Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169results about "Circuit artworks manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of visually inspecting positioning of a pattern on a substrate

InactiveUS6127069AInexpensive and cost-effectiveSure easyRadiation applicationsPhotomechanical apparatusLight beamOptoelectronics

Exposure masks and inspection masks for use in the electronics field may be made using laser beams wherein the mask comprises a substrate which is substantially unaffected by exposure to the laser beam and an opaque pattern forming layer on the substrate, which pattern forming layer absorbs the laser beam and is selectively etched when exposed to the laser beam. A preferred mask has an overcoat transparent layer. A cavity inspection mask is provided having a series of openings in the form of lines formed in the opaque pattern forming layer, the lines bounding the cavity walls, is the mask being used for determining if the cavity is centrally positioned on the substrate and / or that the cavity is of the desired size. Substrates containing identifying masks thereon which cannot be seen by the unaided eye for theft deterrence are also provided.

Owner:IBM CORP

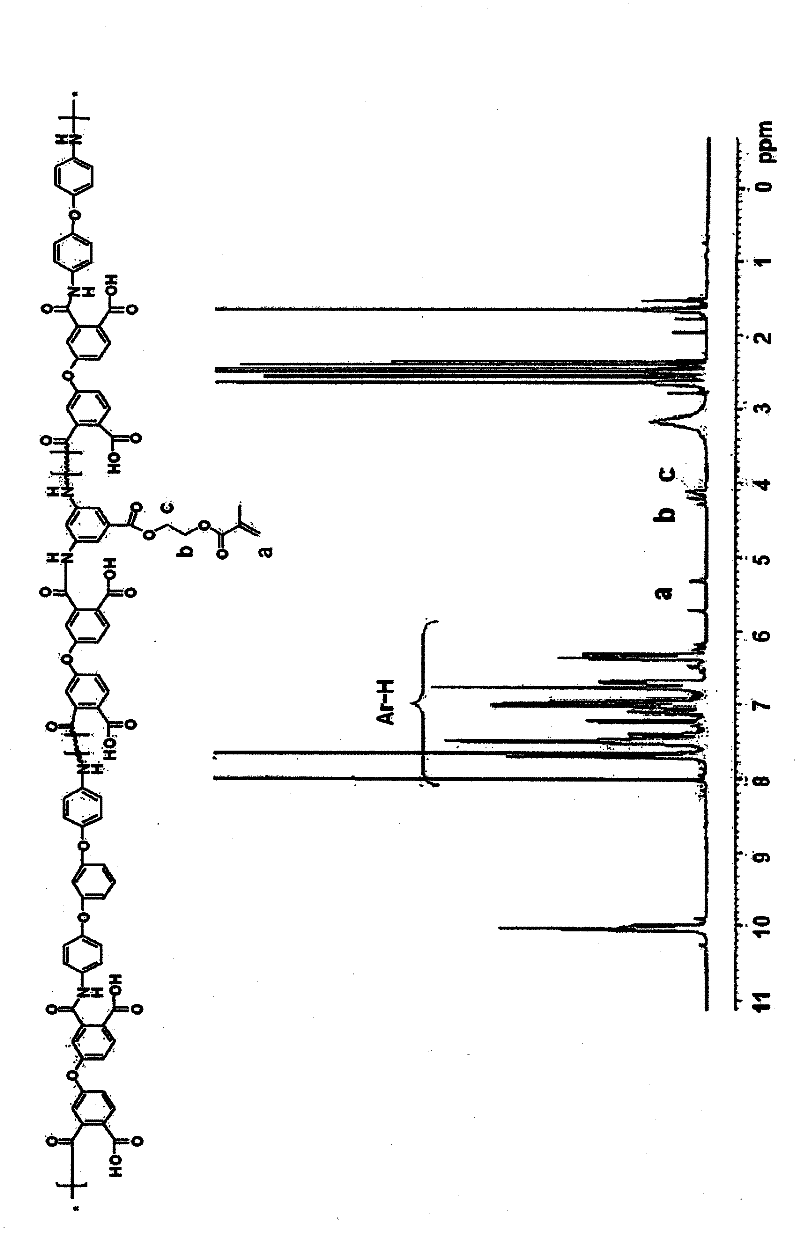

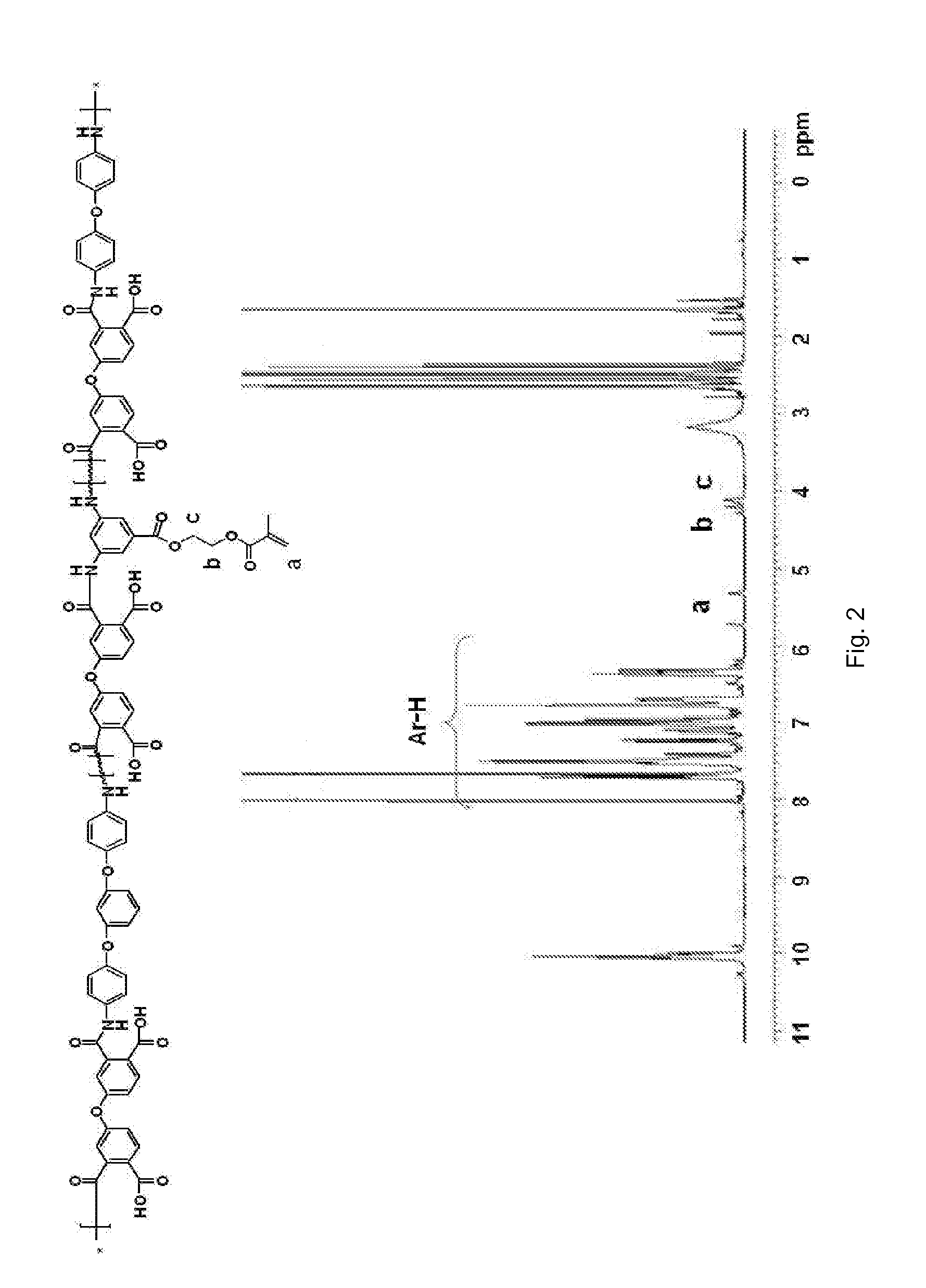

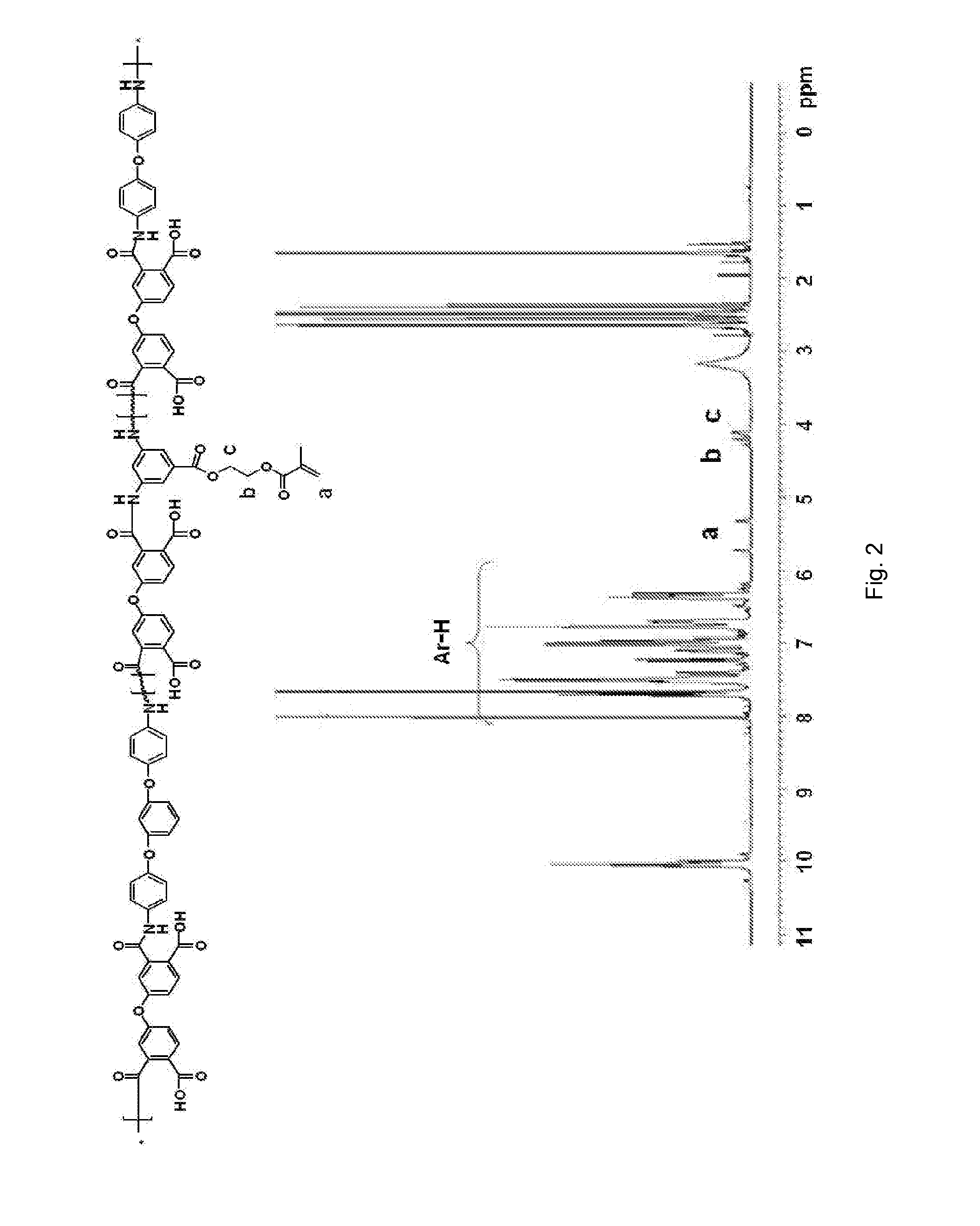

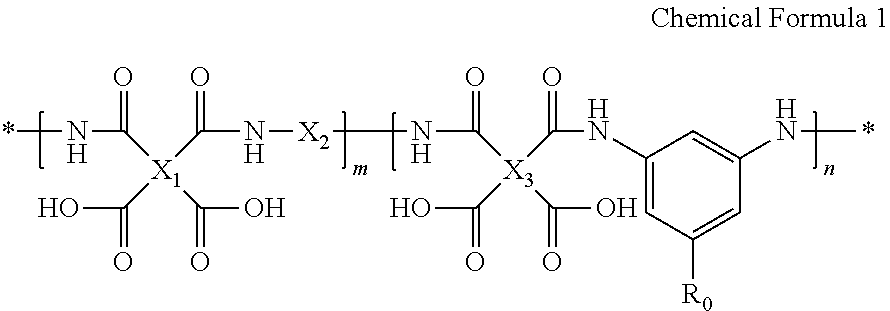

Novel polyamic acid, polyimide, photosensitive resin composition comprising same, and dry film produced from the composition

ActiveCN102361913AHigh resolutionExcellent test toleranceCircuit artworks manufacturePhotosensitive materials for photomechanical apparatusImidePolymer science

The present invention relates to a polyamic acid comprising a thermopolymerizable or photopolymerizable functional group, to a photosensitive resin composition which can form a high-resolution pattern, and which has a superior property of being developable with an aqueous alkaline solution, and which can provide a cured coating film having excellent flexibility, adhesion properties, soldering-heat resistance, and pressure cooker test (PCT) resistance, and to a dry film produced from the composition.

