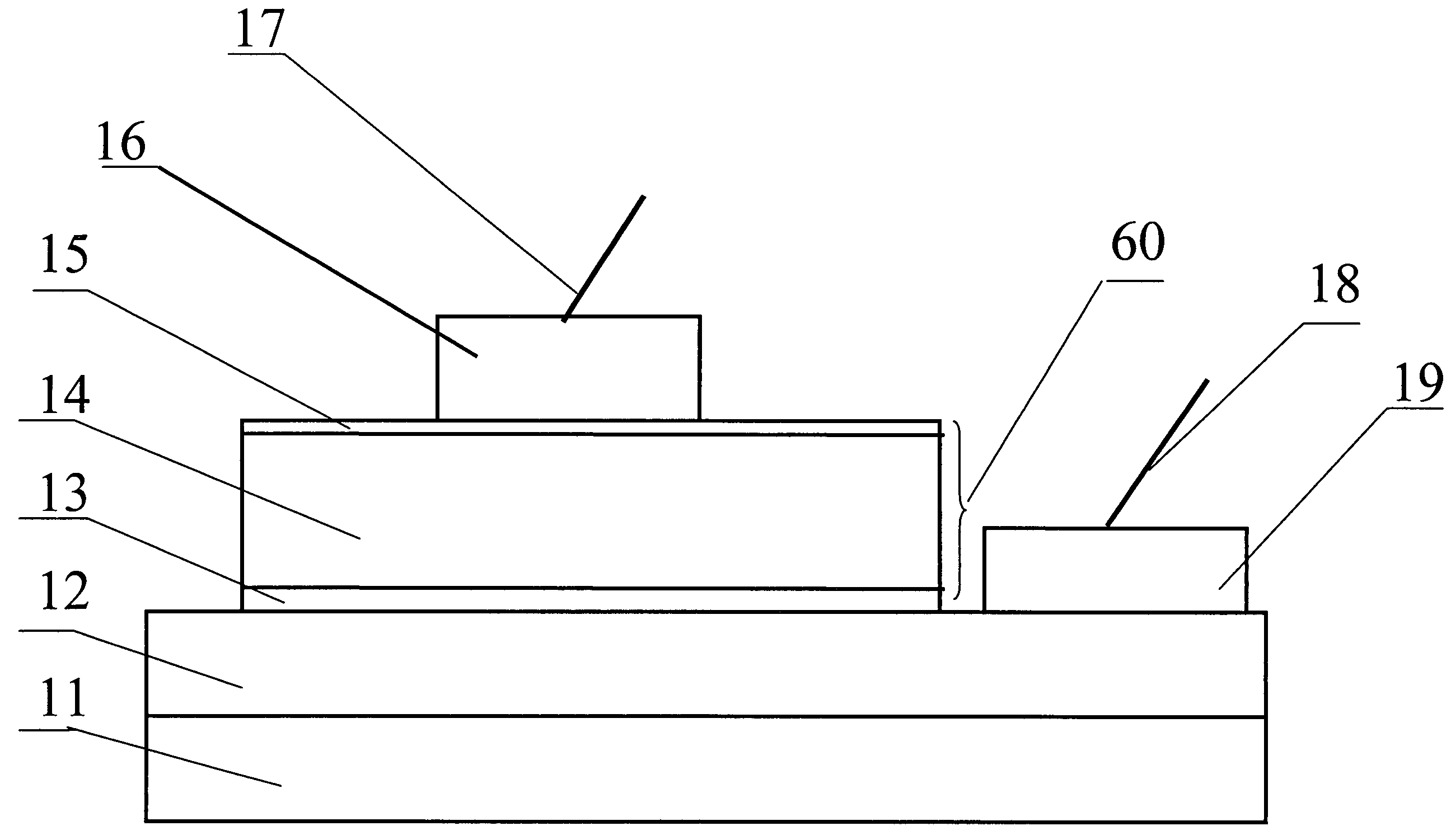

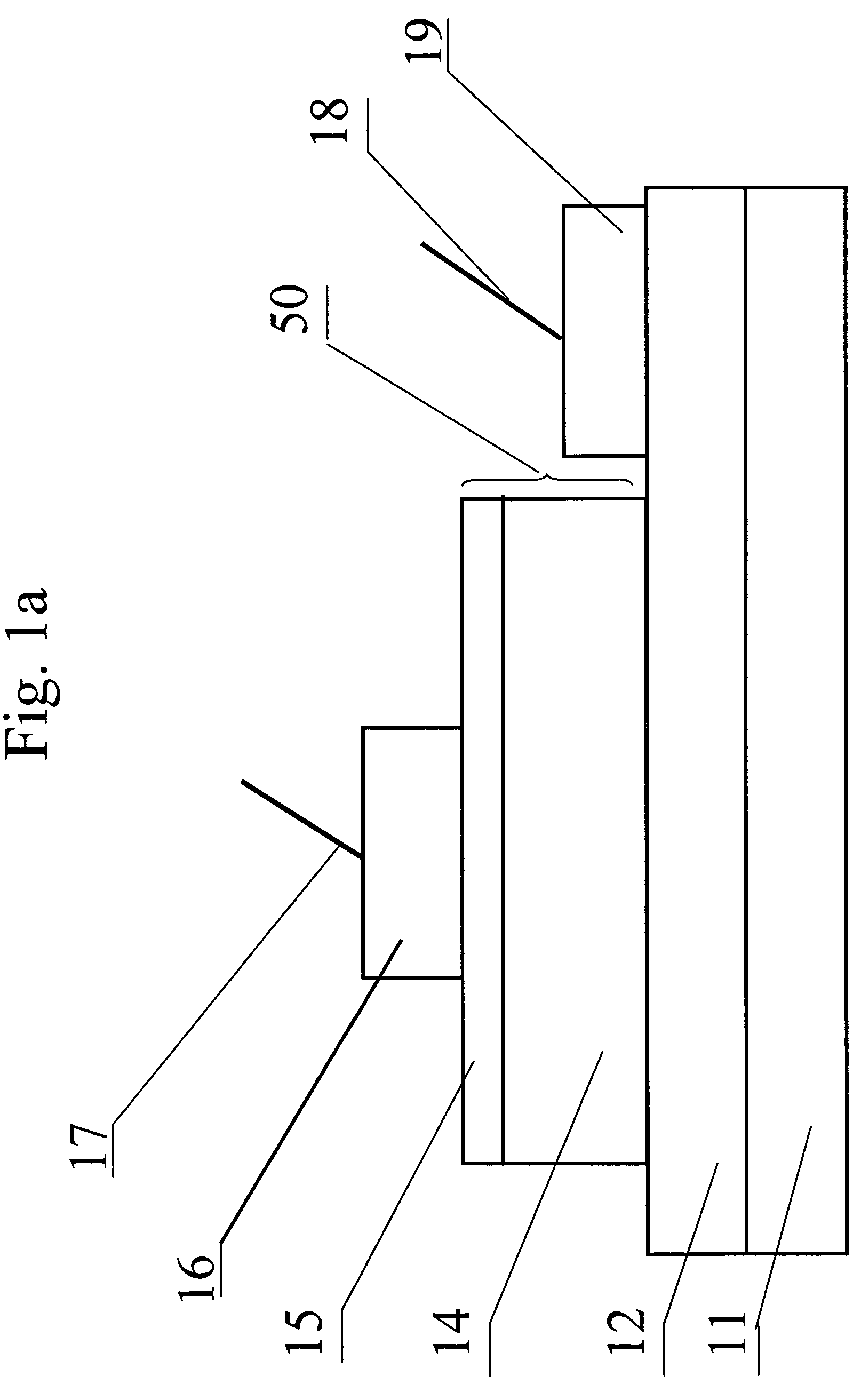

Switchable resistive perovskite microelectronic device with multi-layer thin film structure

ActiveUS7608467B2Reduce voltageImprove configurationSemiconductor/solid-state device manufacturingDigital storageElectrical resistance and conductanceMagnification

A switchable resistive device has a multi-layer thin film structure interposed between an upper conductive electrode and a lower conductive electrode. The multi-layer thin film structure comprises a perovskite layer with one buffer layer on one side of the perovskite layer, or a perovskite layer with buffer layers on both sides of the perovskite layer. Reversible resistance changes are induced in the device under applied electrical pulses. The resistance changes of the device are retained after applied electric pulses. The functions of the buffer layer(s) added to the device include magnification of the resistance switching region, reduction of the pulse voltage needed to switch the device, protection of the device from being damaged by a large pulse shock, improvement of the temperature and radiation properties, and increased stability of the device allowing for multivalued memory applications.

Owner:UNIV HOUSTON SYST

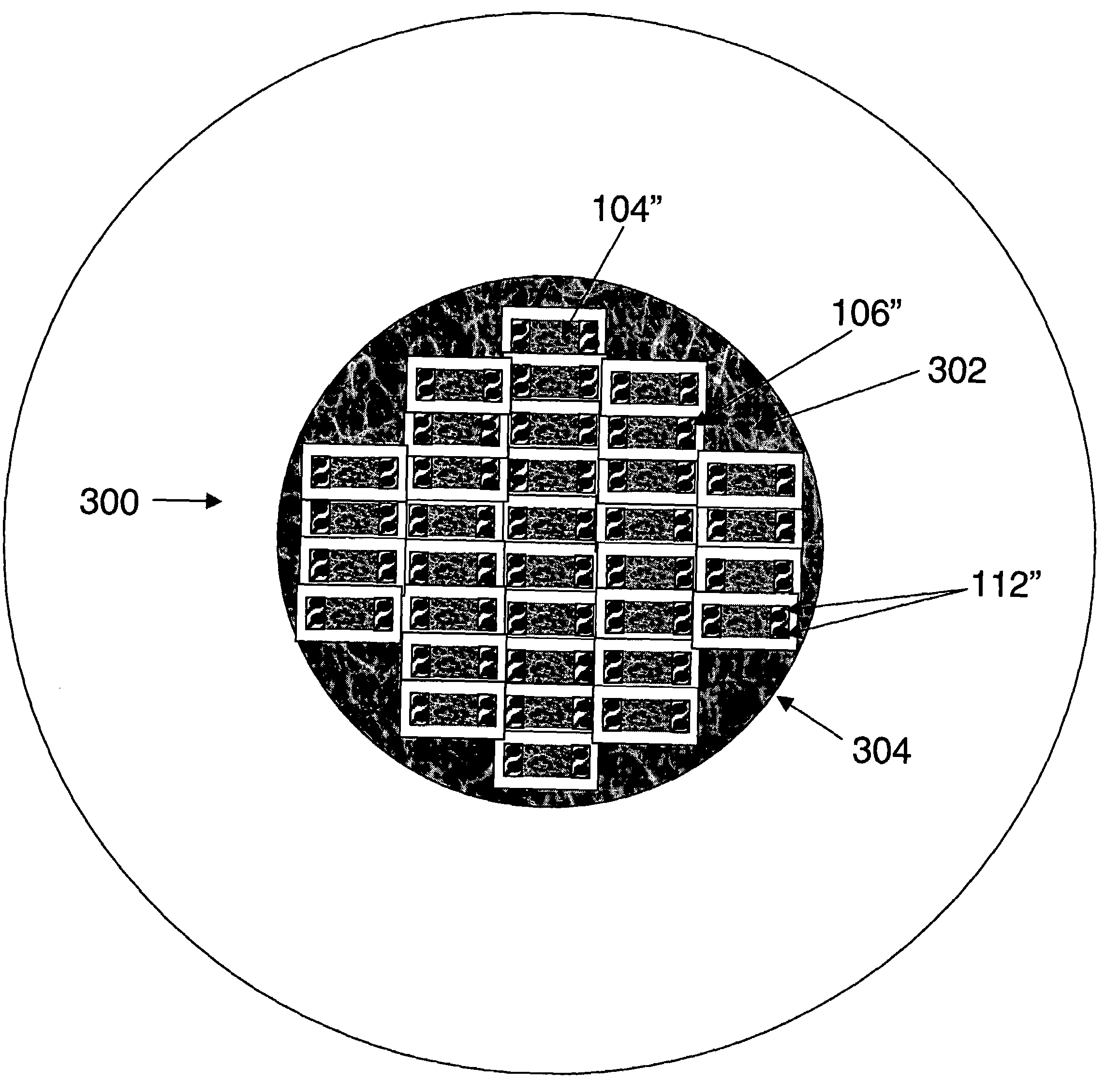

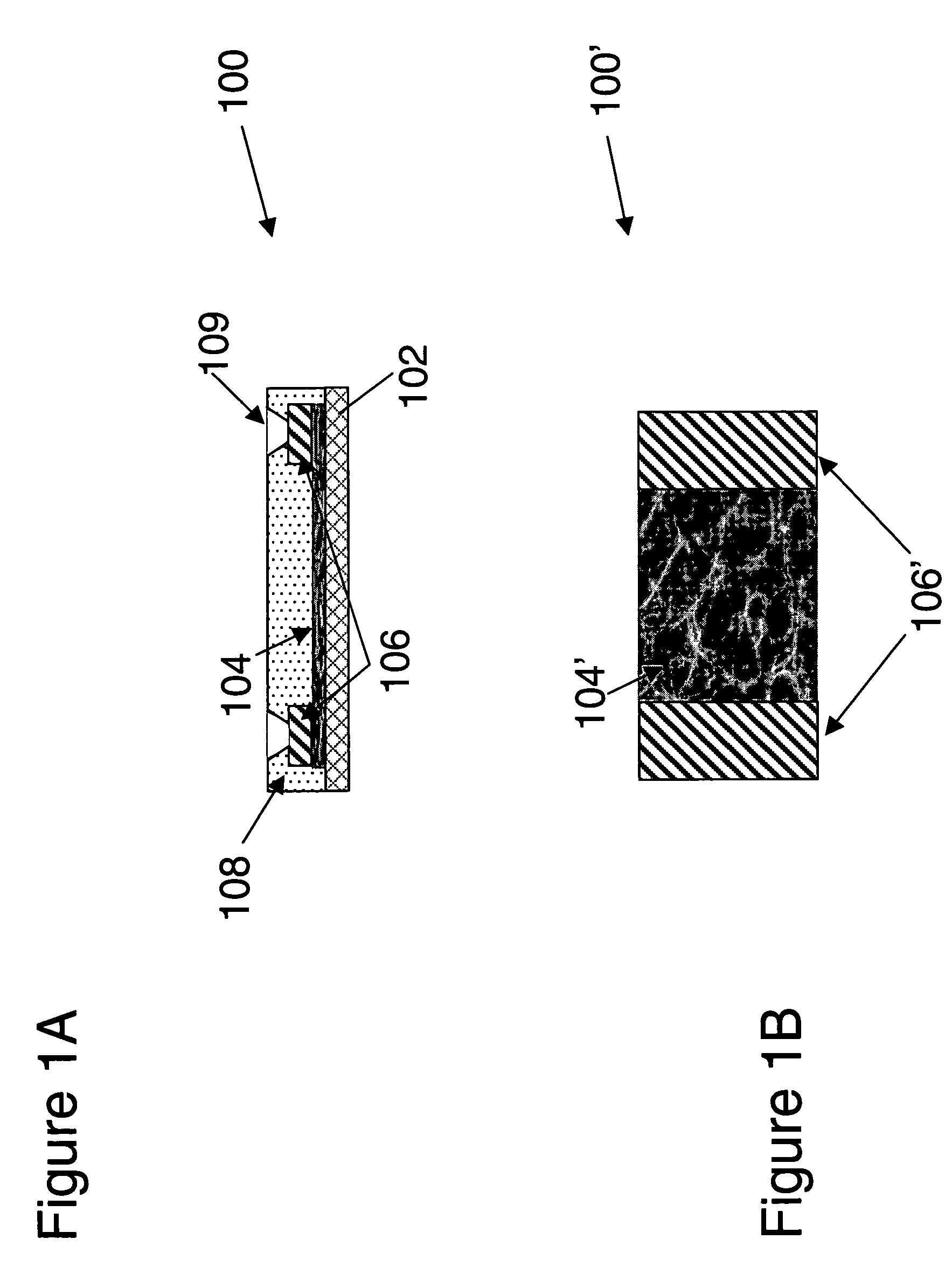

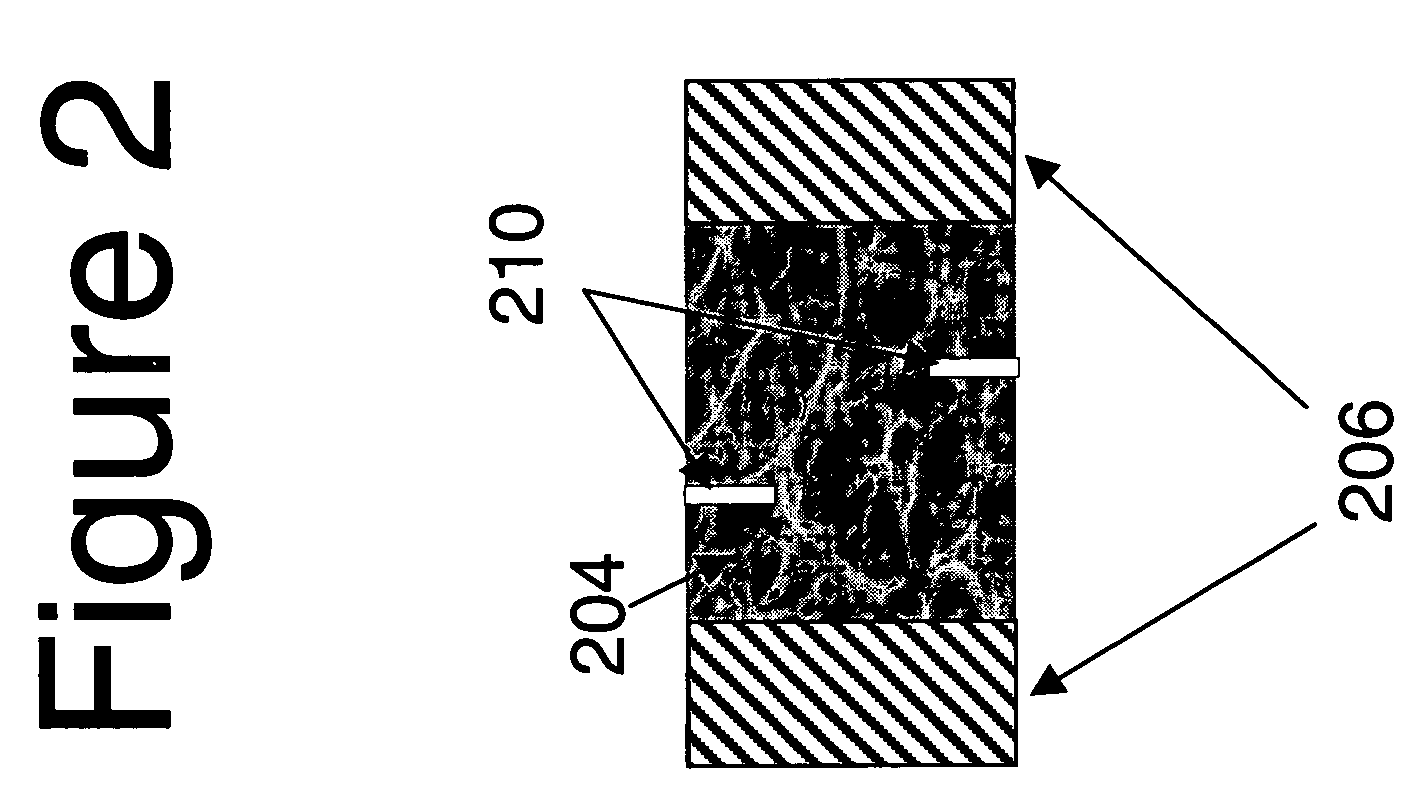

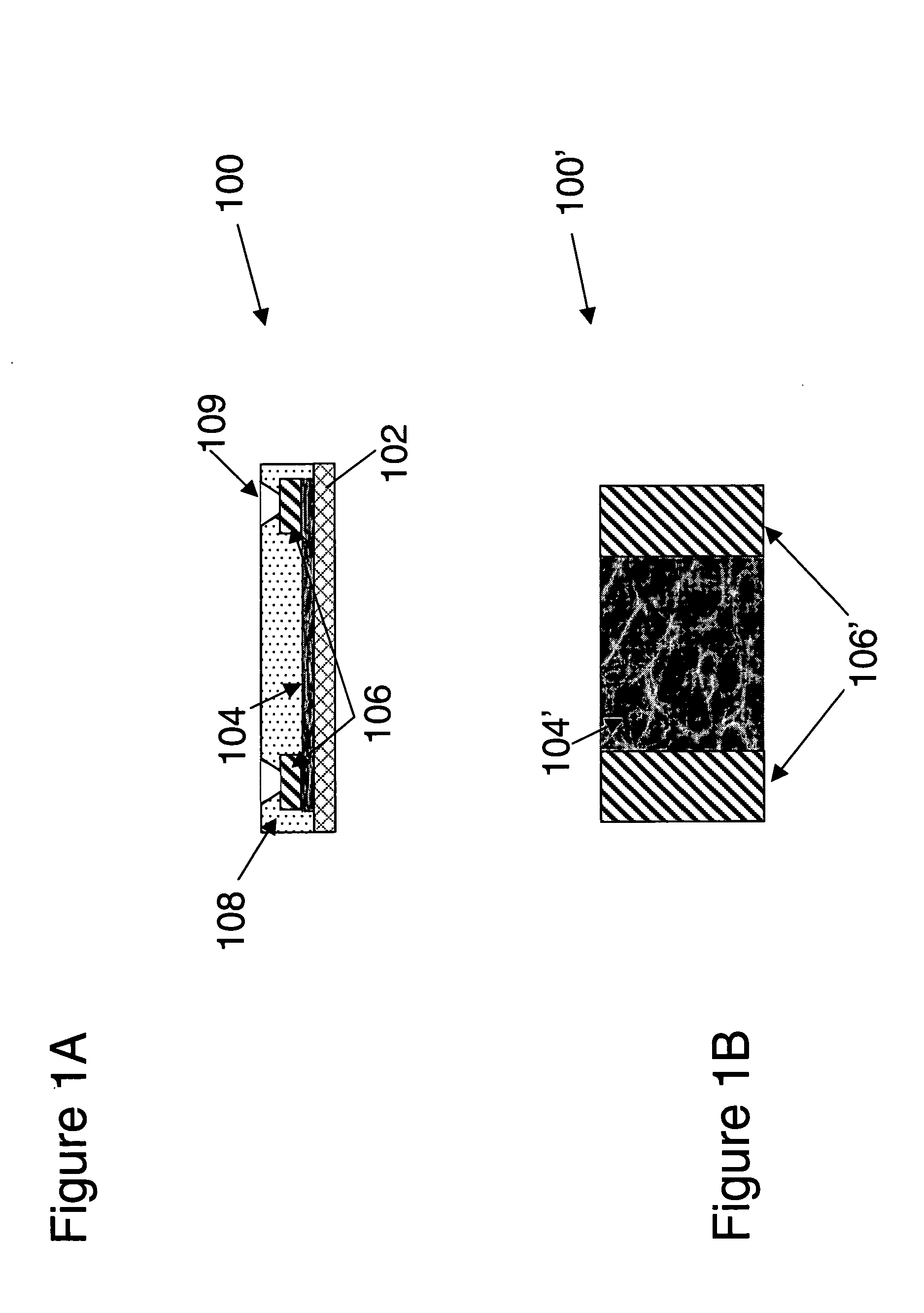

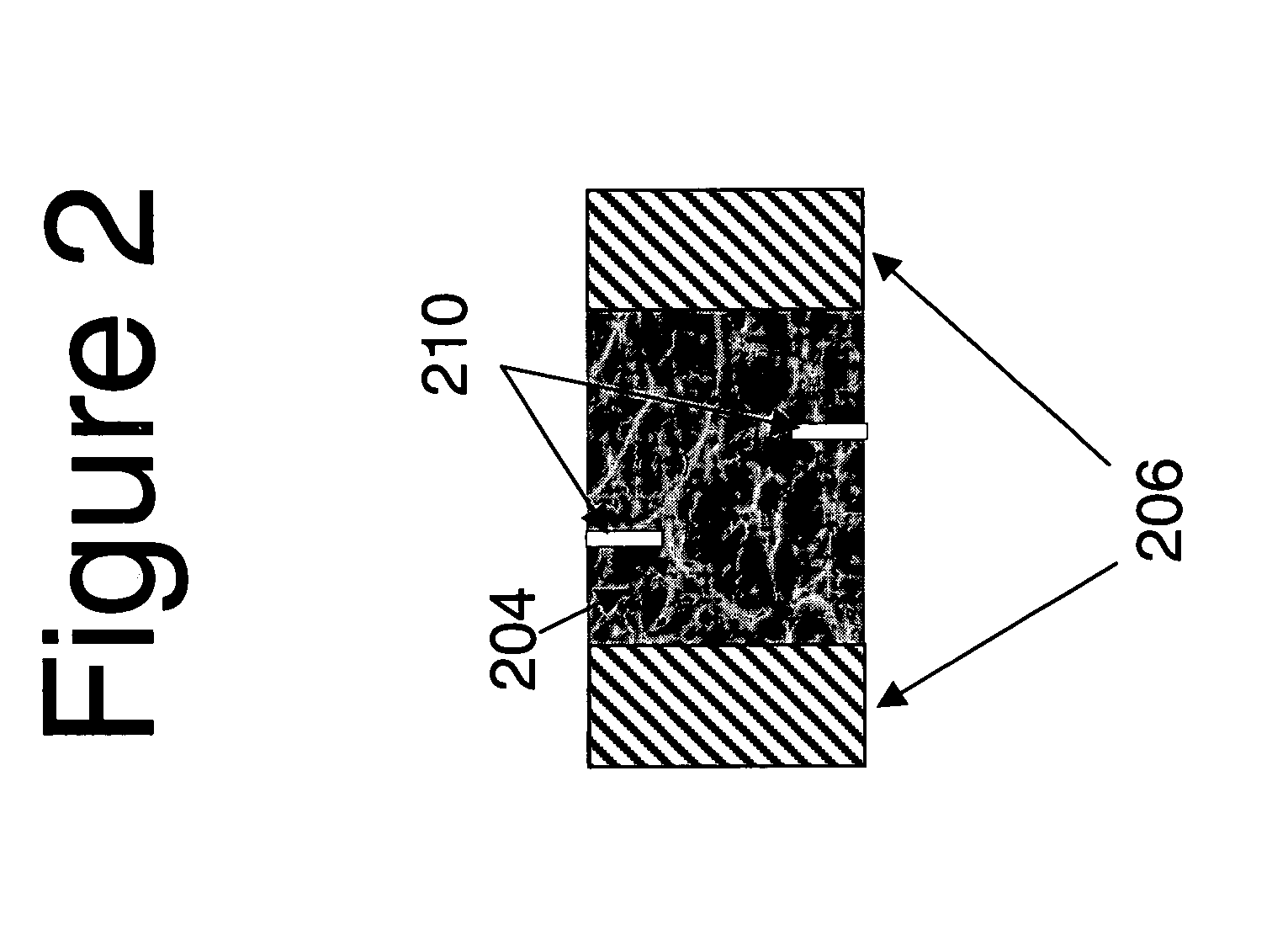

Resistive elements using carbon nanotubes

ActiveUS7365632B2Function increaseEasy parameter controlCurrent responsive resistorsSolid-state devicesBulk resistanceCarbon nanotube

Resistive elements include a patterned region of nanofabric having a predetermined area, where the nanofabric has a selected sheet resistance; and first and second electrical contacts contacting the patterned region of nanofabric and in spaced relation to each other. The resistance of the element between the first and second electrical contacts is determined by the selected sheet resistance of the nanofabric, the area of nanofabric, and the spaced relation of the first and second electrical contacts. The bulk resistance is tunable.

