Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about "Pressure difference control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

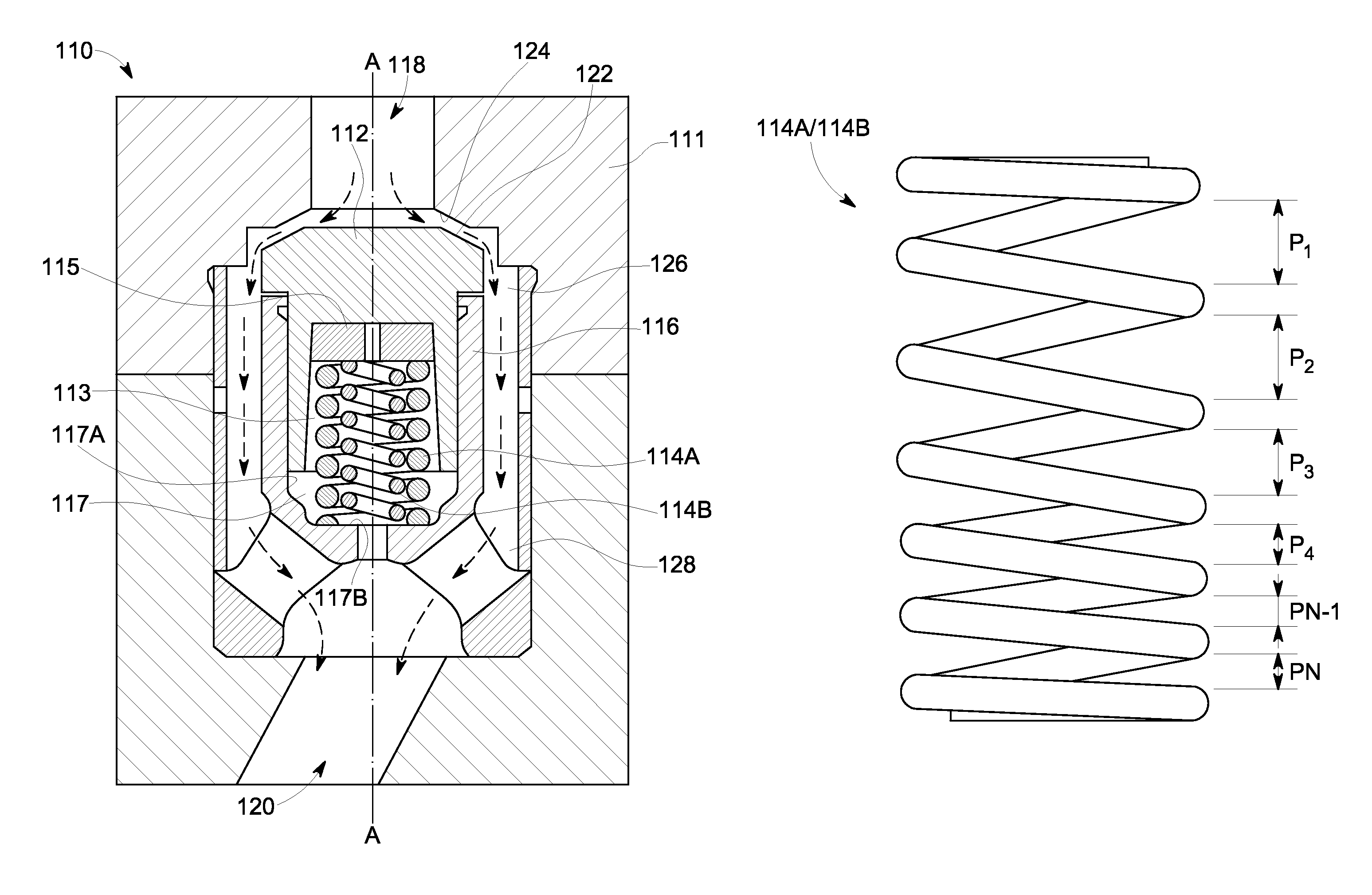

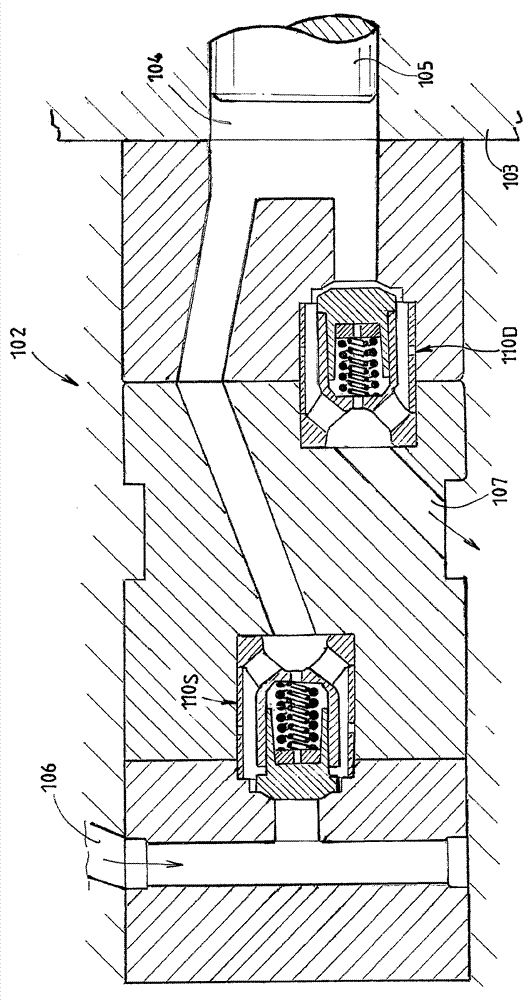

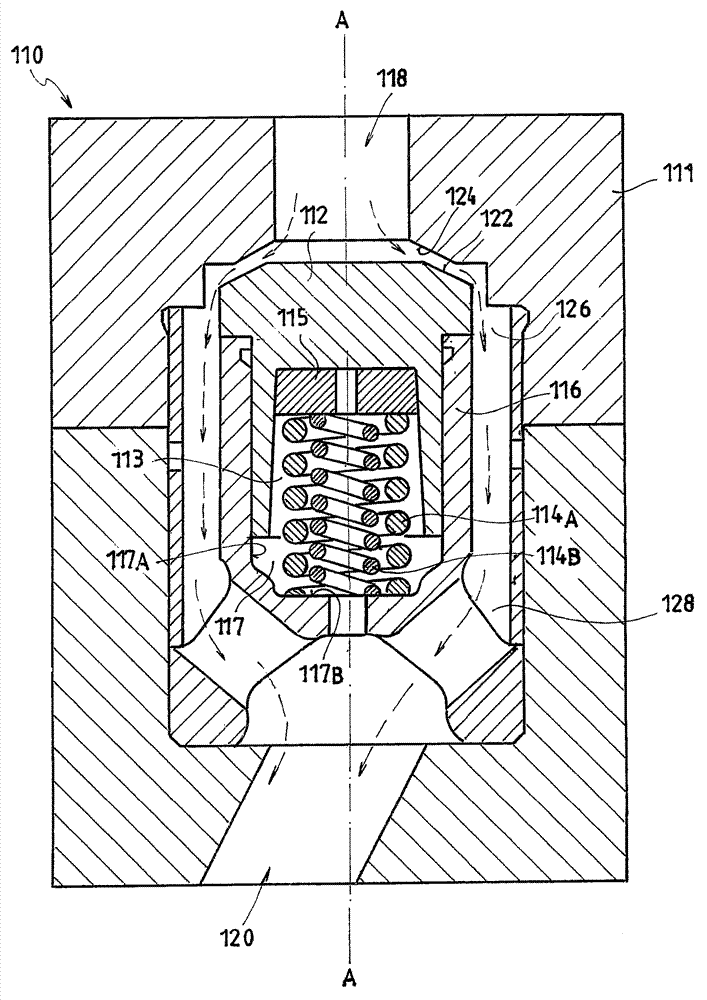

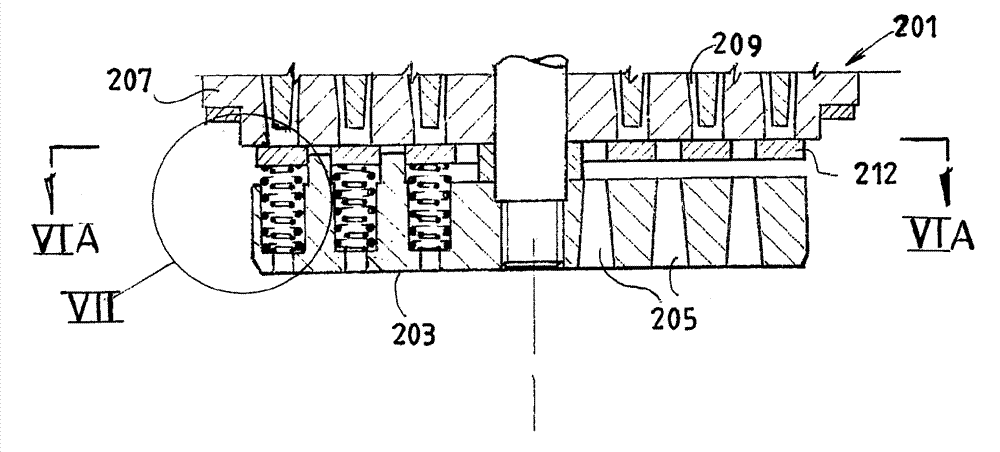

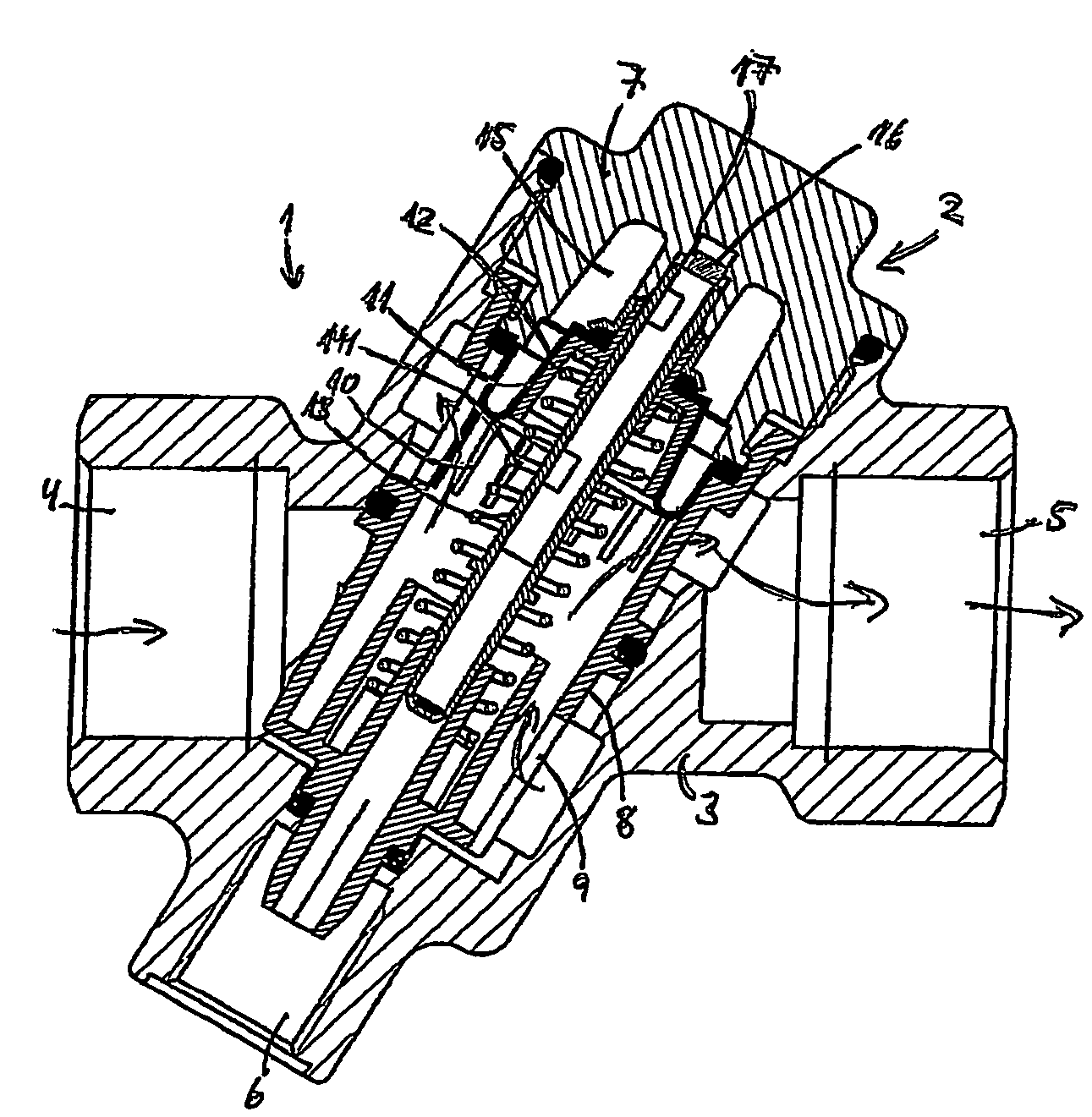

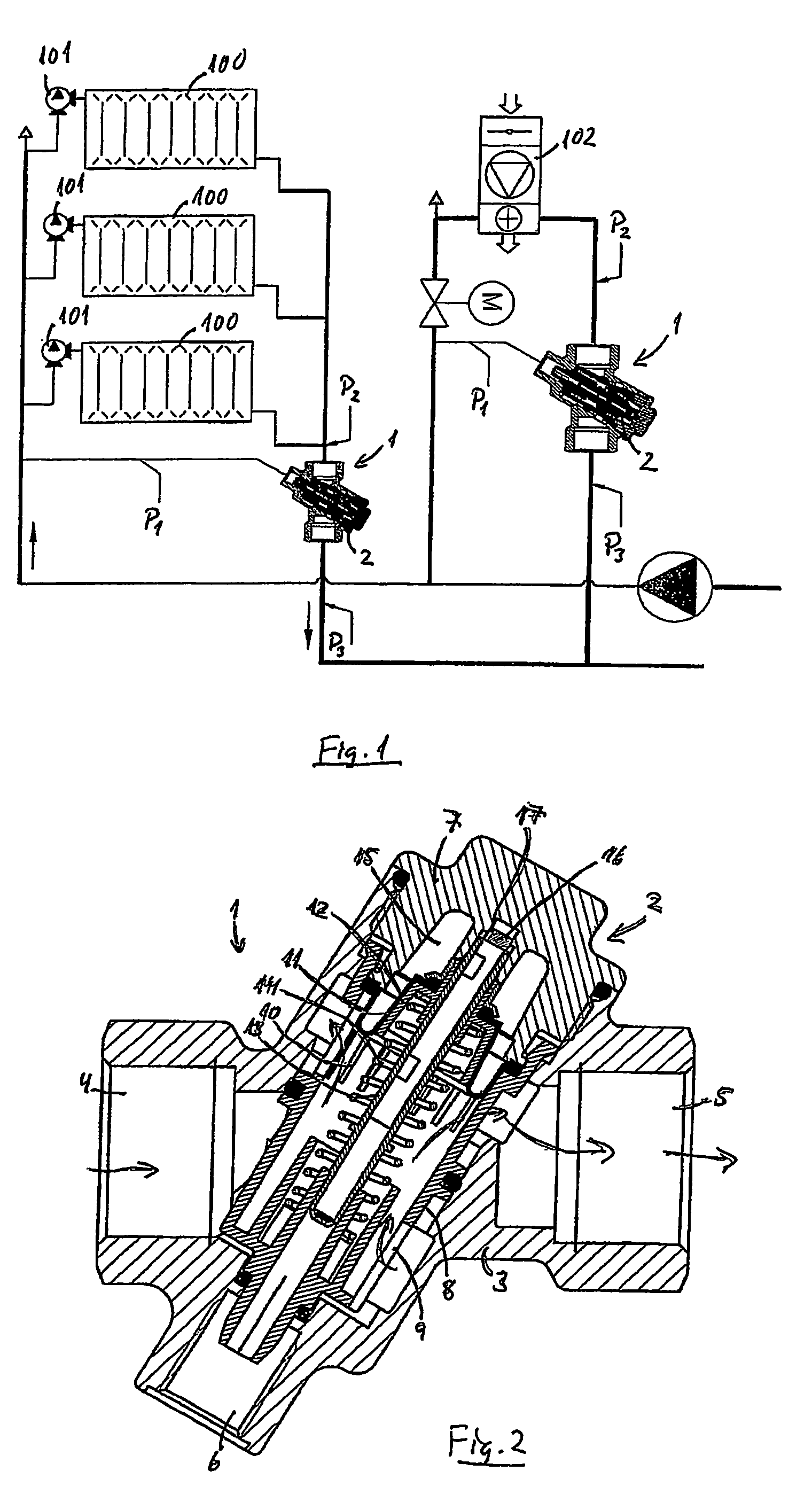

Differential pressure valve with parallel biasing springs and method for reducing spring surge

ActiveUS9297373B2Avoid spreadingReduce inhibitionSpringsPositive displacement pump componentsResonanceDifferential pressure

A differential pressure valve is disclosed, comprising: a valve body, the valve body having at least one flow inlet and one flow outlet; at least one shutter, the shutter being movable between an open position and a closed position under a differential pressure across the valve; a flow passage from the flow inlet to the flow outlet; at least one biasing member configured to bias the shutter towards a closed position so as to block the flow passage through the flow inlet. The biasing member comprises at least two springs arranged in parallel, one of the springs having at least one resonance frequency different from at least one resonance frequency of the other of the two springs.