Owner:LG CHEM LTD

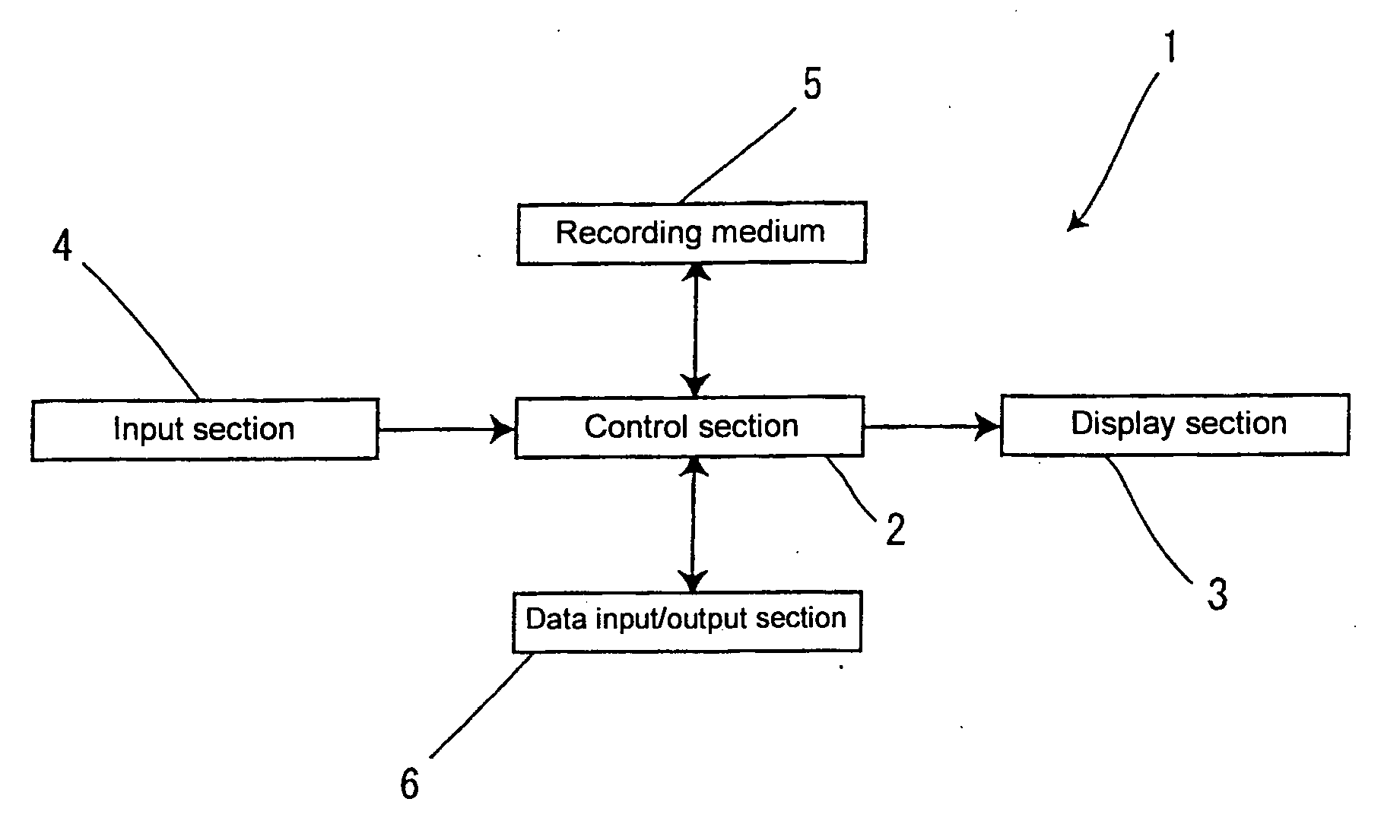

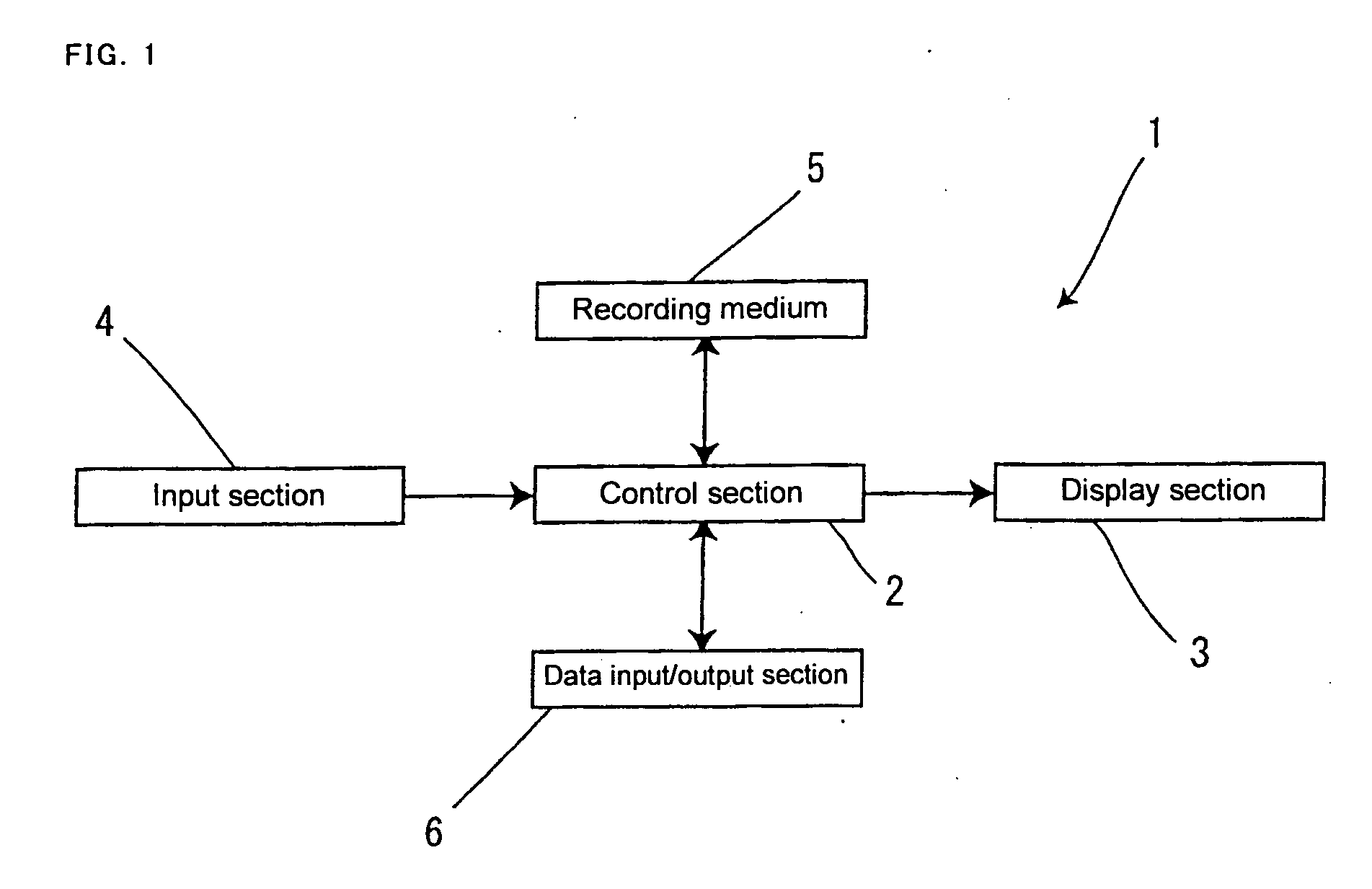

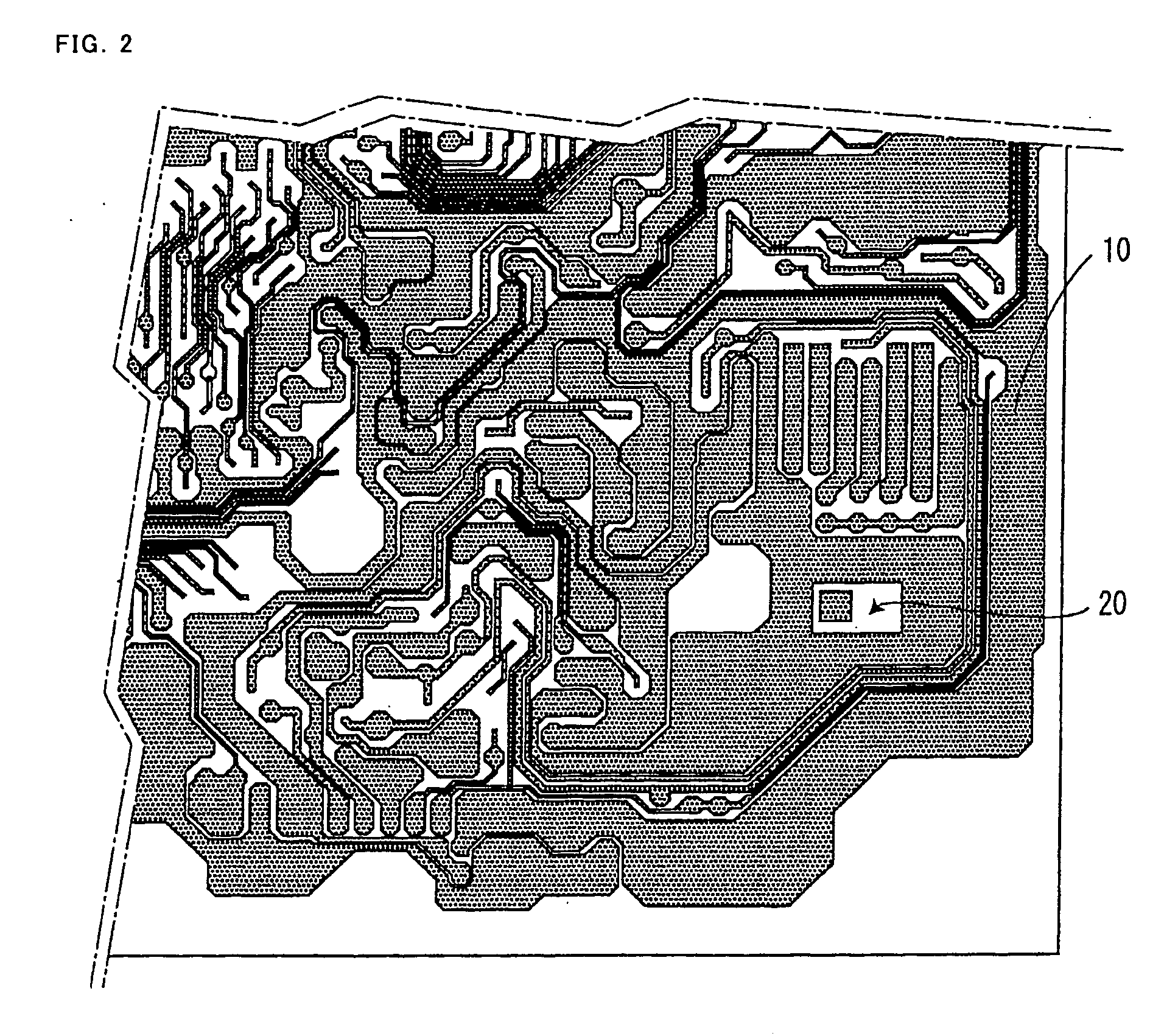

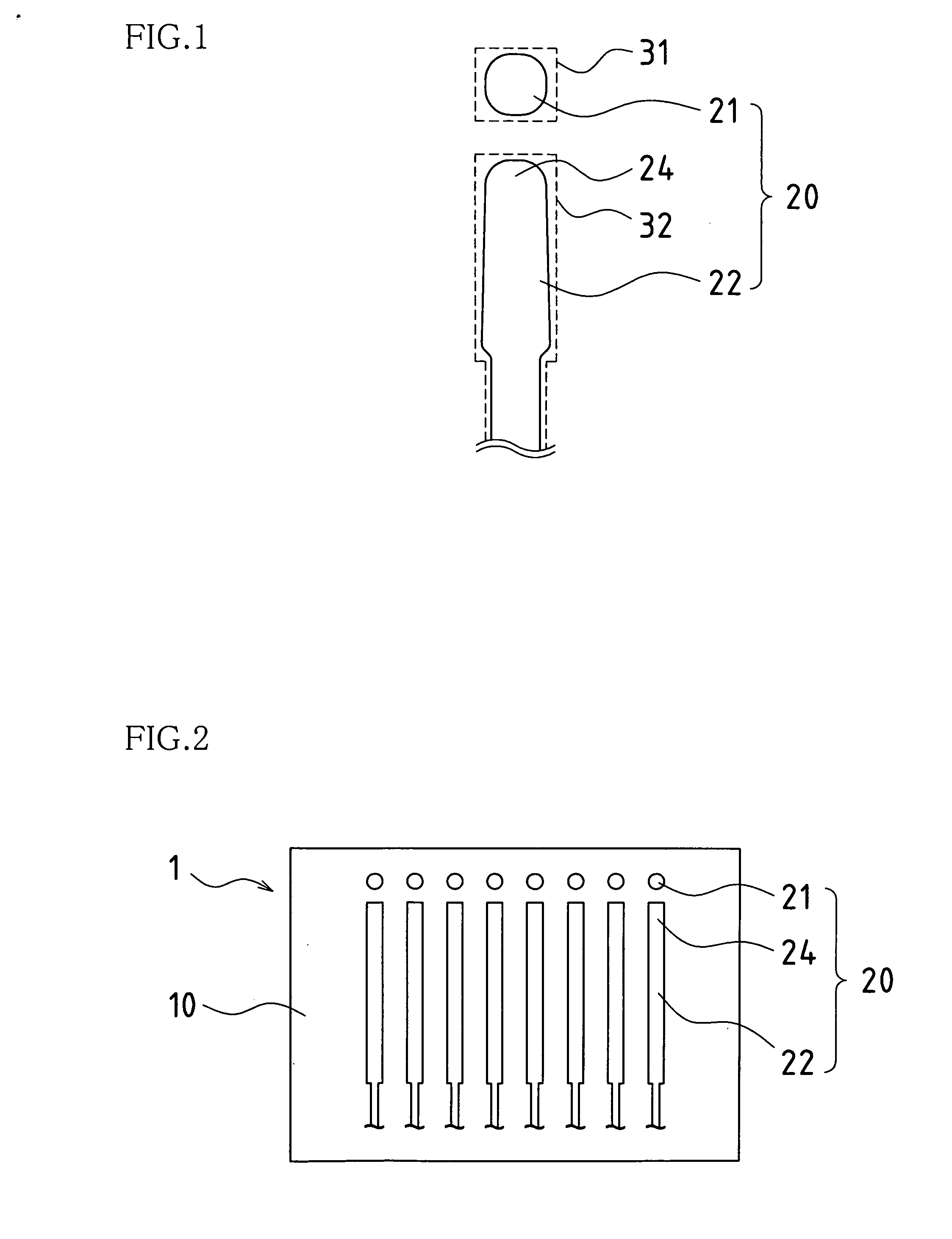

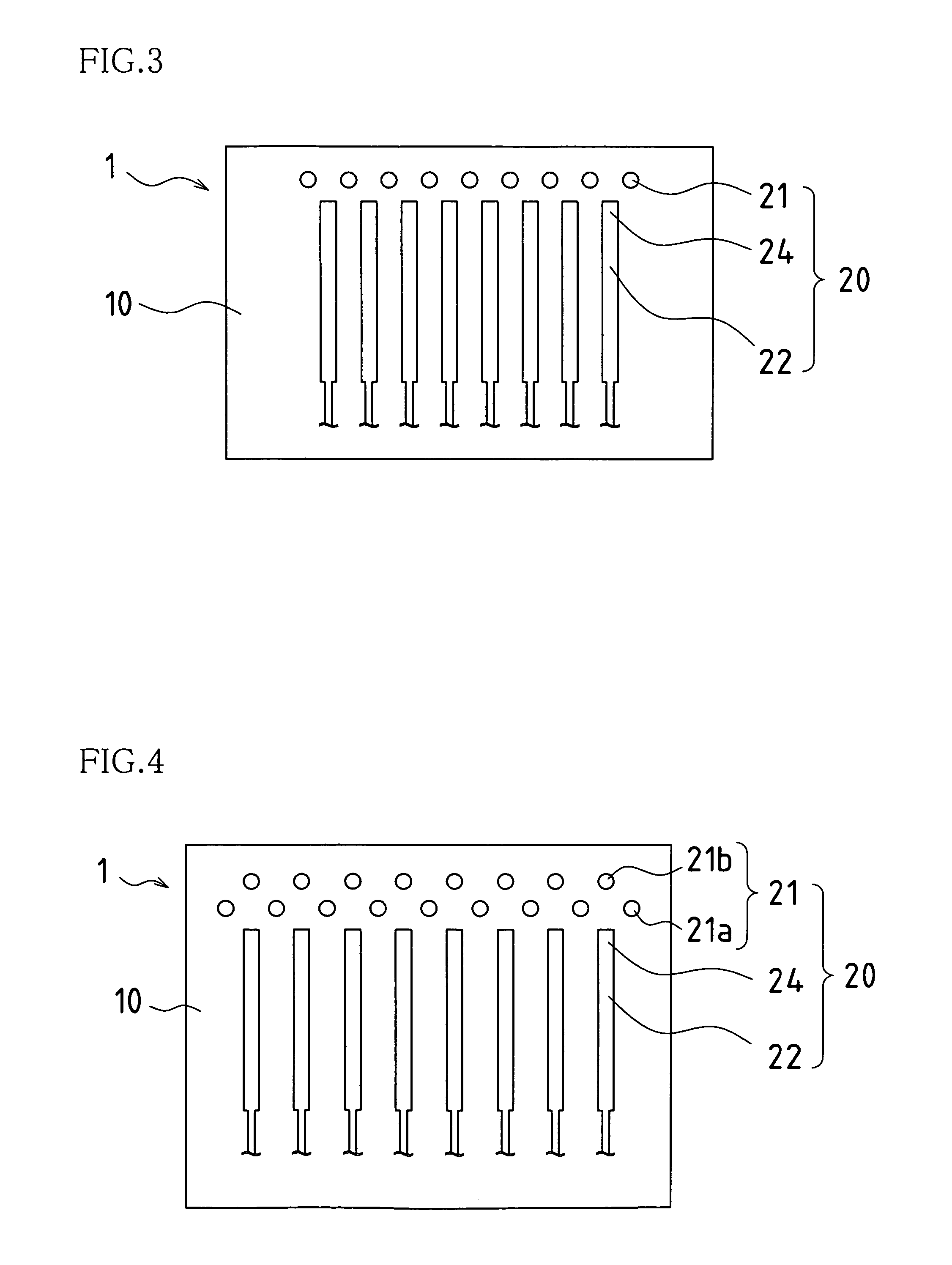

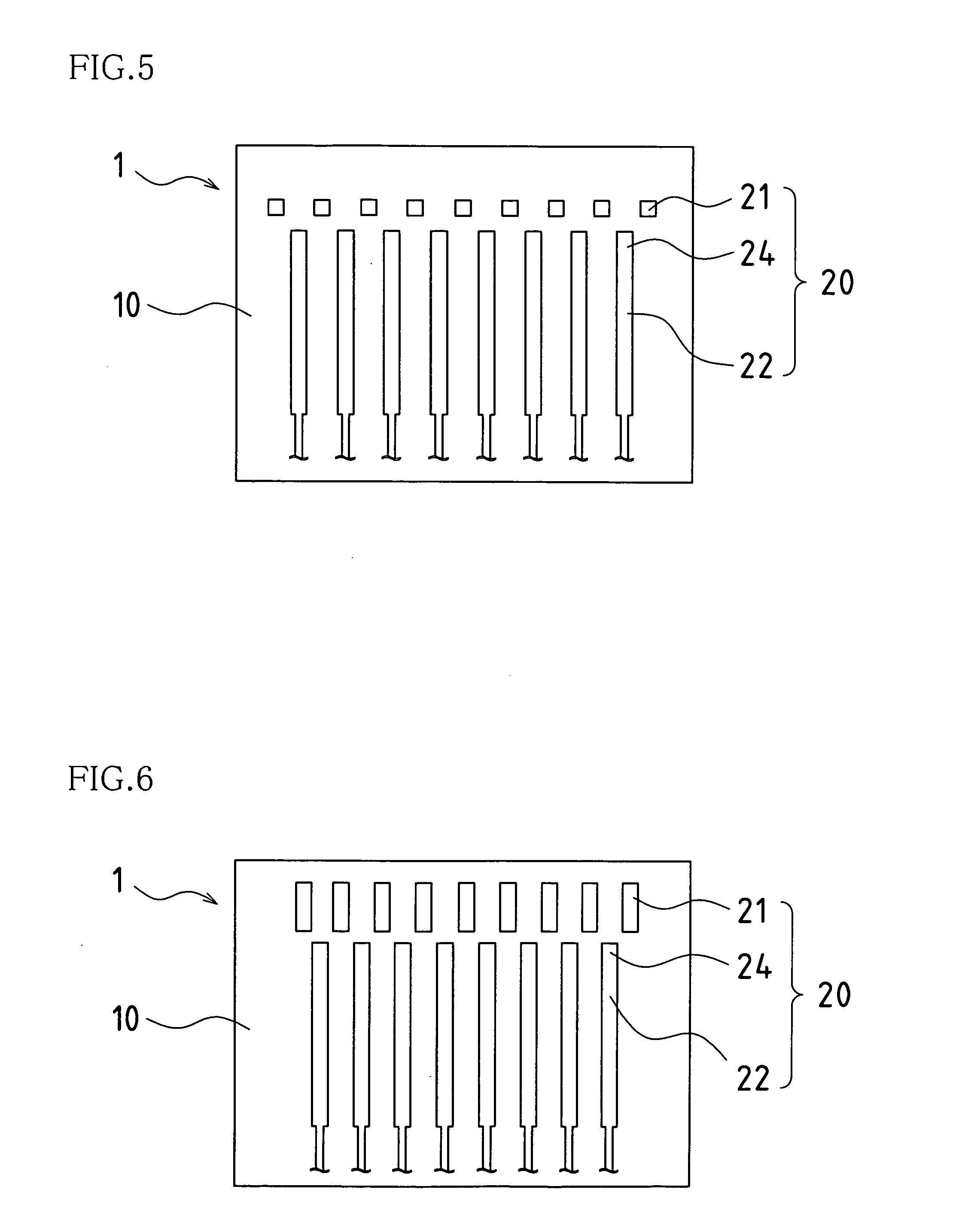

CAD system for a printed circuit board

InactiveUS20060200332A1Valid checkReasonable judgmentPrinted circuit aspectsAnalogue computers for electric apparatusEngineeringPrinted circuit board

A pattern design of a film for manufacturing a printed circuit board is made by using a CAD system, and a plurality of types of Gerber data are produced in which a series of various data has been encoded. For example, a pattern film is formed by combining pattern Gerber data with pattern cut Gerber data. Data for check marks whose sizes are different from each other is added as well as pattern data to each Gerber data such that their central coordinates are to be the same. In this manner, a judgment mark having the check marks combined therewith is formed on the pattern film having the items of Gerber data combined therewith.

