Automatic optical detection device and method

An automatic optical inspection and light technology, which is applied in the direction of using optical devices, measuring devices, optical testing defects/defects, etc., can solve the problems of slow inspection speed, production efficiency and data processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Various modifications can be made to the embodiment of the present invention, and the scope of the present invention is not interpreted as being limited to the embodiment described below. This embodiment is provided only for the purpose of more completely explaining the invention to those skilled in the art. Therefore, the shapes and the like of elements in the drawings are exaggerated for clearer illustration.

[0023] The following will refer to the attached Figure 1 to Figure 4 Embodiments of the present invention will be described in detail. In addition, structural elements having the same function in the above-mentioned drawings are denoted by the same reference numerals.

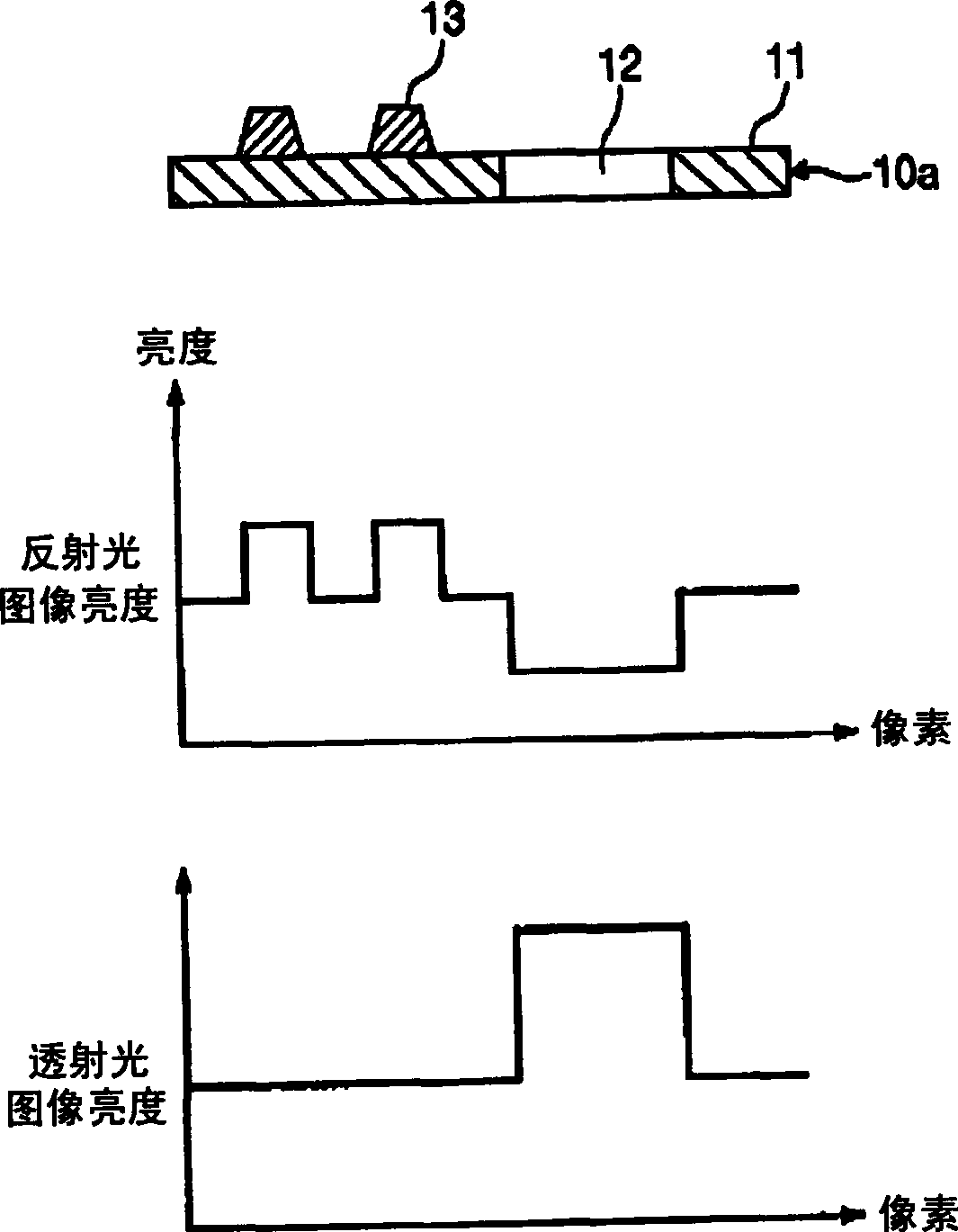

[0024] The inspection apparatus and method of the present invention are very suitable for simultaneously inspecting the appearance (foreign matter, discoloration, contamination, etc.) of a transmissive substrate and the burr of a through hole formed on the substrate.

