Novel polyamic acid, polyimide, photosensitive resin composition comprising same, and dry film produced from the composition

一种聚酰胺酸、感光树脂的技术,应用在聚酰胺酸或聚酰亚胺领域,能够解决限制、耐受性不足等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

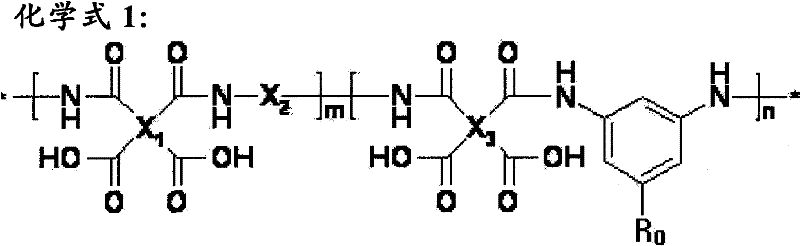

[0113] Embodiment 1: the preparation of polyamic acid and photosensitive resin composition

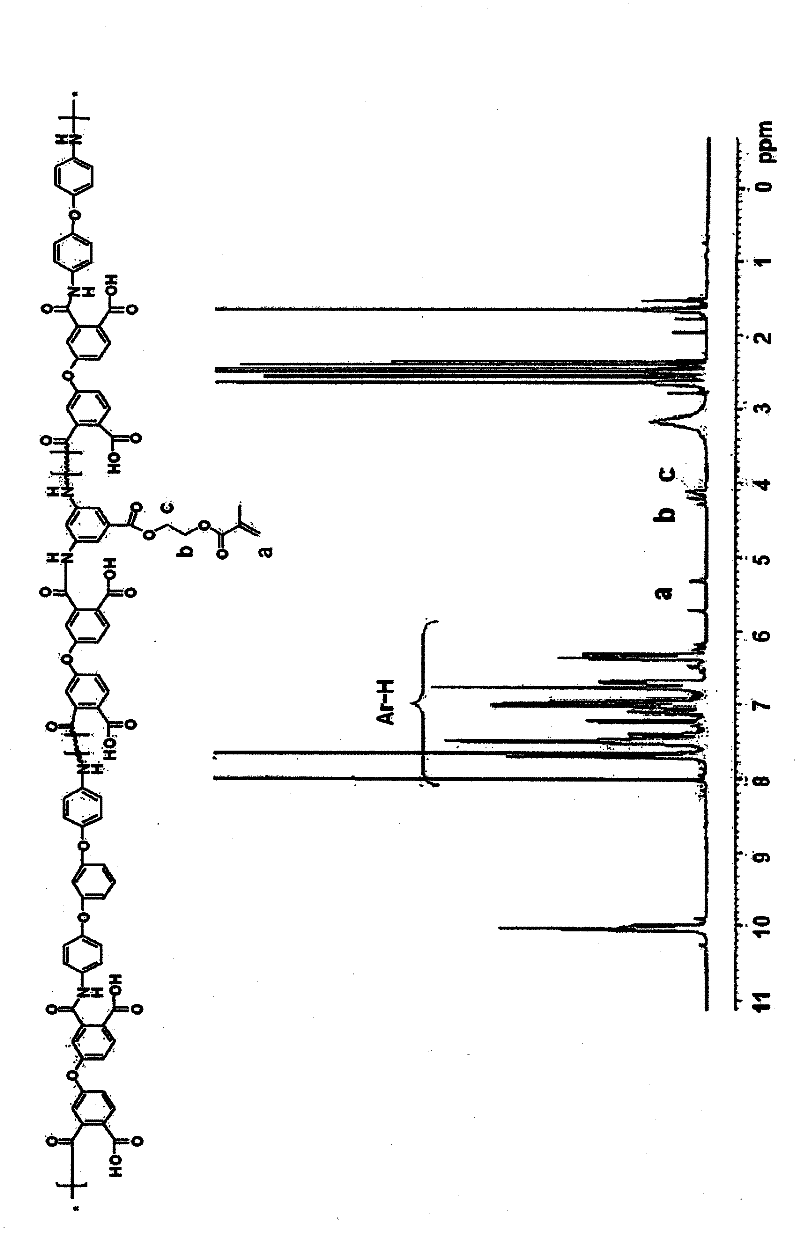

[0114] While passing nitrogen into a four-necked round-bottomed flask equipped with a thermometer, a stirrer, a nitrogen gas inlet, and a powder dispensing funnel, 190 g of N,N-dimethylacetamide (DMAc) was added to the four-necked round-bottomed flask. 7.94 g 4,4'-diaminodiphenyl ether (4,4'-ODA), 27.02 g 1,3-bis(4-aminophenoxy)benzene (TPE-R) and 3.82 g 3,5 -diaminobenzoic acid 2'-(methacryloyloxy)ethyl ester and dissolve it completely by stirring. The solution was cooled to below 15°C, and then 43.18 g of 4,4'-oxydiphthalic anhydride (ODPA) was added slowly. The solution was stirred at 5° C. for 24 hours to obtain a polyamic acid varnish.

[0115] The viscosity of the prepared polyamic acid was 3200 cps. After the product polymer was obtained by precipitation, it was confirmed by NMR analysis that 2'-(methacryloyloxy)ethyl 3,5-diaminobenzoate was intercalated into the polyamic aci...