Owner:ORION ELECTRIC CO LTD

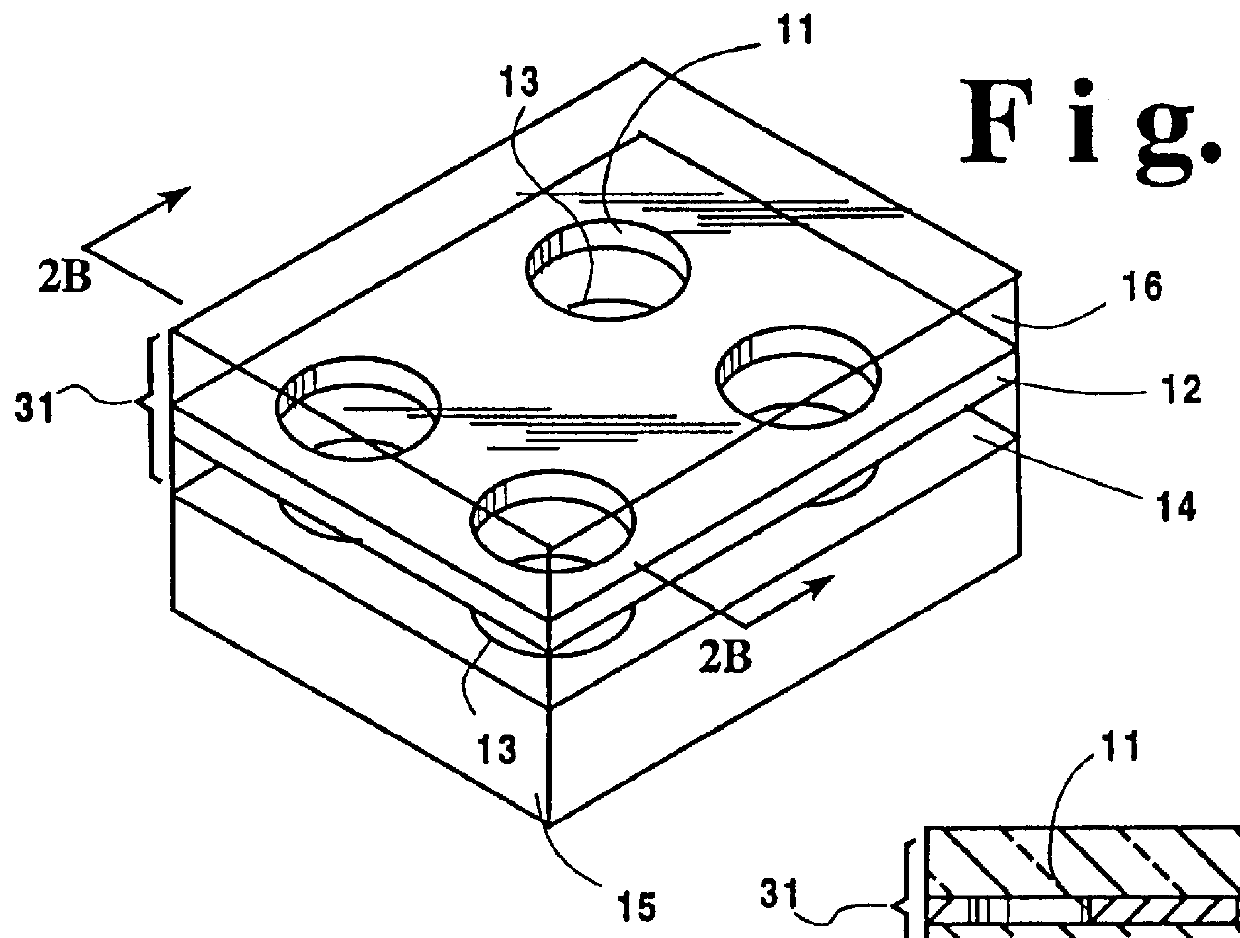

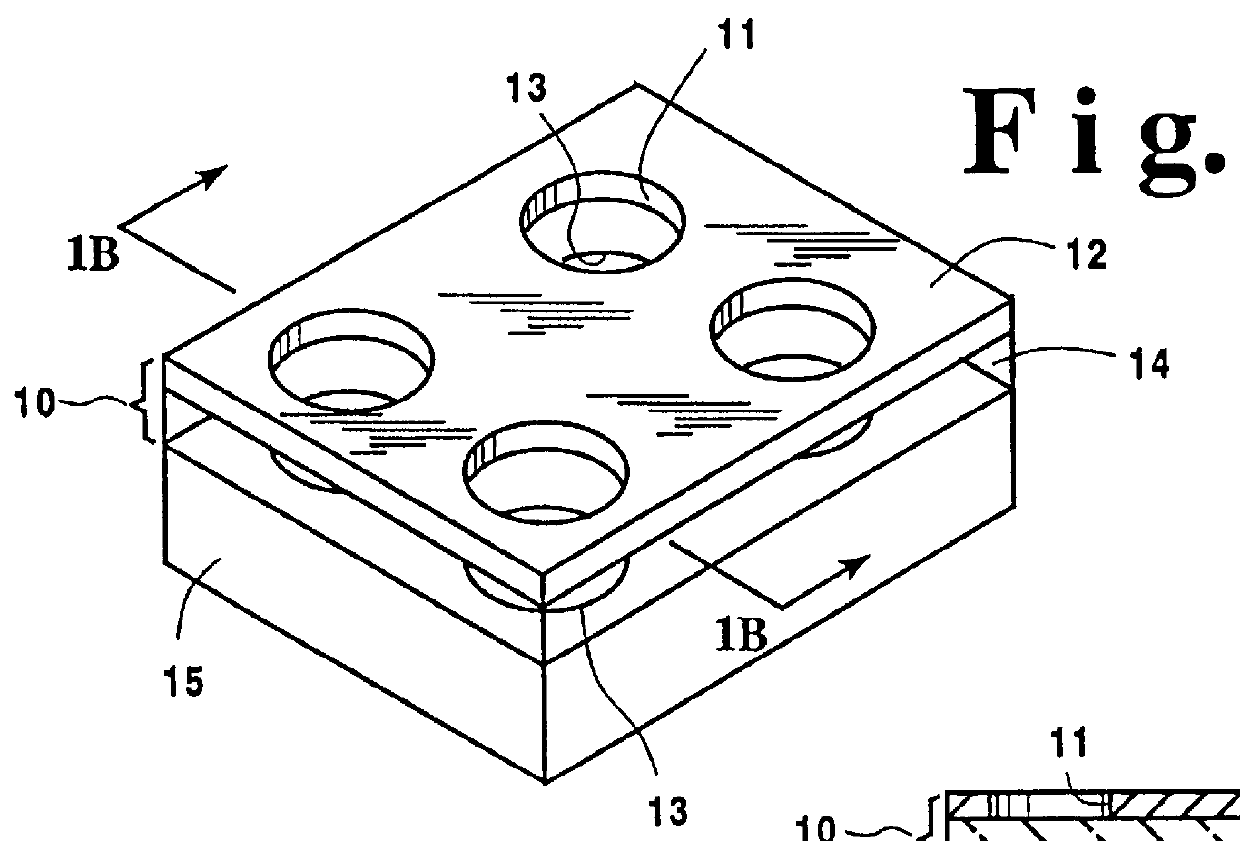

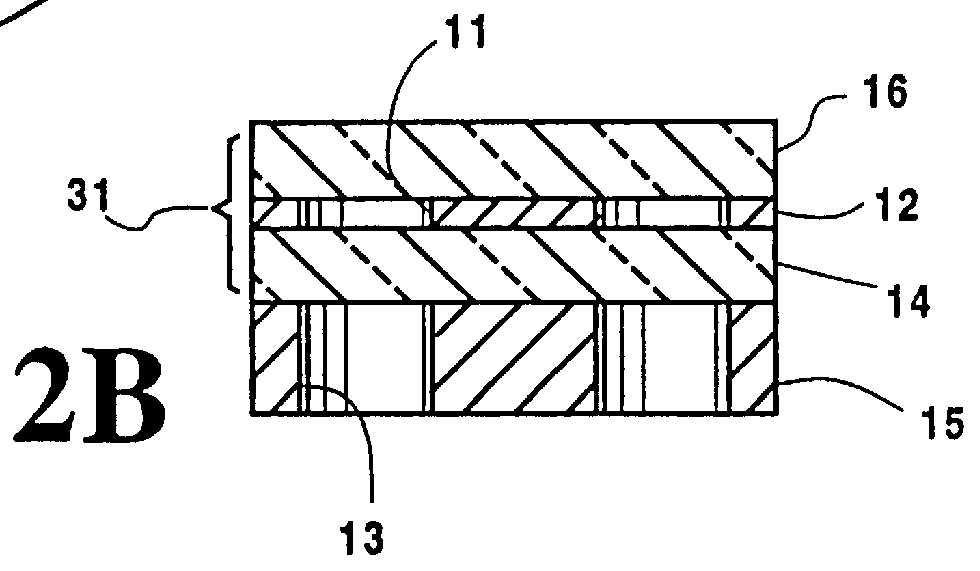

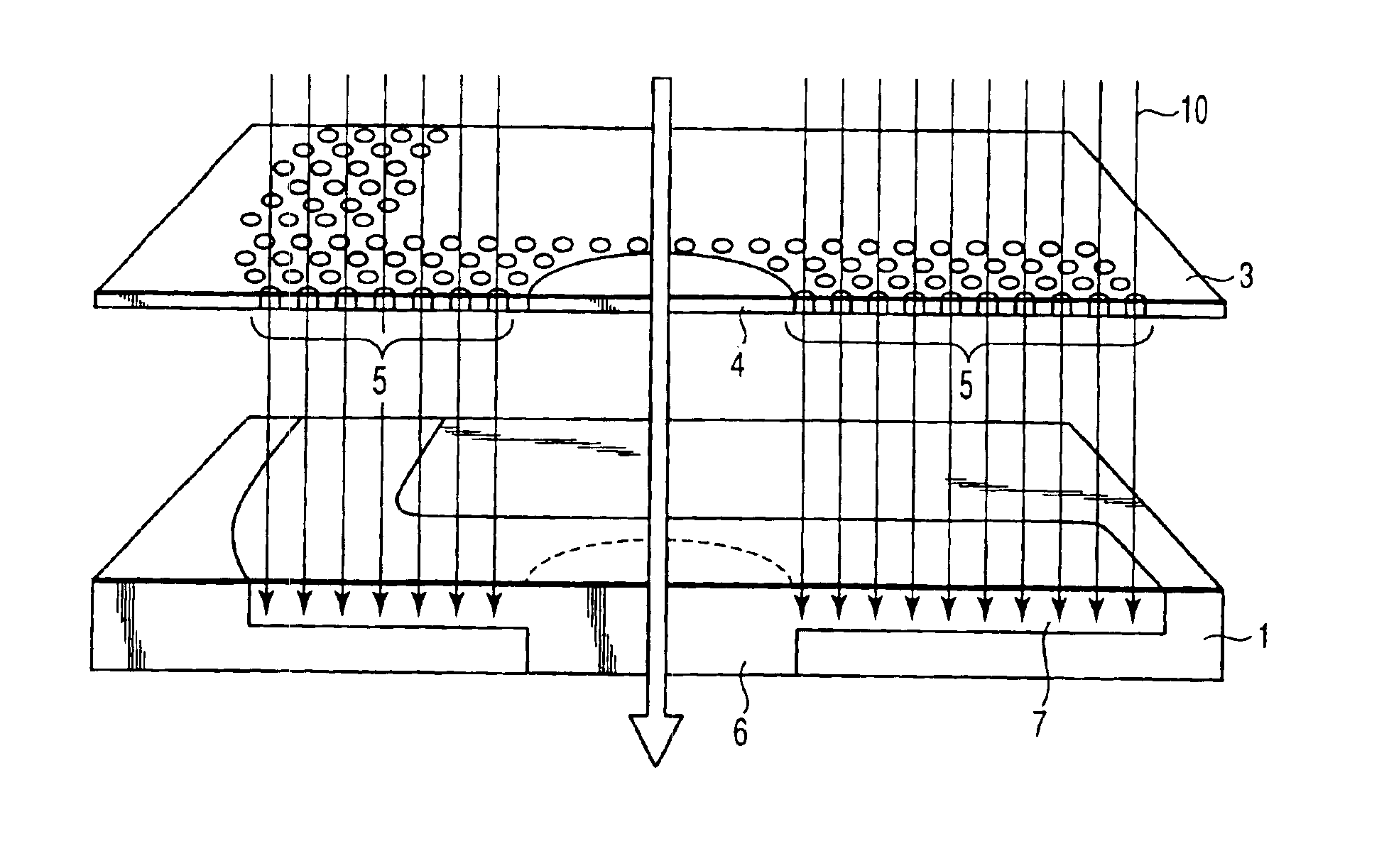

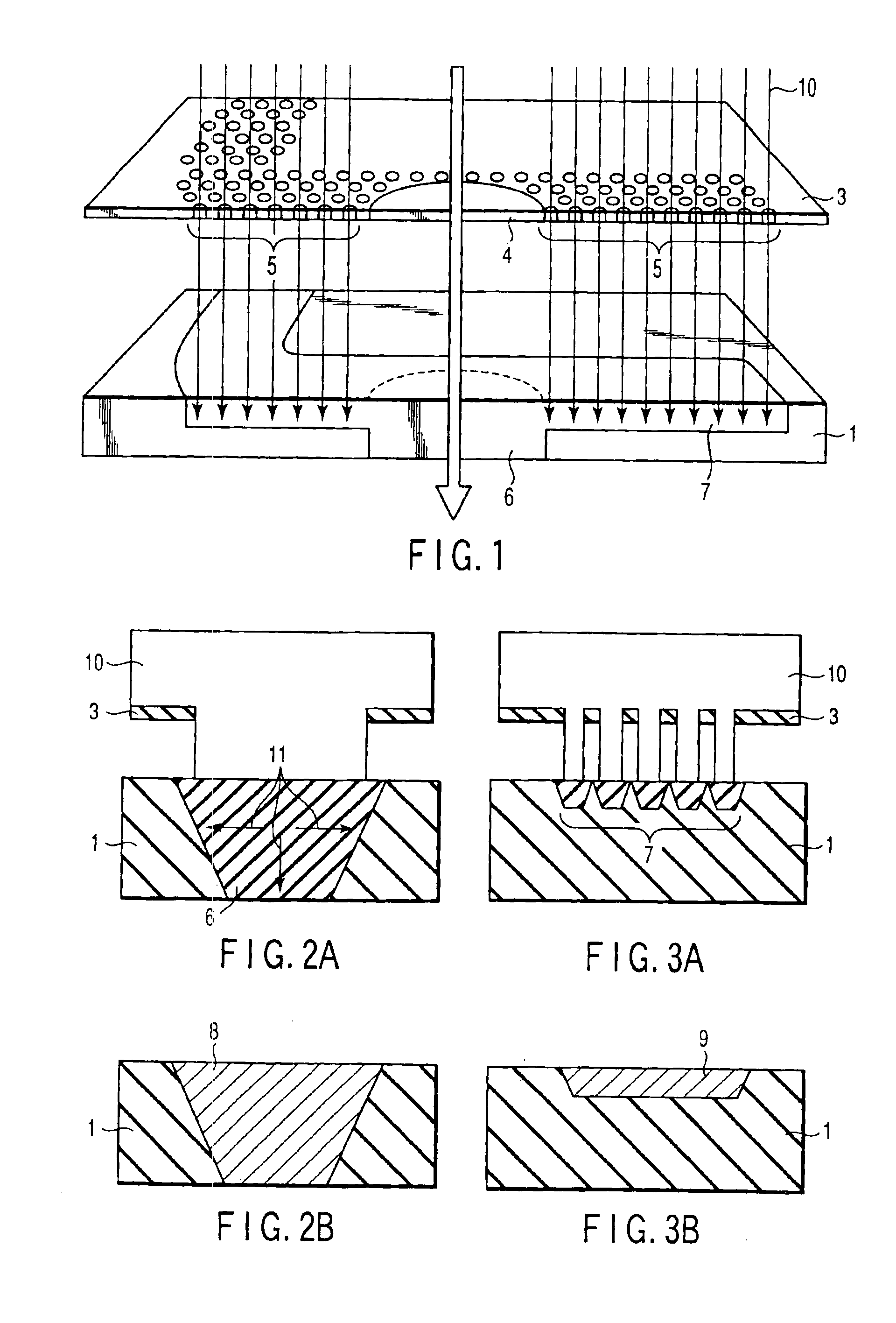

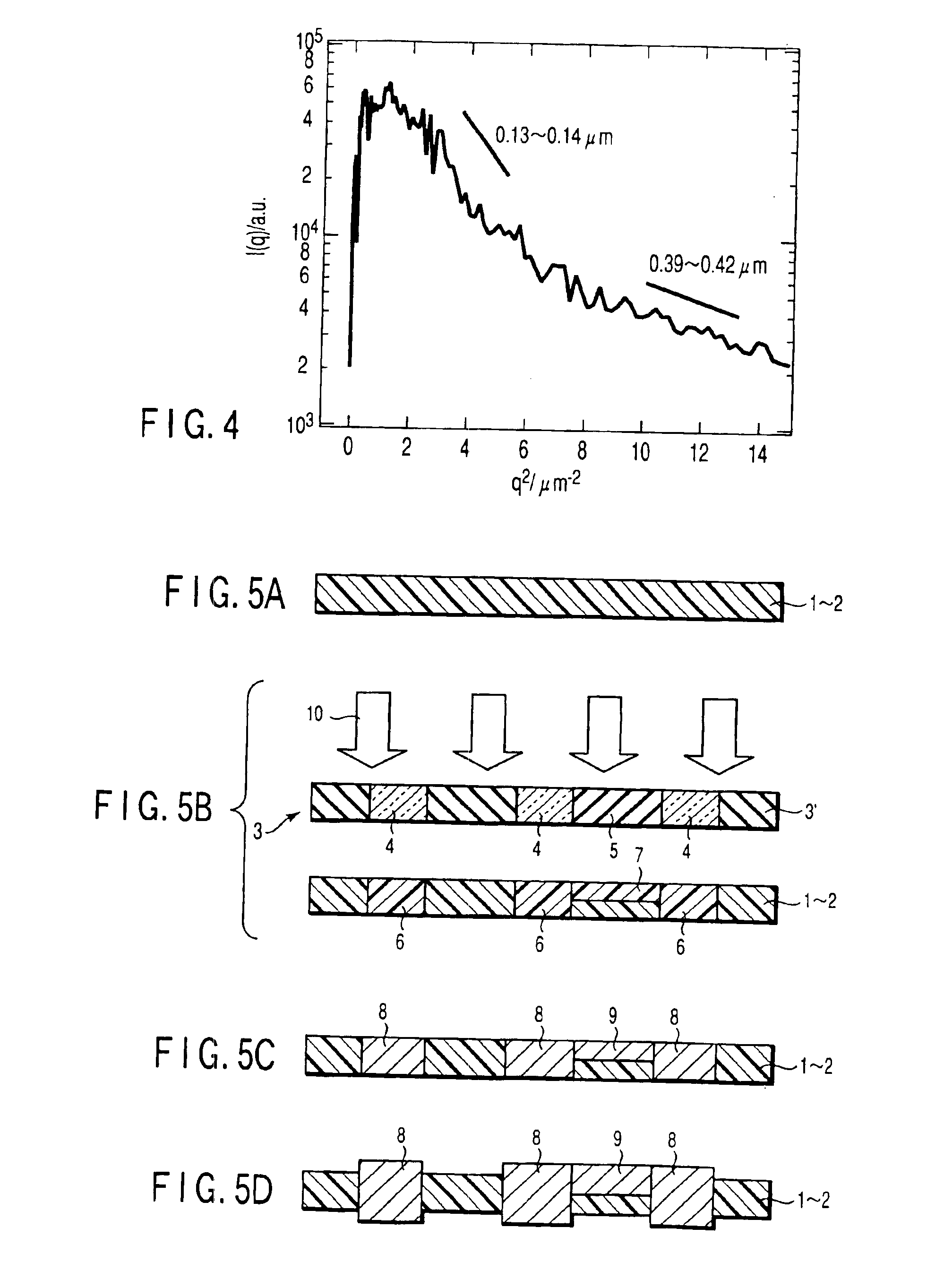

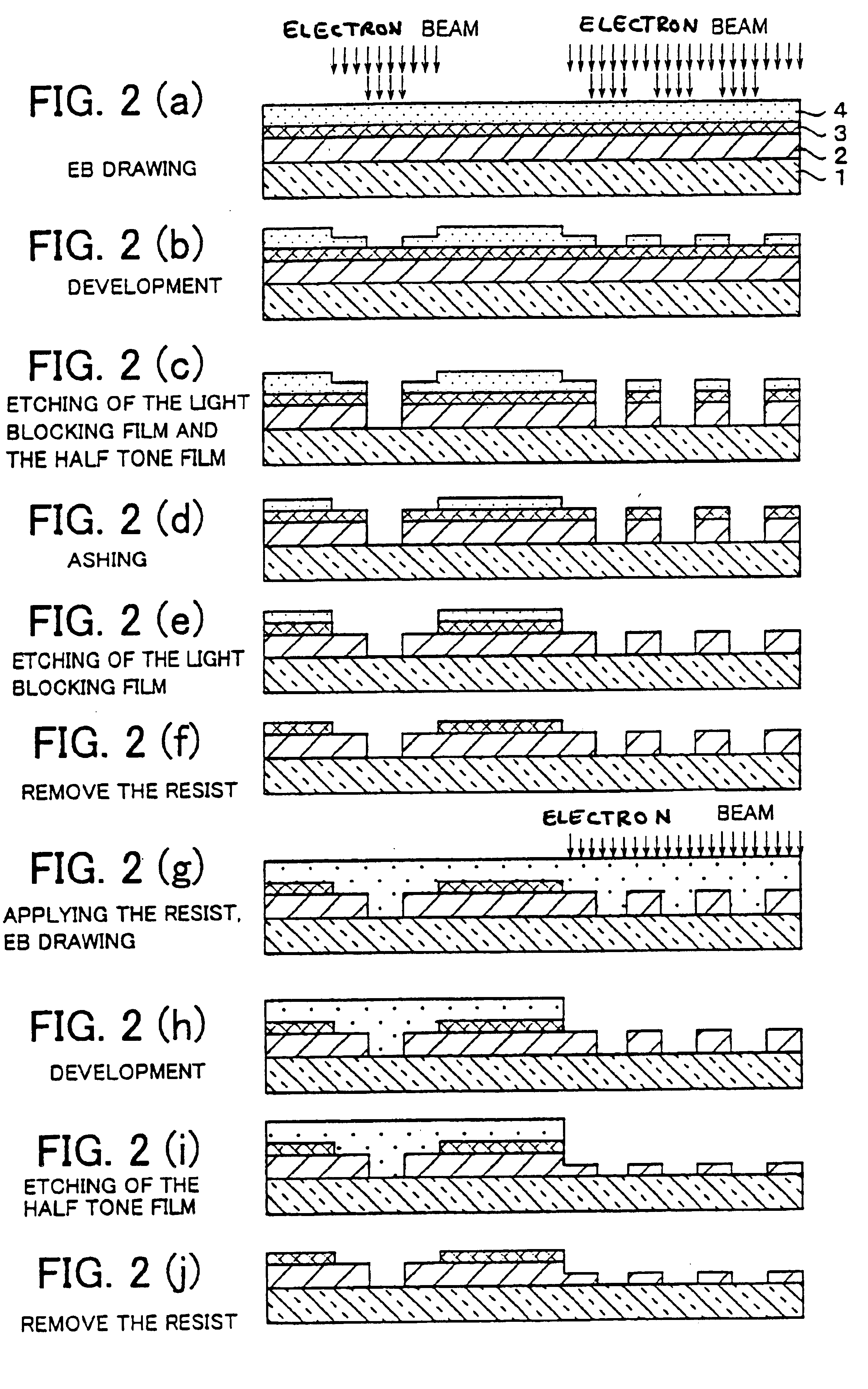

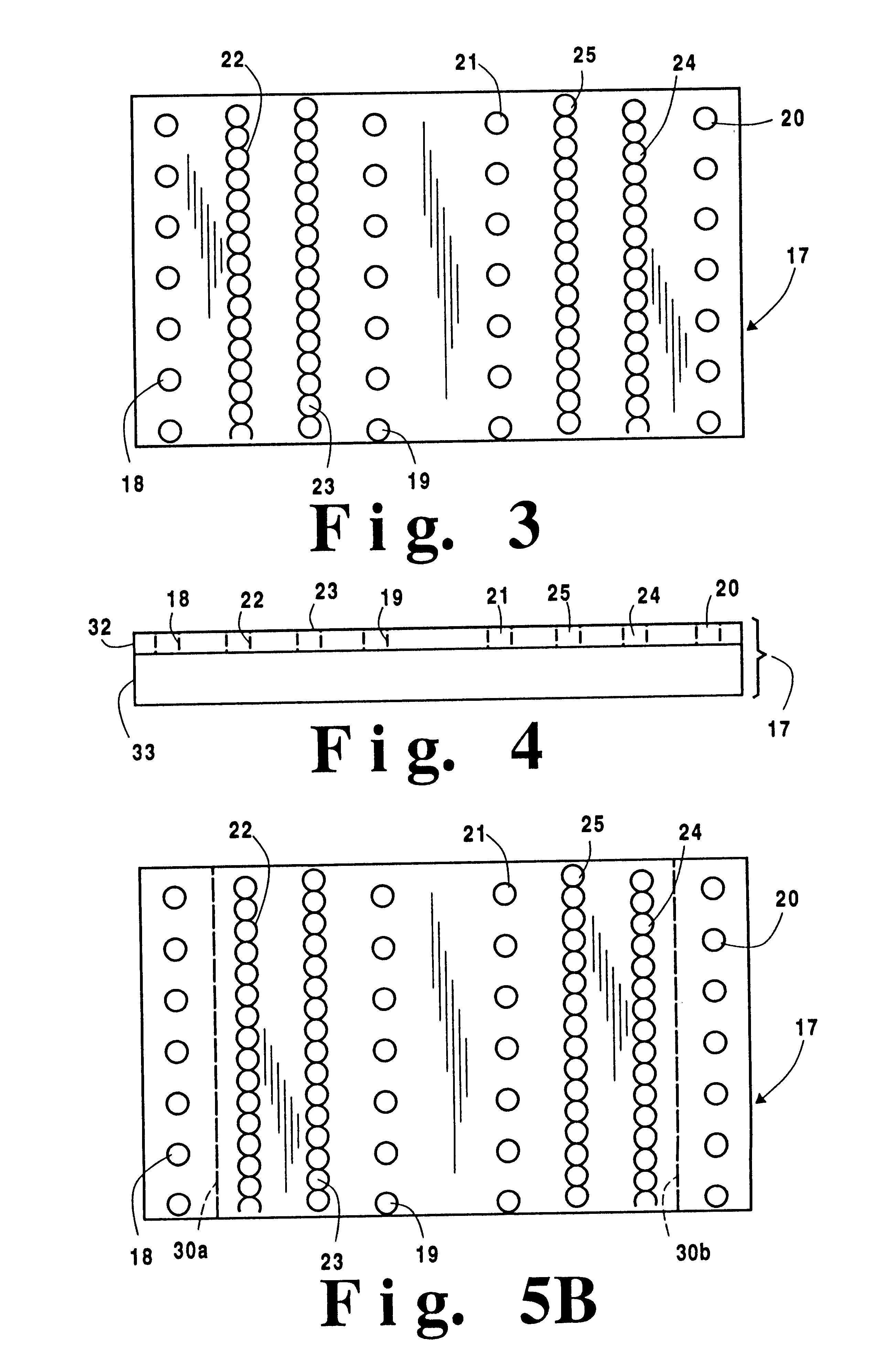

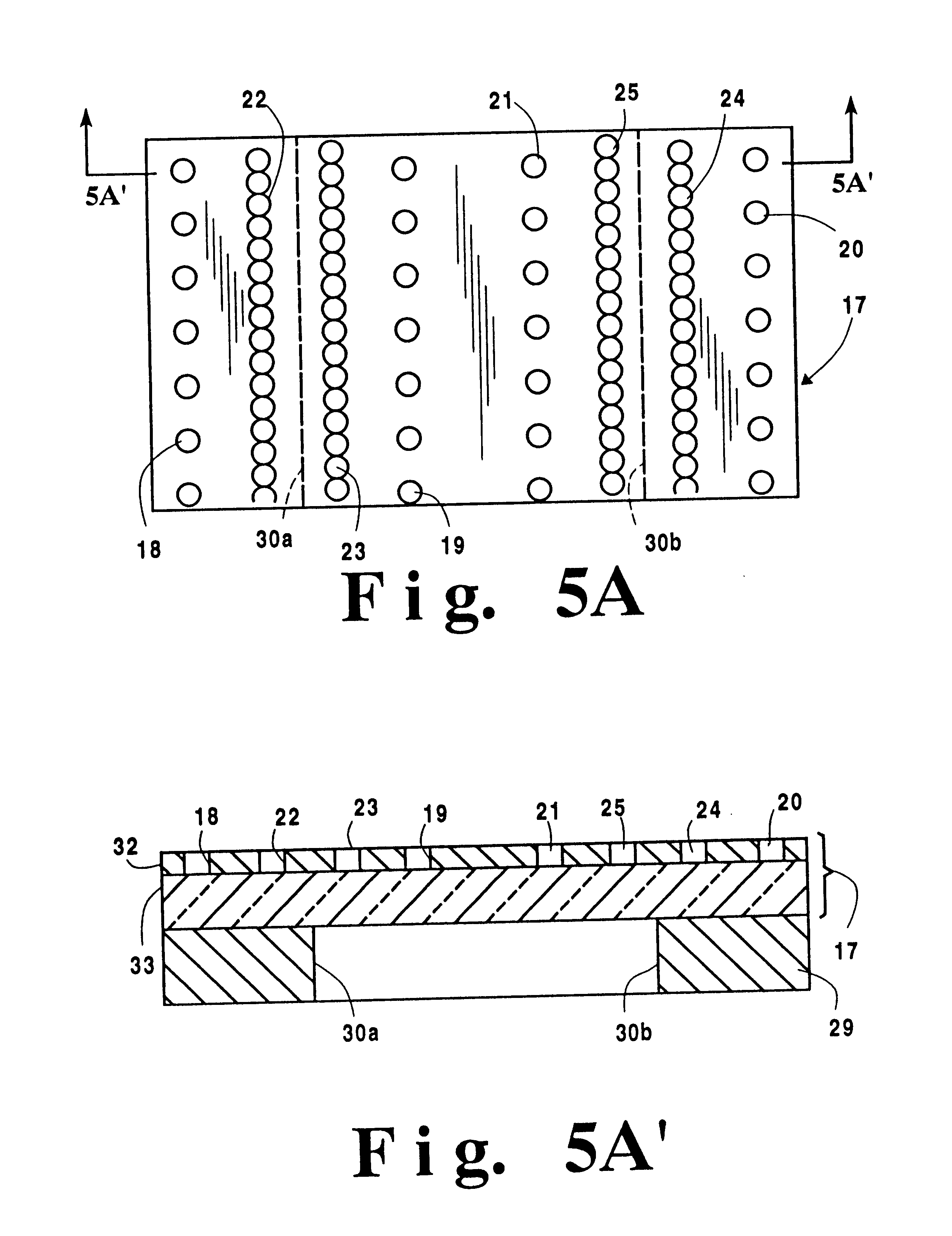

Mask used for exposing a porous substrate

InactiveUS6906423B1Increase freedomPorous dielectricsLayered productsPorous substrateConductive materials

A mask used for exposing a porous substrate to form a first region and a second region, the first region being filled with a conductive material piercing through the entire thickness of the porous substrate to constitute an interfacial conductive portion, the second region being filled with a conductive material not piercing the entire thickness of the porous substrate to constitute a non-interfacial conductive portion. The mask includes a first light-transmitting region for exposing the first region, and a second light-transmitting region for exposing the second region, said second light-transmitting region including an aggregation of fine patterns of which an average aperture ratio is not more than 50% of an average aperture ratio of the first light-transmitting region and a size of said fine patterns of the second light-transmitting region being in the range of 0.1 μm to 10 μm.

Owner:KK TOSHIBA

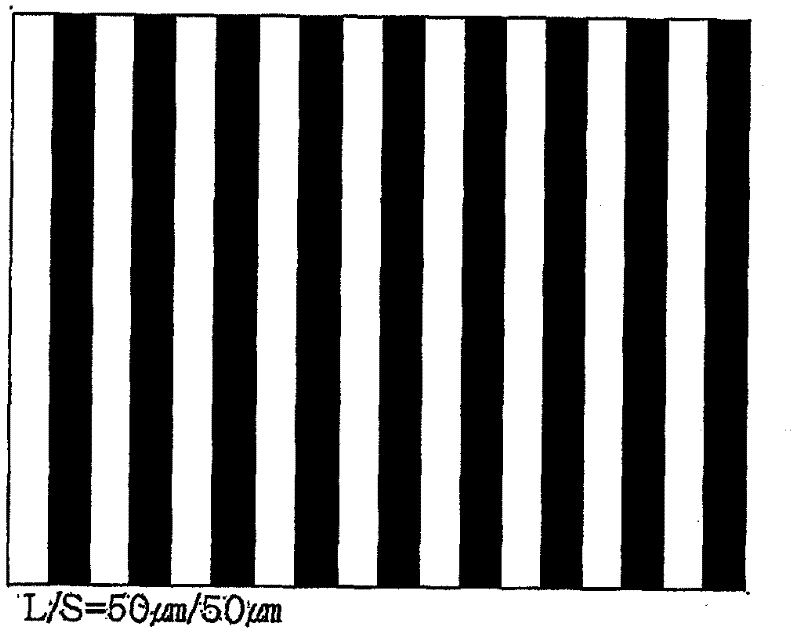

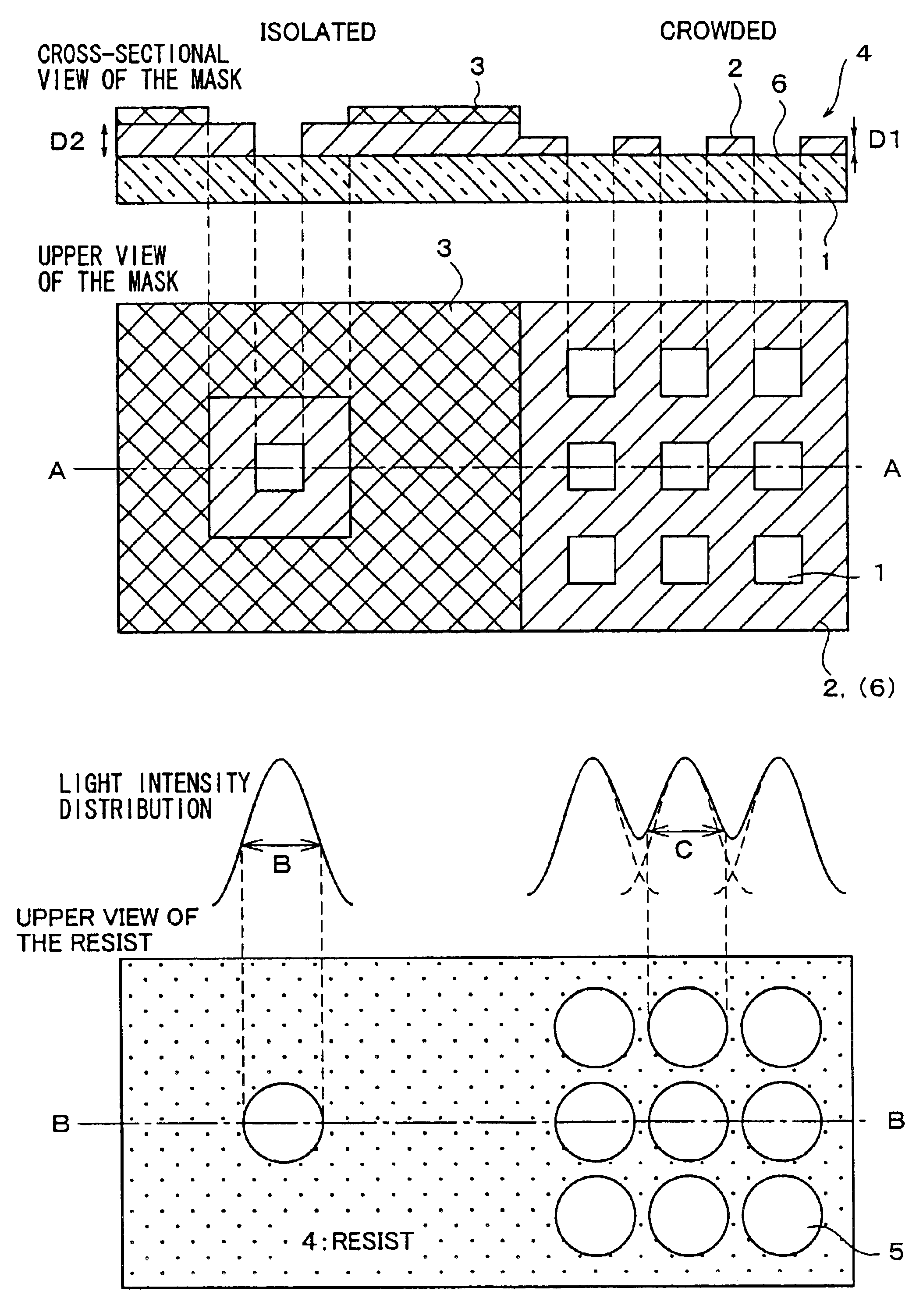

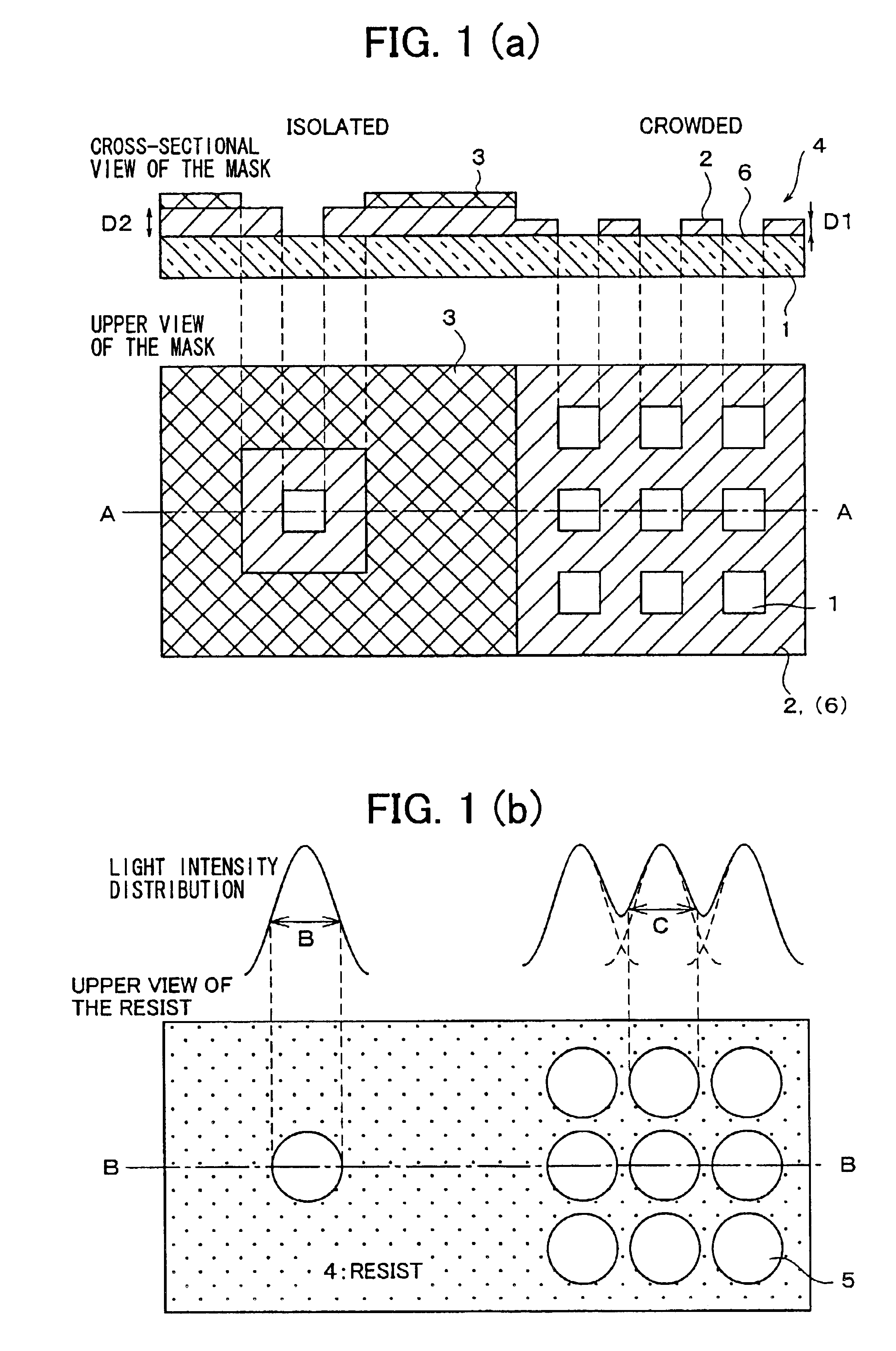

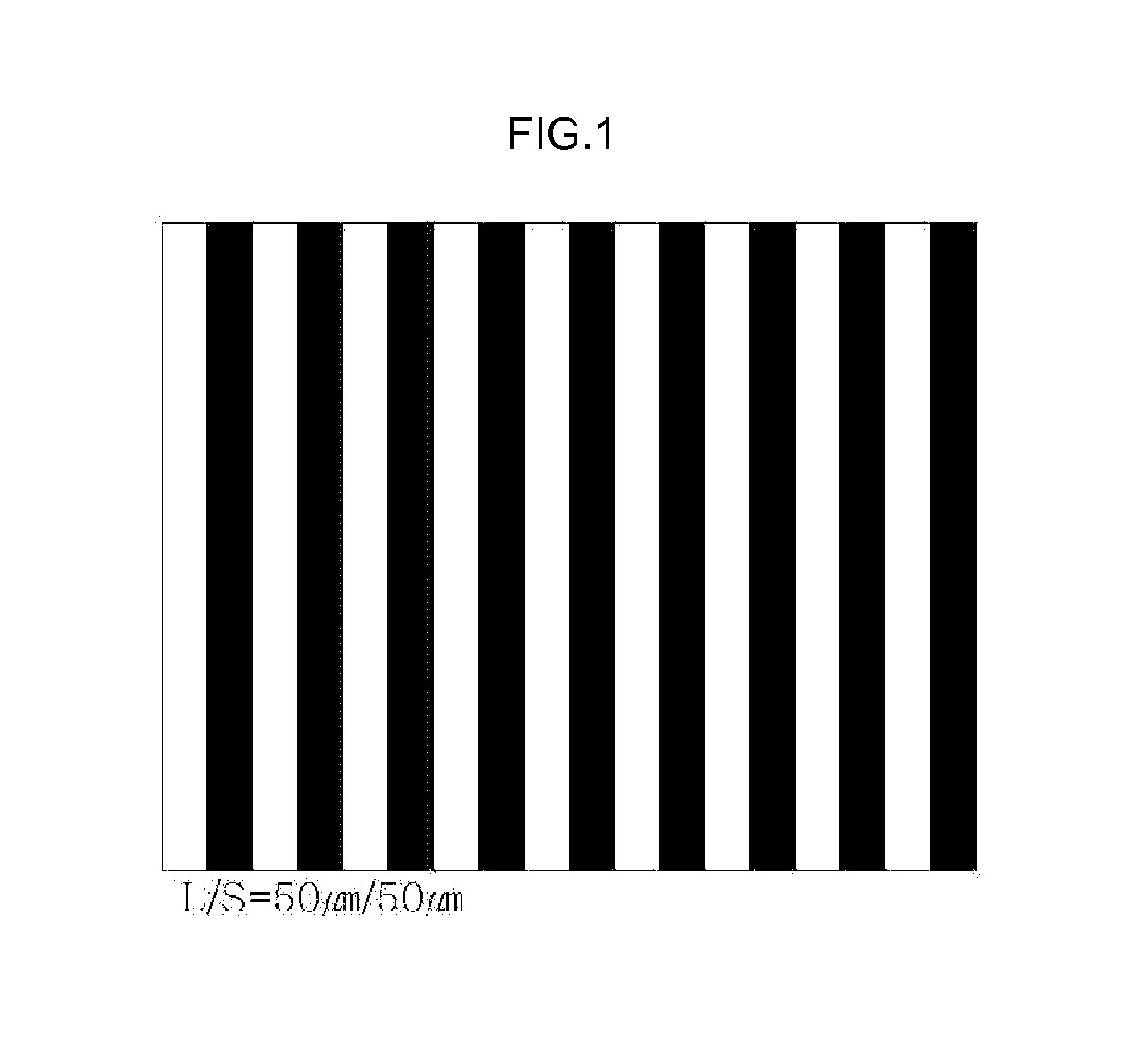

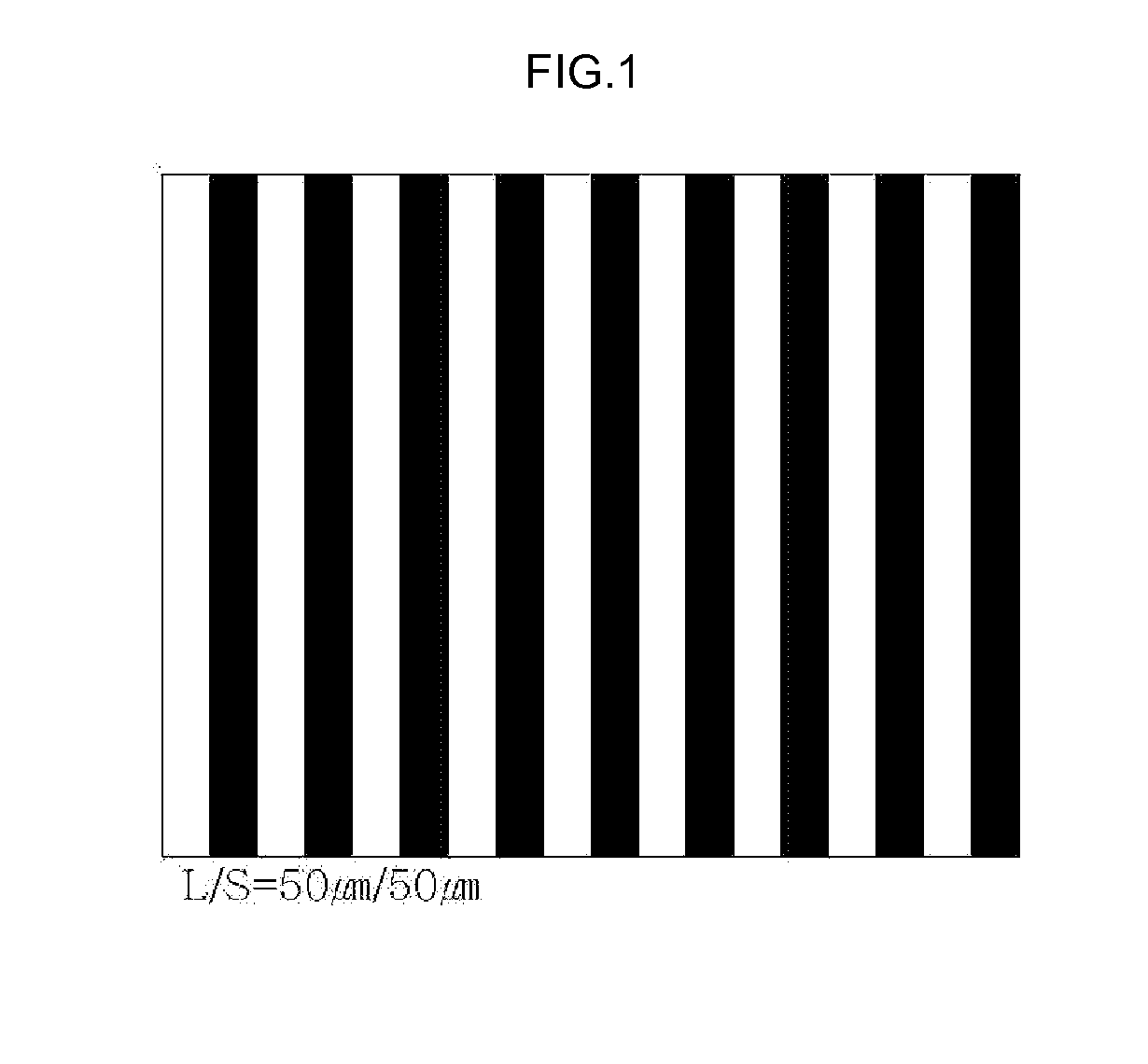

Pattern transfer method using a mask and half tone mask

InactiveUS6902852B2Avoid size differencesSemiconductor/solid-state device manufacturingCircuit artworks manufactureHigh definitionMaterials science

A half tone mask of the present invention is provided with a half tone film in which a thickness of the half tone film in a dense pattern area where optical proximity effect occurs differs from that in an isolated pattern area where the optical proximity effect does not occur, the thickness of the half tone film in the isolated pattern area being adjusted so that difference in size of a resist does not occur between the dense pattern area and the isolated pattern area due to the optical proximity effect, thus preventing the difference in size of the resist between the dense pattern area and the isolated pattern area, even when providing high definition patterns which causes the optical proximity effect.

Owner:SHARP KK

Formation of punch inspection masks and other devices using a laser

InactiveUS6207330B1Inexpensive and cost-effectiveSure easyPhotosensitive materialsDecorative surface effectsLight beamLaser exposure

Exposure masks and inspection masks for use in the electronics field may be made using laser beams wherein the mask comprises a substrate which is substantially unaffected by exposure to the laser beam and an opaque pattern forming layer on the substrate, which pattern forming layer absorbs the laser beam and is selectively etched when exposed to the laser beam. A preferred mask has an overcoat transparent layer. A cavity inspection mask is provided having a series of openings in the form of lines formed in the opaque pattern forming layer, the lines bounding the cavity walls, is the mask being used for determining if the cavity is centrally positioned on the substrate and / or that the cavity is of the desired size. Substrates containing identifying masks thereon which cannot be seen by the unaided eye for theft deterrence are also provided.