Owner:NUOVO PIGNONE TECH SRL

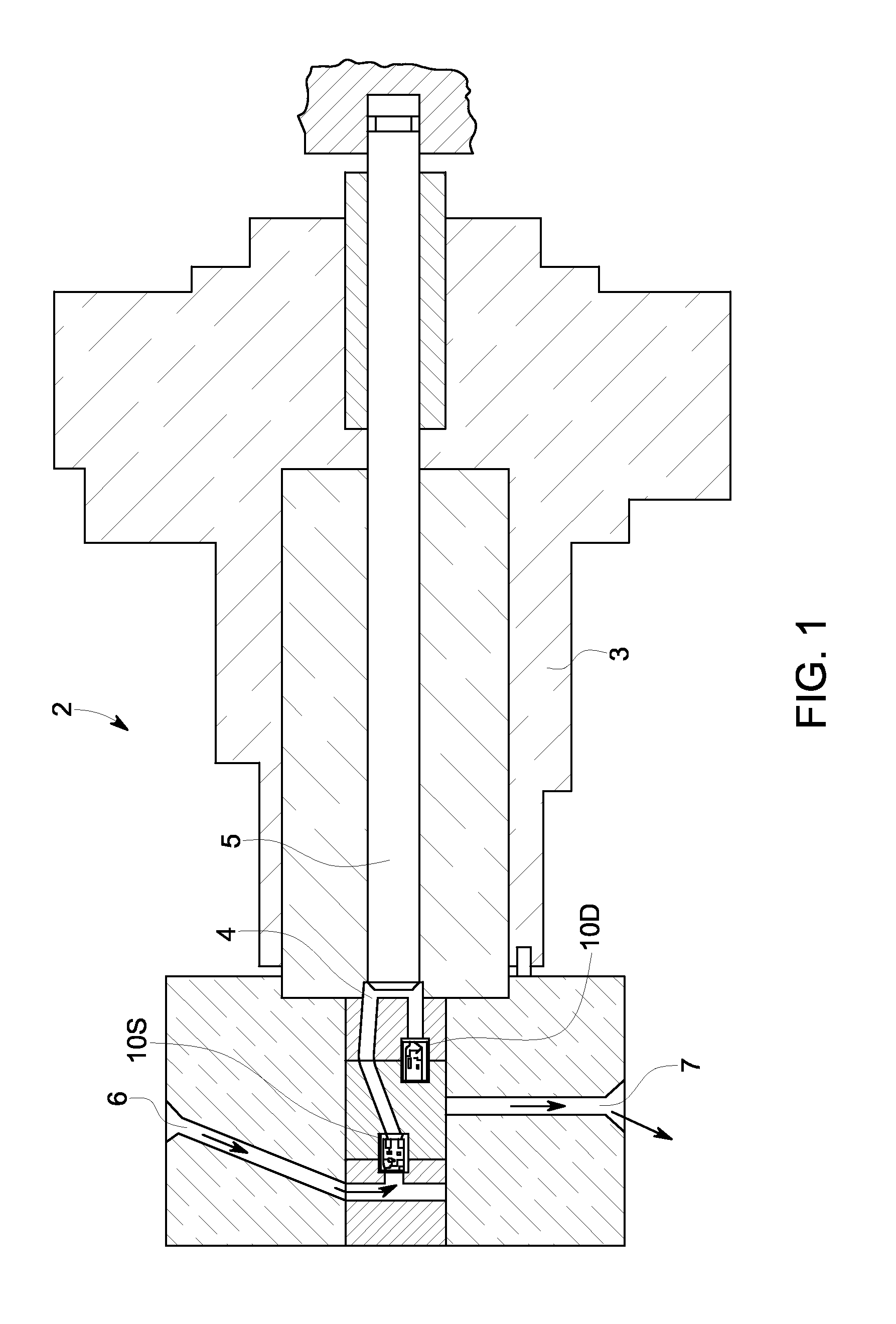

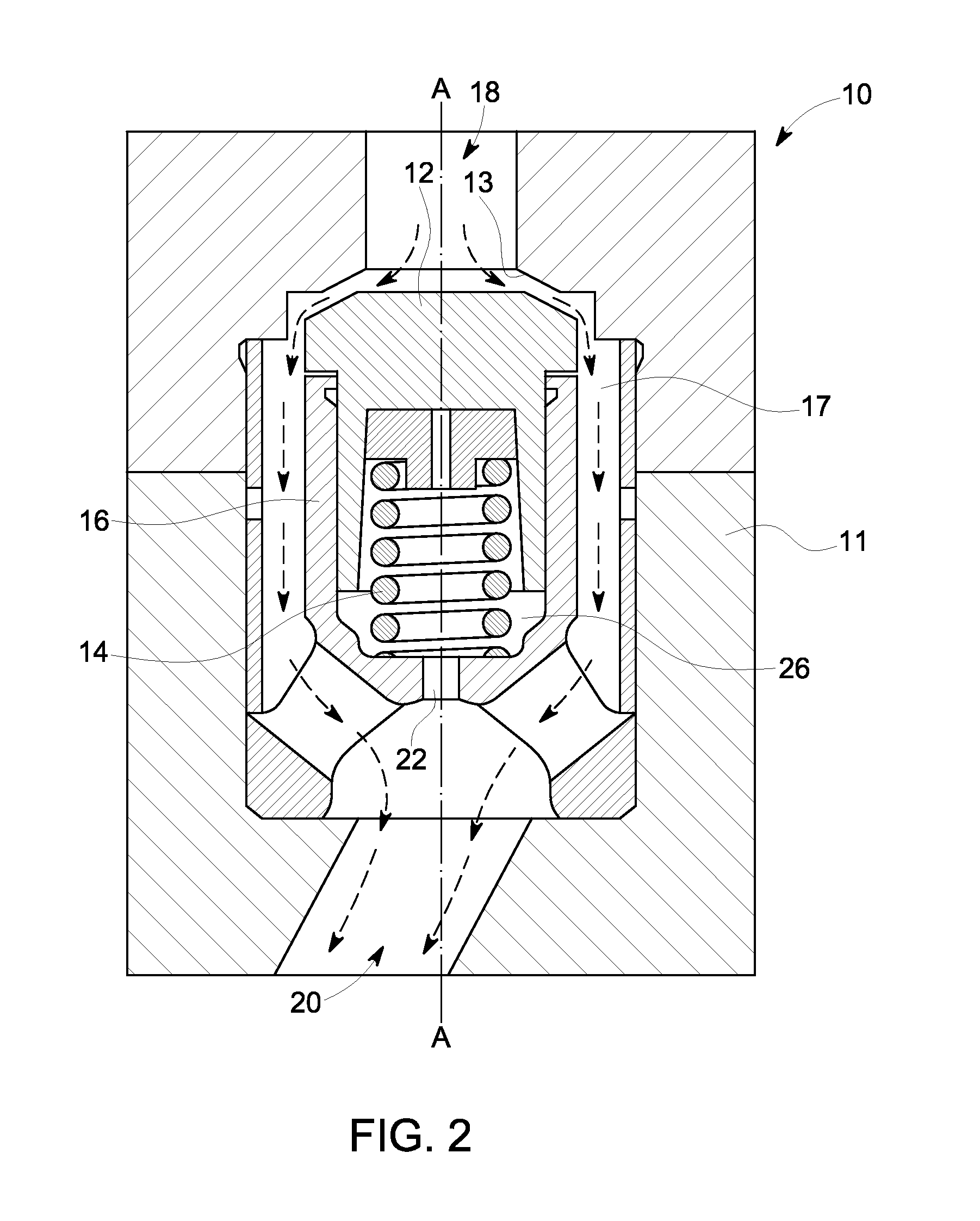

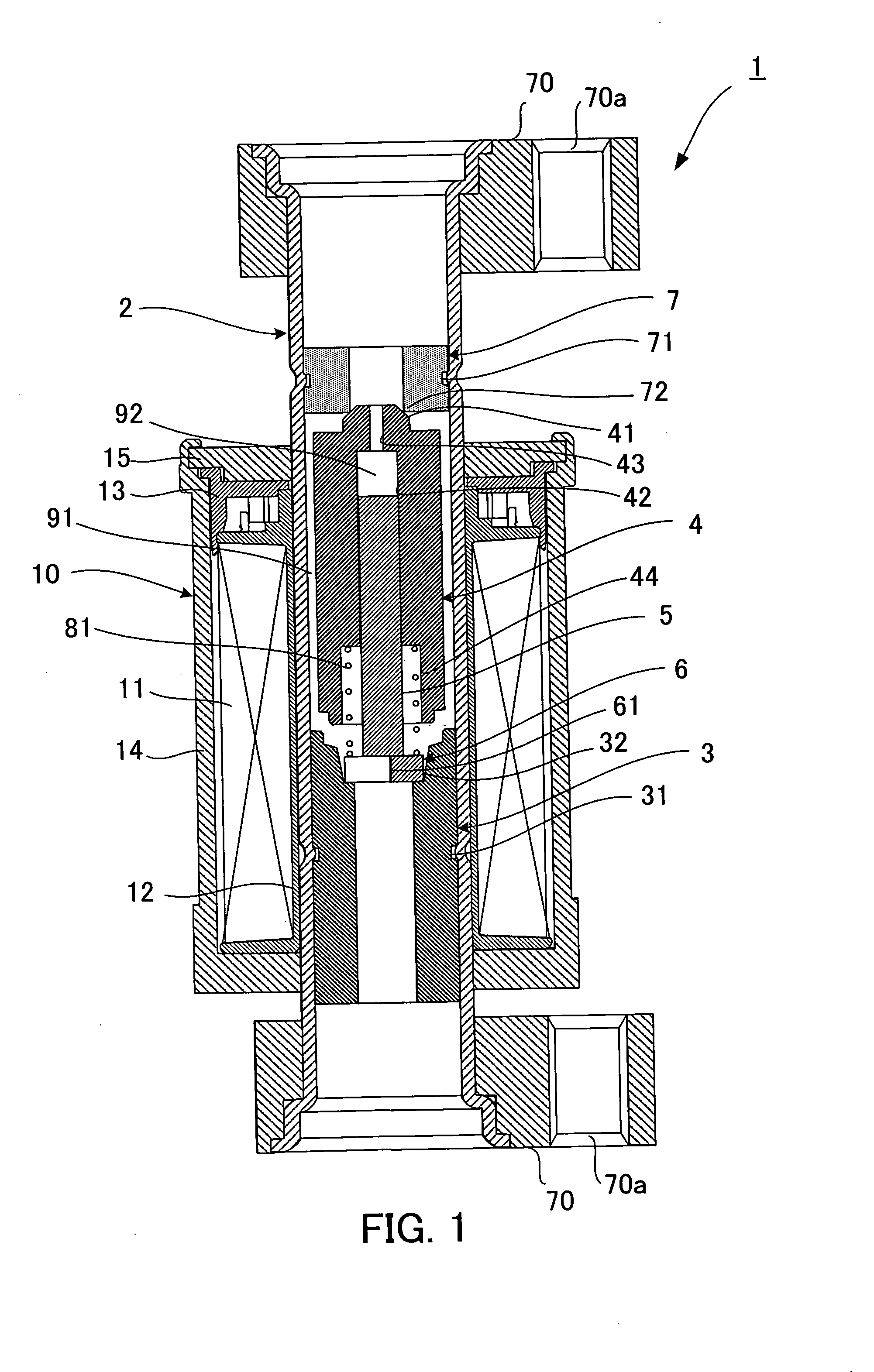

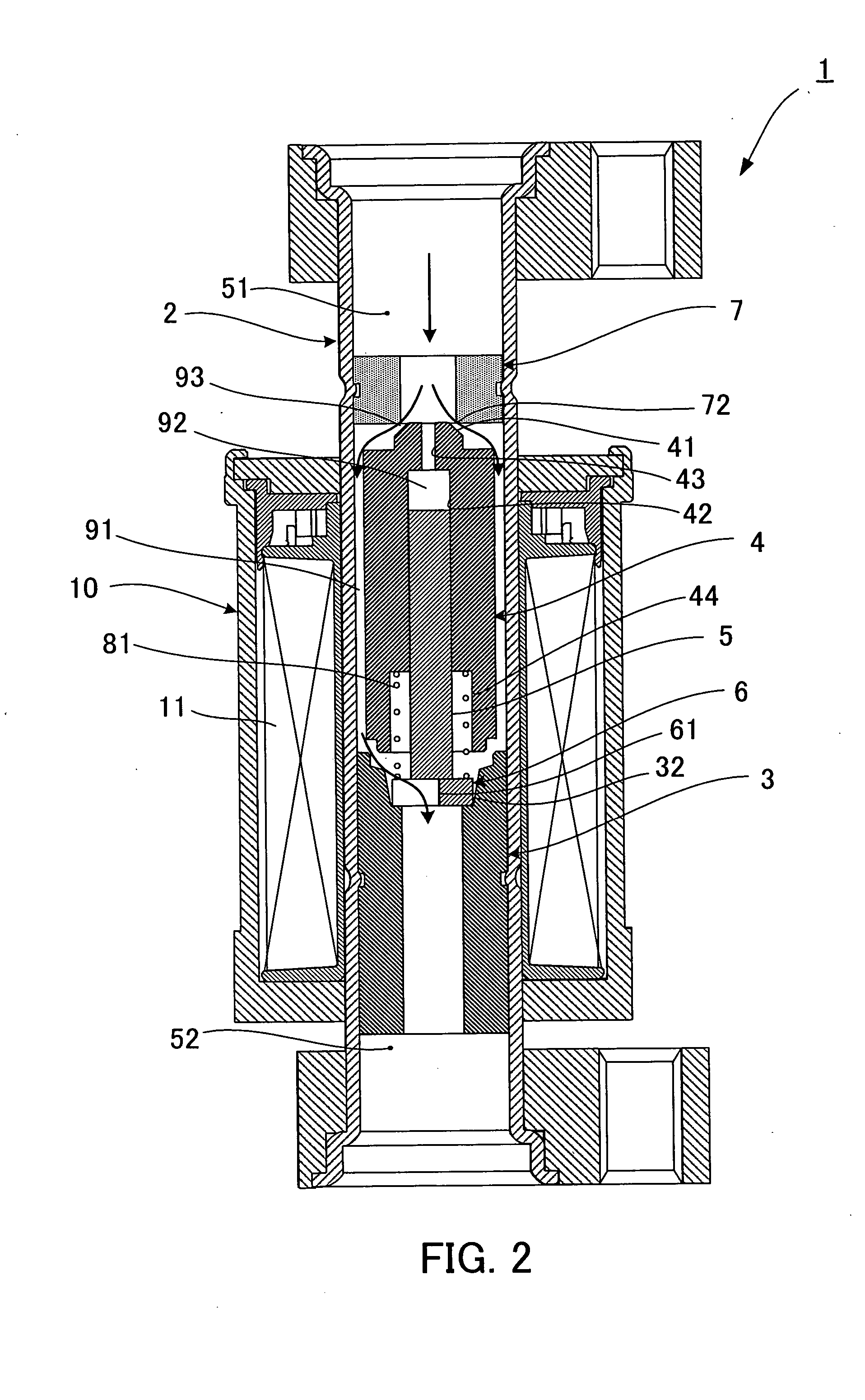

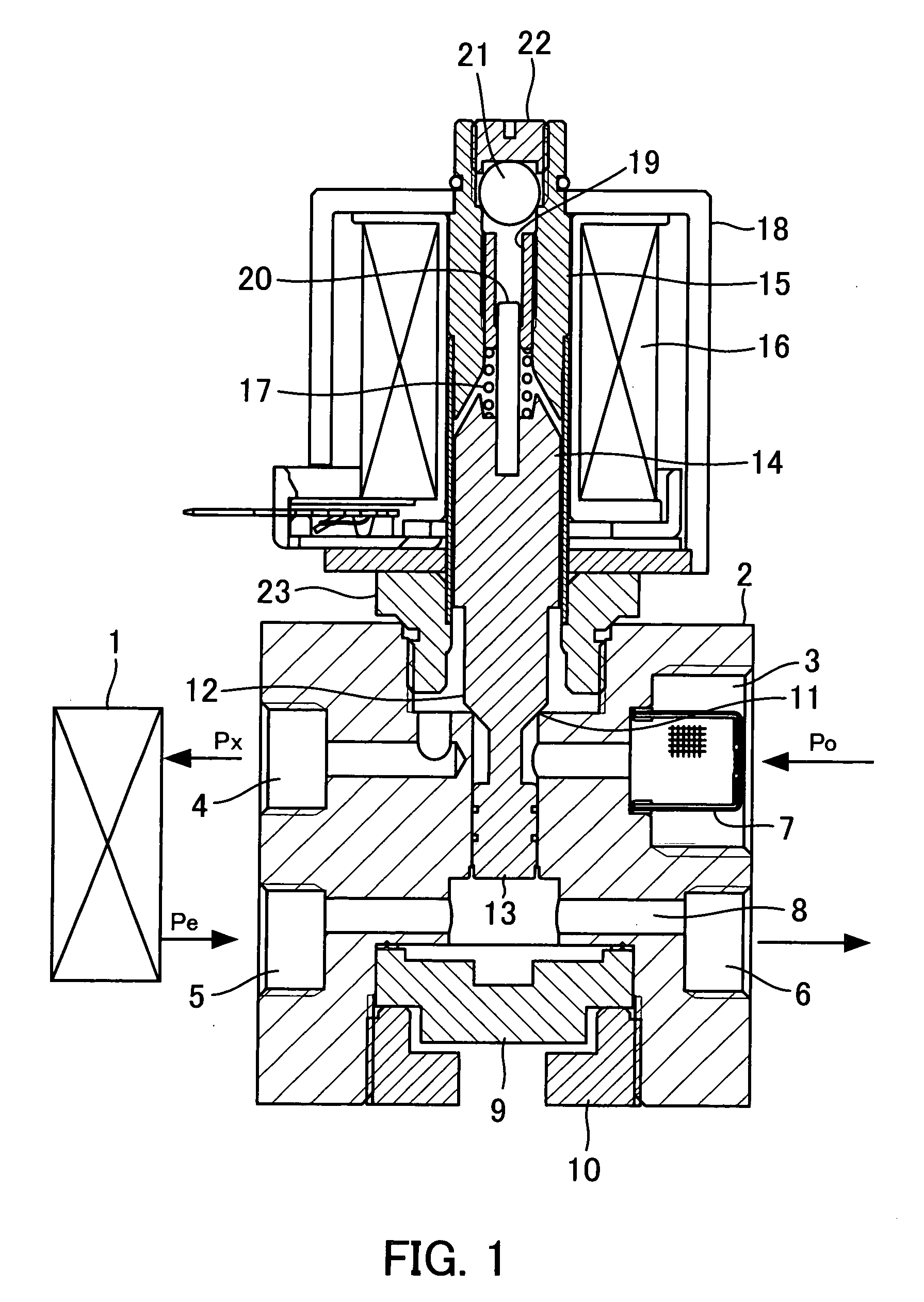

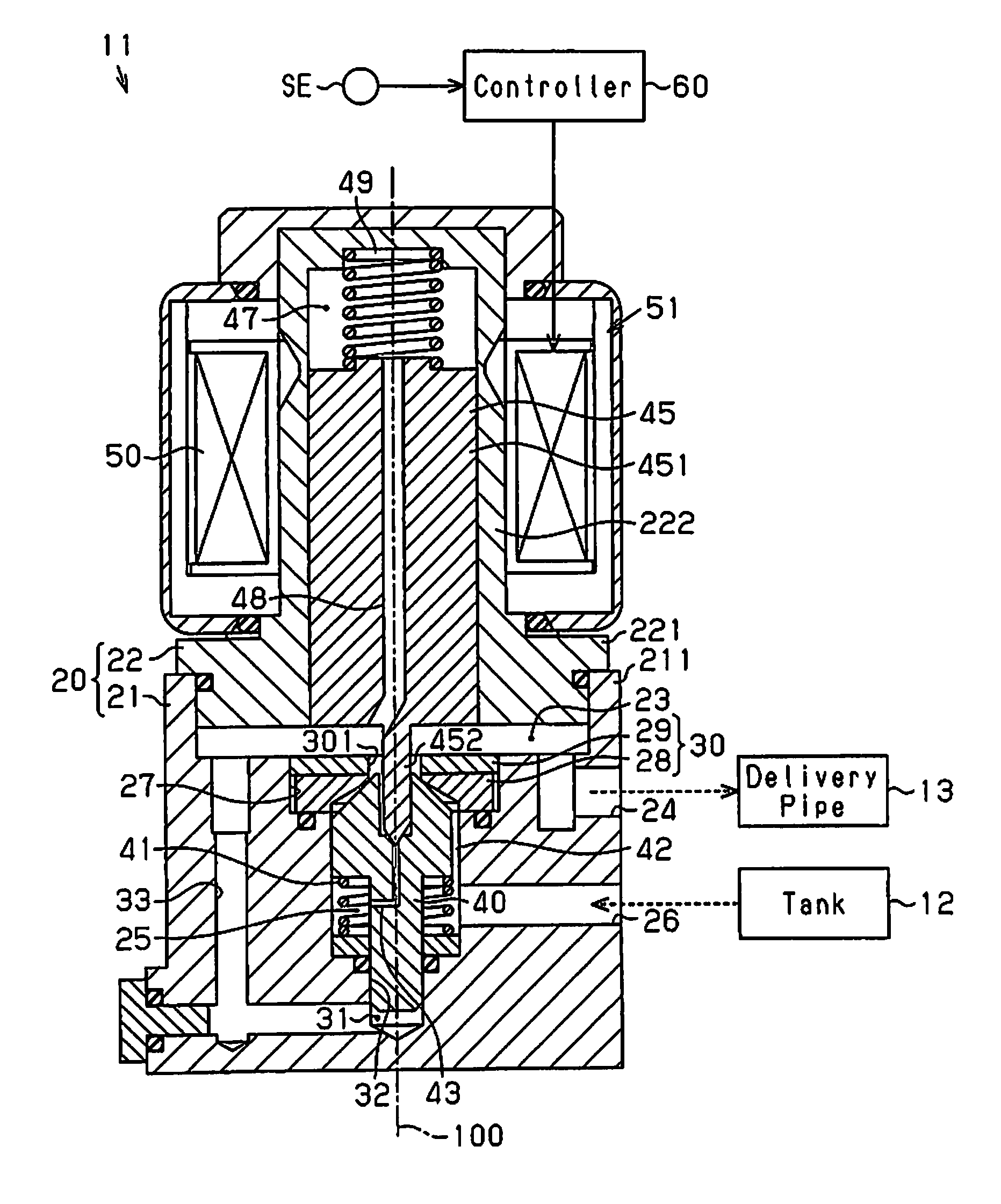

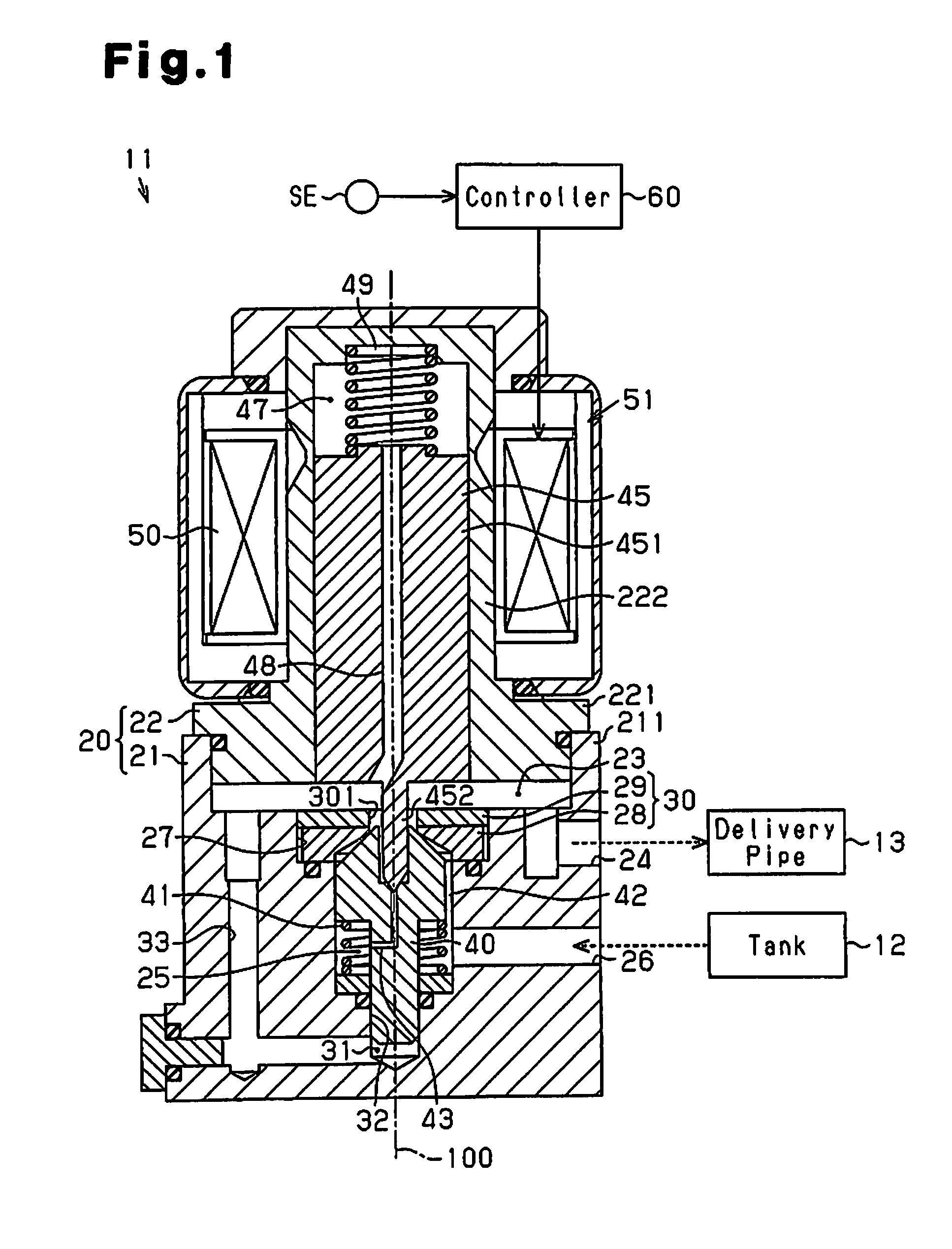

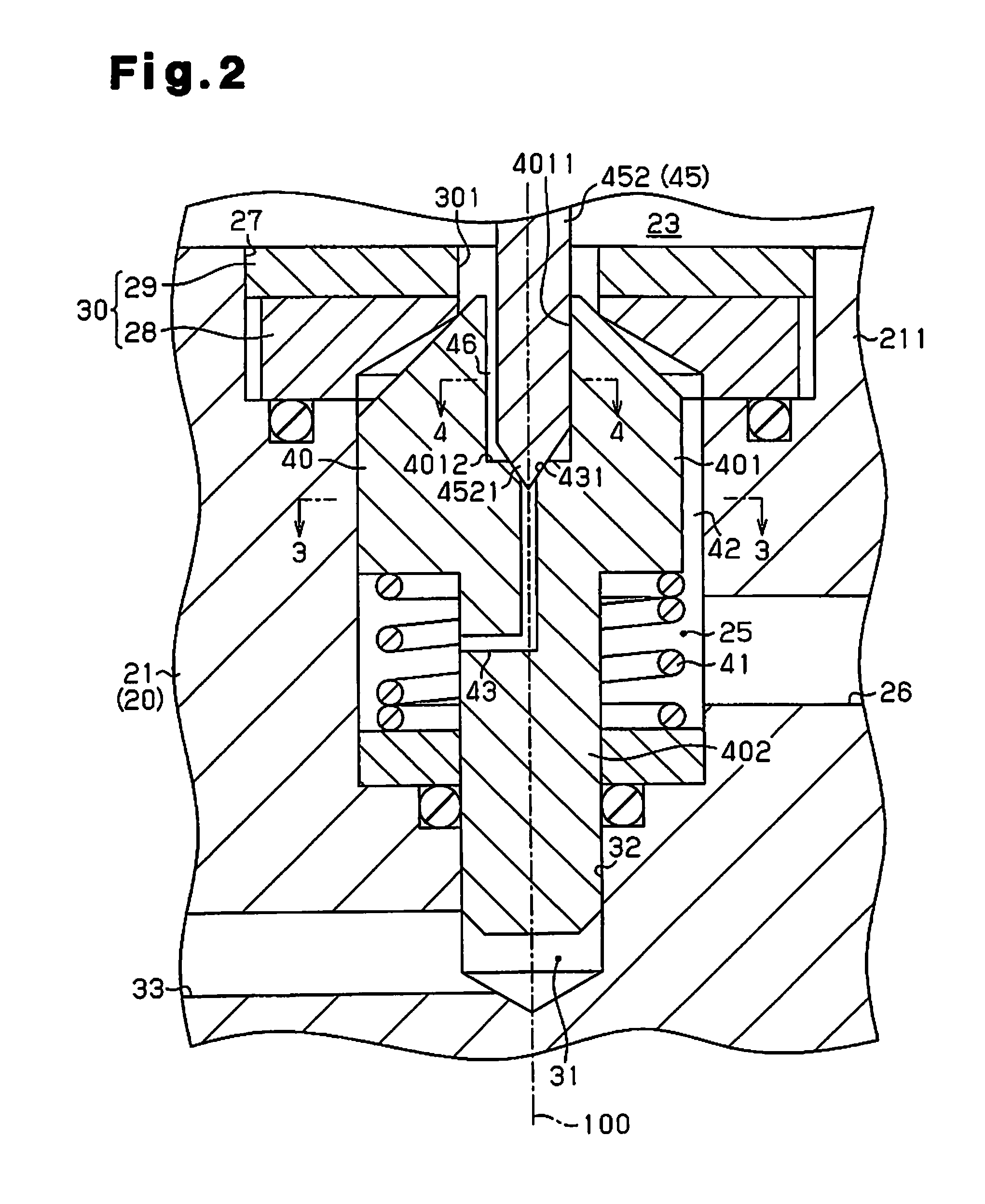

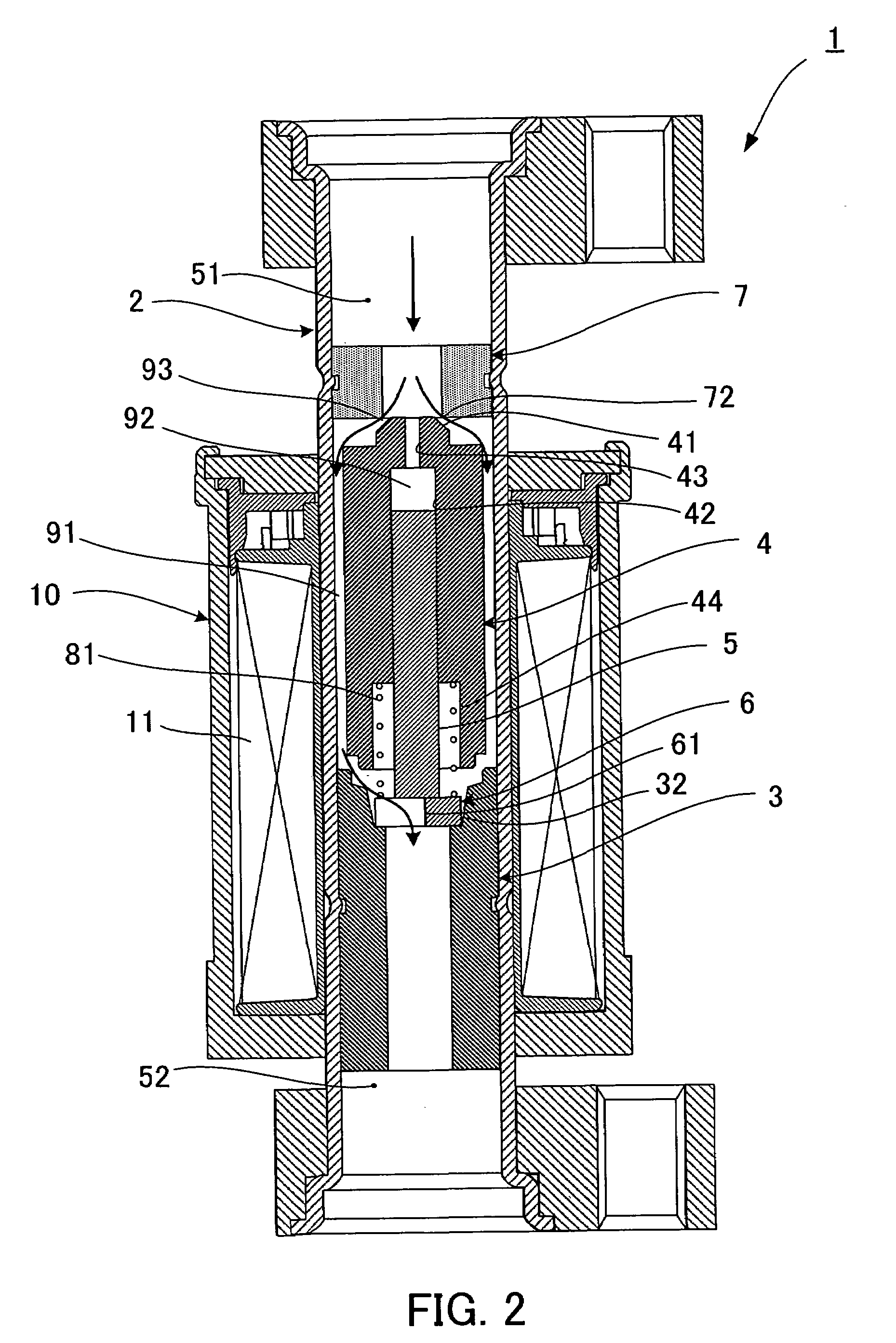

Constant differential pressure valve

InactiveUS20050056050A1Small sizeLow costOperating means/releasing devices for valvesCompression machines with non-reversible cycleDifferential pressureEngineering

To provide a constant differential pressure valve which is compact in size and can be realized at low cost. In the constant differential pressure valve according to the present invention, a pipe forming a body thereof not only accommodates internal structures, such as a differential pressure control mechanism, a movable core, and a fixed core, but also serves as part of piping of a refrigeration cycle. Further, a solenoid section including a solenoid coil is disposed outside the pipe in a manner surrounding the same. Therefore, substantial integration of the differential pressure control mechanism into the piping of the refrigeration cycle can be achieved, which makes the entire constant differential pressure valve very simple in construction. As a result, reduction of the size of the constant differential pressure valve and resultant reduction of material costs and manufacturing costs can be achieved, which makes it possible to achieve low costs of the constant differential pressure valve.

Owner:TGK

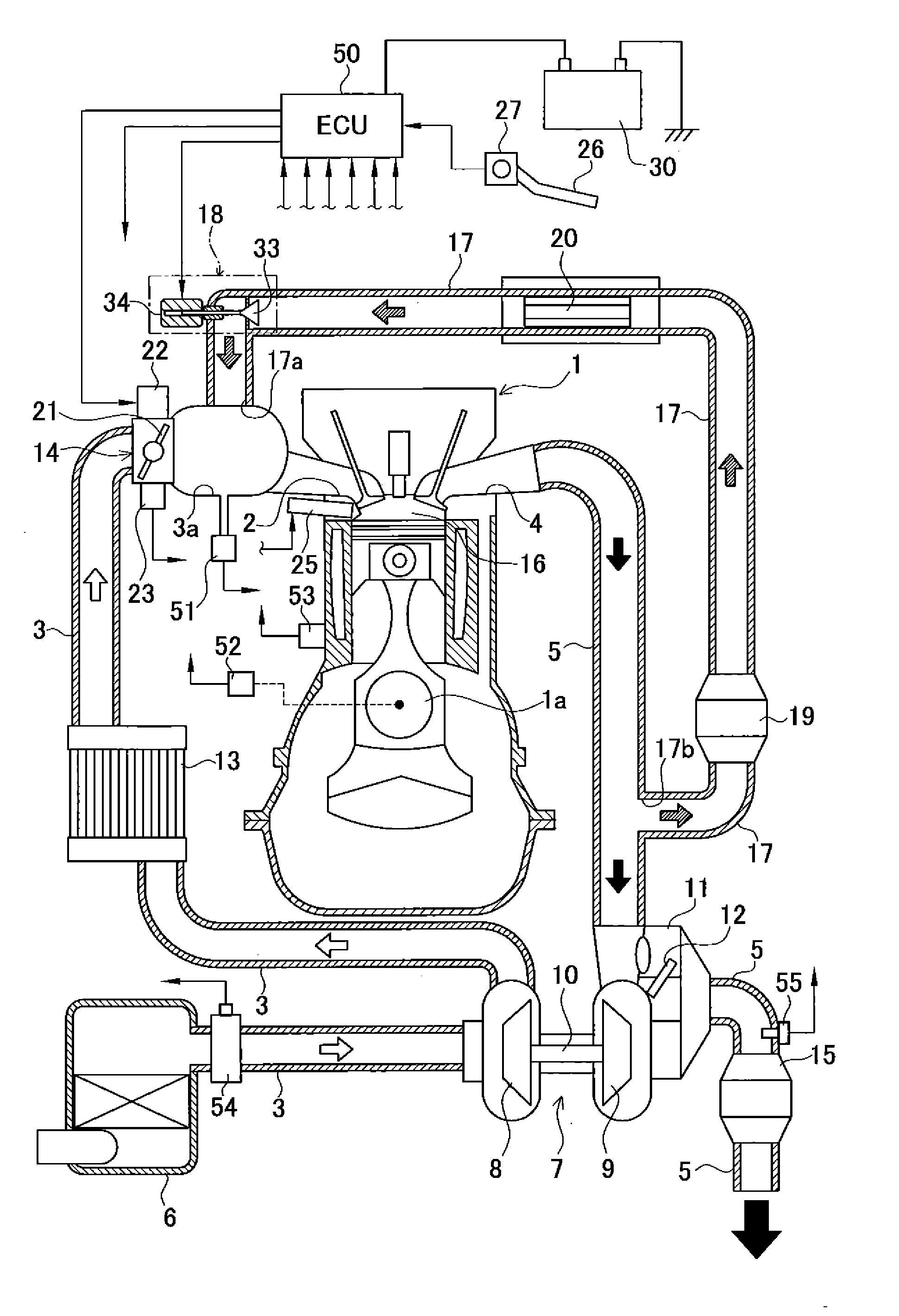

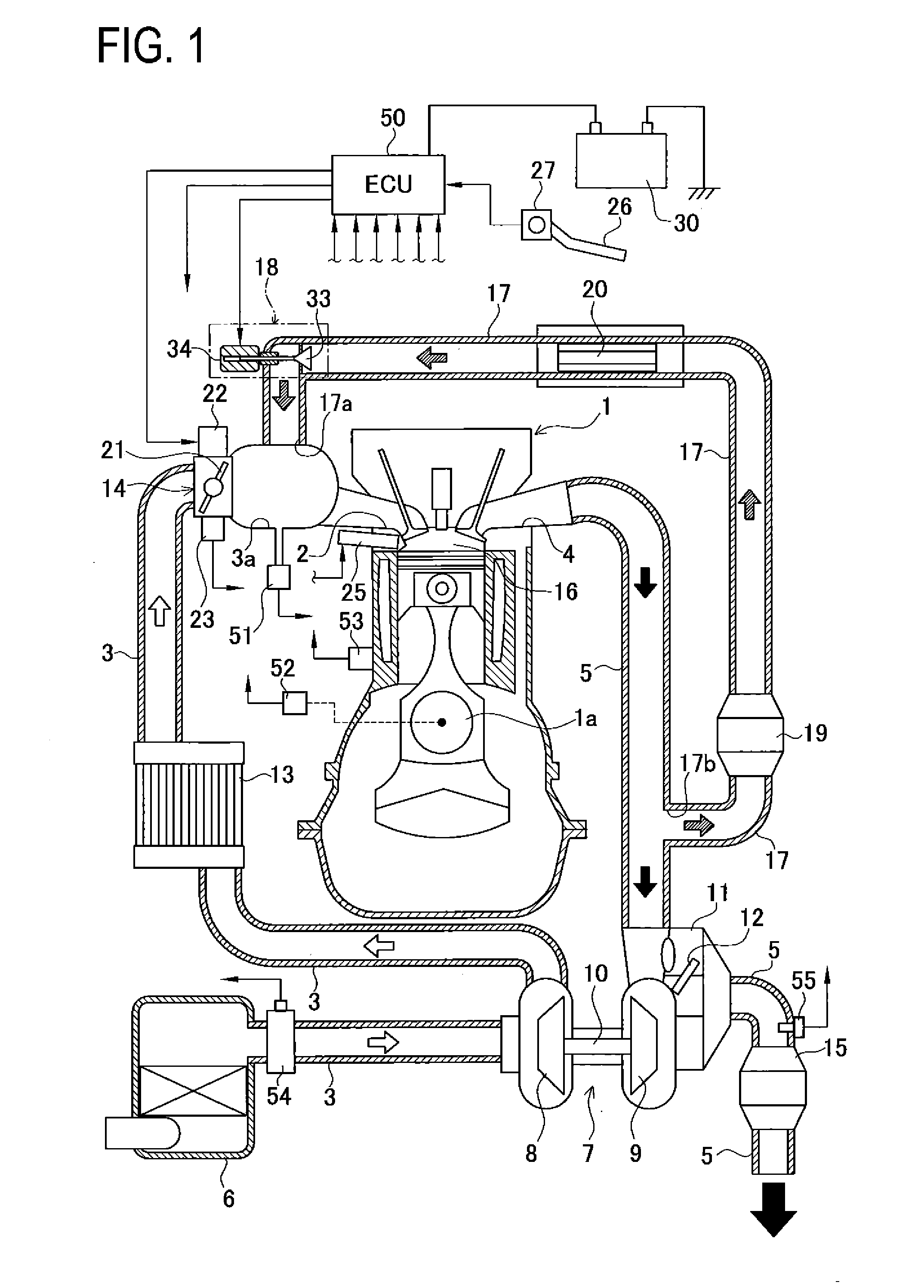

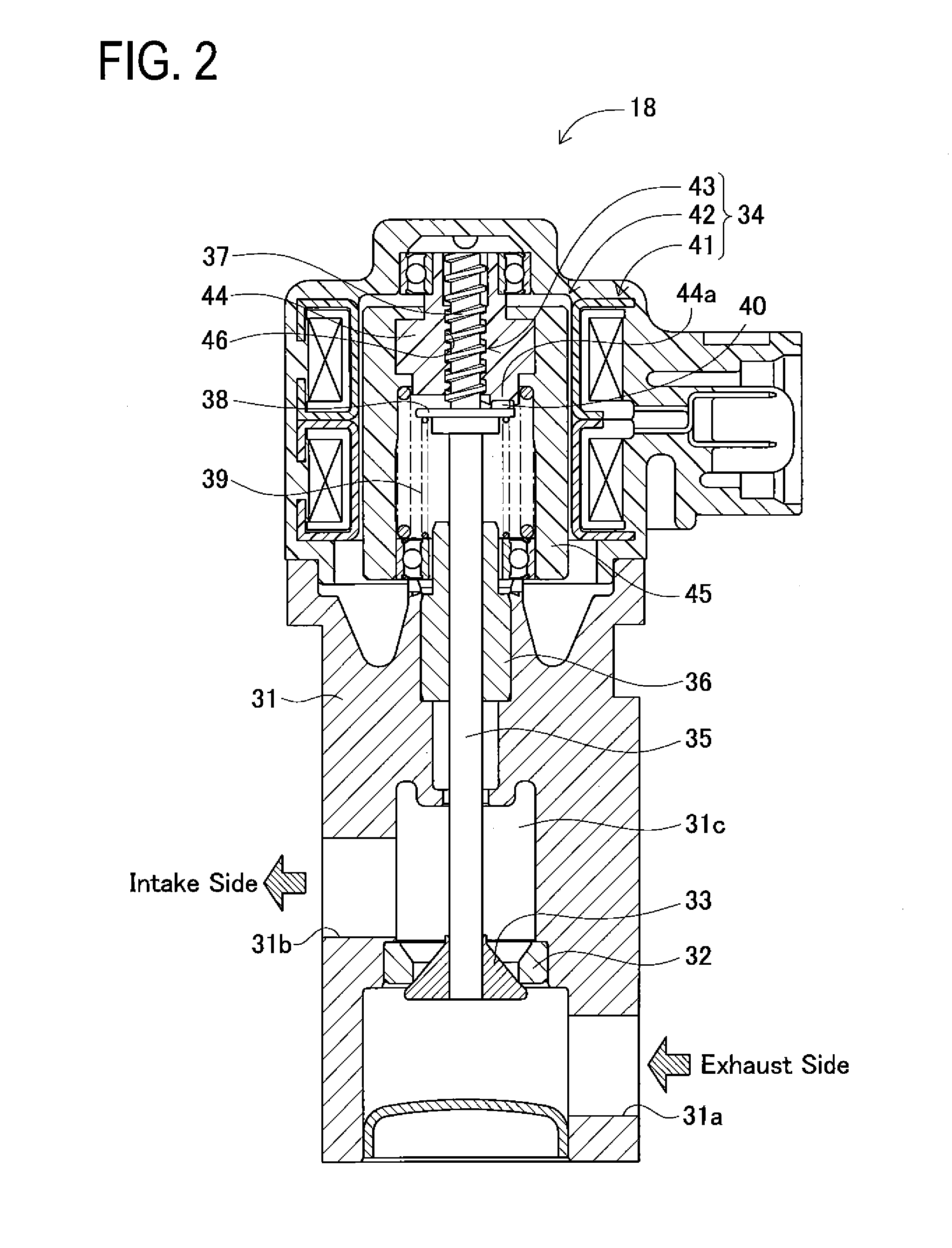

Exhaust gas recirculation apparatus

InactiveUS20140020665A1Increase size and performance of actuatorPrevent deterioration in mountabilityElectrical controlInternal combustion piston enginesIntake pressureExhaust fumes

An EGR apparatus includes an EGR passage and an EGR valve including a valve seat, valve element, and step motor. In a fully closed state of the EGR valve with the valve element seated on the valve seat, a front-side pressure of the valve element is detected by an air flow meter and a back-side pressure of the valve element is detected by an intake pressure sensor. An ECU calculates a differential pressure between the front-side pressure and the back-side pressure as a front-and-back differential pressure. When the front-and-back differential pressure is smaller than a predetermined reference value, the ECU allows opening of the EGR valve from the fully closed state and allows driving of the step motor. The ECU can also correct the reference value according value according to voltage of a battery that supplies electric power to the step motor.

Owner:AISAN IND CO LTD

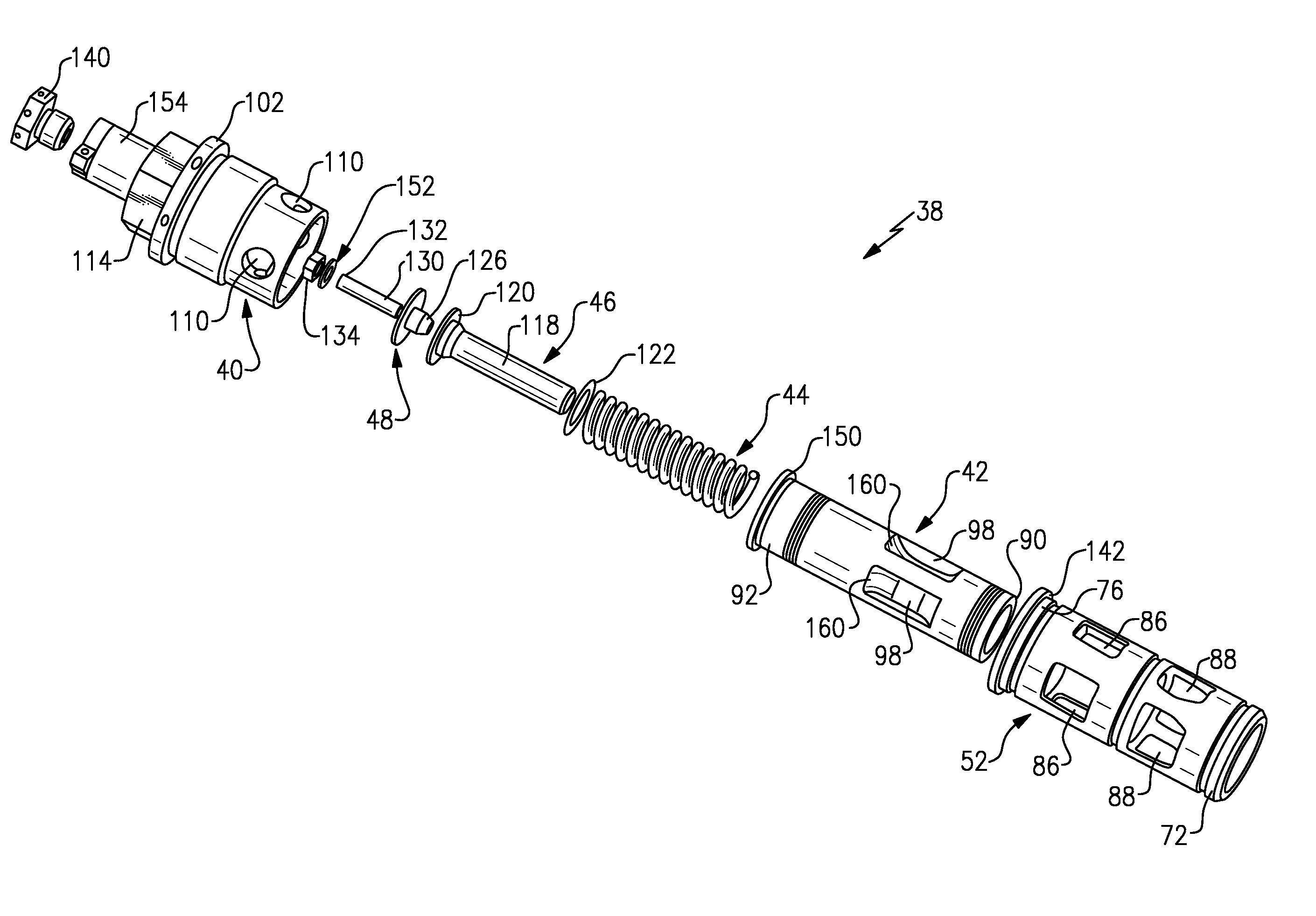

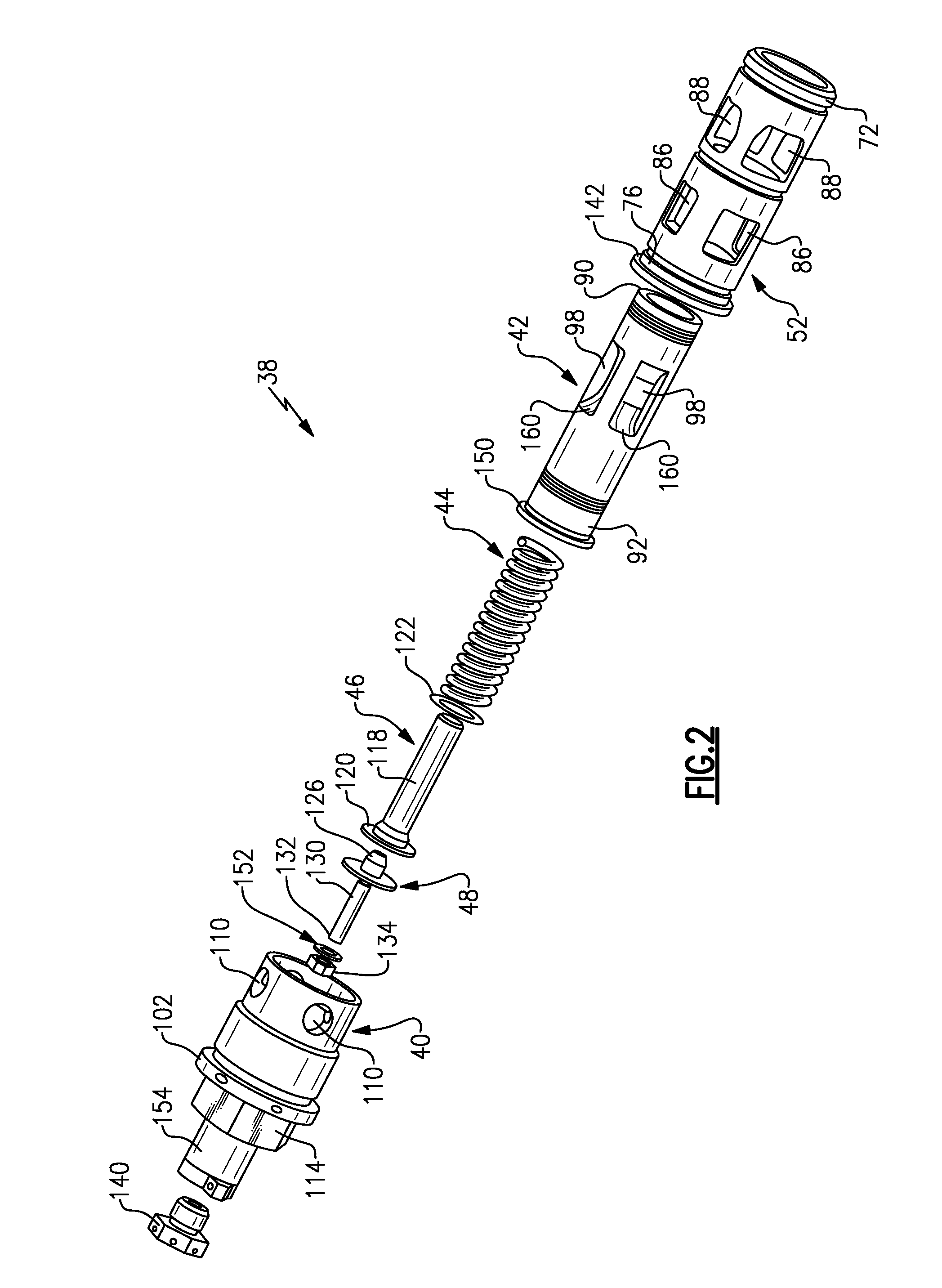

Pressure Regulating Valve

In one featured embodiment, a sleeve for a valve includes a sleeve body surrounding a center axis and defined by an overall length extending from a first end to a second end. The sleeve body has a central bore extending from the first end to the second end. The central bore has a first surface portion comprising a piston contact surface that is defined by a first inner diameter, wherein the piston contact surface is configured to slide against a piston to be received within the central bore. In one example, a ratio of the overall length to the first inner diameter is between 3.51 and 3.63.

Owner:HAMILTON SUNDSTRAND CORP

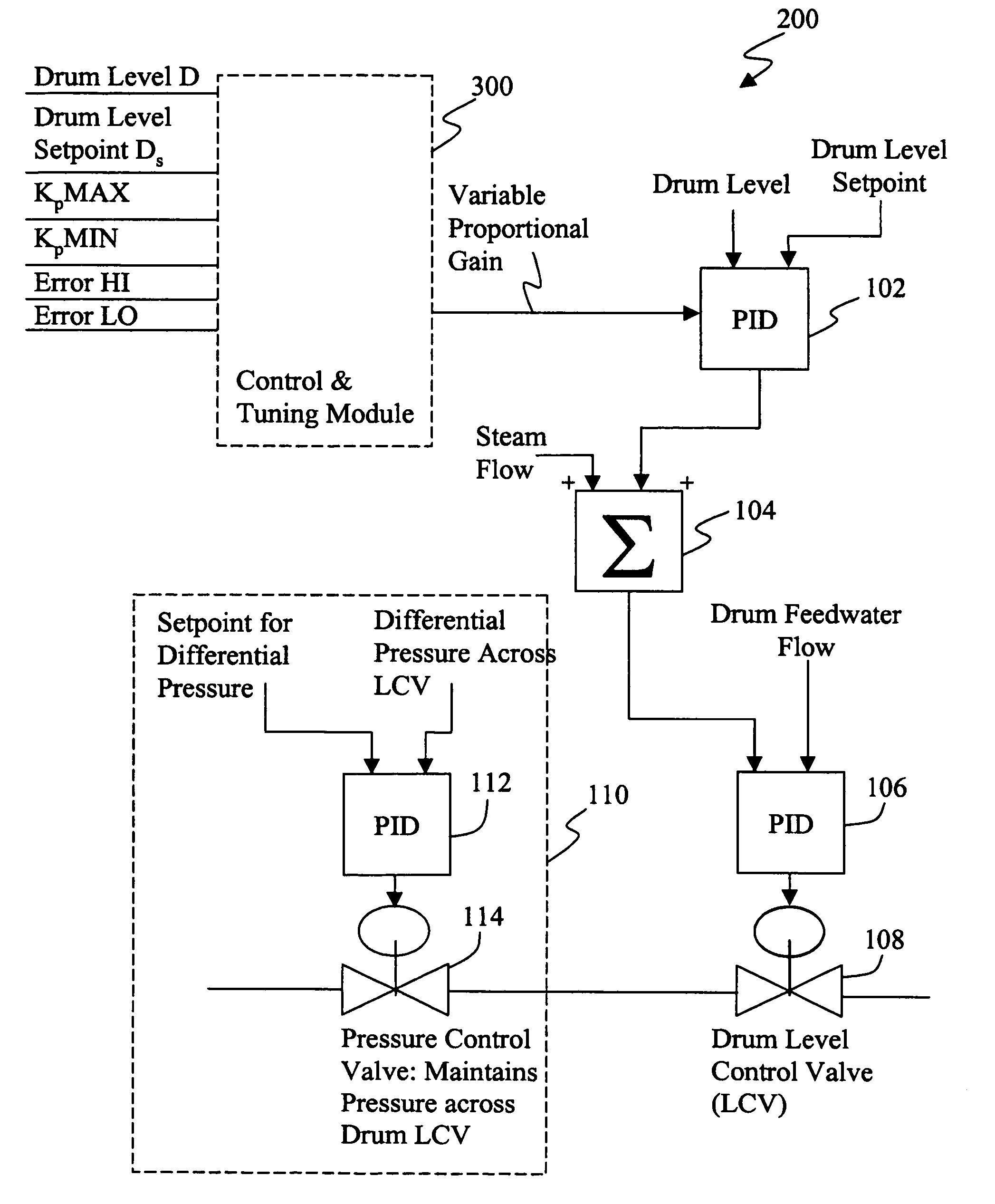

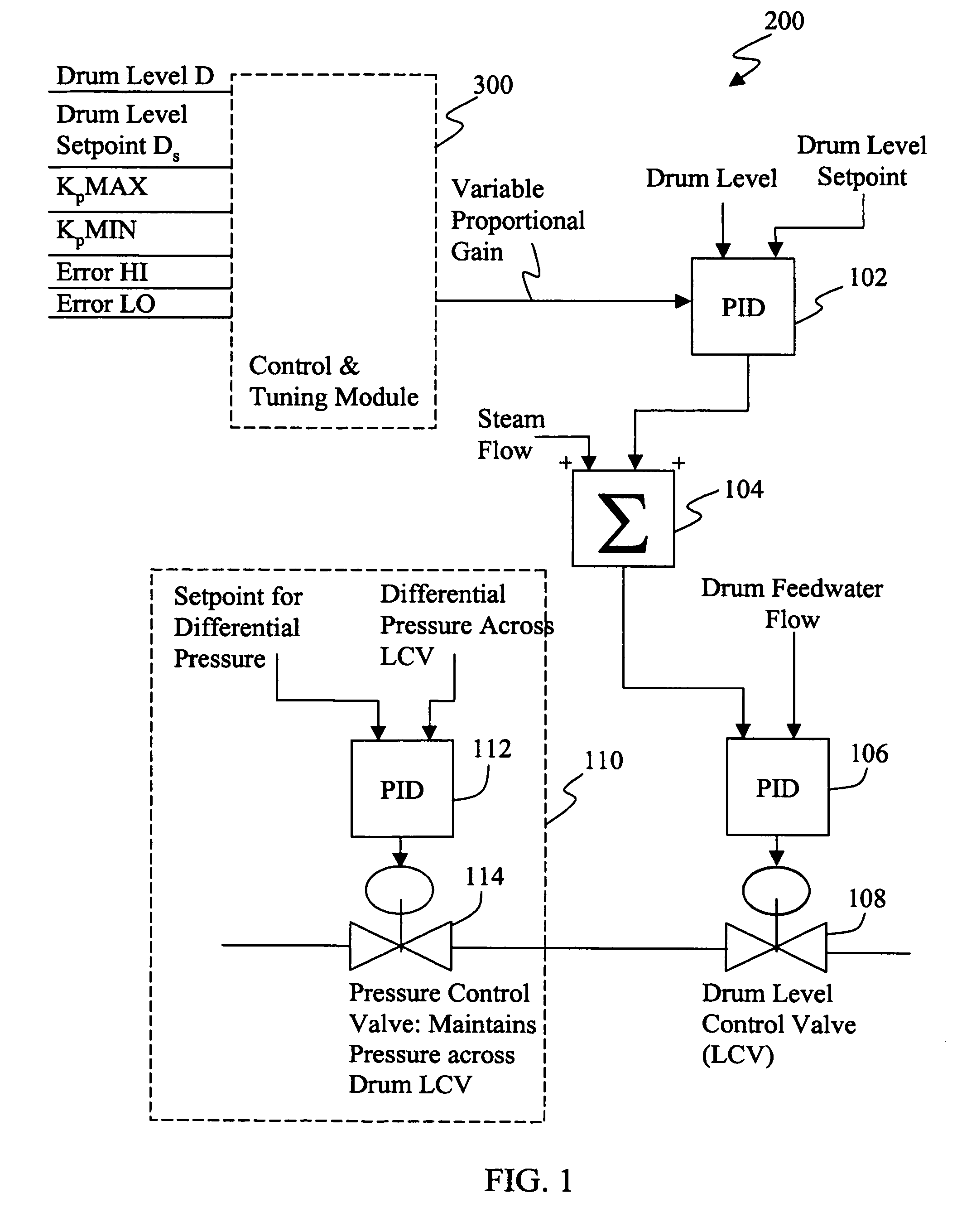

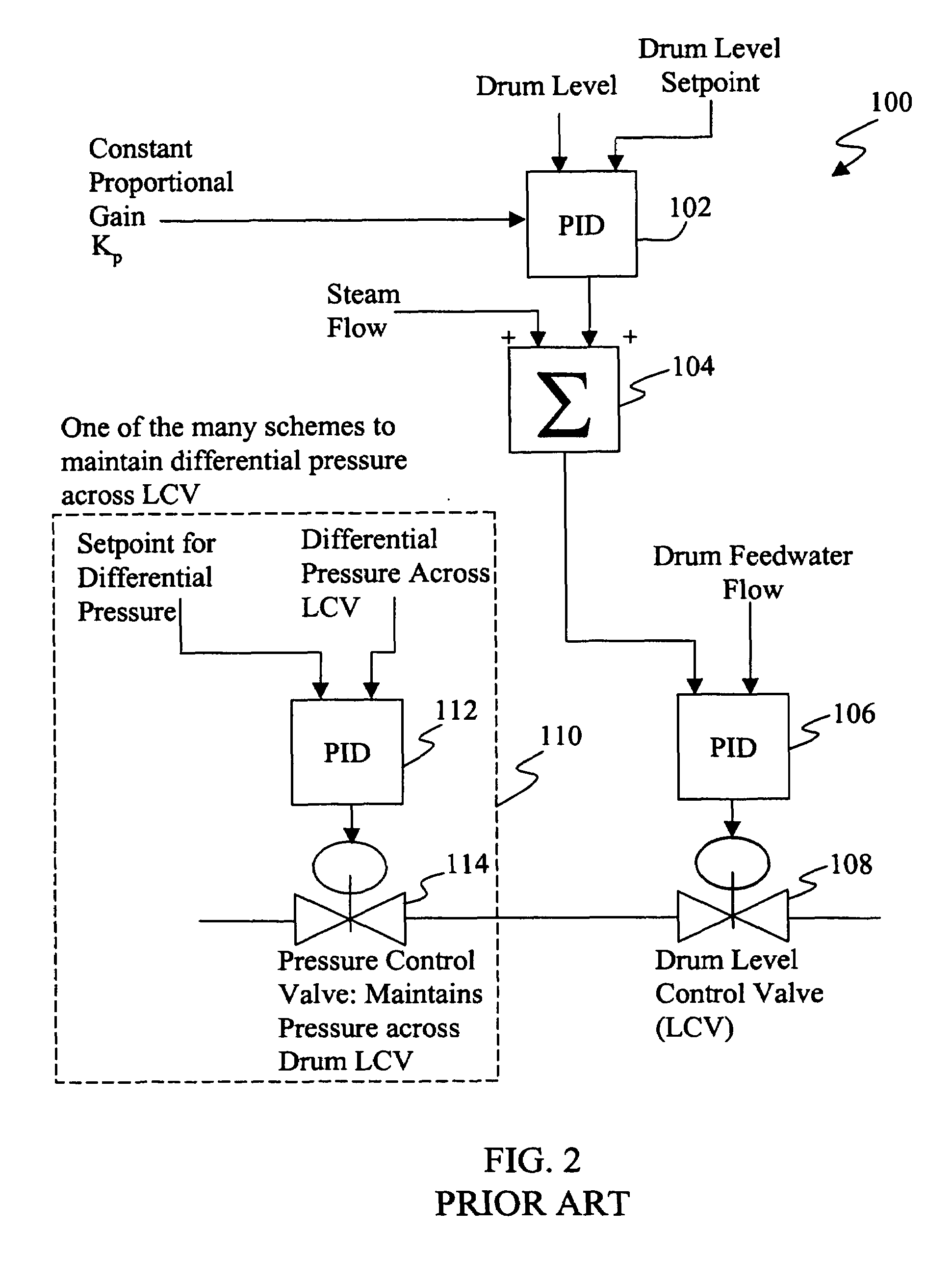

Method and apparatus for drum level control for drum-type boilers

InactiveUS7053341B2Reduce erosionImprove performanceLevel controlGas turbine plantsControl valvesControl theory

A method for controlling the level of a drum in a drum-type boiler includes adjusting a gain of a drum level PID (such as a Proportional Integral Derivative control) in accordance with a signal representative of a set of tuning constants, a signal representative of drum level, and a signal representative of a drum level setpoint. The method also includes utilizing a flow control PID to adjust a drum level control valve, wherein the flow control PID adjusts the drum level control valve in accordance with an output of the drum level PID, a signal representative of steam flow, and a signal representative of drum feedwater flow.