Owner:NANTERO

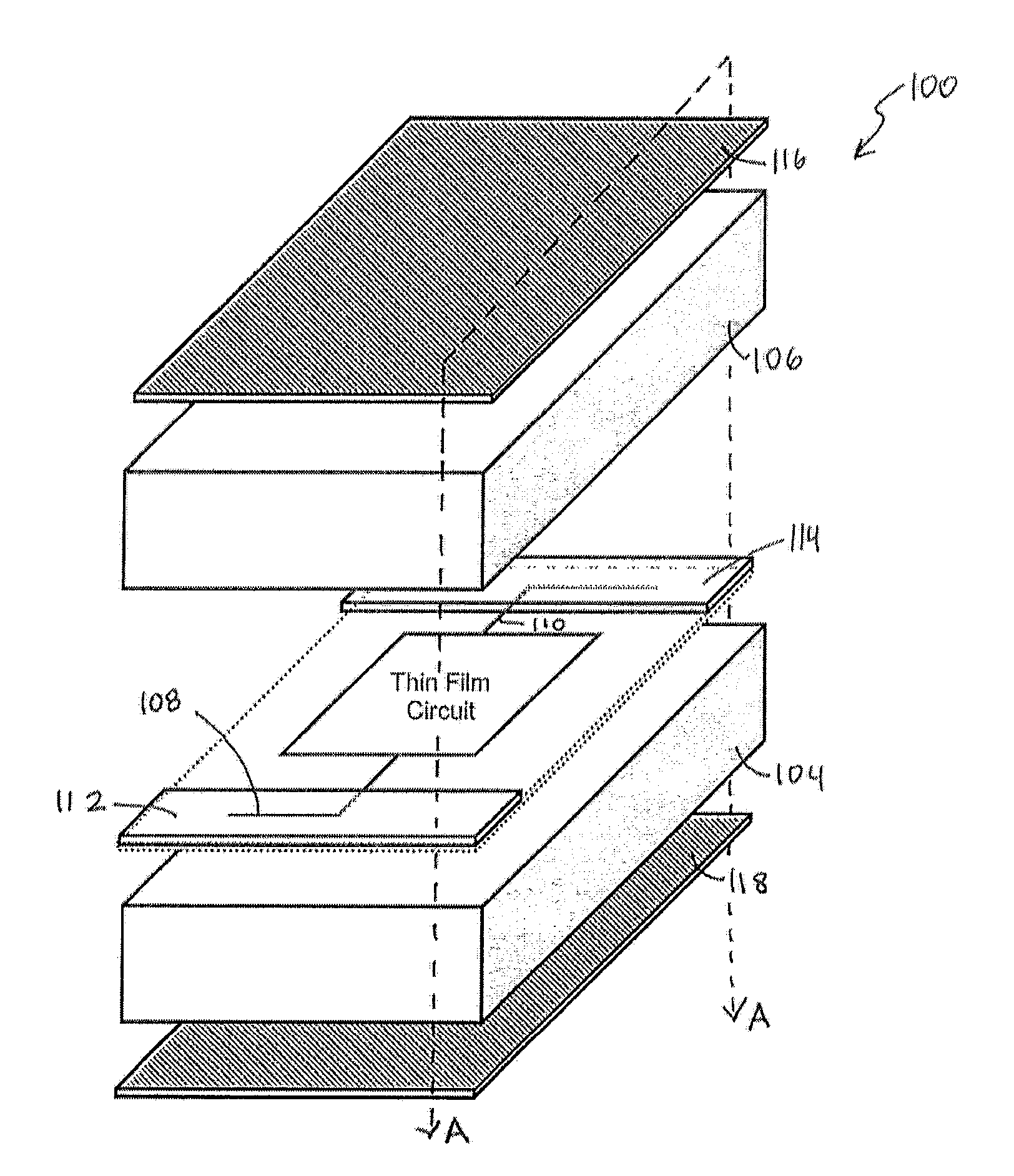

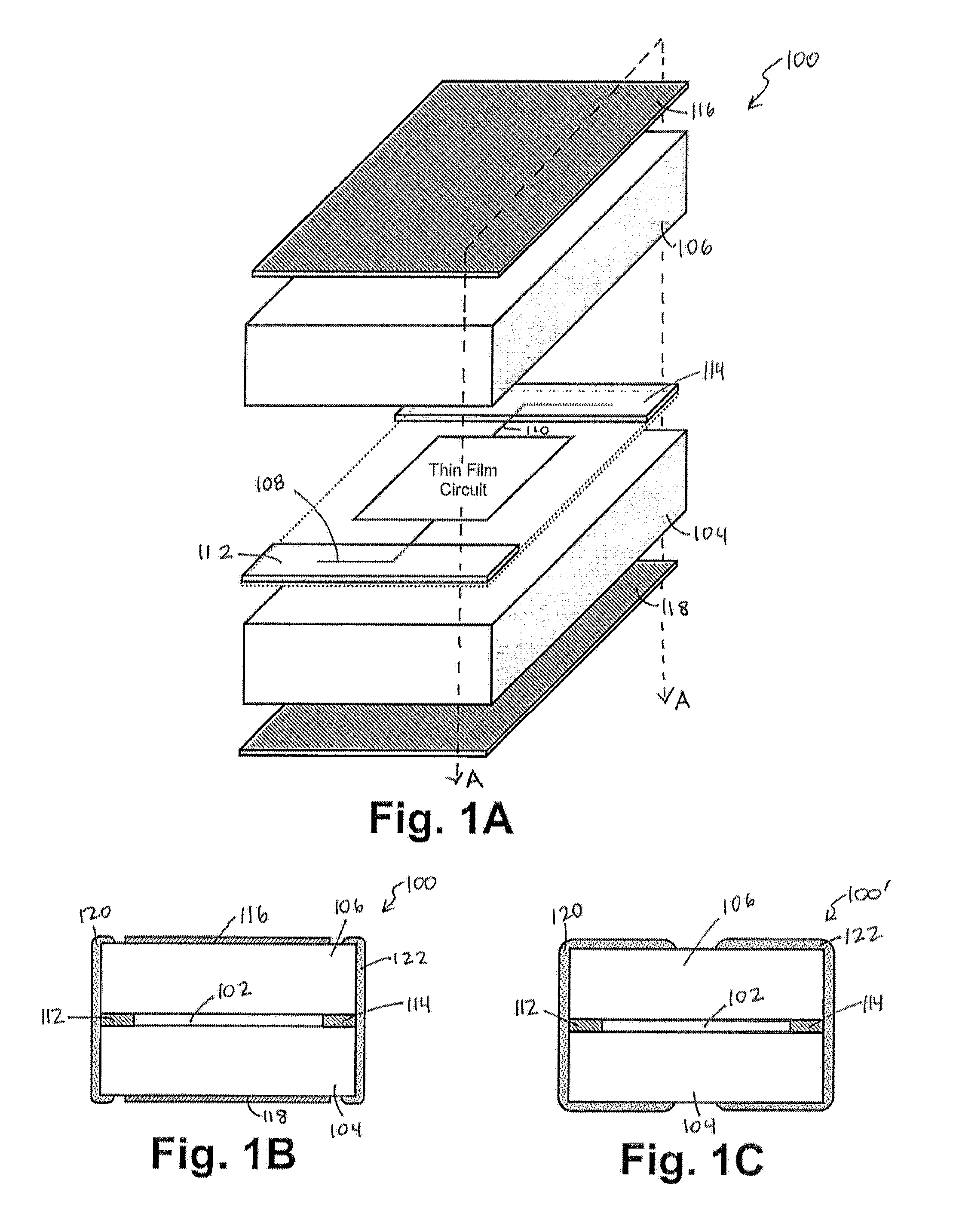

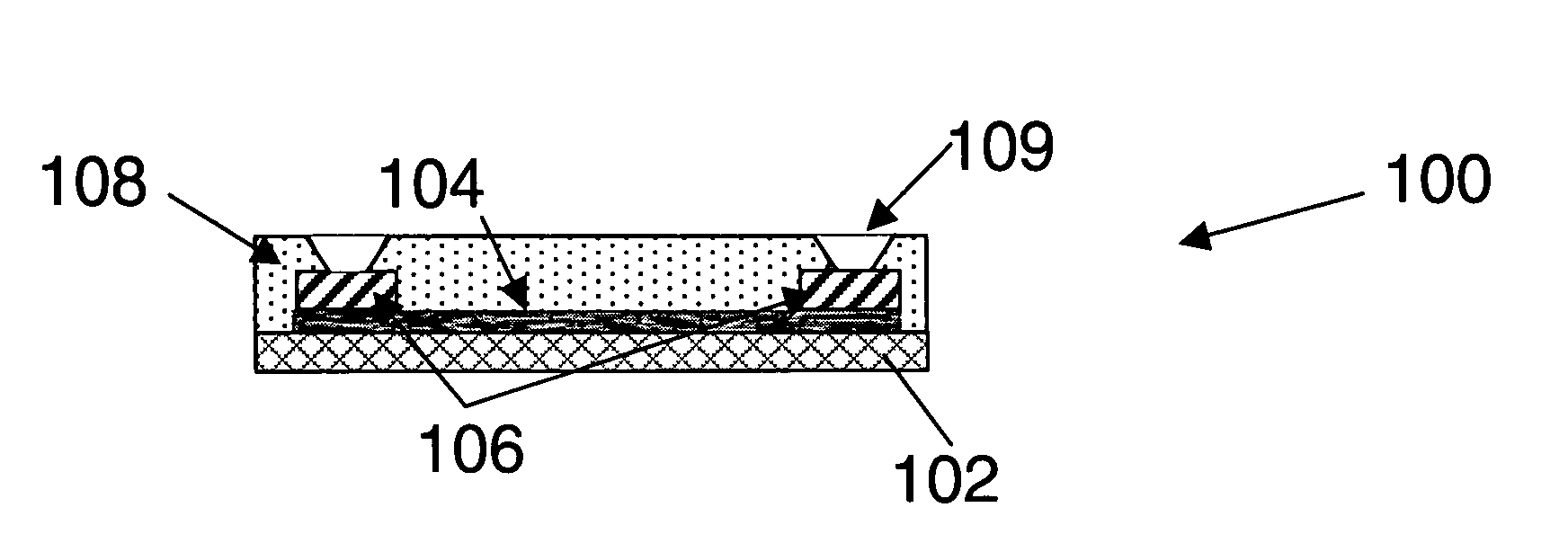

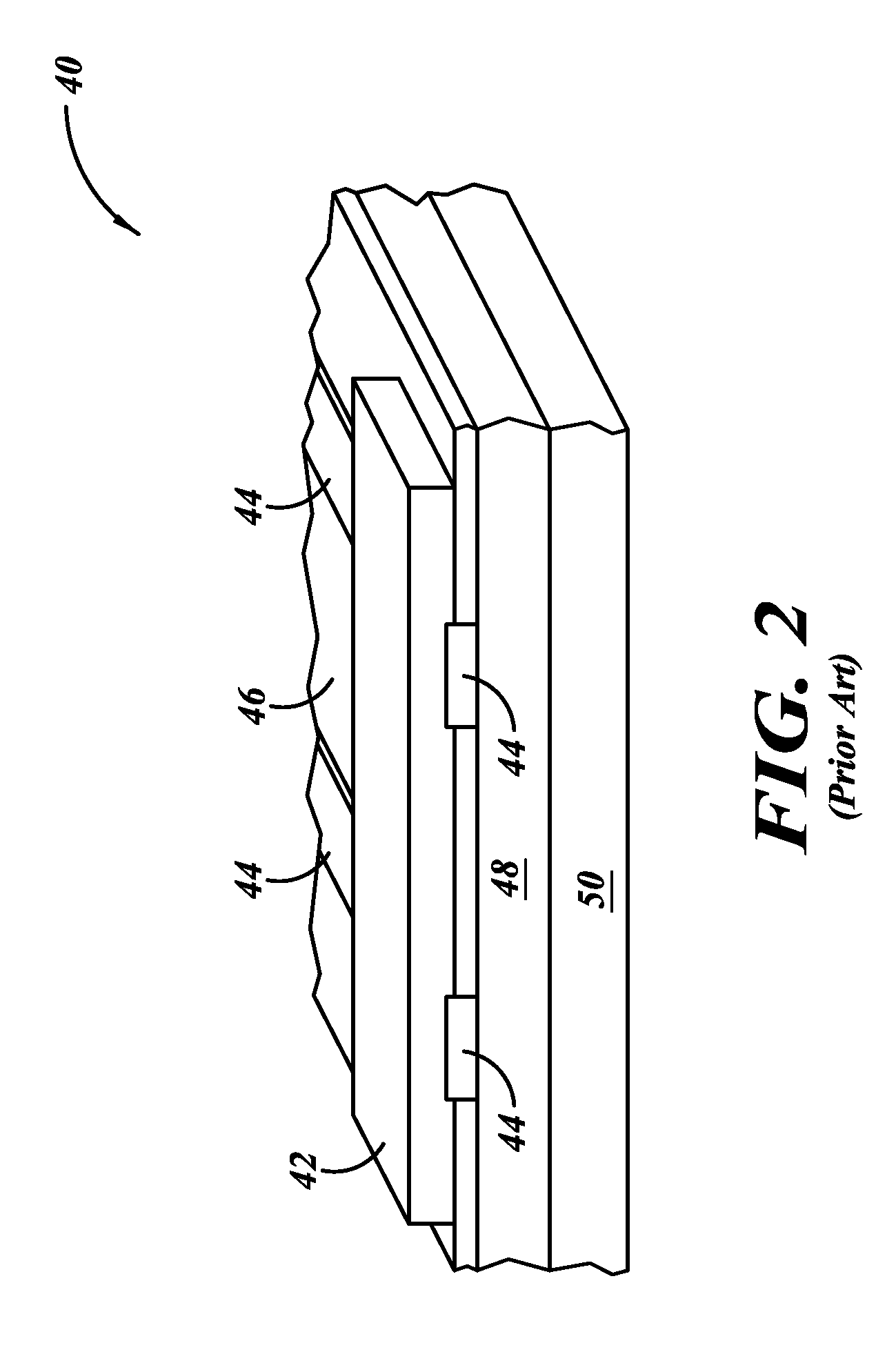

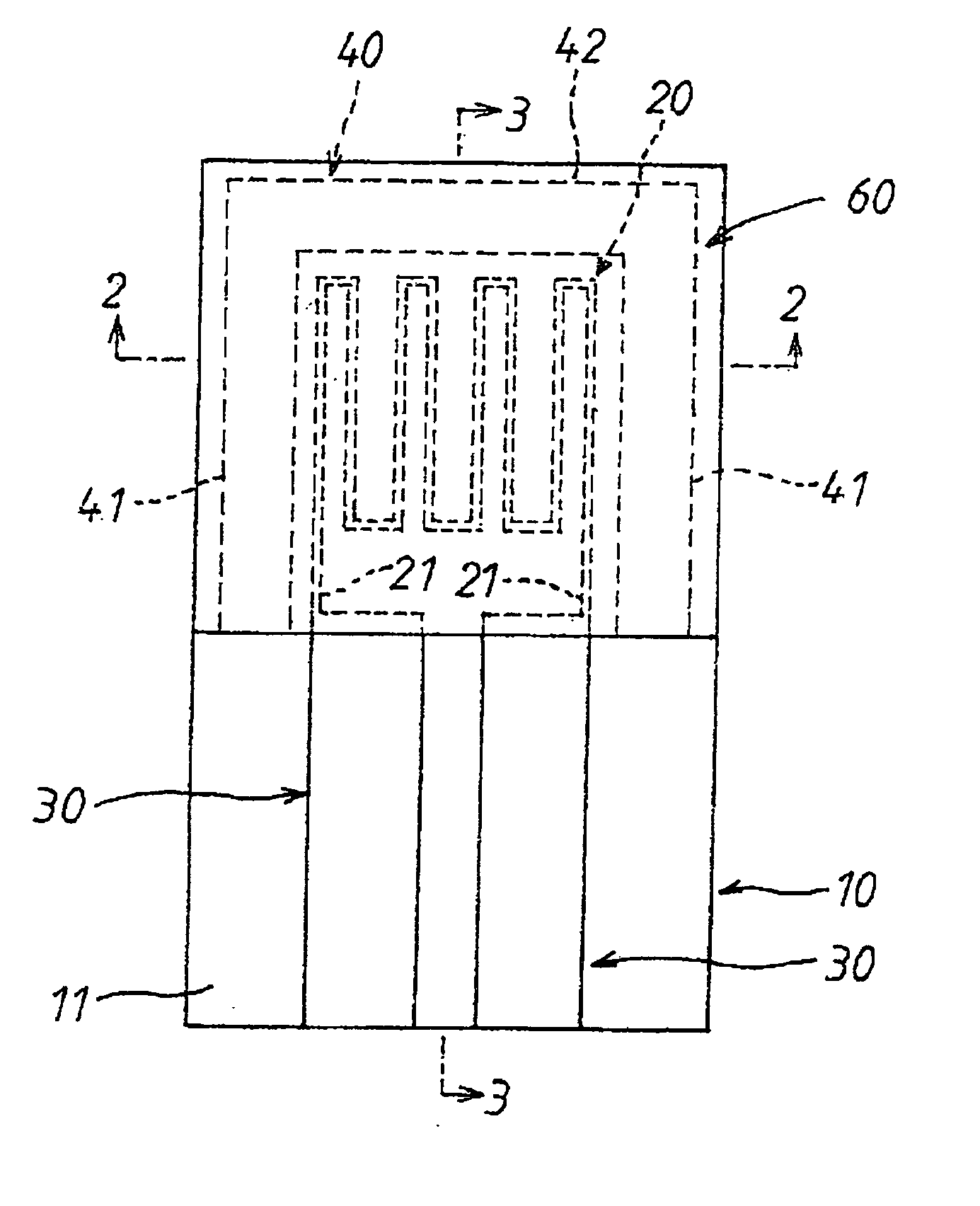

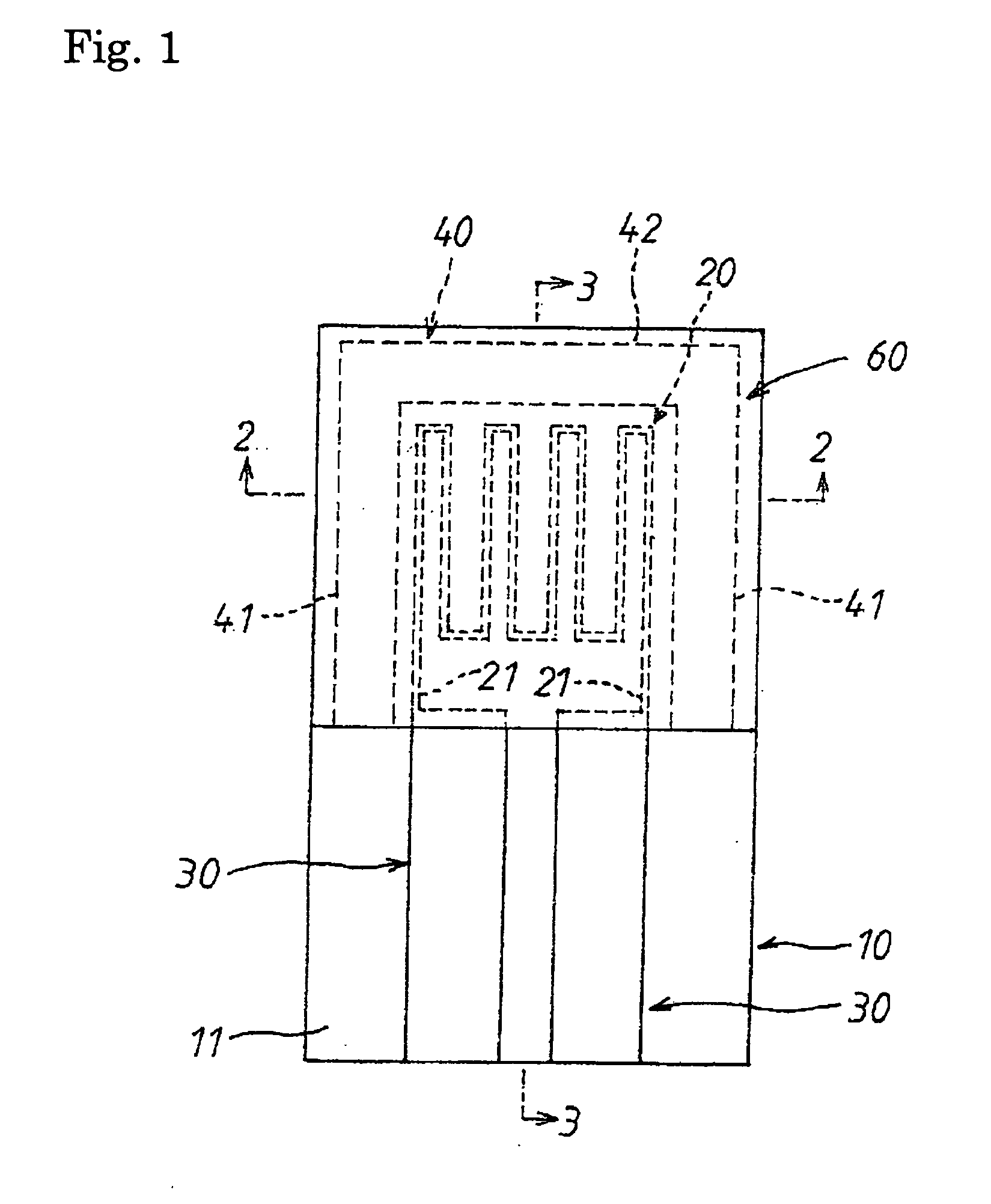

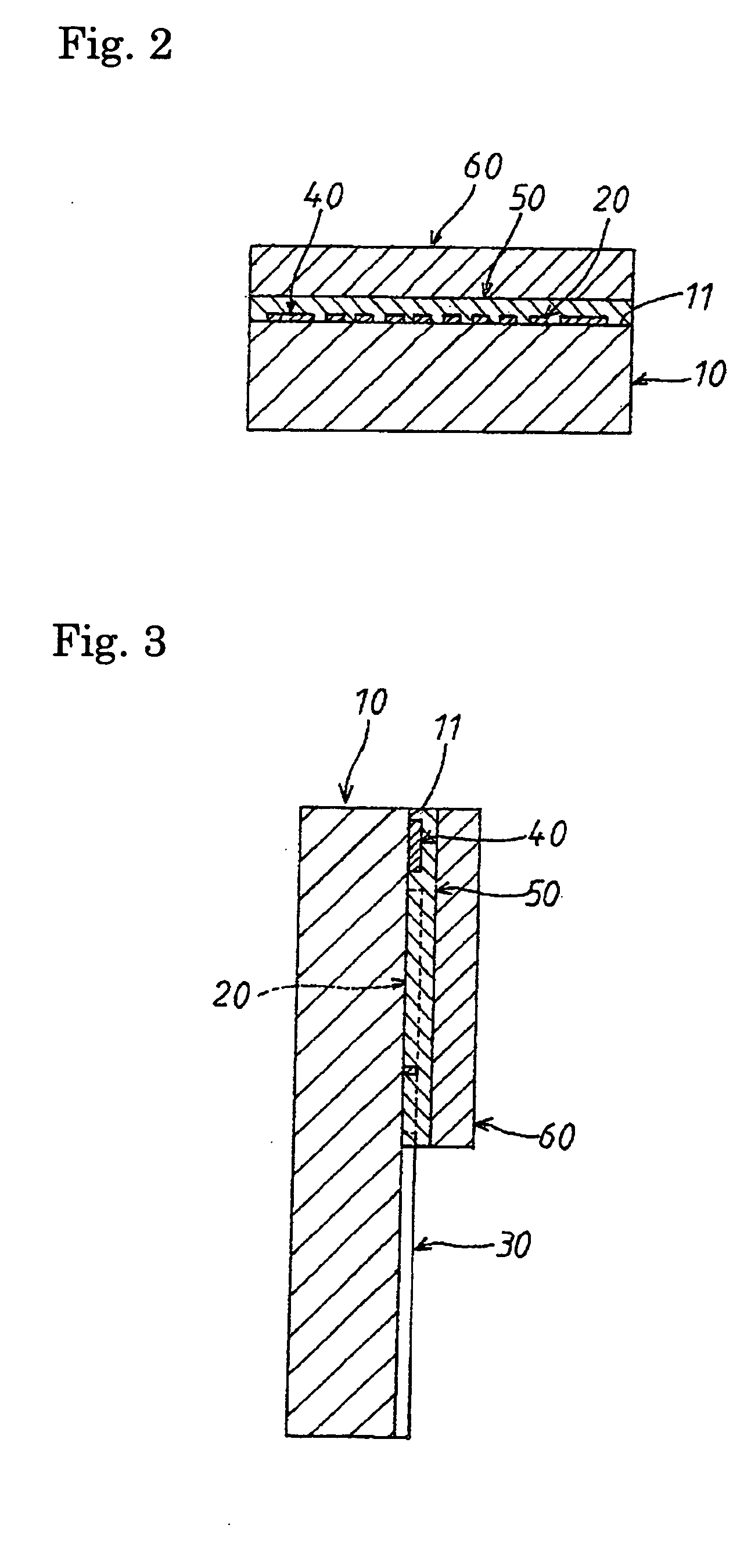

Thin film surface mount components

ActiveUS20110090665A1Lowering termination costImprove functionalityMultiple-port networksDigital data processing detailsSurface mountingConductive polymer

Surface mount components and related methods of manufacture involve one or more thin film circuits provided between first and second insulating substrates. The thin film circuits may include one or more passive components, including resistors, capacitors, inductors, arrays of one or more passive components, networks or filters of multiple passive components. Such thin film circuit(s) can be sandwiched between first and second insulating substrates with internal conductive pads being exposed between the substrates on end and / or side surfaces of the surface mount component. The exposed conductive pads are then electrically connected to external terminations. The external terminations may include a variety of different materials, including at least one layer of conductive polymer and may be formed as termination stripes, end caps or the like. Optional shield layers may also be provided on top and / or bottom device surfaces to protect the surface mount components from signal interference. For embodiments where one or more thin film circuits are provided between insulating base and cover substrates, such thin film circuit(s) can be formed with conductive pads that extend to and are initially exposed along one or more surfaces of the resultant component. The cover substrate is formed with a plurality of conductive elements (e.g., internal active electrodes, internal anchor electrodes and / or external anchor electrodes) that are designed to generally align with the conductive pads formed on the base substrate such that conductive element portions are exposed in groups along one or more peripheral surfaces of a device. External plated terminations are then formed directly to the exposed portions of the conductive elements.

Owner:KYOCERA AVX COMPONENTS CORP

Method of fabricating vertical structure LEDs

InactiveUS20050098792A1Avoid damageSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialReactive-ion etching

A method of fabricating semiconductor devices, such as GaN LEDs, on insulating substrates, such as sapphire. Semiconductor layers are produced on the insulating substrate using normal semiconductor processing techniques. Trenches that define the boundaries of the individual devices are then formed through the semiconductor layers and into the insulating substrate, beneficially by using inductive coupled plasma reactive ion etching. The trenches are then filled with an easily removed layer. A metal support structure is then formed on the semiconductor layers (such as by plating or by deposition) and the insulating substrate is removed. Electrical contacts, a passivation layer, and metallic pads are then added to the individual devices, and the individual devices are then diced out.

