Photosensitive Resin Composition Of Excellent Reliability And Method For Manufacturing Same

A resin composition and a technology for the composition are applied in the directions of optomechanical equipment, photoengraving process of pattern surface, photosensitive material for optomechanical equipment, etc. Different problems, lower production efficiency, etc., to achieve the effect of improving quality stability, shortening preparation time, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

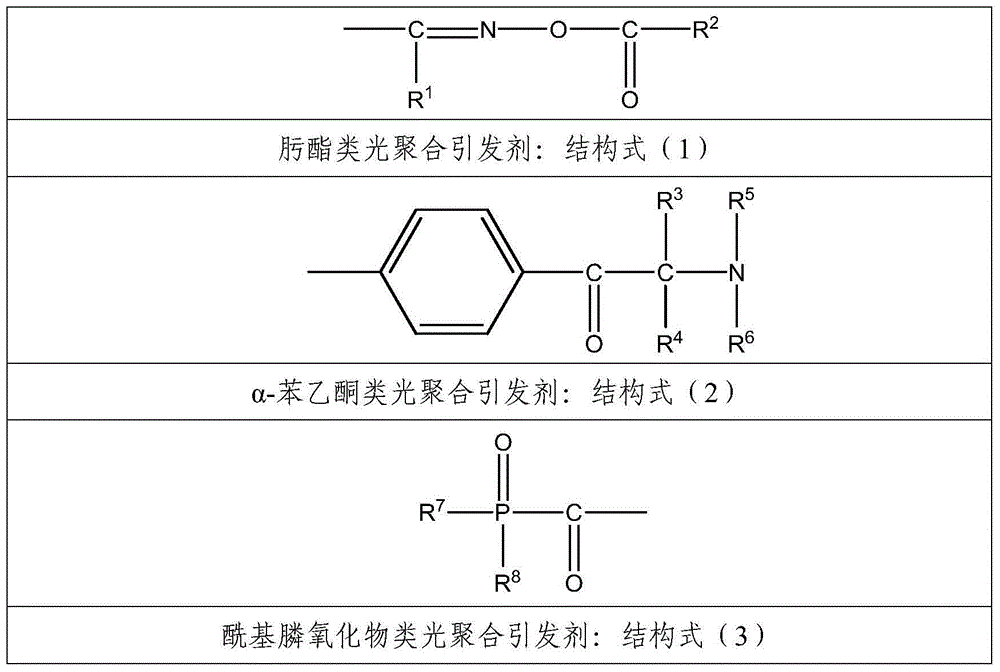

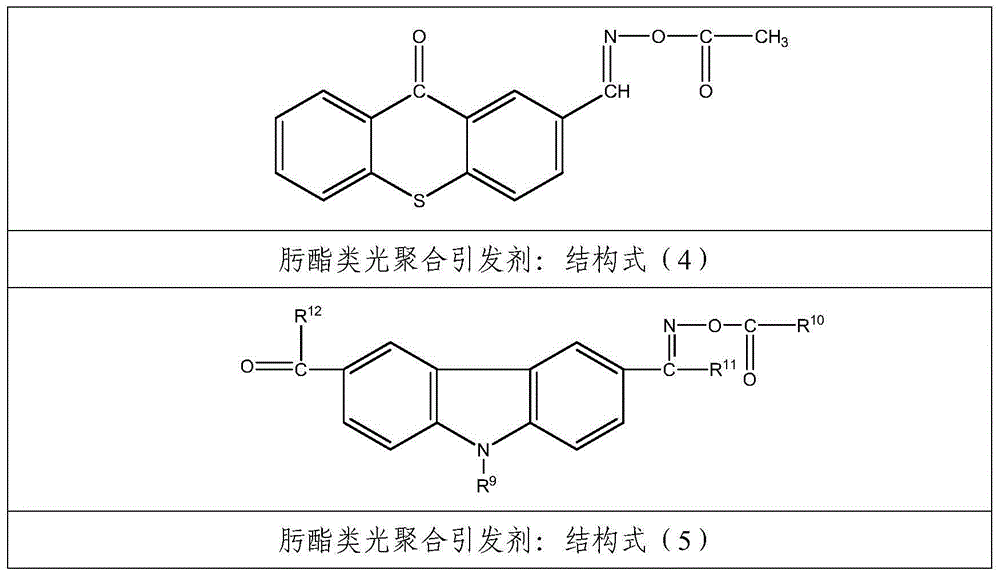

Method used

Image

Examples

specific example

[0092] The photocurable thermosetting resin composition of the present invention can also be obtained by coating the composition on a film such as polyethylene terephthalate and drying it in addition to the method of directly applying it to a substrate in a liquid state. Available in dry film form with solder resist layer. The concrete example that photocurable thermosetting resin composition of the present invention is used as dry film is as follows:

[0093] The dry film is a structure in which a base film, a solder resist layer, and a peelable protective film used as needed are laminated in sequence. The solder resist layer is a layer obtained by applying and drying a photocurable thermosetting resin composition capable of being developed with an alkaline aqueous solution on a base film or a protective film. A dry film can be obtained by forming a solder resist layer on a base film and then laminating a protective film, or forming a solder resist layer on a protective film...