Owner:IBM CORP

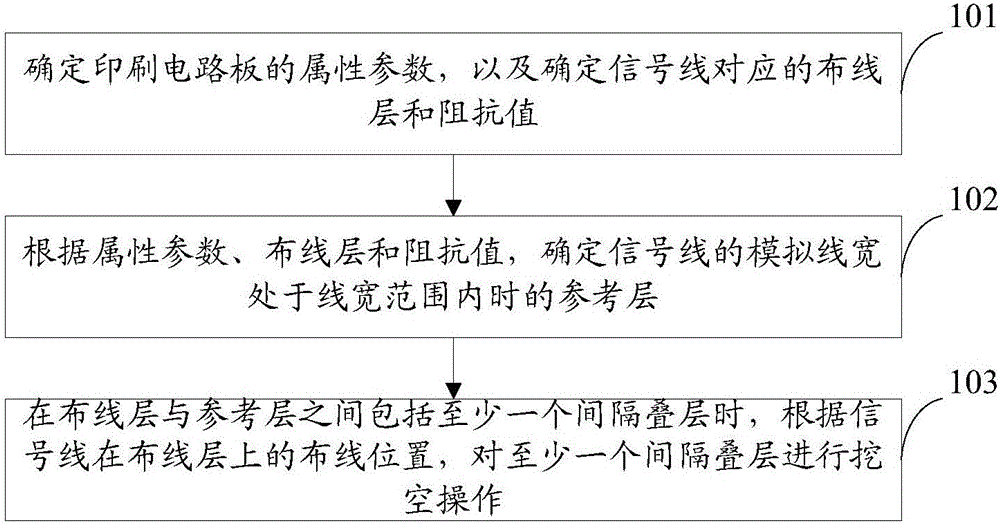

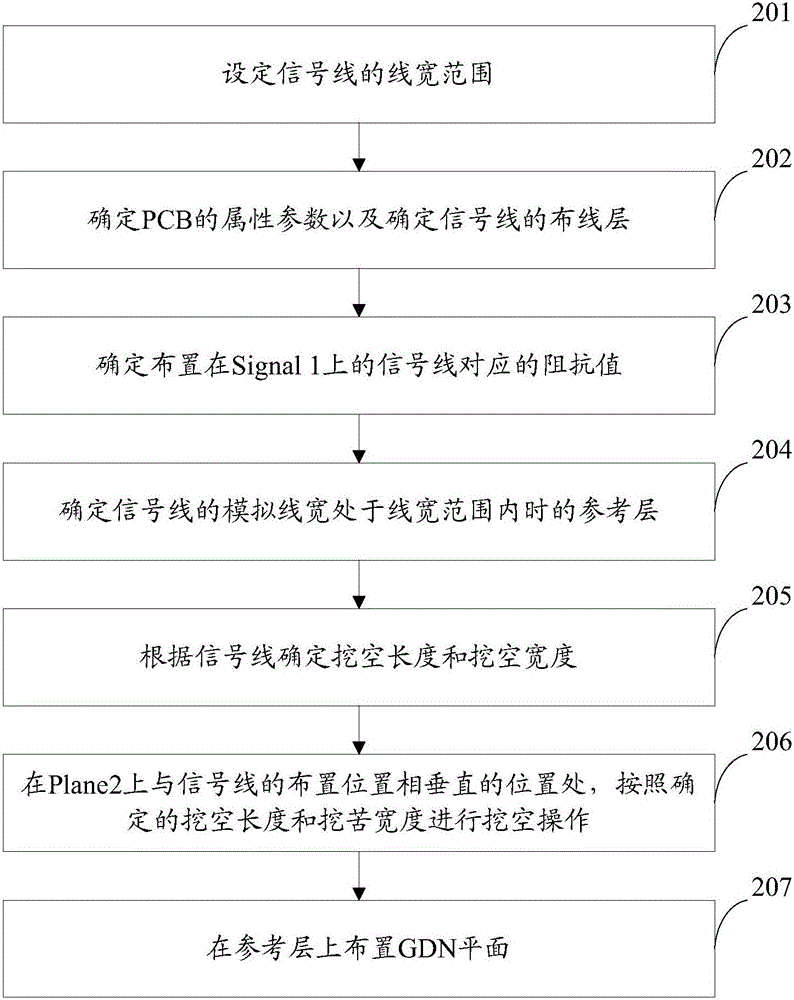

Method and system for determining signal line reference layer

ActiveCN106385765ARealize the signal functionPrinted circuit aspectsCircuit artworks manufactureLine widthPrinted circuit board

The invention provides a method and system for determining a signal line reference layer, and the method comprises the steps: setting a line width range of the signal line; determining attribute parameters of a printed circuit board, and setting a wiring layer and a resistance value corresponding to the signal line; according to the attribute parameters, the wiring layer and the resistance value, determining a reference layer when simulated line width of the signal line is in the line width range; when an interval laminating layer being arranged between the wiring layer and the reference layer, and according to the wiring position of the signal line on the wiring layer, performing hollowing operation on at least one interval laminating layer. According to the scheme, the signal line realizing more signal functions in a proper line width can be guaranteed.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

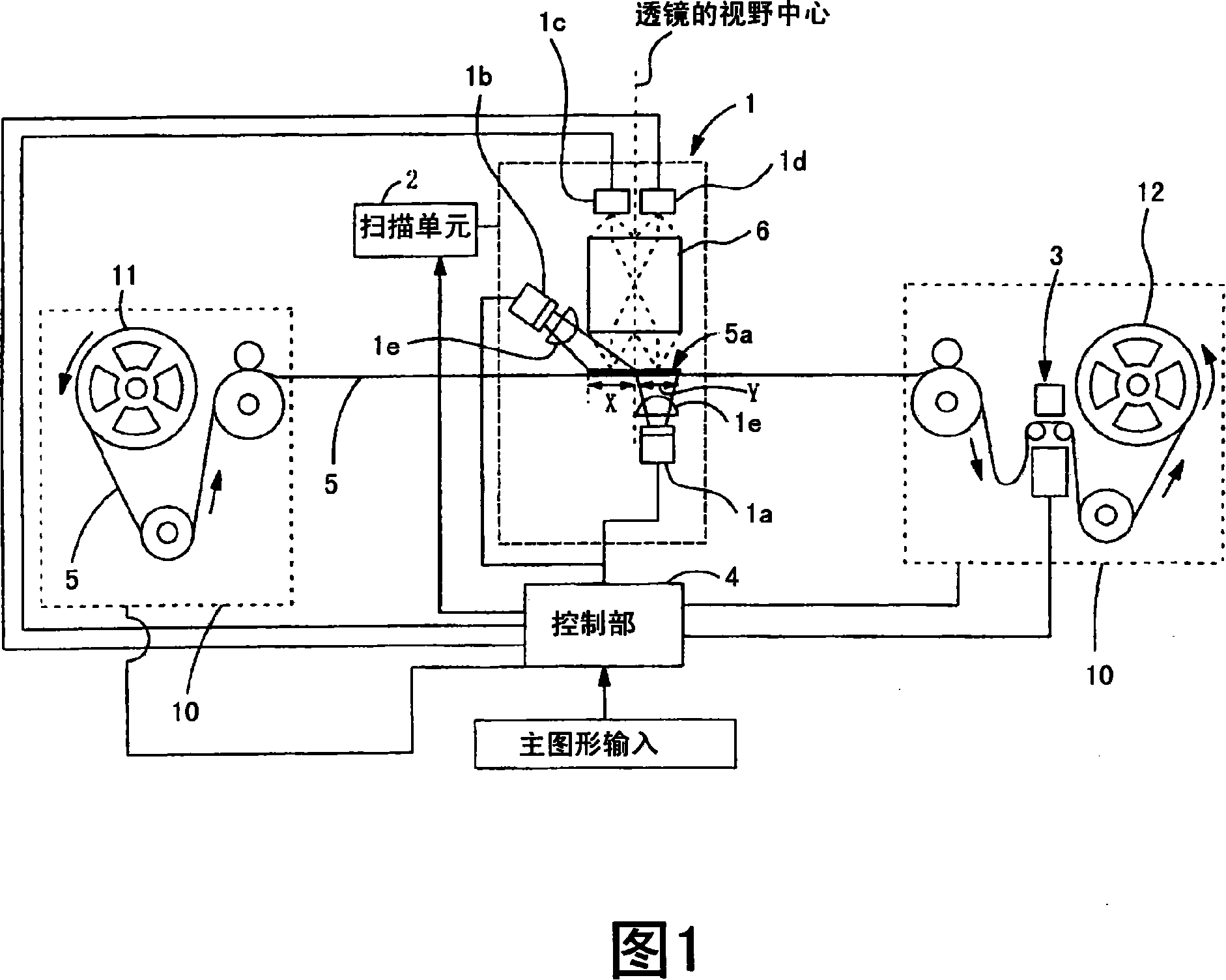

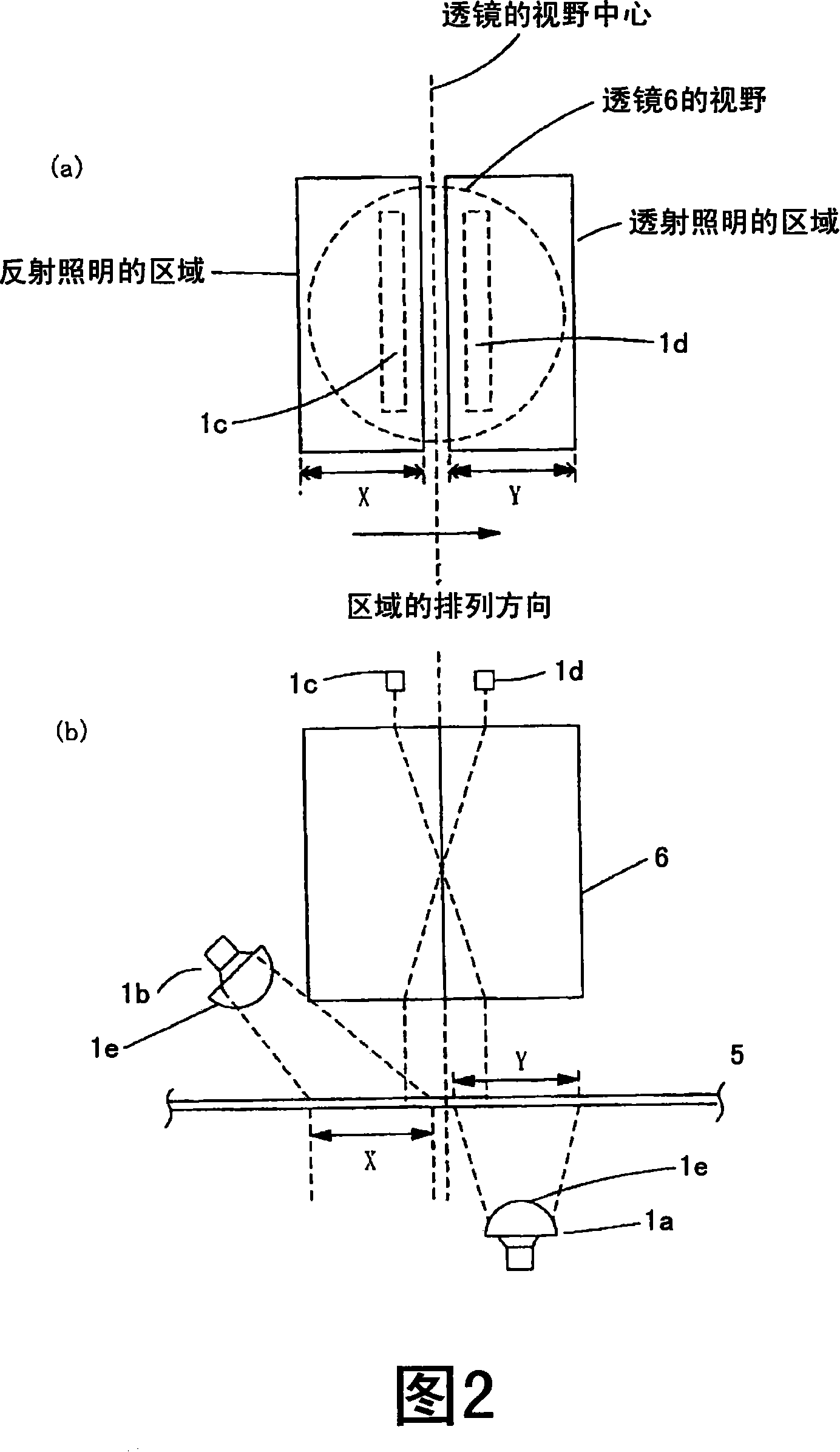

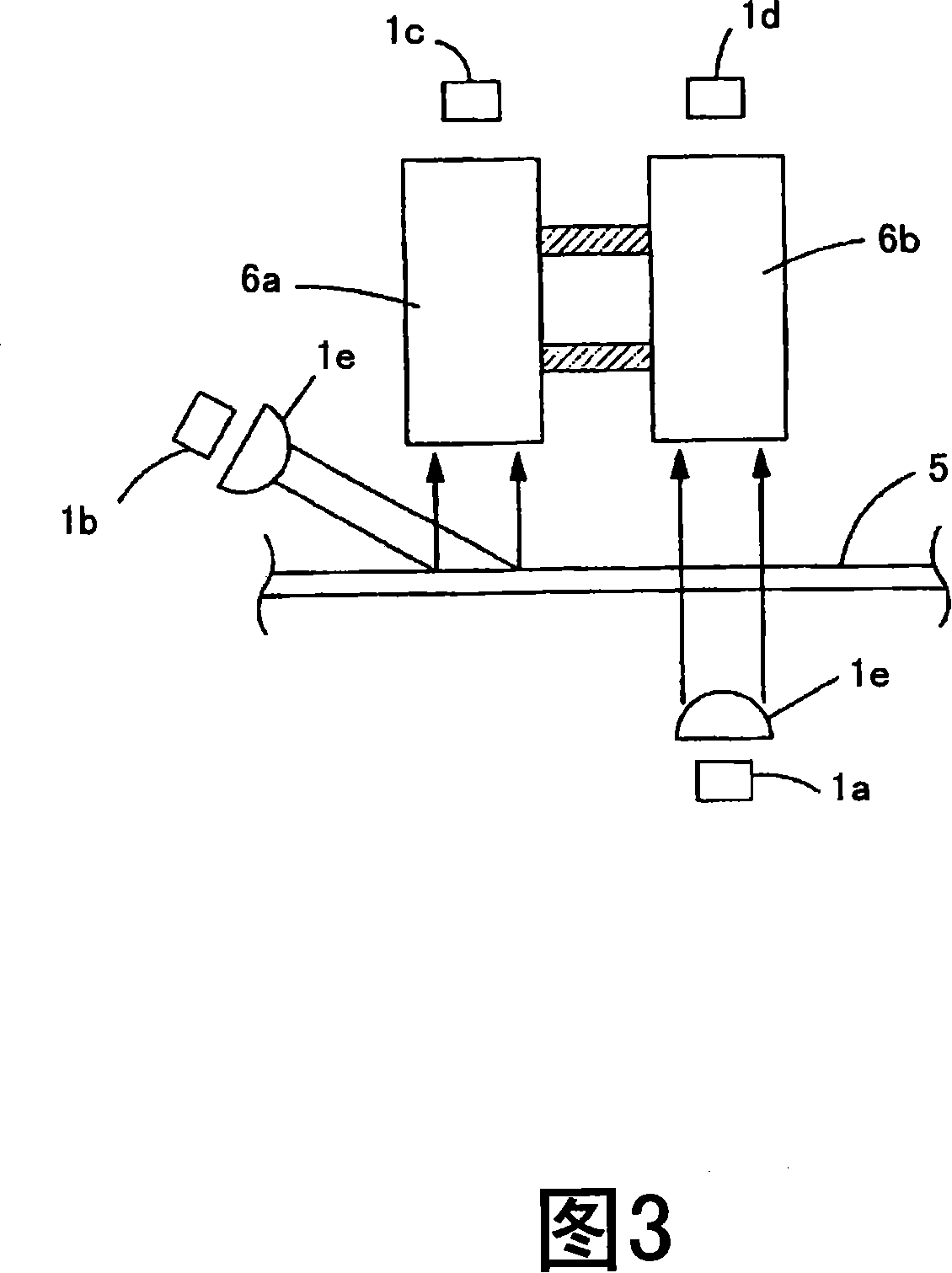

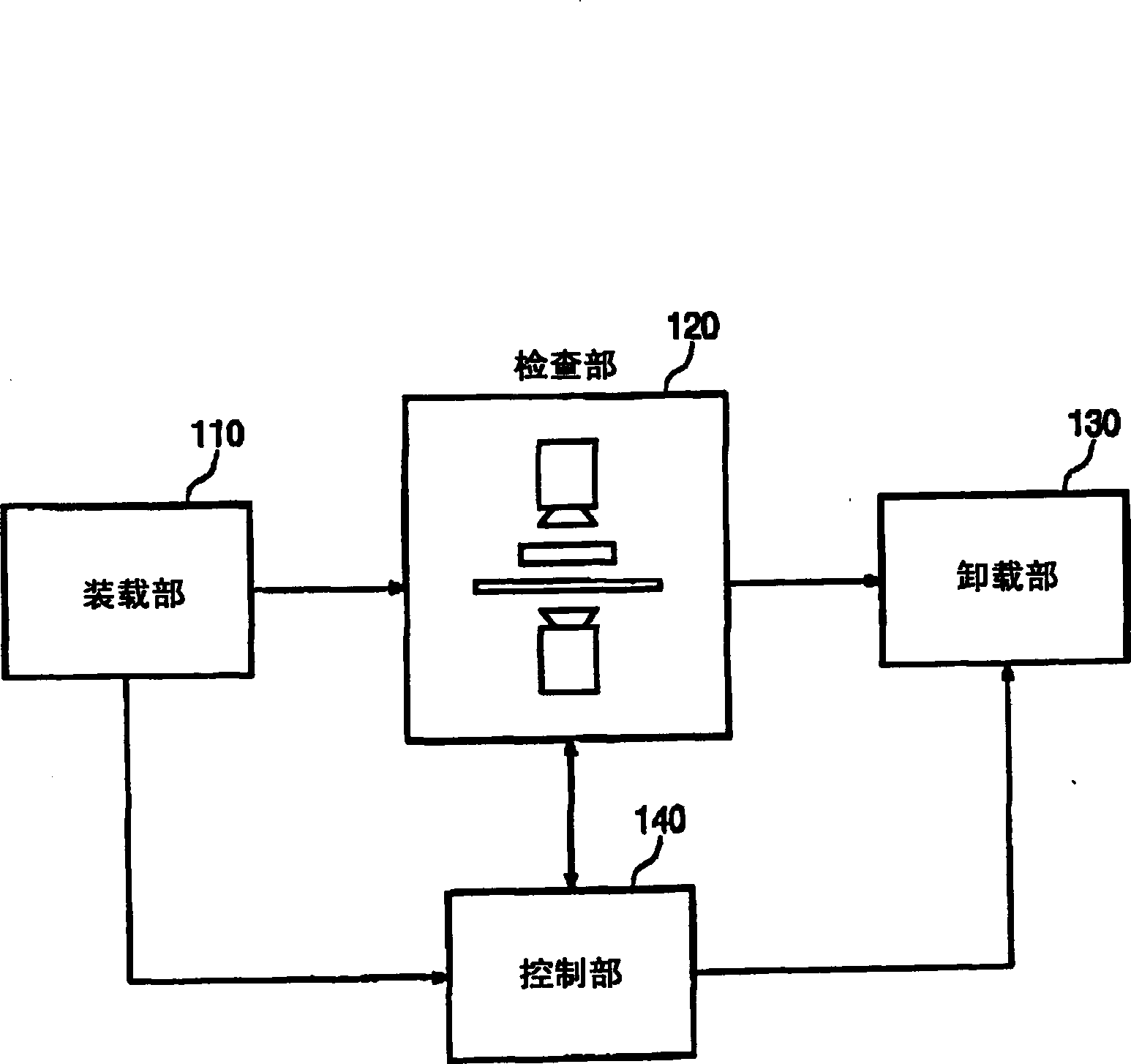

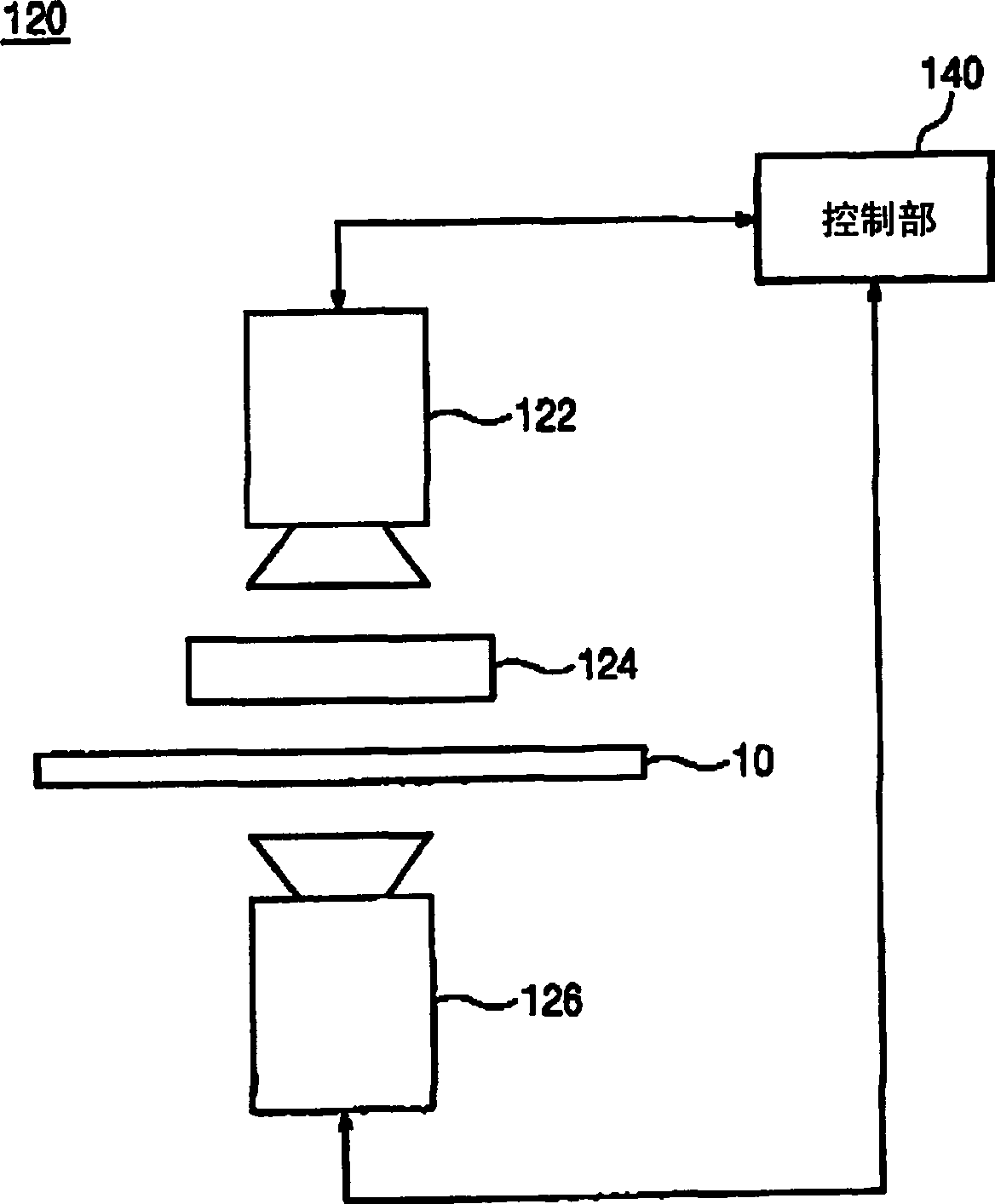

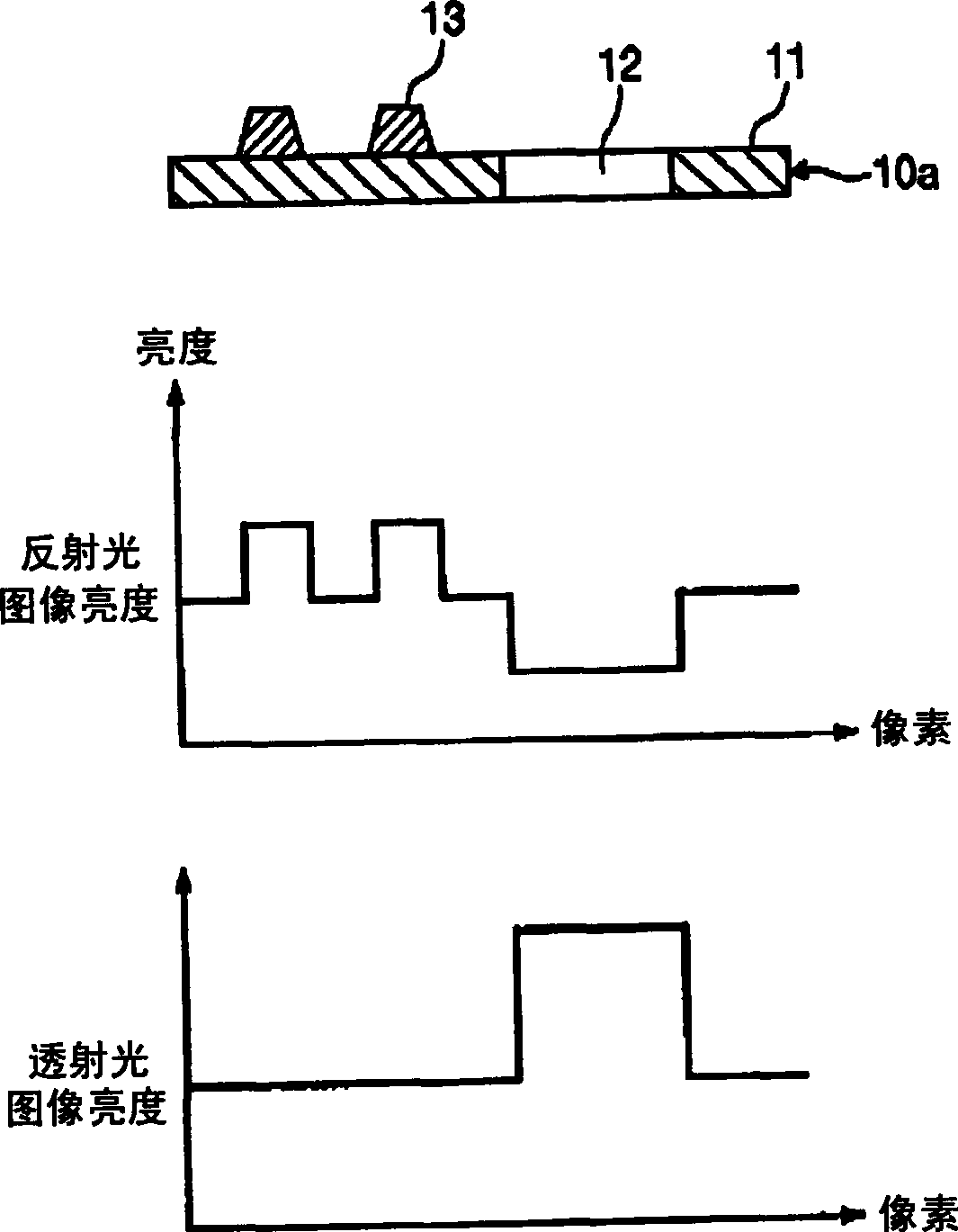

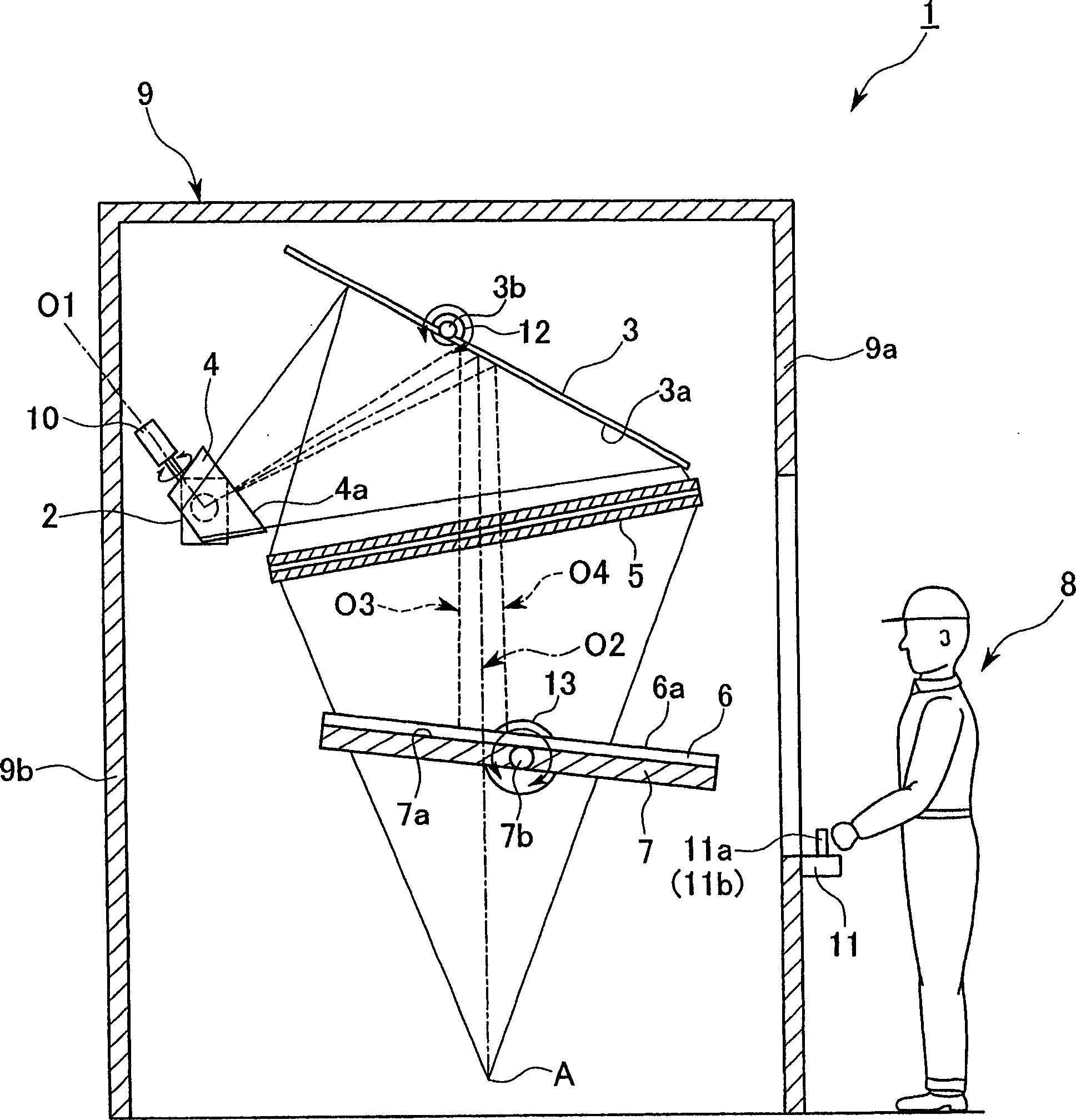

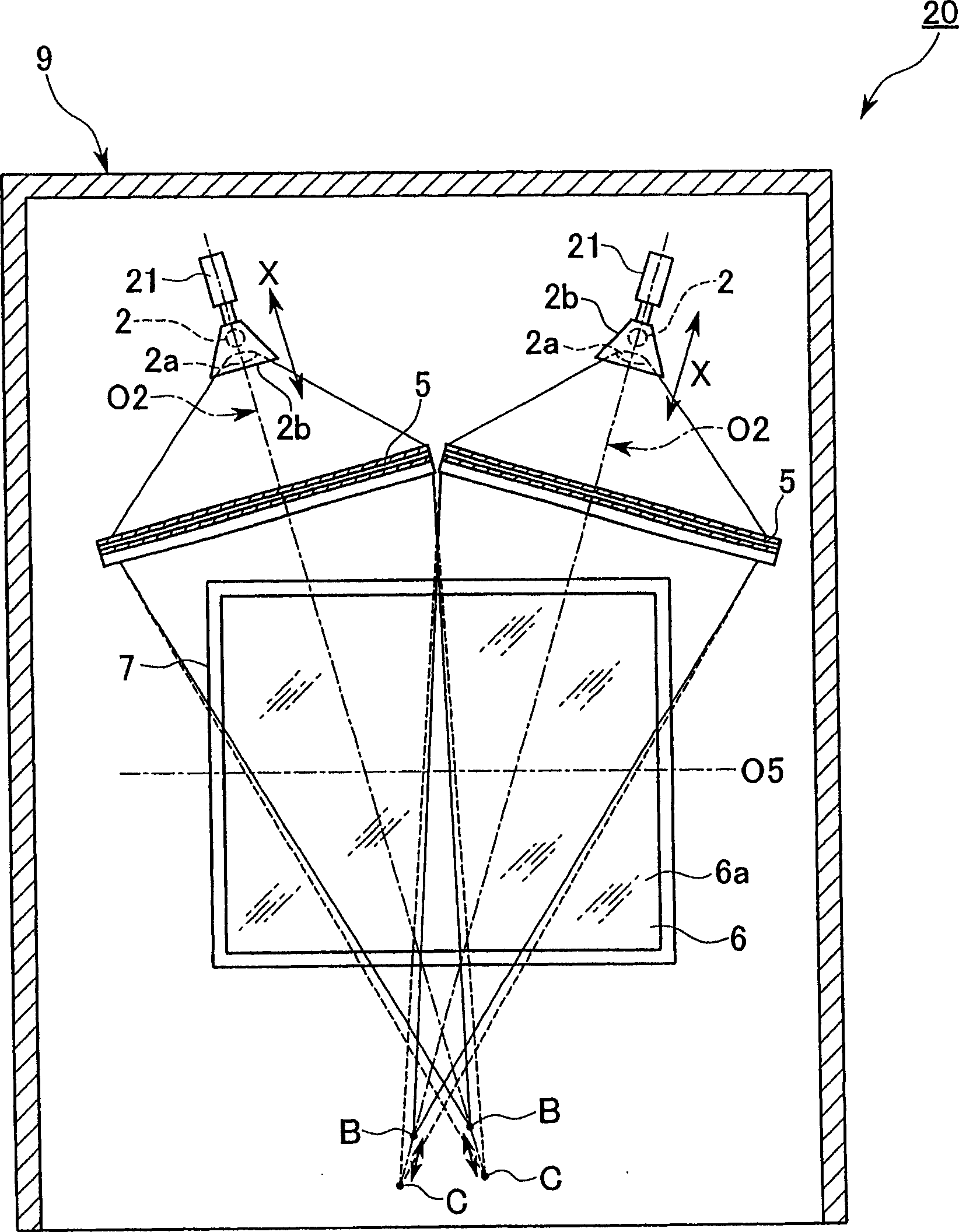

Image checking apparatus

InactiveCN101113958AImprove resolutionAvoid rising costsImage enhancementImage analysisReference patternsPhysics

