Fuel cell humidifying system pressure self-adaptive balancing method based on membrane humidifying

A fuel cell and system pressure technology, applied in fuel cells, fluid pressure control, control/regulation systems, etc., can solve problems such as slow response speed, difficulty in quickly reaching the expected state, and prone to failure of membrane humidifiers. Reduce, improve test efficiency, save the effect of electronic control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

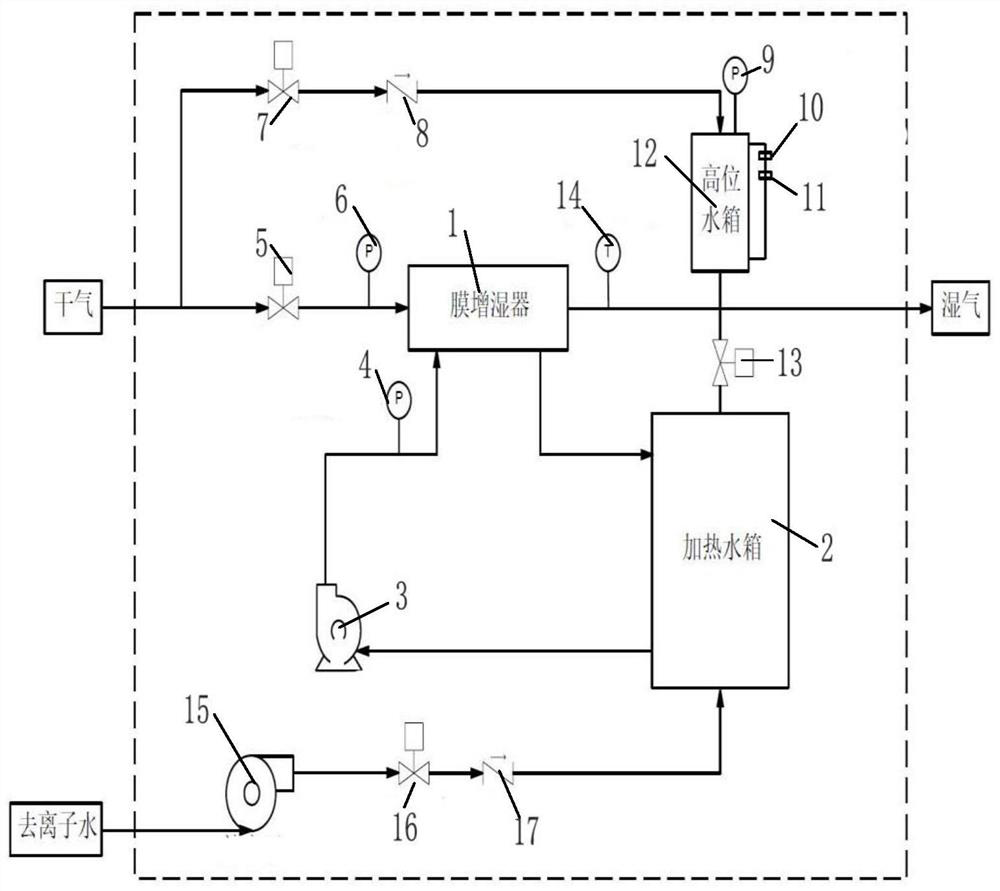

[0037] Such as figure 1 As shown, the fuel cell humidification system pressure adaptive balance method based on membrane humidification, the system includes:

[0038] Warm water circulation circuit, the water supply pump 3 is set in the warm water circulation circuit, and the heating water tank 2 containing deionized water with built-in heating device, the water inlet end of the water delivery pump 3 is connected with the heating water tank 2, the water delivery end of the water delivery pump 3 is connected with the The water inlet of humidifier 1 is connected, and the water outlet of membrane humidifier 1 is connected with heating water tank 2;

[0039] Water supply pipeline, used to connect and replenish deionized water into the heating water tank 2;

[0040] The gas pipeline is used to pass the dry gas into the air inlet of the membrane humidifier 1;

[0041] Connect the moisture output pipeline of the air outlet of the membrane humidifier 1;

[0042] High-level water ta...

