Defect detecting method using a multiple illumination path system

A technology of defect detection and routing, which is applied in the direction of optical test defect/defect, measurement device, printed circuit making wiring diagram, etc., and can solve problems such as unqualified and unqualified production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

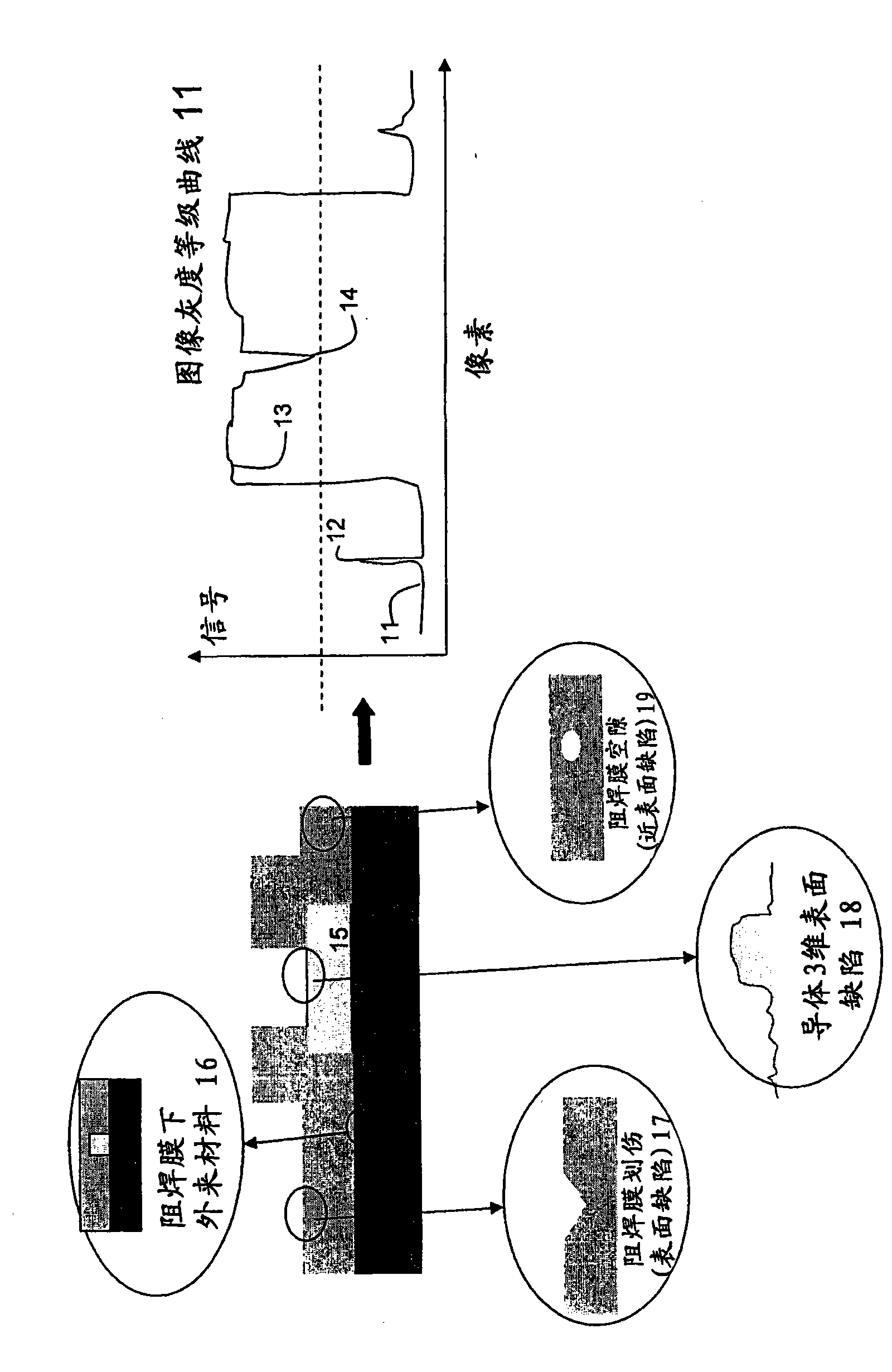

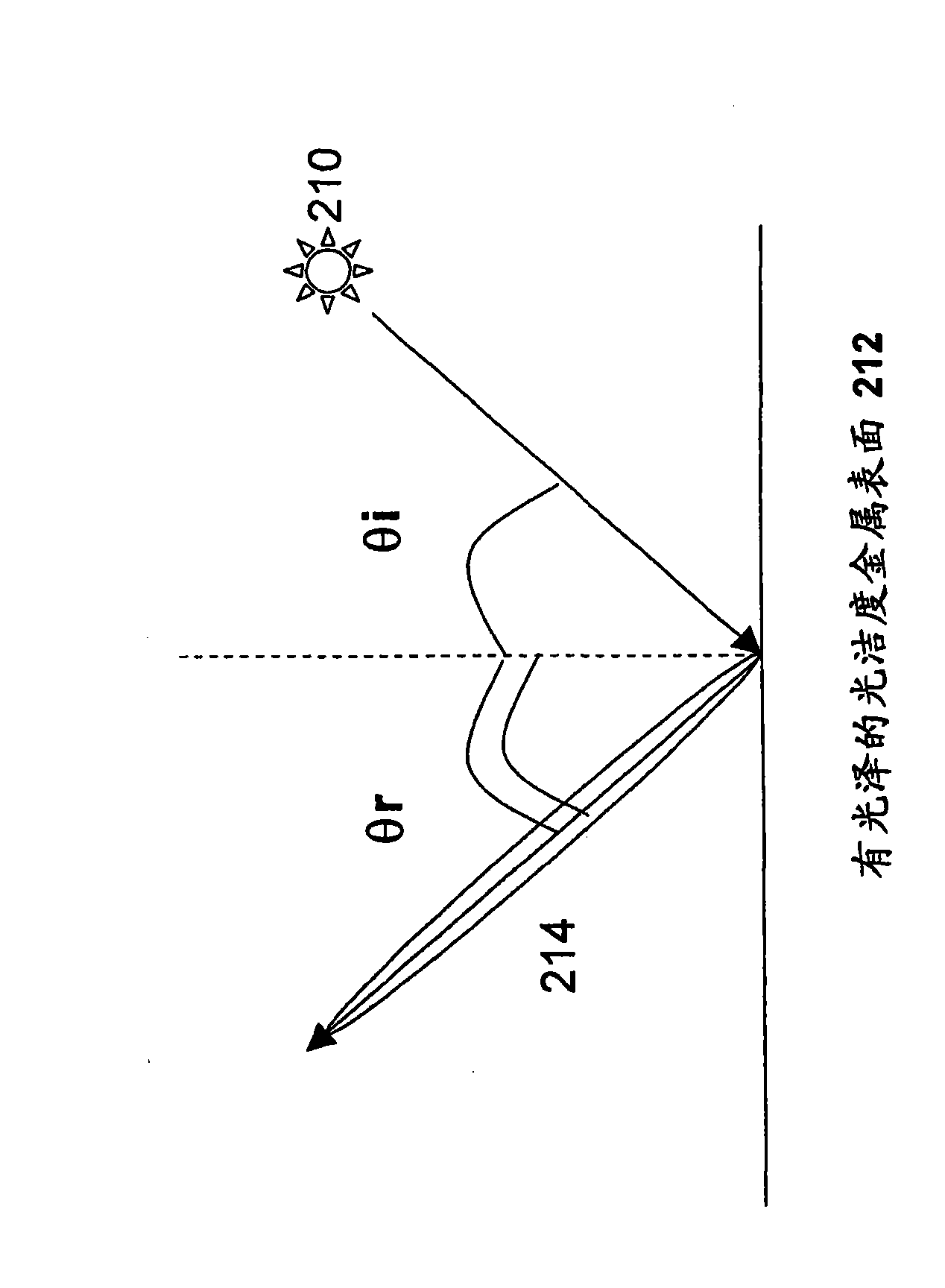

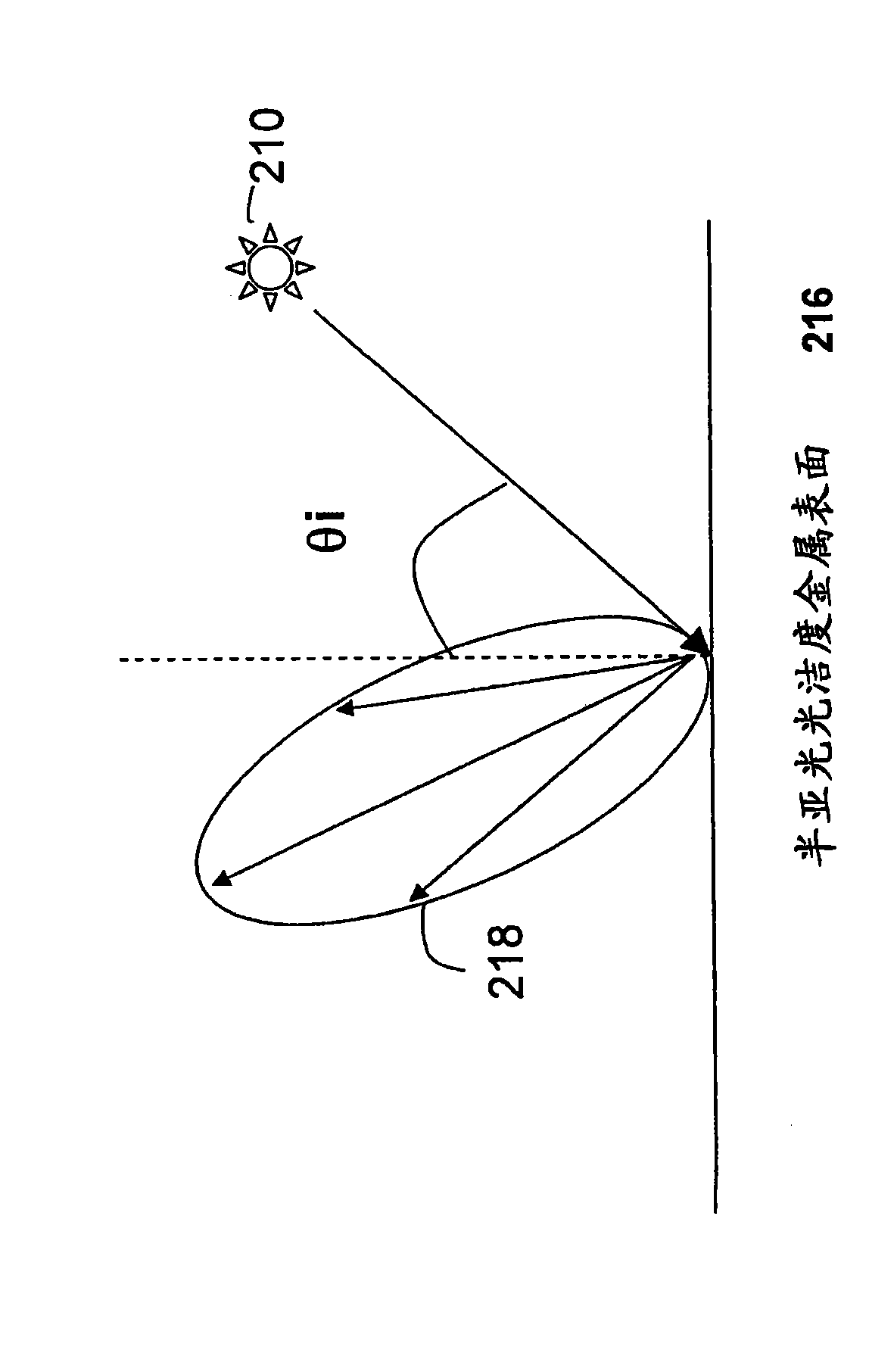

[0031] A multiple lighting path system is provided. It includes multiple illumination paths, processor and imaging paths. The processor is adapted to: (i) control an initial scan of the object; (ii) segment the object into segments based on detection signals obtained during the initial scan; (iii) determine the surface roughness of each segment; and (iv) A selected illumination path to be activated during defect detection of the segment is selected for each segment based on at least one parameter selected from the segment's primary material and the segment's surface roughness level. Multiple illumination paths are used to illuminate objects simultaneously during the initial scan. During a defect detection scan of the object, the selected illumination path illuminates the segment associated with the selected illumination path. The imaging path is adapted to generate a detection signal indicative of a defect in response to said illumination.

[0032] Advantageously, the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com