Owner:USHIO DENKI KK

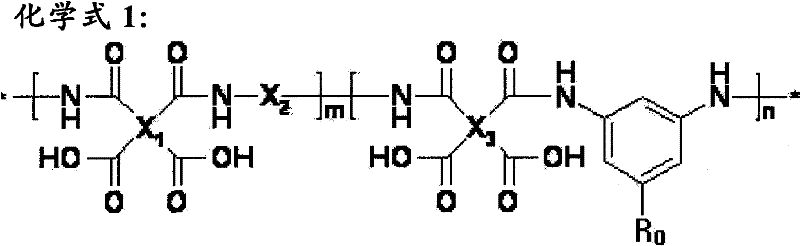

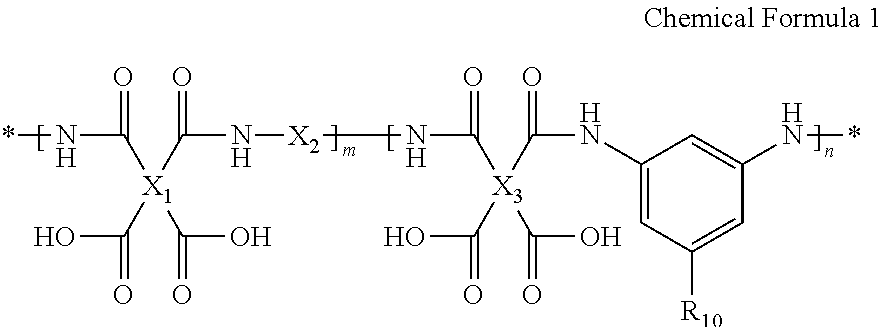

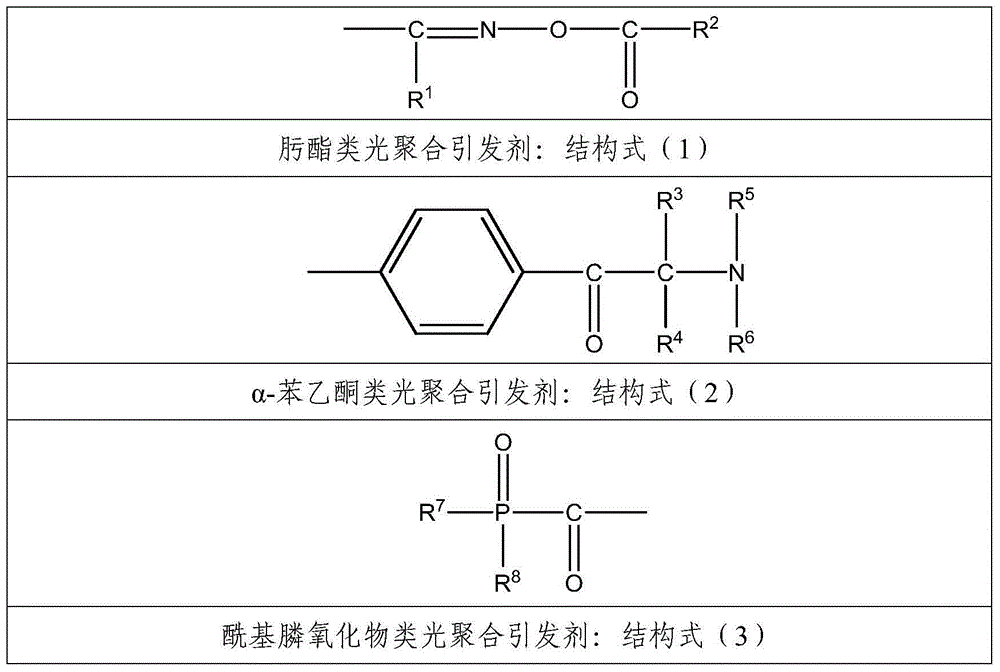

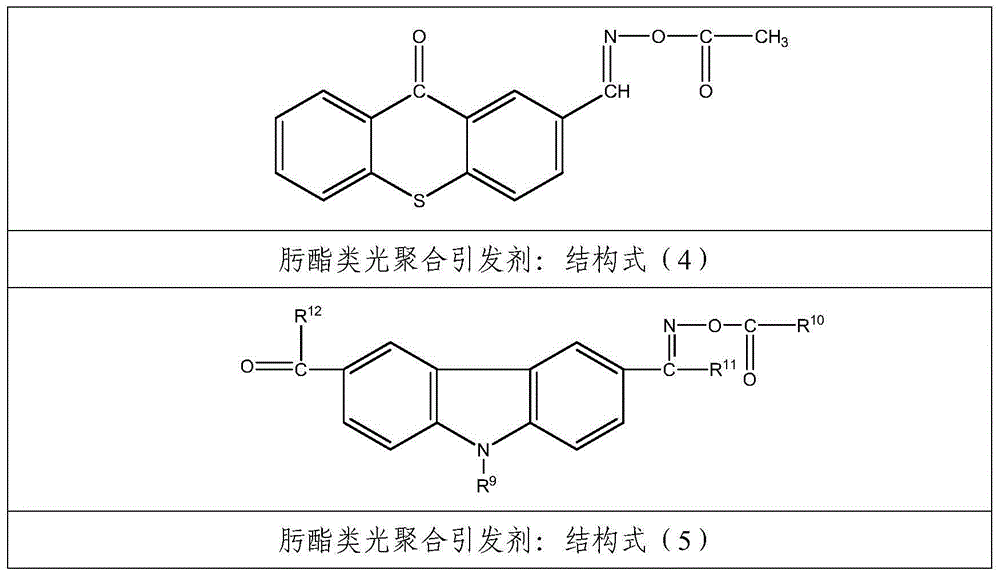

Polyamic acid, polyimide, photosensitive resin composition comprising the same and dry film manufactured by the same

InactiveUS20110200939A1High resolutionGood adhesivenessPhotosensitive materialsPrinted circuit manufacturePolyamic acidAqueous solution

The present invention relates to a polyamic acid or polyimide comprising a heat-polymerizable or photo-polymerizable functional group, a photosensitive resin composition comprising the polyamic acid or the polyimide, a photosensitive resin composition being capable of providing a cured film that can be used for patterning at a high resolution and that has an excellent developing property in an alkaline aqueous solution, flexibility, adhesion strength, resistance to welding heat, and pressure cooker test (PCT) resistance, and a dry film prepared from the composition.

Owner:LG CHEM LTD

Printed wiring board fabrication method, printed wiring board photomask, and program for creating a photomask

InactiveUS20070034596A1Suppress side etchingDimensional precision can be increasedPrinted circuit aspectsCircuit artworks manufactureResistEtching

The present invention is configured such that a wiring pattern, formed by forming an etching resist on metal foil that has been layered on an insulating resin board and performing etching via this etching resist, is provided with a circuit pattern constituting an electronic circuit and a dummy pattern provided in the vicinity of and separated from the circuit pattern, such that side etching of the circuit pattern is suppressed by mitigating the rate at which etching advances for the circuit pattern.

Owner:SHARP KK

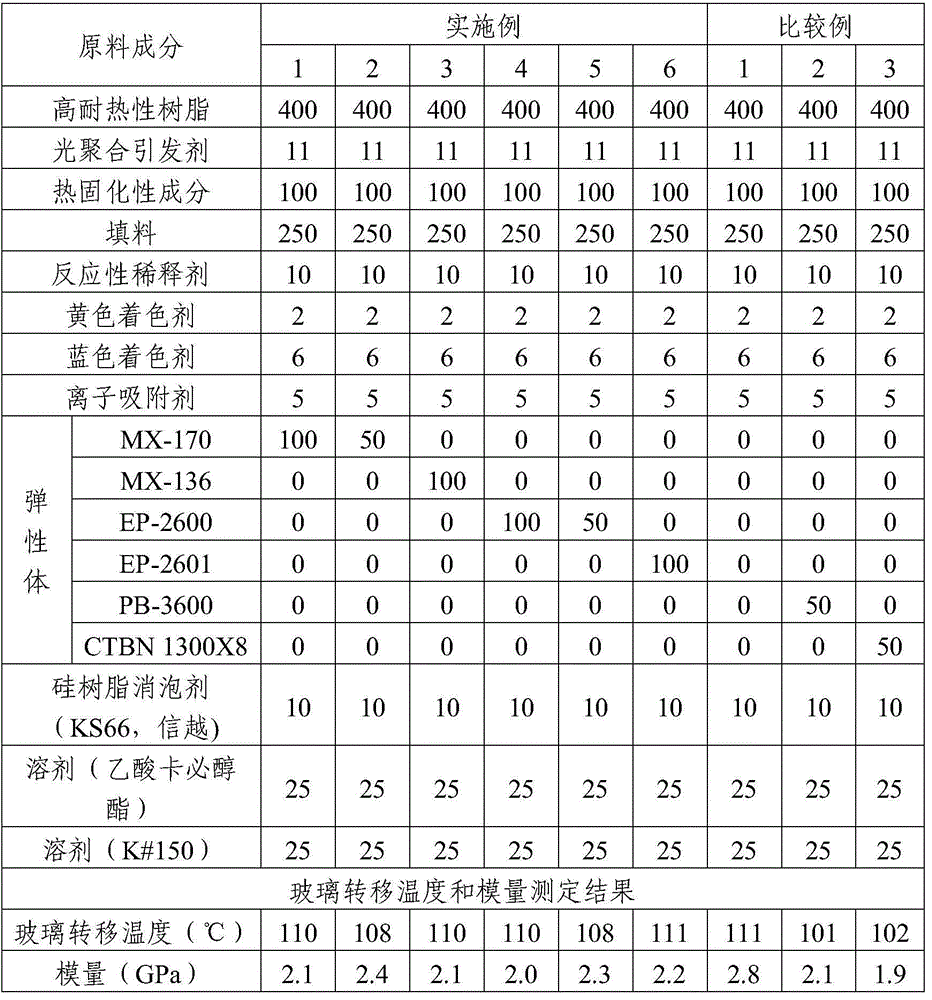

Photosensitive Resin Composition Of Excellent Reliability And Method For Manufacturing Same

InactiveCN104423165AGood flexibilityEnsuring PCT ToleranceCircuit artworks manufacturePhotosensitive materials for photomechanical apparatusResistSemiconductor package

The present invention relates to a photosensitive resin composition of an excellent reliability and a method for manufacturing the same, in particular to a photocuring and thermocuring resin composition which can guarantee the important characteristics, such as the PCT resistance, the HAST resistance, the non-electrolytic gold plating resistance, the thermal shock resistance, etc., of a semiconductor package solder resist, and also can form a cured film having the excellent flexibility, a method for manufacturing the same, a dry film, a cured material, and a printed circuit board formed by the cured film forming the solder resist and the like.

Owner:KCC CORP CO LTD

Automatic optical detection device and method

The invention provides an automatic optical inspection device of printed circuit substrate for inspecting the appearance of the inspected objects. The automatic optical inspection device of printed circuit substrate of the invention comprises: an illuminator for illuminating light to one side of the printed circuit substrate, a first shooting part for shooting the reflected image by using the reflected light reflected from one side of the printed circuit substrate, a second shooting part for shooting the transmission image using the transmission light transmitted from the side of the printed circuit substrate to the other side and a controlling part for receiving the reflected image and transmission image from the first and second shooting parts to judge whether there is foreign matter.

Owner:AJUHITEK

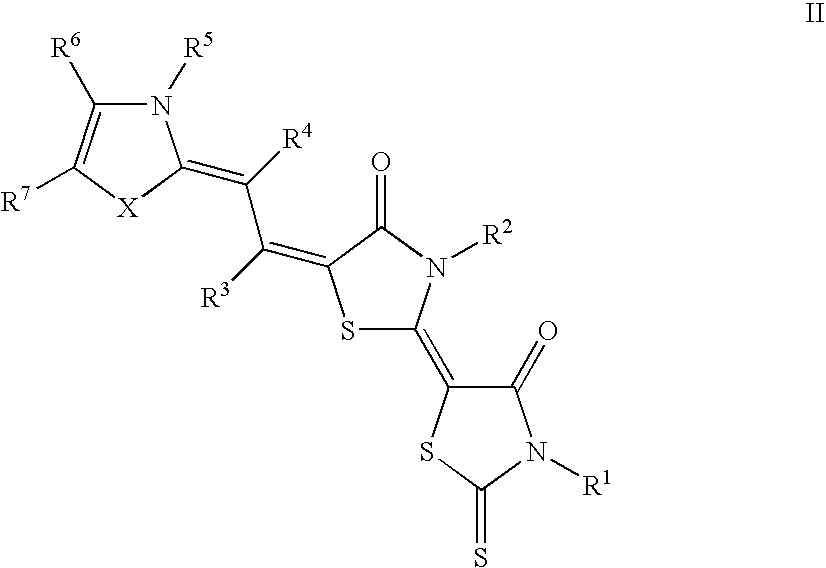

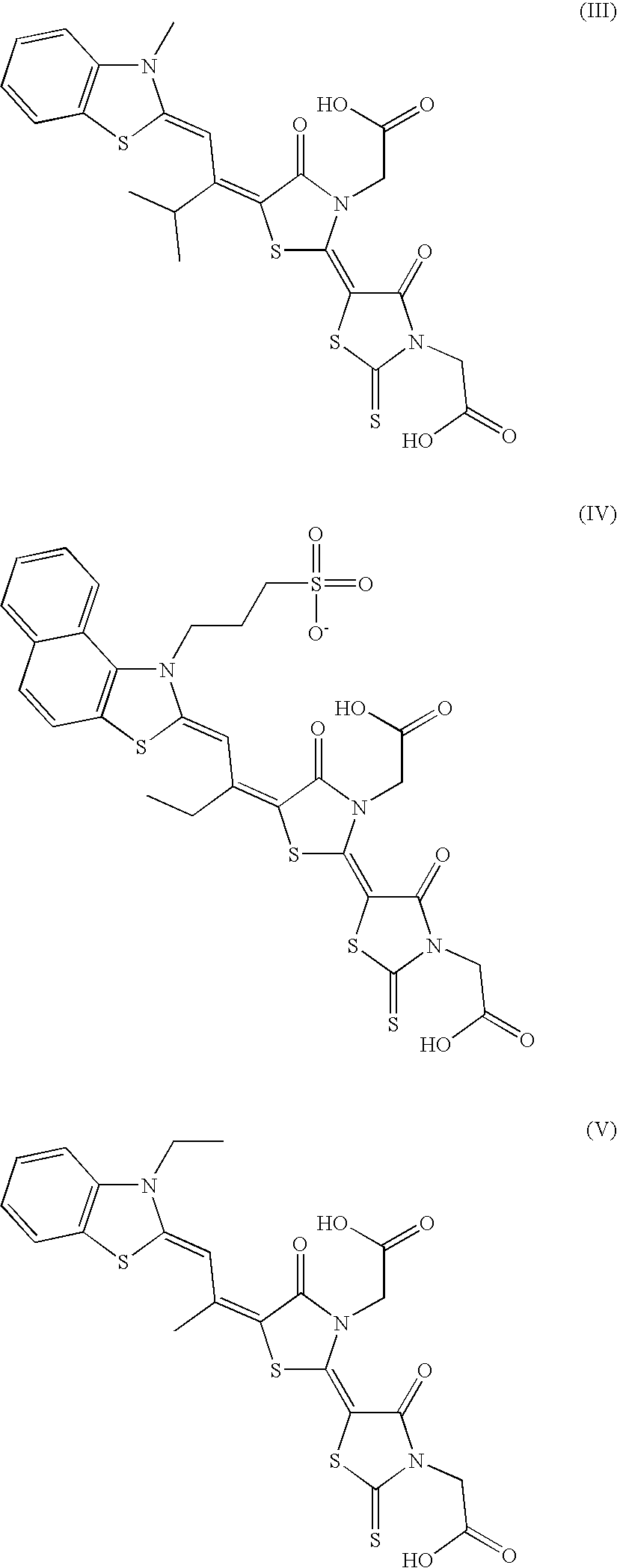

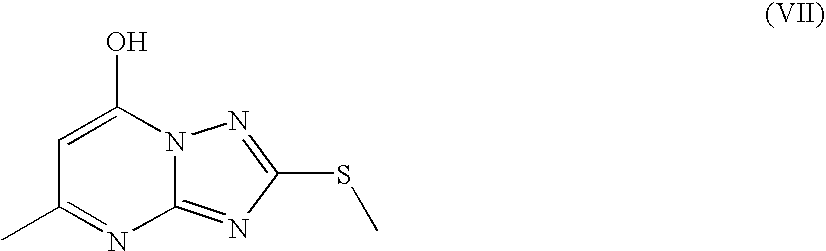

Photographic materials having improved keeping properties

InactiveUS7351523B2Prevent speedingShorten speedPhoto-taking processesPhotomechanical apparatusDopantSulfur

The use of a red-sensitising trinuclear merocyanine dye and an osmium dopant according to formula (I): [Os(NZ)L5]r wherein Z is sulphur or oxygen, L is a ligand and r is 0, −1, −2 or −3, in photographic silver halide emulsions for use in photographic materials, result in a reduction and / or prevention of speed gain in the emulsion over time without significant speed loss.

Owner:EASTMAN KODAK CO

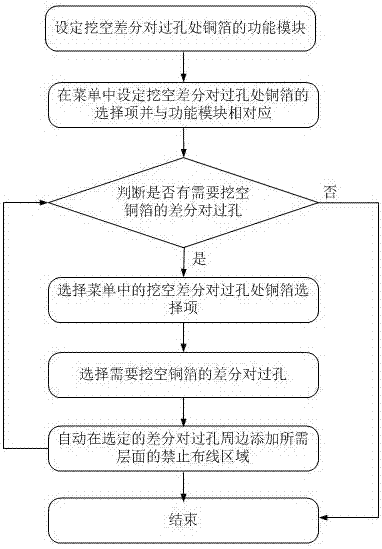

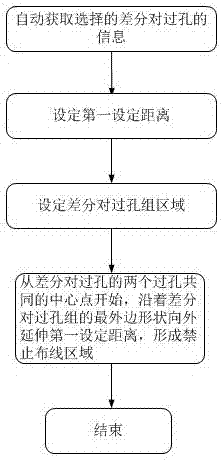

Method for hollowing copper foil at position of differential pair via hole

InactiveCN107466161AImprove design efficiencyReduce workloadPrinted circuit aspectsCircuit artworks manufactureComputer moduleCopper foil

The invention provides a method for hollowing a copper foil at the position of a differential pair via hole. In the design process of a PCB, before the step of copper paving, the method comprises the following steps: step one, setting a functional module for hollowing the copper foil at the position of the differential pair via hole; step two, setting an option for hollowing the copper foil at the position of the differential pair via hole in a menu, and enabling the option to correspond to the functional module in the step one; step three, judging whether the differential pair via hole of the copper foil needs to be hollowed, if the differential pair via hole of the copper foil needs to be hollowed, selecting an option of the copper foil at the position of the differential pair via hole in the menu, entering into step four; if the differential pair via hole of the copper foil does not need to be hollowed, entering into step six; step four, selecting the differential pair via hole of the copper foil needing to be hollowed; step five, automatically adding a wiring forbidden area of a required layer surface on the periphery of the selected differential pair via hole; returning to step three; and step six, ending. The copper foil at the position of the differential pair via hole can be hollowed with one key, so that the Layout design efficiency is improved, and the workload of manual operation of Layout engineers is reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Printed wiring board fabrication method, printed wiring board photomask, and program for creating a photomask

The present invention is configured such that a wiring pattern, formed by forming an etching resist on metal foil that has been layered on an insulating resin board and performing etching via this etching resist, is provided with a circuit pattern constituting an electronic circuit and a dummy pattern provided in the vicinity of and separated from the circuit pattern, such that side etching of the circuit pattern is suppressed by mitigating the rate at which etching advances for the circuit pattern.

Owner:SHARP KK

Appearance checking device and method

The invention relates to a testing device for appearance and the testing method. The said testing device can distinguish the false drawback cause by light source or optical element and the real drawback of base plate. The process is as that: said testing device (1) testing base plate by viewing the reflect light of illumination ray on surface (6a) of base plate, changing optical axis or focal point position through the periodical or free swinging or bending of optical element, of which comprises light source (2), and the second reflecting mirror (3) and the first reflecting mirror (4) or collective lens (5); then said false drawback will swing, through which realizes said distinguish.

Owner:OLYMPUS CORP

Polyamic acid, polyimide, photosensitive resin composition comprising the same, and dry film manufactured from the same

InactiveUS20120012366A1High resolutionMaintain good propertiesPhotosensitive materialsCircuit artworks manufactureImidePolymer science

The present invention relates to a polyamic acid or polyimide comprising a heat-polymerizable or photo-polymerizable functional group, a photosensitive resin composition comprising the polyamic acid or the polyimide, a photosensitive resin composition being capable of providing a cured film that can be used for patterning at a high resolution and that has an excellent developing property in an alkaline aqueous solution, flexibility, adhesion strength, resistance to welding heat, and pressure cooker test (PCT) resistance, and a dry film prepared from the composition.

Owner:LG CHEM LTD

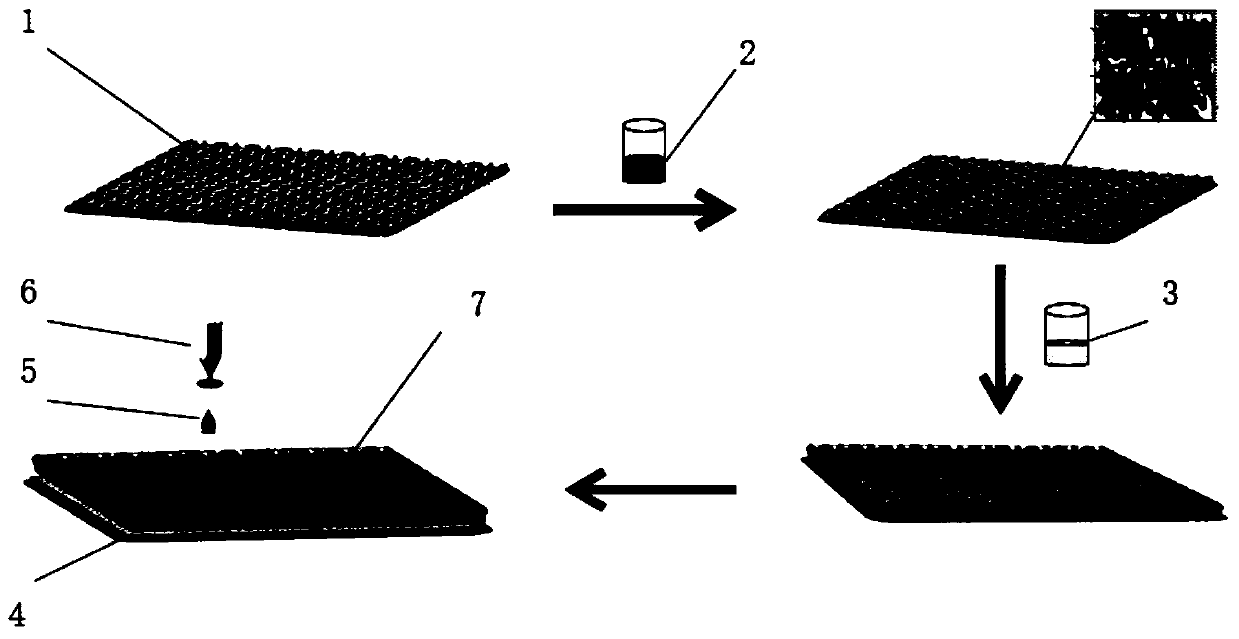

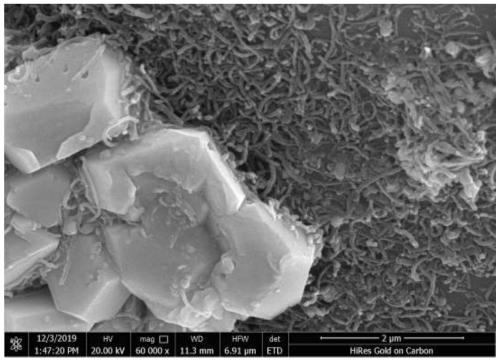

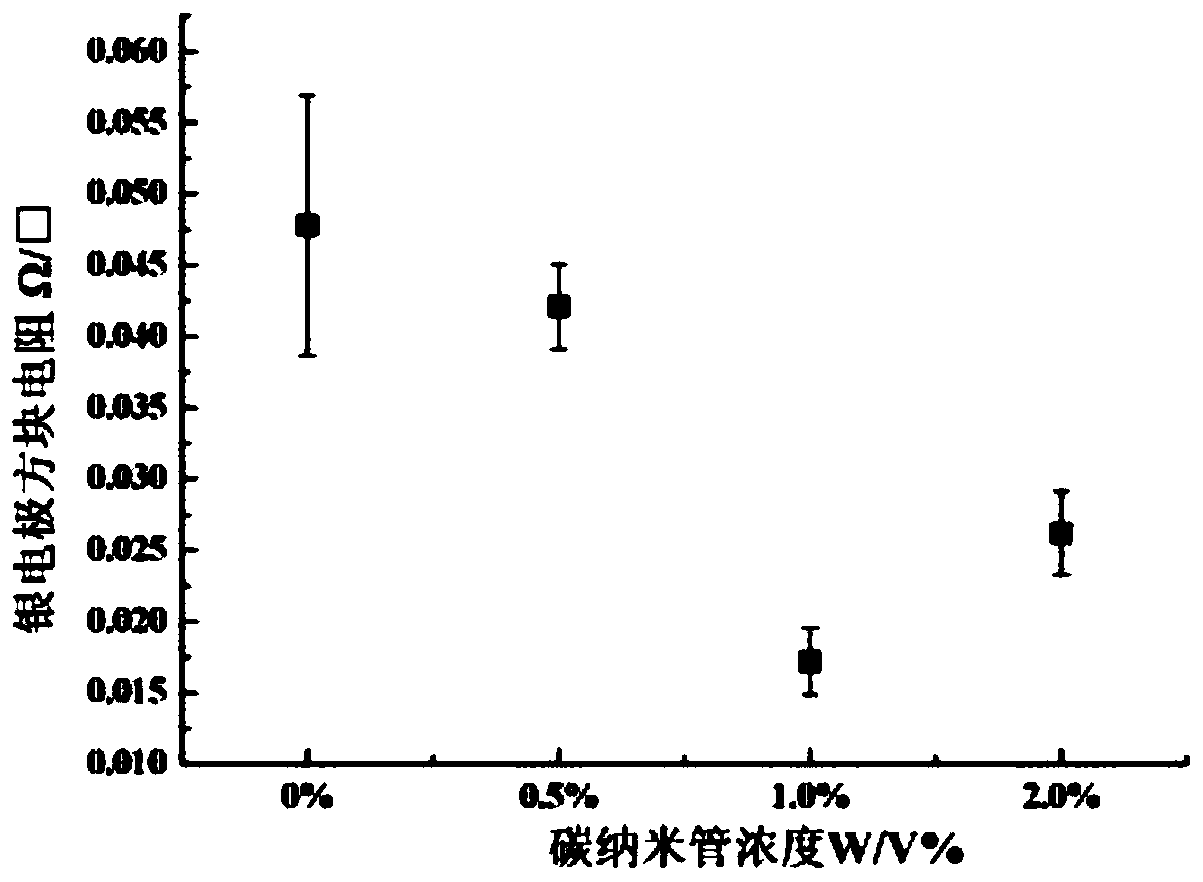

Manufacturing method of ultralow-resistance flexible conductive circuit

ActiveCN111432560AImprove conductivityConductivity does not affectInksCircuit artworks manufactureEngineeringMetal substrate

The invention discloses a manufacturing method of an ultralow-resistance flexible conductive circuit. The method comprises the following steps of firstly preparing a fabric substrate, a precursor solution and ink; taking a proper amount of precursor solution to completely wet the fabric substrate, and placing the fabric substrate on a metal substrate; putting a proper amount of ink into a piezoelectric spray head of a micro-droplet jetting device, starting the micro-droplet jetting device to print the ink on the fabric substrate on the metal substrate drop by drop until the ink forms a printing circuit after multi-layer printing; and finally, cleaning the printed circuit with alcohol and deionized water in sequence, putting the printed circuit into a curing oven for heating and curing treatment, and cooling to obtain the ultralow-resistance flexible conductive circuit. According to the manufacturing method of the ultralow-resistance flexible conductive circuit, the problems that in theprior art, a flexible conductive circuit is complex in preparation process, the resistance value of the conductive circuit is high, and the bonding performance of the conductive circuit and fabric ispoor are solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