Owner:SUZHOU LEKIN SEMICON CO LTD

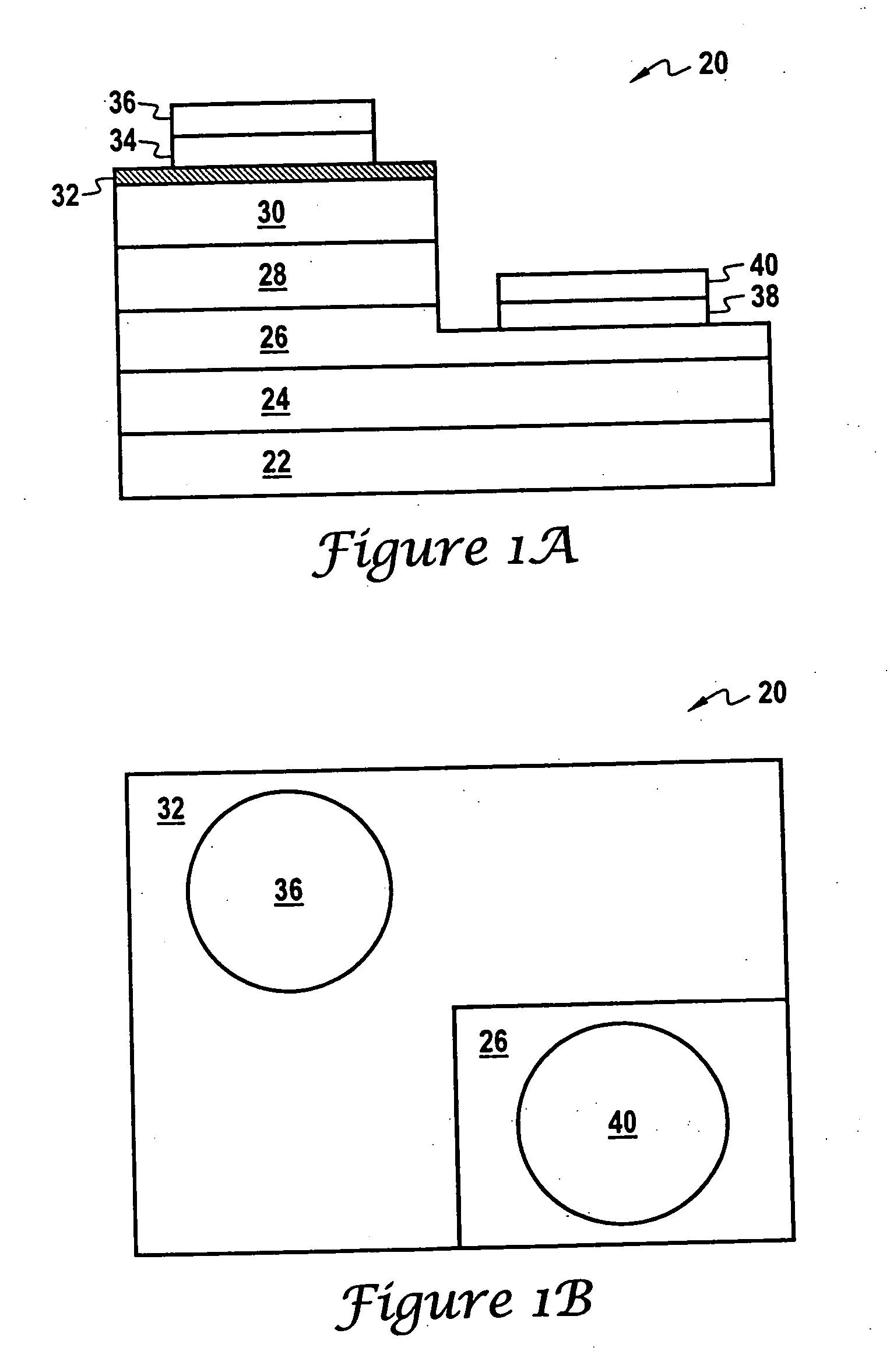

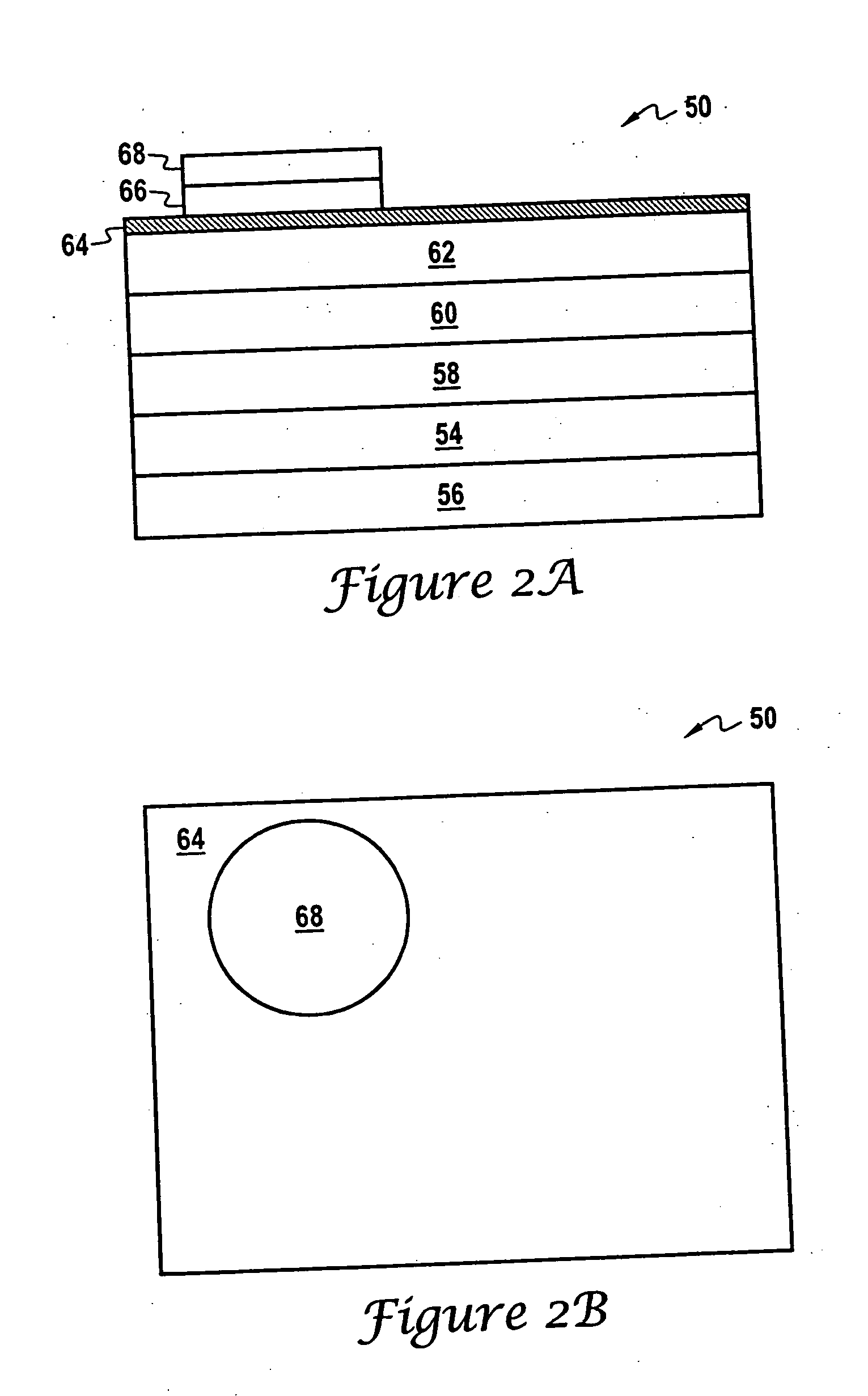

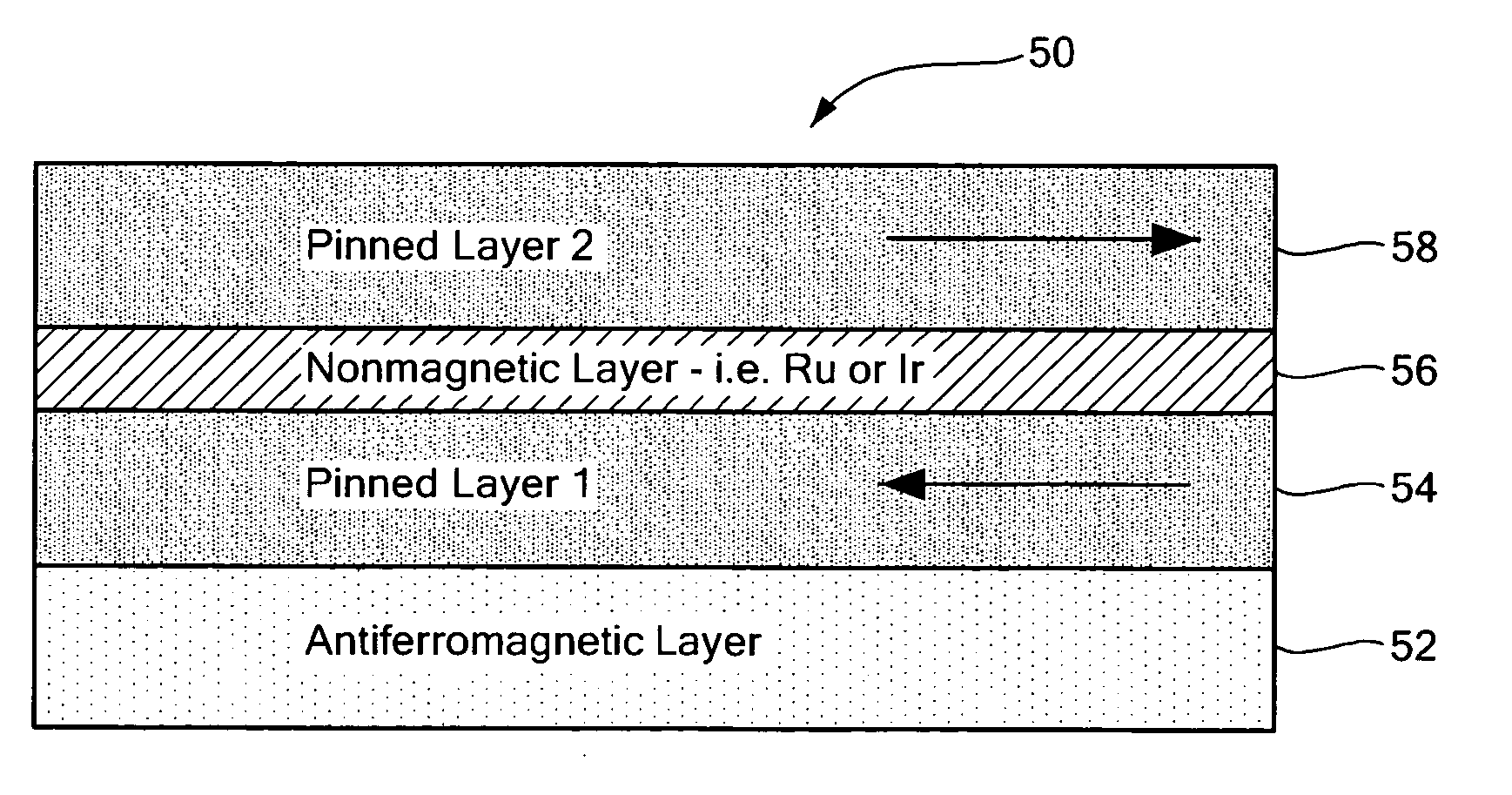

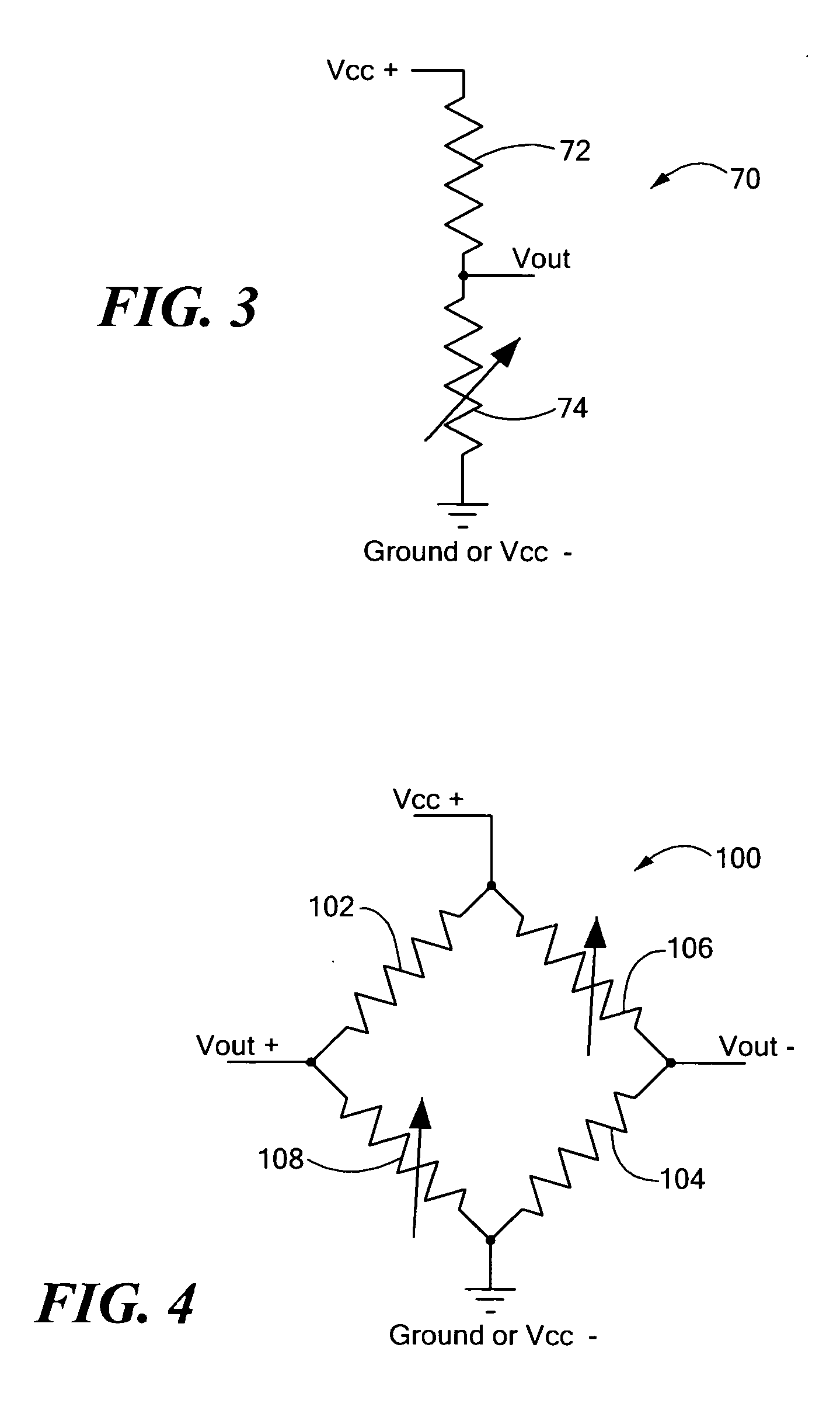

Resistor having a predetermined temperature coefficient

ActiveUS20060077598A1NanomagnetismSolid-state devicesElectrical resistance and conductanceMagnetic reluctance

A material stack has an electrical resistance generally the same in the presence of a magnetic field and in the presence of no magnetic field. The electrical resistance of the material stack has a temperature coefficient generally the same as a magnetoresistance element.

Owner:ALLEGRO MICROSYSTEMS INC

Method of fabricating vertical structure LEDs

InactiveUS20060071230A1Avoid damageSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialReactive-ion etching

A method of fabricating semiconductor devices, such as GaN LEDs, on insulating substrates, such as sapphire. Semiconductor layers are produced on the insulating substrate using normal semiconductor processing techniques. Trenches that define the boundaries of the individual devices are then formed through the semiconductor layers and into the insulating substrate, beneficially by using inductive coupled plasma reactive ion etching. The trenches are then filled with an easily removed layer. A metal support structure is then formed on the semiconductor layers (such as by plating or by deposition) and the insulating substrate is removed. Electrical contacts, a passivation layer, and metallic pads are then added to the individual devices, and the individual devices are then diced out.

Owner:SUZHOU LEKIN SEMICON CO LTD

Resistance changing element, semiconductor device, and method for forming resistance change element

ActiveUS20120280200A1Operation voltage adverselyForming voltage can be reducedSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceOptoelectronics

Owner:NANOBRIDGE SEMICON INC

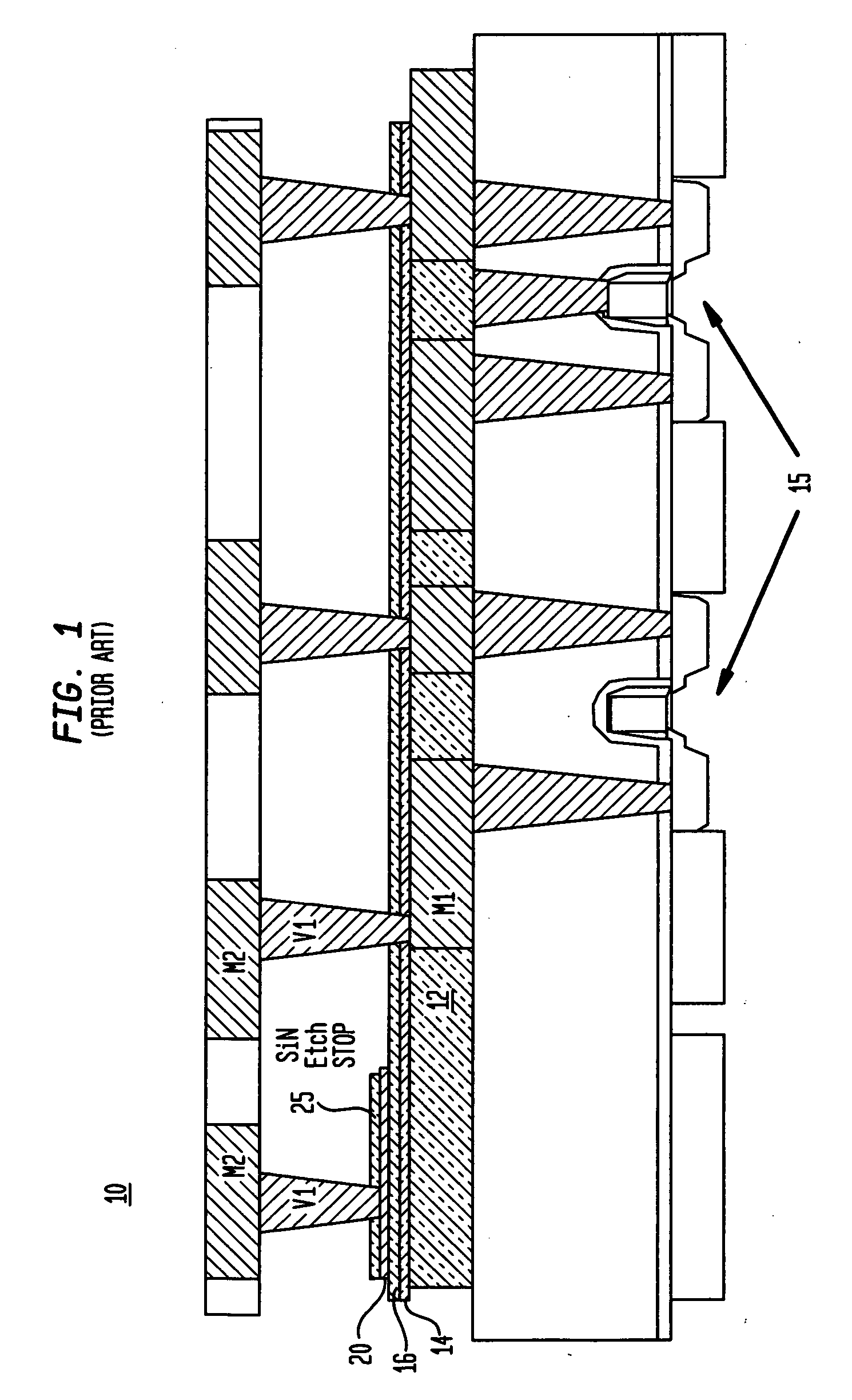

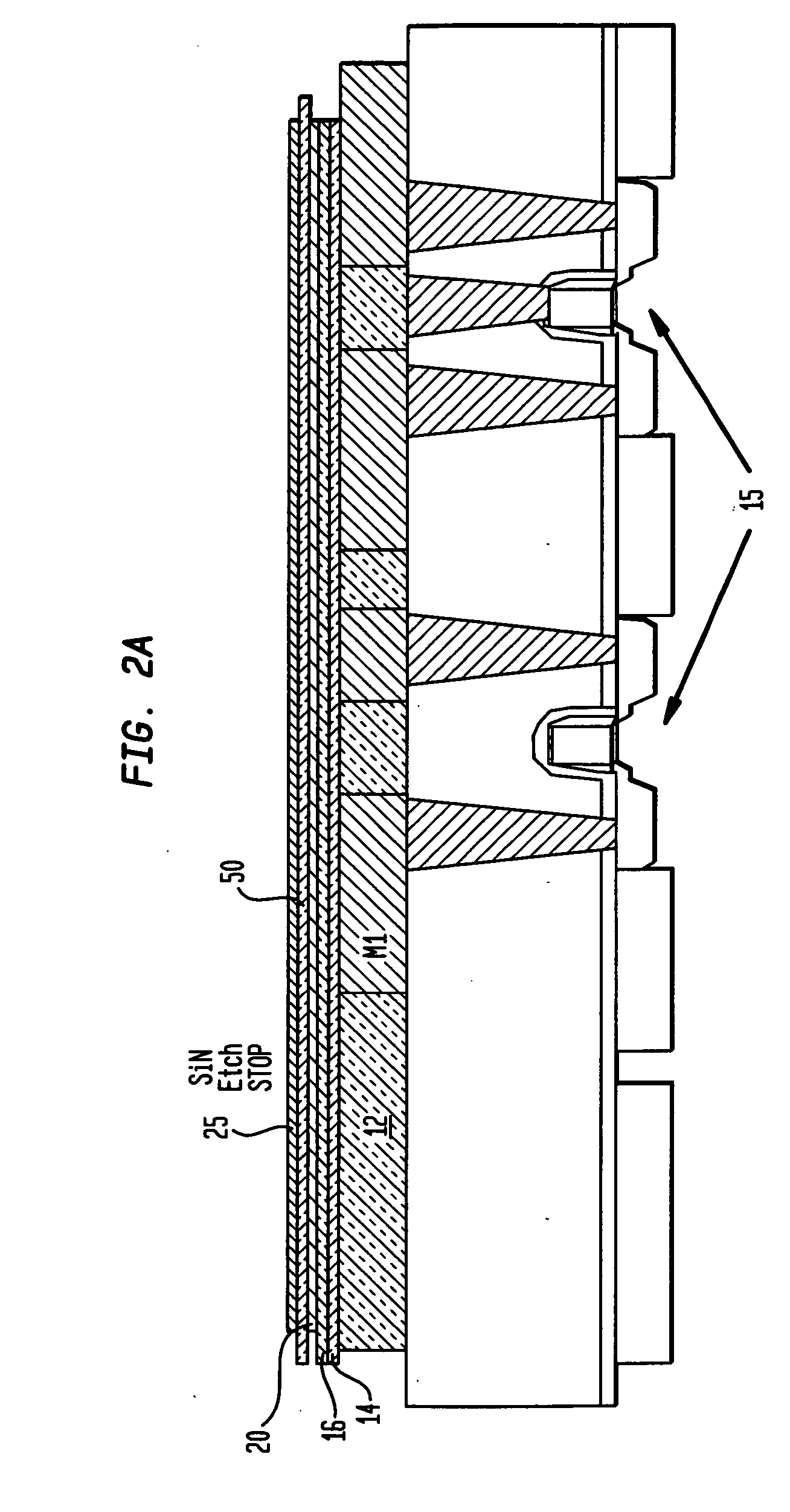

Method of fabrication of thin film resistor with zero TCR

InactiveUS6890810B2Reduce interfacial resistanceKeep shapeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringEffective temperature

A thin film resistor that has a substantially zero TCR is provided as well as a method for fabricating the same. The thin film resistor includes at least two resistor materials located over one another. Each resistor material has a different temperature coefficient of resistivity such that the effective temperature coefficient of resistivity of the thin film resistor is substantially 0 ppm / ° C. The thin film resistor may be integrated into a interconnect structure or it may be integrated with a metal-insulator-metal capacitor (MIMCAP).

Owner:IBM CORP

Resistor having a predetermined temperature coefficient

ActiveUS7777607B2Galvano-magnetic devicesNanomagnetismElectrical resistance and conductanceMagnetic reluctance

A material stack has an electrical resistance generally the same in the presence of a magnetic field and in the presence of no magnetic field. The electrical resistance of the material stack has a temperature coefficient generally the same as a magnetoresistance element.

Owner:ALLEGRO MICROSYSTEMS INC

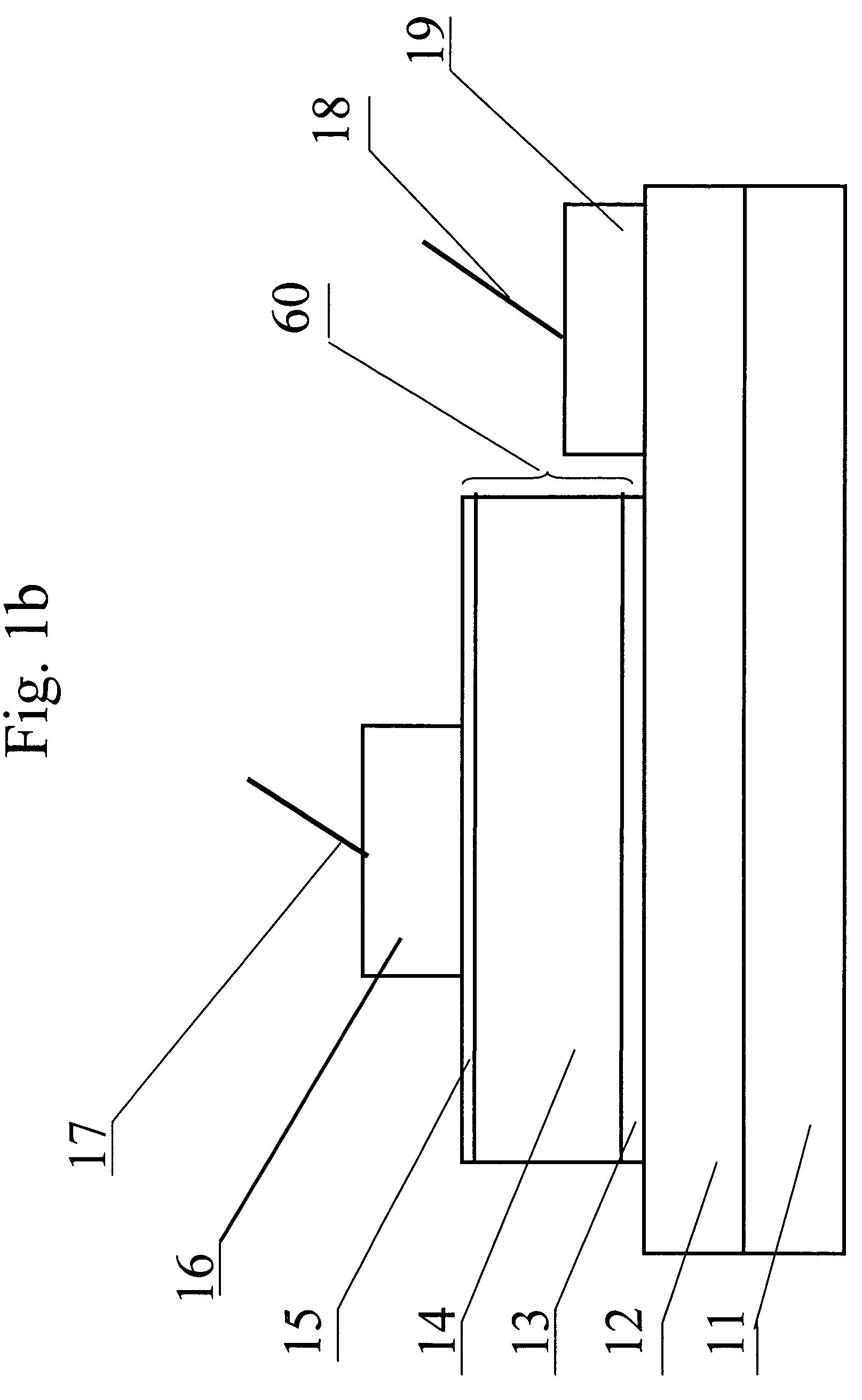

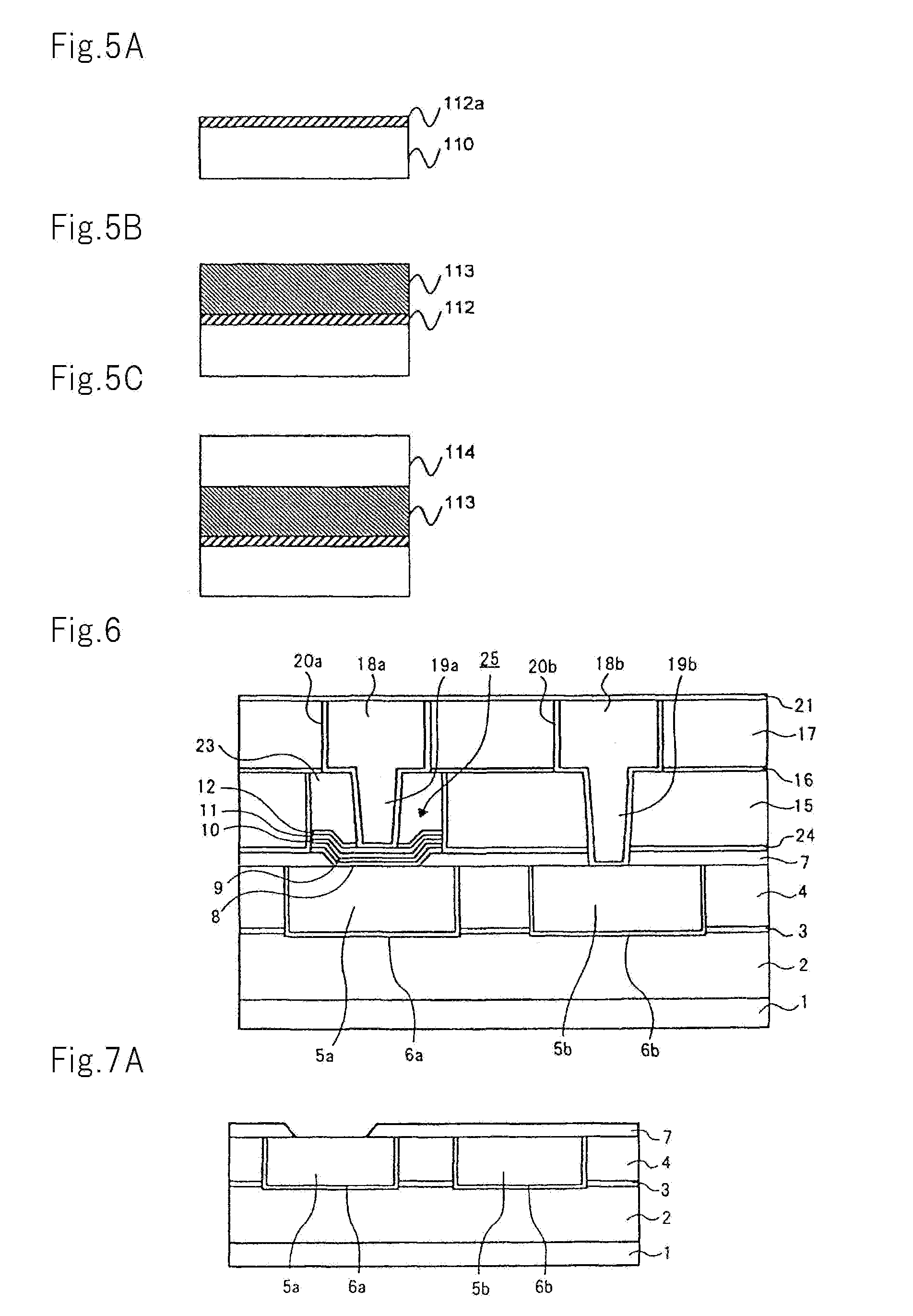

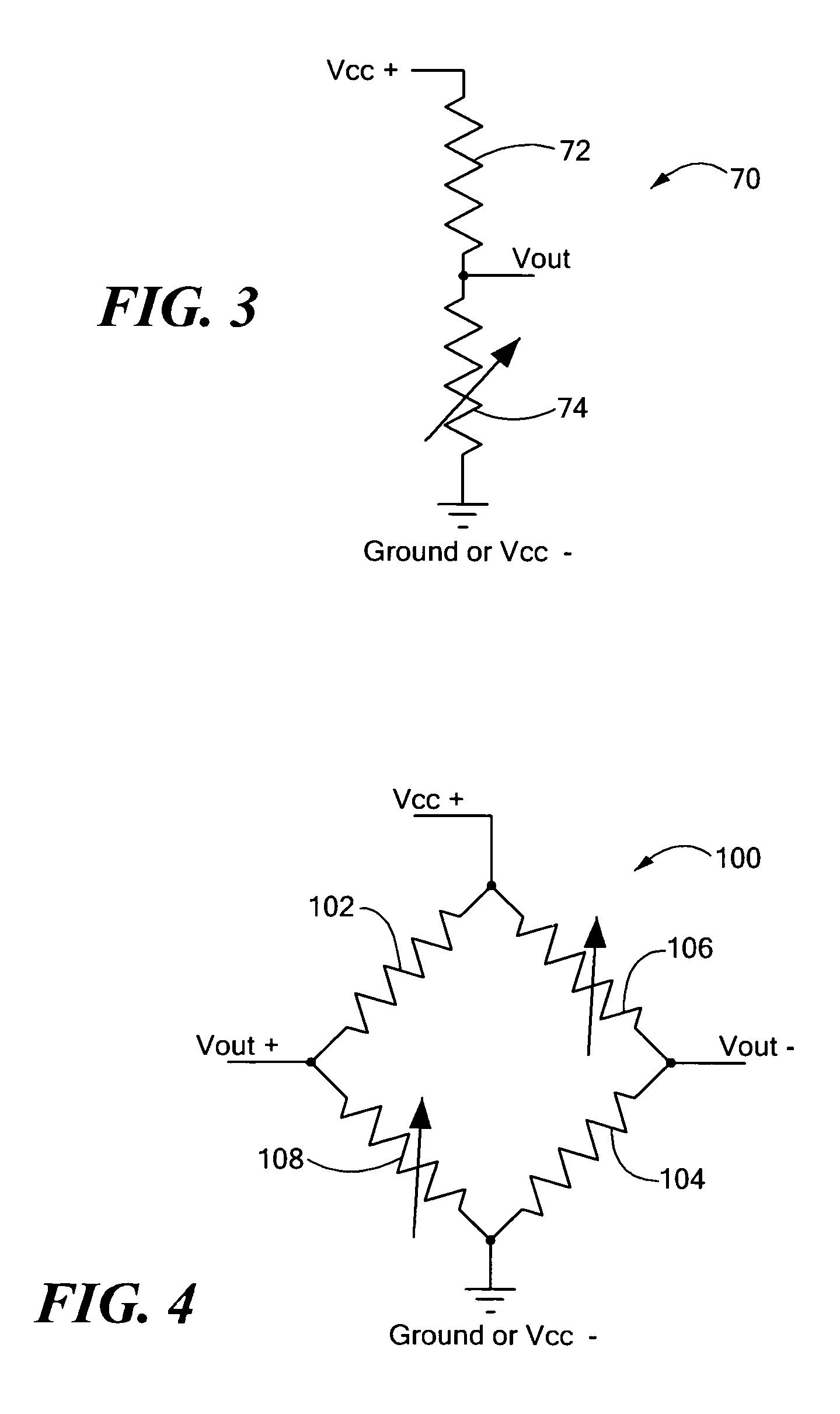

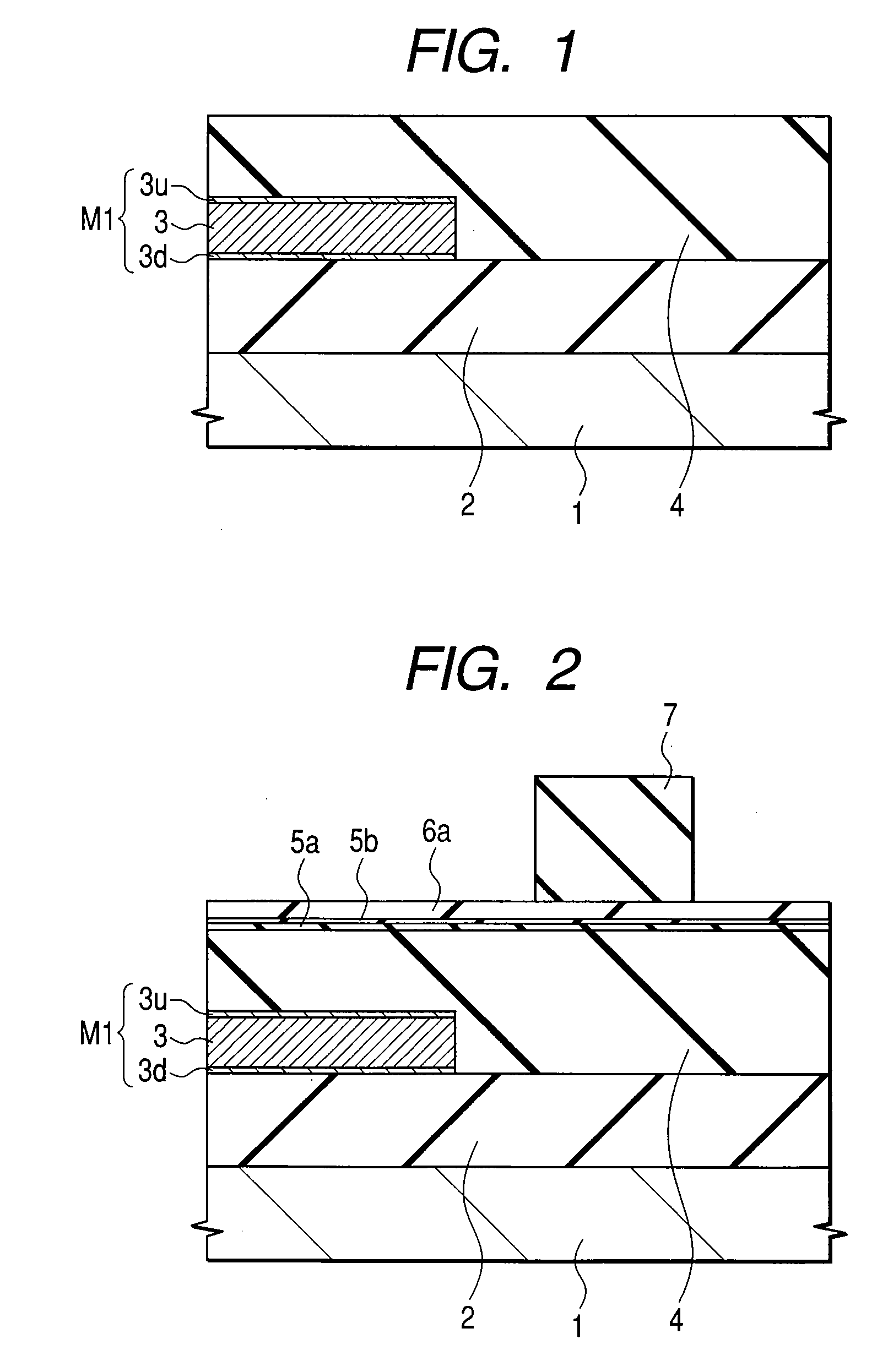

Thin film resistor with current density enhancing layer (CDEL)

ActiveUS20060181388A1Current-carrying capability can be increasedImprove adhesionTransistorElectrostatic/electro-adhesion relaysHigh current densityElectrical conductor

A thin film resistor device and method of manufacture includes a layer of a thin film conductor material and a current density enhancing layer (CDEL). The CDEL is an insulator material adapted to adhere to the thin film conductor material and enables the said thin film resistor to carry higher current densities with reduced shift in resistance. In one embodiment, the thin film resistor device includes a single CDEL layer formed on one side (atop or underneath) the thin film conductor material. In a second embodiment, two CDEL layers are formed on both sides (atop and underneath) of the thin film conductor material. The resistor device may be manufactured as part of both BEOL and FEOL processes.