Owner:GENERAL ELECTRIC CO

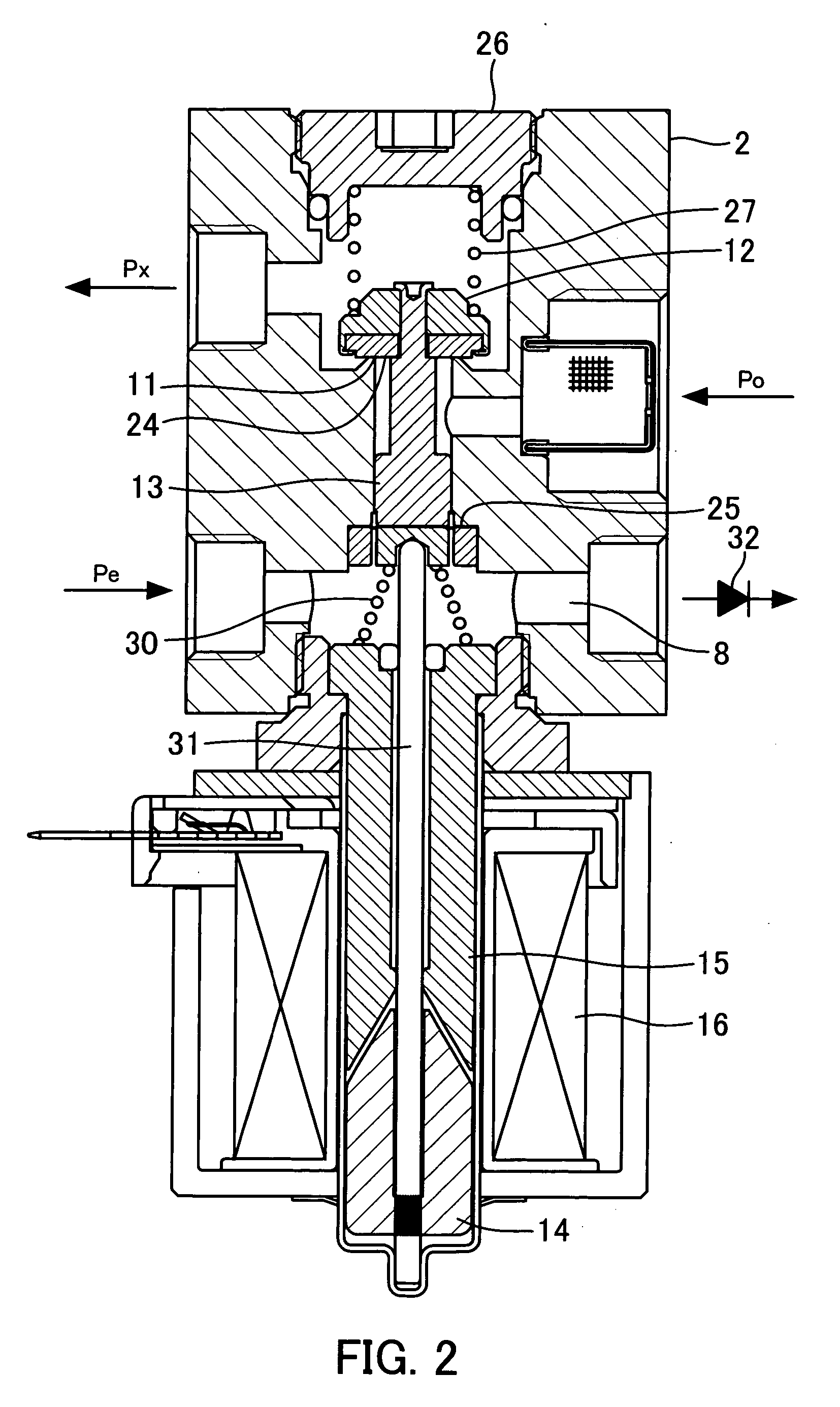

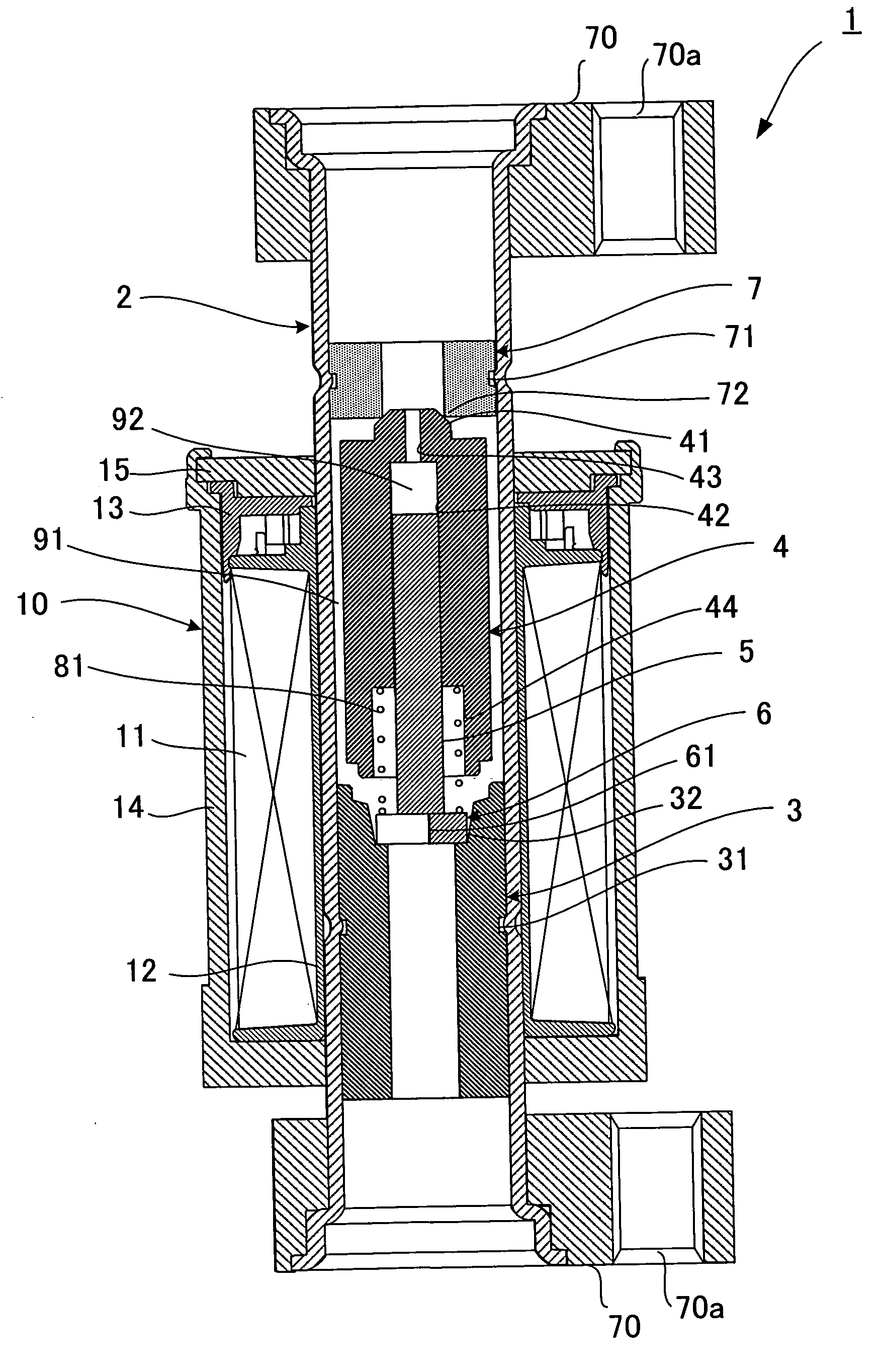

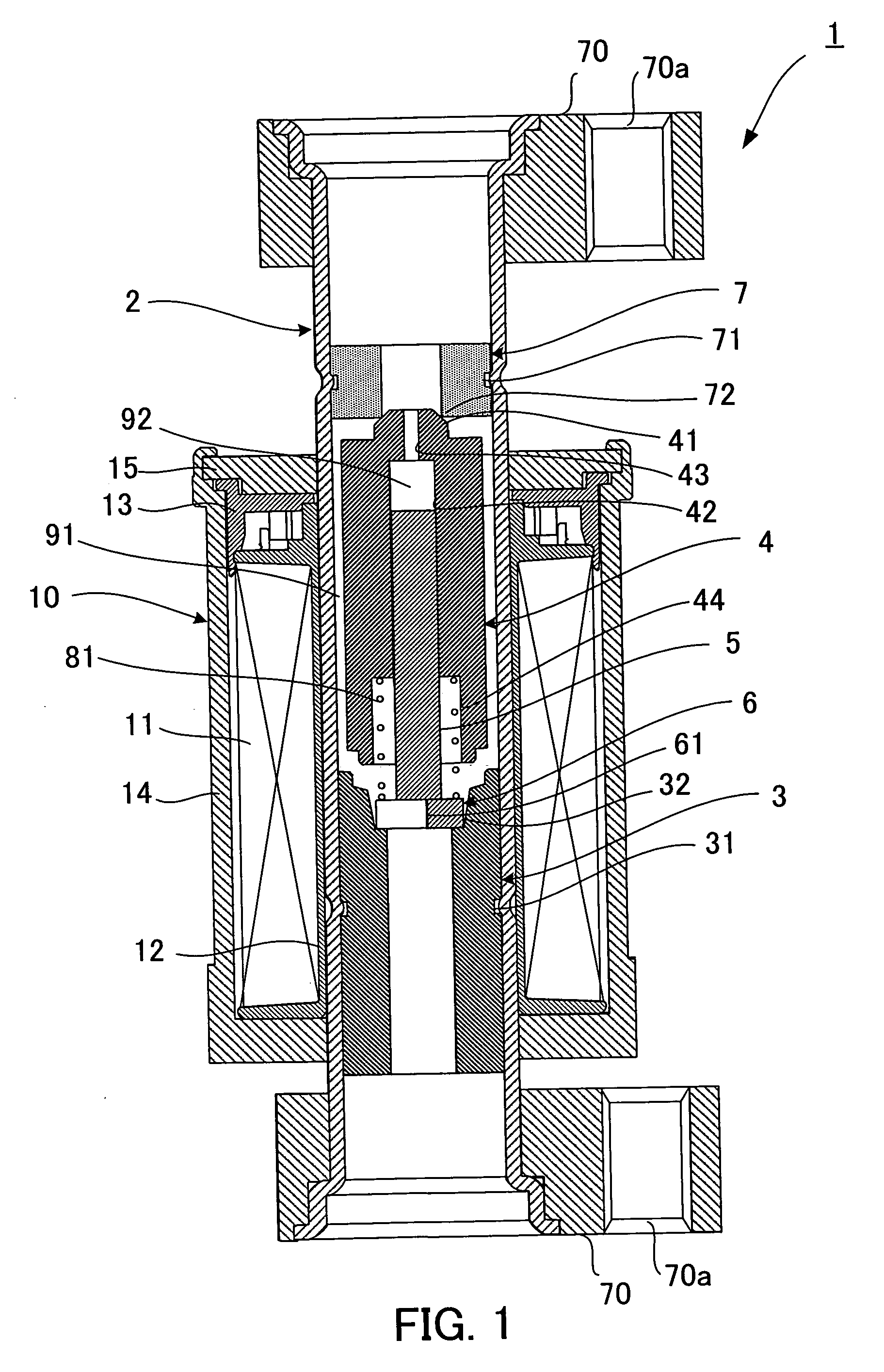

Flow rate control valve

InactiveUS20060005556A1Easy constructionAir-treating devicesCompression machines with non-reversible cycleDifferential pressureEngineering

There is provided a flow rate control valve of a constant flow-rate control type, which is simple in construction. The flow rate control valve is configured, by regarding a evaporator as a restriction passage, to include a constant differential pressure control valve for controlling the differential pressure before and after pressure loss caused by passage of refrigerant through the evaporator to be substantially constant. In the constant differential pressure control valve, a valve element receives pressure from the outlet of the flow rate control valve in a valve-closing direction, and a piston receives pressure from the outlet of the evaporator in a valve-opening direction. By controlling the differential pressure between pressure at the inlet of the evaporator and the pressure at the outlet of the evaporator such that it is substantially constant, the constant differential pressure control valve causes the refrigerant to flow into the evaporator at a constant flow rate dependent on electric current that energizes a solenoid. This makes it unnecessary to form a restriction passage in the flow rate control valve, and hence the construction of the flow rate control valve can be simplified, which makes it possible to provide a flow rate control valve manufactured at low cost.

Owner:TGK

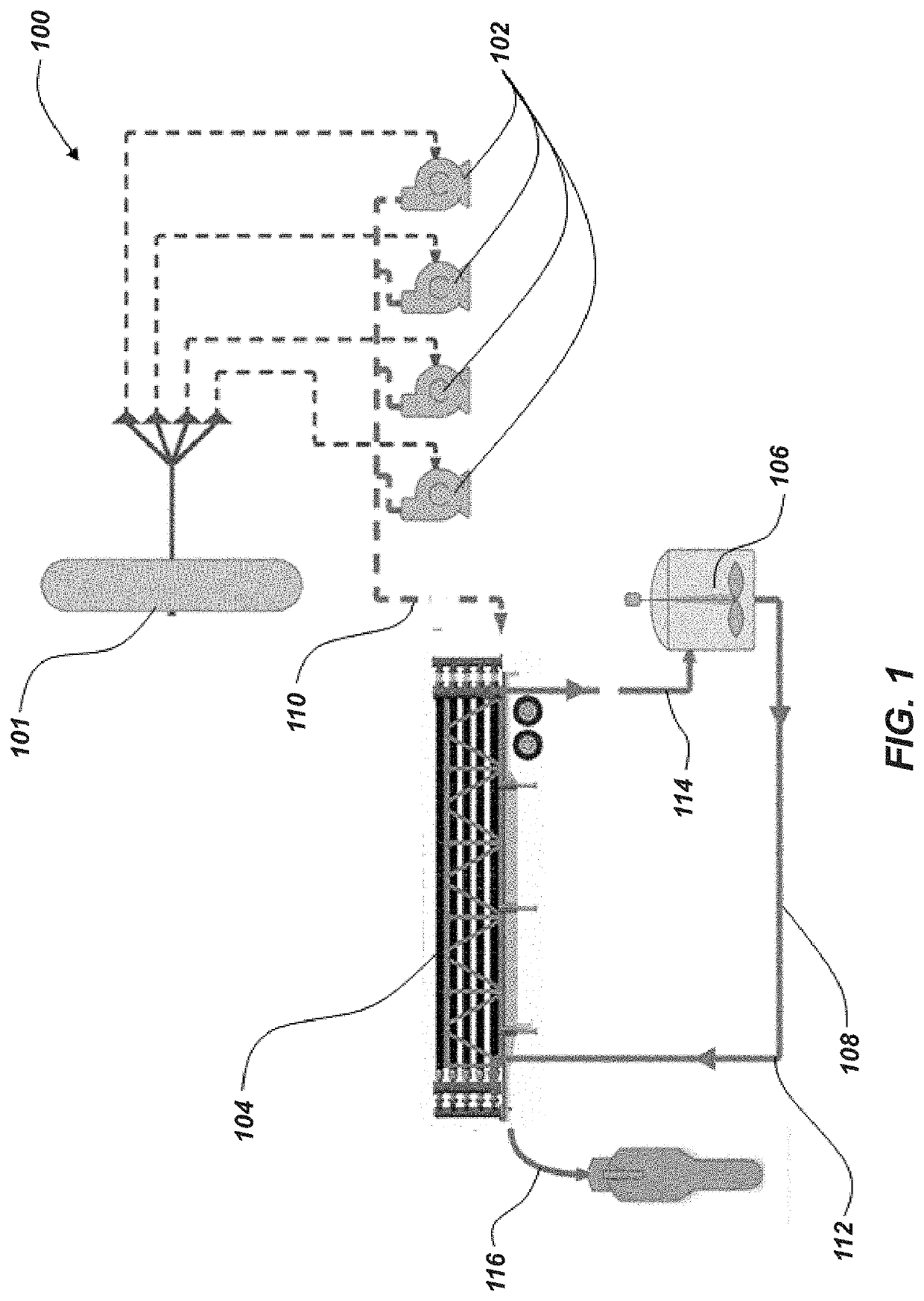

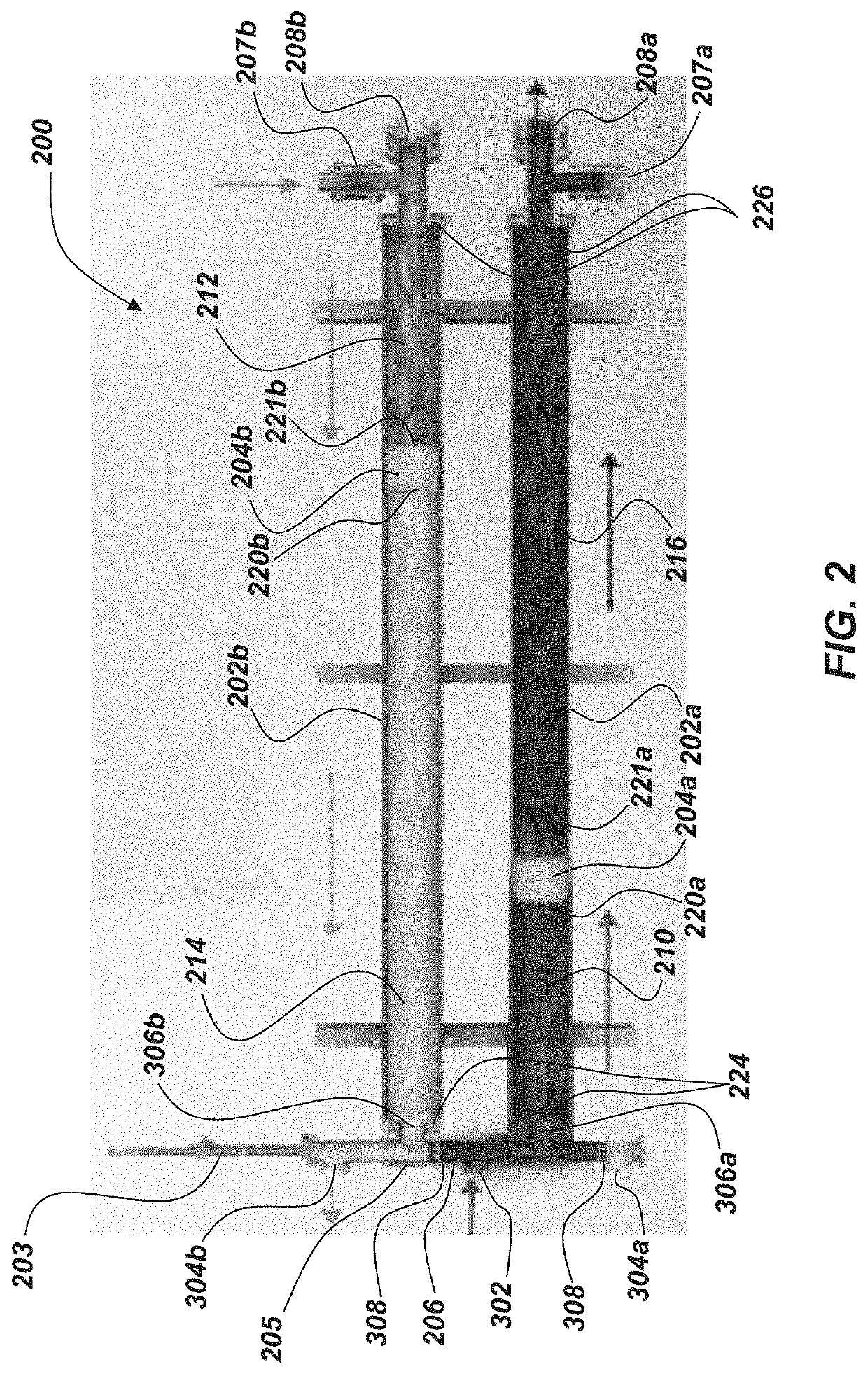

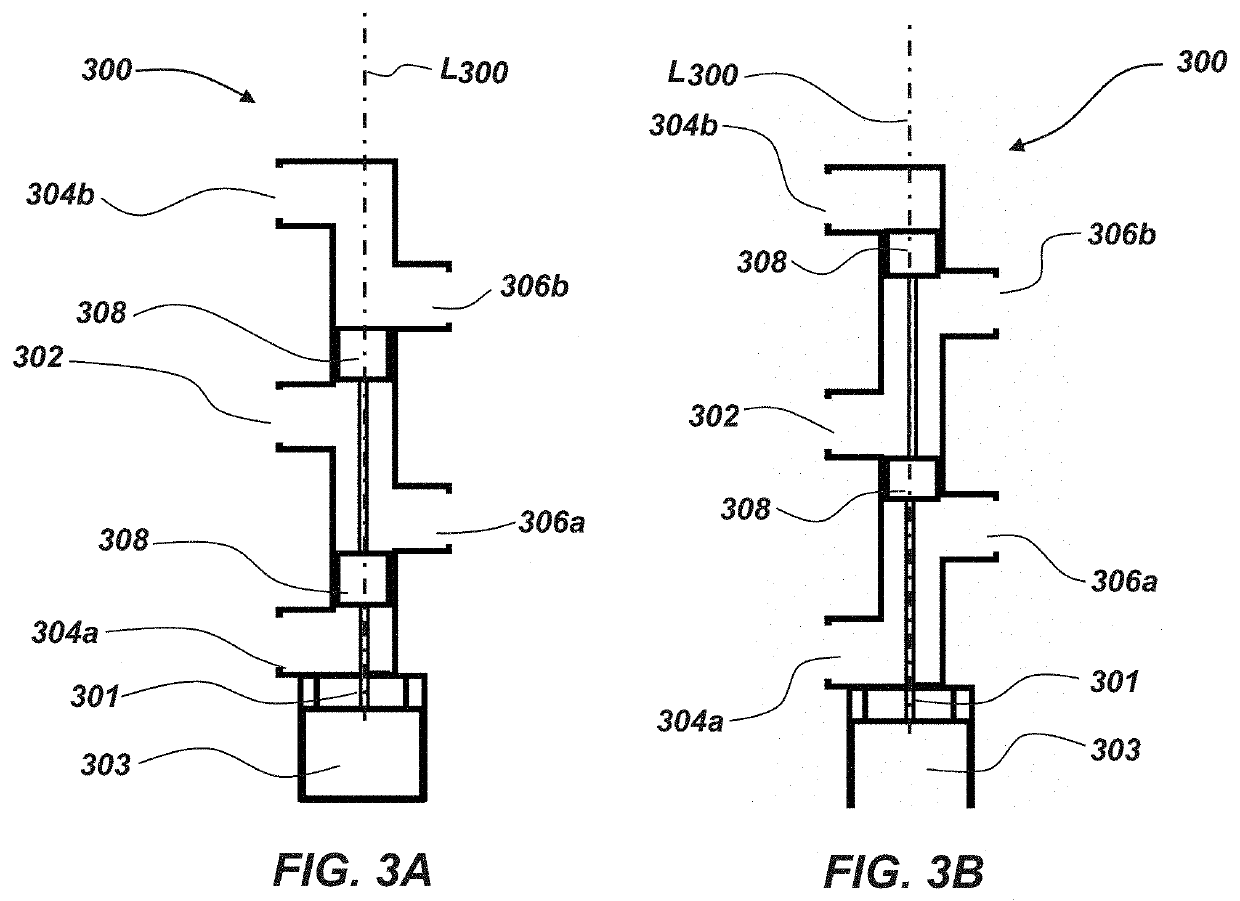

Valves including one or more flushing features and related assemblies, systems, and methods

ActiveUS20200149657A1Reduce pressureHollow article cleaningCheck valvesEngineeringPressure exchanger

Valve and related assemblies, systems, and methods may include a self-cleaning feature that may be configured to at least partially displace material from a portion of the valve. Such valves may be utilized in a pressure exchanger.

Owner:FLOWSERVE PTE LTD

Variable pressure difference load sensitive multiple-way valve

ActiveCN109441905APromote intelligent developmentOvercome immobilityOperating means/releasing devices for valvesServomotor componentsDifferential pressureElectro hydraulic

The invention discloses a variable pressure difference load sensitive multiple-way valve. According to the variable pressure difference load sensitive multiple-way valve disclosed by the invention, each linked valve group adopts a novel element electro hydraulic pressure compensation valve, so that compensation pressure difference real-time continuous control and compensation valve core real-timeposition feedback monitoring are realized, and the problems that under the flow rate saturated working condition, a conventional LS system flow rate is mismatched, the diversion ratio of an LUDV system is fixed, and the motor coordination performance of an executor is poor are solved. The variable pressure difference load sensitive multiple-way valve disclosed by the invention has the advantages of being high in working condition applicability, high in flow distribution precision, high in technical performance and the like.