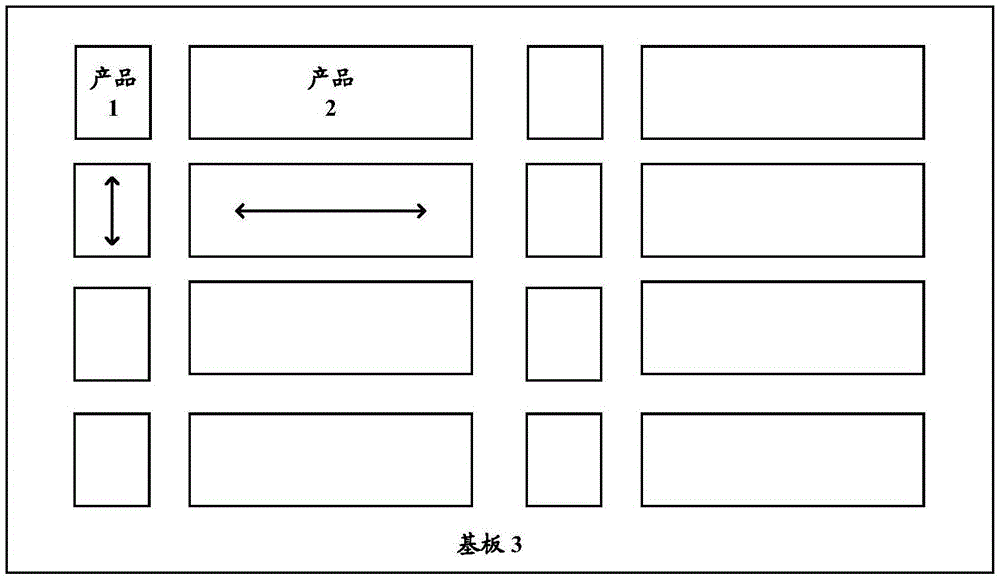

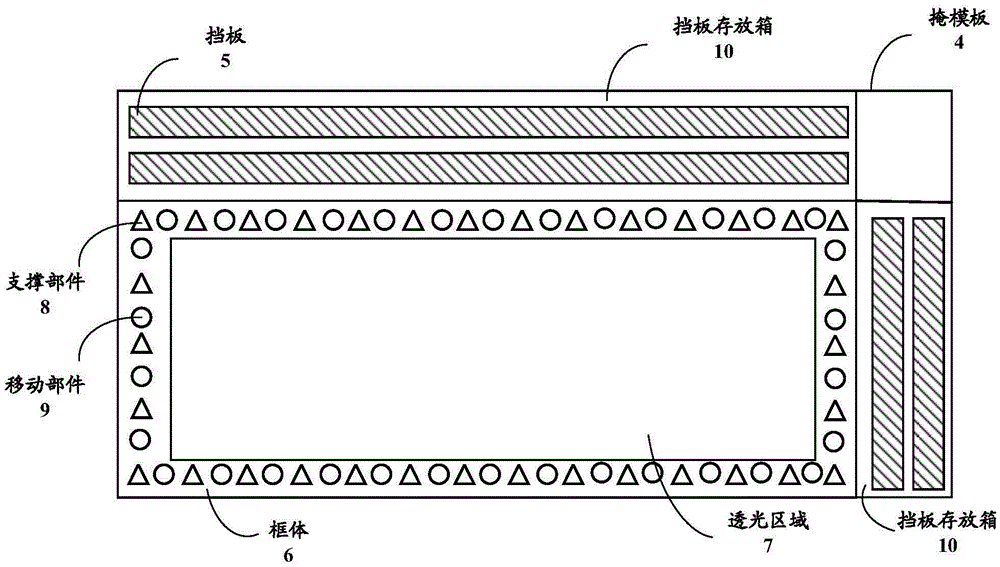

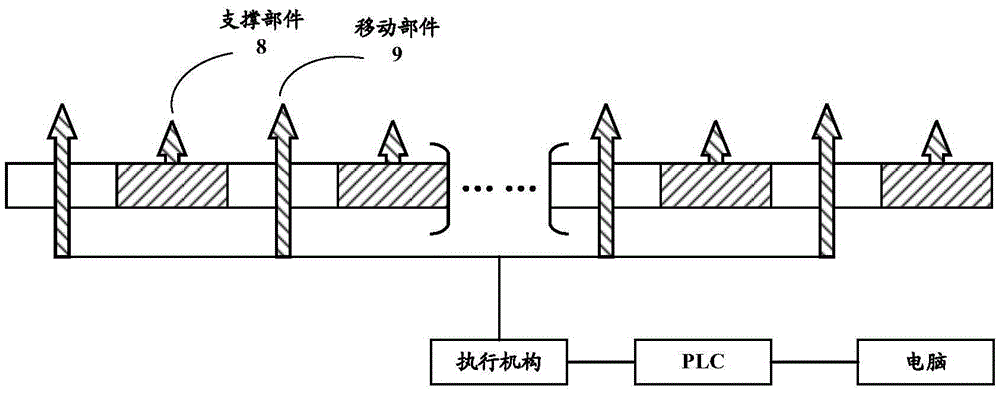

Mask plate and light alignment method

ActiveCN105572975ASimple production processLow costUsing optical meansCircuit artworks manufactureMoving partsEngineering

The embodiment of the invention provides a mask plate. The mask plate comprises a plurality of baffles, a frame body and a light transmission region. The framework is provided with a supporting part and a movable part. Each baffle is configured to the light transmission region used for shielding. The supporting part is configured to a baffle for supporting the light transmission region. The movable part is configured to move the baffles to positions for shielding the light transmission region. With the adoption of the mask plate provided by the embodiment of the invention, one mask plate can be used for producing different MMG products; in a production process, the mask plate does not need to be replaced and irradiation and orientation can be carried out; the mask plate does not need to be detached in a normal service life range; and a production process is optimized and the cost is effectively reduced.

Owner:BOE TECH GRP CO LTD +1

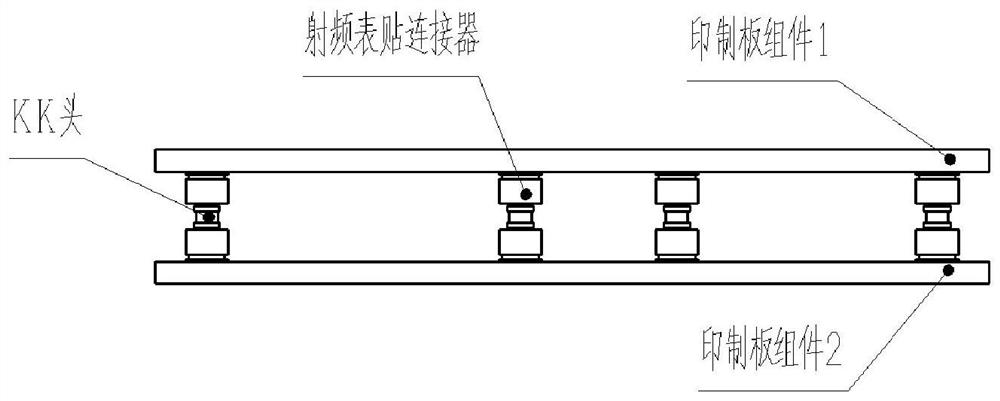

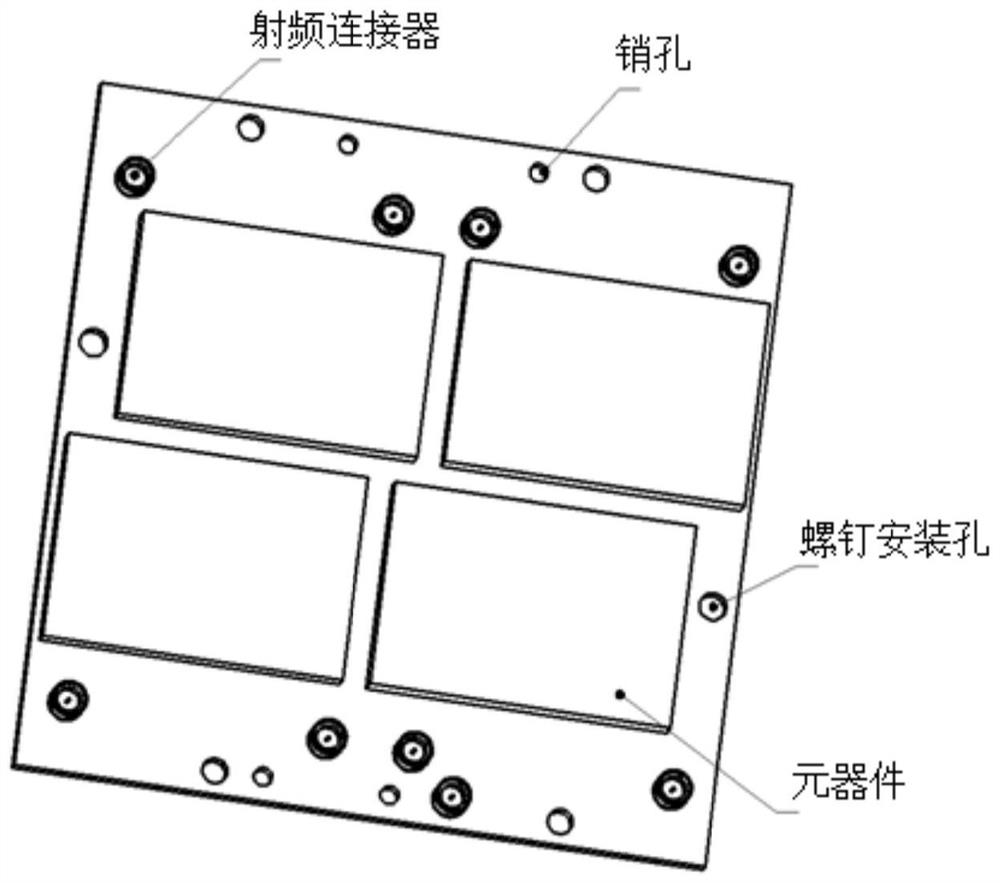

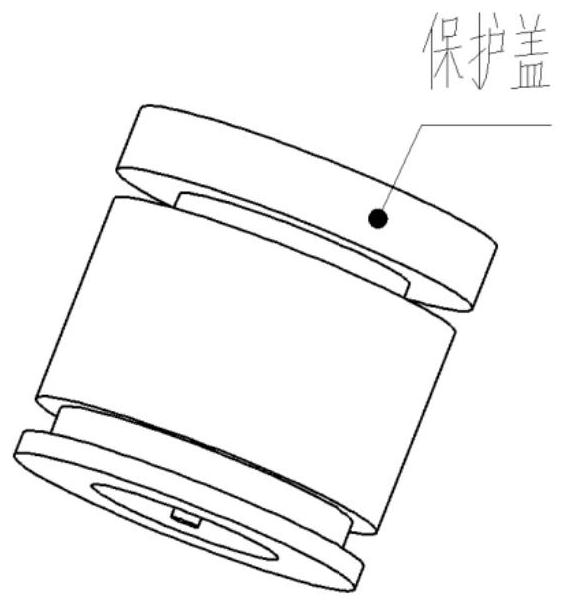

Design method and welding method based on inter-board vertical interconnection printed board assembly

ActiveCN113301726AAccurate welding positionImprove welding mechanical strengthPrinted circuit assemblingCircuit artworks manufactureSpecial designEngineering

The invention relates to the field of electronic equipment, and discloses a design method and a welding method of a printed board assembly based on inter-board vertical interconnection, and the method carries out the special design of a printed board bonding pad of a surface-mounted connector and an opening of a screen printed by soldering paste, thereby achieving the self-positioning of the surface-mounted connector. A printed board anti-deformation design and an anti-deformation welding clamp are adopted to control buckling deformation in the processing and welding processes of the printed board, and accurate positioning and reliable welding of the surface-mounted connector on the printed board assembly based on inter-board vertical interconnection are achieved. According to the design method and the welding method of the printed board assembly based on the vertical interconnection between the boards, the problems that the position of the surface-mounted connector on the printed board assembly is deviated, the connector is inclined and floated, and the printed board is warped and deformed are solved, so that the realizability and the reliability of the vertical interconnection between the boards are improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

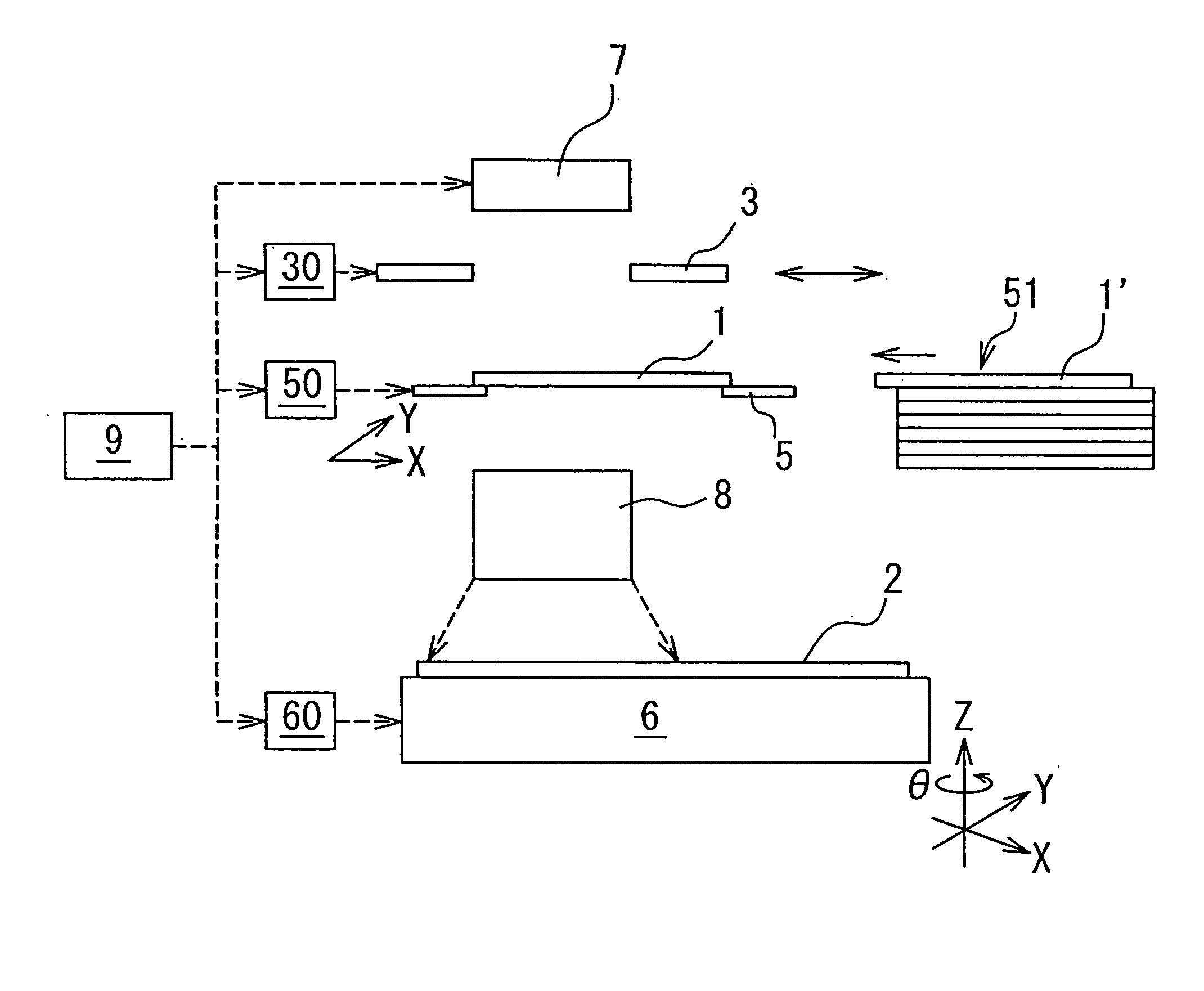

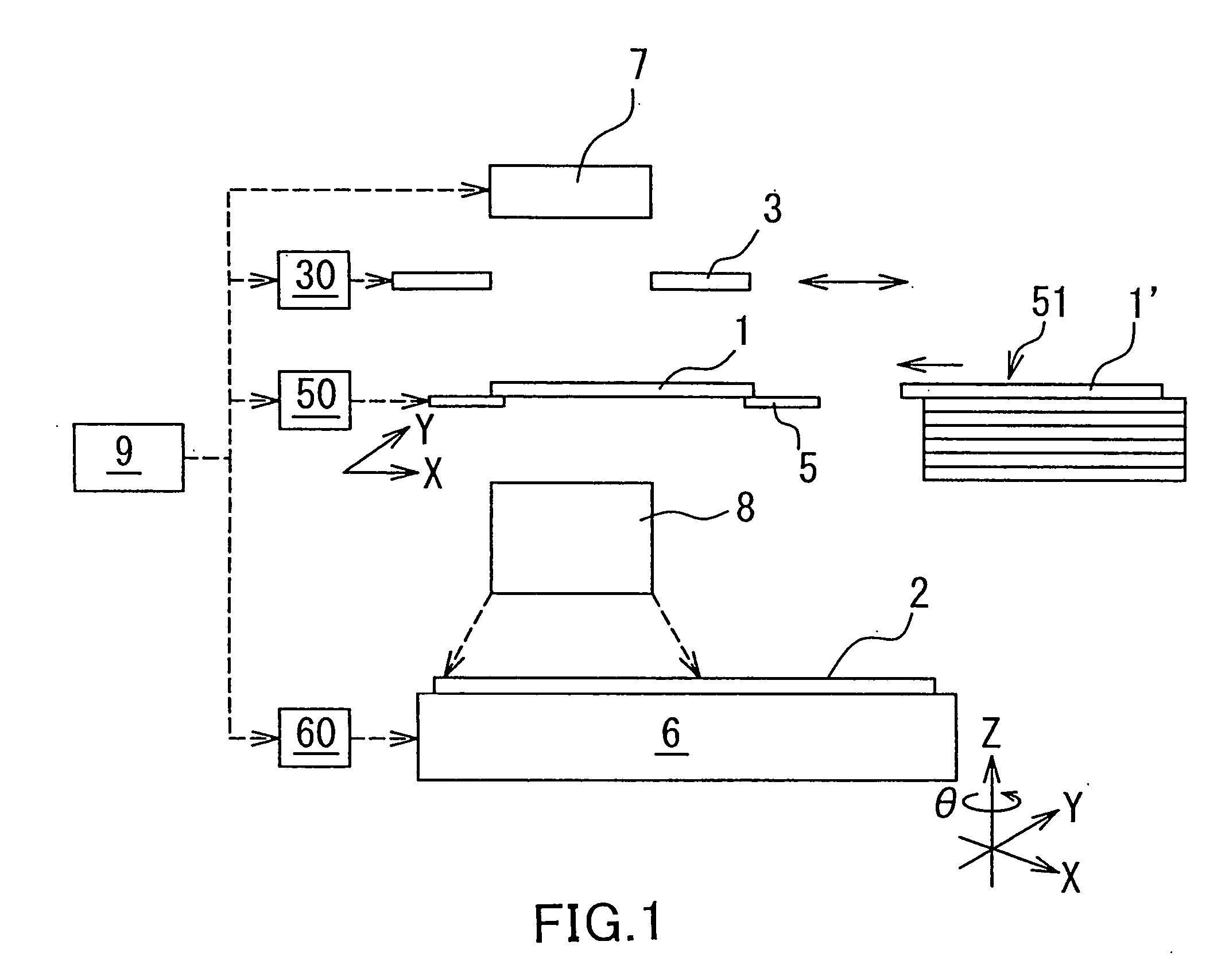

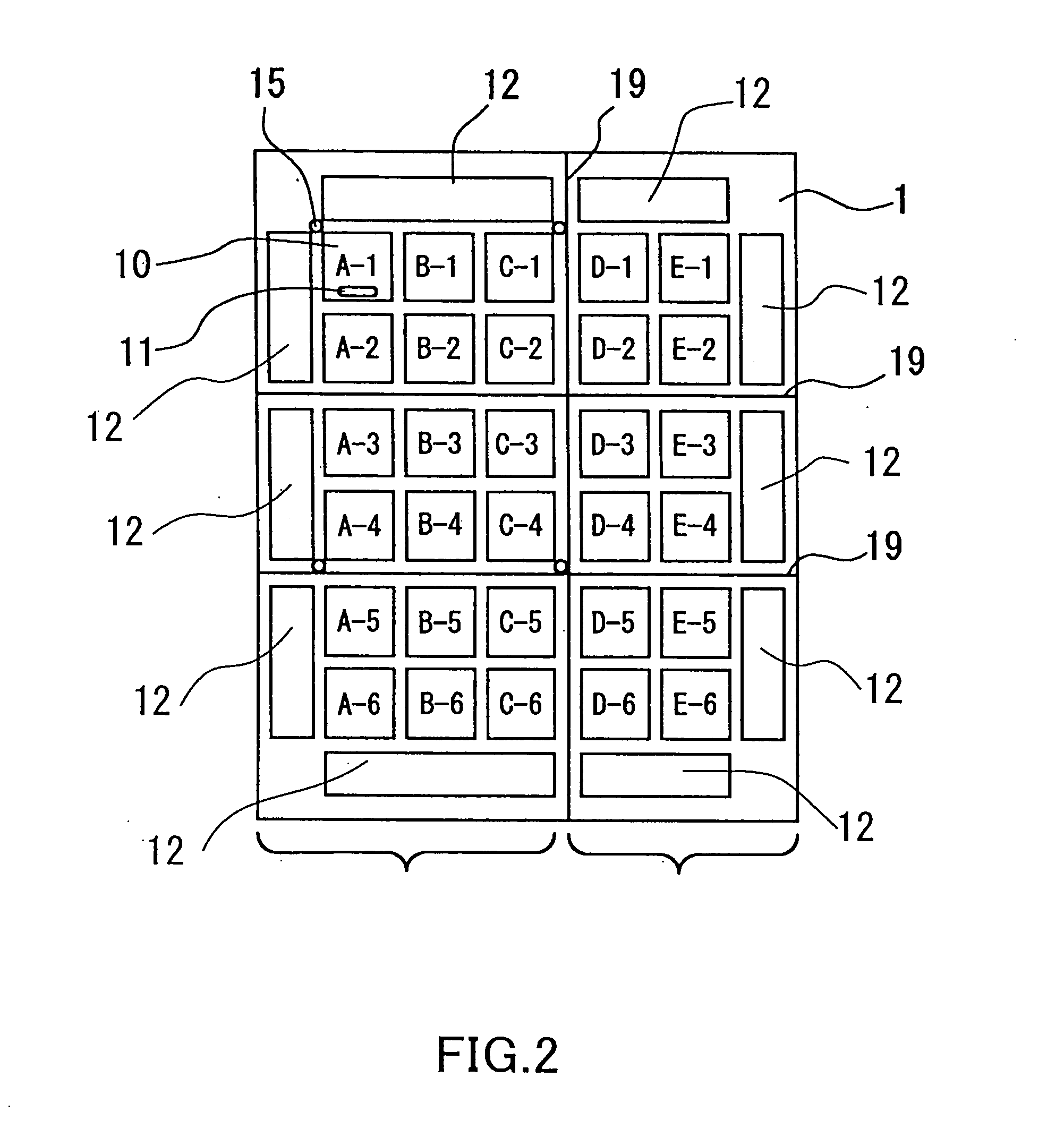

Projection exposure apparatus and method for producing a printed circuit board

ActiveUS20060050254A1Change sizePrinted circuit aspectsCircuit artworks manufacturePrinted circuit boardPhotomask

A projection exposure apparatus and a method for producing a printed circuit board wherein, the whole pattern including pieces 10 and coupons 12 to be exposed on a print circuit board 2 is depicted on a photo mask 1 divided in six areas by divide line 19, the exposure will be made with respect to the each divided area of the photo mask 1 mounted on a movable photo mask stage 5 with using a masking device 3 masking other area than the exposing area.

Owner:ADTEC ENG

Manufacturing process of flexible circuit board

InactiveCN111113784ASimple production processProduction is easy to controlFlexible printed circuitsCircuit artworks manufactureScreen printingManufacturing technology

The invention relates to the technical field of flexible circuit board production, and particularly discloses a manufacturing process of a flexible circuit board. The process comprises the following steps that an adhesive film part is provided; conductive ink and silk-screen printing equipment are provided, wherein the conductive ink is printed on one side of the adhesive film part by using the silk-screen printing equipment to form a conductive circuit; and an injection mold is provided, wherein a plastic part is formed on the adhesive film part in an injection molding mode by using the injection mold, the conductive circuit formed by printing the conductive ink on the adhesive film part is clamped between the adhesive film part and the plastic part, and the adhesive film part, the conductive ink and the plastic part are combined to form the flexible circuit board. Processes of electroless plating copper, etching and the like of a flexible circuit board in the prior art are cancelled,so that a production process flow of the flexible circuit board is greatly simplified, the production of the flexible circuit board is simpler and more controllable, the production efficiency of theflexible circuit board is improved, and the manufacturing cost of the flexible circuit board is reduced.

Owner:DONGGUAN HIROCA AUTOMOTIVE TRIM TECH CO LTD

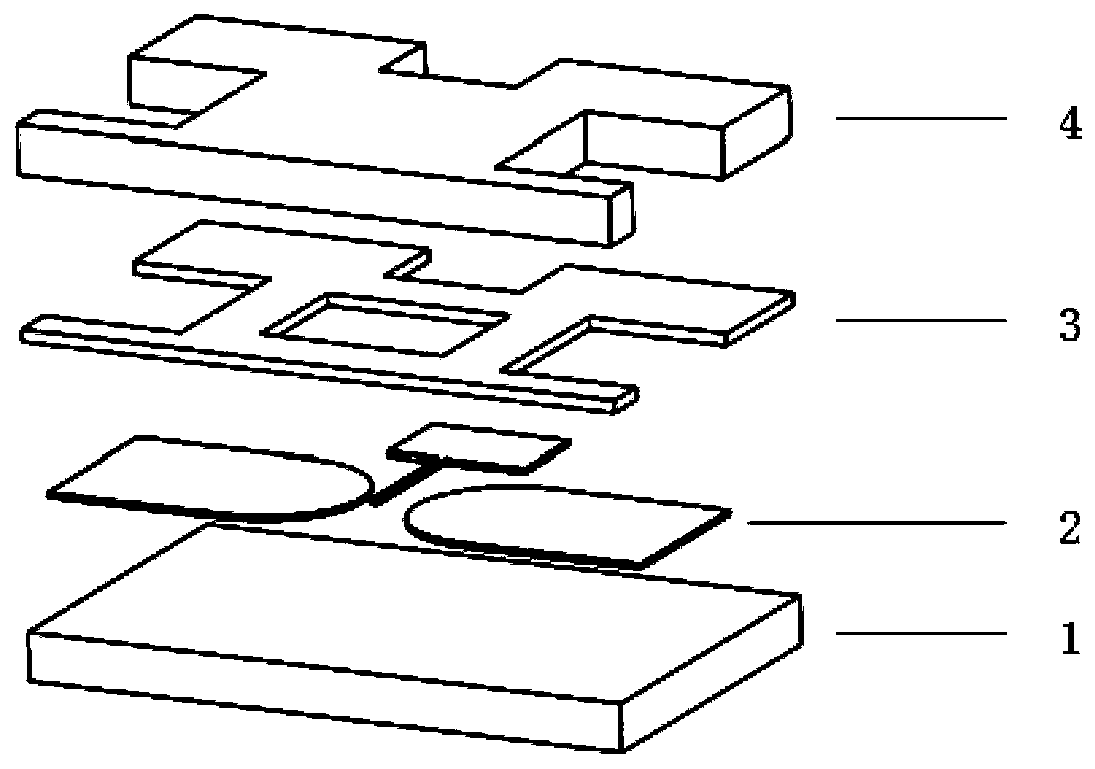

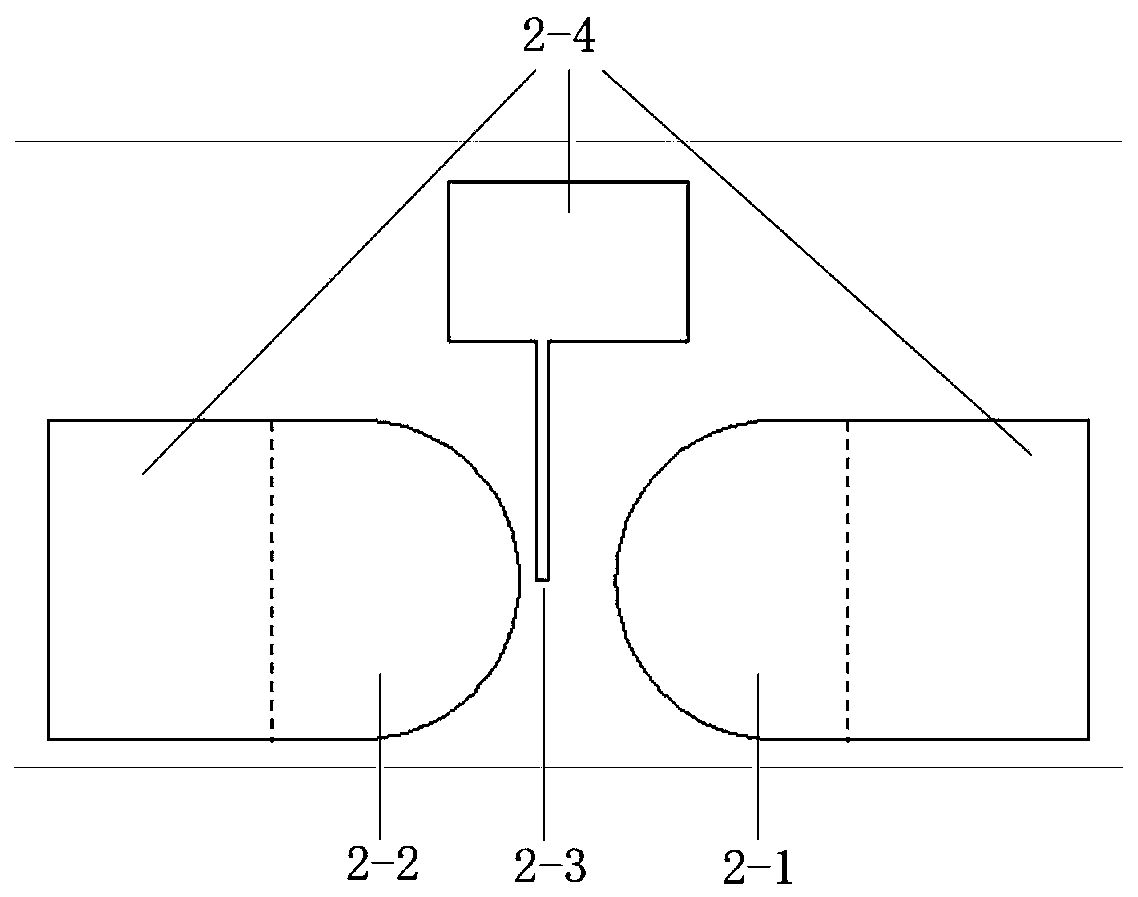

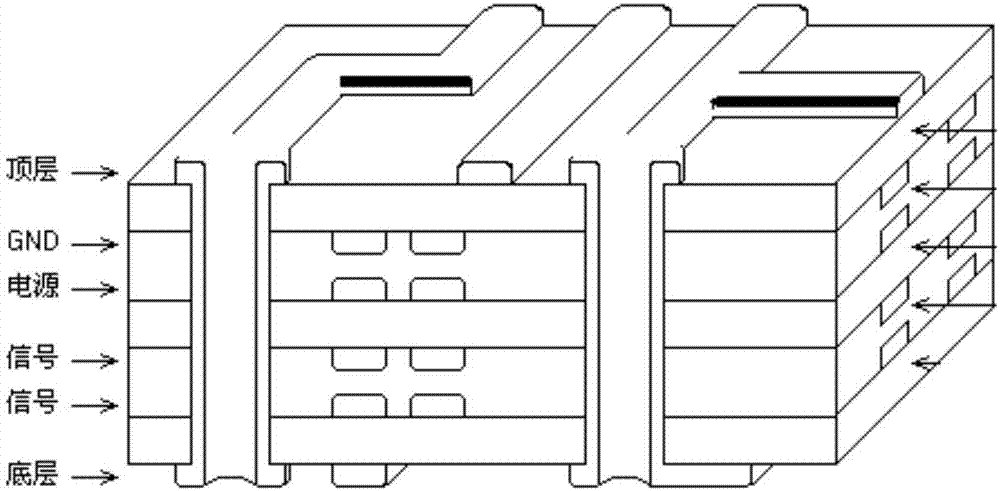

Closed planar three-electrode spark switch and preparation method thereof

ActiveCN110649467AMature and reliable technologyLow priceSparking plugsSpark gap detailsPulse power systemsEngineering

The invention belongs to the field of high-power pulses, and particularly relates to a closed planar three-electrode spark switch and a preparation method thereof. The closed planar three-electrode spark switch sequentially comprises a bottom layer PCB, a circuit layer, a PP layer and a top layer PCB, and the bottom layer PCB is a substrate of a switch circuit layer; the circuit layer comprises ananode, a cathode, a trigger electrode and a bonding pad connected with the anode, the cathode and the trigger electrode; pad windows are formed in the PP layer corresponding to the bonding pad, and electrode windows are formed in the PP layer corresponding to the electrodes; a bonding pad groove is formed in the position, corresponding to the bonding pad, of the top layer PCB, and a blind grooveis formed in the position, corresponding to the electrode, of the top layer PCB; the PP layer is used as a dielectric layer for bonding the top layer PCB and the bottom layer PCB, and the bottom layerPCB and the bottom layer PCB are laminated by using the PP layer, so that a cavity is formed in the whole switch. The planar three-electrode spark switch is made into a closed type by using a printedcircuit board technology, so that the working environment of the switch is stabilized, the high overload resistance of the switch is improved, the cost is greatly reduced, and the planar three-electrode spark switch can be widely applied to pulse power systems such as exploding foil exploders and electric cannons.