Owner:GLOBALFOUNDRIES US INC

Resistive elements using carbon nanotubes

ActiveUS20070236325A1Easy parameter controlFunction increaseCurrent responsive resistorsSolid-state devicesBulk resistanceCarbon nanotube

Resistive elements include a patterned region of nanofabric having a predetermined area, where the nanofabric has a selected sheet resistance; and first and second electrical contacts contacting the patterned region of nanofabric and in spaced relation to each other. The resistance of the element between the first and second electrical contacts is determined by the selected sheet resistance of the nanofabric, the area of nanofabric, and the spaced relation of the first and second electrical contacts. The bulk resistance is tunable.

Owner:NANTERO

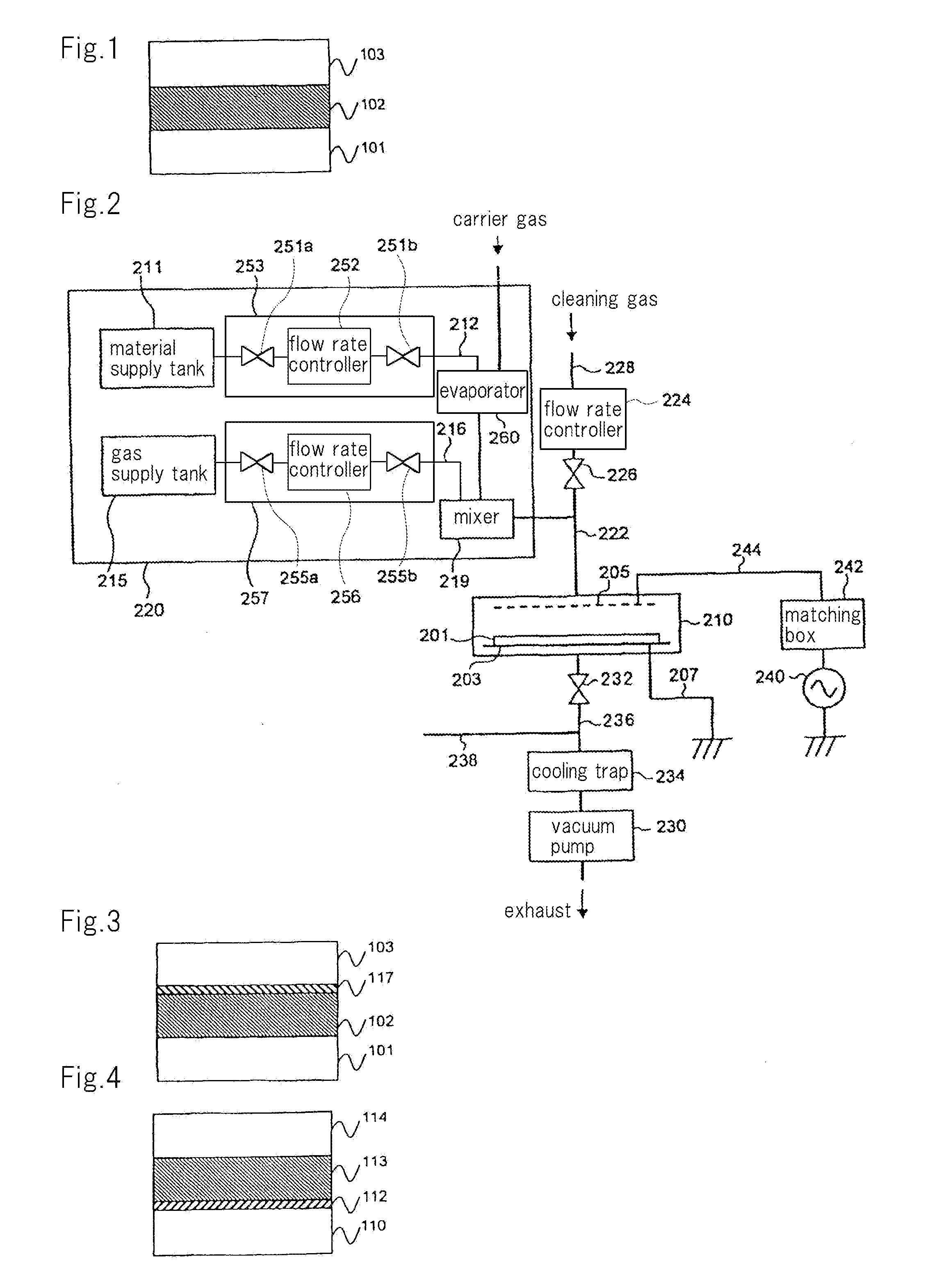

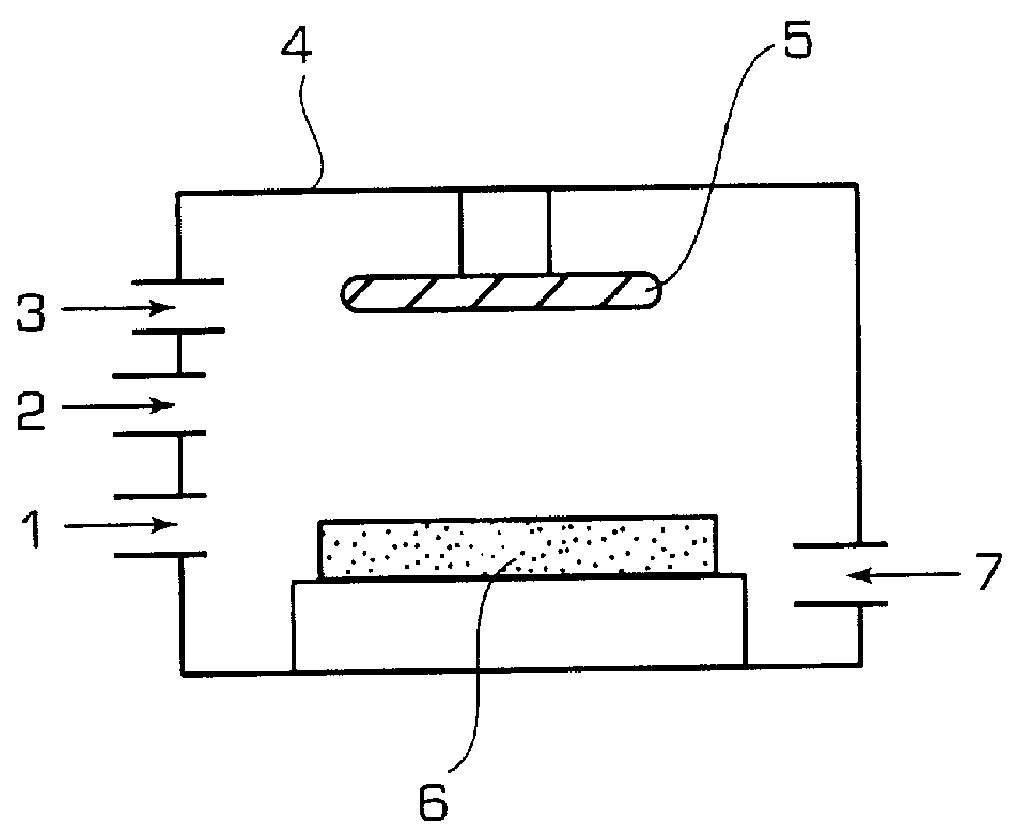

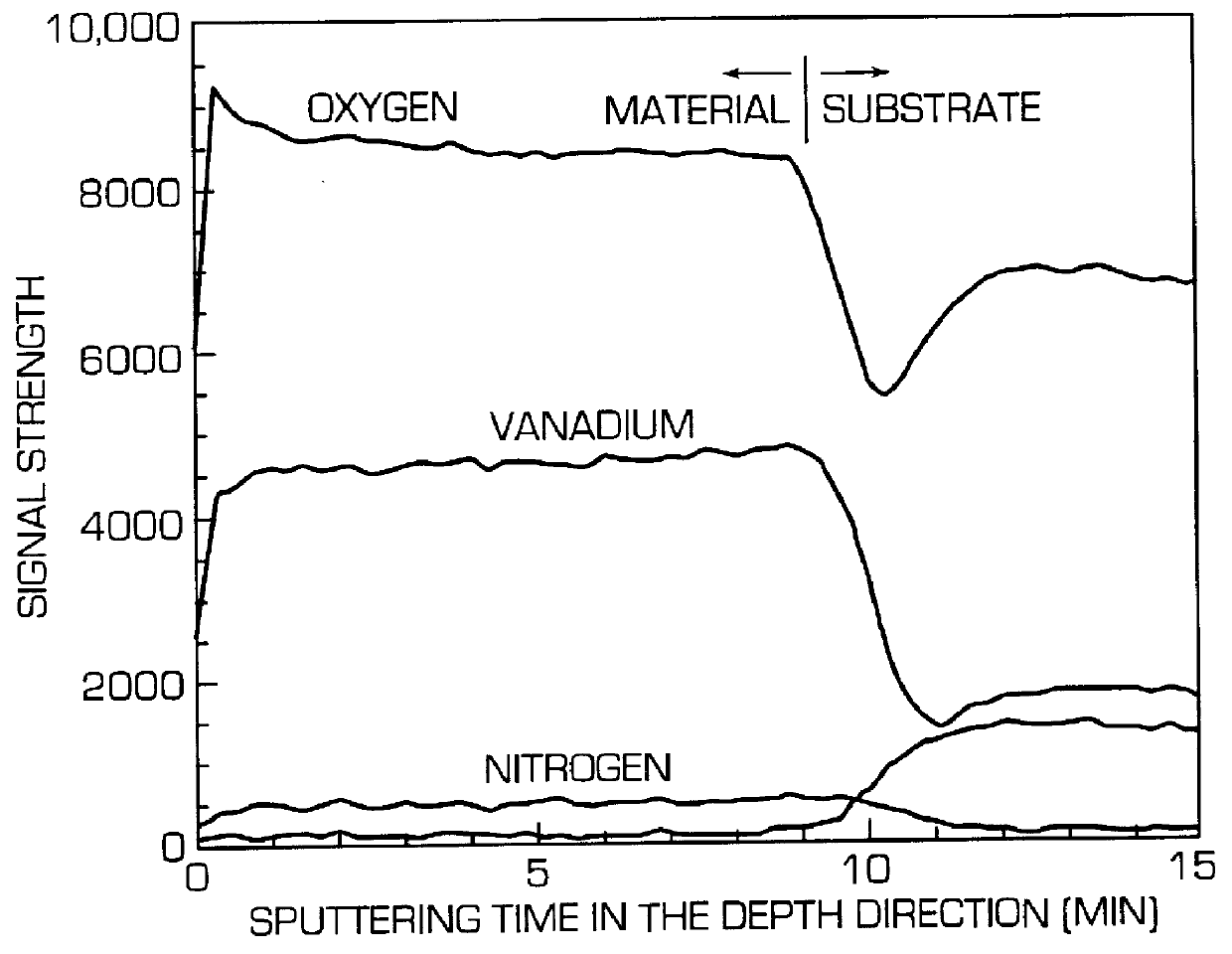

Thin-film temperature-sensitive resistor material and production process thereof

Described are a thin-film temperature-sensitive resistor material which comprises, at a temperature-sensitive resistor portion, a mixed crystal of a nitride and oxide of a transition metal such as vanadium preferably, that represented by the formula: MNxOy wherein 0<x<1, and 2< / =y< / =13 / 6, simultaneously exhibits a high temperature coefficient of resistance and a low specific resistance at about room temperature, and has excellent sensitivity at about room temperature; and a process for the production of a thin-film temperature-sensitive resistor material, which comprises forming its temperature-sensitive resistor portion by using a gas-atmosphere composed mainly of a nitrogen gas preferably, a mixed gas composed of nitrogen, argon and oxygen, and has a flow rate ratio of nitrogen to oxygen (nitrogen / oxygen) of 14 / 1 to 23 / 1.

Owner:NEC CORP

Platinum temperature sensor and its method of production

InactiveUS6653926B1Connected deterioration of property is preventedEnvelope/housing resistor manufactureThermometers using electric/magnetic elementsPlatinumMetallurgy

A Platinum temperature sensor comprises a ceramic substrate and a platinum thin-film resistor applied to said ceramic substrate, a ceramic cover layer and a connecting layer generated from a ceramic green layer by pressure and temperature treatment. The ceramic cover layer is connected with the ceramic substrate in such a way via the connecting layer that the platinum thin-film resistor is sealingly encapsulated with regard to the environment.

Owner:BORGWARNER BERU SYST

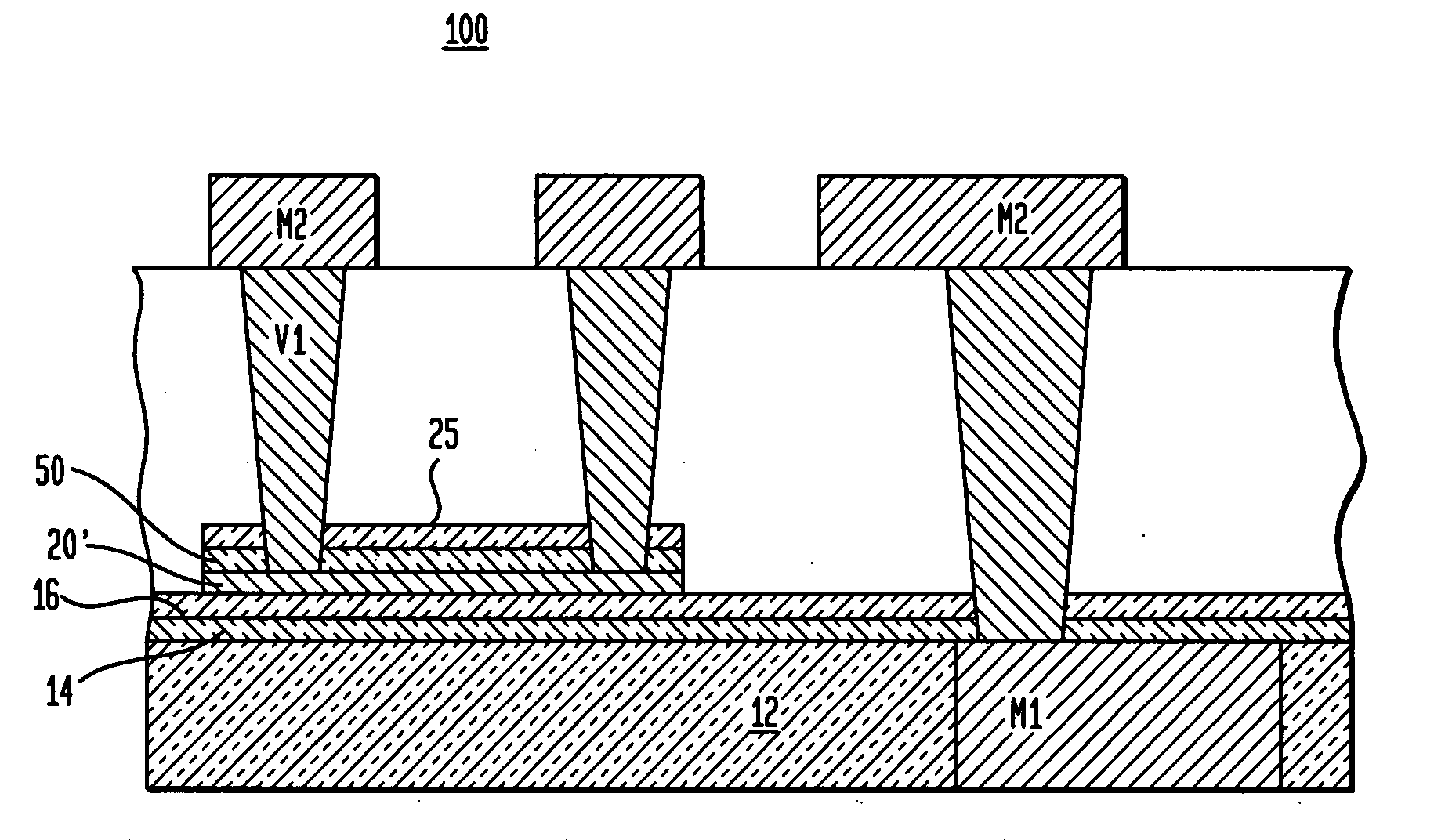

Via-less thin film resistor with a dielectric cap

ActiveUS20120049997A1Stable temperature characteristicsHeat dissipationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