Owner:TAIYUAN UNIV OF TECH

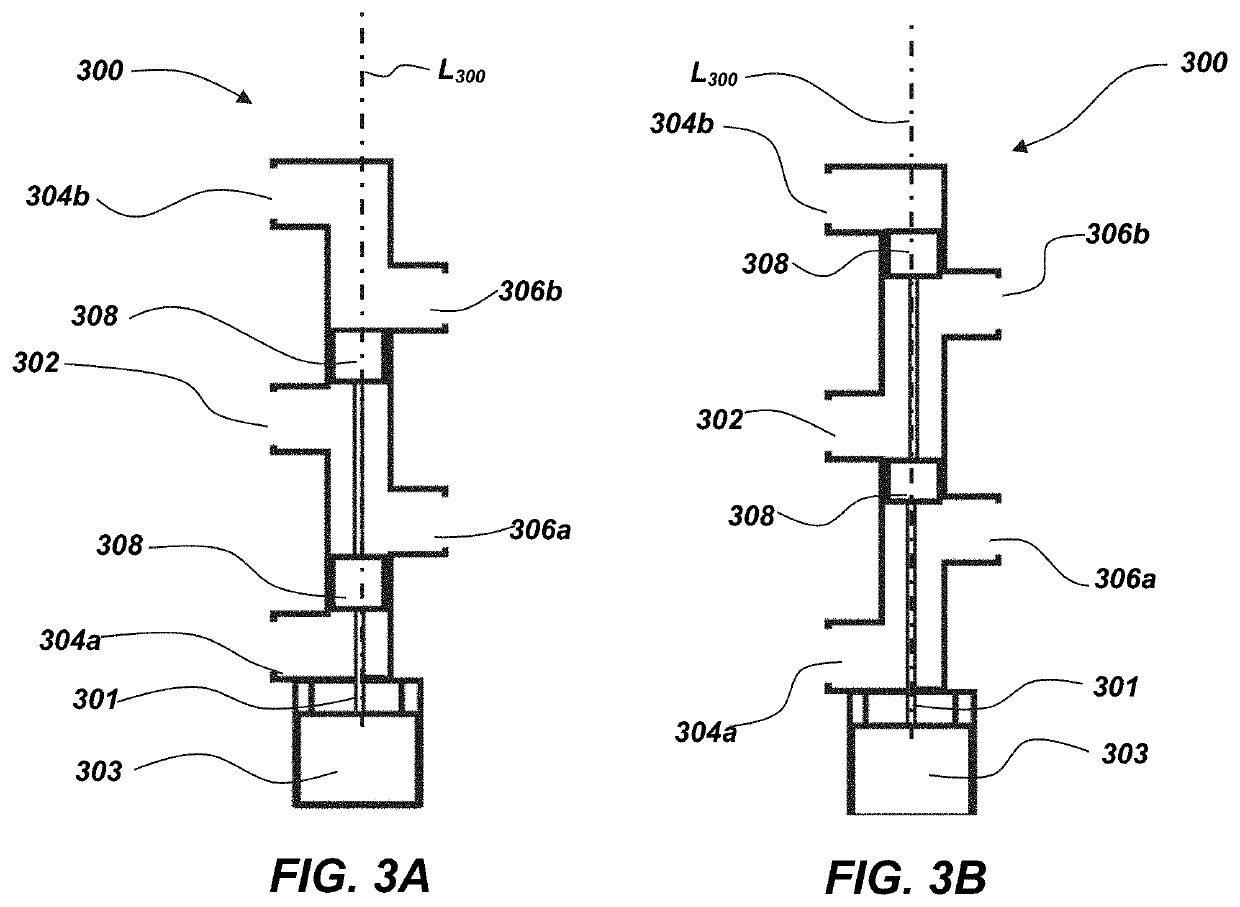

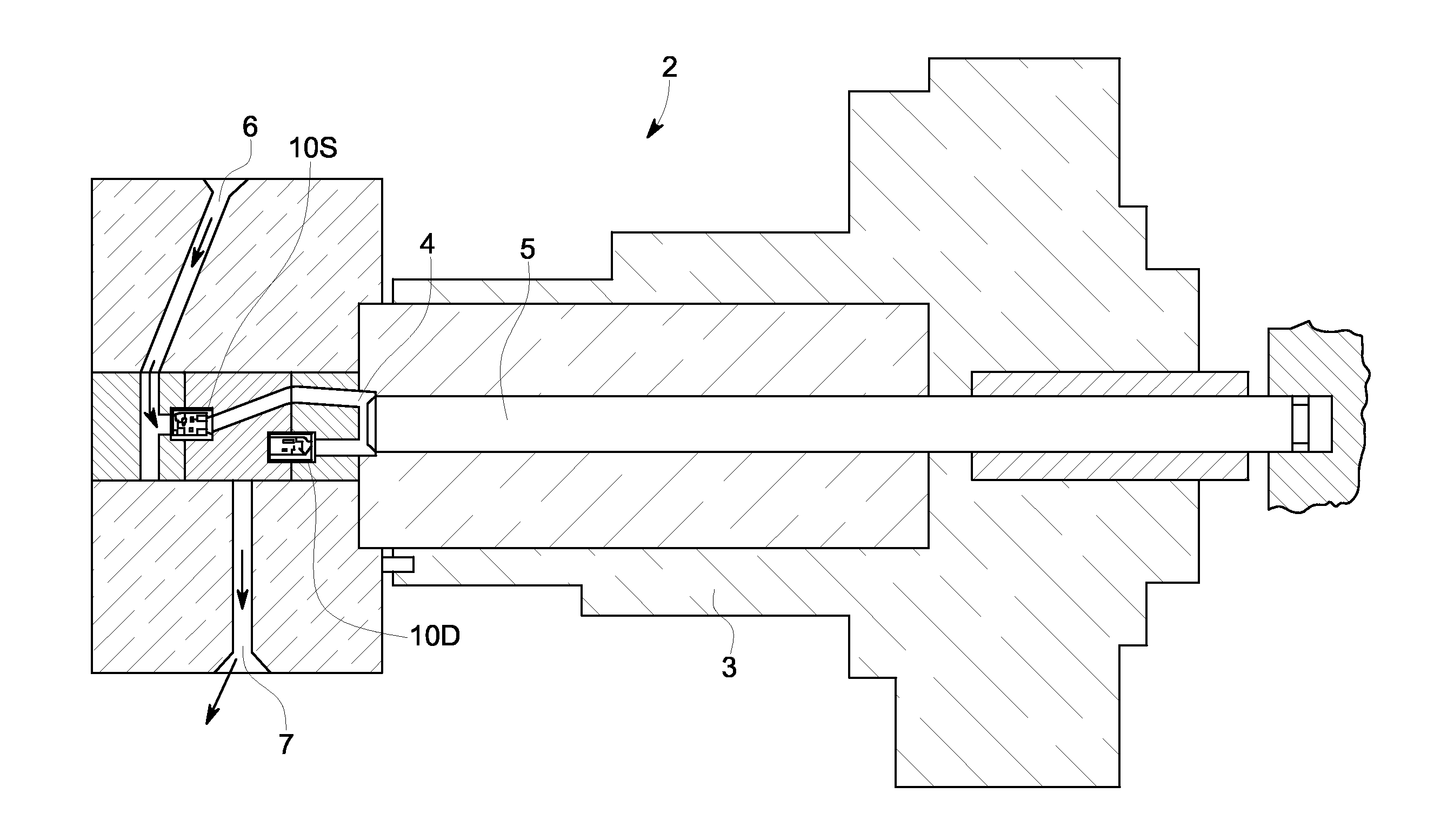

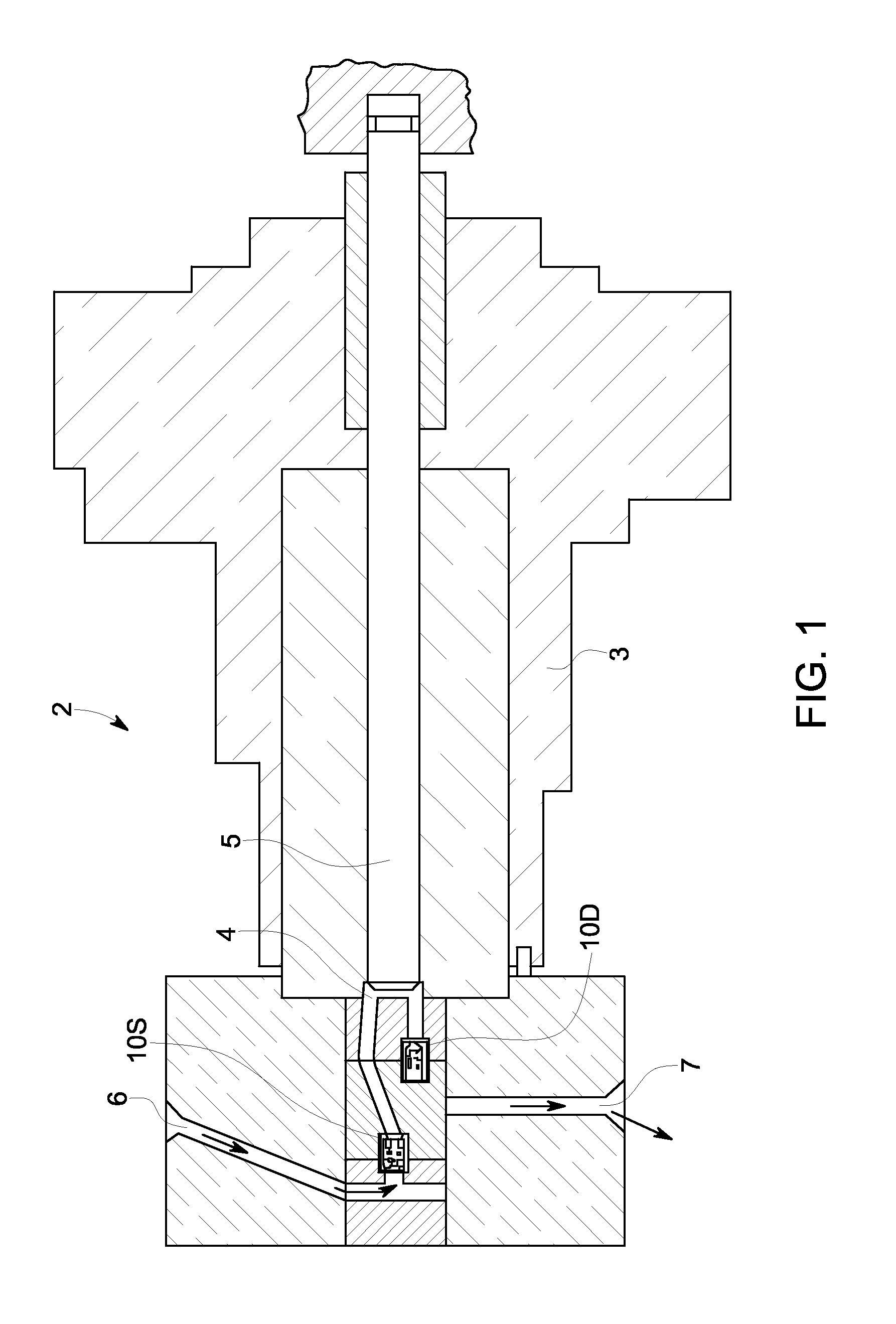

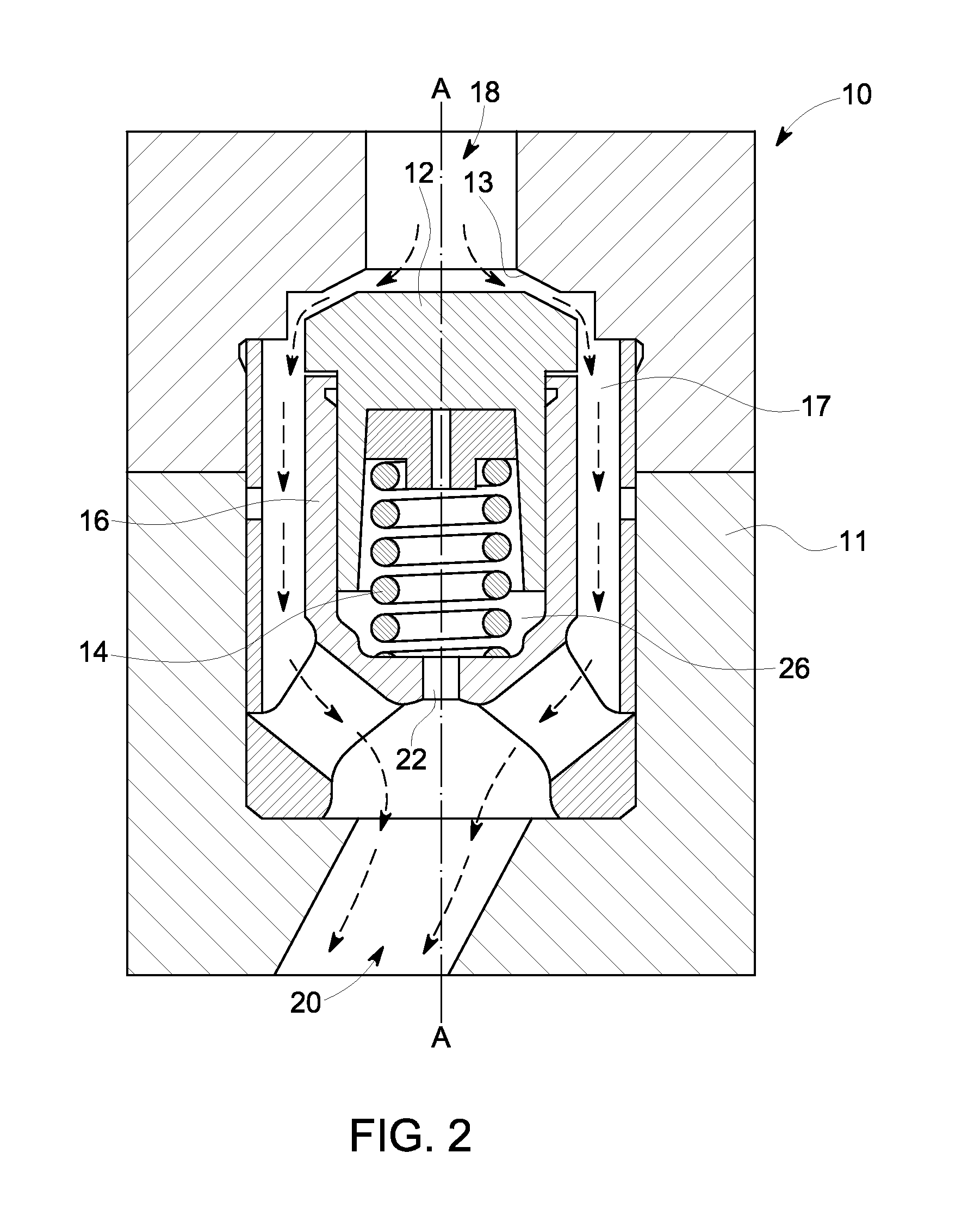

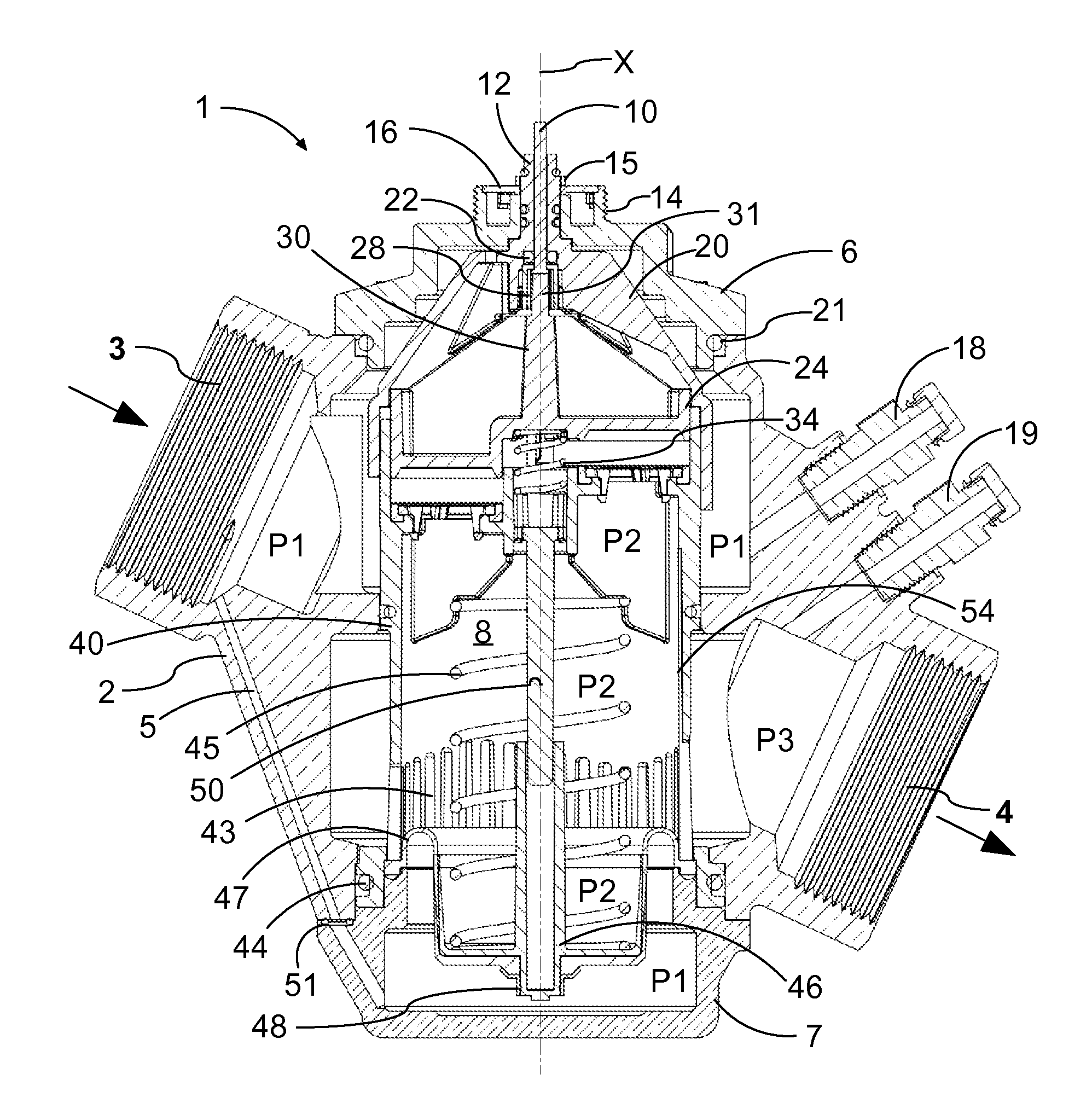

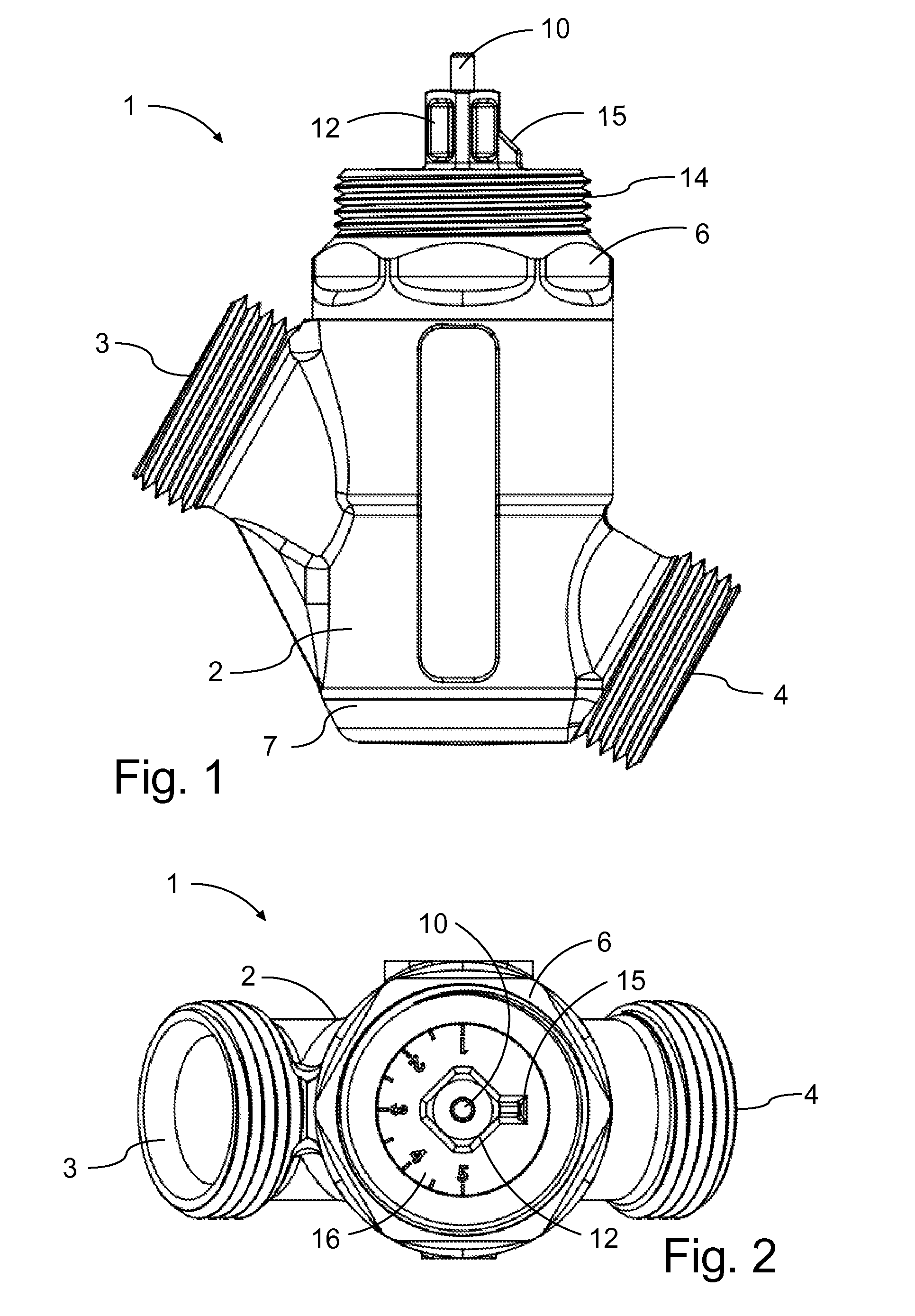

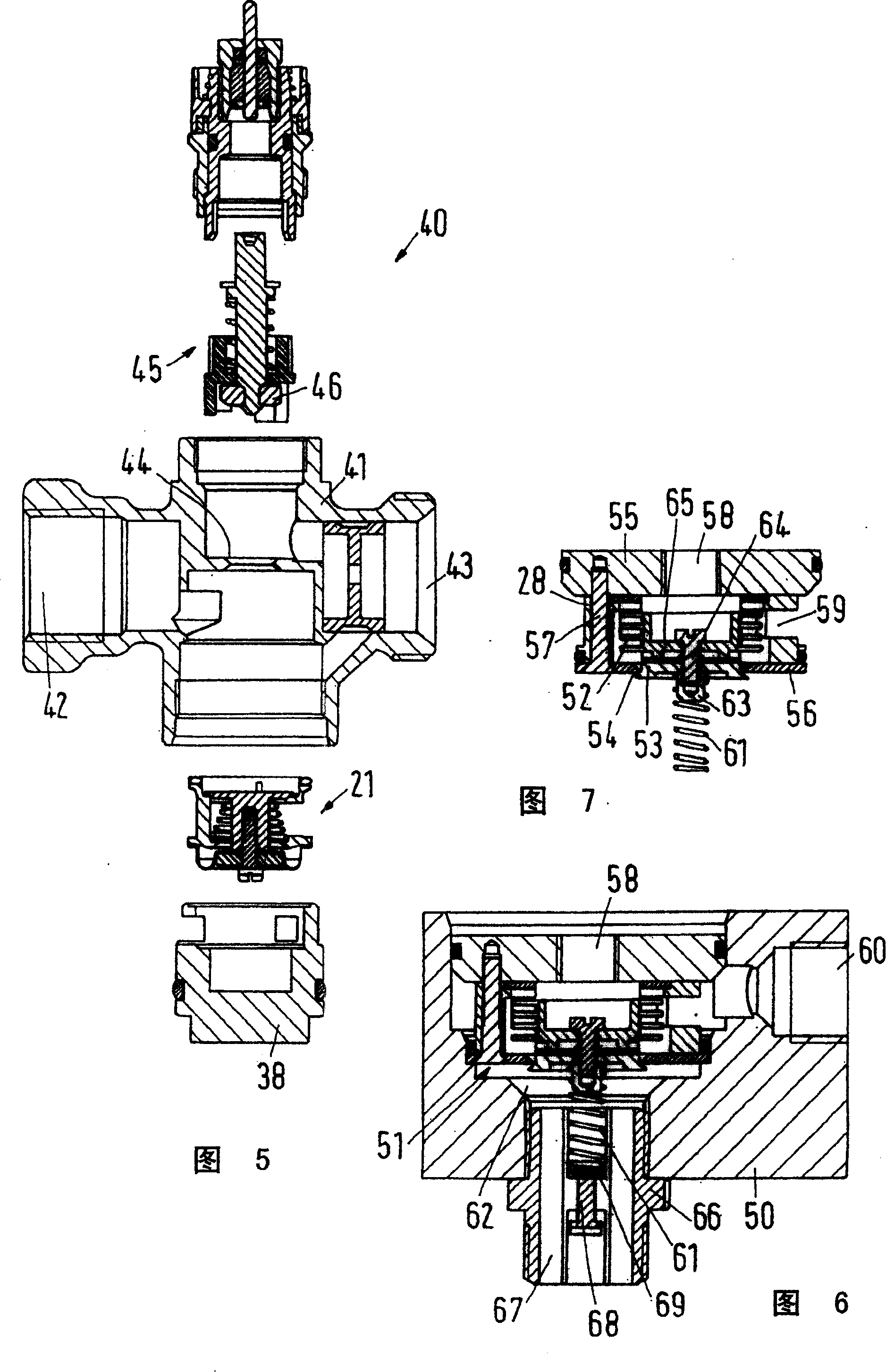

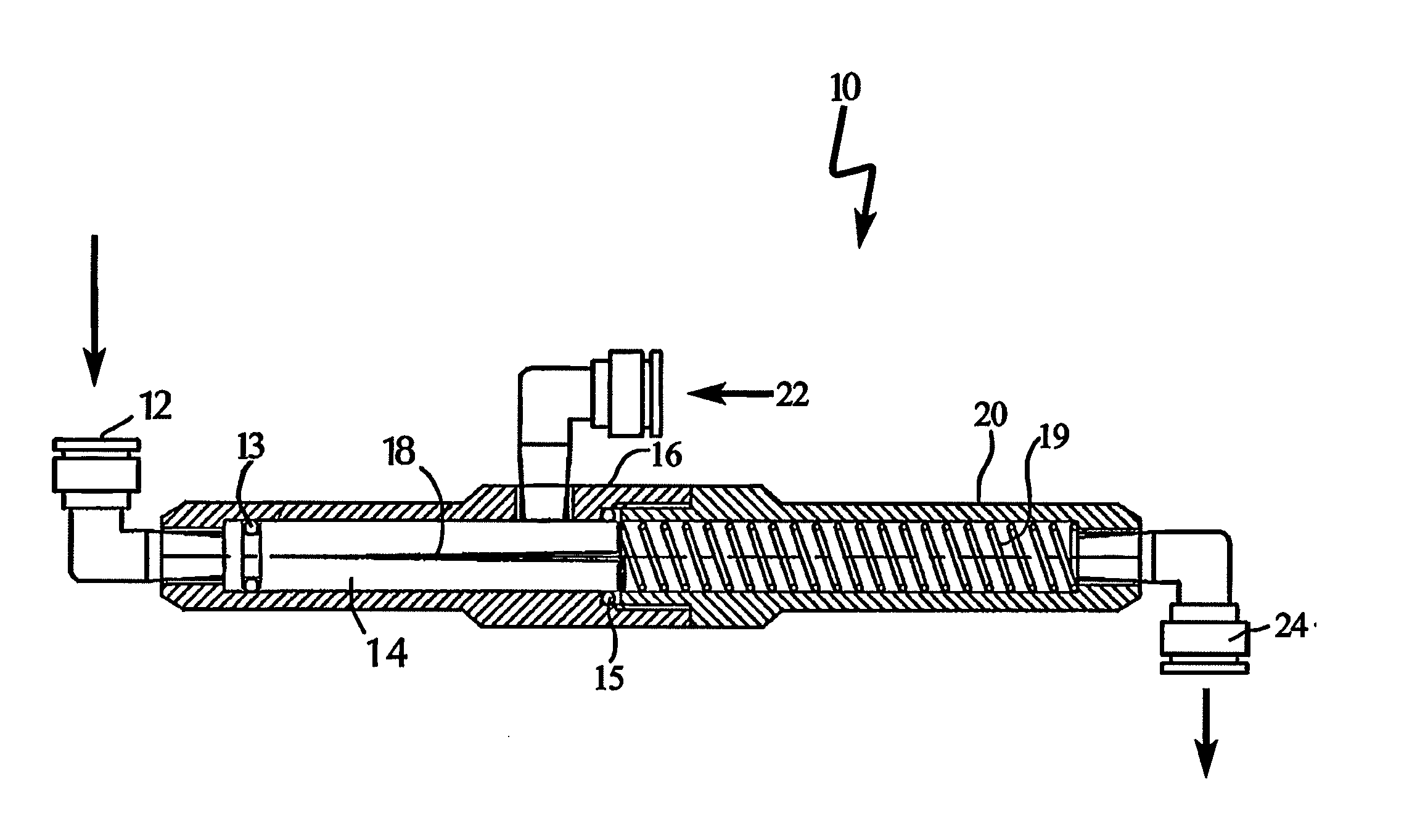

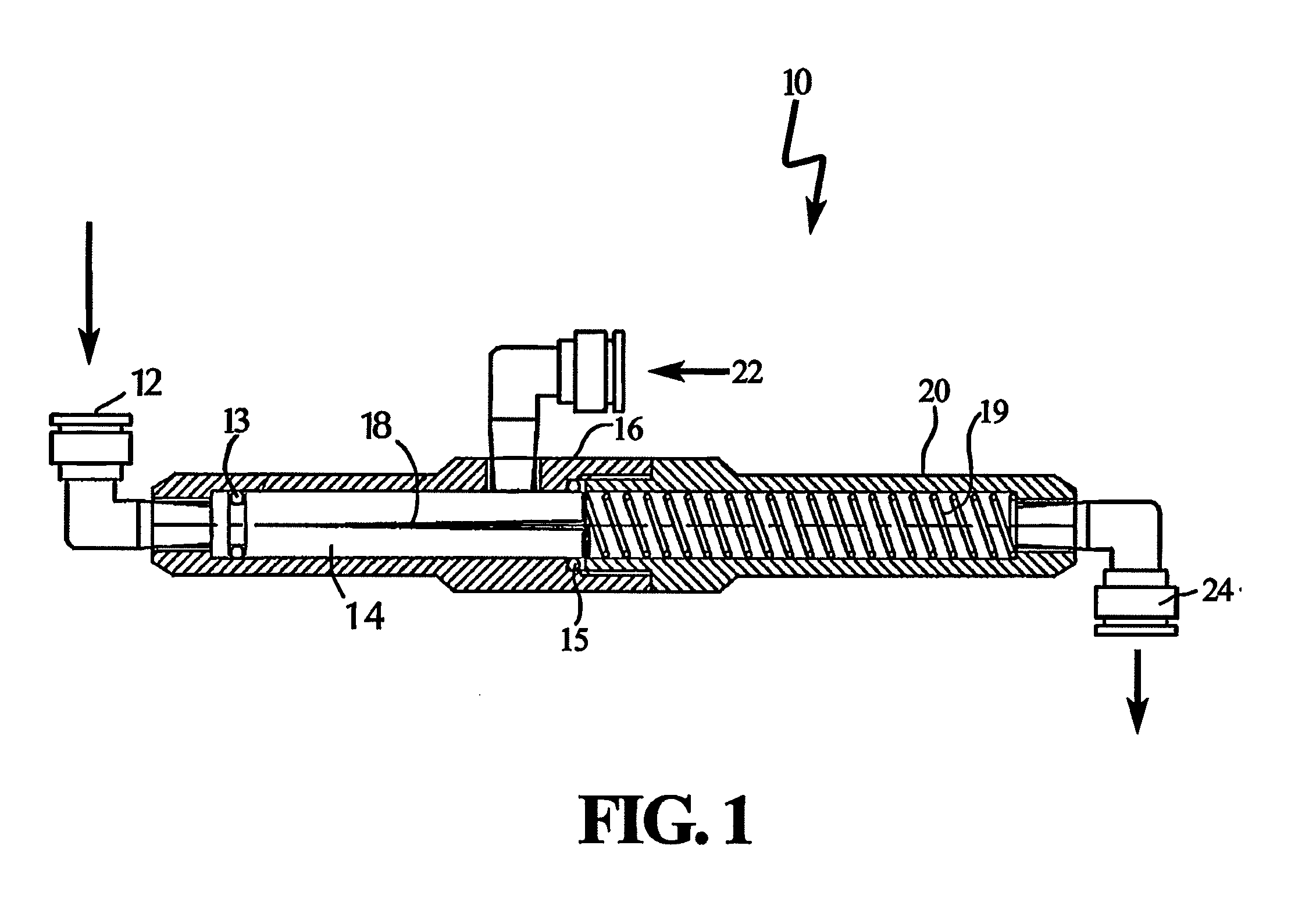

A differential pressure valve with parallel biasing springs and method for reducing spring surge

The invention relates to a differential pressure valve with parallel biasing springs and a method for reducing spring surge. The differential pressure valve is disclosed, comprising: a valve body (111), said valve body having at least one flow inlet (118) and one flow outlet (120); at least one shutter (112), said shutter being movable between an open position and a closed position under a differential pressure across the valve; a flow passage (126) from the flow inlet (118) to the flow outlet (120); at least one biasing member (114) configured to bias the shutter (112) towards a closed position so as to block the flow passage through the flow inlet (118). The biasing member (114) comprises at least two springs (114A, 114B) arranged in parallel, one of said springs having at least one resonance frequency different from at least one resonance frequency of the other of said two springs.

Owner:NUOVO PIGNONE TECH SRL

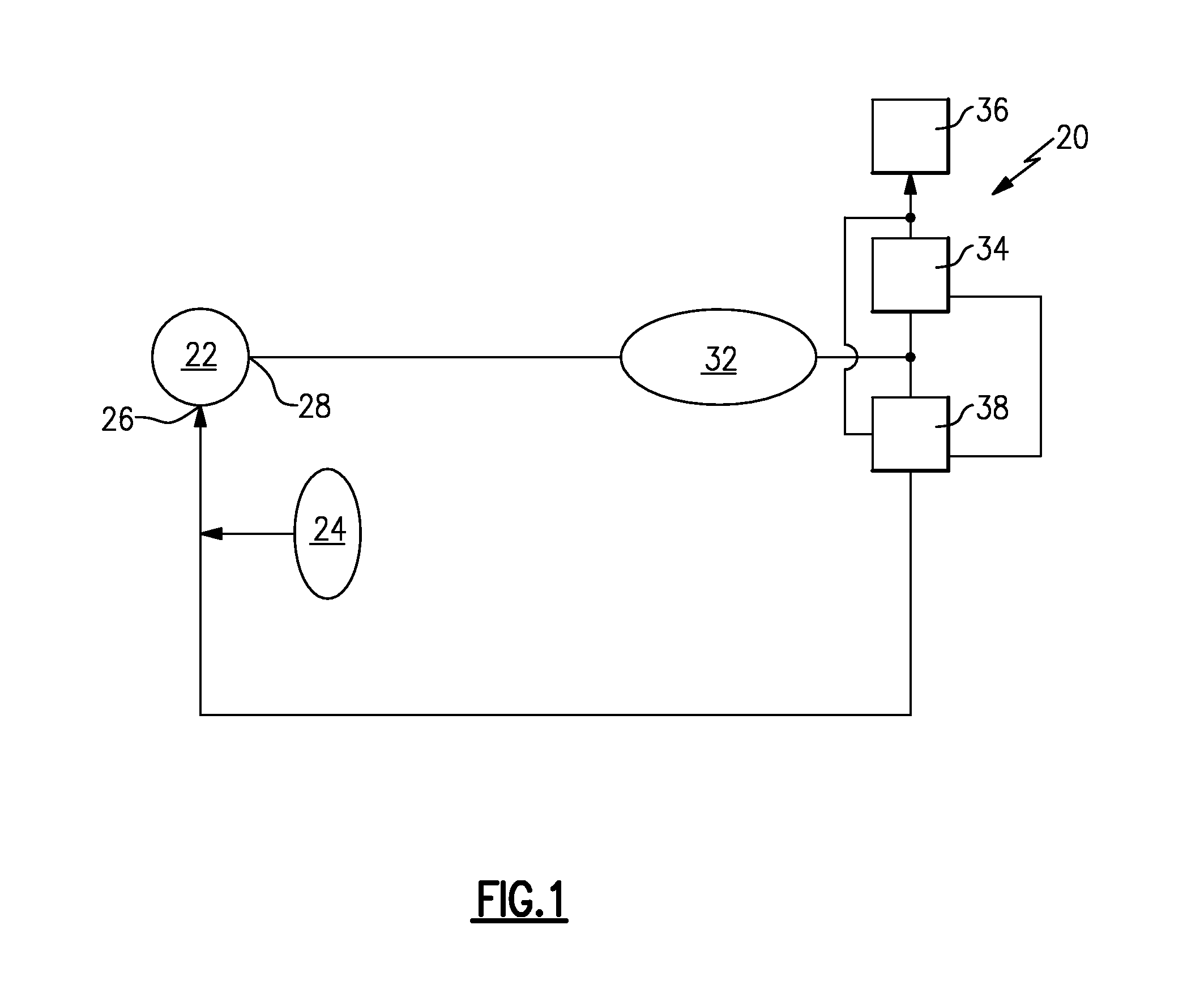

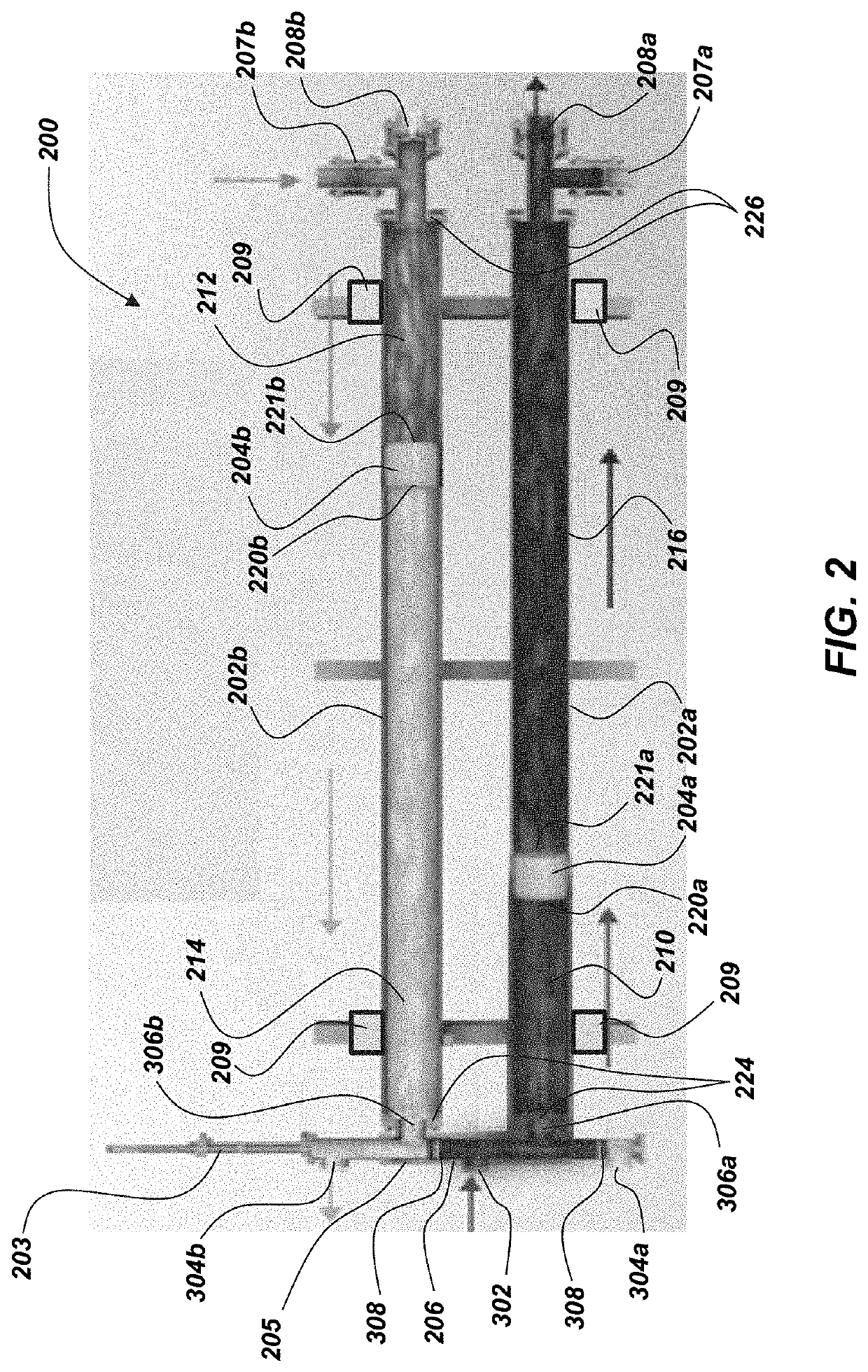

Fluid exchange devices and related systems, and methods

Devices and systems for exchanging properties between at least two fluid streams and related methods may include a valve device comprising a valve actuator configured to move at variable rates in order to selectively fill and empty at least one tank. Devices for exchanging properties between at least two fluid streams may include a valve device comprising staggered and overlapping openings positioned along a path of a valve actuator. The staggered and overlapping openings may be configured to selectively and gradually place an inlet in communication with at least one tank.

Owner:FLOWSERVE PTE LTD

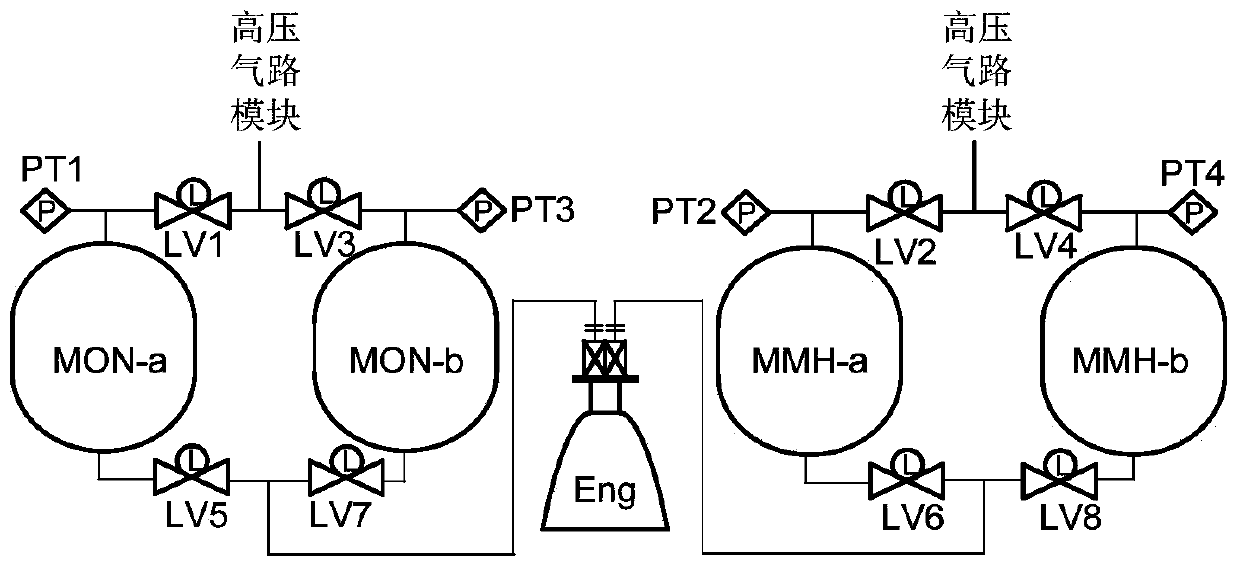

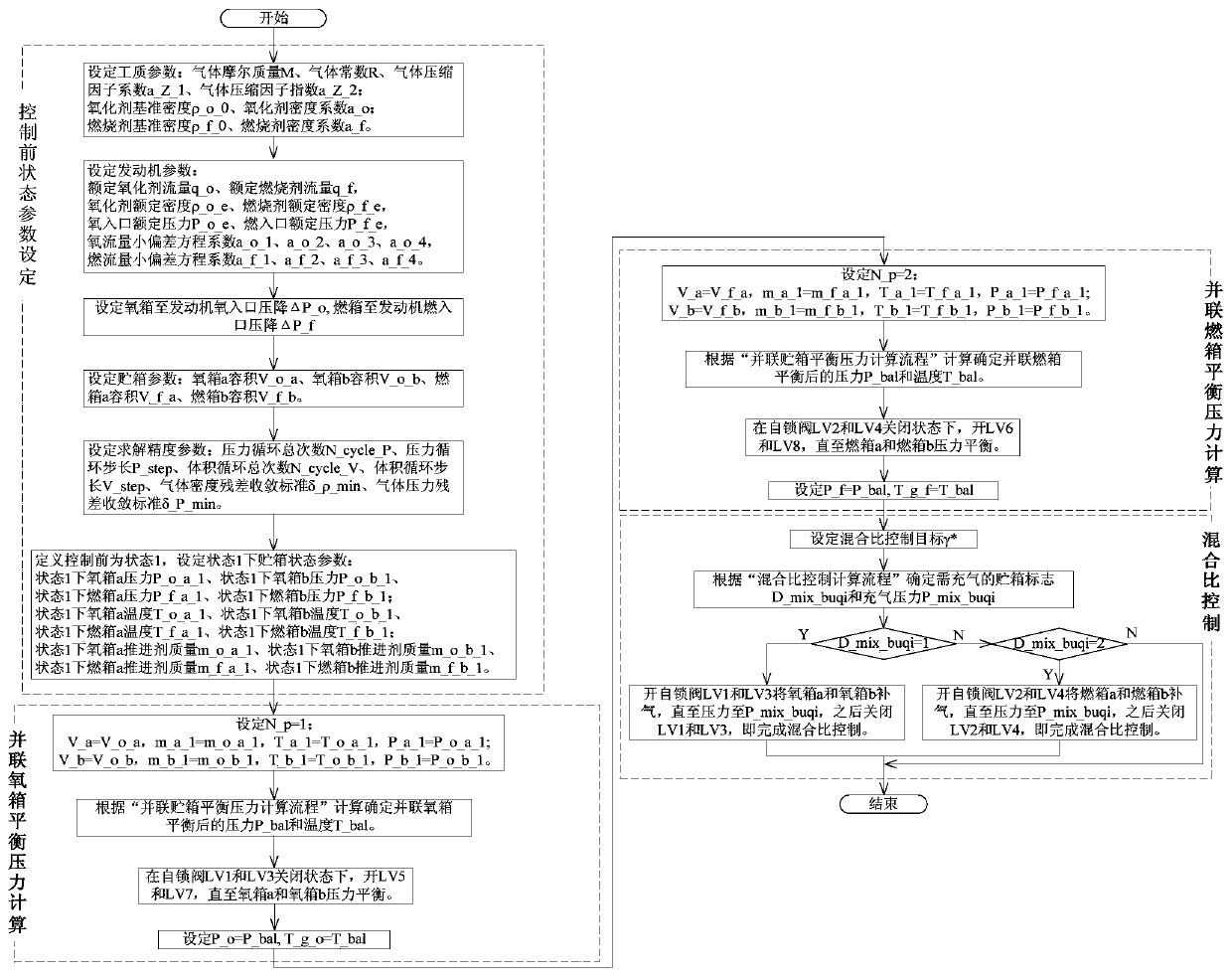

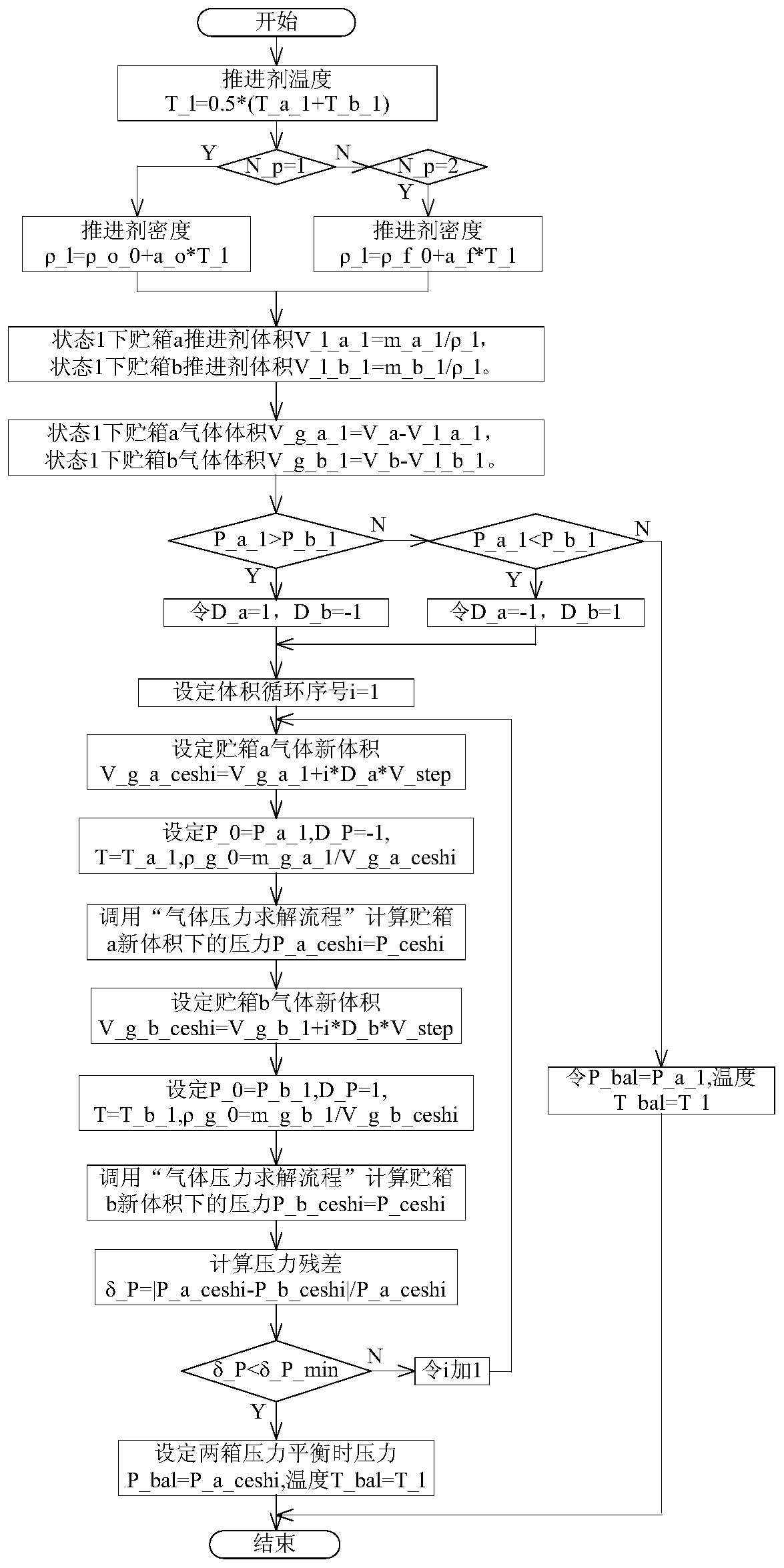

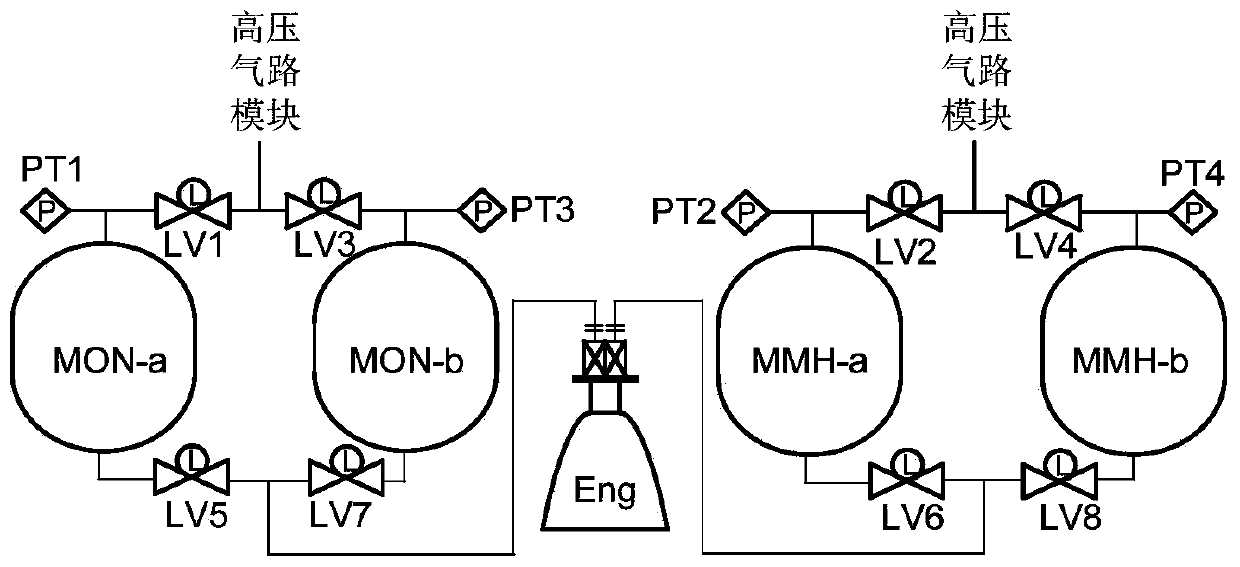

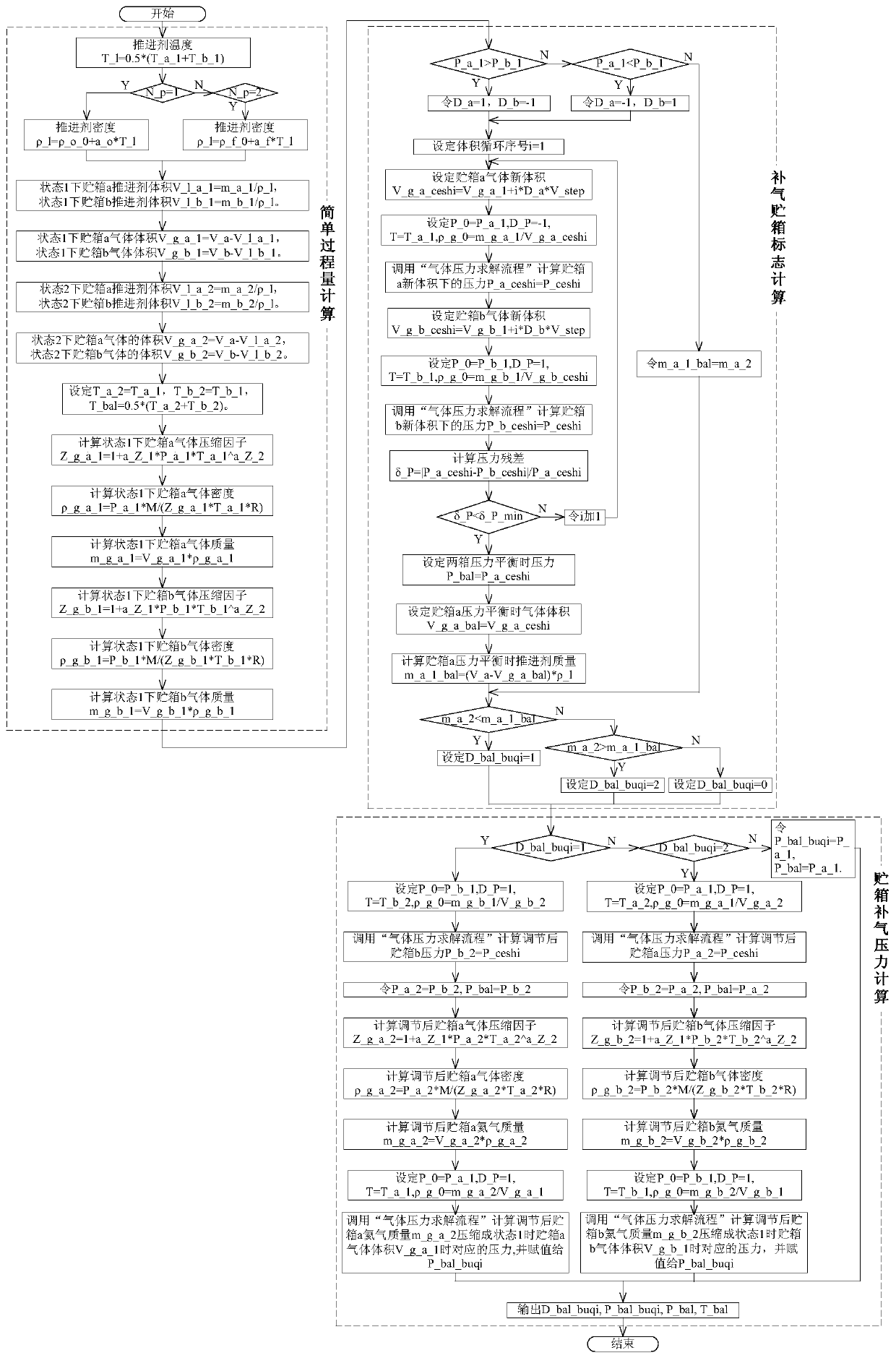

Propelling system mixing ratio control method considering parallel storage tank pressure difference