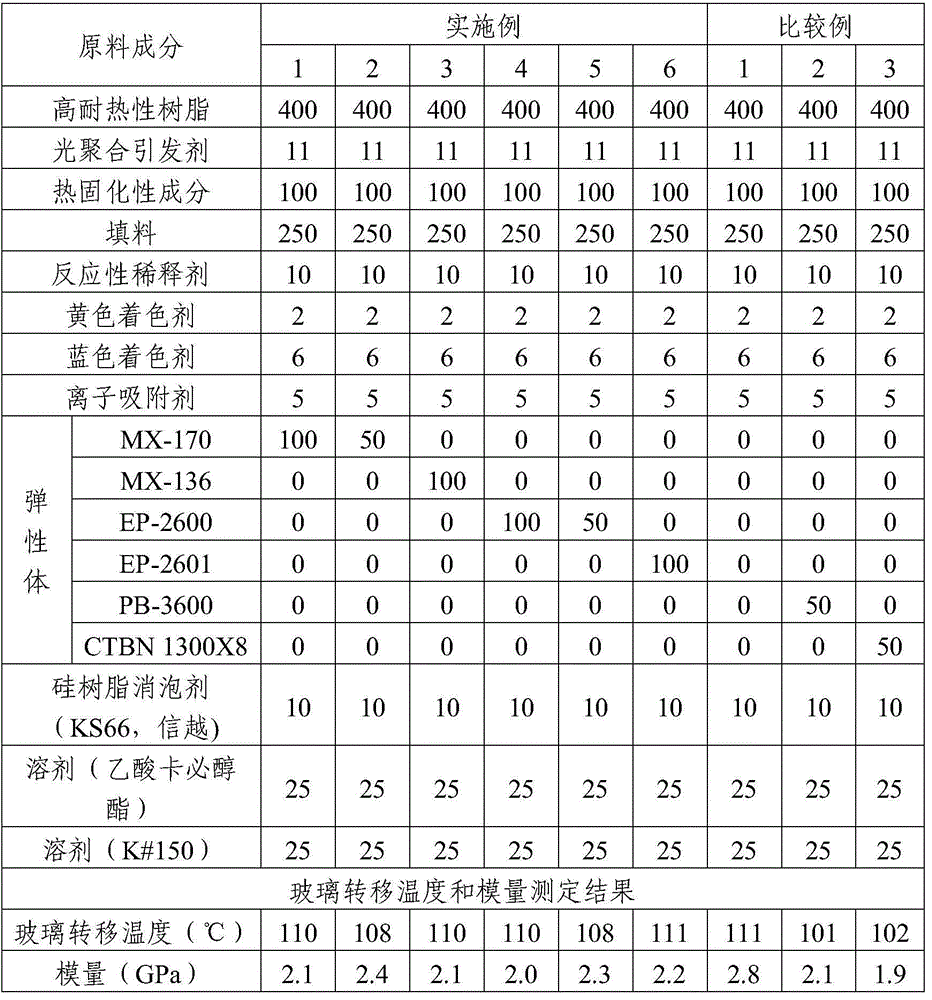

Embodiment 1

[0106] Put 400g of high heat-resistant resin (SR90-B3T4, solid content = 65%, acid value = 57mgKOH / g, KCC) containing unsaturated double bonds and carboxyl groups into a reactor with a stirring device, bisphenol A type thermosetting 100 g of the active ingredient (YD-012, bisphenol A epoxy resin, softening point=80° C., equivalent weight=650, Kokudo Chemical) was stirred at 500 rpm for 10 minutes. After stirring, 10 g of the reactive diluent dipentaerythritol hexaacrylate (DPHA) (Nippon Kayaku) and 30 g of the photopolymerization initiator (Irgacure 369, oxime ester photopolymerization initiator, BASF) containing unsaturated double bonds were added, and then the Yellow coloring agent (pigment yellow 147, BASF) 2g, blue coloring agent (pigment blue 16:00, BASF) 6g and ion adsorbent (IXEPLAS, the mixture of hydrotalcite and zirconium phosphate, Dong Ya synthetic) 5g, stir 10 with 500rpm minute. After the stirring is completed, drop in 100 g of core-shell particle type elastomer...

Embodiment 2

[0108] Prepare a photocurable thermosetting resin composition in the same manner as in Example 1, except that a core-shell particle-type elastomer (MX-170, core: silicone resin, core content: 25%, dispersion medium : bisphenol A epoxy resin, KANEKA) 50g. The prepared photocurable thermosetting resin composition had a solid content of 73% and a viscosity of 12500 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com