Owner:STMICROELECTRONICS SRL

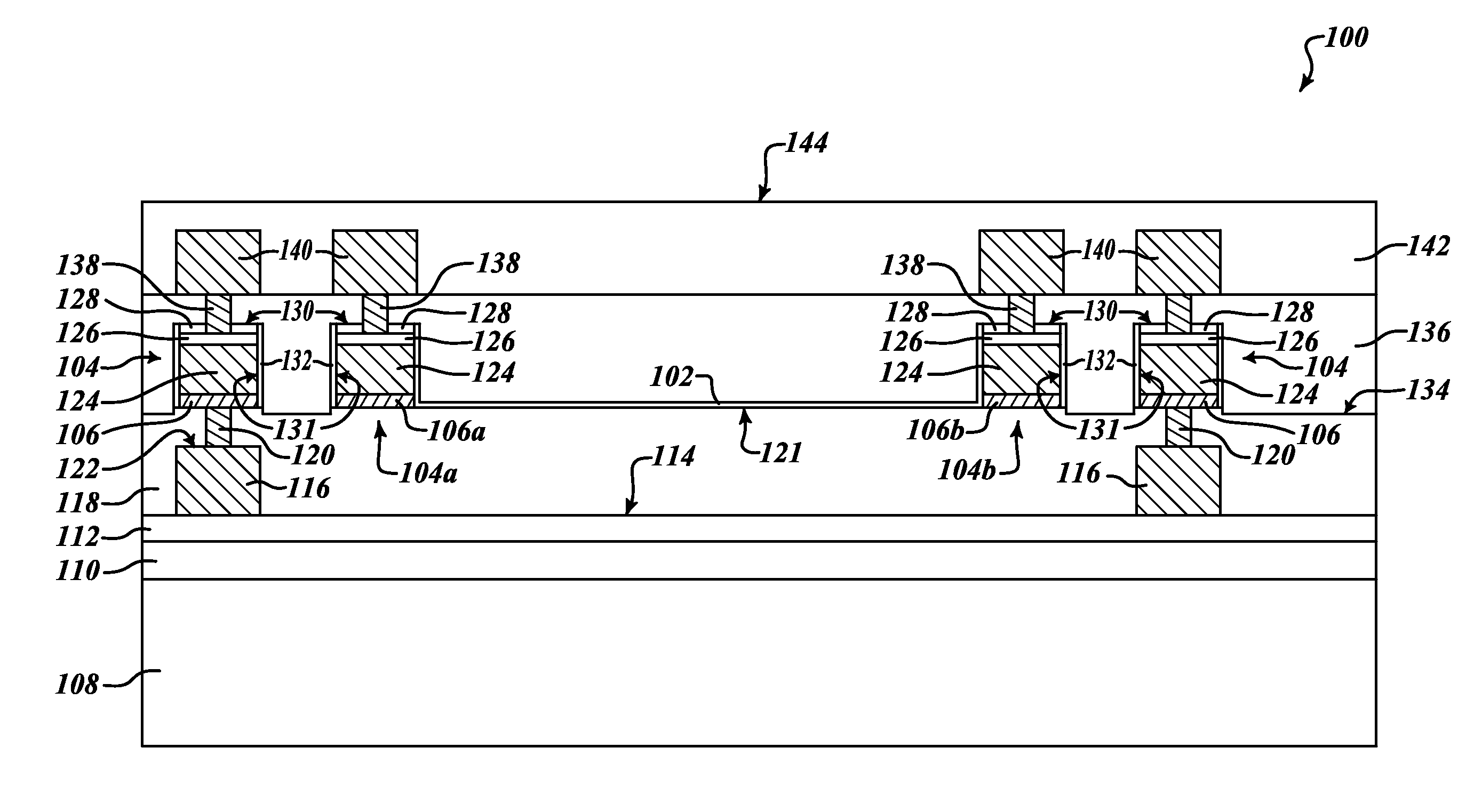

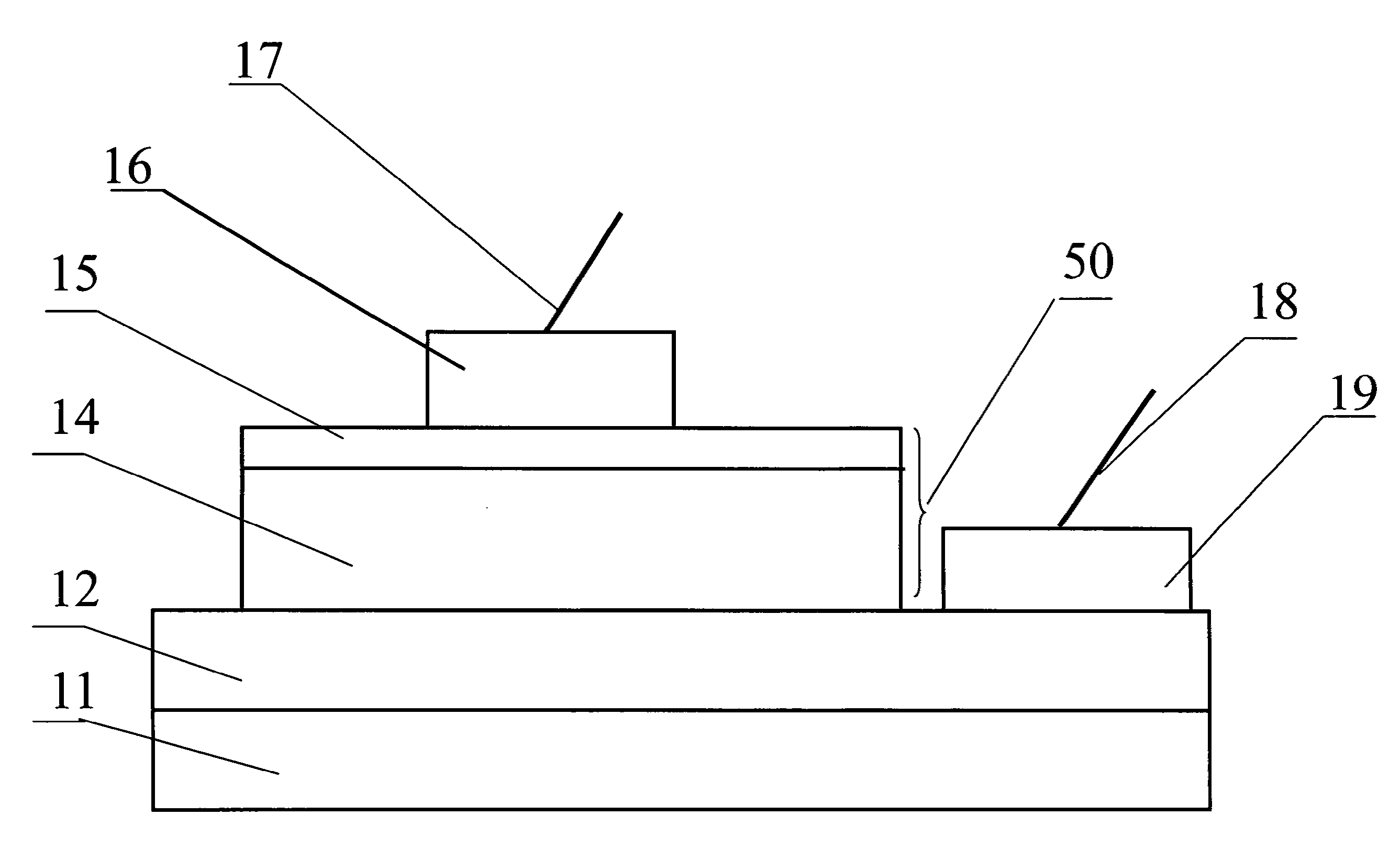

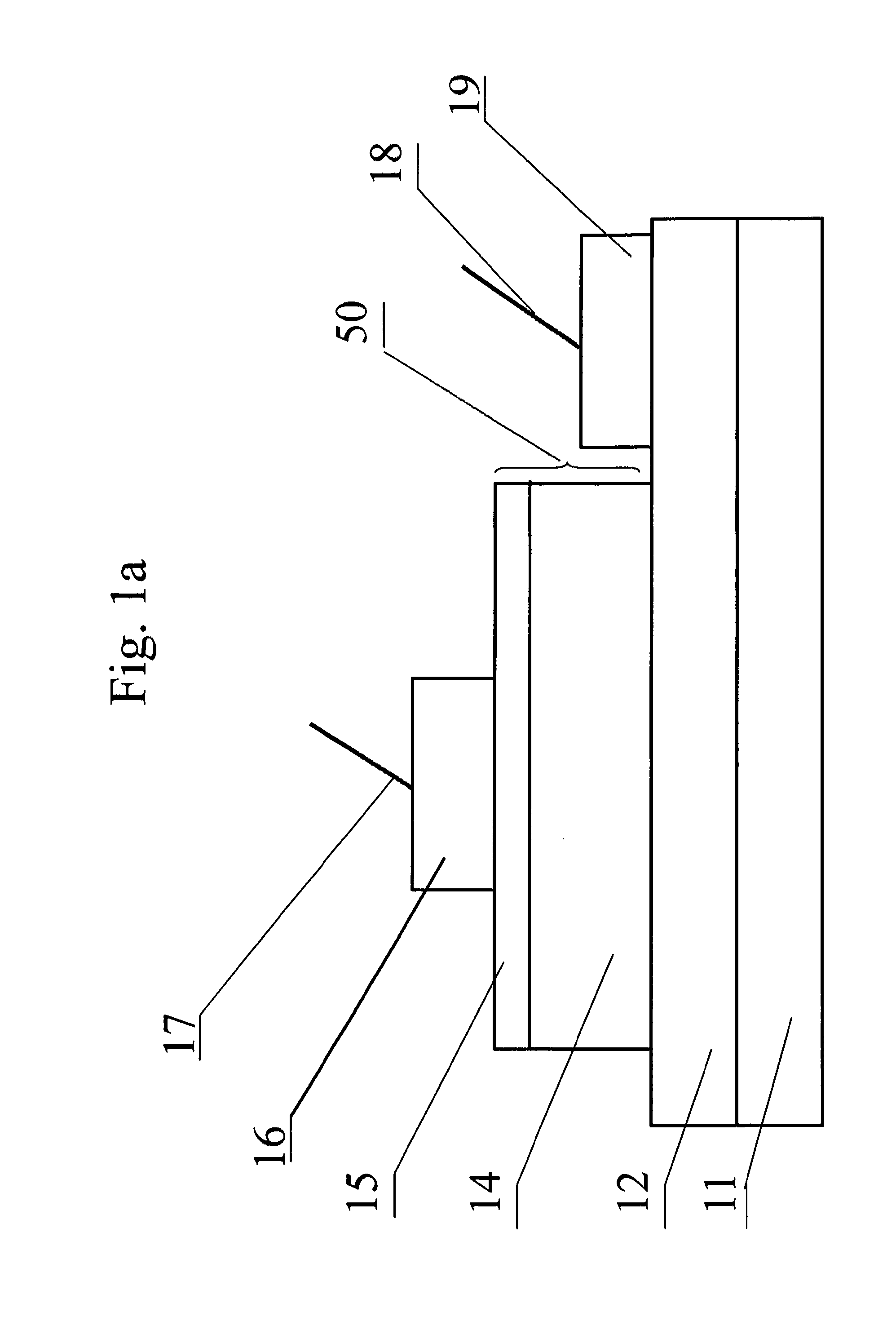

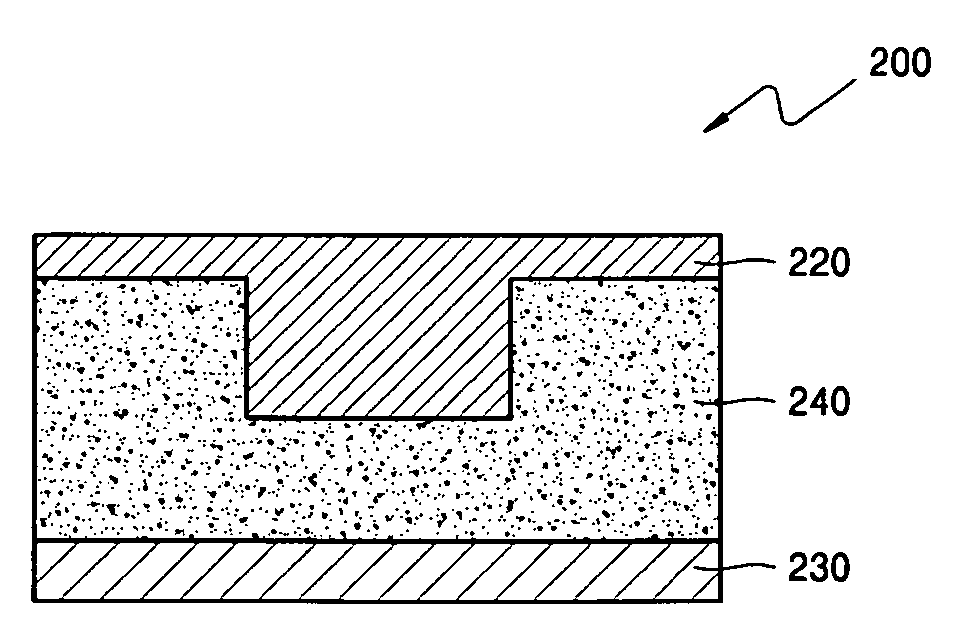

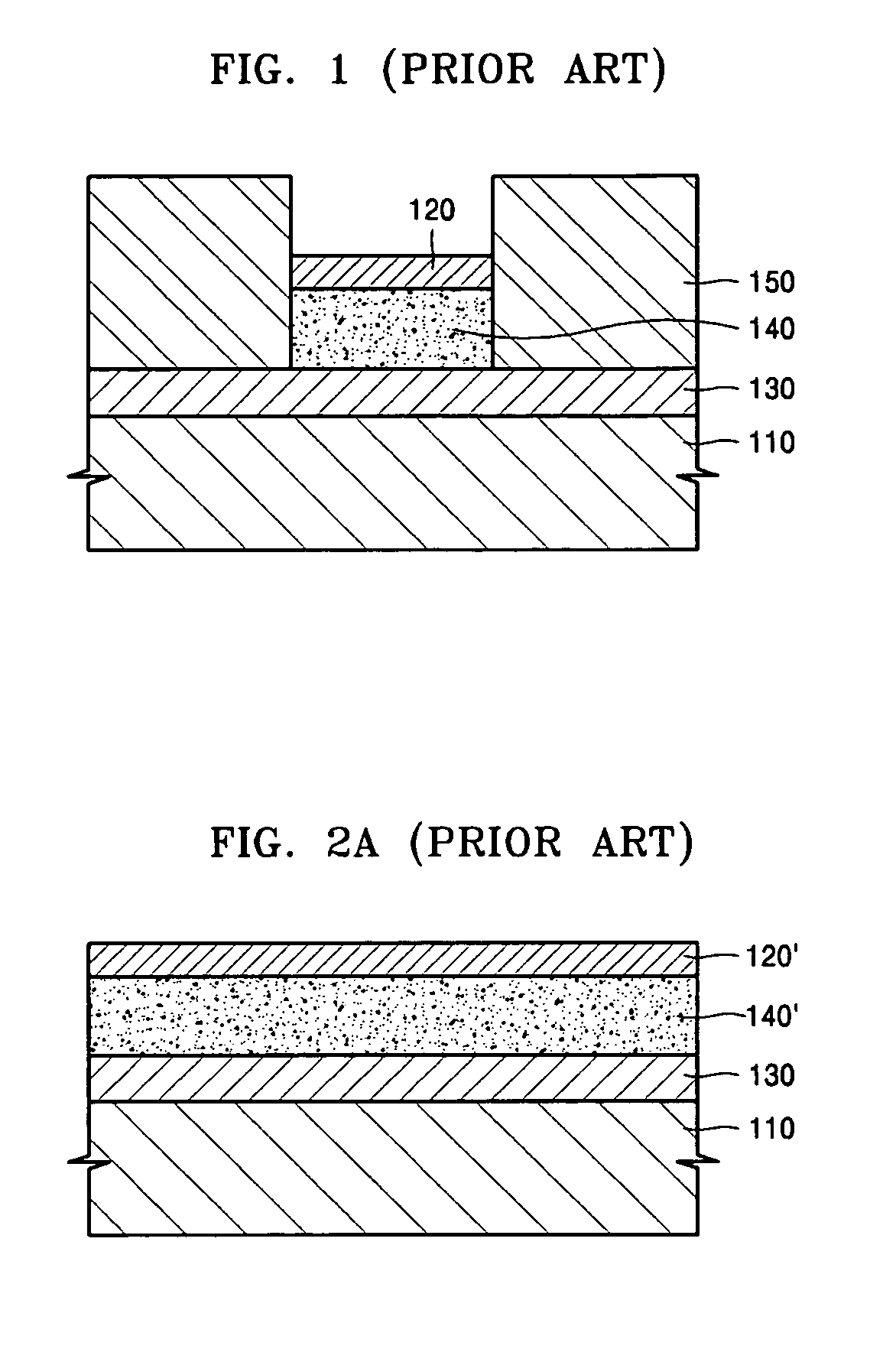

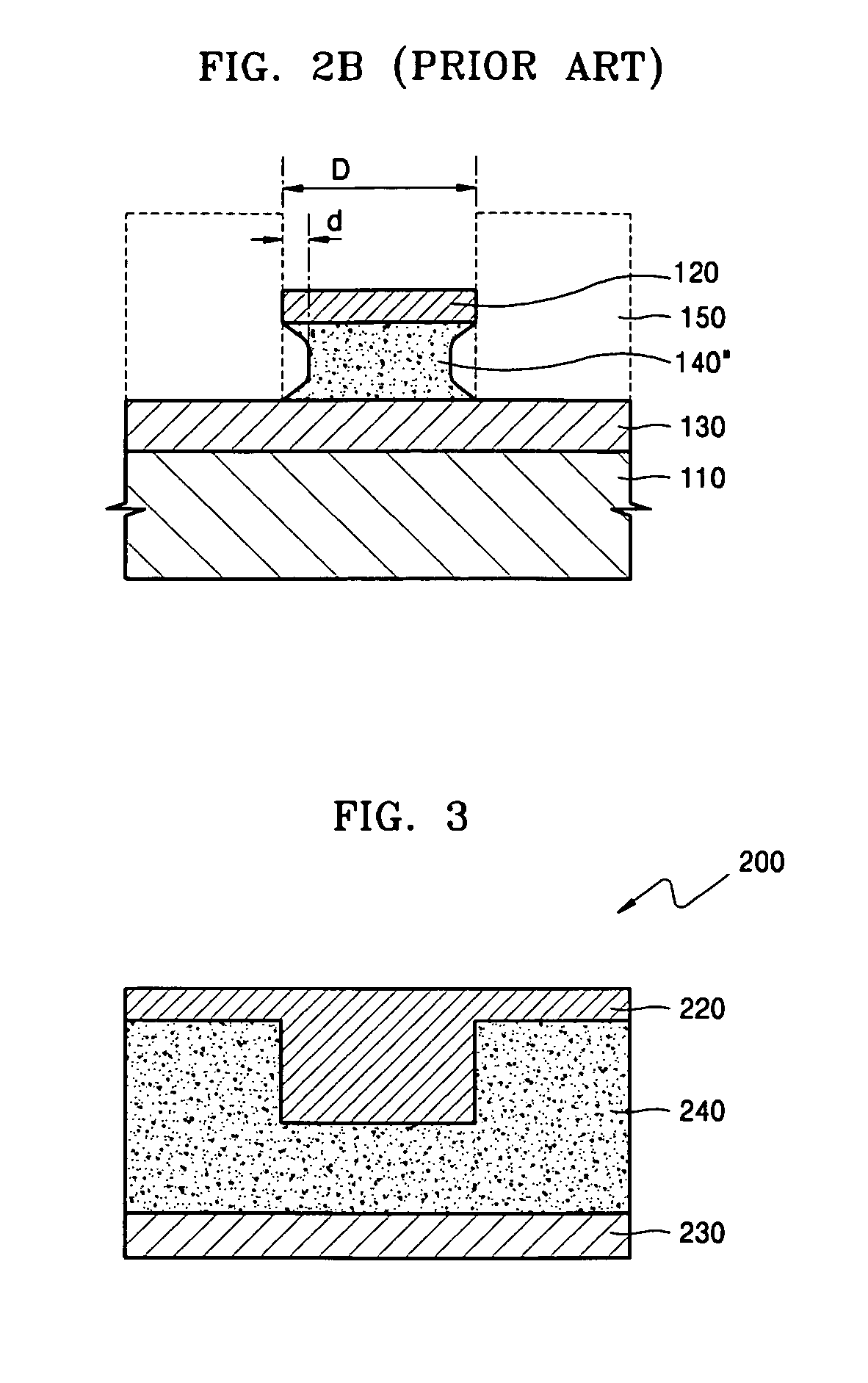

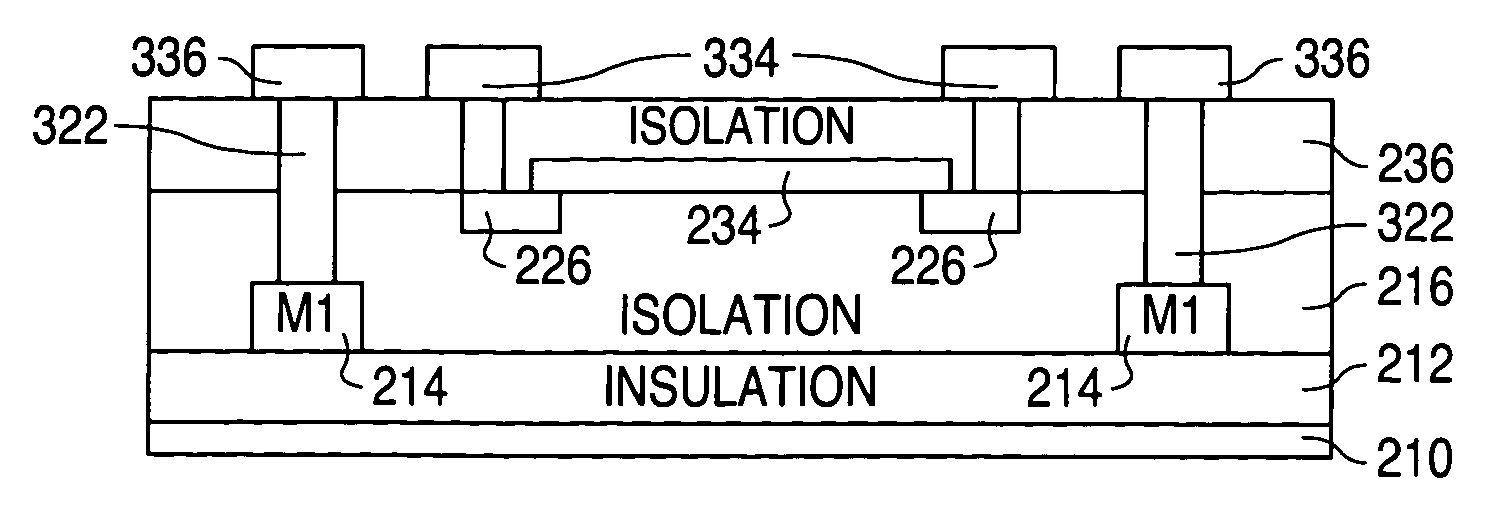

Two terminal multi-layer thin film resistance switching device with a diffusion barrier and methods thereof

ActiveUS20120126195A1Alleviate challengeAvoid relative motionSemiconductor/solid-state device manufacturingDigital storageDiffusion barrierActive layer

An electric-pulse-induced-resistance change device (EPIR device) is provided which is a resistance switching device. It has a buffer layer inserted between a first active resistance switching layer and a second active resistance switching layer, with both active switching layers connected to electrode layers directly or through additional buffer layers between the active resistance switching layers and the electrodes. This device in its simplest form has the structure: electrode-active layer-buffer layer-active layer-electrode. The second active resistance switching layer may, in the alternative, be an ion donating layer, such that the structure becomes: electrode-active layer-buffer layer-ion donating layer-electrode. The EPIR device is constructed to mitigate the retention challenge.

Owner:UNIV HOUSTON SYST

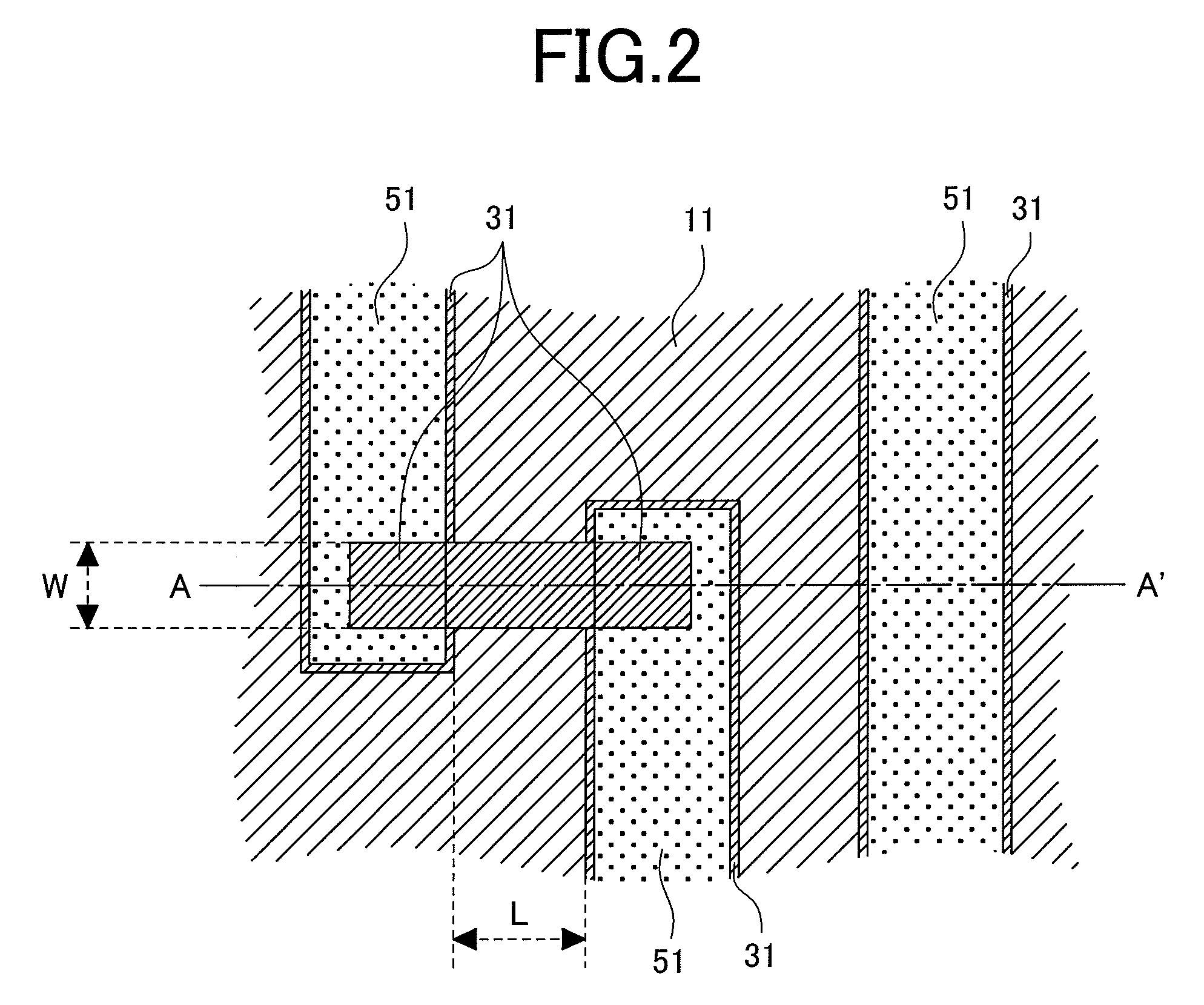

Semiconductor memory device with three dimensional solid electrolyte structure, and manufacturing method thereof

InactiveUS20060209495A1Reduce the overall heightElectrolytic capacitorsSolid-state devicesElectrical resistance and conductanceEngineering

The semiconductor memory device includes a variable resistance device having a solid electrolyte in a three-dimensional structure. The variable resistance device includes a first electrode; the solid electrolyte, which has at least two regions with different heights, formed on the first electrode; and a second electrode made of a conductive material formed on the solid electrolyte to cover the regions with different heights. In addition, a multibit semiconductor memory device is provided which includes a bias circuit that can control the intensity of a current and time the current is supplied to the variable resistance device inside a memory cell in multiple steps to configure multibits.

Owner:SAMSUNG ELECTRONICS CO LTD

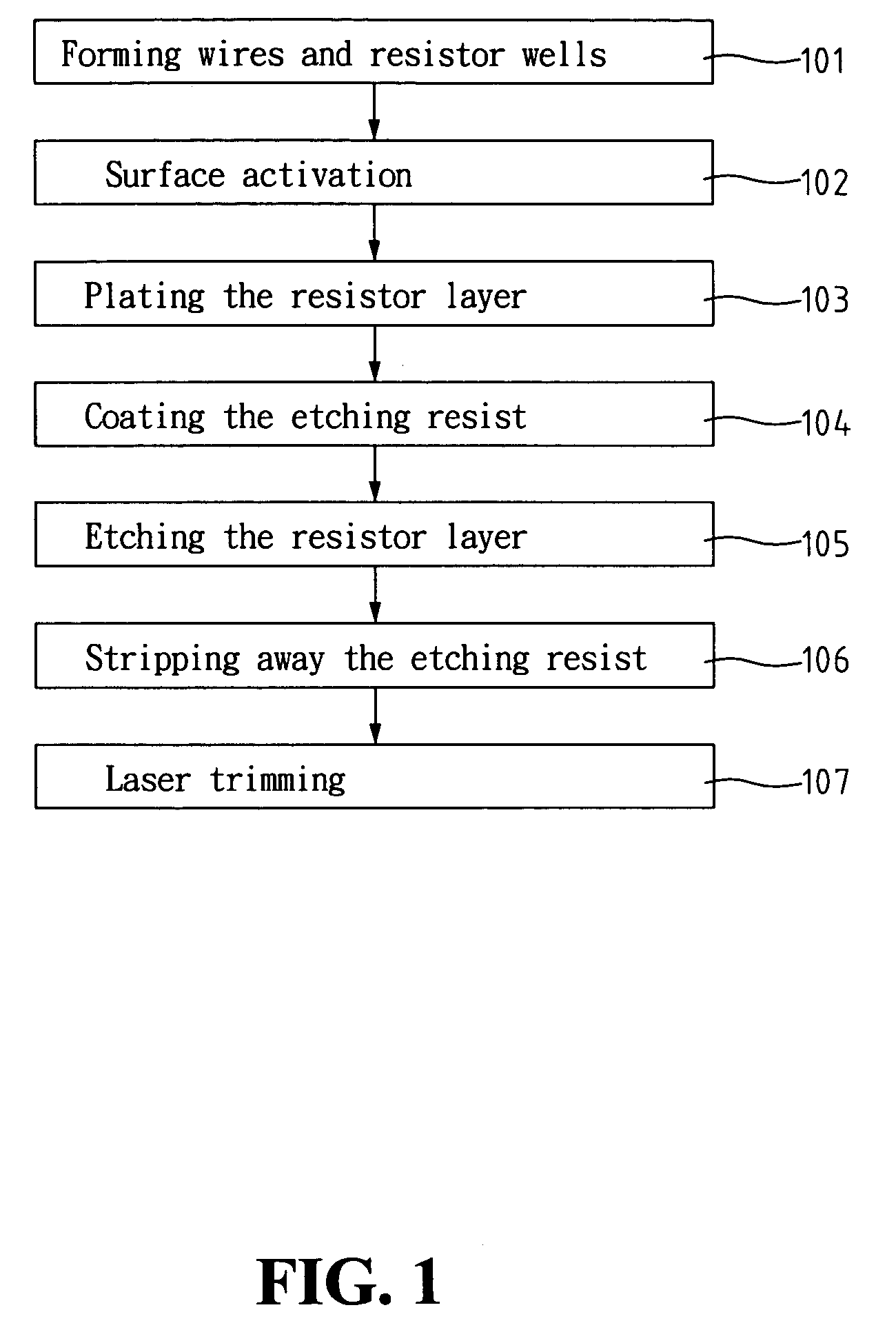

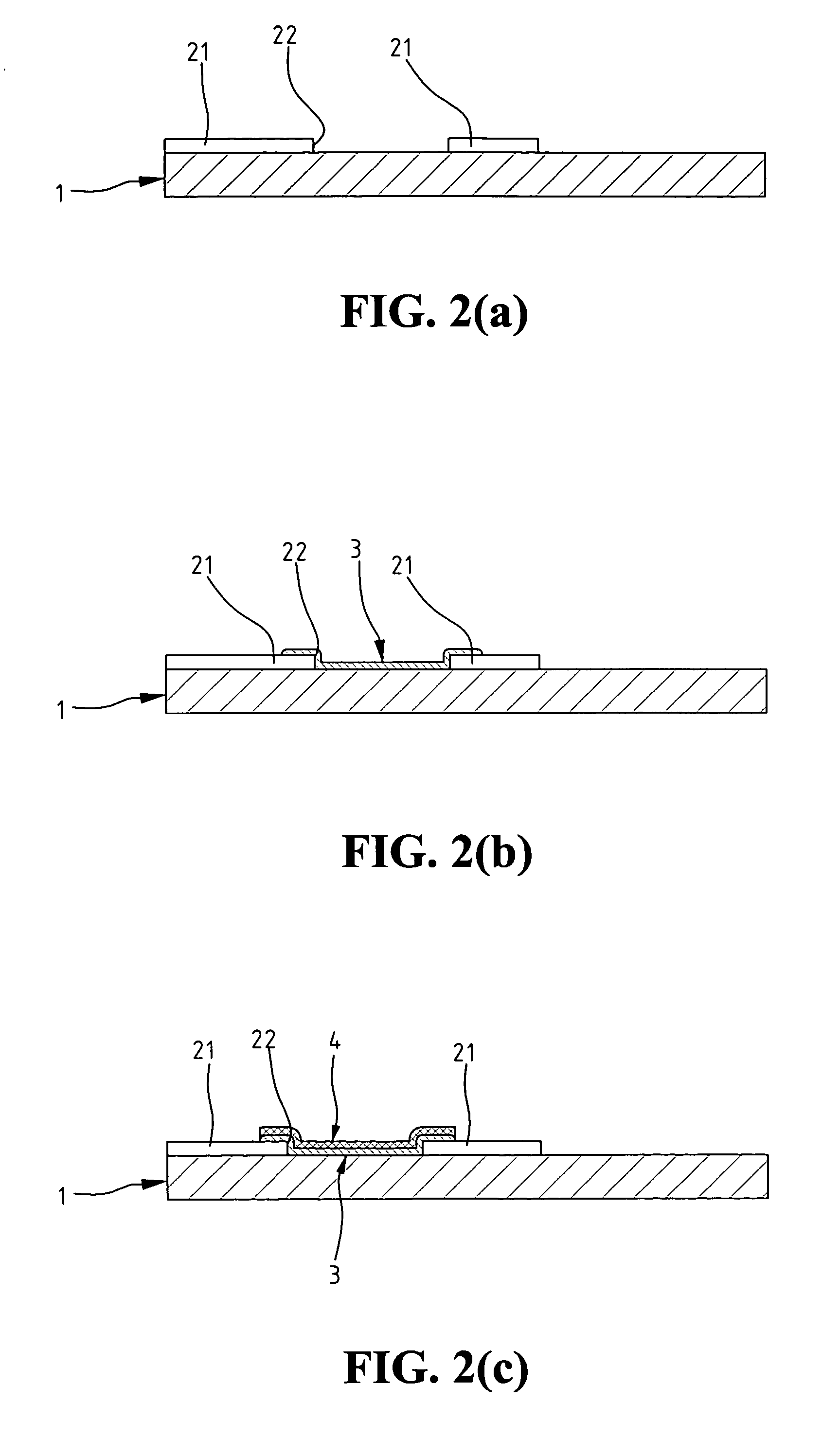

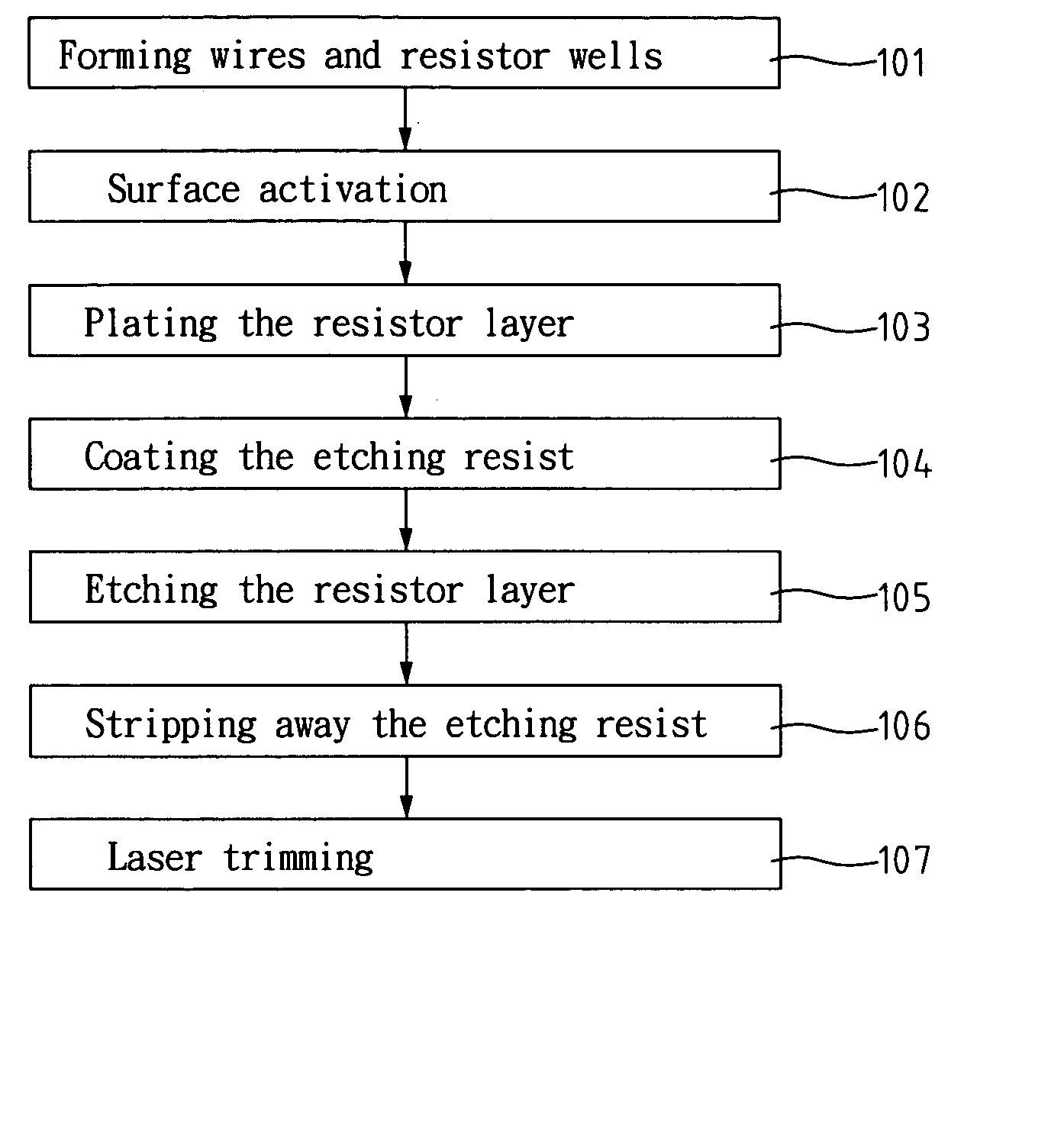

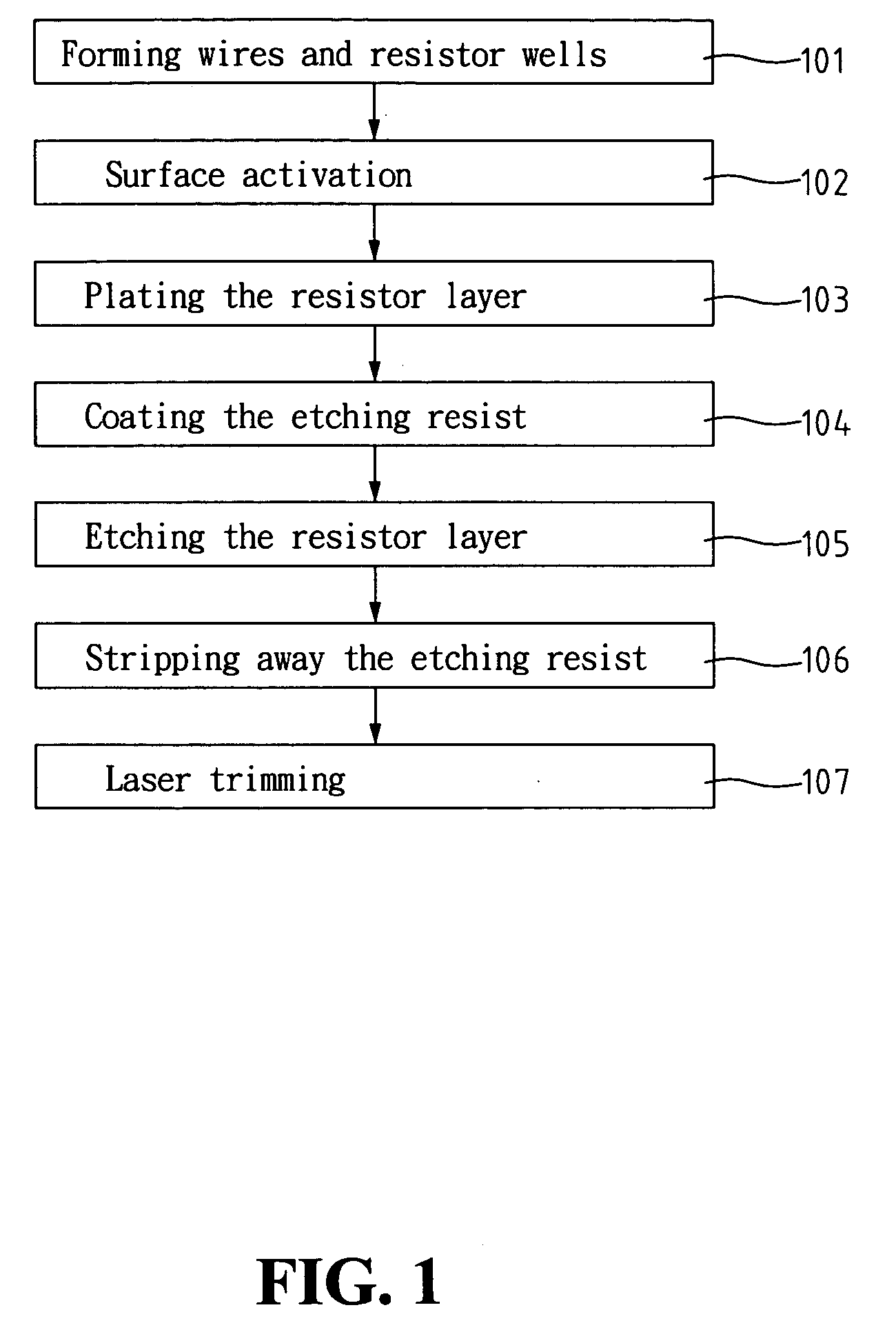

Method for fabricating embedded thin film resistors of printed circuit board

InactiveUS7213327B2Finer circuit layoutSmall sizePrinted circuit assemblingElectrically conductive connectionsManufacturing cost reductionPrinted circuit board

A method for fabricating the embedded thin film resistors of a printed circuit board is provided. The embedded thin film resistors are formed using a resistor layer built in the printed circuit board. Compared with conventional discrete resistors, embedded thin film resistors contribute to a smaller printed circuit board as the space for installing conventional resistors is saved, and better signal transmission speed and quality as the capacitive reactance effect caused by two connectors of the conventional resistors is avoided. The method for fabricating the embedded thin film resistors provided by the invention can be conducted using the process and equipment for conventional printed circuit boards and thereby saving the investment on new types of equipment. The method can be applied in the mass production of printed circuit boards and thereby reduce the manufacturing cost significantly.