ActiveCN110525694AEfficient use ofThe mixing ratio is determinedCosmonautic vehiclesCosmonautic propulsion system apparatusCombustionState parameter

The invention discloses a propelling system mixing ratio control method considering parallel storage tank pressure difference. The method comprises the following steps of (1) setting a state parameterbefore controlling; (2) calculating the balance pressure of parallel oxidant tanks; (3) calculating the balance pressure of parallel combustion agent tanks; and (4) controlling the mixing ratio. According to the method, the actual on-orbit working condition that the pressure between the two parallel storage tanks is imbalance before the mixing ratio of a spacecraft parallel storage tank propelling system is controlled is considered, the calculation flow of the balance pressure between the two parallel storage tanks before mixing ratio control is given, the method is suitable for the state that the on-orbit pressure of the parallel storage tank propelling system is unbalanced, and the on-orbit efficient utilization of propellant is realized; and the main process and the sub-process are all-parametric, iterative loop, interpretation branch and other calculation modes are introduced, so that a calculation program is convenient to compile, and then the time for determining a control parameter is reduced.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

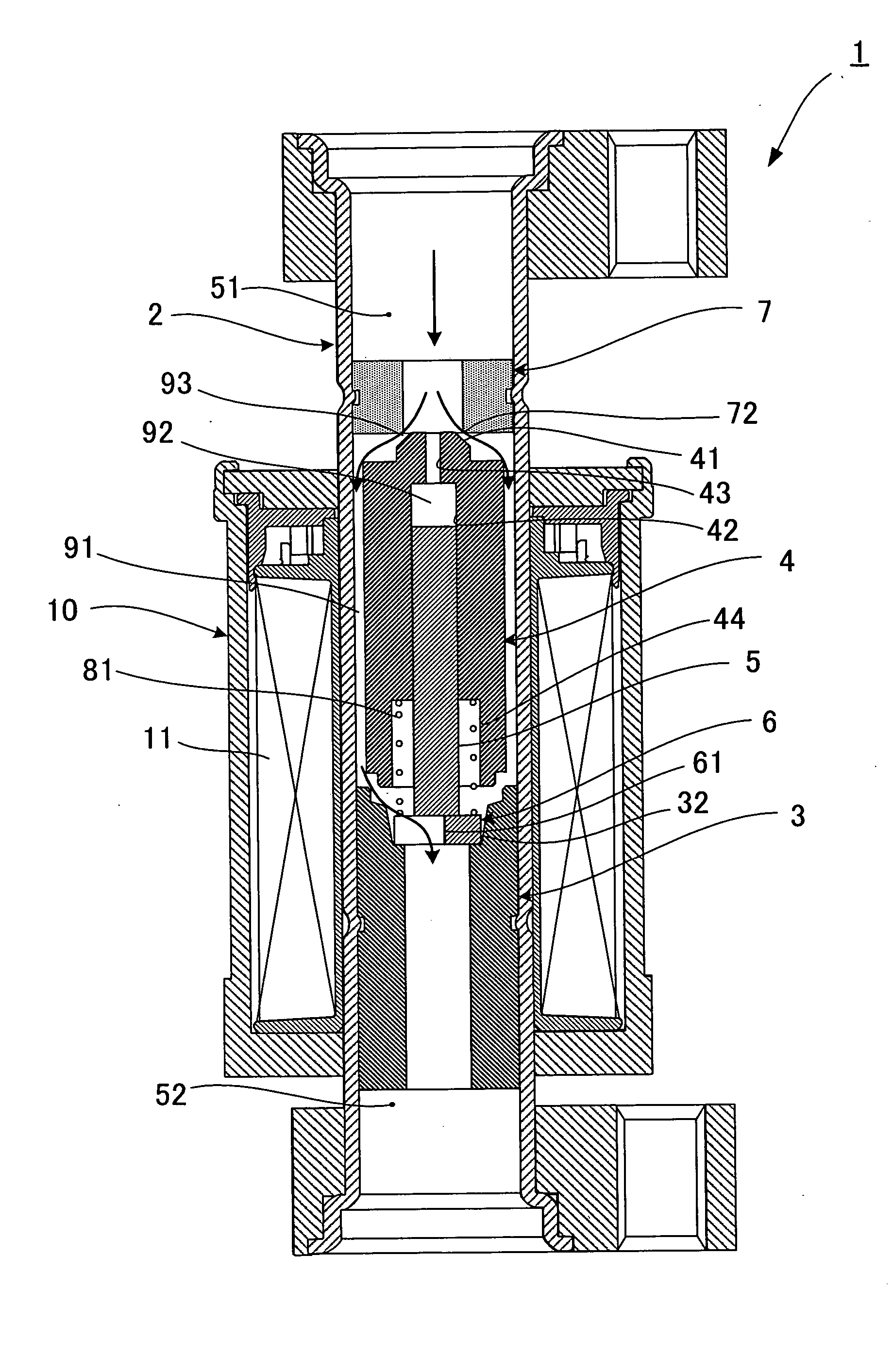

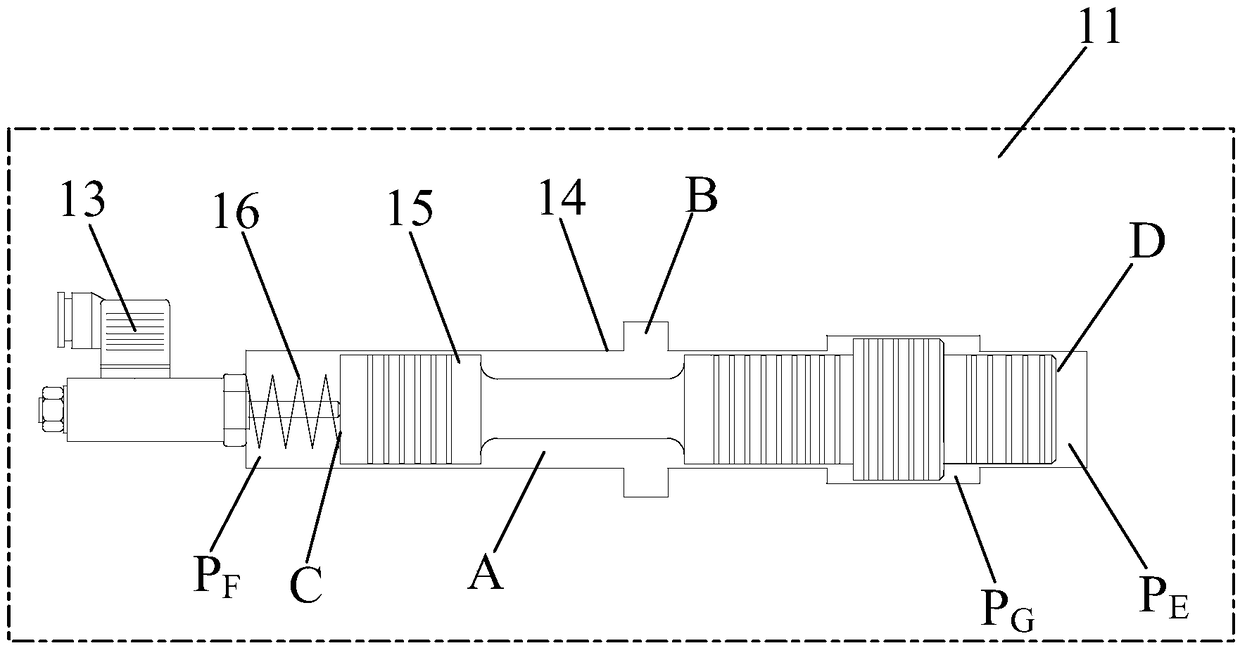

Pressure regulating valve

InactiveUS20150059878A1Suppress mutationOperating means/releasing devices for valvesInternal combustion piston enginesActuatorPiston

A pressure regulating valve includes a device body and an actuator. The device body includes a valve seat member, a valve, which is capable of closing the first opening of the valve seat member, an urging member, which urges the valve toward the valve seat member, a piston arranged opposite to the valve across the valve seat member, an actuator, which adjusts the position of the piston, and a protrusion provided on at least one of the piston and the valve. When the tip end of the protrusion comes into contact with the piston or the valve, the second opening of the second fluid passage is closed. When the tip end of the protrusion is not in contact with any of the piston and the valve and the second opening is opened, the second fluid passage is in communication with the pressure regulation chamber.

Owner:AISAN IND CO LTD

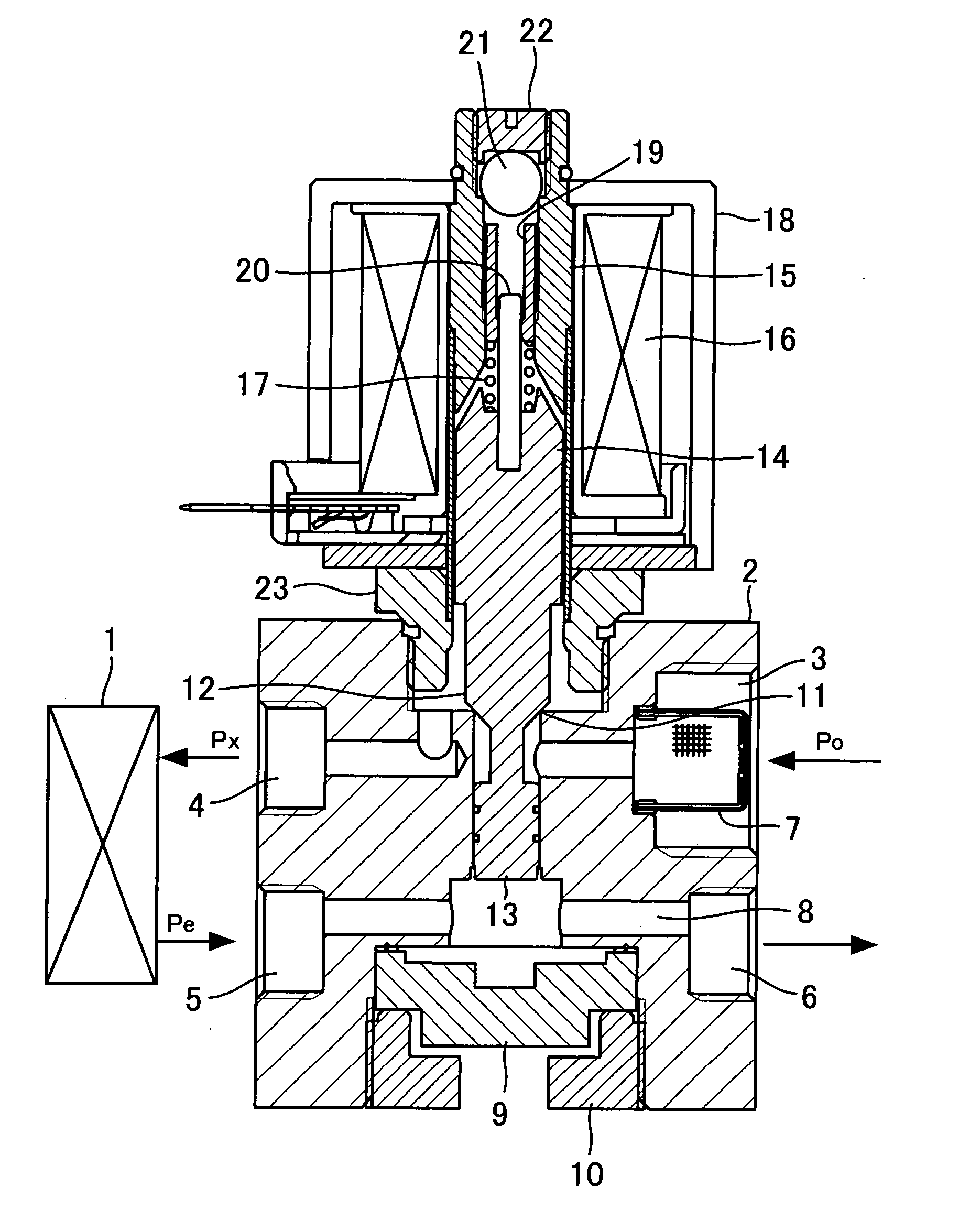

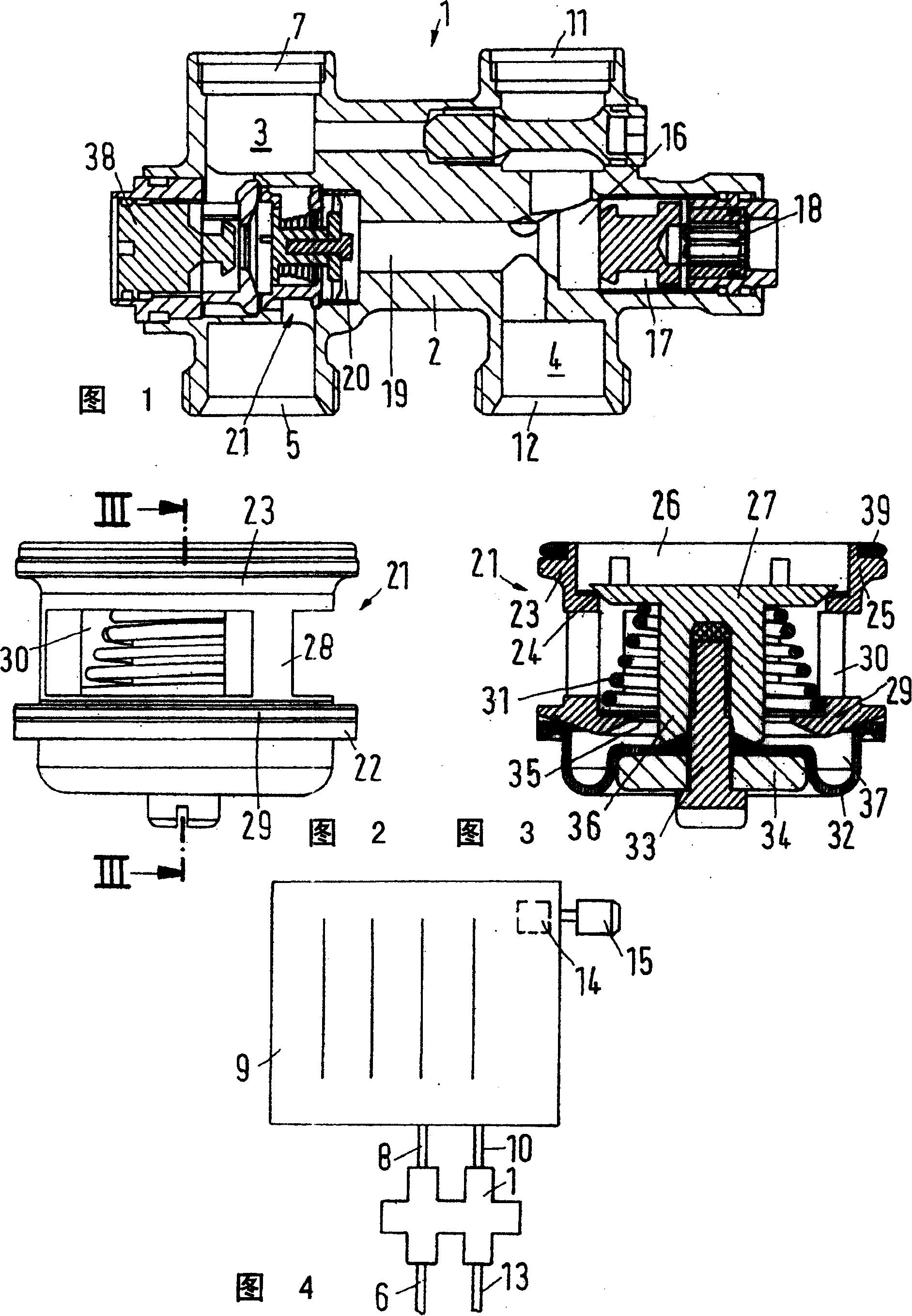

Constant differential pressure valve

InactiveUS7047763B2Small sizeLow costOperating means/releasing devices for valvesCompression machines with non-reversible cycleDifferential pressureEngineering

To provide a constant differential pressure valve which is compact in size and can be realized at low cost.In the constant differential pressure valve according to the present invention, a pipe forming a body thereof not only accommodates internal structures, such as a differential pressure control mechanism, a movable core, and a fixed core, but also serves as part of piping of a refrigeration cycle. Further, a solenoid section including a solenoid coil is disposed outside the pipe in a manner surrounding the same. Therefore, substantial integration of the differential pressure control mechanism into the piping of the refrigeration cycle can be achieved, which makes the entire constant differential pressure valve very simple in construction. As a result, reduction of the size of the constant differential pressure valve and resultant reduction of material costs and manufacturing costs can be achieved, which makes it possible to achieve low costs of the constant differential pressure valve.

Owner:TGK

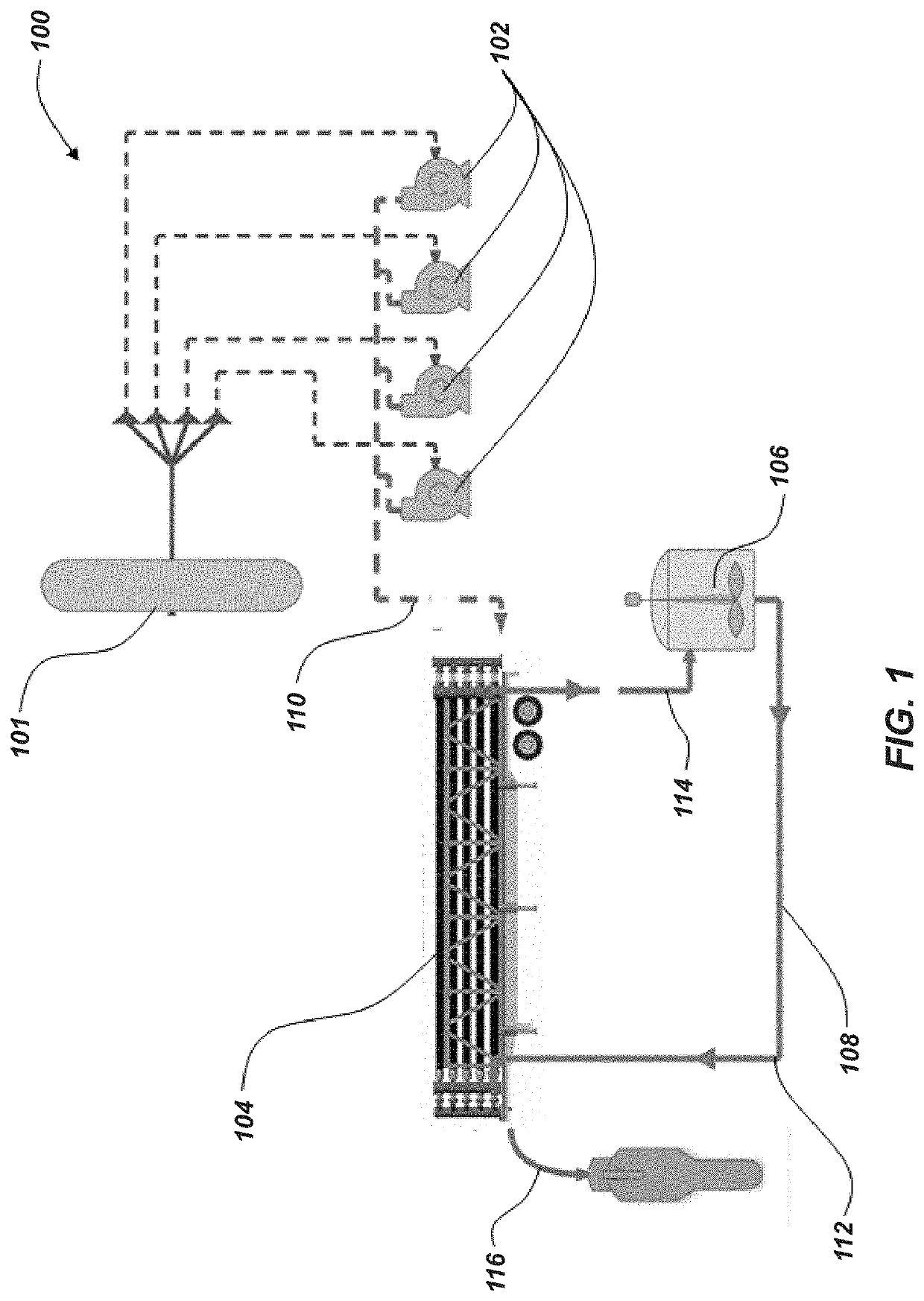

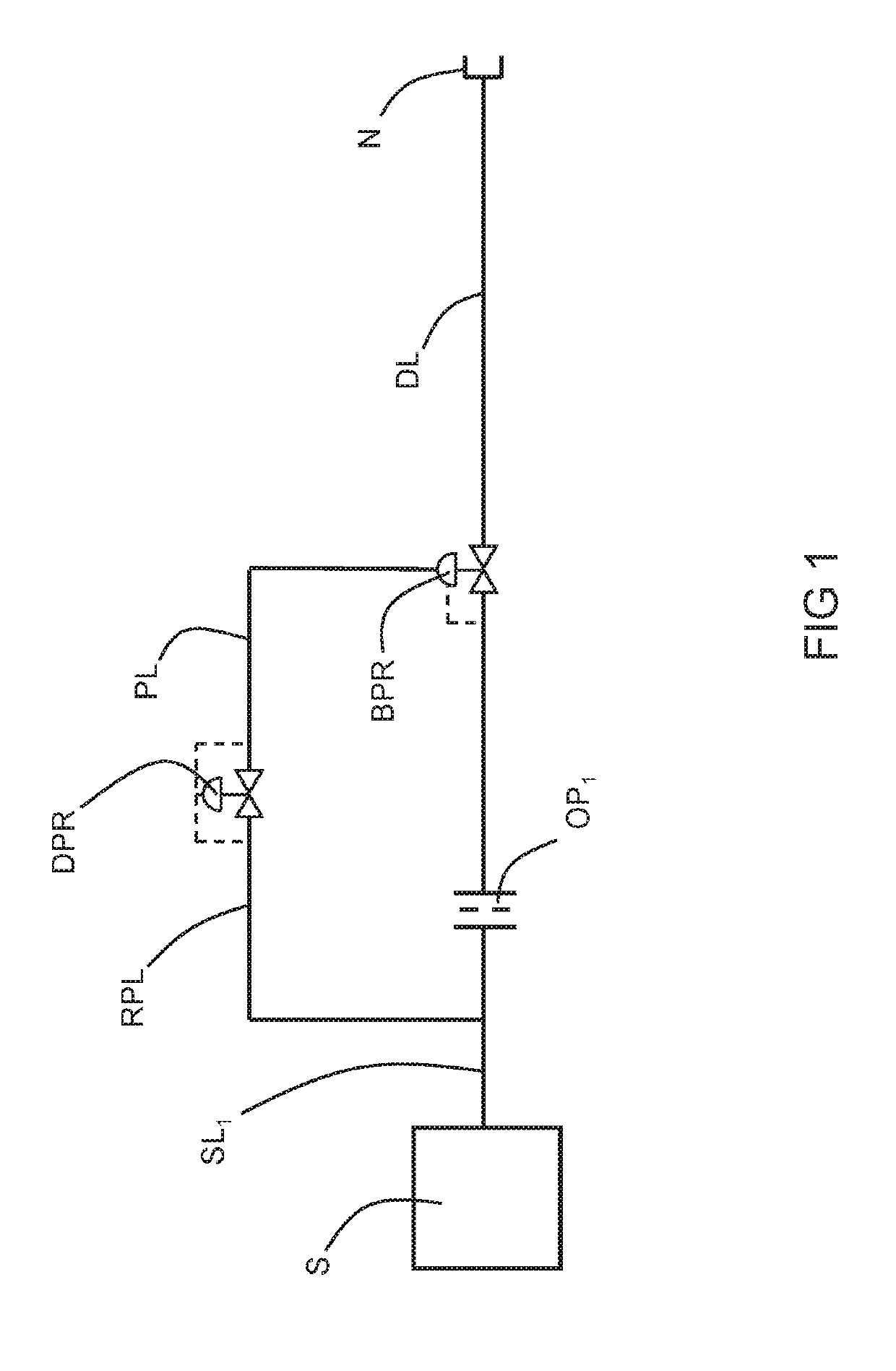

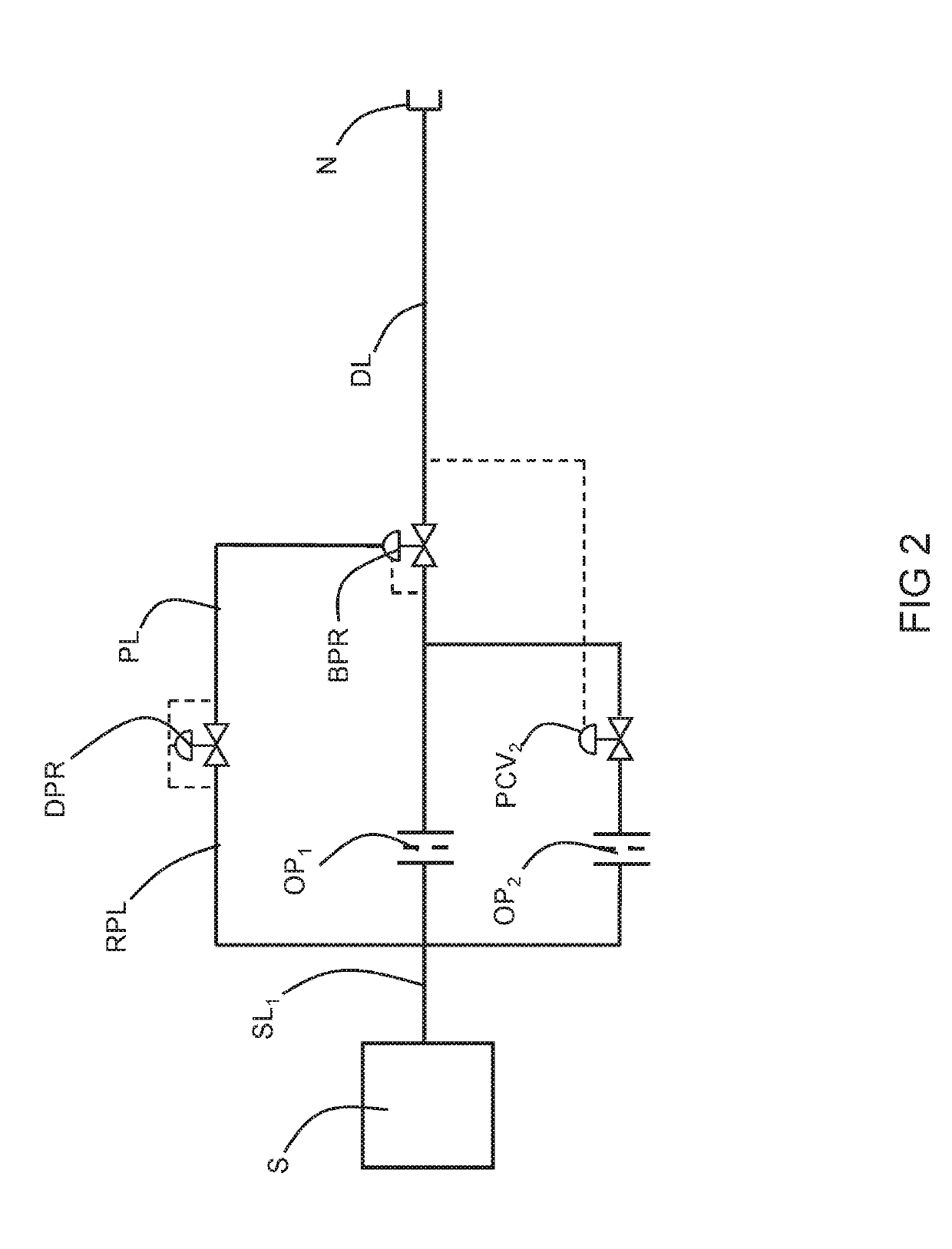

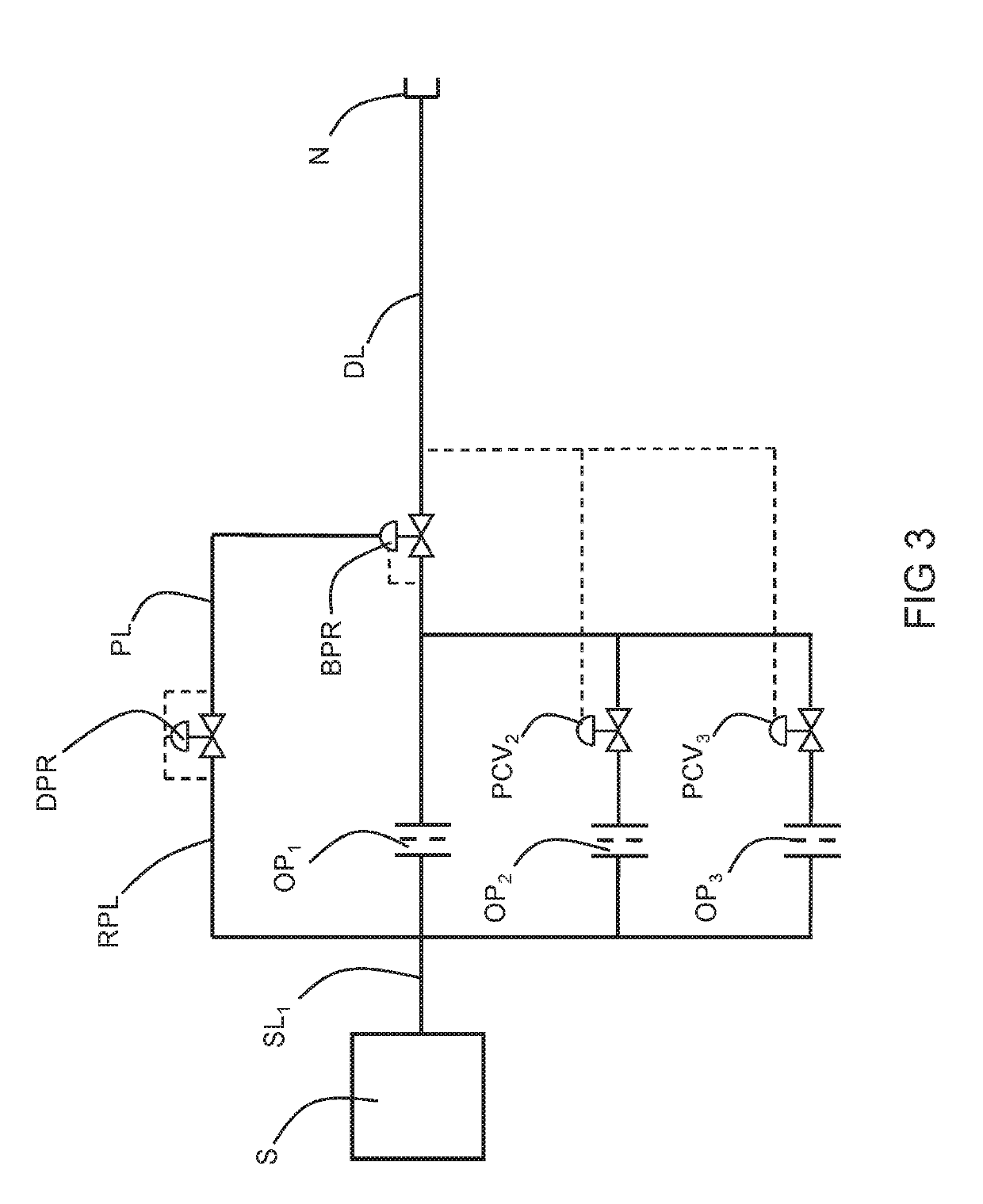

Mobile hydrogen dispenser for fuel cell vehicles

ActiveUS20190271439A1Vessel mounting detailsGas handling applicationsDifferential pressureEngineering

A mobile dispenser may be used to at least partially fill hydrogen tanks of fuel cell-powered vehicles. The dispenser uses a purely mechanical control of the fill using an orifice plate across which a pressure differential is maintained through use of a backpressure regulator whose reference pressure is controlled by a differential pressure regulator. Because it does need or use electrical power, it may be used in situations where no electrical power is available or convenient.

Owner:AIR LIQUIDE ADVANCED TECH U S

Differential pressure valve with parallel biasing springs and method for reducing spring surge

ActiveUS20140014190A1Avoid spreadingReduce inhibitionOperating means/releasing devices for valvesSpringsDifferential pressureResonance

A differential pressure valve is disclosed, comprising: a valve body, the valve body having at least one flow inlet and one flow outlet; at least one shutter, the shutter being movable between an open position and a closed position under a differential pressure across the valve; a flow passage from the flow inlet to the flow outlet; at least one biasing member configured to bias the shutter towards a closed position so as to block the flow passage through the flow inlet. The biasing member comprises at least two springs arranged in parallel, one of the springs having at least one resonance frequency different from at least one resonance frequency of the other of the two springs.

Owner:NUOVO PIGNONE TECH SRL

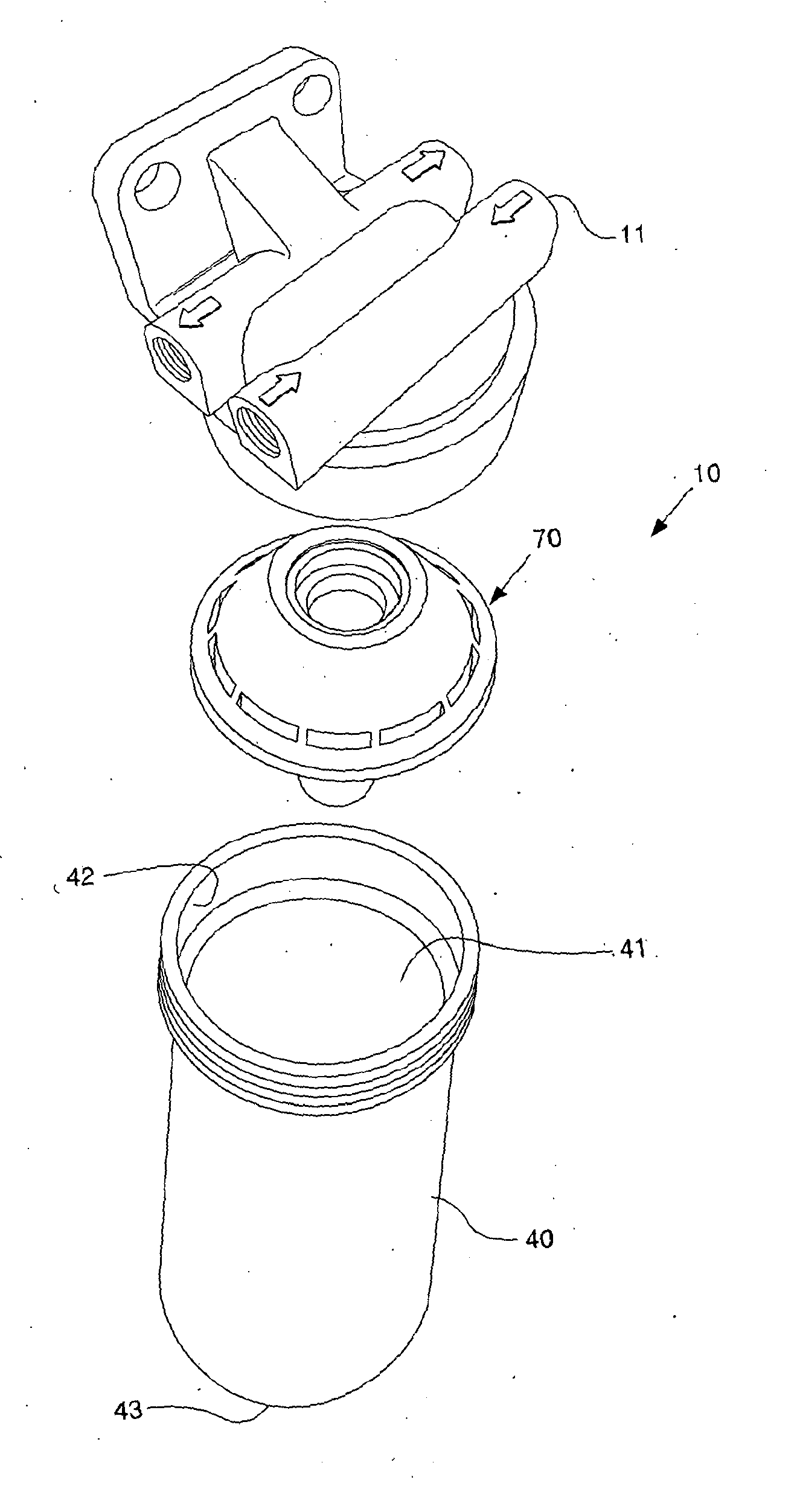

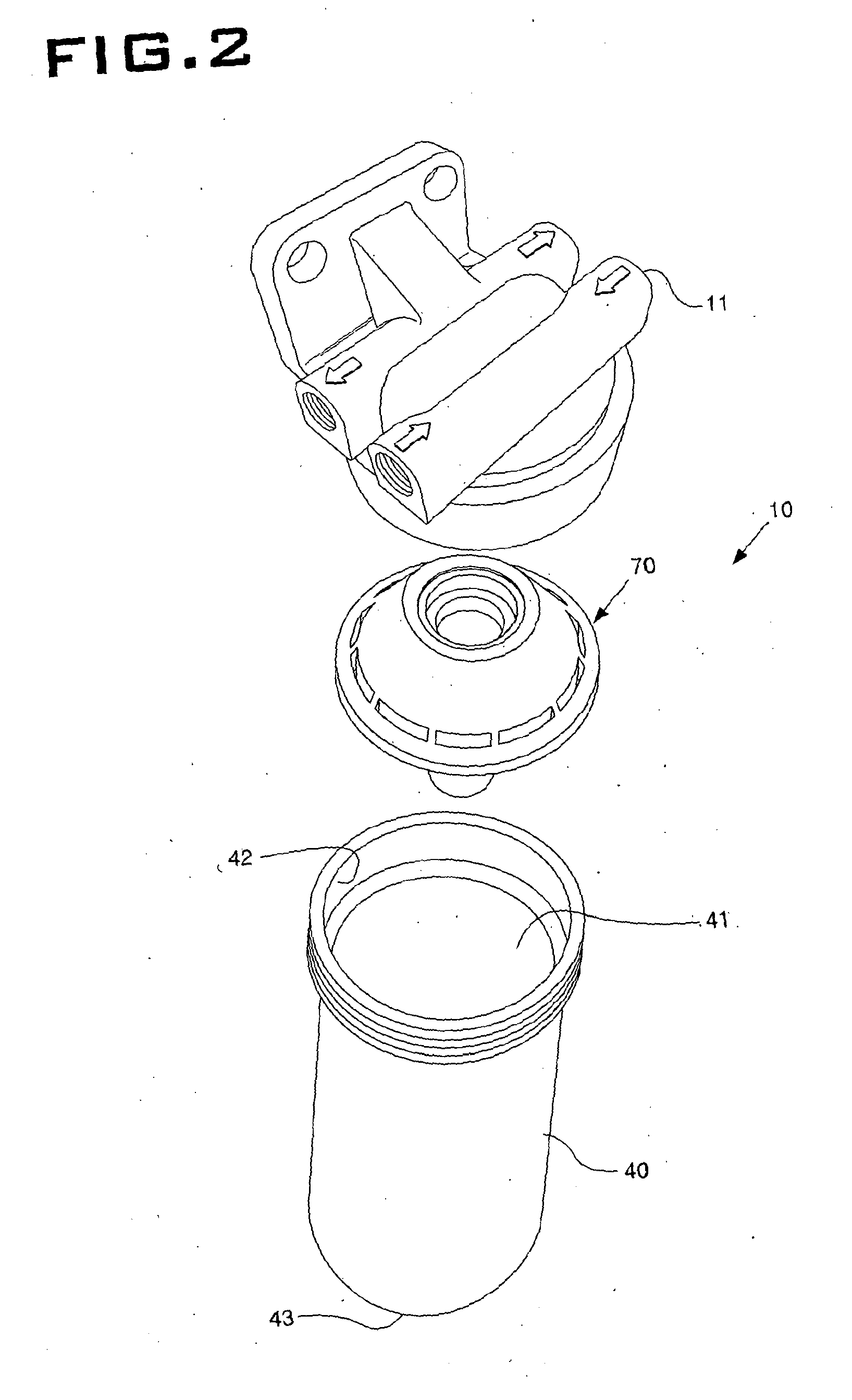

Pressurization Device

InactiveUS20140352675A1Non-fuel substance addition to fuelInternal combustion piston enginesBiomedical engineeringLubricant

The present disclosure relates to an apparatus (10) for pressurizing a first substance, such as a liquid, gas or particulate material, to a pressure substantially equal or similar to the pressure of a second substance, i.e. a reference substance. The pressure of the reference substance may be transient so the pressure of the first substance must be varied accordingly. The present disclosure includes a bladder (71) disposed within a sealed can (40), an inlet passage (24a) in communication with the interior (41) of the can and an outlet passage (26a) in communication with the interior of bladder (71). The reference substance may be directed into the interior (41) of the can (40) via the inlet passage (24a) and pressurizes the bladder (71) and thus the first substance stored therein, thereby causing the first substance to be expelled via the outlet passage (26a) with a pressure substantially corresponding to that of the reference substance. Many applications exist that require two substances to be of a similar pressure. For example, an engine may be adapted to run on low lubricity fuel provided a pressurized lubricant is introduced to the pressurized fuel before being directed towards the injector.