Embodiment 2 to 5 and comparative Embodiment 1

[0118] The polyamic acid and photosensitive resin compositions were prepared in the same manner as in Example 1, except that the ingredients and their compositions in Table 1 were used.

[0119] [Table 1]

[0120]

[0121] ODPA: 4,4'-oxydiphthalic anhydride

[0122] 4,4'-ODA: 4,4'-diaminodiphenyl ether

[0123] TPE-R: 1,3-bis(4-aminophenoxy)benzene

[0124] HEMA-DA: 2′-(methacryloyloxy)ethyl 3,5-diaminobenzoate

[0125] Experimental Example: Membrane Physical Property Evaluation

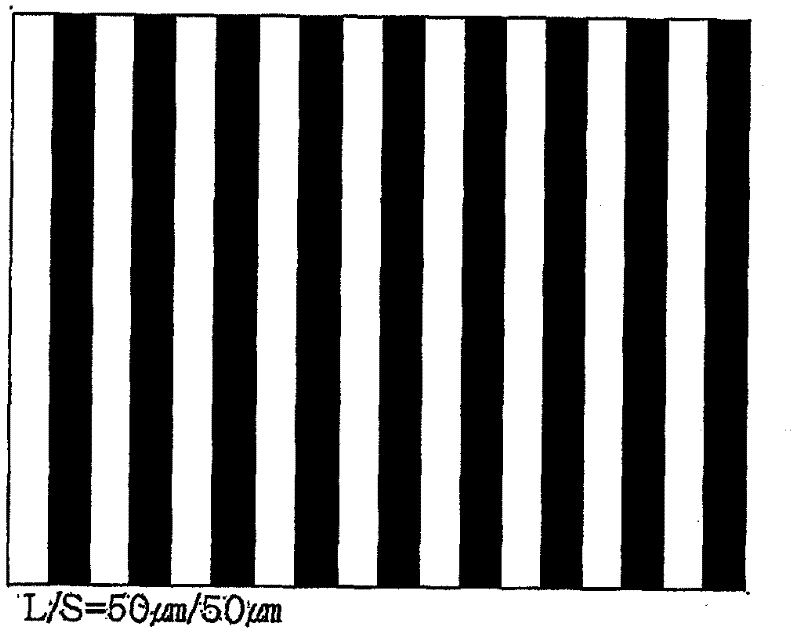

[0126] The photosensitive resin compositions obtained in Examples 1 to 5 and Comparative Example 1 were coated on a polyethylene terephthalate (PET) film with a thickness of 71 μm using a doctor blade, and then dried in an oven at 80° C. for 15 minutes to obtain a dry film with a thickness of 25 μm.

experiment Embodiment 1

[0127] Experimental Example 1: Transparency

[0128] The transparency of the dried film was observed with the naked eye, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com