Owner:SU SUNG LING

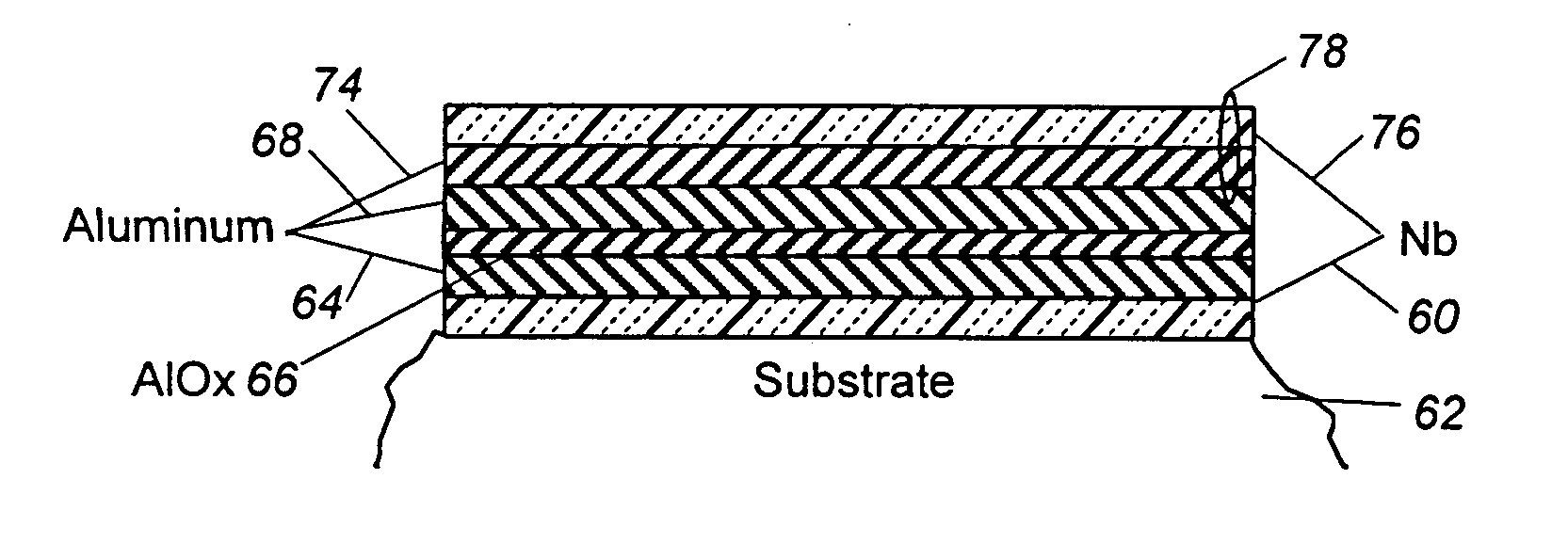

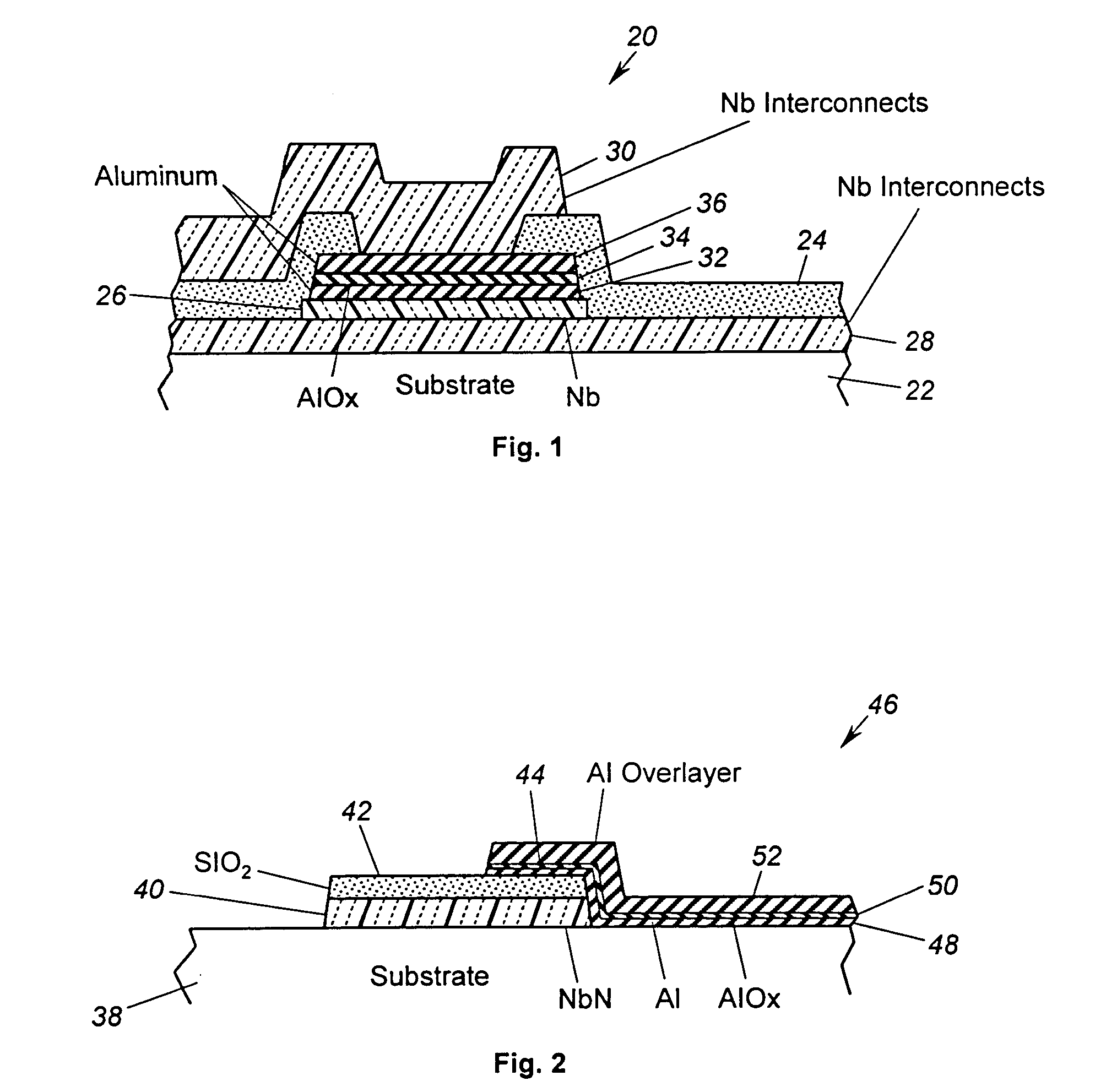

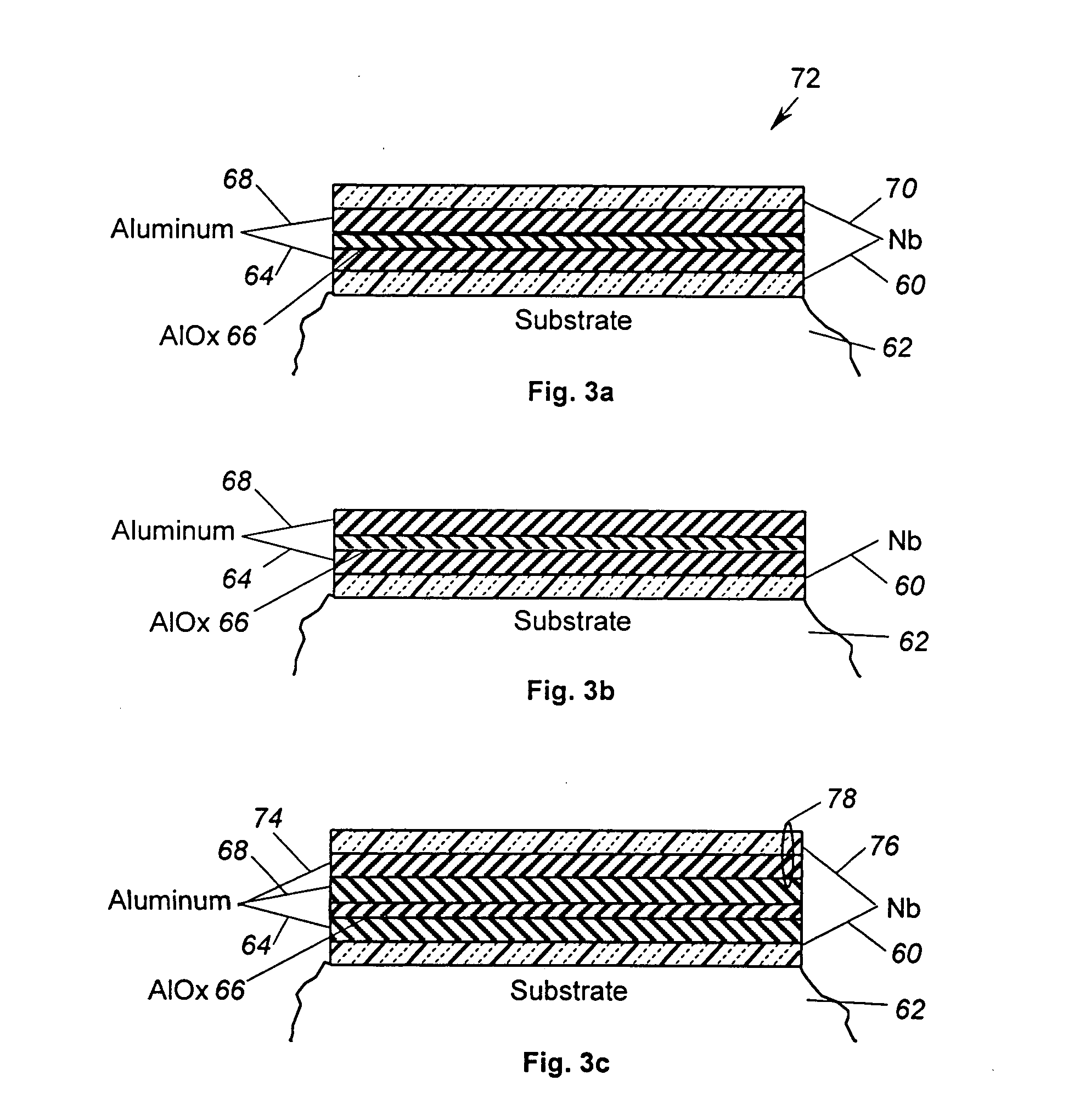

A1/A1Ox/A1 resistor process for integrated circuits

InactiveUS20050062131A1Solid-state devicesResistor manufactureSuperconducting integrated circuitsIntegrated circuit

A structure and a method for forming a vertical resistor on a superconducting integrated circuit. The resistance structure is formed from a Al / AlOx / Al material system. In particular, the resistance structure includes a layer of aluminum, in-situ oxidation of the aluminum surface and further deposition of aluminum. The resistance of the Al / AlOx / Al structure primarily comes from the aluminum oxide layer rather than the aluminum. As such, any aluminum removed during the interconnect pre-cleaning process will have a negligible impact on the overall resistance of the structure.

Owner:NORTHROP GRUMAN CORP

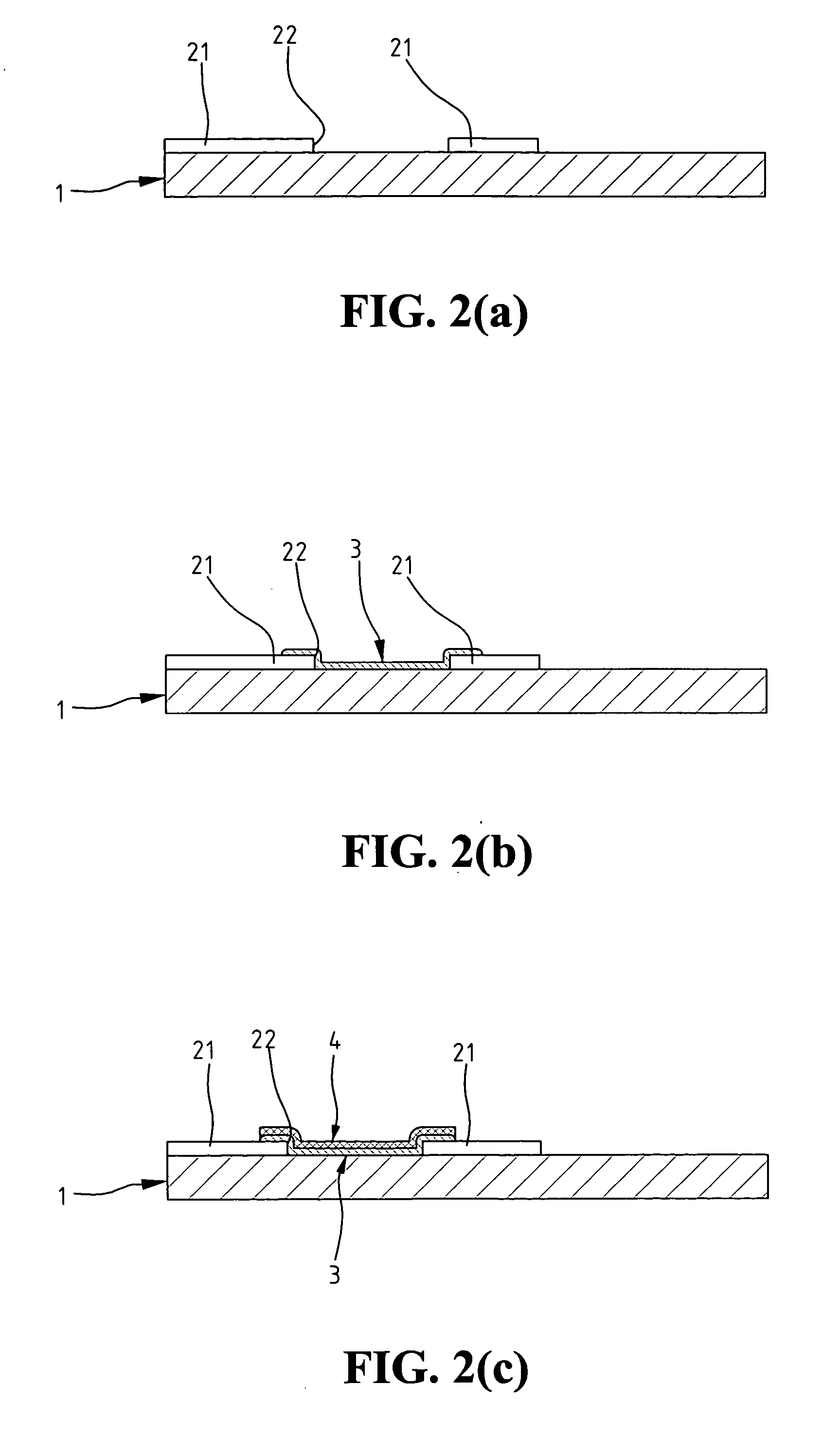

Method for fabricating embedded thin film resistors of printed circuit board

InactiveUS20050196966A1Finer circuit layoutSmall sizePrinted circuit assemblingElectrically conductive connectionsManufacturing cost reductionHigh volume manufacturing

A method for fabricating the embedded thin film resistors of a printed circuit board is provided. The embedded thin film resistors are formed using a resistor layer built in the printed circuit board. Compared with conventional discrete resistors, embedded thin film resistors contribute to a smaller printed circuit board as the space for installing conventional resistors is saved, and better signal transmission speed and quality as the capacitive reactance effect caused by two connectors of the conventional resistors is avoided. The method for fabricating the embedded thin film resistors provided by the invention can be conducted using the process and equipment for conventional printed circuit boards and thereby saving the investment on new types of equipment. The method can be applied in the mass production of printed circuit boards and thereby reduce the manufacturing cost significantly.

Owner:SU SUNG LING

Oxide thin film for bolometer and infrared detector using the oxide thin film

ActiveUS20050167592A1Improve performanceLow device resistanceMaterial analysis by optical meansNegative temperature coefficient thermistorsIon beamBolometer

The present invention relates to an oxide thin film for a bolometer-type uncooled infrared detector having high sensitivity. A vanadium tungsten oxide (V—W—Ox), i.e. a tungsten-doped vanadium oxide, is provided as an oxide film for a bolometer. An oxide for bolometer having characteristics of low resistance of 5 to 200 kΩ and variable TCR between −1.5 and −4.1% / ° C. can be obtained by an oxidation of vanadium-tungsten metal film at a low temperature around 300° C., with changing a tungsten content and oxidation time. And a reproducible thin film can be fabricated by low price equipment for thin film deposition, without expensive ion beam or laser apparatus. Accordingly, an oxide for bolometer having characteristics of resistance lower than 100 kΩ and TCR higher than −3% / ° C. can be obtained with reproducibility, whereby an uncooled-type infrared detector having high sensitivity can be fabricated.

Owner:KOREA INST OF SCI & TECH

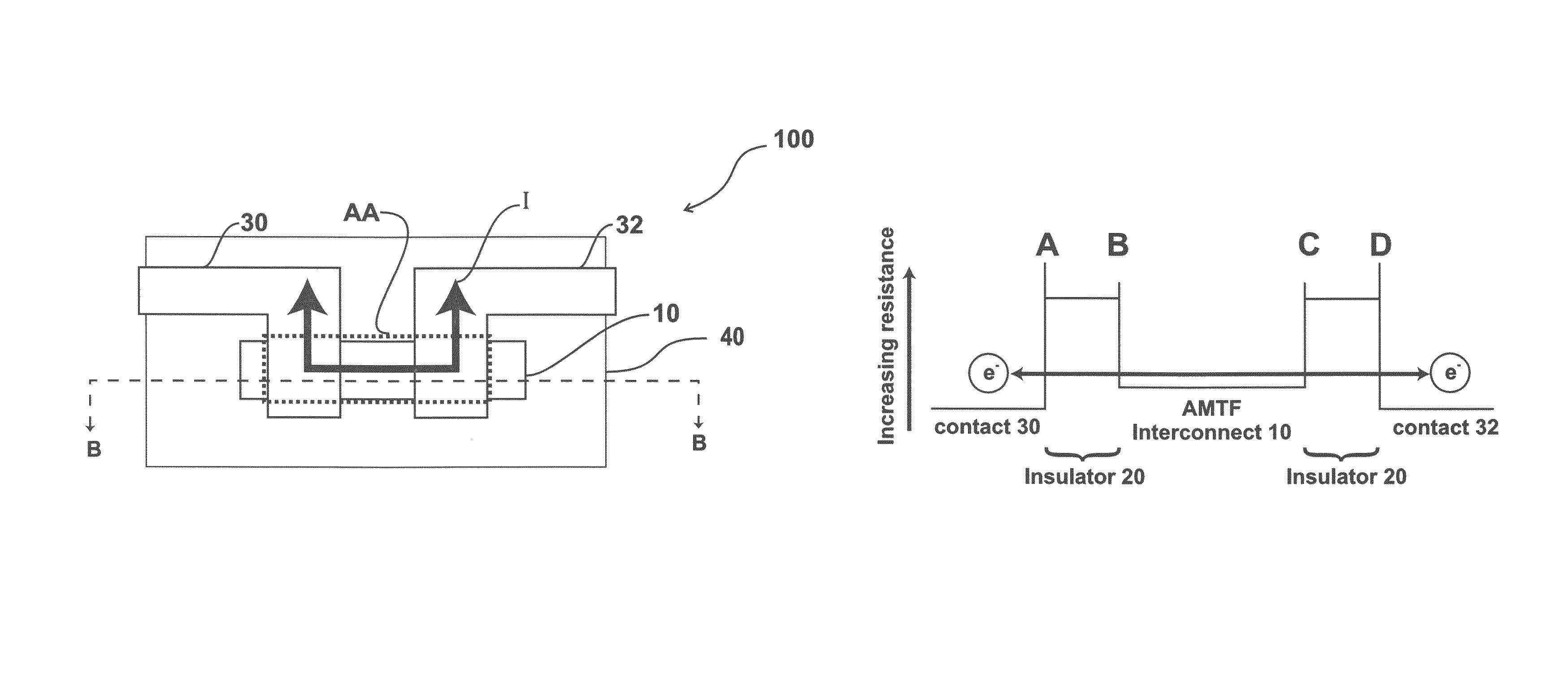

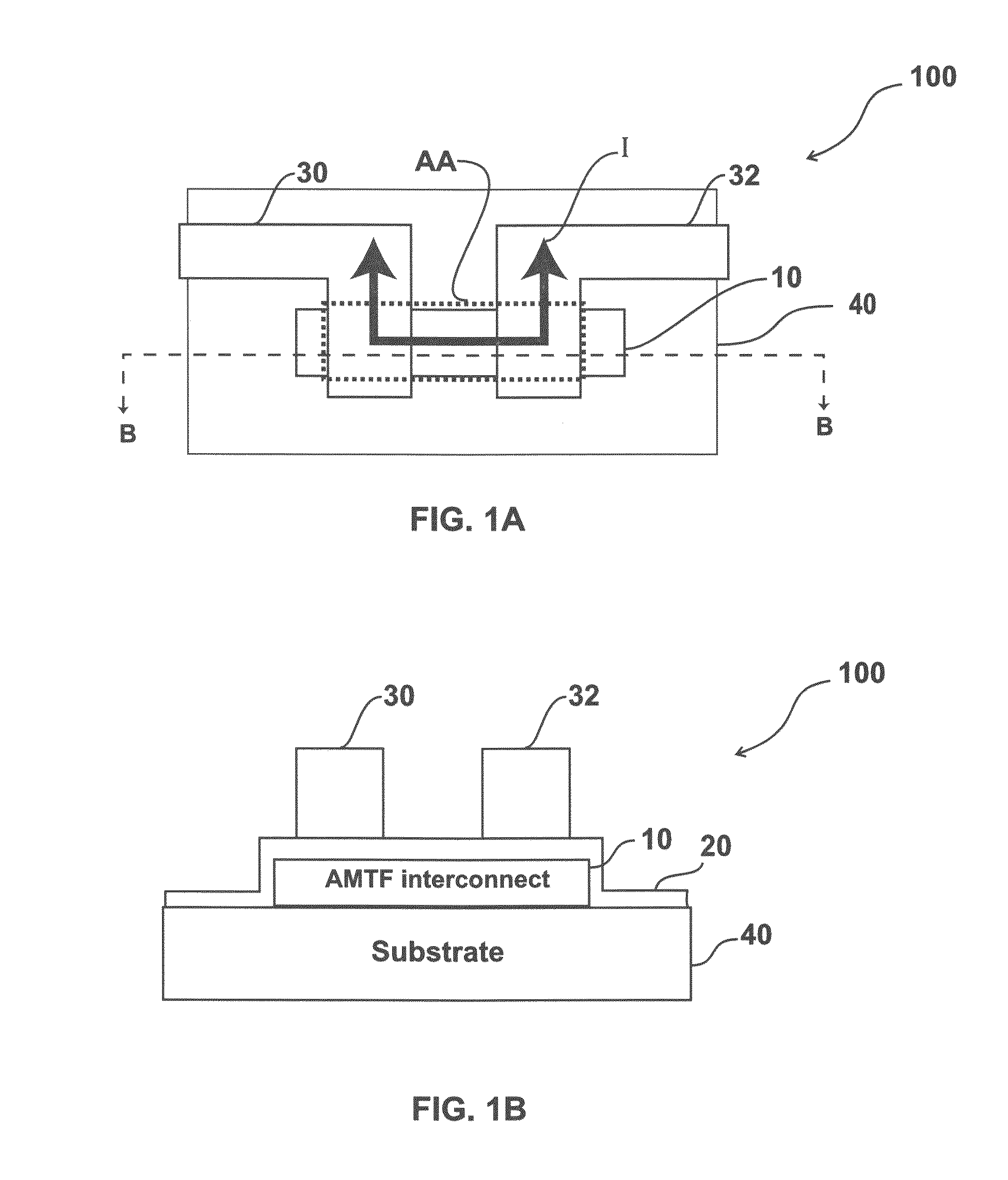

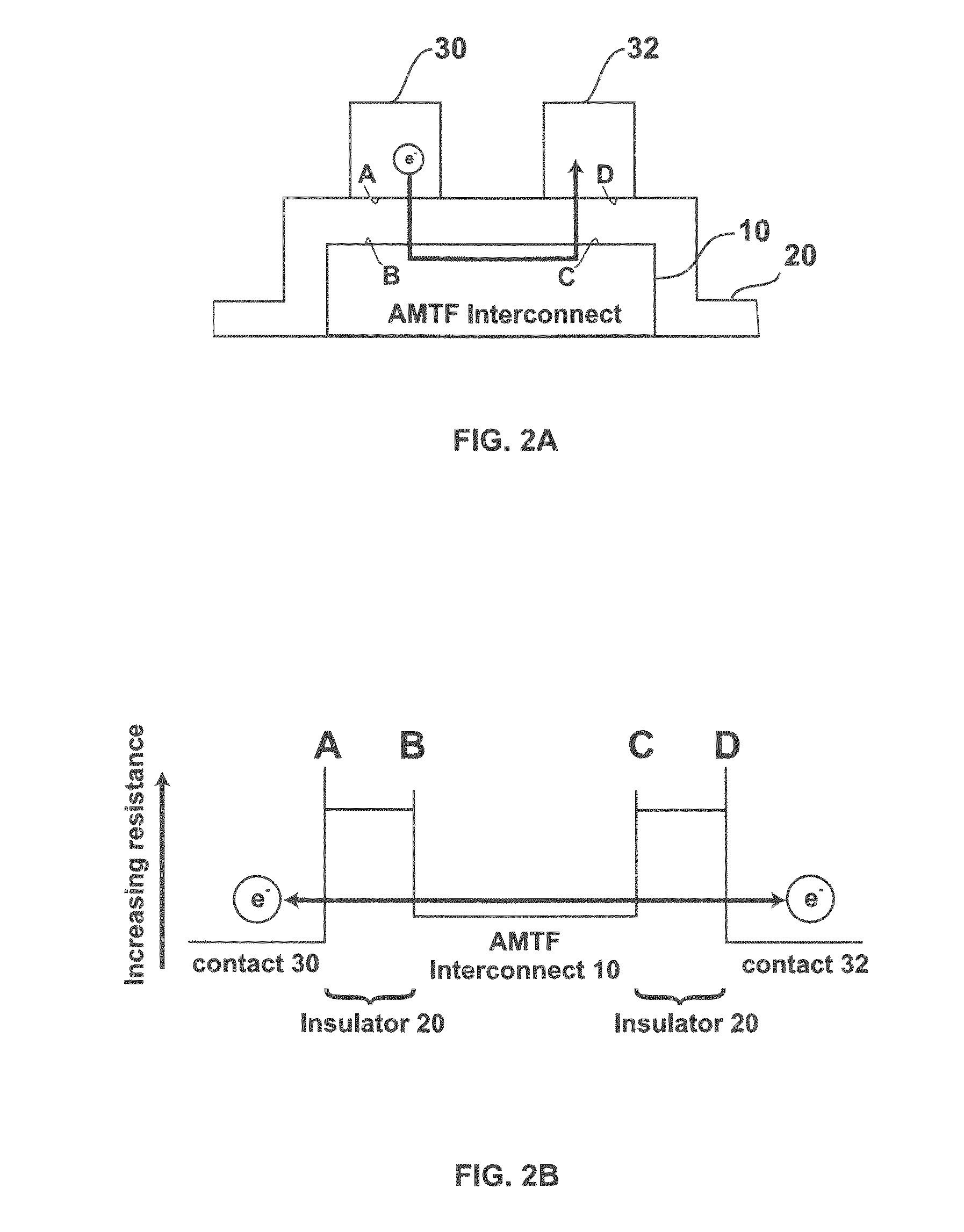

Amorphous metal thin-film non-linear resistor

An amorphous metal thin-film non-linear resistor (AMNR) is provided. The AMNR is an electronic device possessing symmetric non-linear current-voltage (I-V) characteristics, an exemplary configuration of which may comprise three sequentially deposited layers which include a lower amorphous metal thin-film (AMTF) interconnect, a thin-film insulator located on top of the AMTF interconnect, and two upper conductive contacts located on top of the insulator and disposed in the same physical plane.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