Owner:PERKINS ENGINES

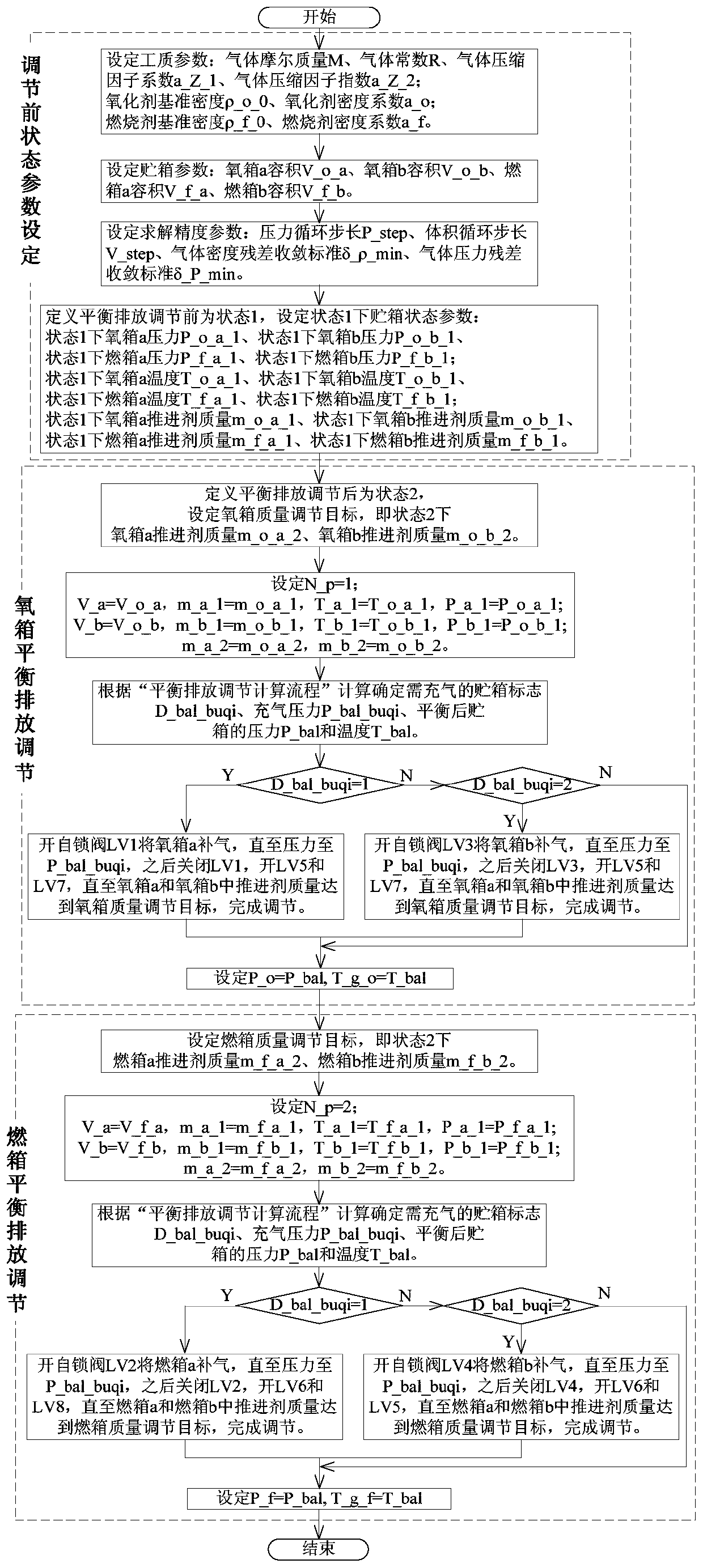

Comprehensive balance discharge adjustment method for parallel tank propulsion system

ActiveCN110525693AAdapt to the needs of comprehensive balance adjustmentEasy to identifyCosmonautic vehiclesCosmonautic propulsion system apparatusOxygen tankState parameter

The invention discloses a comprehensive balance discharge adjustment method for a parallel tank propulsion system. The adjustment method comprises the following steps of (1), setting state parametersbefore adjustment, (2) performing oxygen tank balance discharge adjustment, and (3) performing fuel tank balance discharge adjustment. According to the comprehensive balance discharge adjustment method, the fact that the actual installation positions of spacecraft parallel tanks are discrepant is considered, and the mass of residual propellant in the two tanks after adjustment is independent of the mass before adjustment in the process of balance discharge adjustment of the parallel tank propulsion system so that comprehensive balance adjustment requirements of 'propellant mass * tank axis distance' can be realized and adapted. A main process and a sub process are fully parameterized, and an iterative cycle, an interpretation branch and other calculation methods are introduced so as to facilitate programming of the calculation program, thus reducing the time for determining control parameters.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

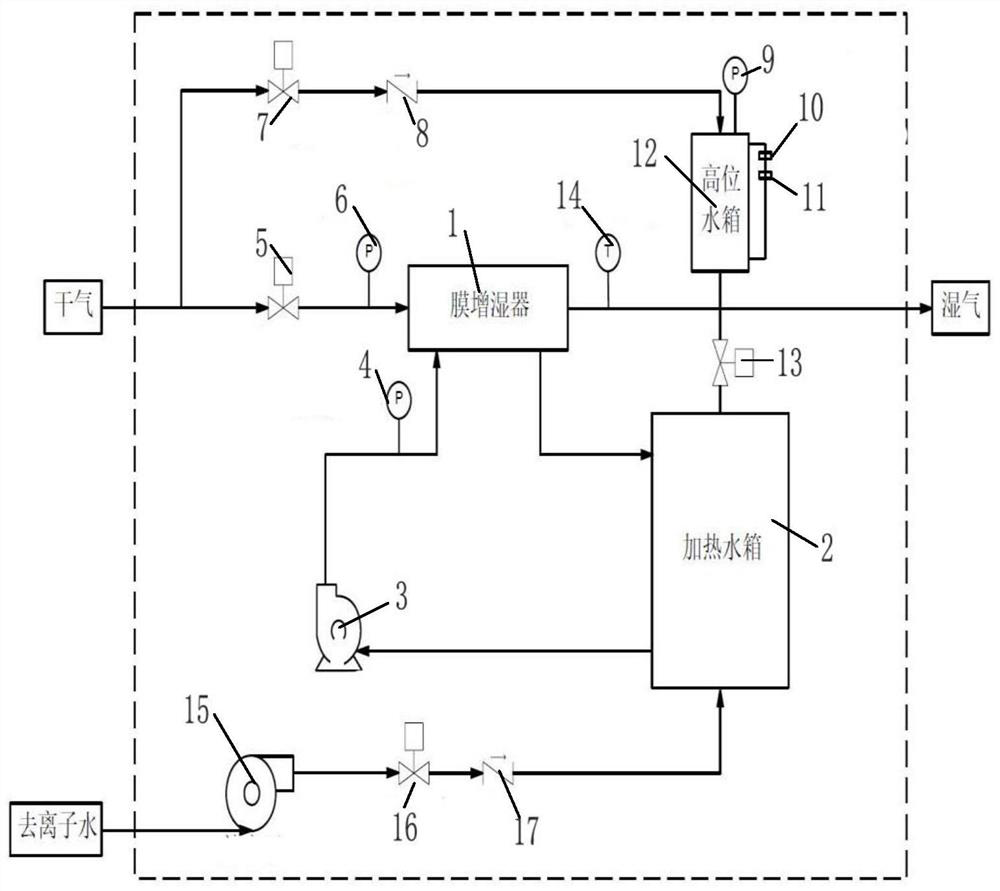

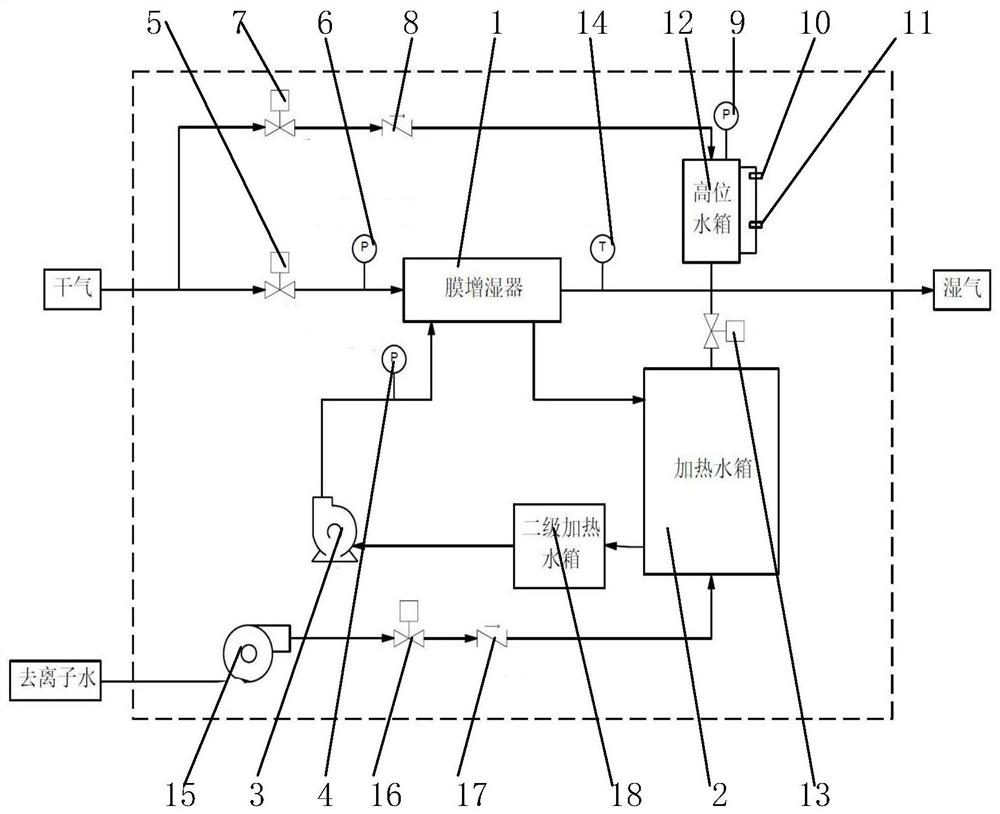

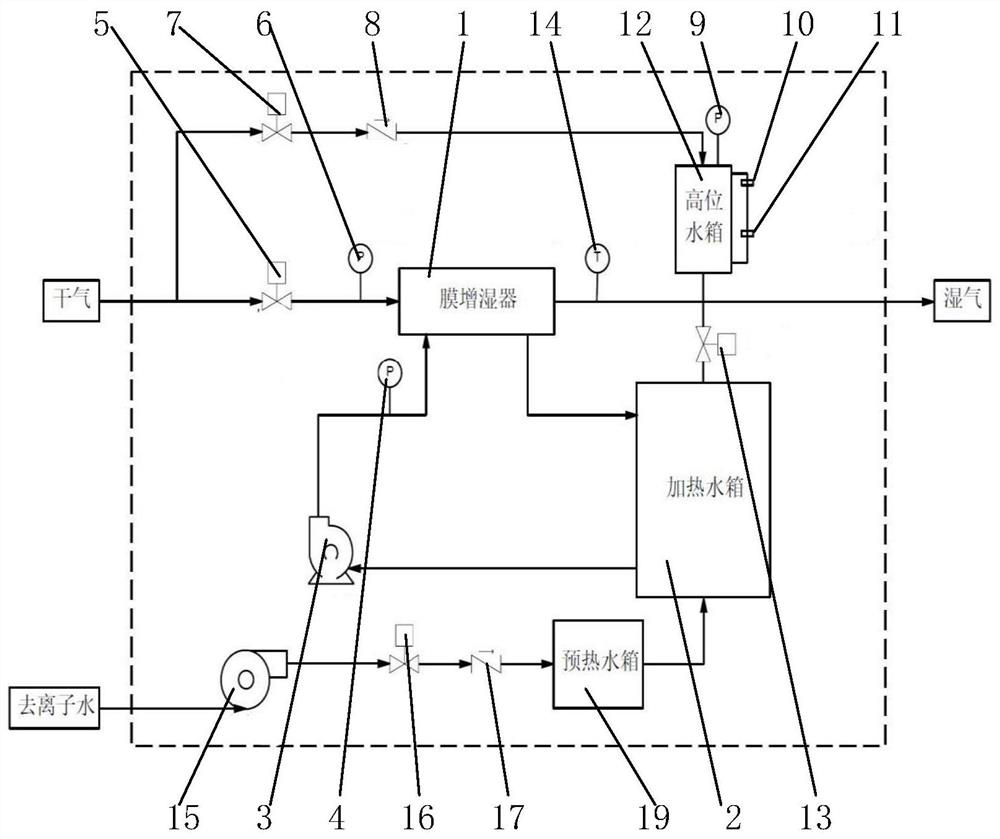

Fuel cell humidifying system pressure self-adaptive balancing method based on membrane humidifying

ActiveCN111883803ASolve frequent failuresImprove reliabilityPressure difference controlFuel cellsFuel cellsProcess engineering

The invention relates to a fuel cell humidifying system pressure self-adaptive balancing method based on membrane humidification in the technical field of fuel cell testing. A membrane humidifier is applied to a fuel cell test board humidifying system, the power consumption of a test board can be greatly reduced, the structure of the test board is simplified, and the size of the test board is reduced. By the adoption of the pressure balance self-adaptive control method, rapid and automatic balance of pressure at the two sides of gas and water of the membrane humidifier can be achieved, so thatthe failure rate of the membrane humidifier due to pressure imbalance is greatly reduced, and the reliability of the fuel cell test board adopting the membrane humidifier as a humidifying scheme is improved. The method provided by the invention can be applied to the fuel cell test board and also can be applied to the fuel cell system integration.

Owner:SHANGHAI JIAO TONG UNIV

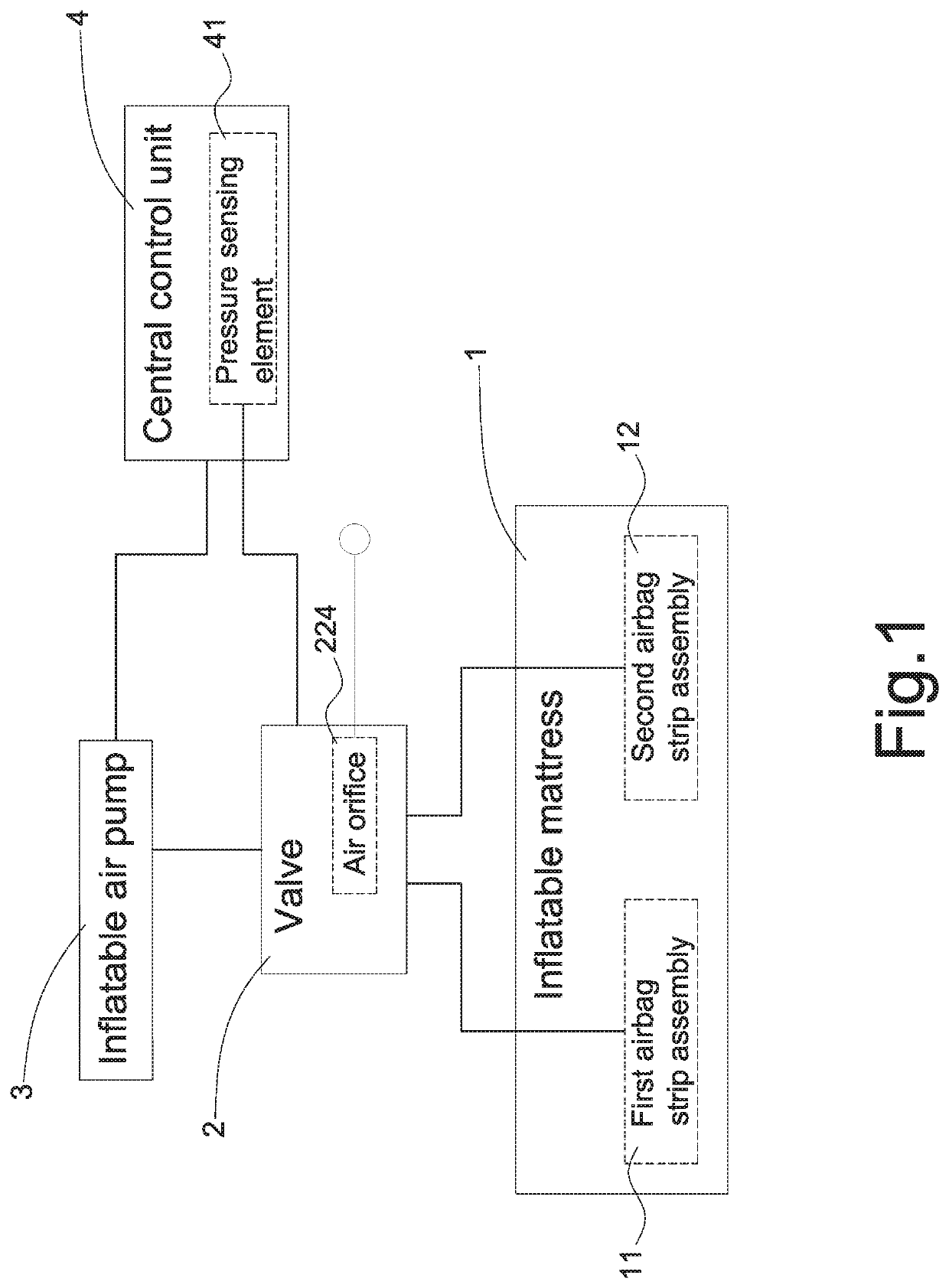

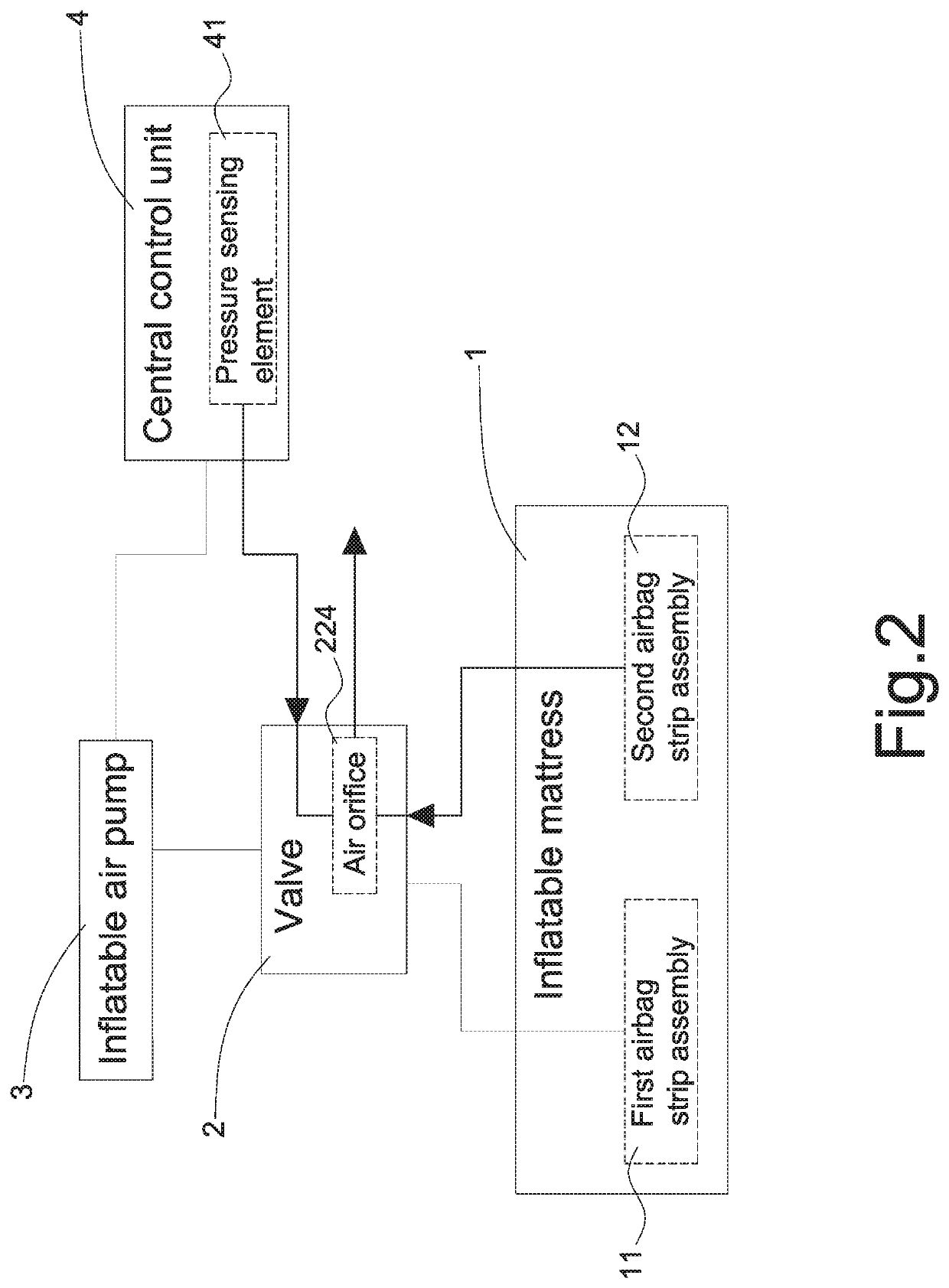

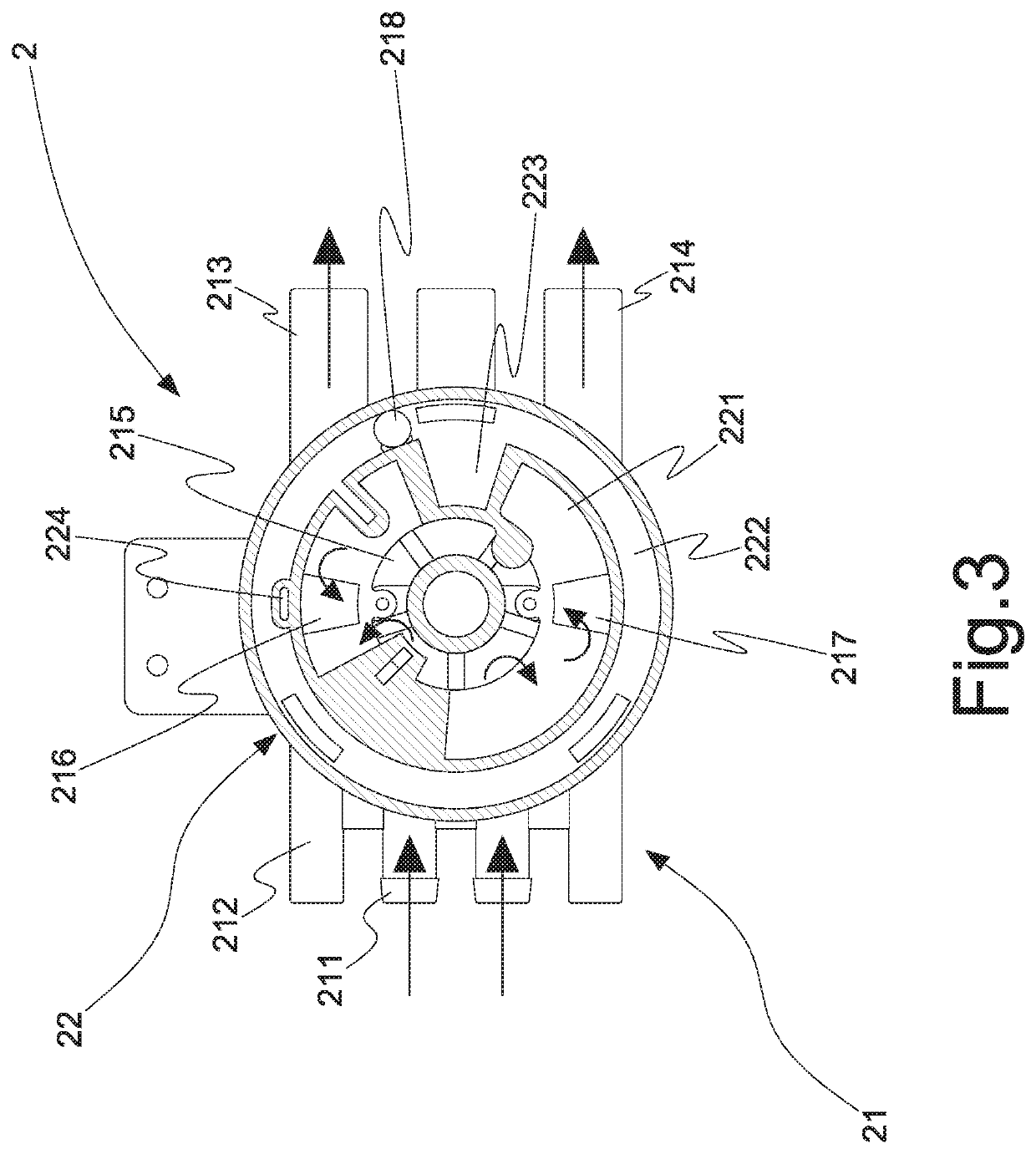

Pressure reference resetting structure of inflatable mattress

A pressure reference resetting structure of an inflatable mattress, the inflatable mattress contains a valve connected with an end of the inflatable mattress, an inflatable air pump connected with the valve, and the valve being connected with a pressure detection pipe which is coupled with a pressure sensing element. The valve includes an air orifice communicated with the pressure detection pipe so that the pressure sensing element detects a pressure of an external environment via the pressure detection pipe and the air orifice, and a reference pressure of the inflatable mattress is reset to inflate the inflatable mattress based on the reference pressure.

