Image checking apparatus

A technology for inspection devices and graphics, applied in measuring devices, image enhancement, image analysis, etc., can solve the problems of difficult design, lower resolution, high lens price, etc., and achieve the effect of preventing the increase of device cost and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

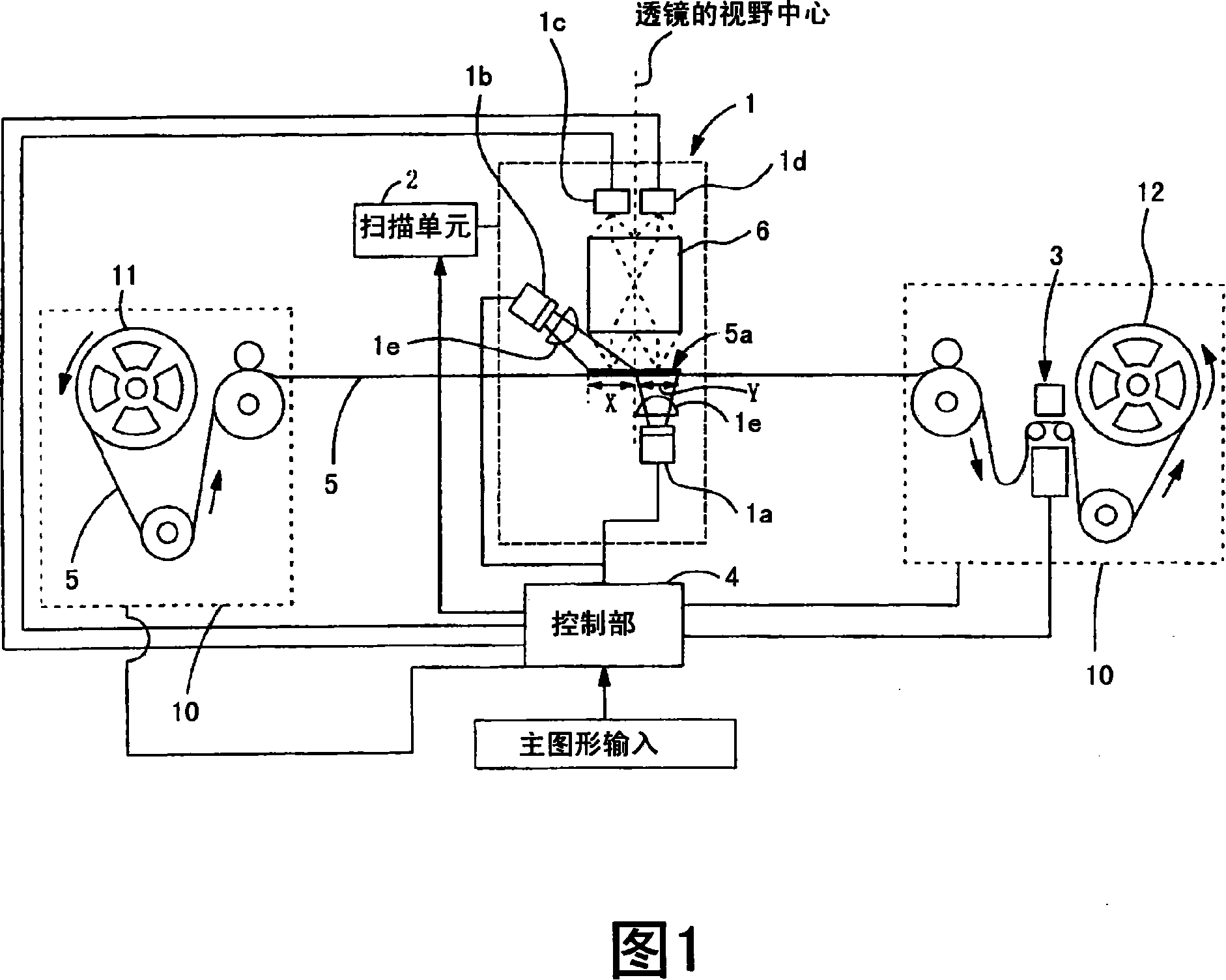

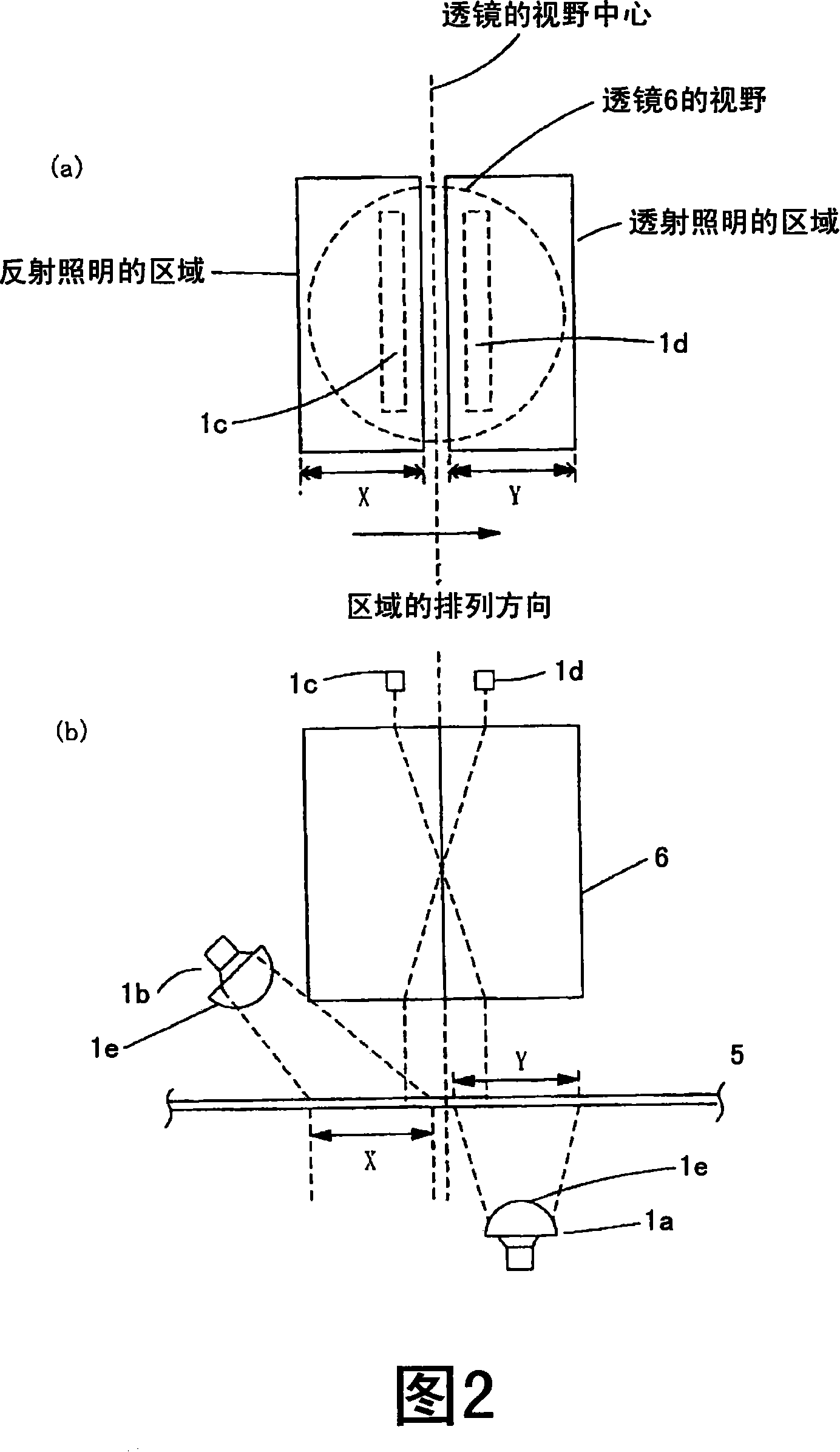

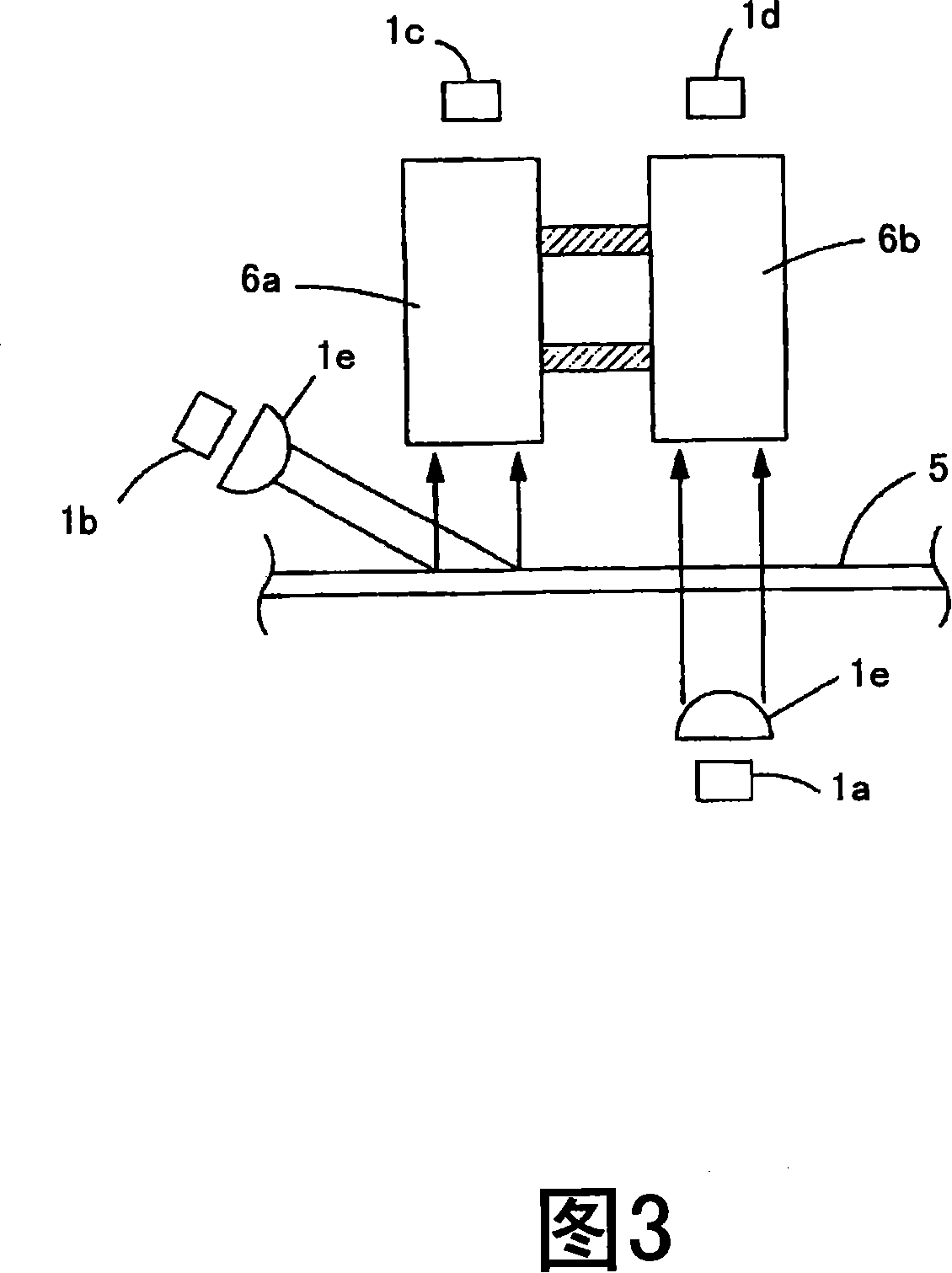

[0038] Fig. 1 is a block diagram of a wiring pattern inspection device according to a first embodiment of the present invention. In addition, in any of the embodiments shown below, the case where the substrate is a TAB tape will be described, but the present invention can be applied to pattern inspection of various substrates capable of transmitted illumination other than the TAB tape. For example, a silicon wafer can transmit infrared rays. If infrared rays are used for reflected illumination light and transmitted illumination light, the same inspection can be performed on the above-mentioned wiring pattern formed on the silicon wafer.

[0039] The graphic inspection apparatus of the present embodiment, as shown in Figure 1, possesses: tape conveying mechanism 10, is made up of sending out reel 11 and take-up reel 12 by conveying TAB tape 5; The tape 5 irradiates transmitted illumination light and reflected illumination light, and images the pattern 5a; the scanning unit 2 sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com