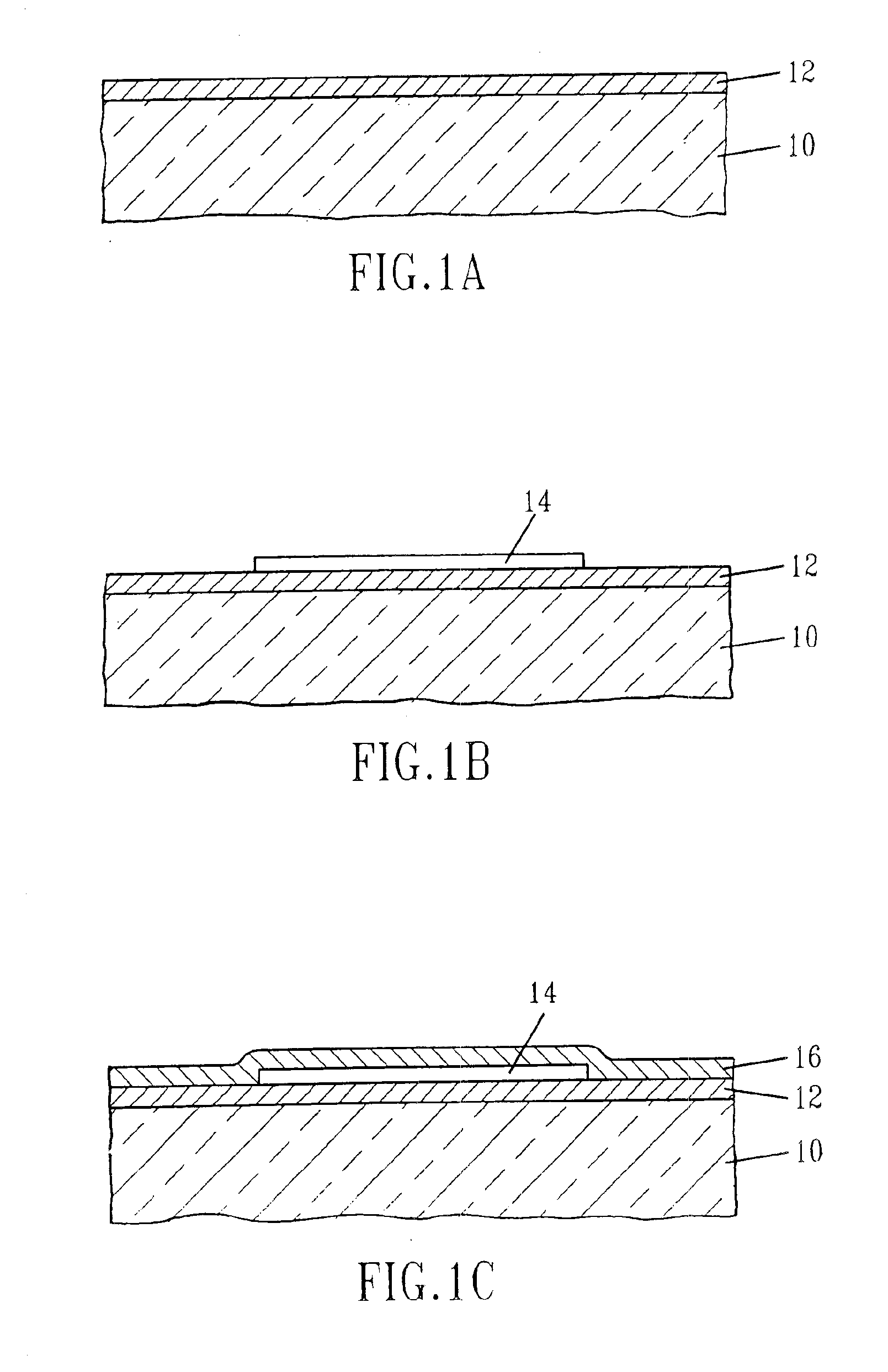

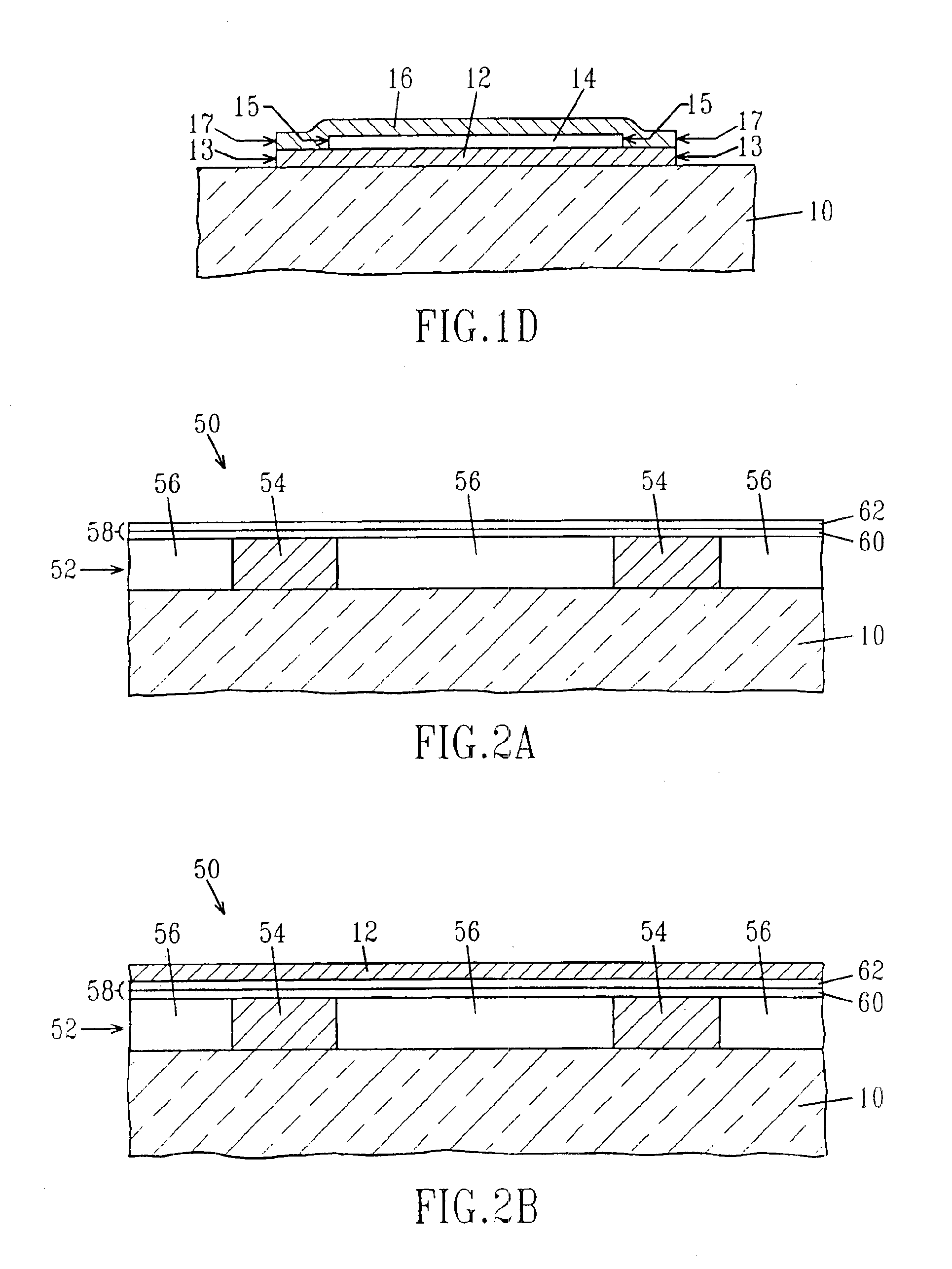

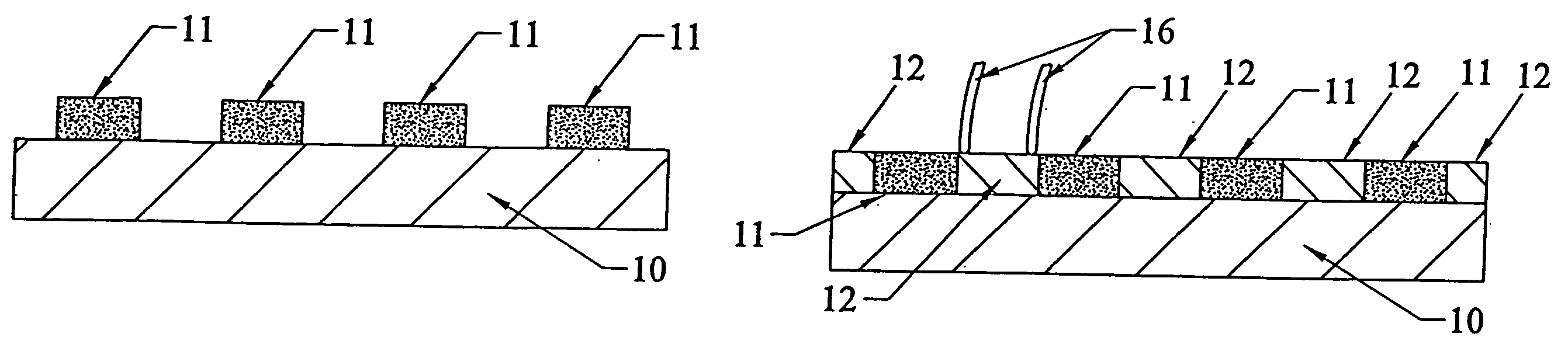

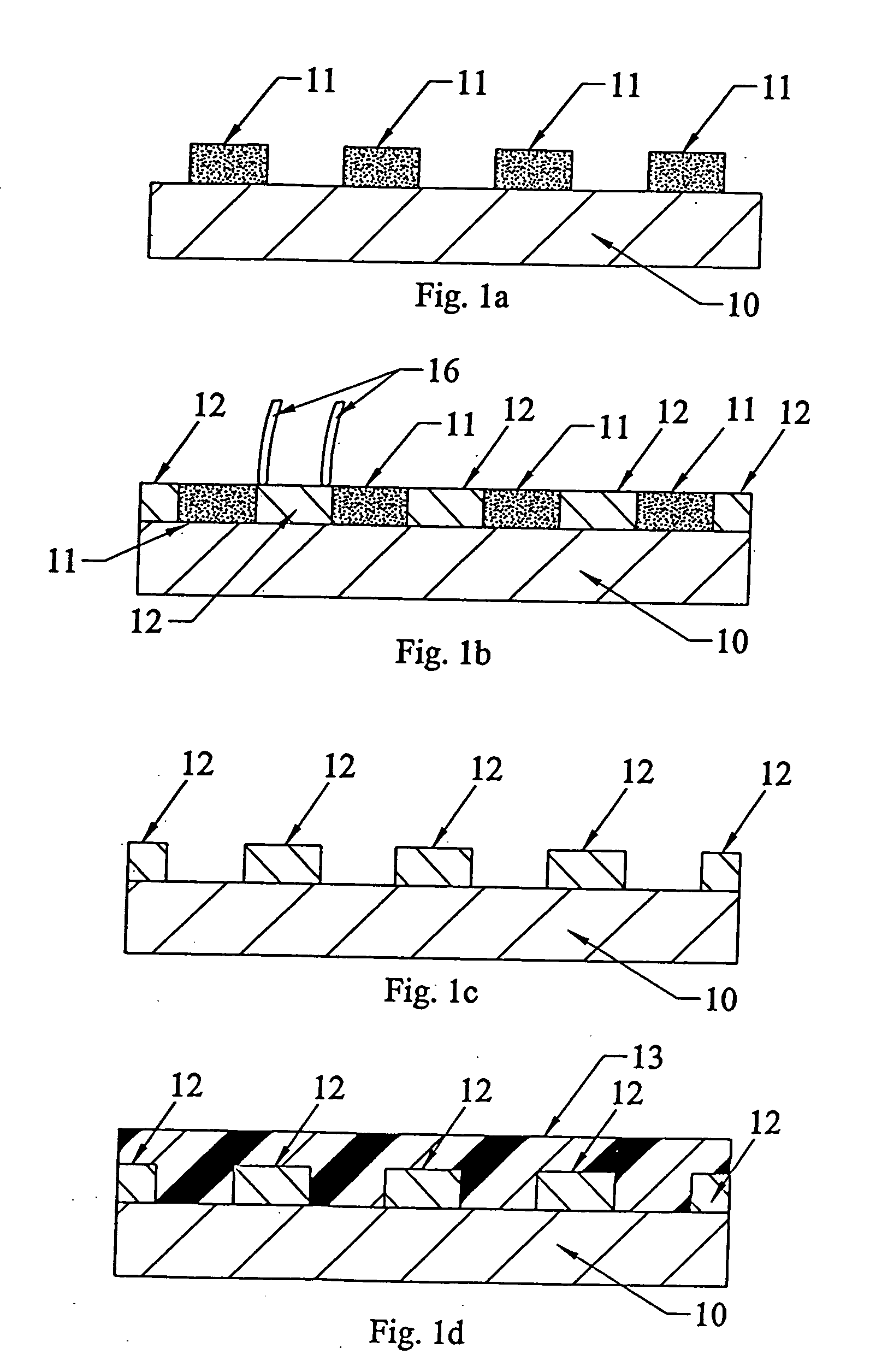

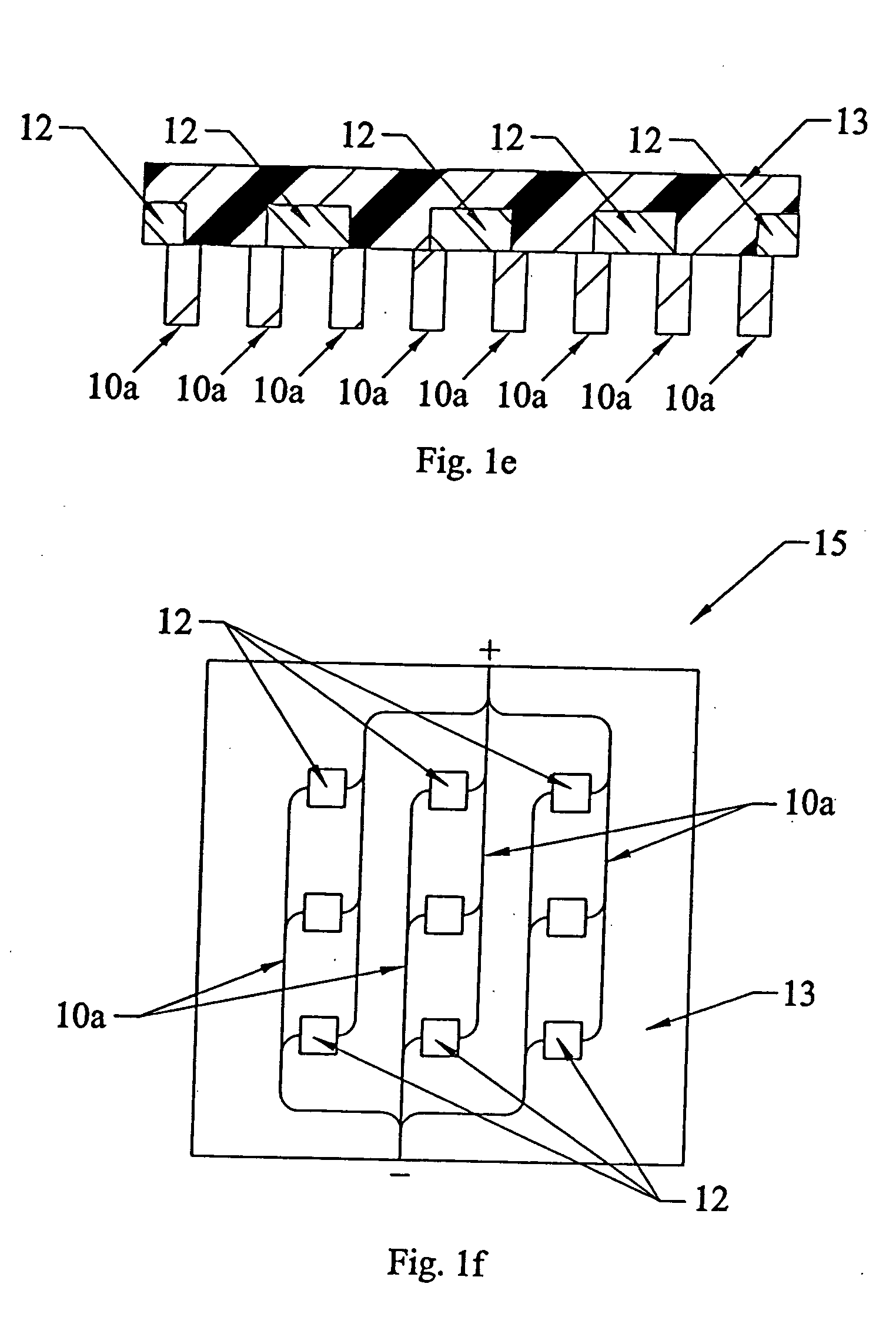

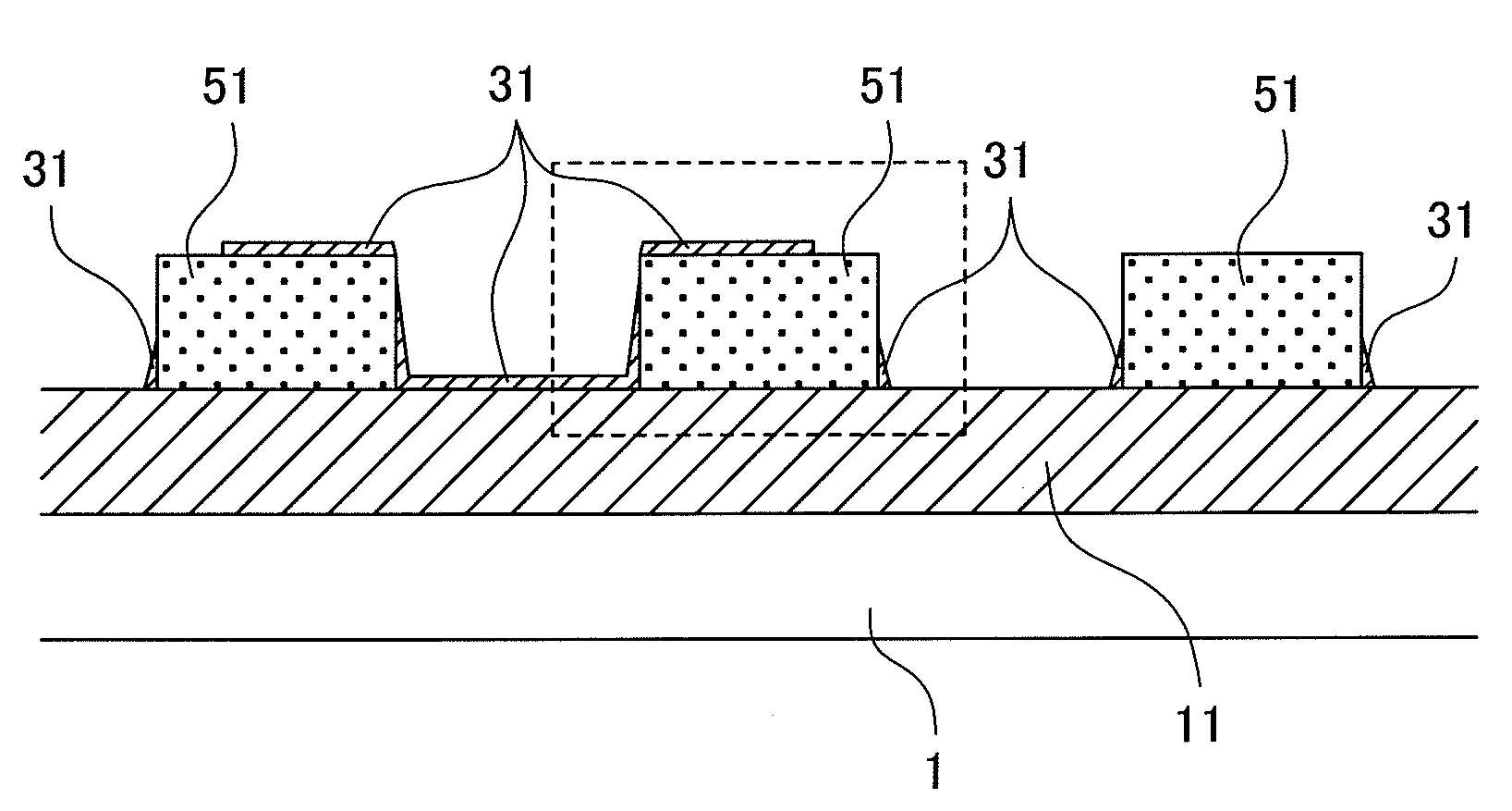

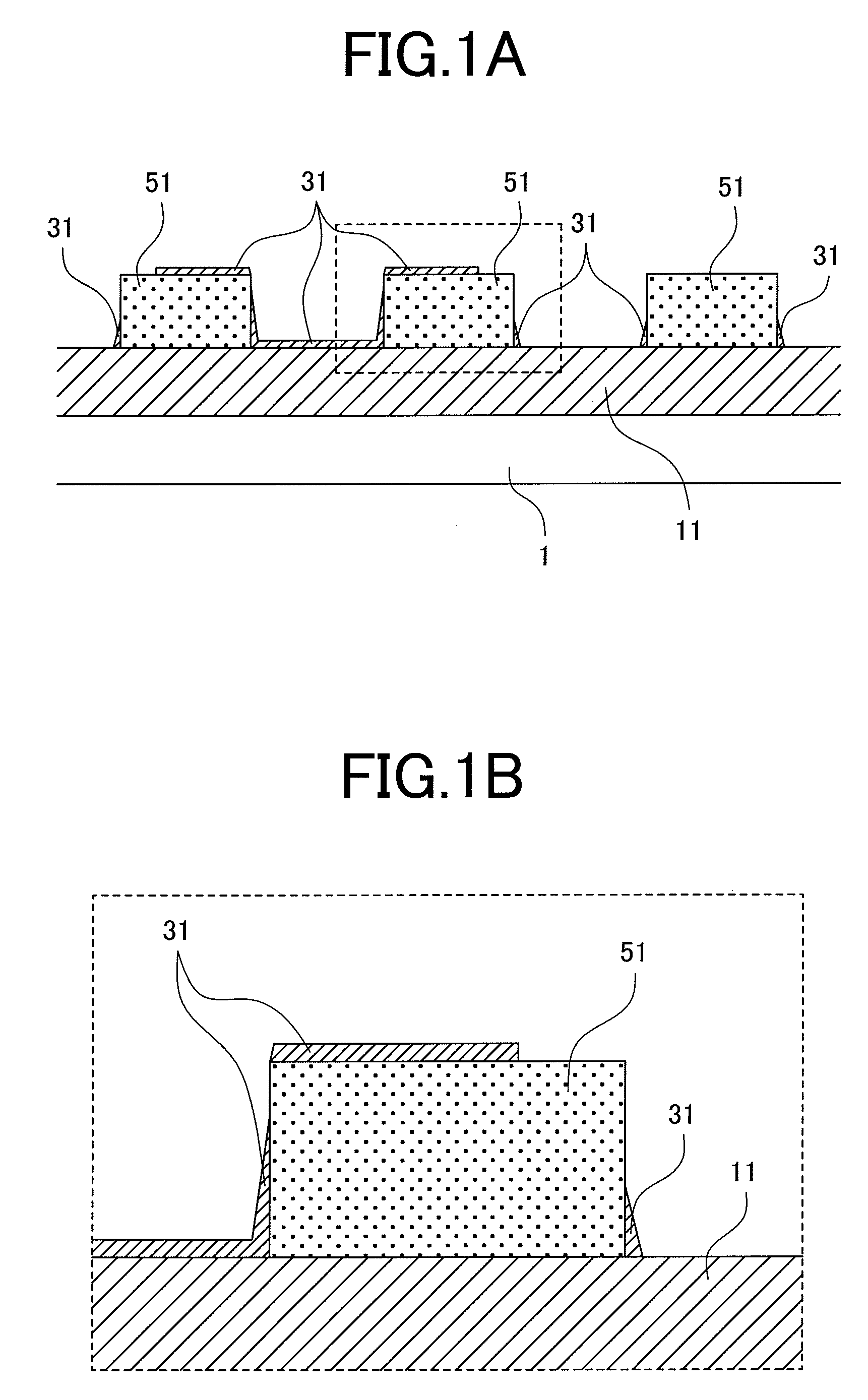

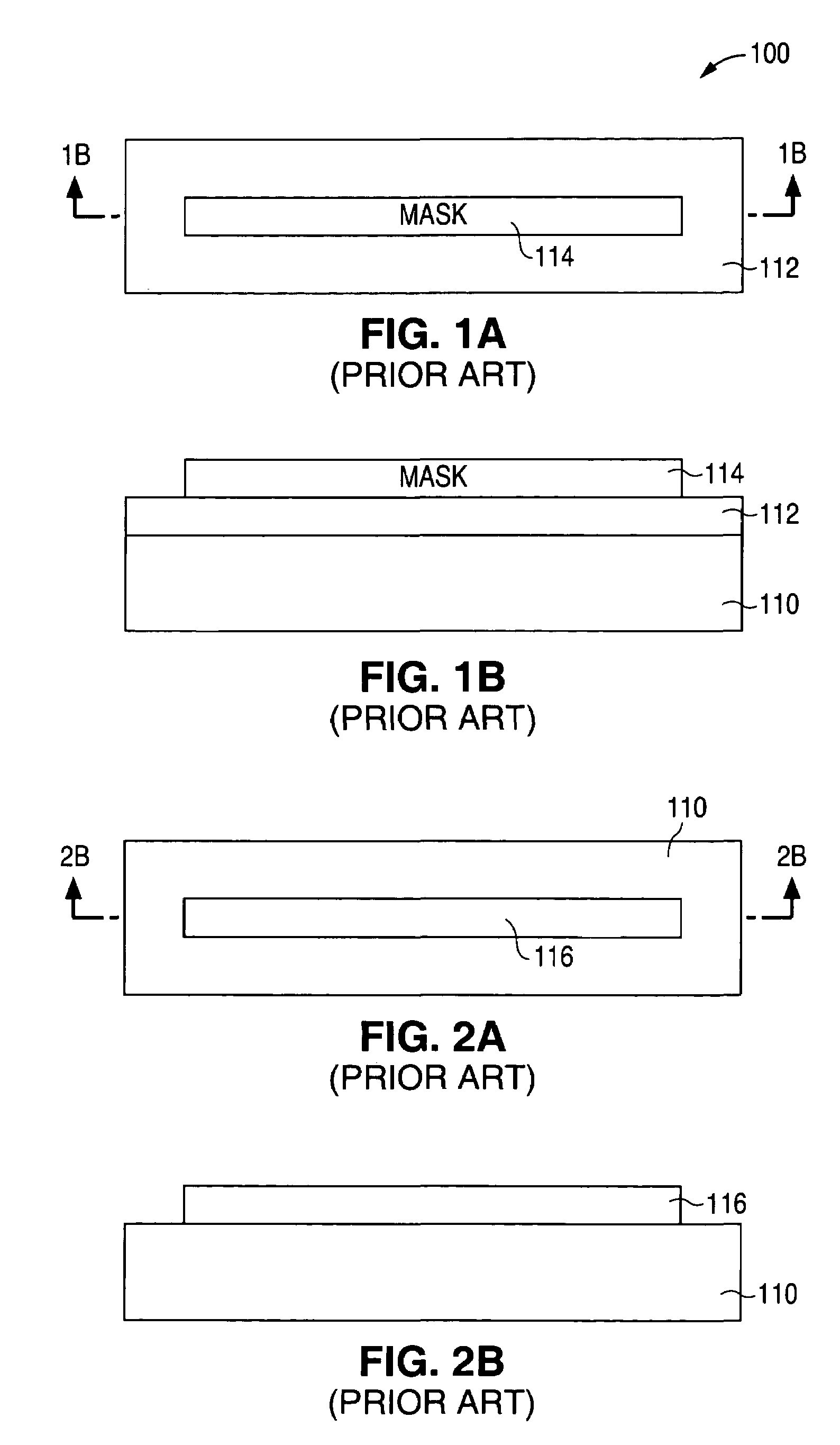

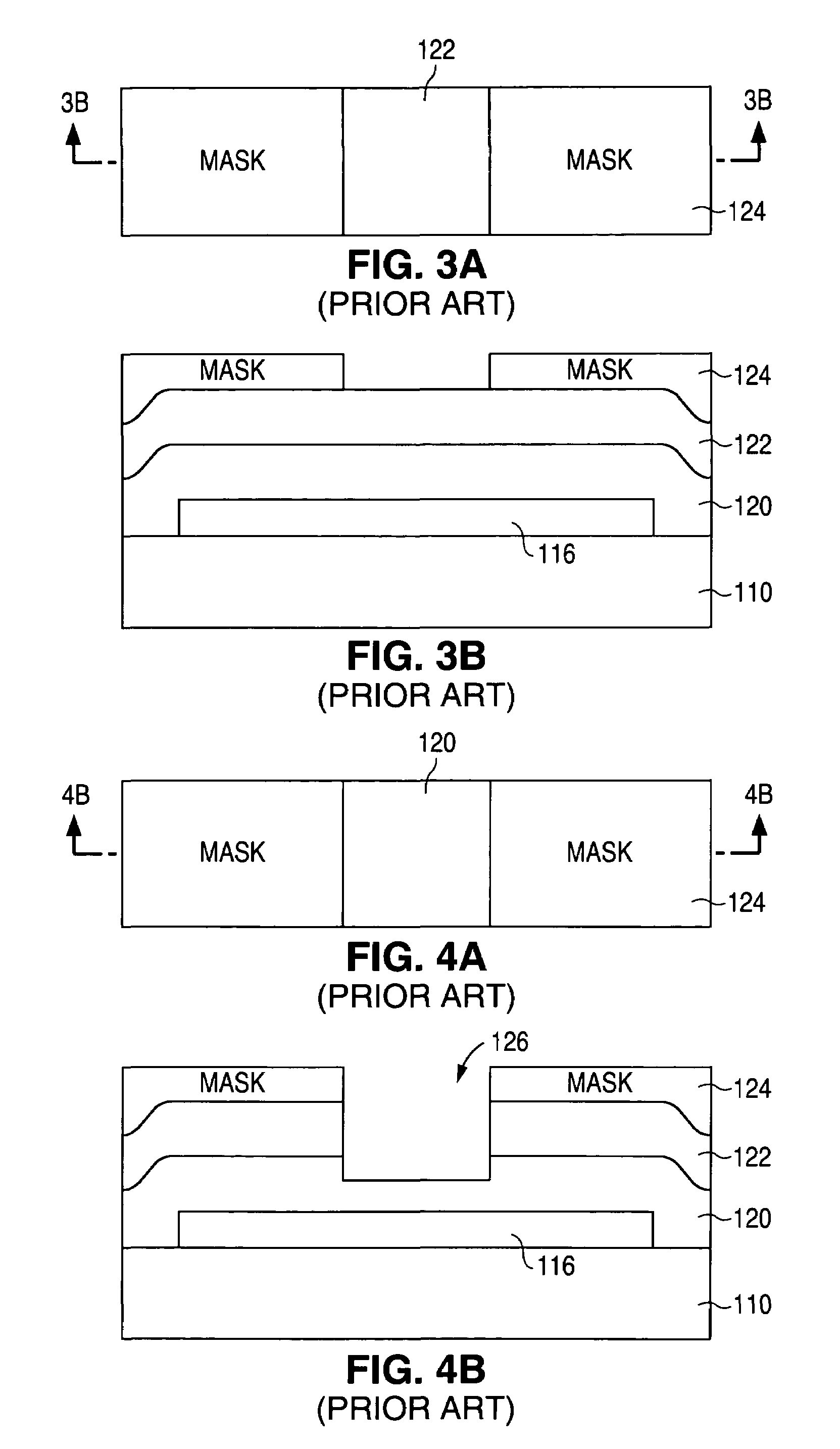

Selective area deposition and devices formed therefrom

InactiveUS20080057687A1Few process stepsRealize economic benefitsThin/thick film capacitorSemiconductor/solid-state device manufacturingGas phaseDevice form

Patterned thin film layers (12) are applied to a substrate (10) surface by masking selective areas of a substrate surface, e.g., with a printed pattern (11) of a material such as an oil, and vapor-depositing thin film material. The masking material is subsequently removed.