Owner:WU SHANG NENG

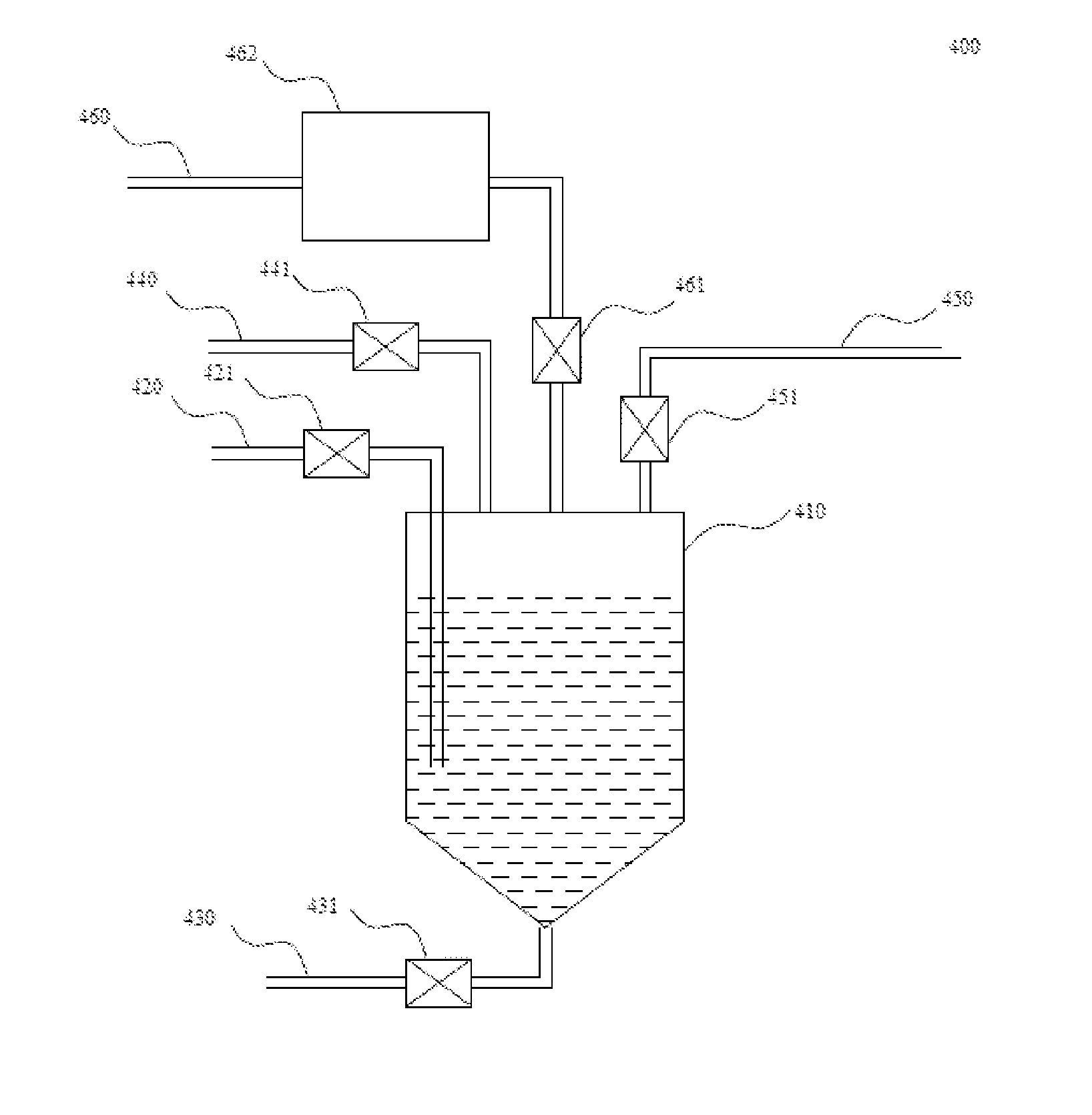

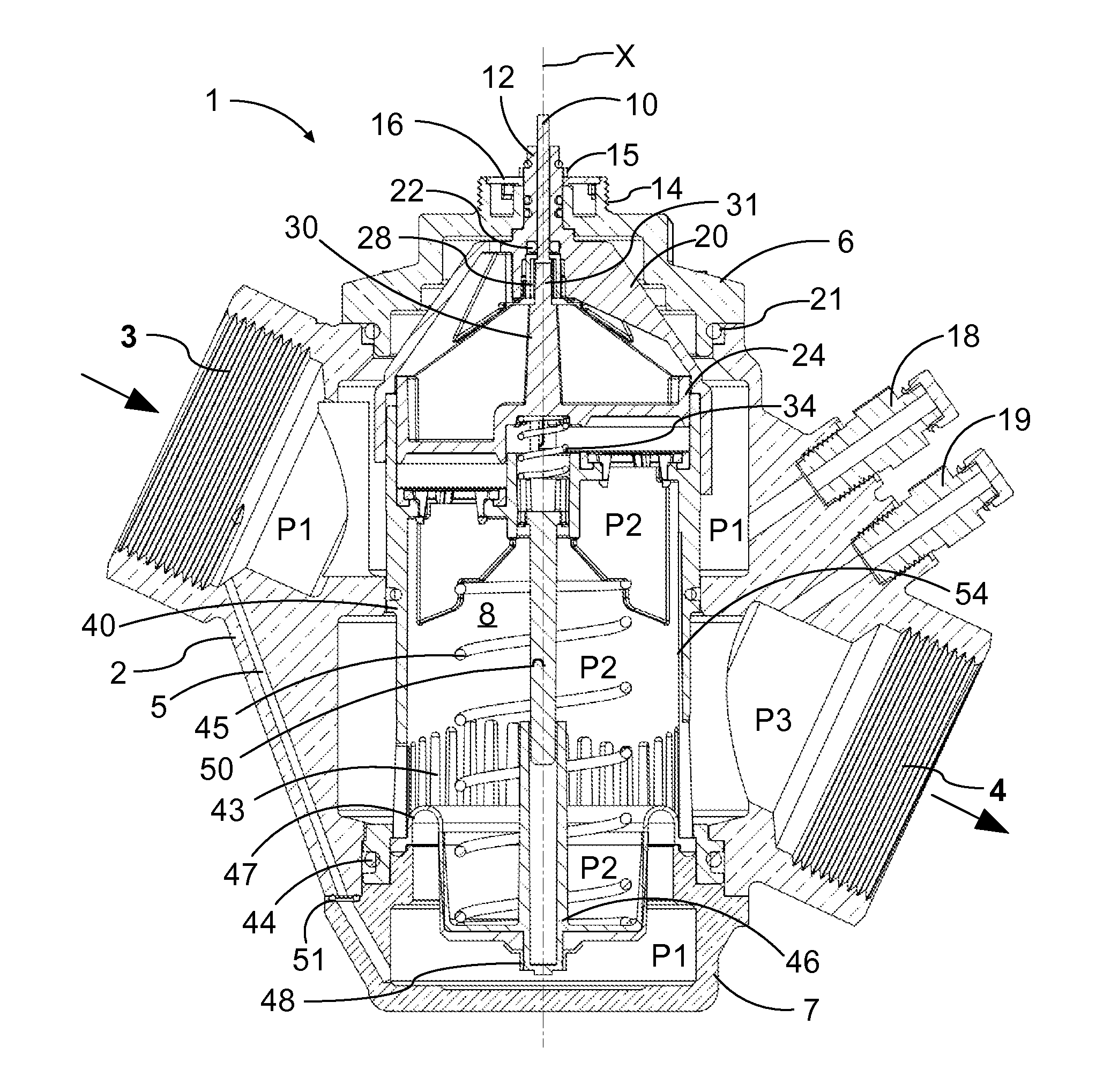

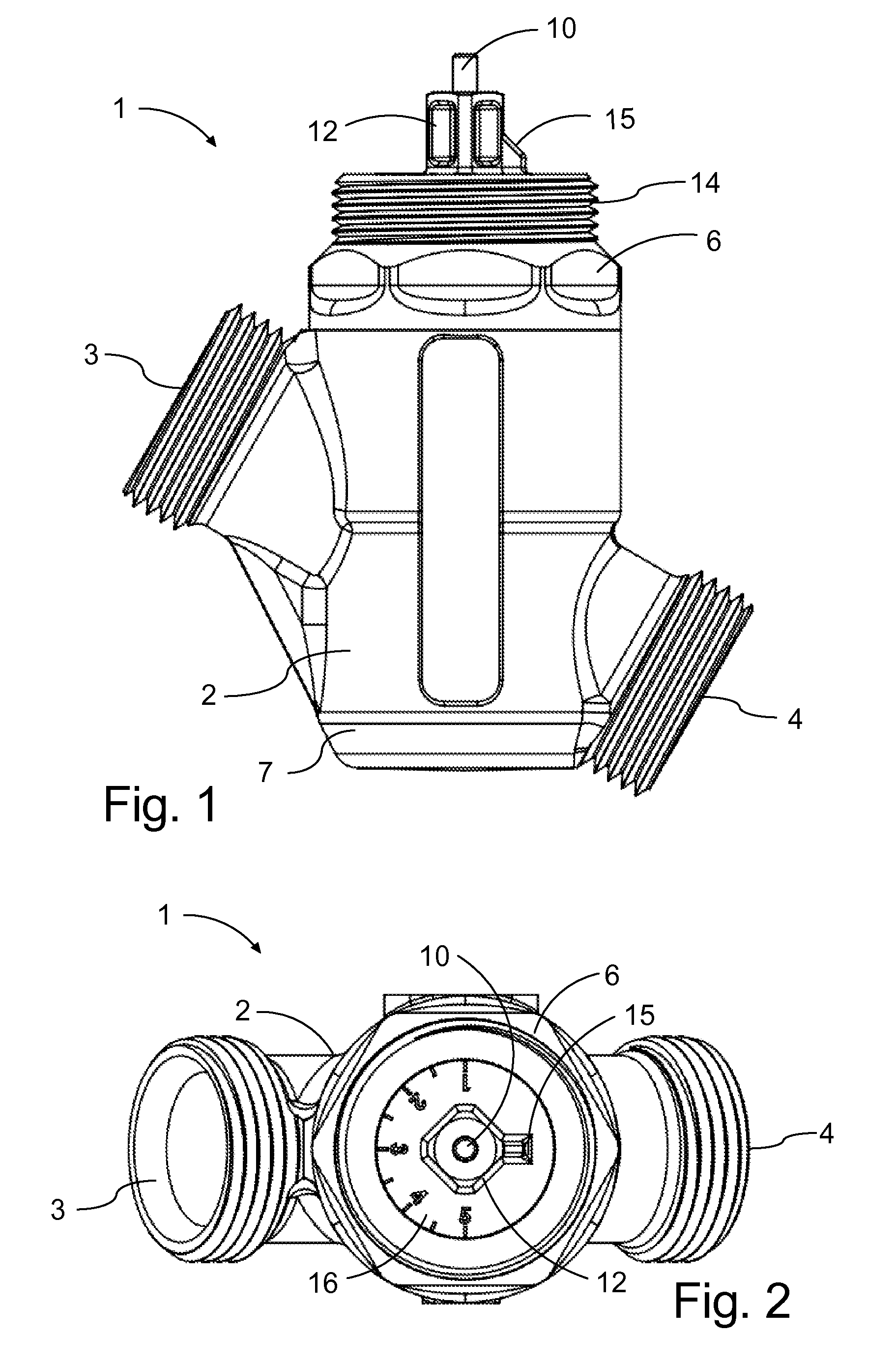

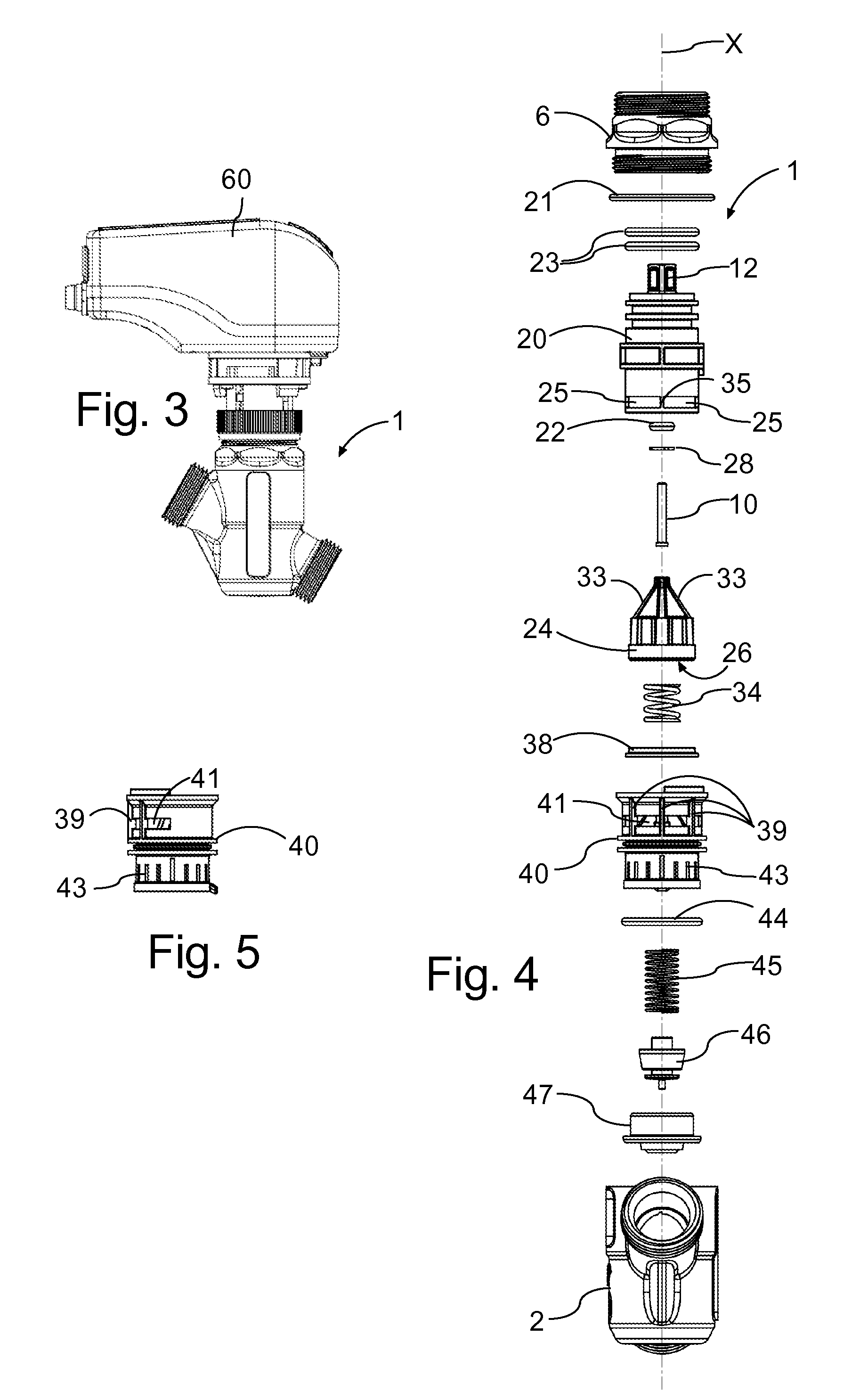

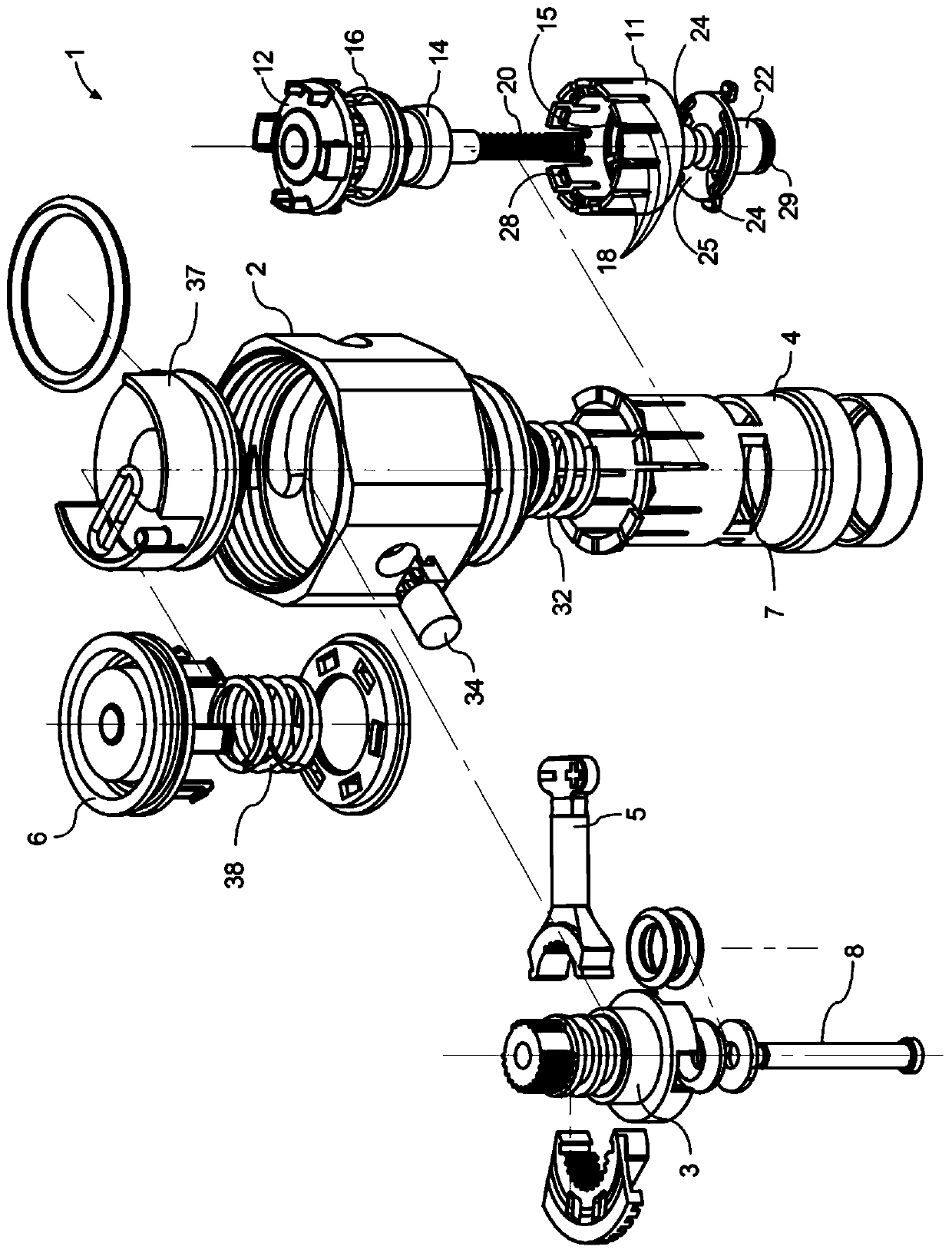

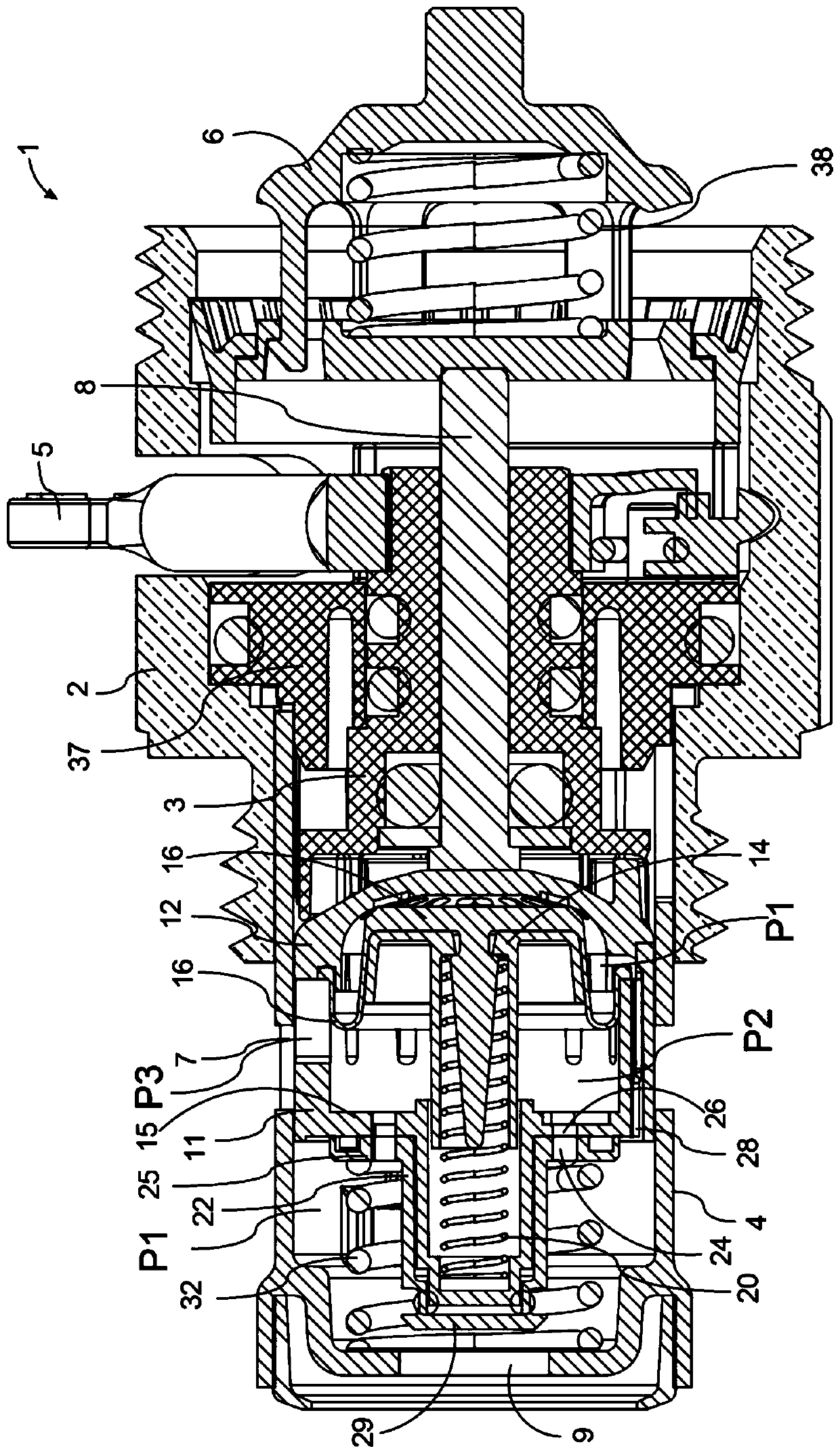

Control valve

ActiveUS20150198263A1Reduce decreasePressure relieving devices on sealing facesPressure difference controlDifferential pressureEngineering

A control valve (1) for controlling liquid flow in a heating and / or cooling installation. The control valve (1) comprises a valve housing (2) with an inlet (3) and an outlet (4), a flow area regulator for regulating a flow area of an entry opening through which the liquid flowing through the control valve (1) from the inlet (3) to the outlet (4) has to pass, the flow regulator comprises at least one valve member (24) that is rotatable between a fully open position that corresponds to a largest possible flow area of the entry opening (53) and a fully closed position that corresponds to the smallest possible flow area of the entry opening, in which the entry opening is essentially closed, a pressure regulating arrangement downstream of the flow area regulator with a pressure chamber (8) upstream of the flow area regulator and downstream of the pressure regulating arrangement, the pressure regulating arrangement being configured for maintaining an essentially constant differential pressure between the pressure (P1) in the inlet (3) and the pressure (P2) in the pressure chamber (8) and a drain passage (54) connecting the pressure chamber (8) to the outlet (4).

Owner:FLOWCON INT

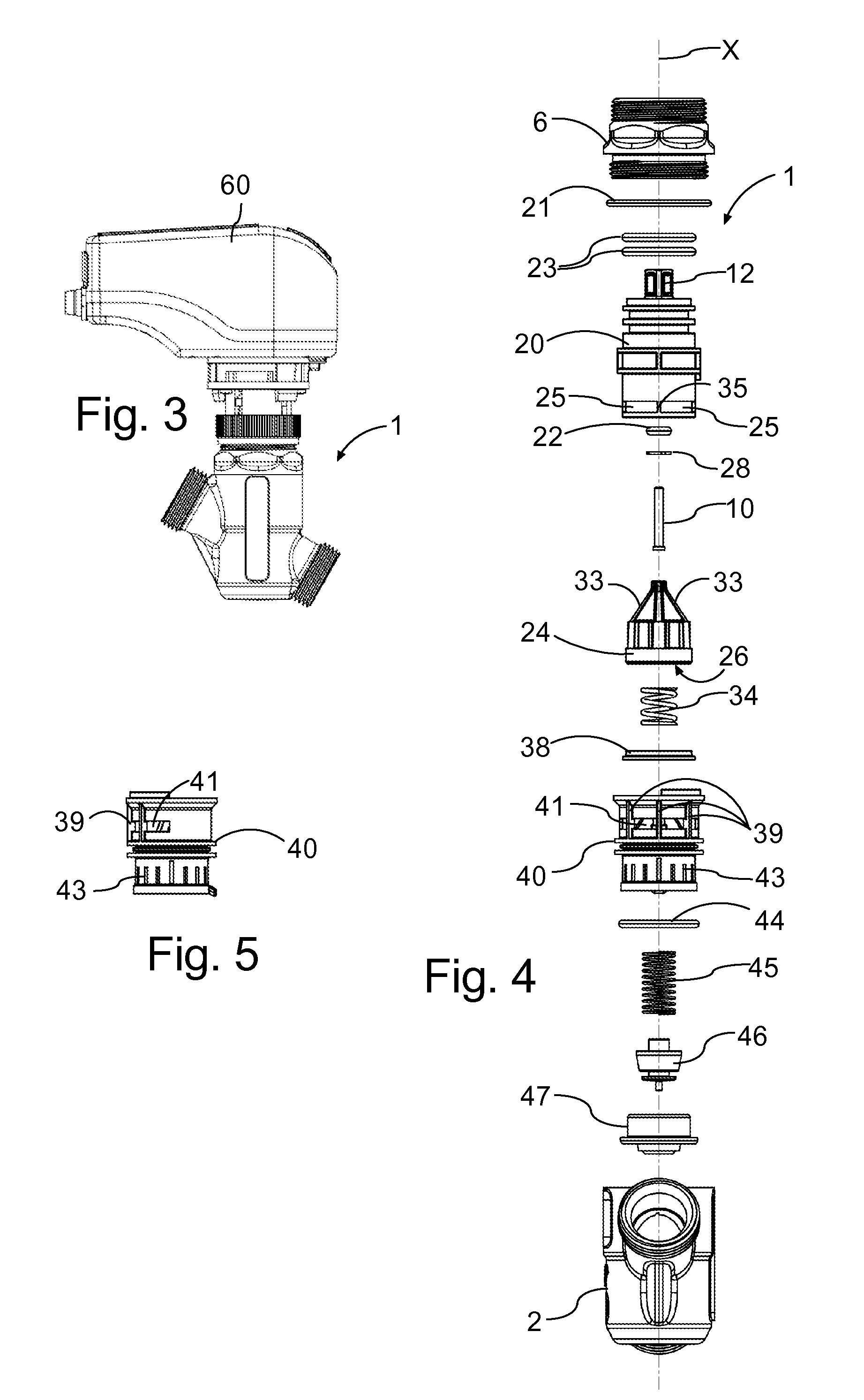

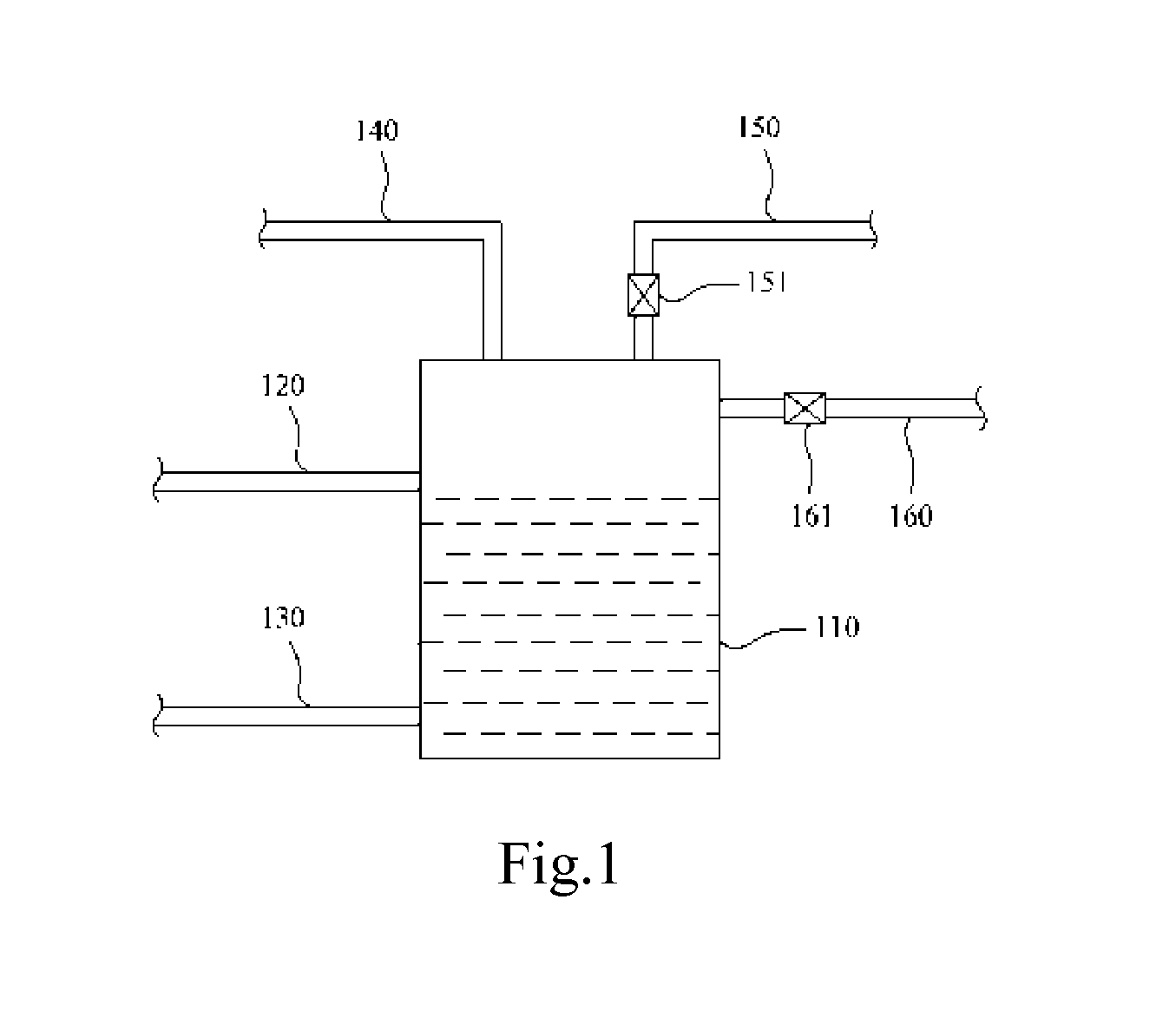

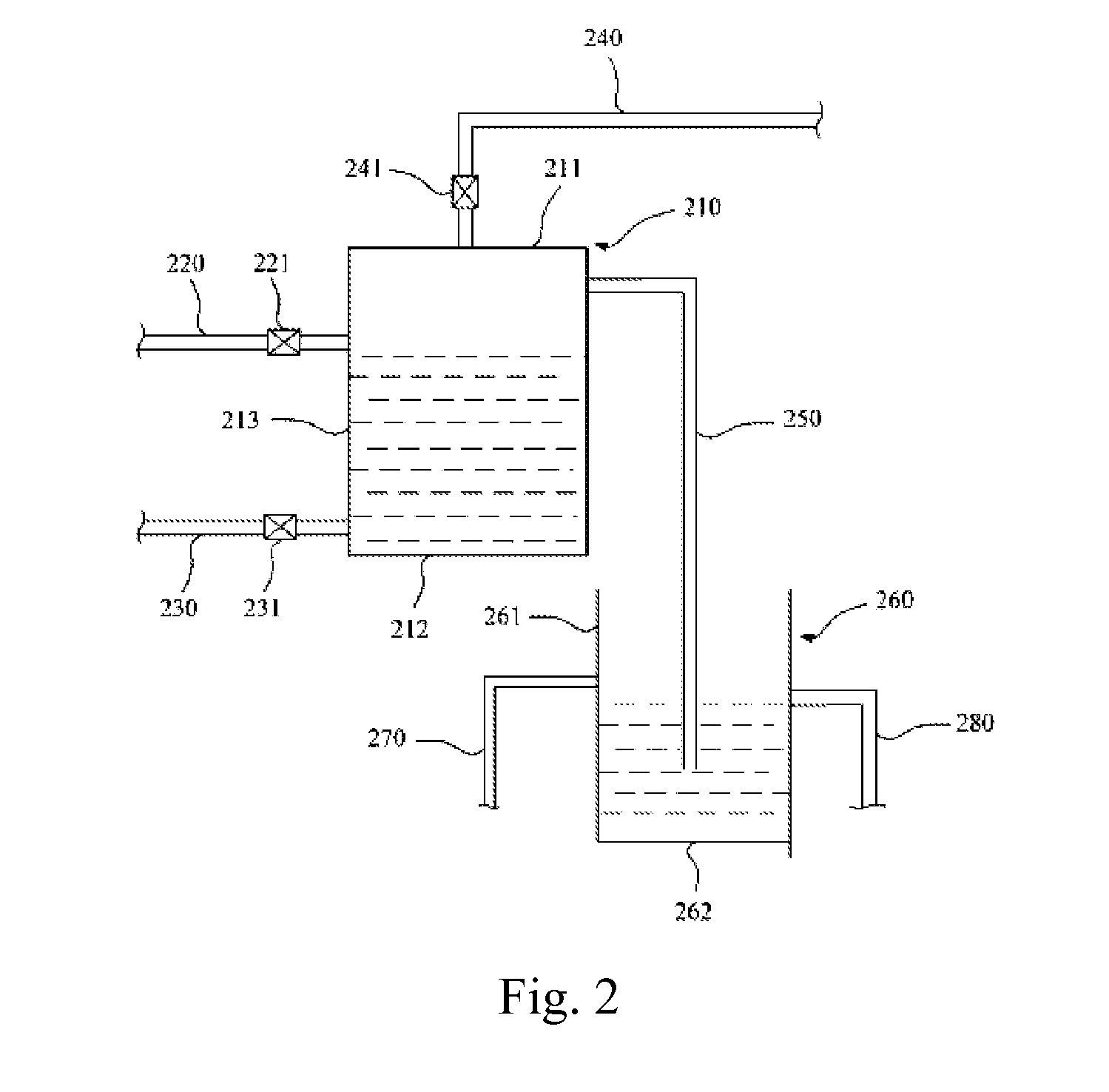

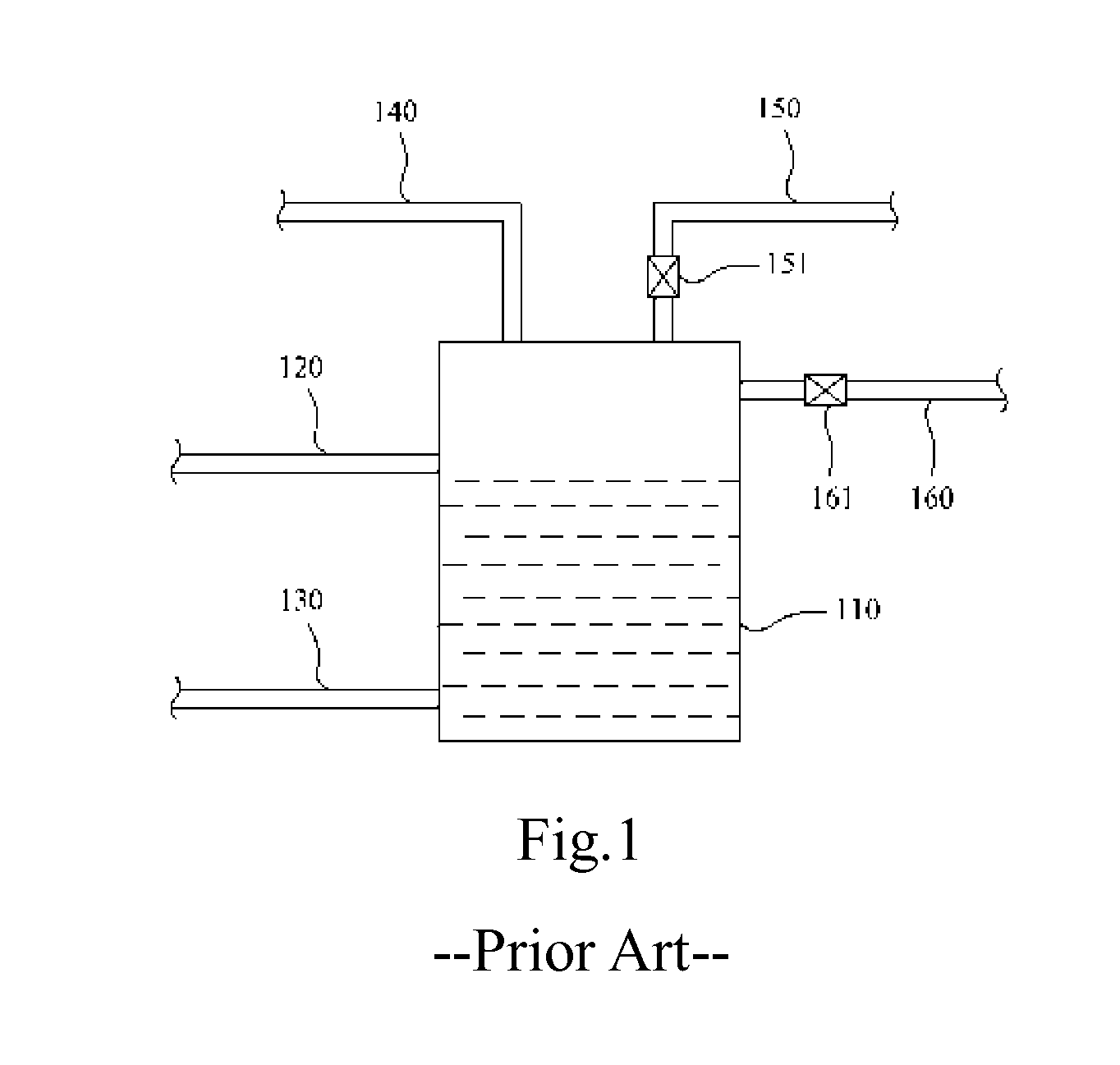

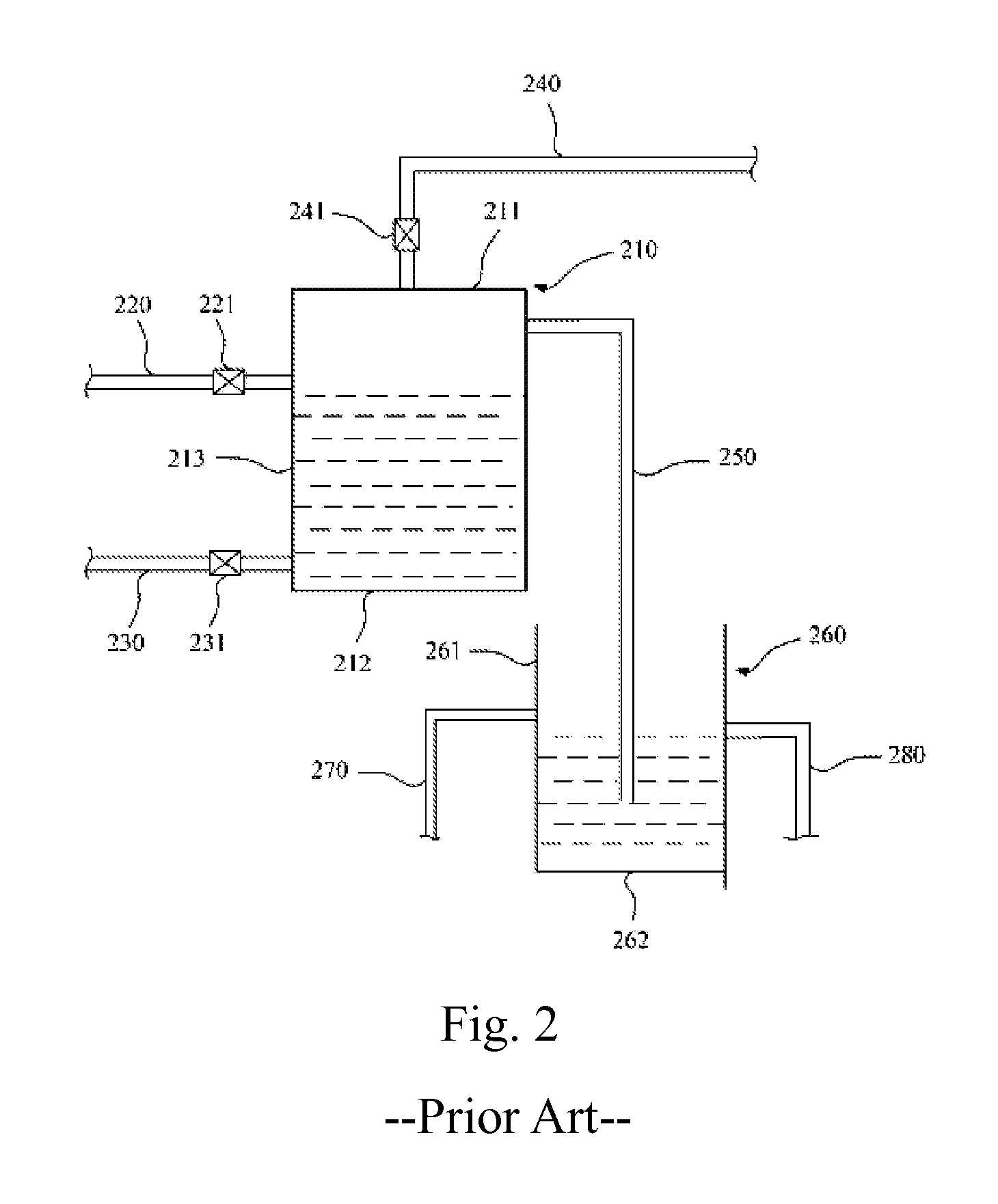

Liquid storage device

ActiveUS20130174919A1Fast supplyAvoid damagePressure pumpsFluid pressure control with auxillary non-electric powerManufacturing technologyDifferential pressure

The present invention provides a liquid storage device relates to the field of semiconductor manufacturing technology comprising: a liquid storage tank, a liquid intake tube, a liquid discharge tube and a gas discharge tube; the liquid intake tube, the liquid discharge tube and the gas discharge tube are all connected with the liquid storage tank; the liquid storage device also comprises a gas compensating tube connected with the liquid storage tank; the gas compensating tube comprises a differential pressure mechanism and a gas storage tank; one end of the differential pressure mechanism is connected with the liquid storage tank, and the other end is connected with the gas storage tank; the differential pressure mechanism is used for controlling the connection or disconnection between the liquid storage tank and the gas storage tank according to the pressure difference therebetween.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

