Control valve for heating and/or cooling system

A technology for controlling valves and pressure, applied in the field of heating and/or cooling facilities, can solve problems such as leakage across the diaphragm, and achieve the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

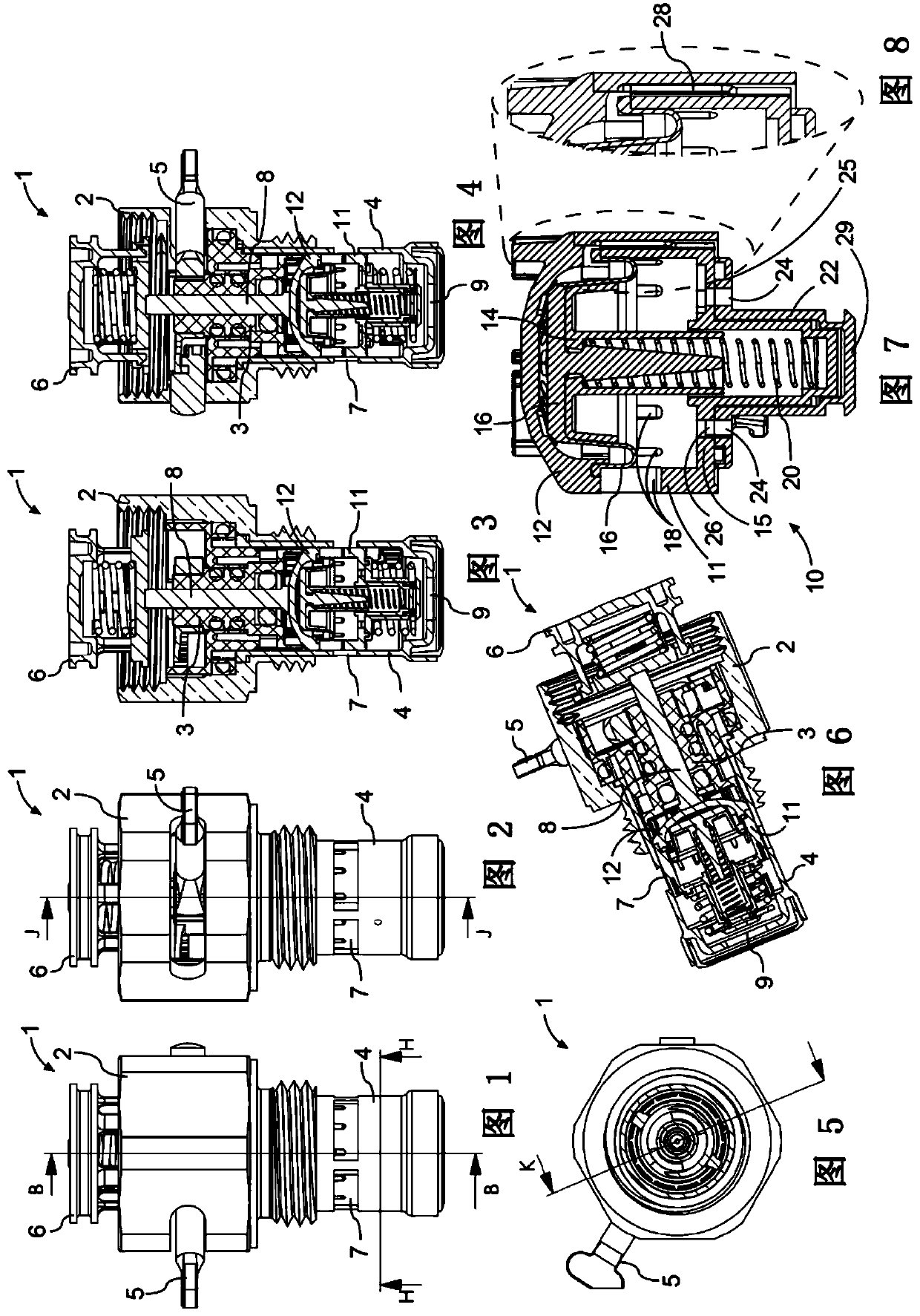

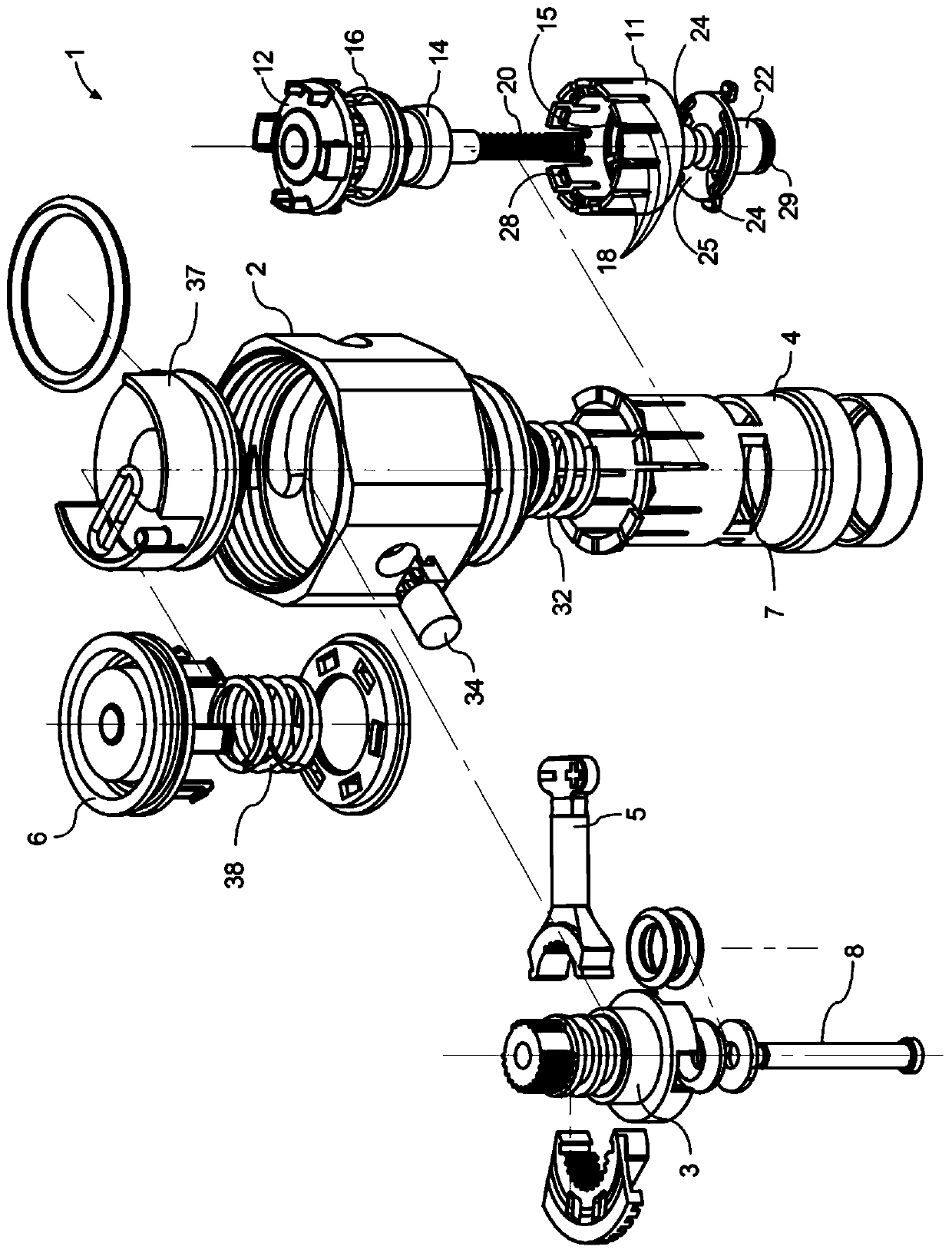

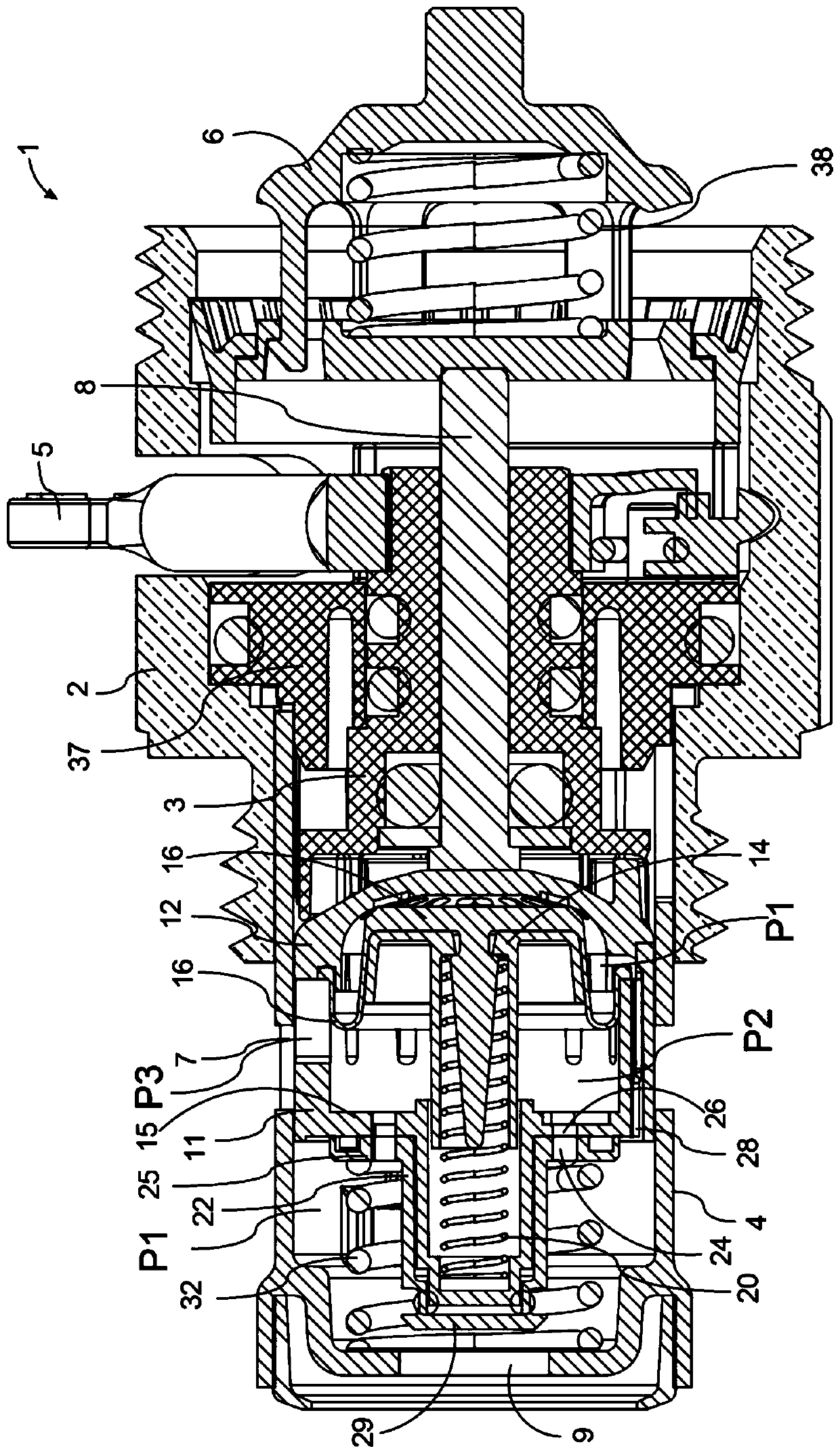

[0093] Reference Figure 1 to Figure 15 Describe the control valve. The control valve 1 includes a valve body 2. The valve body 2 is generally rotationally symmetric, and includes a part having a hexagonal outer contour and a cylindrical part 4. It should be noted, however, that the part having a hexagonal column type (order: column type) does not necessarily have a hexagonal outer shape, and other suitable shapes familiar to those skilled in the art, such as, for example, a simple columnar shape.

[0094] The valve body 2 is provided with a thread at or near one of its longitudinal ends for coupling with a linear actuator provided with a corresponding thread, such as an electric actuator (not shown). The valve body 2 is also provided with threads for threaded engagement with a housing or a body such as a manifold 40. Both the cylindrical part 4 and the part with a hexagonal exterior have a hollow interior in which most of the components of the control valve 1 are arranged.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com