Owner:NGIMAT CO

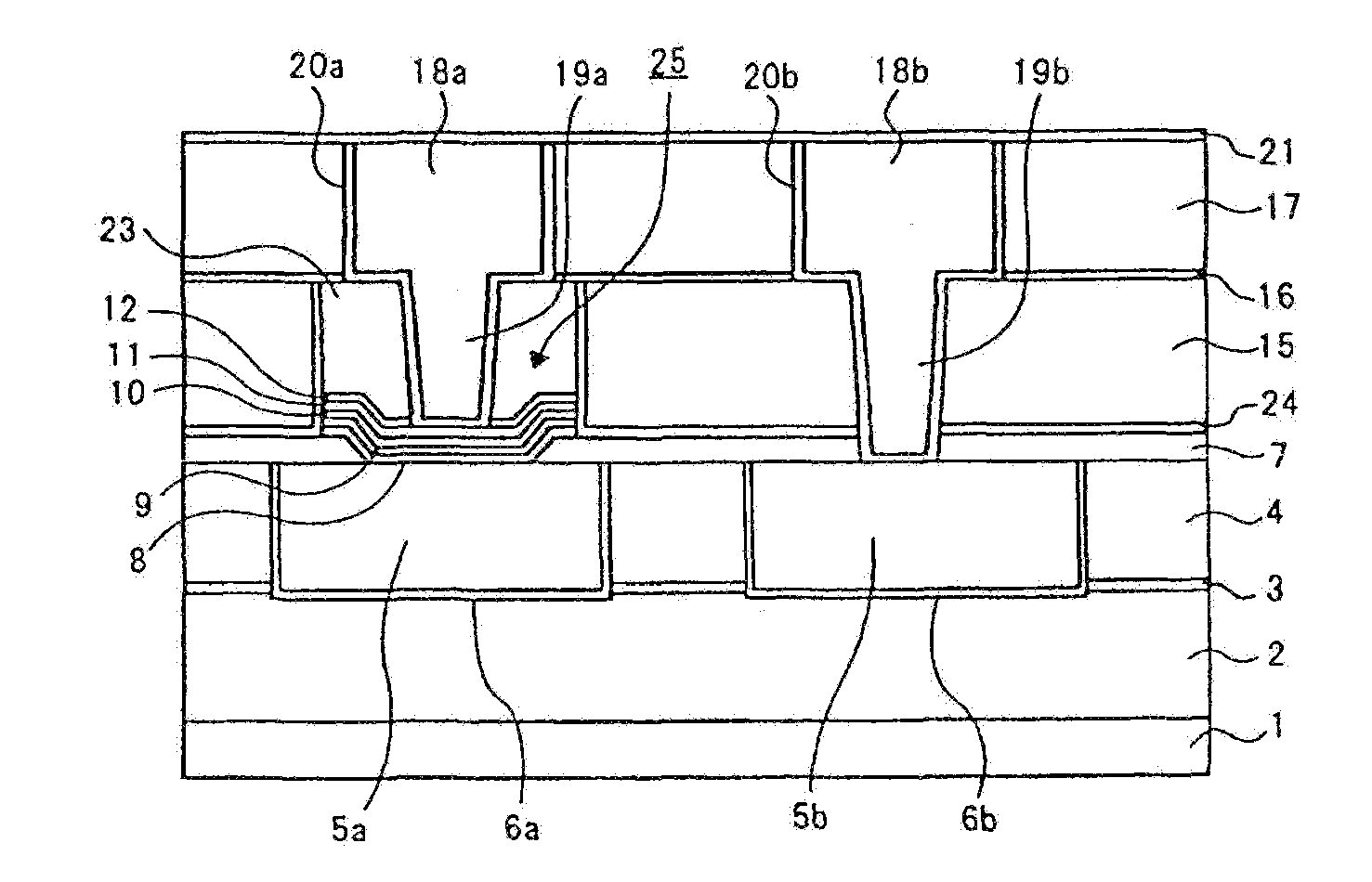

Semiconductor device and method of manufacturing the same

InactiveUS20080217740A1Improve accuracyChange electrical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingThin metalStraddle

An object of the invention is to provide a resistor element whose contact area is self-alignedly formed to reduce the contact area size and contact resistance variation and which can be formed finely and with high precision at low cost. A thin metal film is deposited on a substrate surface covered with an insulation film on which wirings are formed. The thin metal film is anisotropically etched to leave a desired portion such that the desired portion straddles between wirings, self-alignedly connecting the thin metal film to be a resistor and the wirings.

Owner:HITACHI LTD

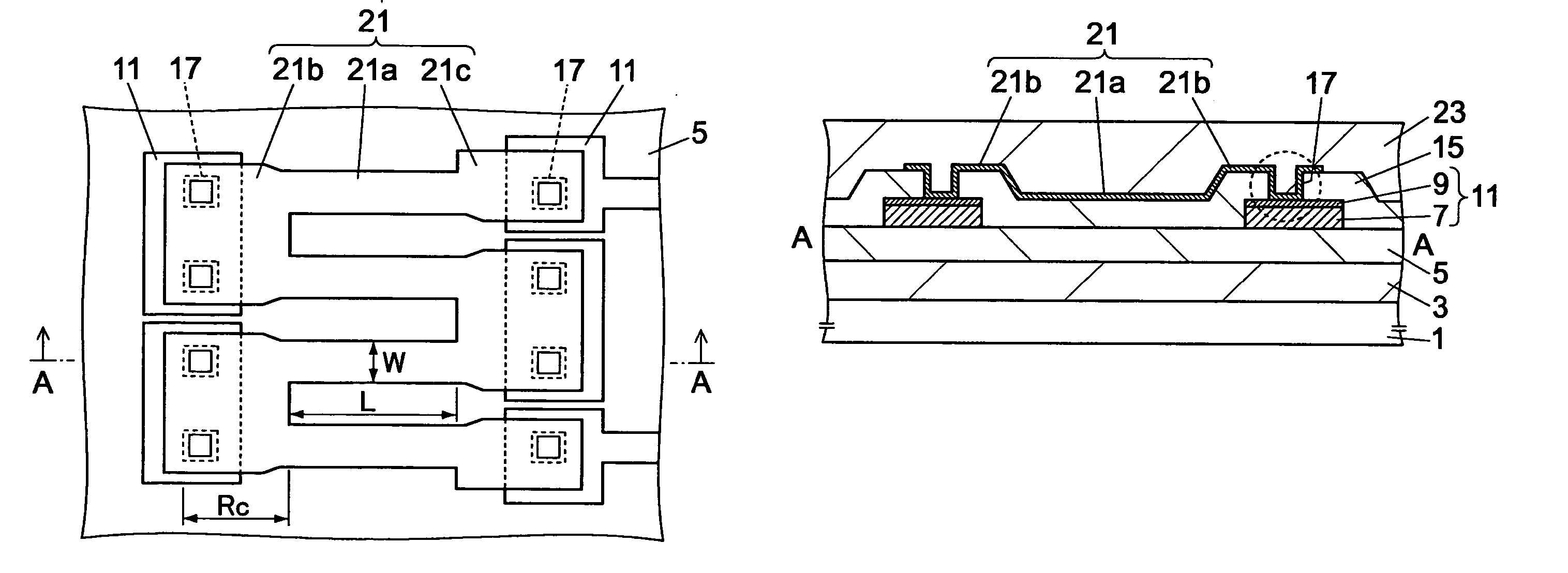

Semiconductor device

InactiveUS20050218478A1Accurate resistanceHigh yieldSemiconductor/solid-state device detailsSolid-state devicesDevice materialBand shape

A semiconductor device is provided that includes: a base insulating film; a metal thin-film resistor that is provided on the base insulating film; a lower-layer insulating film that is formed under the base insulating film; and a wiring pattern that is formed on the lower-layer insulating film. In this semiconductor device, the base insulating film is formed on the lower-layer insulating film and the wiring pattern, and connecting holes are formed in the base insulating film located on the wiring patterns. The metal thin-film resistor has at least two belt-like portions and a return portion that continues to the belt-like portions. The belt-like portions are located at a distance from the region on the wiring pattern. The return portion connects at least two belt-like portions in a position at a distance from the region on the wiring pattern. The return portion is formed in a connecting hole via the region on the wiring pattern.

Owner:RICOH KK

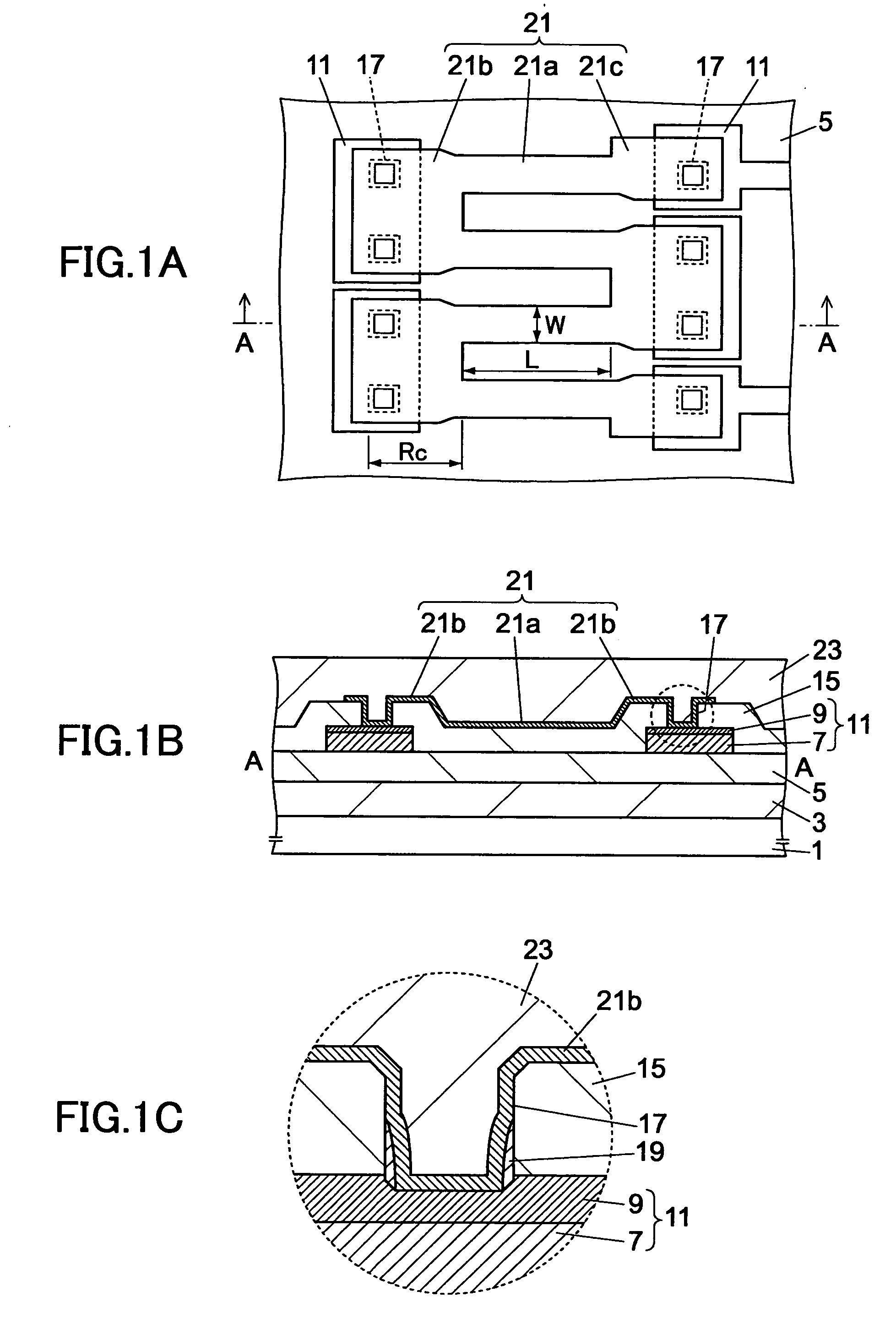

Thin film resistor and method of forming the resistor on spaced-apart conductive pads

A thin film resistor is formed to have very accurately defined dimensions which, in turn, allow the resistive value of the resistor to be very accurately defined. The resistor is formed on spaced-apart conductive pads which, in turn, are electrically connected to conductive plugs that are spaced apart from the resistor.

Owner:NAT SEMICON CORP

Semiconductor device and method for manufacturing the same

InactiveUS20090015369A1Reduce parasitic capacitanceResistance change ratioSemiconductor/solid-state device detailsSolid-state devicesSputteringTantalum nitride

A resistor R1 formed by forming a first resistor layer 5a of 20 nm thickness including a tantalum nitride film at a concentration of nitrogen of less than 30 at % and a second resistor layer of 5 nm thickness including a tantalum nitride film at a concentration of nitrogen of 30 at % or more successively by a reactive DC sputtering method using tantalum as a sputtering target material and using a gas mixture of argon and nitrogen as a sputtering gas, and then fabricating the first and the second resistor layers, in which the resistance change ratio of the resistor can be suppressed to less than 1% even when a thermal load is applied in the interconnection step, by the provision of the upper region at a concentration of nitrogen of 30 at % or more.

Owner:HITACHI LTD

Platinum resistor temperature sensor

ActiveUS20050200448A1Easy to evaporateGood effectTemperature measurement in motorsThermometers using electric/magnetic elementsPlatinumPorous layer

A platinum temperature sensor incorporating an evaporation-suppressing layer containing platinum in the vicinity of the platinum thin-film resistor of the sensor. The evaporation-suppressing layer is preferably positioned between the platinum resistor and a porous layer that is formed close to the platinum resistor and in contact with the evaporation-suppressing layer.

Owner:NGK SPARK PLUG CO LTD

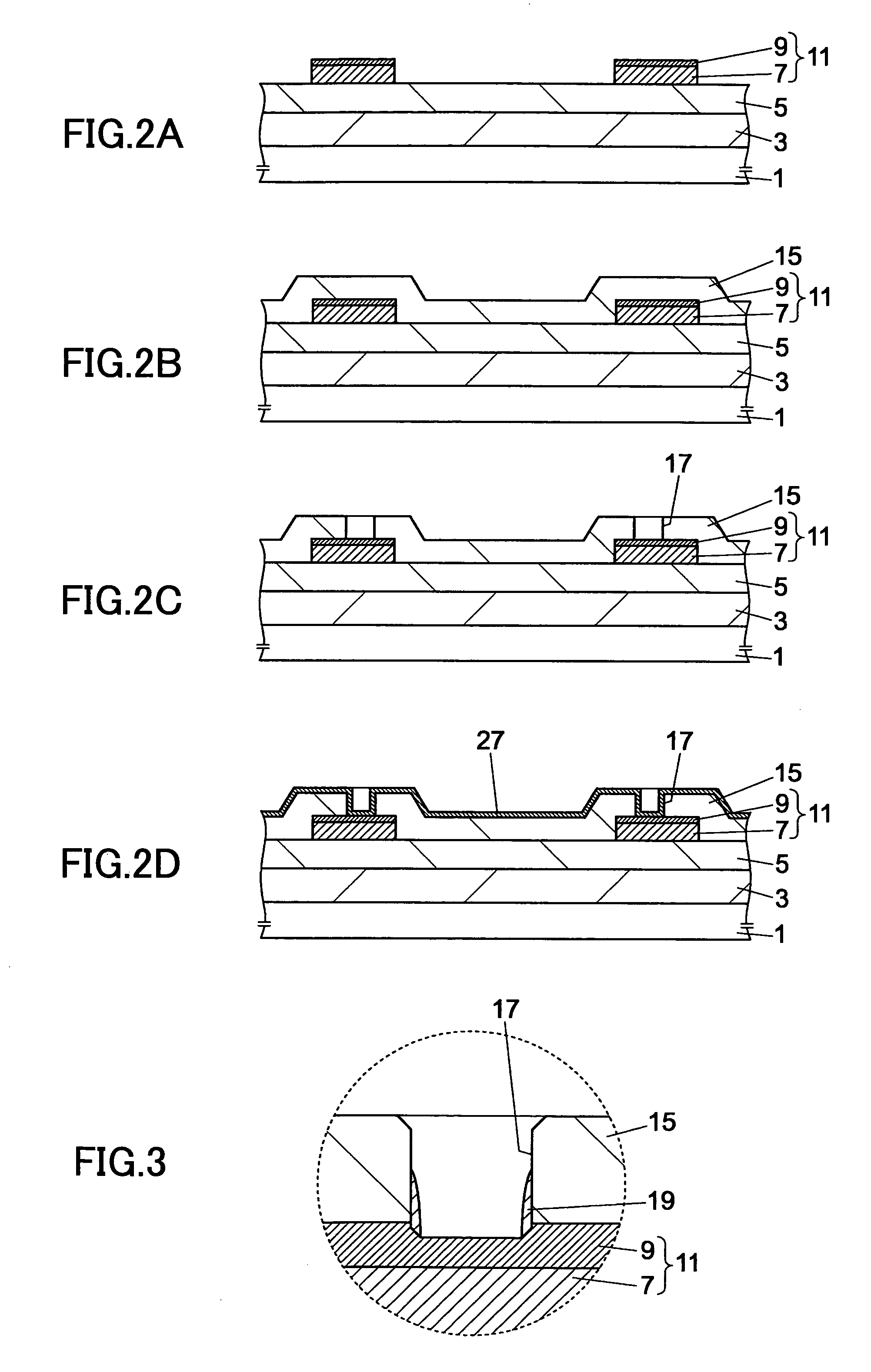

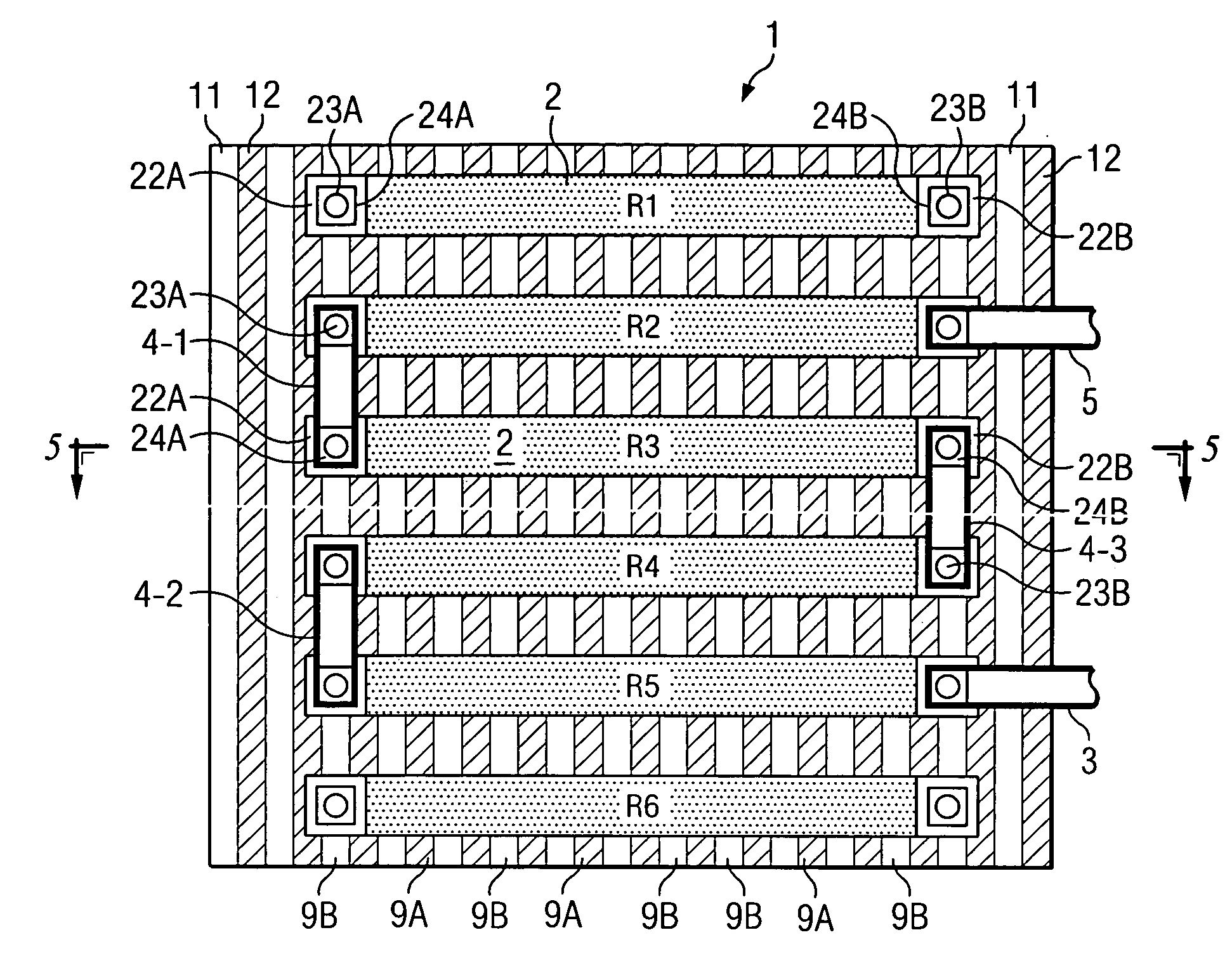

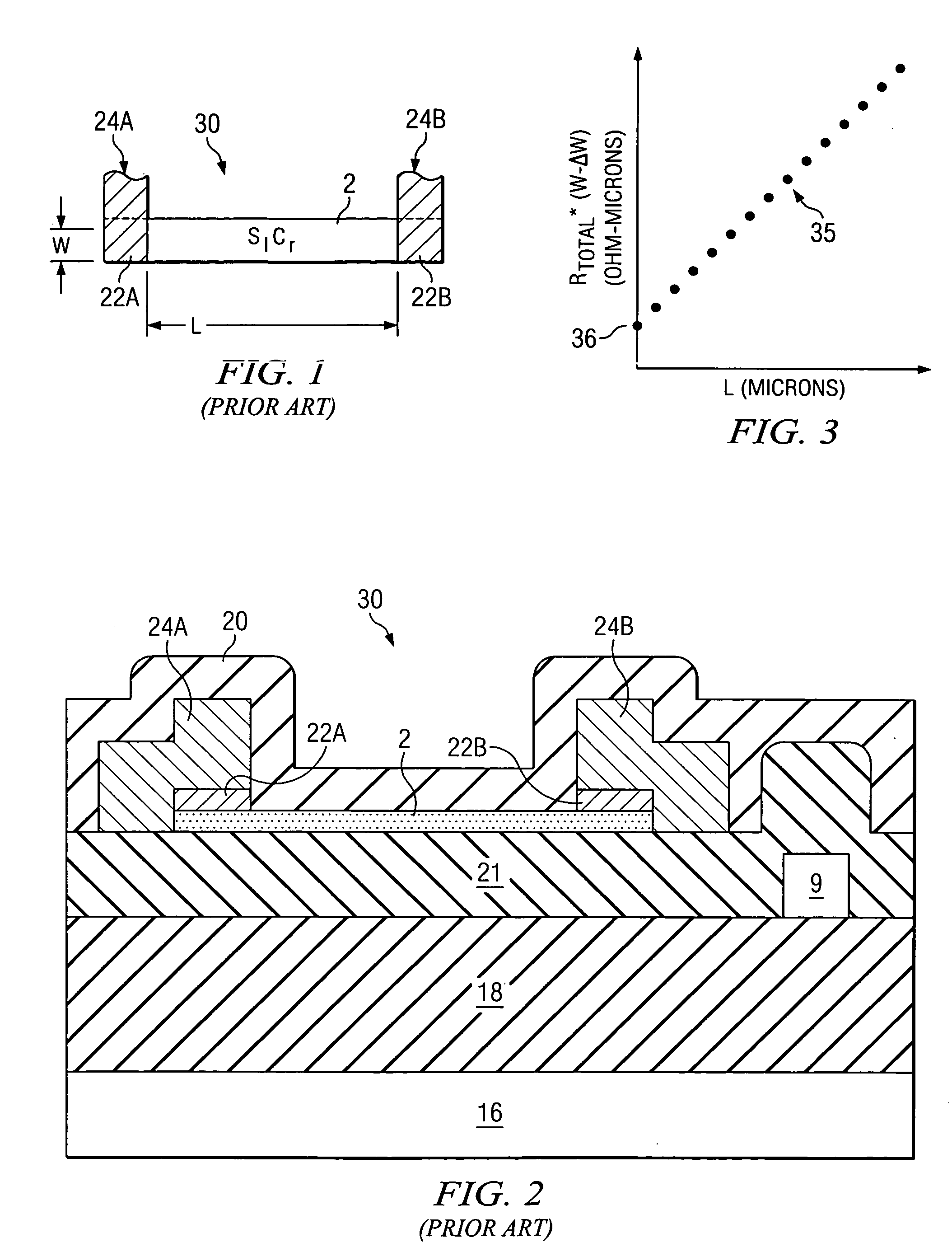

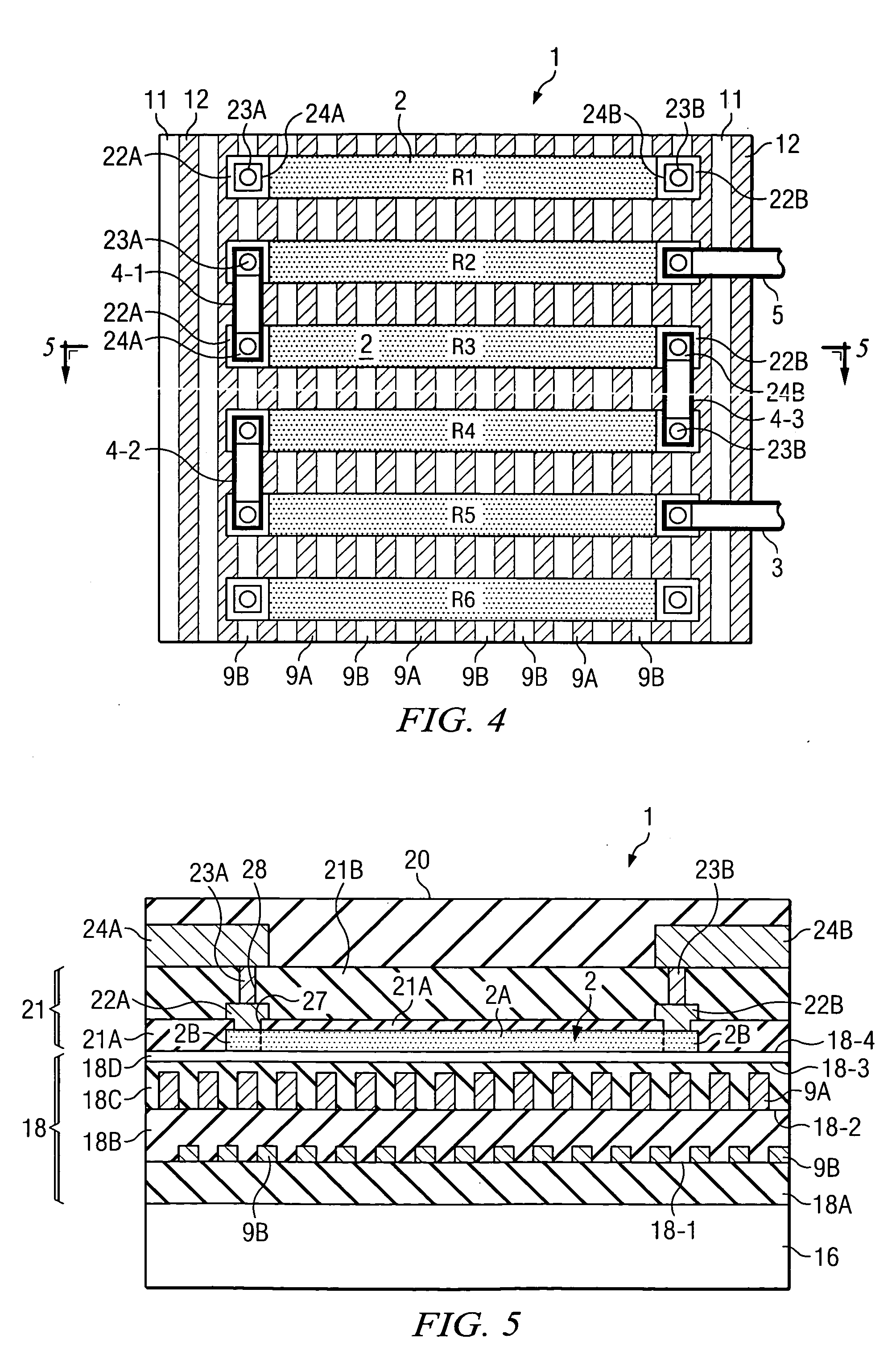

Thin film resistor head structure and method for reducing head resistivity variance

ActiveUS20060228879A1Improved, inexpensive integrated circuit thin-film resistor structureReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesMultiple edgesEngineering

A method of making integrated circuit thin film resistor includes forming a first dielectric layer (18B) over a substrate and providing a structure to reduce variation of head resistivity thereof by forming a dummy fill layer (9A) on the first dielectric layer, and forming a second dielectric layer (18D) over the first dummy fill layer. A thin film resistor (2) is formed on the second dielectric layer (18D). A first inter-level dielectric layer (21A) is formed on the thin film resistor and the second dielectric layer. A first metal layer (22A) is formed on the first inter-level dielectric layer and electrically contacts a portion of the thin film resistor. Preferably, the first dummy fill layer is formed as a repetitive pattern of sections such that the repetitive pattern is symmetrically aligned with respect to multiple edges of the thin-film resistor (2). Preferably, the first dummy fill layer is formed so as to extend sufficiently far beyond ends of the thin-film resistor to ensure only a negligible amount of systematic resistance error due to misalignment.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com