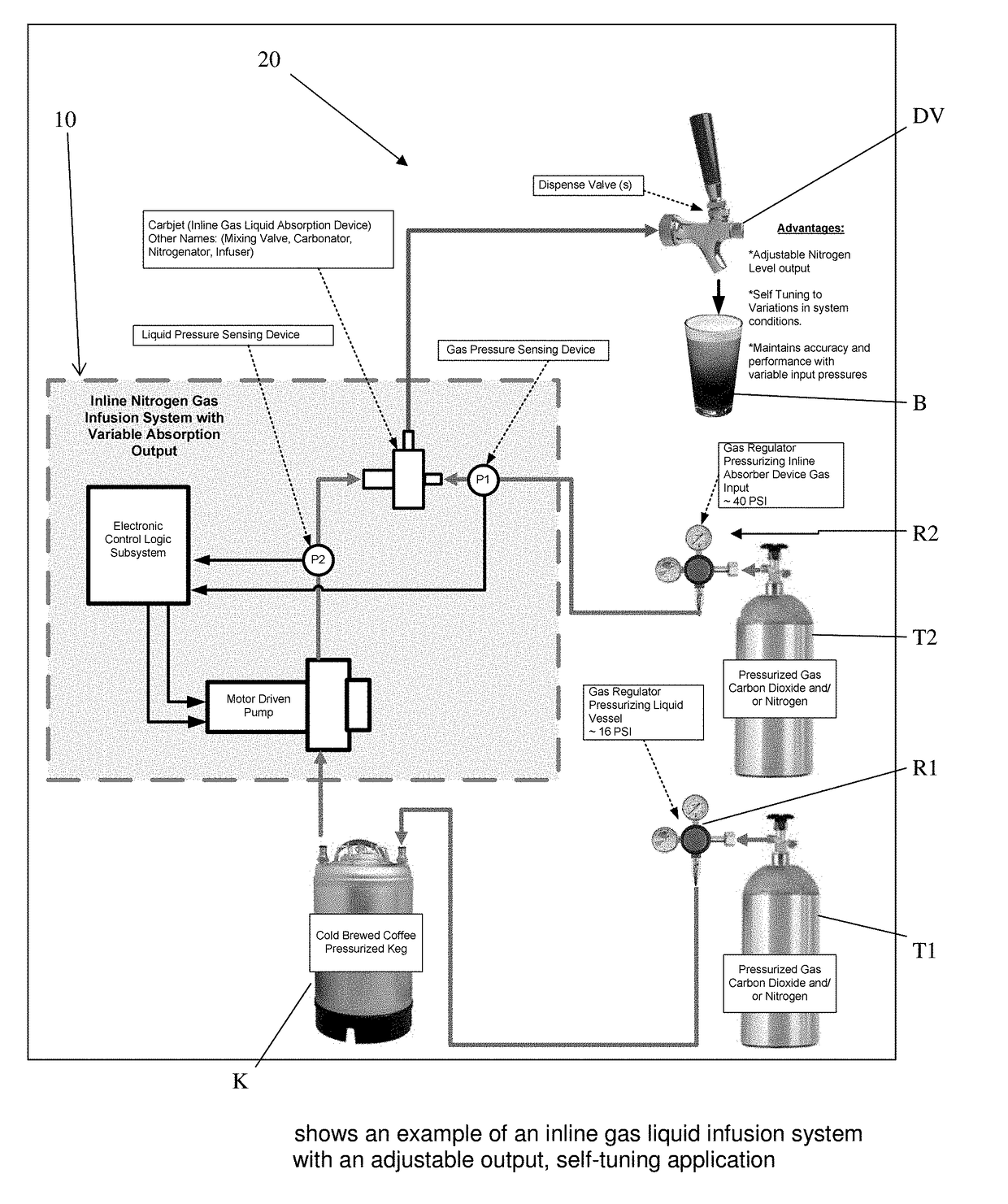

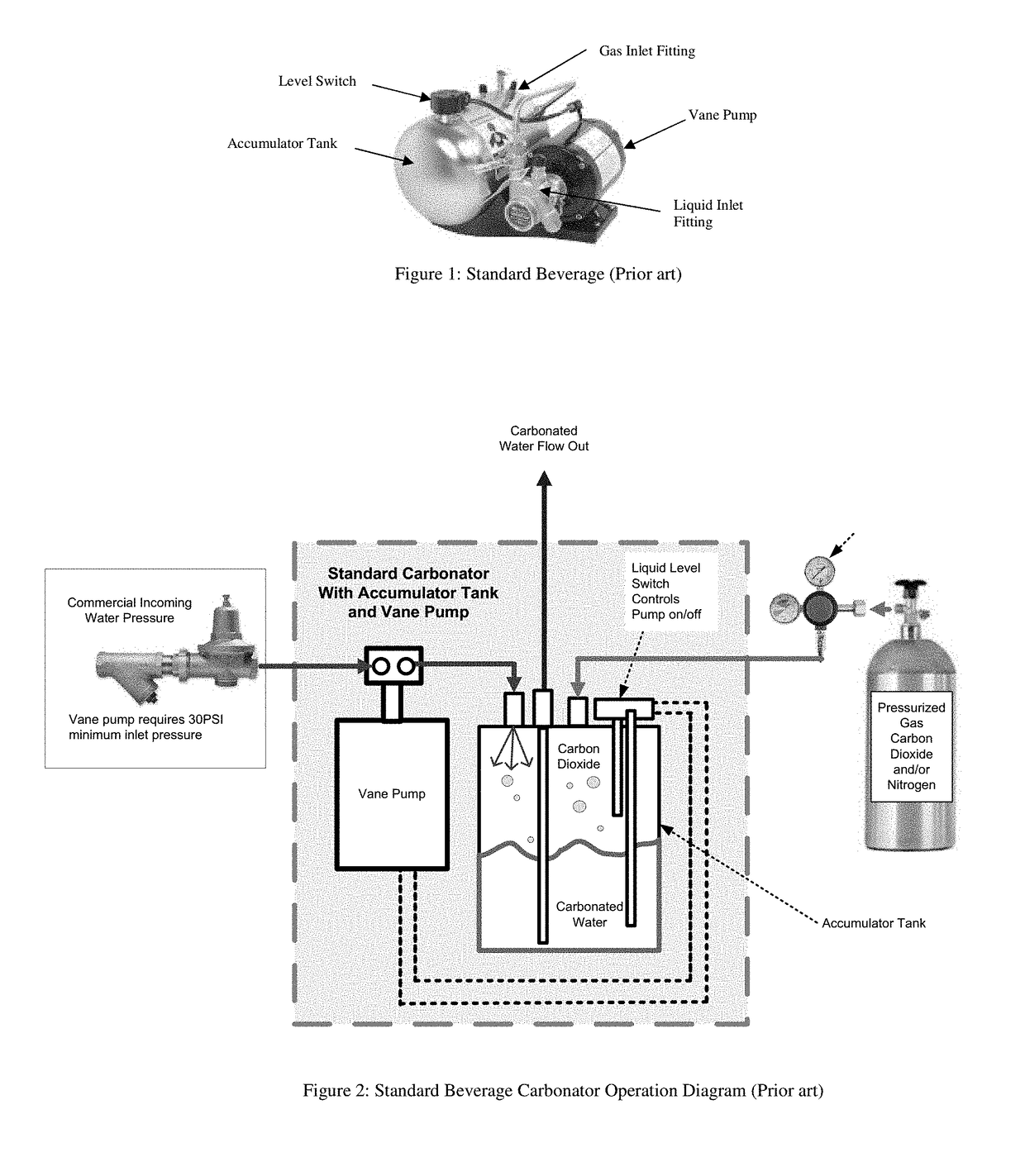

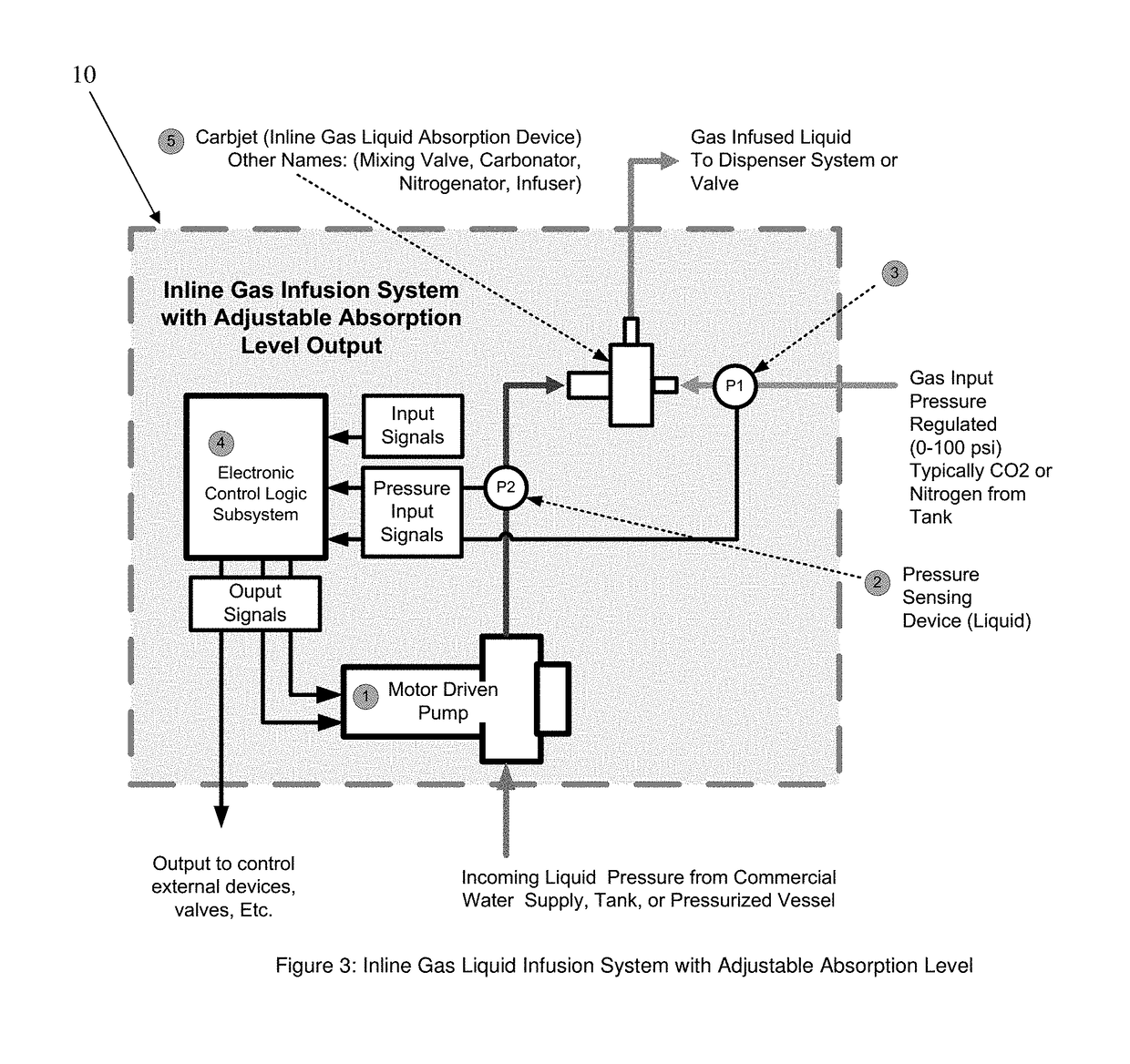

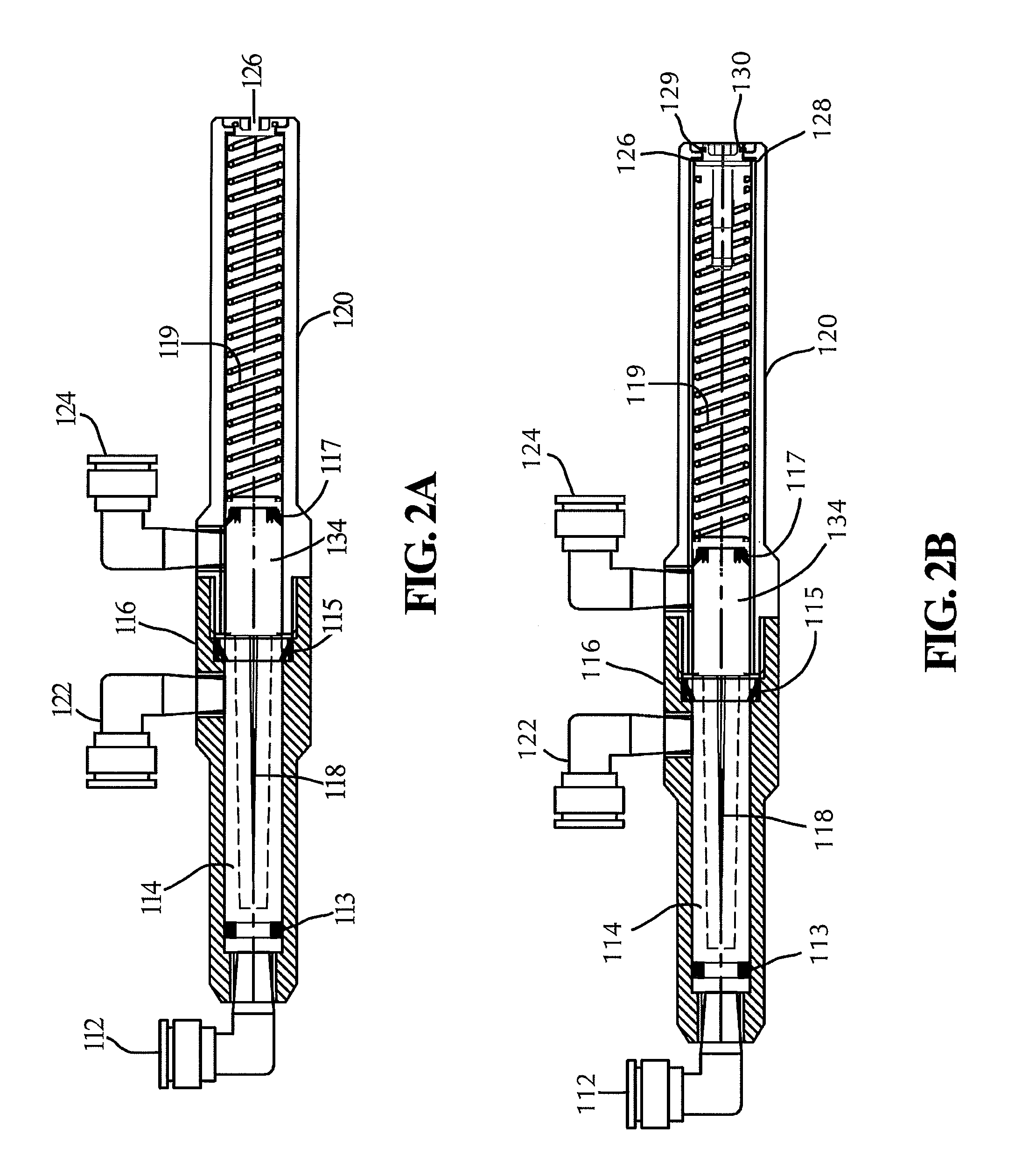

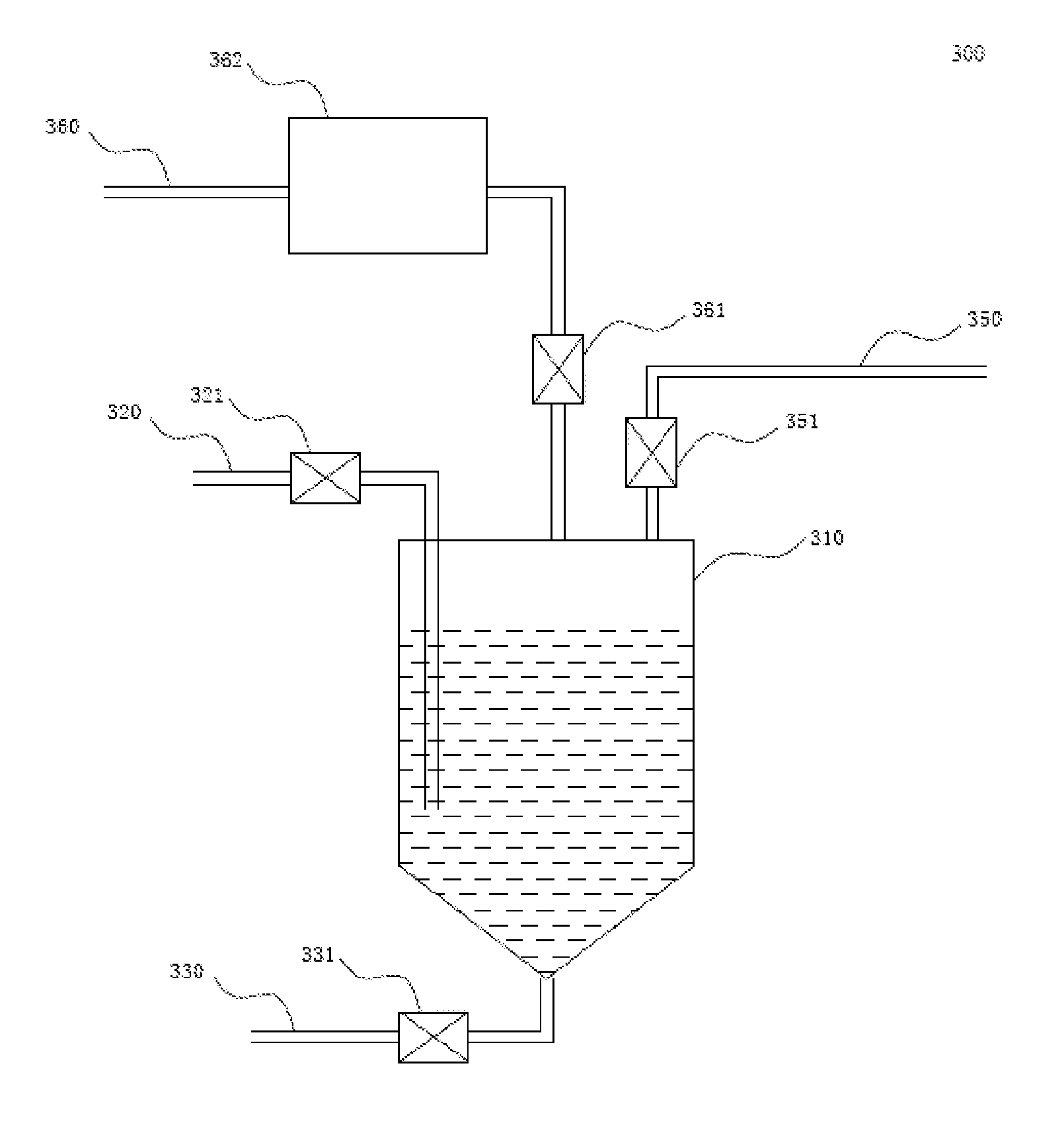

Inline gas/liquid infusion system with adjustable absorption output and self-tuning capability

An inline gas / liquid infusion system featuring an electronic control logic and subsystem having a signal processor configured to: receive signaling containing information about a liquid pressure of an incoming liquid provided from a pump to an inline gas liquid absorption device and about a gas pressure of an incoming gas provided to the inline gas liquid absorption device; and determine corresponding signaling containing information to control the liquid pressure of the incoming liquid provided from the pump to the inline gas liquid absorption device in order to provide real time adjustable set point output levels of gas absorption in the inline gas liquid absorption device, based upon the signaling received.

Owner:FLOW CONTROL LLC

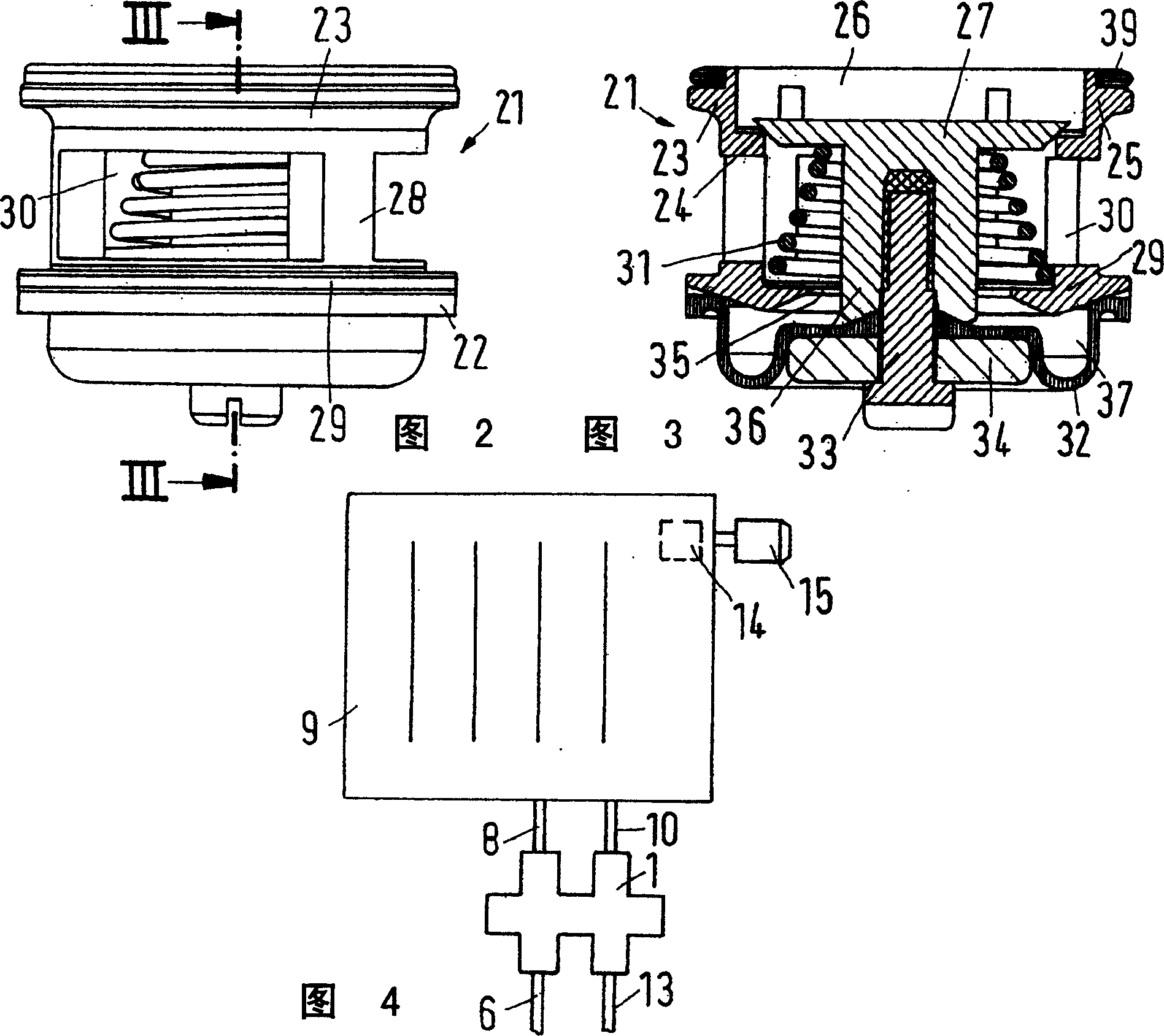

Regulator insert with hydraulic damping in outlet

InactiveUS7343928B2Reaction is slowOperating means/releasing devices for valvesLighting and heating apparatusEngineeringMembrane configuration

A regulator insert for valves includes inflow openings and a plurality of slot-shaped outflow openings extending in the axial direction of the insert and being, via a roller membrane, closable in response to the difference in pressure across the insert under the influence of a spring that seeks to keep the outflow openings open. The slot-shaped outflow openings have at least two different lengths, whereby complete closure of at least some of the outflow openings can take place only consecutively. At least one of the slot shaped outflow openings has such length that complete closure thereof by means of the roller membrane is not possible.

Owner:FLOWCON INT

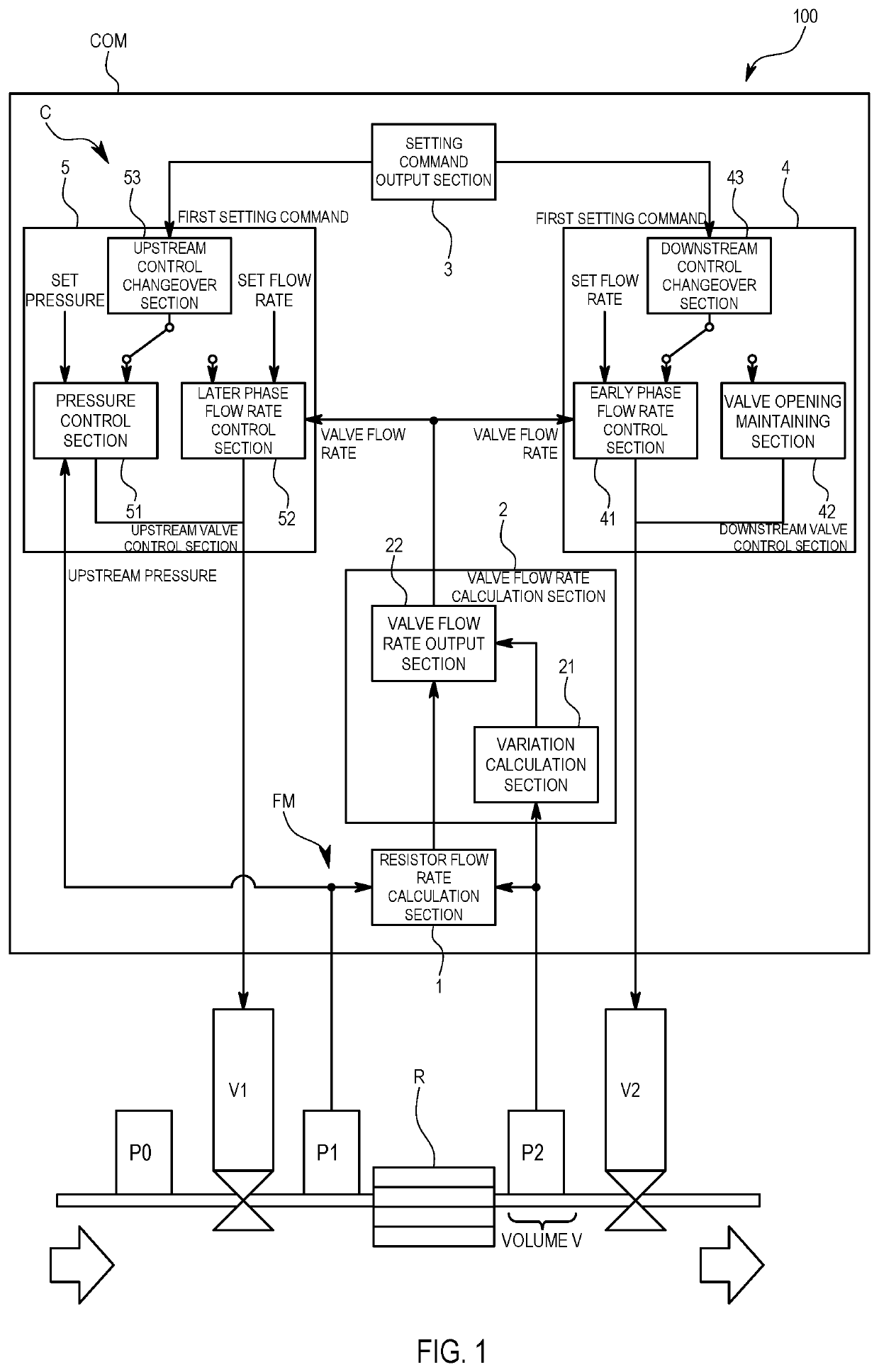

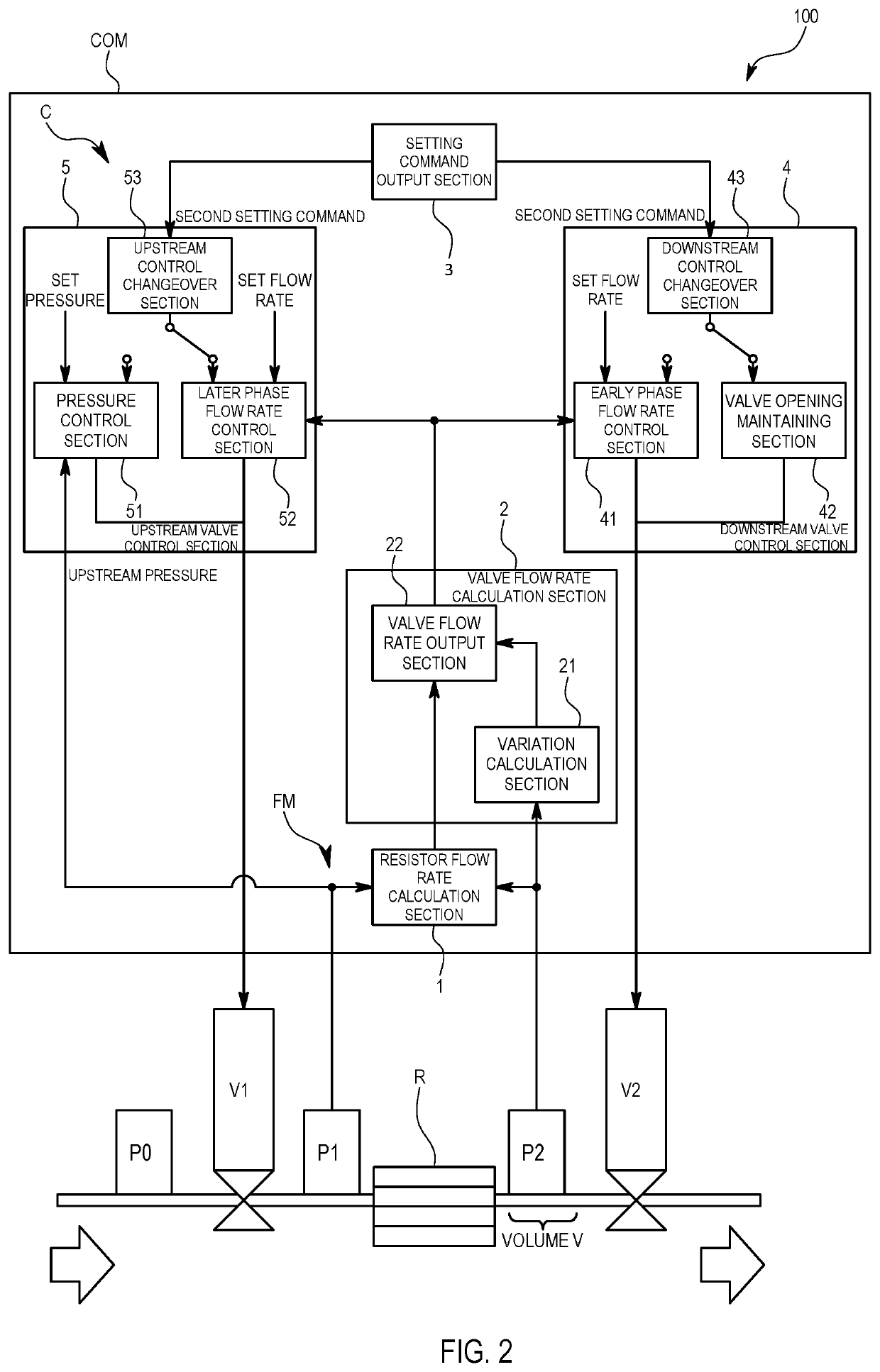

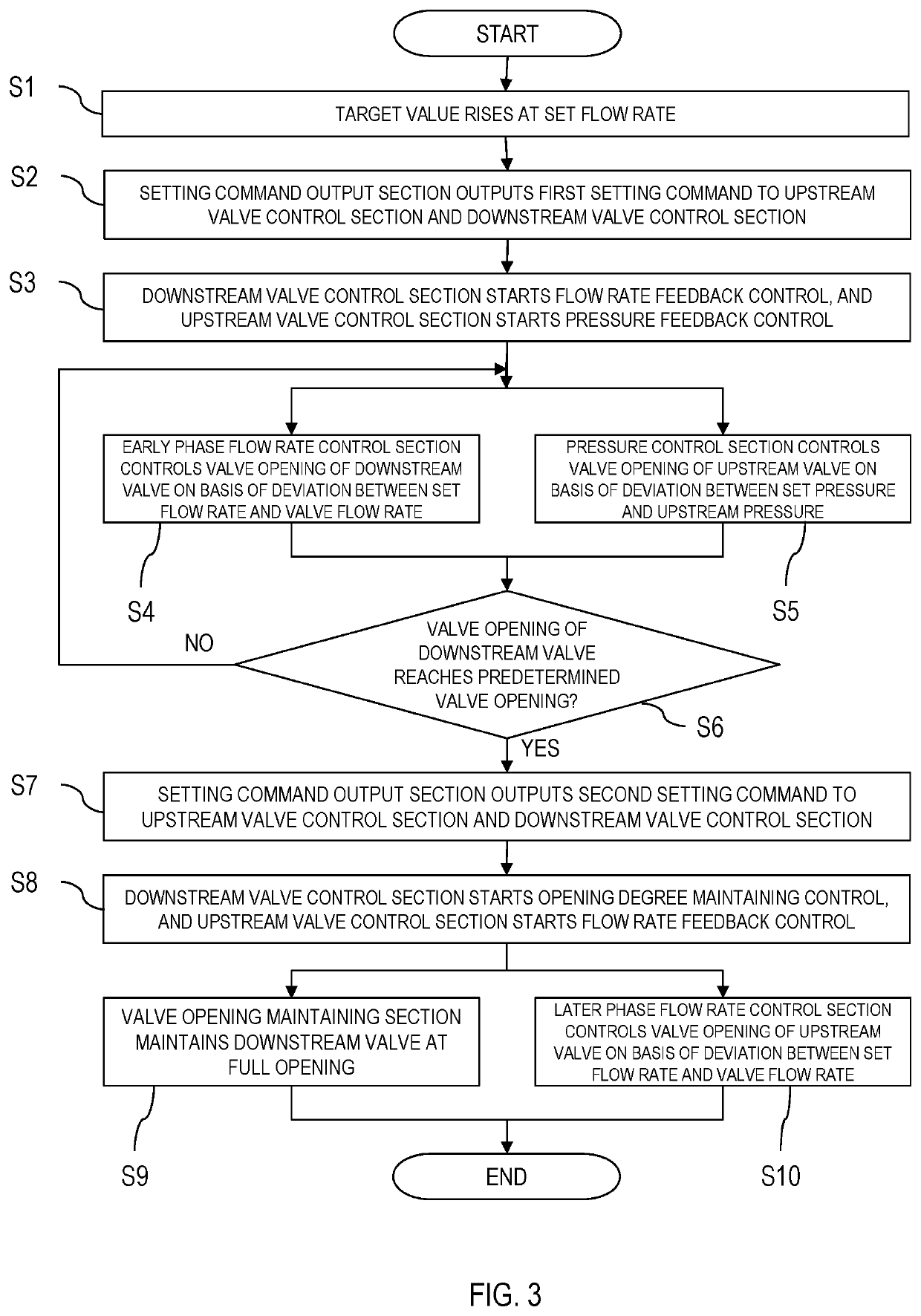

Flow rate control apparatus, flow rate control method, and program recording medium having recorded therein program for flow rate control apparatus

ActiveUS20200026311A1Avoid excessive controlFlow control using electric meansPressure difference controlControl theoryMechanics

In order to provide a flow rate control apparatus capable of reducing pressure loss due to a downstream valve while enhancing responsiveness in flow rate control, a controller is designed to control the downstream valve on the basis of a flow rate deviation when a valve opening of the downstream valve is smaller than a predetermined valve opening. The controller is designed to control an upstream valve on the basis of the flow rate deviation when the valve opening of the downstream valve is the predetermined valve opening or more.

Owner:HORIBA STEC CO LTD

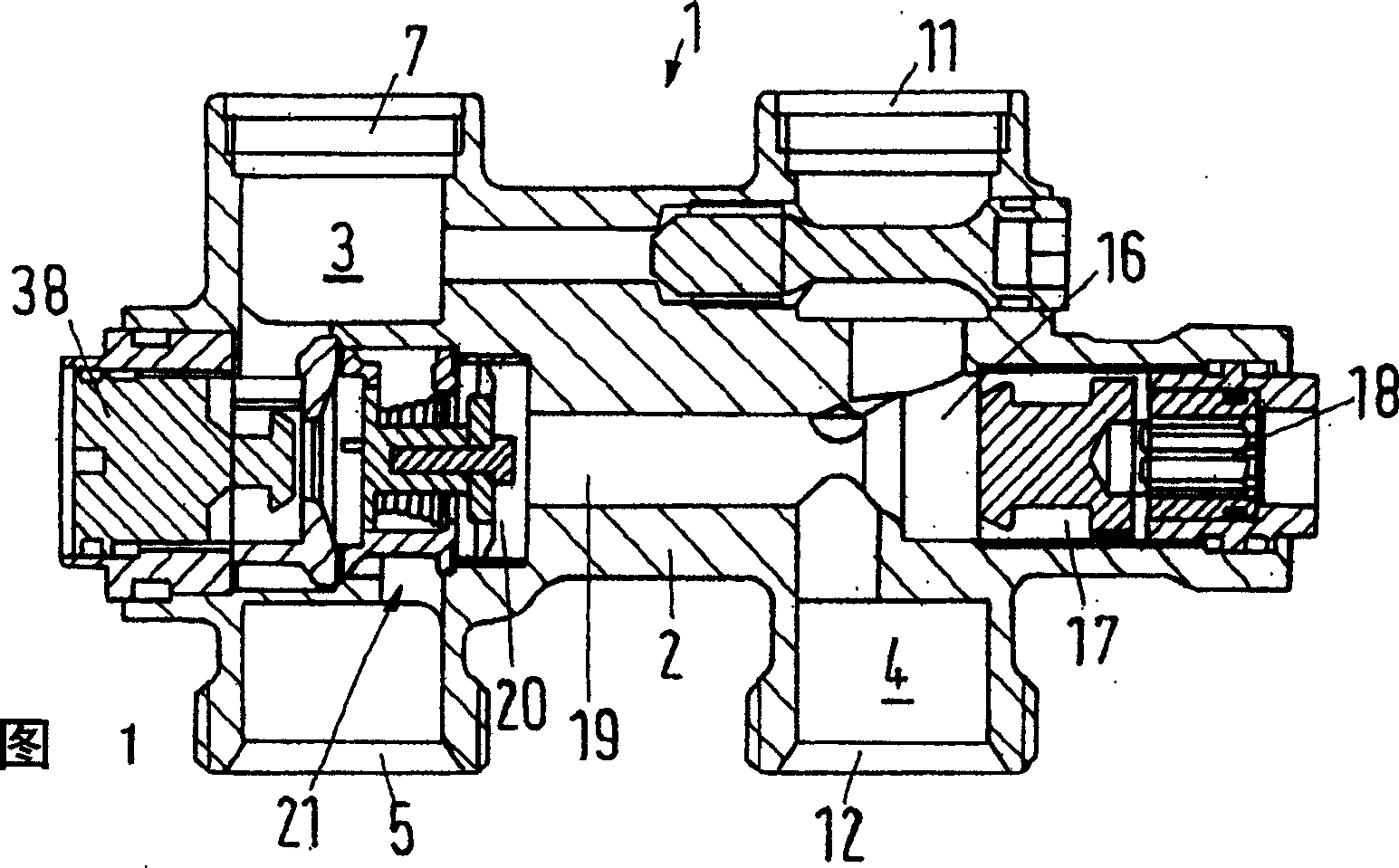

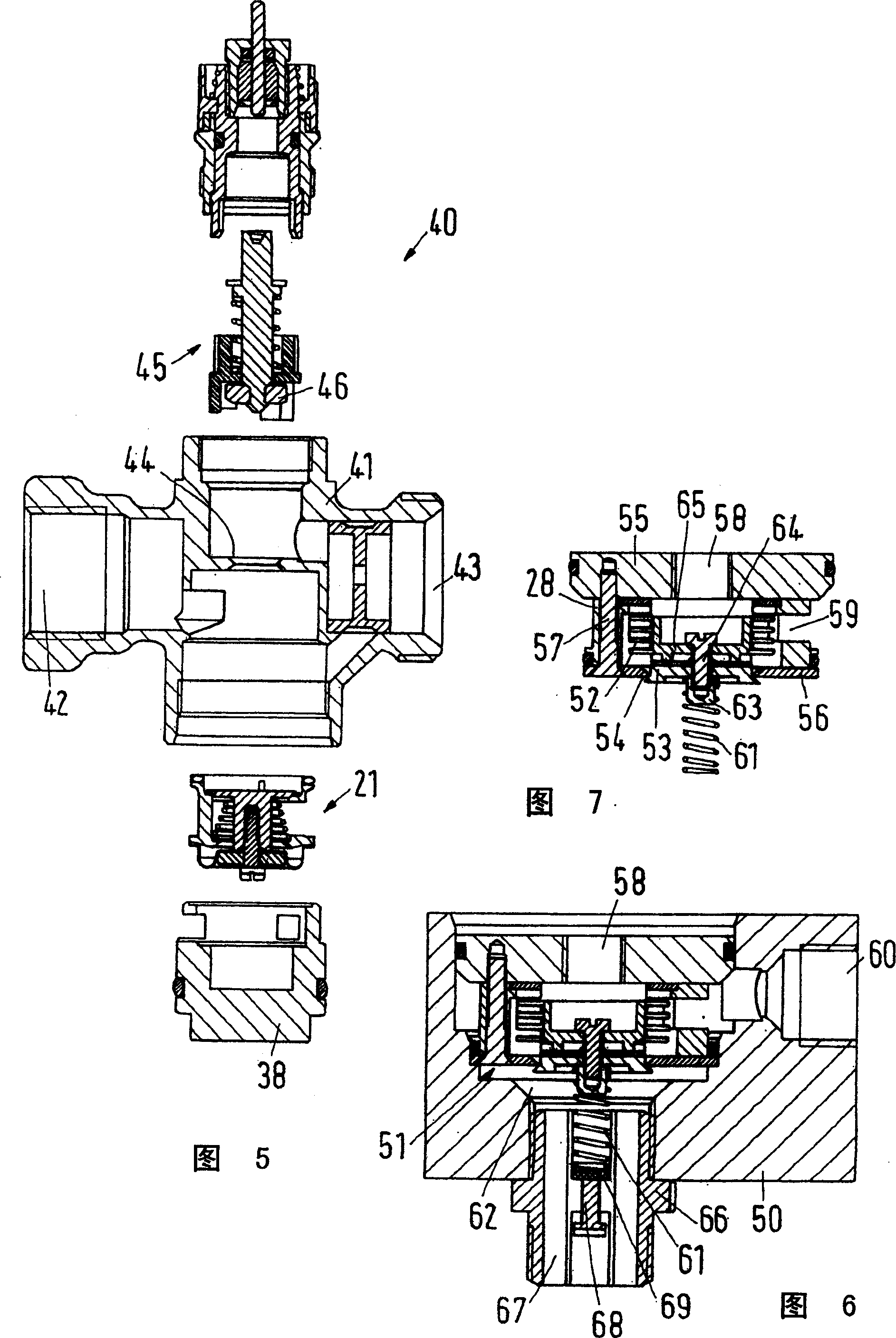

Valve apparatus for heat transfer

InactiveCN100394089CReduce manufacturing costEasy loadingFluid heatersEqualizing valvesEngineeringValve seat

Owner:DANFOSS AS

Control valve

ActiveUS9285059B2Reduce decreasePressure relieving devices on sealing facesFlow control without auxillary powerAuto regulationDifferential pressure

A control valve for controlling liquid flow in a heating and / or cooling installation. The control valve includes differential pressure regulating facilities and flow area regulating facilities. The control valve is provided with means for manually presetting a maximum flow through area and with means for automatically adjusting the flow through area within the preset maximum.

Owner:FLOWCON INT

Valve apparatus for heat transfer, especially for heating element

Heat exchanger valve arrangement, especially for a radiator valve has a valve seat (24), valve element (27), spring element (31) and a pressure reaction apparatus (32), which serves to maintain a constant pressure across the valve, that are joined together by a single connection (33). The whole assembly then forms a single handheld unit that can be inserted into the valve housing.

Owner:DANFOSS AS

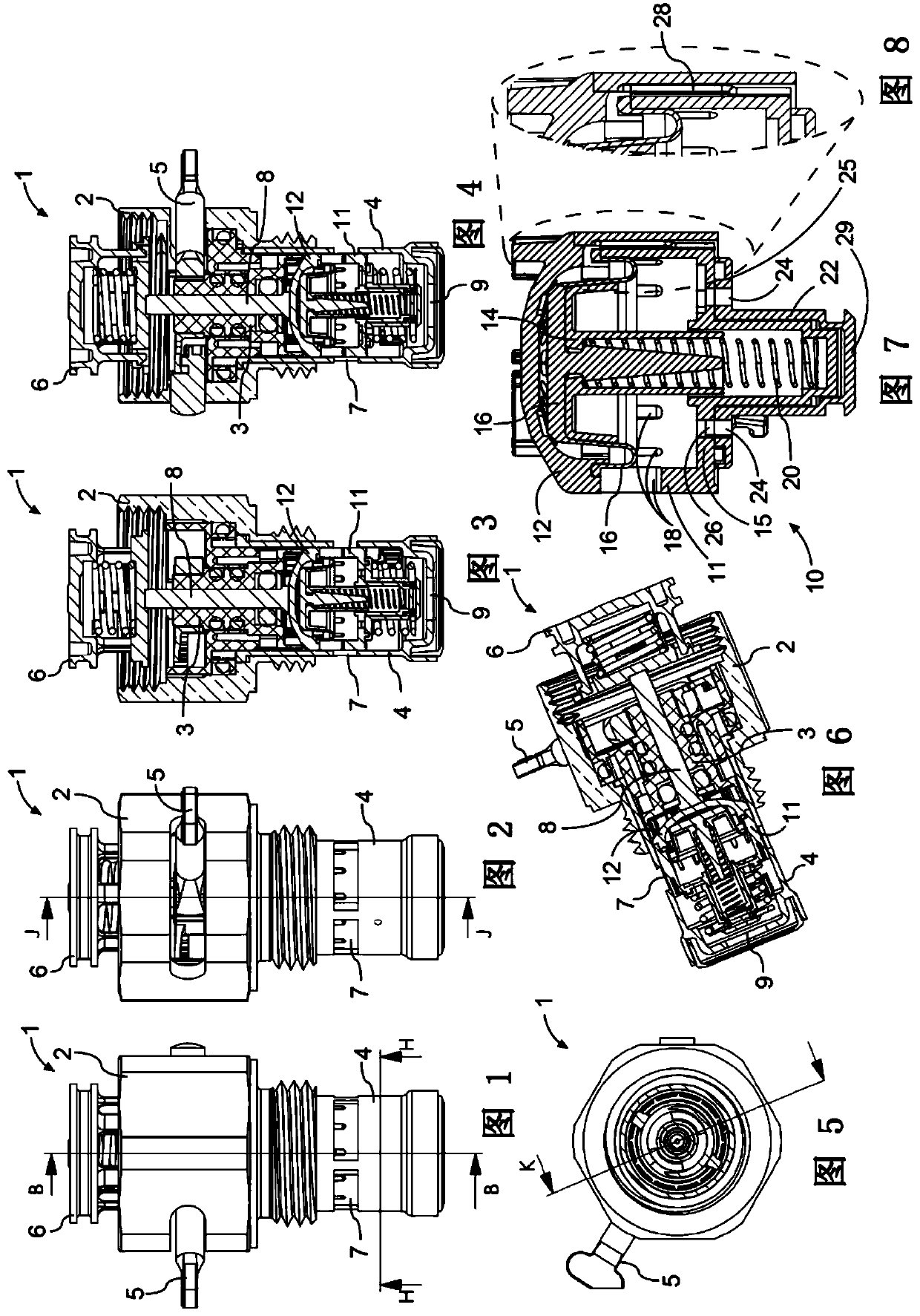

Control valve for heating and/or cooling system

A control valve (1) for controlling flow of liquid in a heating and / or cooling installation with a pressure regulating arrangement for maintaining a constant differential pressure between a first pressure (PI) and a second pressure (P2) in the control valve ( 1). A movable throttle member (16) is urged to increase or decrease the flow resistance. The movable throttle member comprises a rolling diaphragm (16) that interacts with a plurality of exit openings (18) formed radially through the annular body (11). The rolling diaphragm (16) has a circular circumference attached to an annular body (11) that is arranged in the control valve (1). At least one pressure communication channel (28) extends in said annular body (11) for communicating the differential pressure P1 / P2 in the control valve (1). A manifold (40) for a heating system comprises a plurality of sockets (42) and a plurality of flow control valves (1) with a pressure regulating arrangement for maintaining a substantially constant differential pressure in the control valve (1). A floor heating system comprising the manifold (40).

Owner:FLOWCON INT

Variable drain flow restrictor

ActiveUS20170028352A1Avoid pollutionGeneral water supply conservationReverse osmosisDifferential pressureWastewater

A proportioning valve for a reverse osmosis system that controls the production of product water by the differential pressure across the purification membrane. By sensing increasing tank pressure to actuate the proportioning valve, the flow of waste water is restricted. Placement of seals within the cavity of the valve, as well as placement of waste water inlet and outlet ports, protects tension components that provide reverse tank pressure from waste water exposure. A needle valve assembly responsive to an actuating assembly that senses tank pressure removes the need for an inlet tank water port while restricting water flow.

Owner:ECOWATER SYST

Liquid storage device

ActiveUS8794257B2Avoid damageFast supplyPressure pumpsFluid pressure control with auxillary non-electric powerManufacturing technologyDifferential pressure

The present invention provides a liquid storage device relates to the field of semiconductor manufacturing technology comprising: a liquid storage tank, a liquid intake tube, a liquid discharge tube and a gas discharge tube; the liquid intake tube, the liquid discharge tube and the gas discharge tube are all connected with the liquid storage tank; the liquid storage device also comprises a gas compensating tube connected with the liquid storage tank; the gas compensating tube comprises a differential pressure mechanism and a gas storage tank; one end of the differential pressure mechanism is connected with the liquid storage tank, and the other end is connected with the gas storage tank; the differential pressure mechanism is used for controlling the connection or disconnection between the liquid storage tank and the gas storage tank according to the pressure difference therebetween.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com