Owner:NANJING UNIV OF SCI & TECH

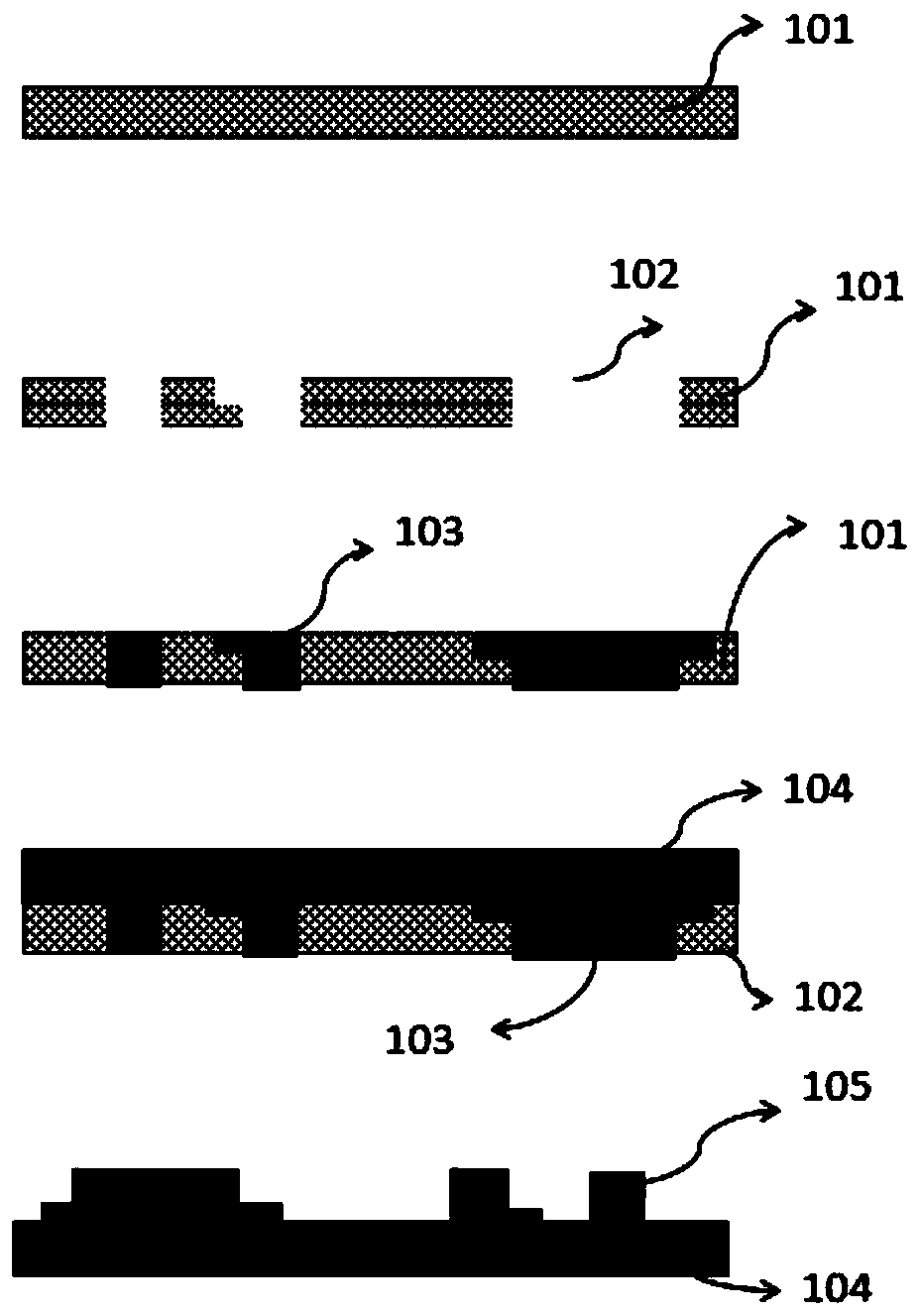

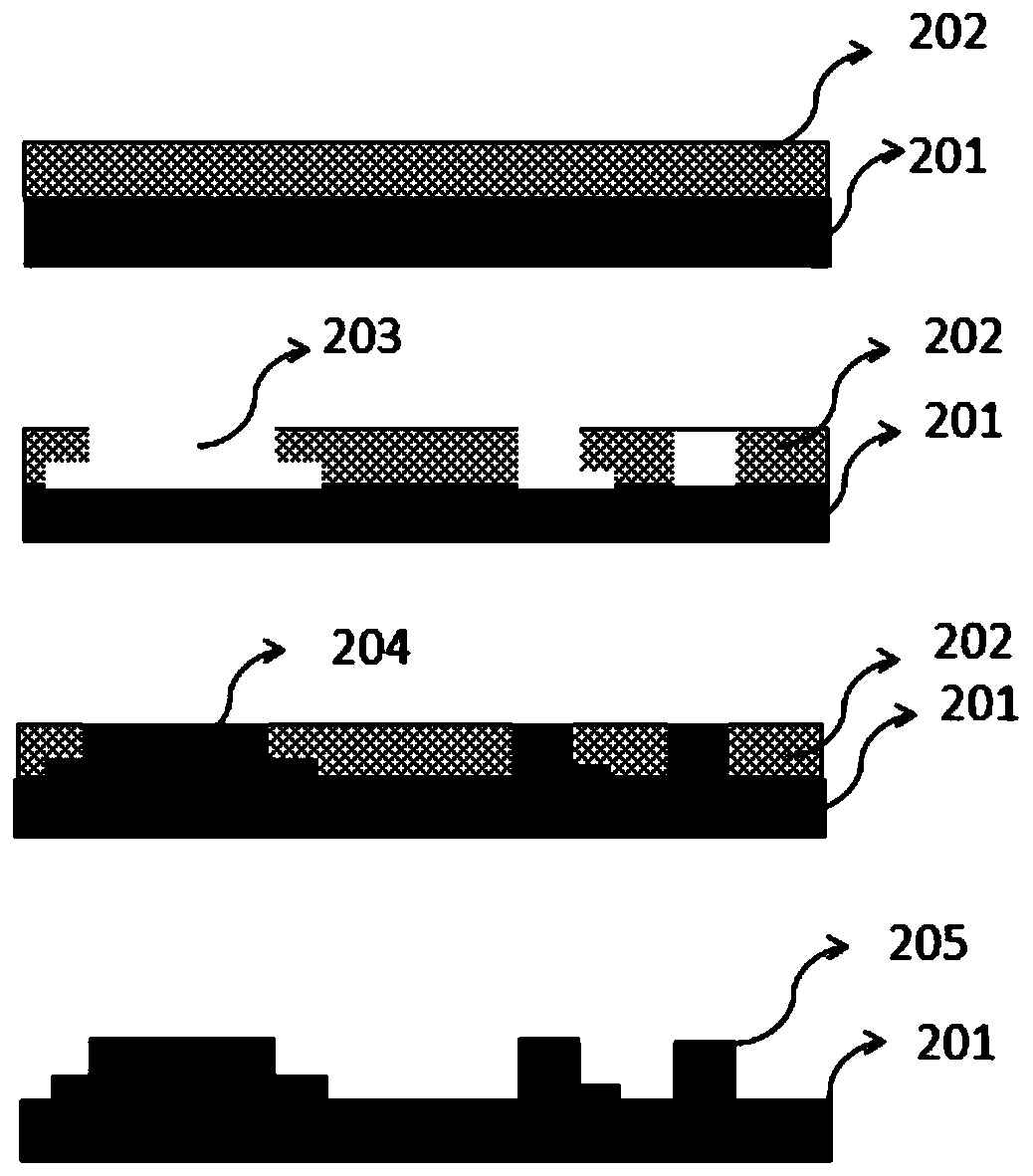

Three-dimensional conductive circuit and preparation method thereof

PendingCN111511121AHigh precisionHigh groove precisionCircuit artworks manufactureConductive pattern formationEngineeringSlurry

The invention discloses a three-dimensional conductive circuit and a preparation method thereof. A designed circuit groove formed by an organic material layer is adopted, the depth of the groove is 1-1.25 times of the height of a conductive circuit, the designed circuit groove formed by the organic material layer is filled with conductive slurry, the conductive slurry is solidified, then the organic material layer is removed, and the conductive circuit is formed through heat treatment of the conductive slurry. According to the three-dimensional conductive circuit, the organic material layer isused as a groove die orifice, the depth of the groove is 1-1.25 times of the height of the conductive circuit, the groove precision is high, the shape and the circuit precision are controlled to be close to ideal design values, and the high-precision conductive circuit can be prepared.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

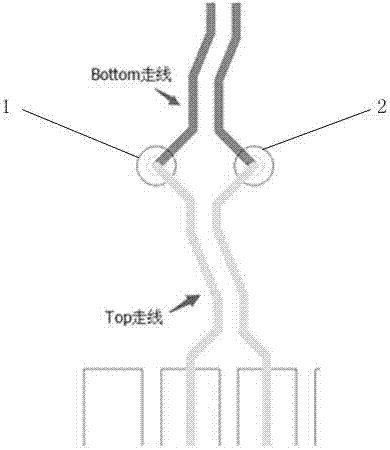

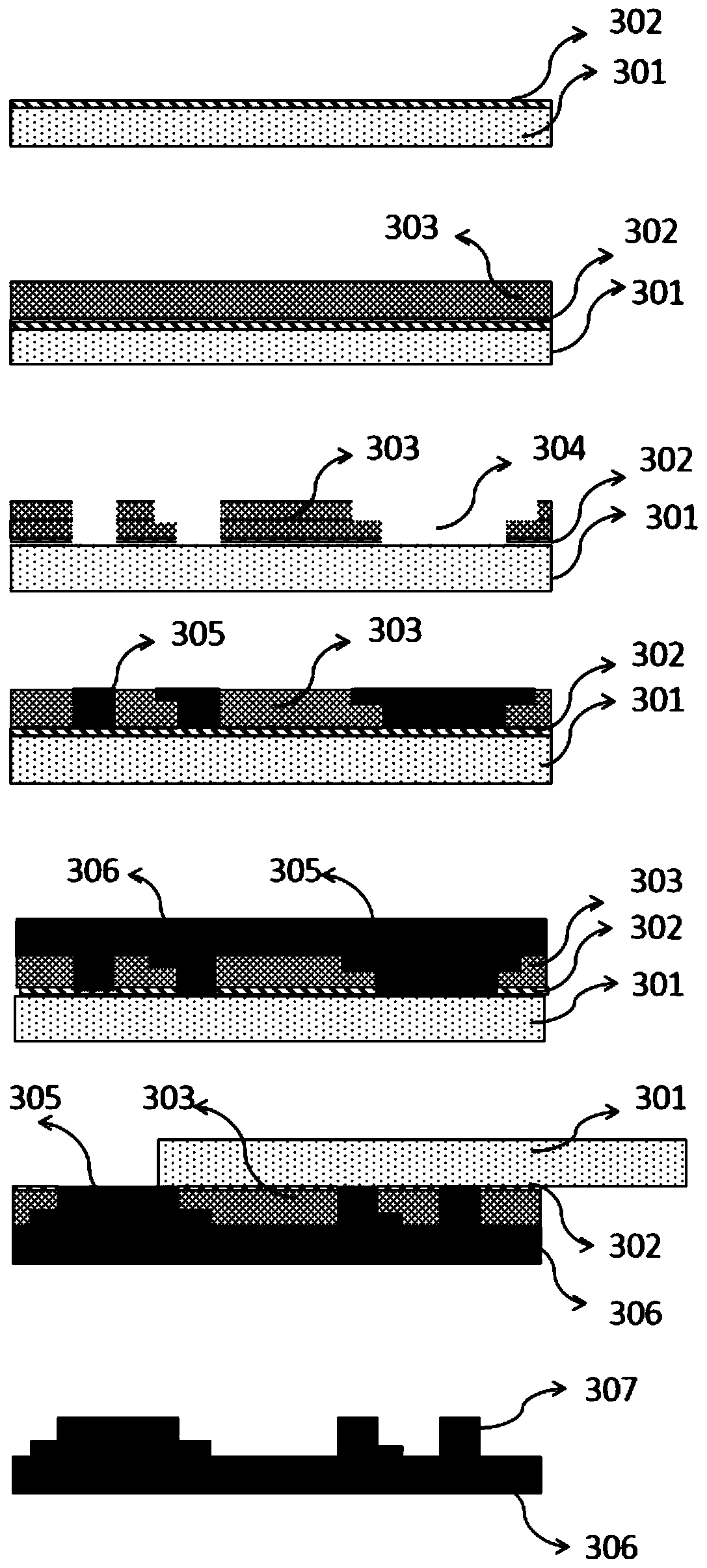

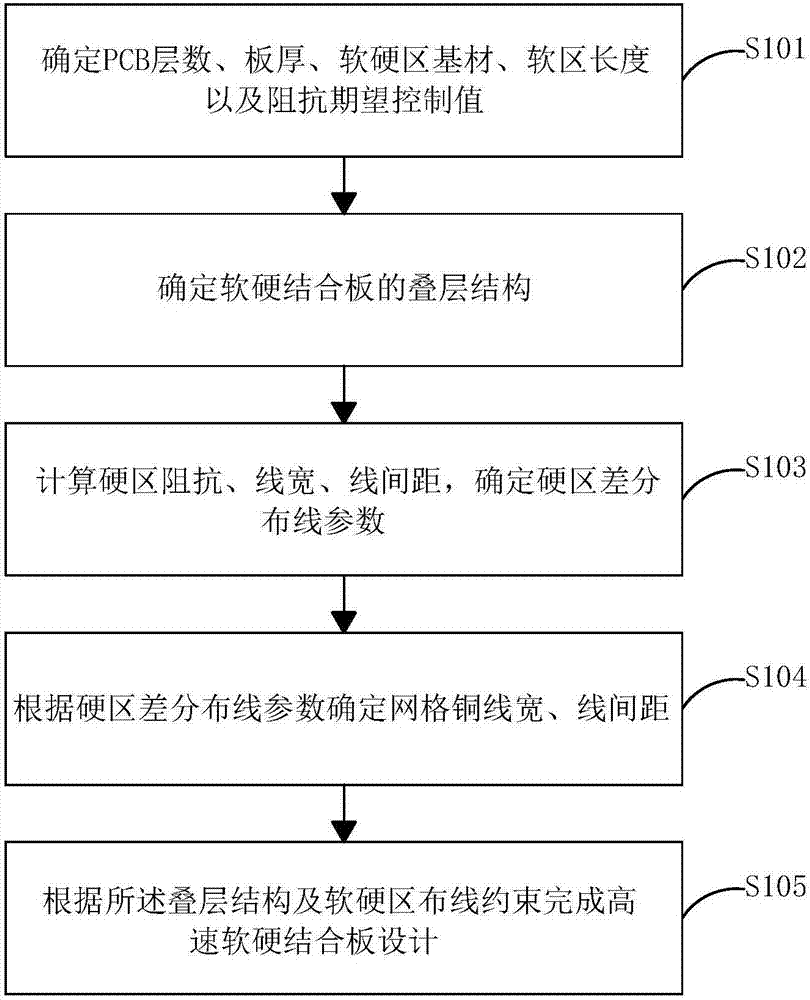

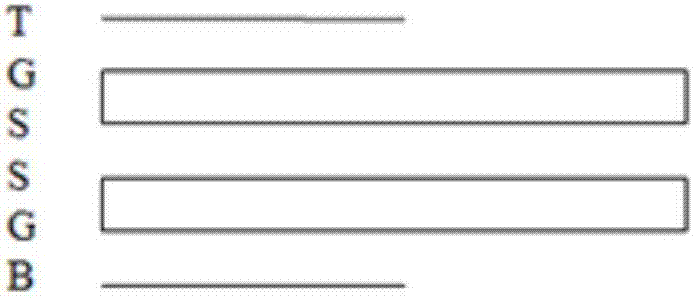

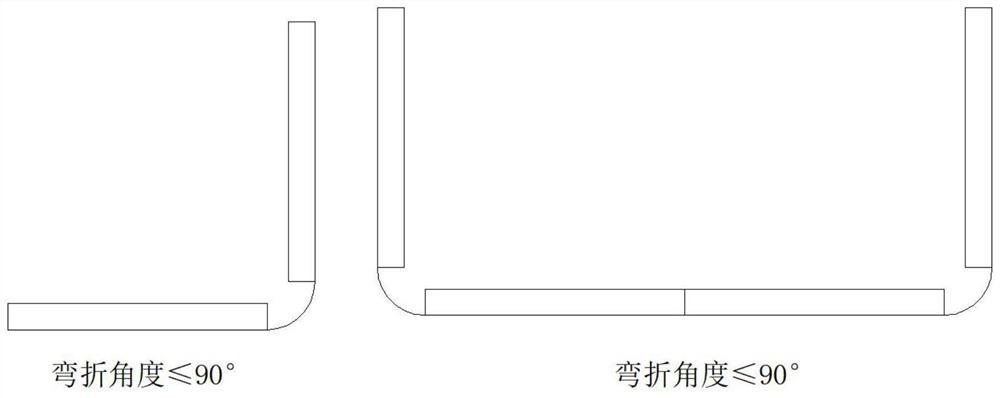

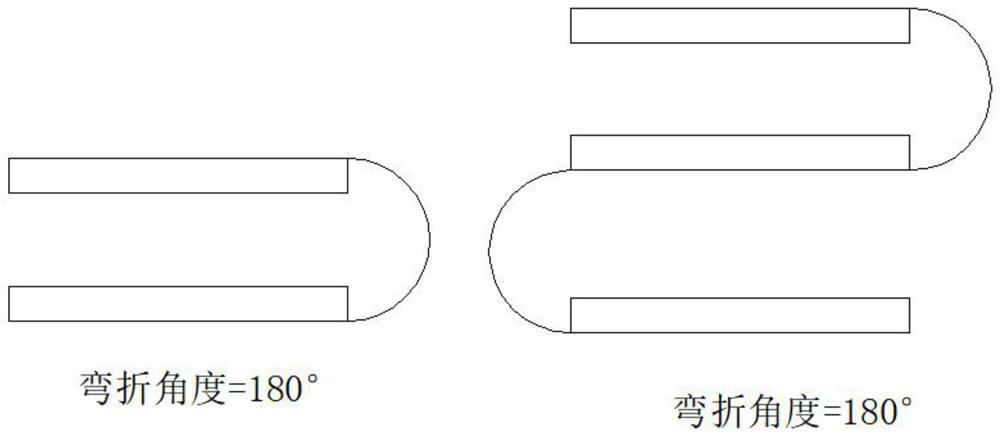

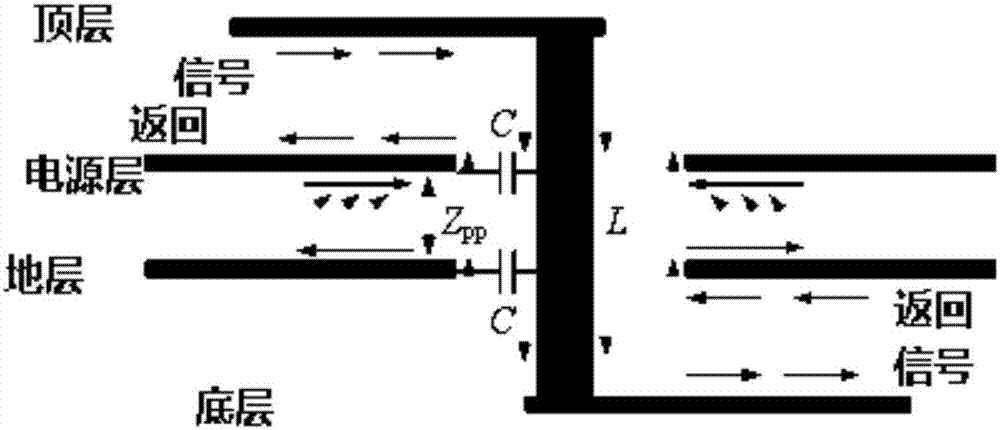

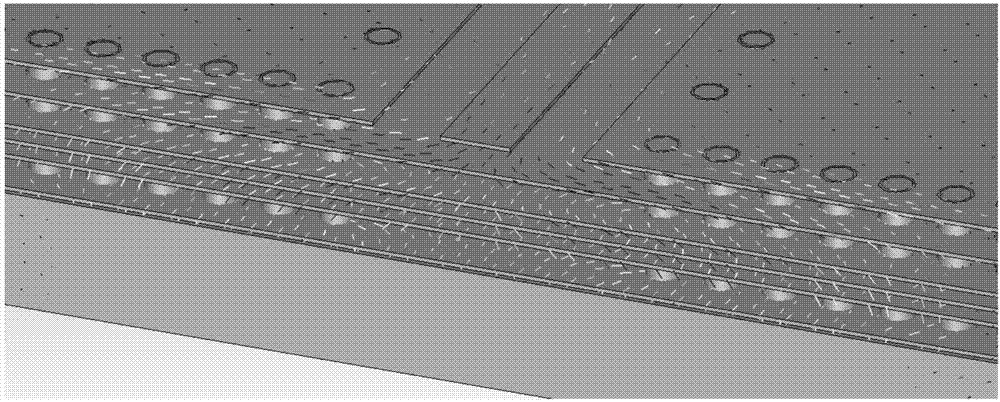

High speed rigid-flexible PCB design method

ActiveCN106961799ASolve the problem of impedance mutual influenceAvoid reflectionsPrinted circuit aspectsCircuit artworks manufactureWire widthCopper wire

The invention discloses a high speed rigid-flexible PCB design method. The high speed rigid-flexible PCB design method comprises steps that S101, a number of layers, thickness, base materials of a flexible region and a rigid region, a length of a flexible region, and an impedance expected control value are determined; S102, the laminated structure of the rigid-flexible PCB is determined; S103, impedance, a line width, and a line interval of a rigid region are calculated, and the difference wiring parameters of the rigid region are determined; S104, a grid copper wire width and the line width are determined according to the difference wiring parameters of the rigid region; S105, the design of the high speed rigid-flexible PCB is completed according to the laminated structure and rigid-flexible region wiring constraints. By adopting the reasonable laminated structure, a mutual influence problem of adjacent single chip impedances caused by the bending of the flexible region of the rigid-flexible PCB is solved, and the grid copper wires are used to constrain the wiring parameters of the flexible region and the rigid region to be consistent with each other, and reflection caused by a variable wire width of a flexible-rigid transition region is prevented; by controlling intervals among the high speed signal lines of the flexible region, signal integrity is prevented from being damaged by crosstalk between the high speed signal lines.