Embodiment 2

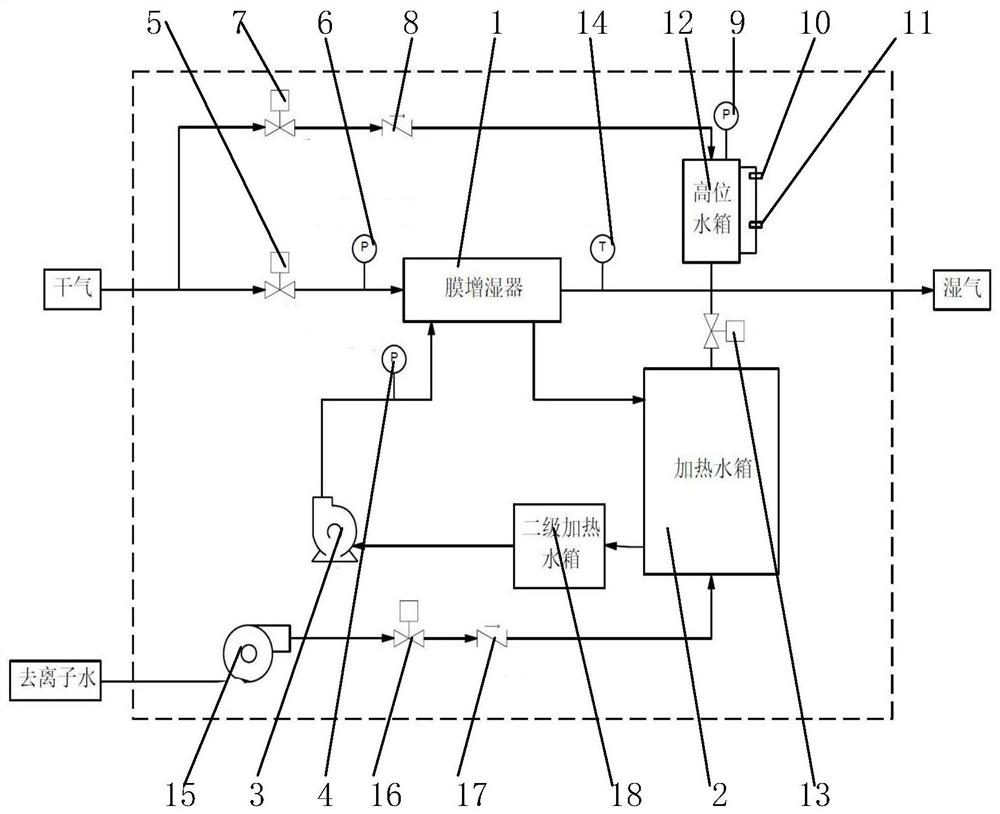

[0058] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that: in the warm water circulation circuit, a secondary heating water tank 18 is provided on the path from the heating water tank 2 to the water delivery pump 3, and the secondary heating water tank 18 has a built-in heating device to assist Heating deionized water; in the application process, the high liquid level sensor 10 and the low liquid level sensor 11 are far apart, and the supplementary water pump 15 works intermittently. When replenishing water, the water temperature of the heating water tank 2 will decrease. Compensate the temperature of deionized water to avoid fluctuations in water temperature.

Embodiment 3

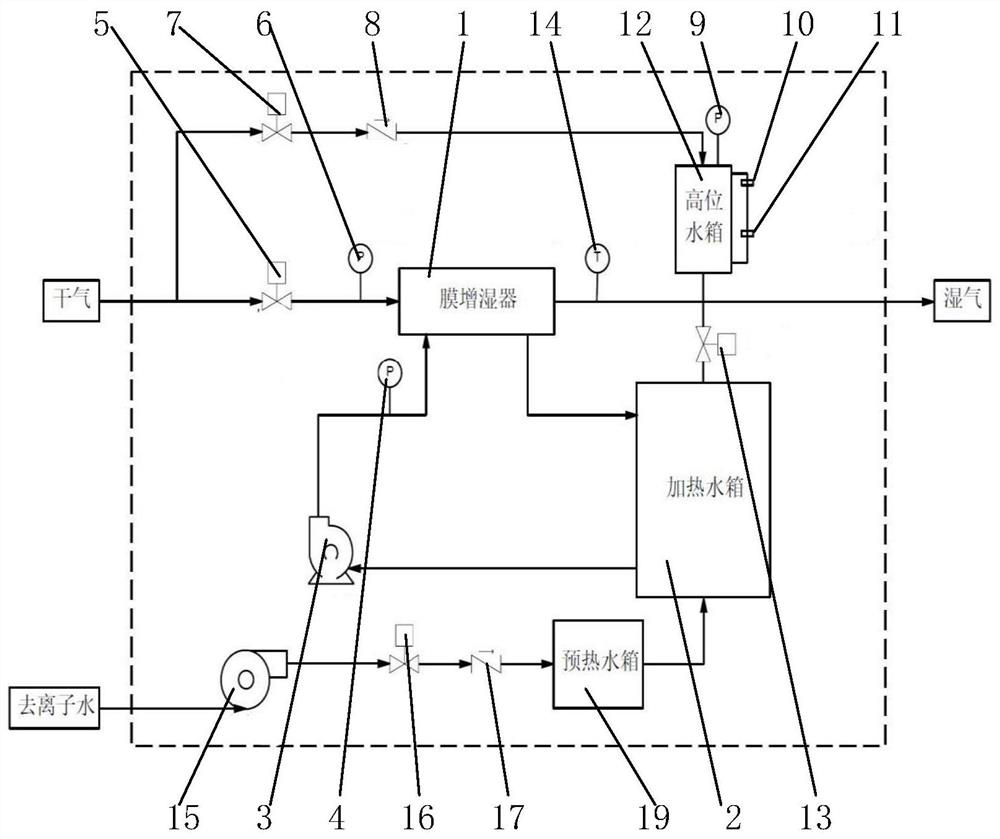

[0060] Such as image 3 As shown, the difference between embodiment 3 and embodiment 1 is that: a preheating water tank 19 is connected to the water supply pipeline, and a heating device is built in the preheating water tank 19 to preheat deionized water. On the passage between the valve 17 and the heating water tank 2; in the application process, the high liquid level sensor 10 and the low liquid level sensor 11 are far apart, the supplementary water pump 15 works intermittently, and the water temperature of the heating water tank 2 will decrease when replenishing water. Therefore, before the deionized water enters the heating water tank 2, the preheating water tank 19 is used to increase the water temperature to avoid fluctuations in the water temperature in the heating water tank 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com