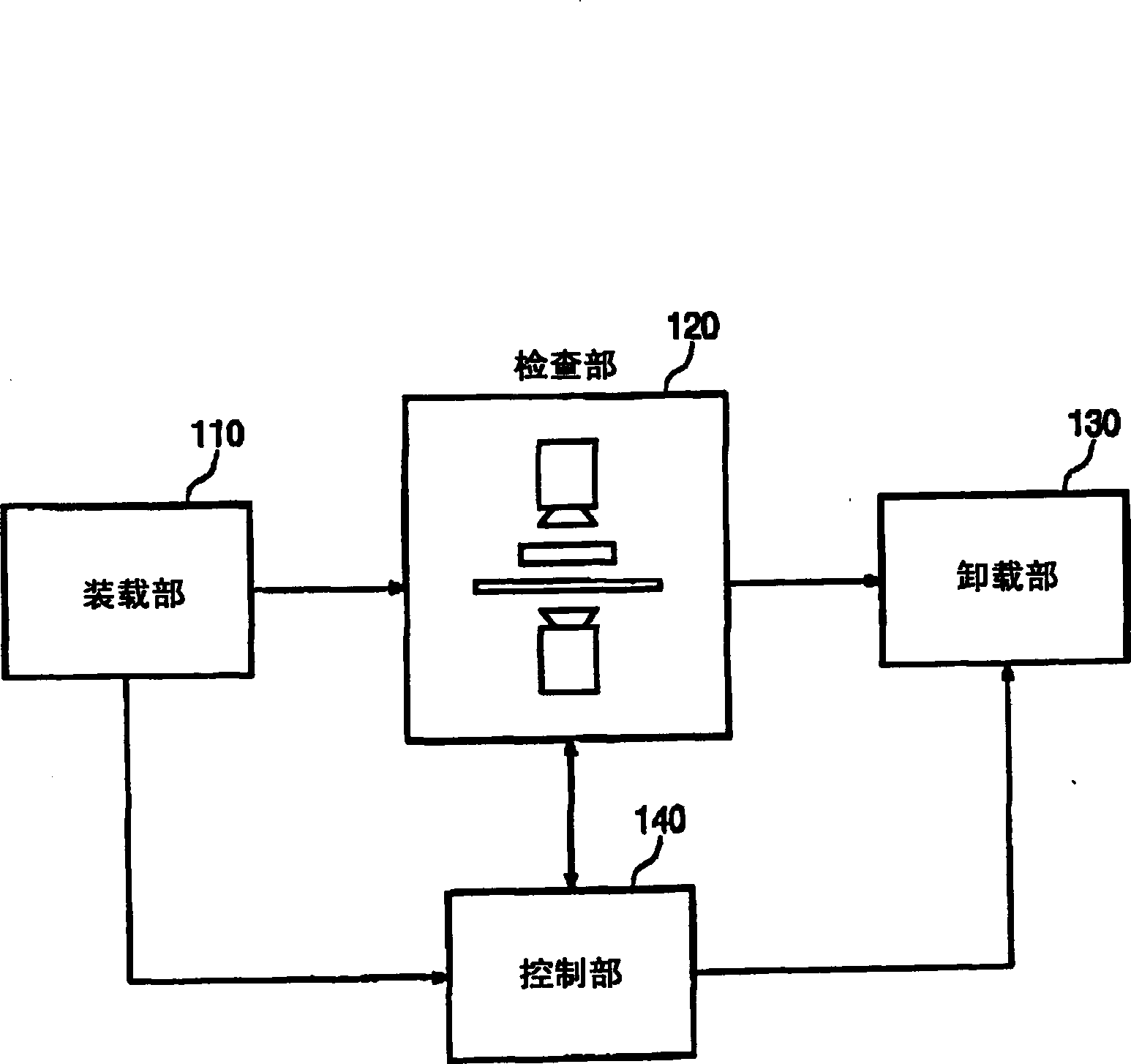

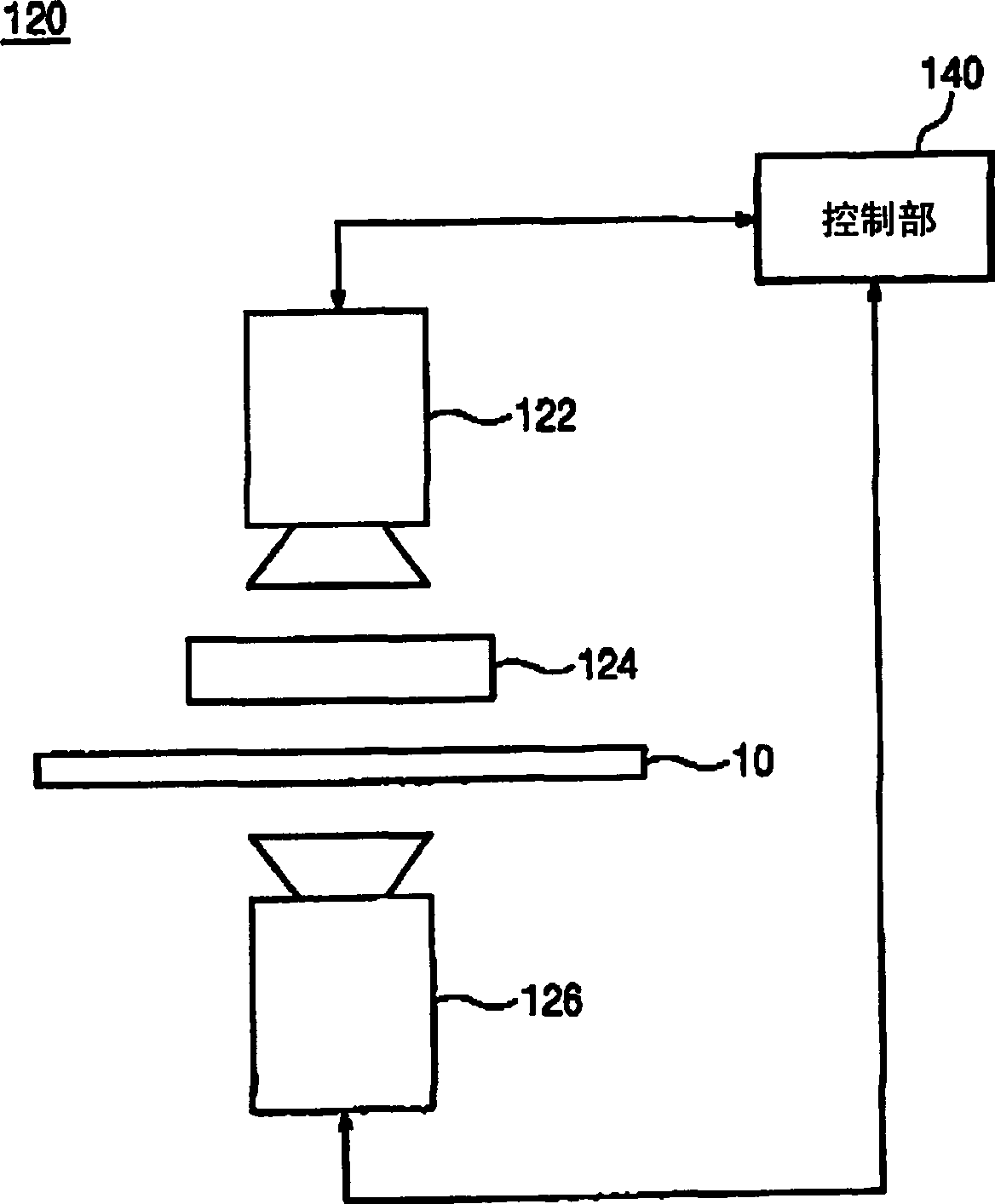

[0025] figure 1 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com