Owner:P C B A ELECTRONICS WUXI

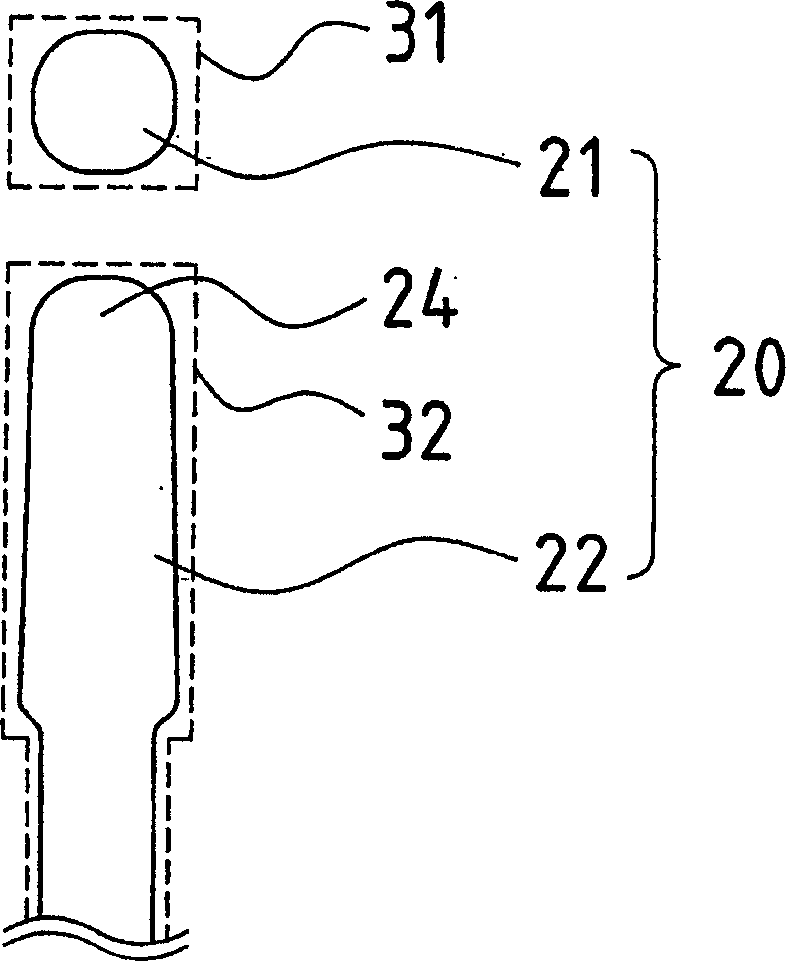

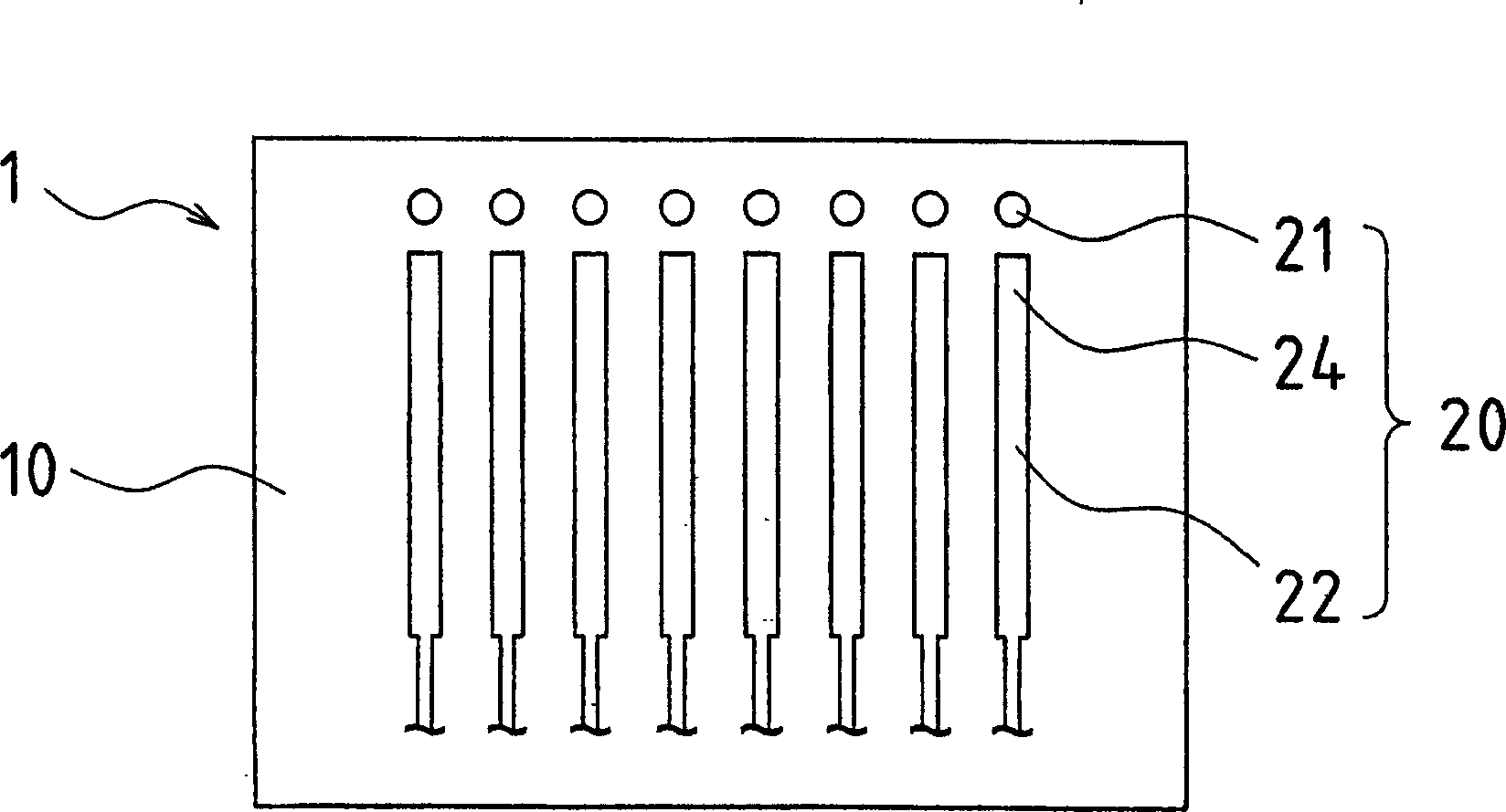

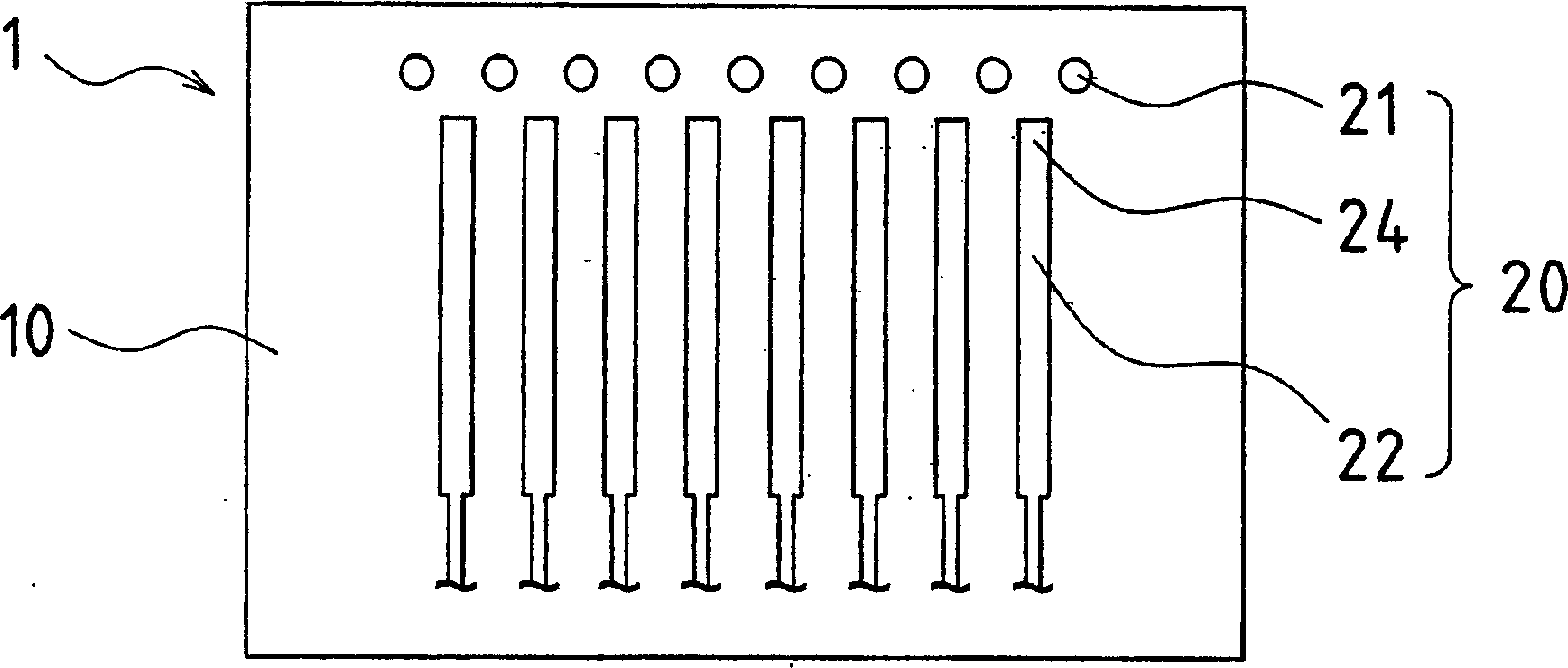

Vehicle-mounted Ethernet circuit board

InactiveCN106487520ASolve the problem of insufficient anti-interference performanceImprove anti-interference abilityData switching detailsCircuit artworks manufactureDifferential lineComputer module

A vehicle-mounted Ethernet circuit board relates to the field of automobile electronic technologies, and aims at solving the technical problem in anti-interference. The circuit board comprises a PCB substrate, and an Ethernet driving module and an Ethernet connecting piece mounted on the PCB substrate; the PCB substrate is printed with differential and backflow lines through which the Ethernet driving module is mounted with the Ethernet connecting piece, differential and backflow lines are laid on layers not adjacent to each other, and the differential line is provided with first and second common-mode inductors, first and second static inhibition diodes, first to fourth filtering capacitors and first to fourth filtering resistors. The circuit board provided by the invention is high in anti-interference capability.

Owner:YANFENG VISTEON ELECTRONICS TECH (SHANGHAI) CO LTD

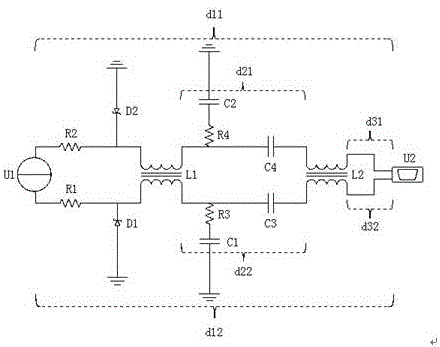

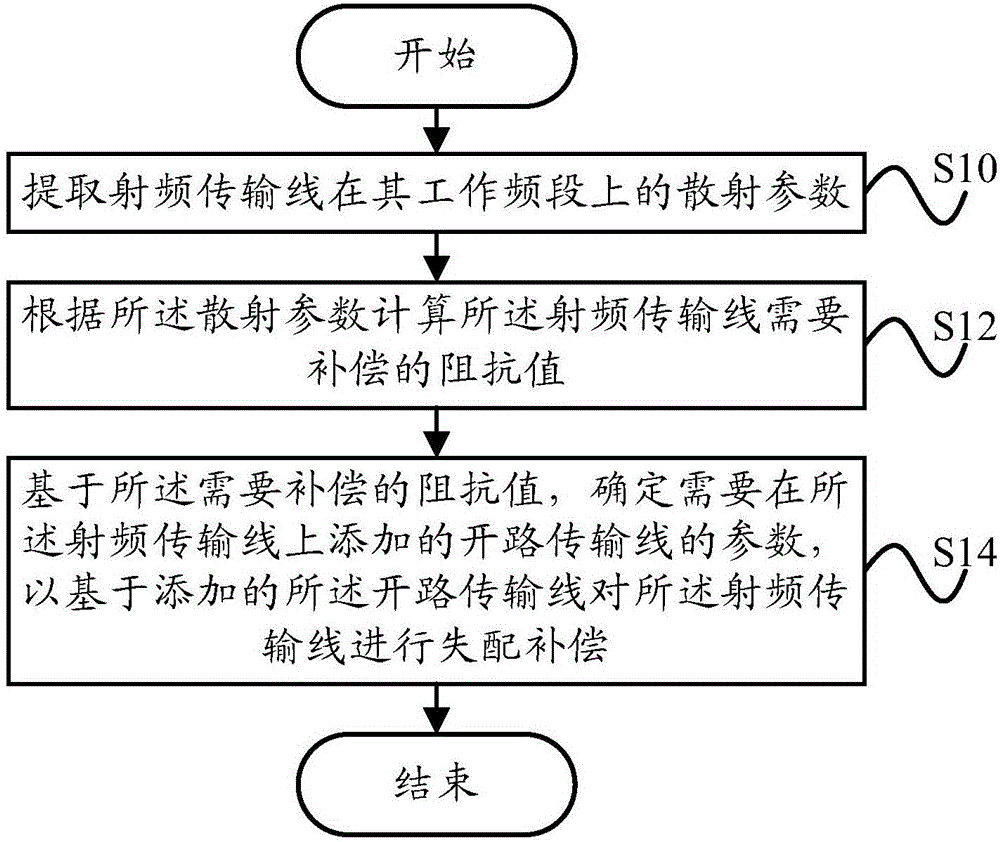

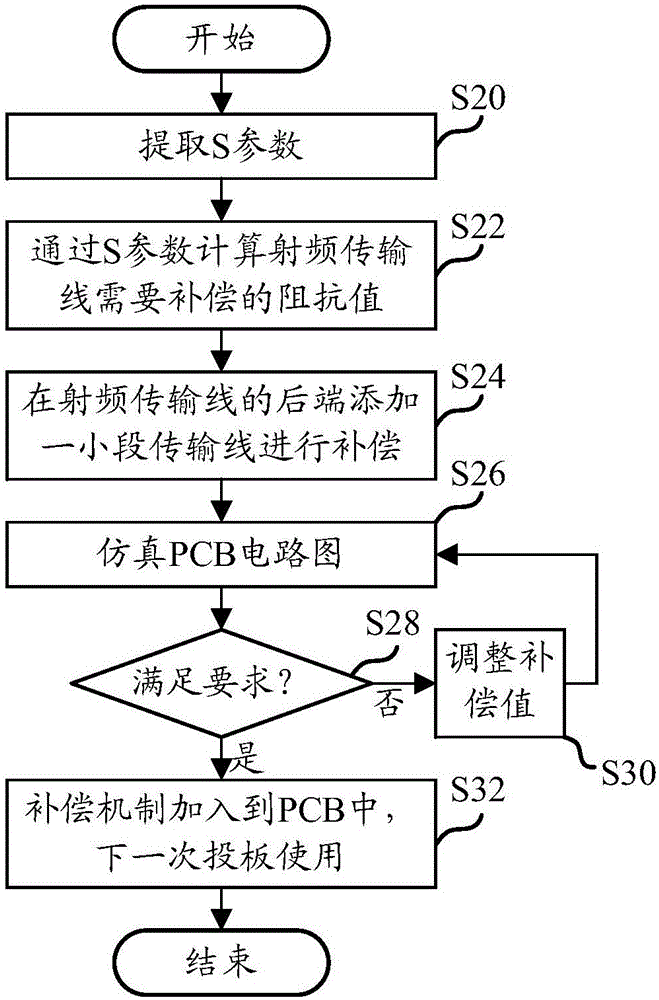

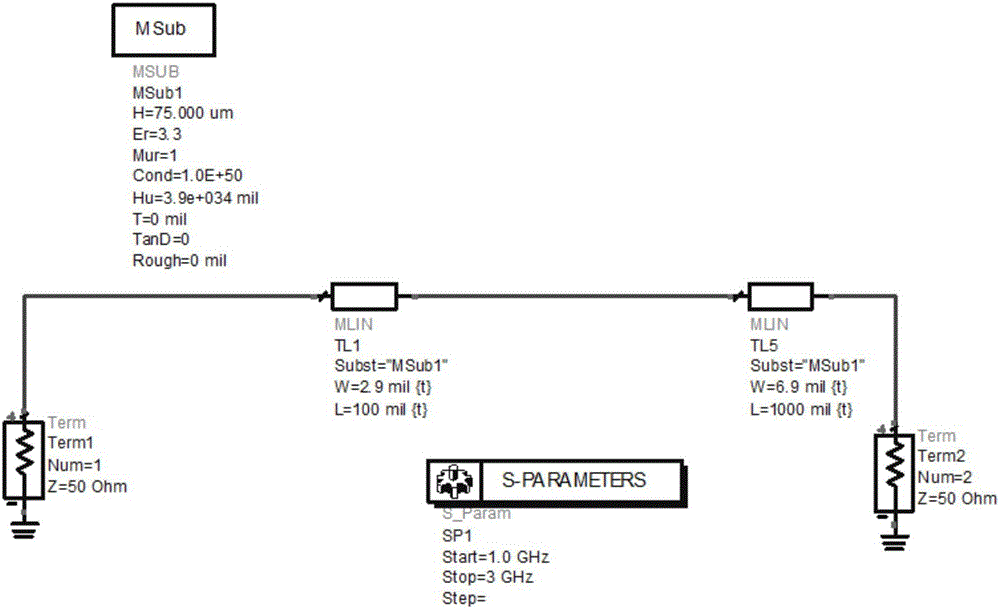

Mismatch compensation method and mismatch compensation device for radio-frequency transmission line

ActiveCN106413259AAvoid mismatchImpedence matching networksPrinted circuit aspectsEngineeringCompensation methods

The invention provides a mismatch compensation method and a mismatch compensation device for a radio-frequency transmission line. The mismatch compensation method for the radio-frequency transmission line comprises the following steps: extracting scattering parameters of the radio-frequency transmission line within the working frequency range of the radio-frequency transmission line; calculating an impedance value for which the radio-frequency transmission line needs to be compensated according to the scattering parameters; and based on the impedance value for which the radio-frequency transmission line needs to be compensated, determining parameters of an open-circuit transmission line that needs to be added to the radio-frequency transmission line, so that mismatch compensation of the radio-frequency transmission line can be carried out based on the added open-circuit transmission line. The mismatch compensation method and the mismatch compensation device adopting the technical scheme have the advantages that through the addition of the transmission line, the radio-frequency transmission line can be compensated for the mismatched impedance within the working frequency range of the radio-frequency transmission line, so that the mismatch problem of the radio-frequency transmission line can be effectively solved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

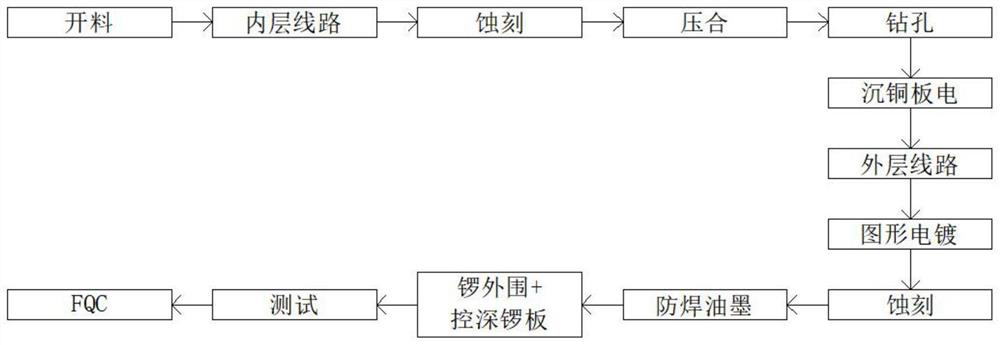

Technological process for manufacturing rigid bent plate

PendingCN111836468ALight in massCompact structureCircuit artworks manufactureScreen printingGlass fiber

The invention discloses a technological process for manufacturing a rigid bent plate. The technological process comprises the steps of selecting a proper copper-clad substrate for cutting operation when the rigid bent plate is manufactured; attaching a circuit board printed in the earlier stage to the copper-clad substrate on the cut copper-clad substrate; etching the circuit after transfer printing, and cleaning the circuit board when the copper film exposed on the circuit board is completely etched; additionally arranging a copper-clad substrate on the etched circuit board, and laminating the copper-clad substrate and the circuit board; metalizing resin and glass fiber of the non-conductor part on the hole wall of the circuit board, and carrying out electro-coppering on the circuit board; mounting an outer layer circuit according to the requirement of manufacturing the circuit board; carrying out copper plating and tin plating on the outer-layer circuit; etching a dry film on the circuit board and the copper under the protection of the dry film, and printing solder mask ink on the circuit board through silk-screen printing; and adopting a depth-controlled milling machine and a Cvertical special milling tool. The rigid bent plate designed by the invention can be bent according to installation requirements so as to adapt to different installation environments.

Owner:科惠白井(佛冈)电路有限公司

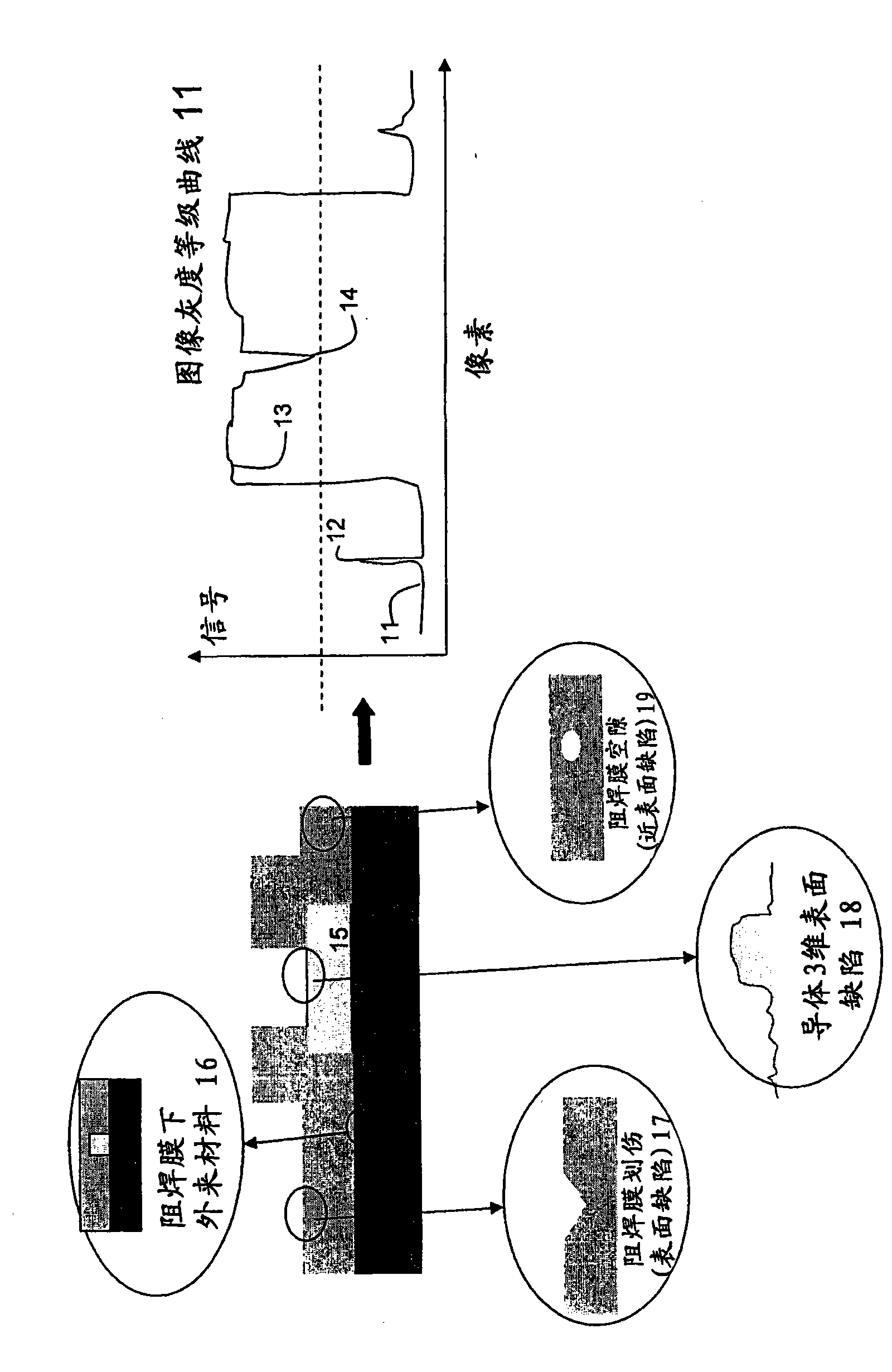

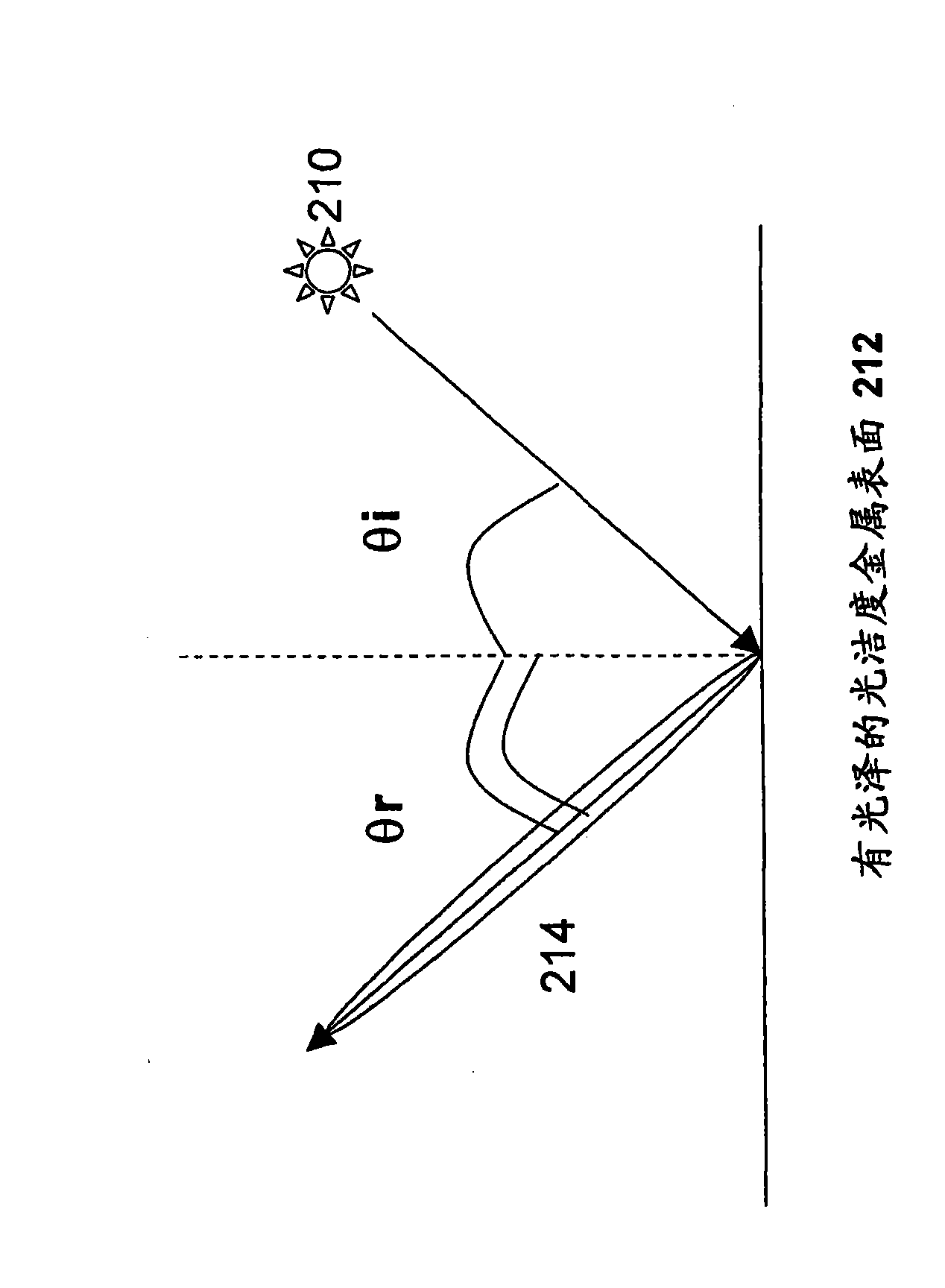

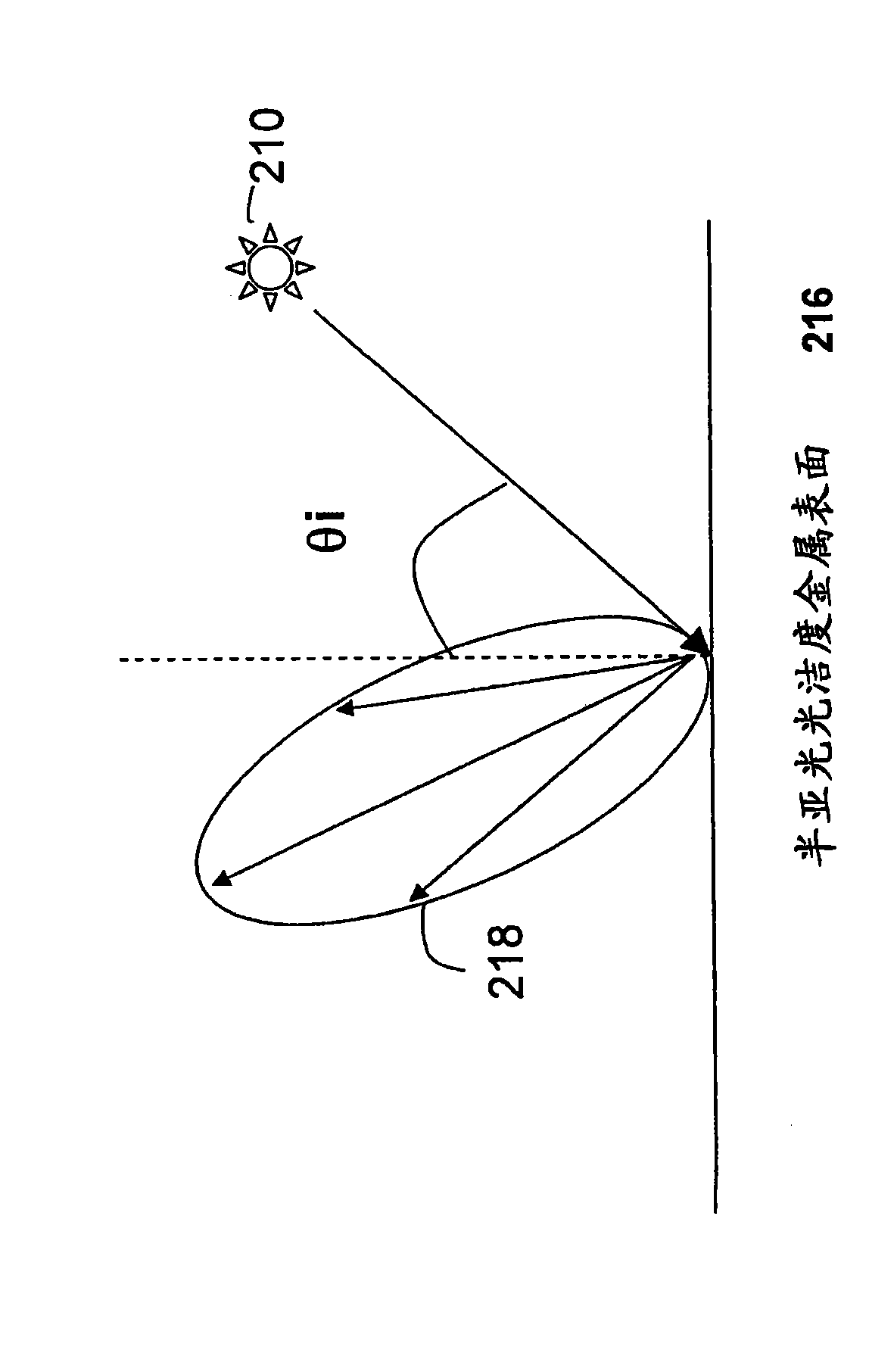

Defect detecting method using a multiple illumination path system

The invention provides an efficient method and a system for detection of defect for which need grows more and more. In the multiple illumination path system for detection of defect, a plurality of illumination paths irradiate an object simultaneously during the initial scanning of the object to segment the object to a segment in respons to a detected signal acquired during initial scanning, while during scanning for detection of defect of the segment an illumination path is selected to be active phase for each segment in respons to at least a parameter selected from the main material of the segment and surface roughness level of the segment, each segment of the object is illuminated by only the illumination path selected for the object, and a detected signal is generated indicating defect in respons to the illumination step concerned.

Owner:CAMTEK LTD

Method of realizing grounding circuit to improve matching characteristics of microwave multi-layer board

InactiveCN107484339AReduce reflectionImprove performancePrinted circuit groundingCross-talk/noise/interference reductionGround planeRadio frequency

The invention relates to a method of realizing a grounding circuit to improve matching characteristics of a microwave multi-layer board. The method comprises the steps of carrying out reasonable distribution verification of metal through holes vertical to the direction of a substrate through simulation software; meanwhile through a signal return path displayed by the simulation software, interconnecting printed boards on the signal path by connecting a radio frequency ground plane with a large ground plane of the back of the multi-layer substrate in a printed board edge gilding manner; and then welding the ground plane of the back of the substrate onto a carrier of a microwave signal common ground plane to reduce the impedance between a micro-strip ground plane and the microwave signal common ground plane and thus optimize the radio frequency path performance.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

Popular searches

Originals for photomechanical treatment Inspection/indentification of circuits CAD circuit design Computer designed circuits Special data processing applications Radiation-sensitive masks exposure Semiconductor/solid-state device details Solid-state devices Thin material handling Circuit susbtrate materials

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com