Manufacturing method of ultralow-resistance flexible conductive circuit

A technology of conductive circuit and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit wiring diagram, etc., can solve the problems of complex preparation process, poor conductivity, poor combination, etc., achieve simple process, improve conductivity, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

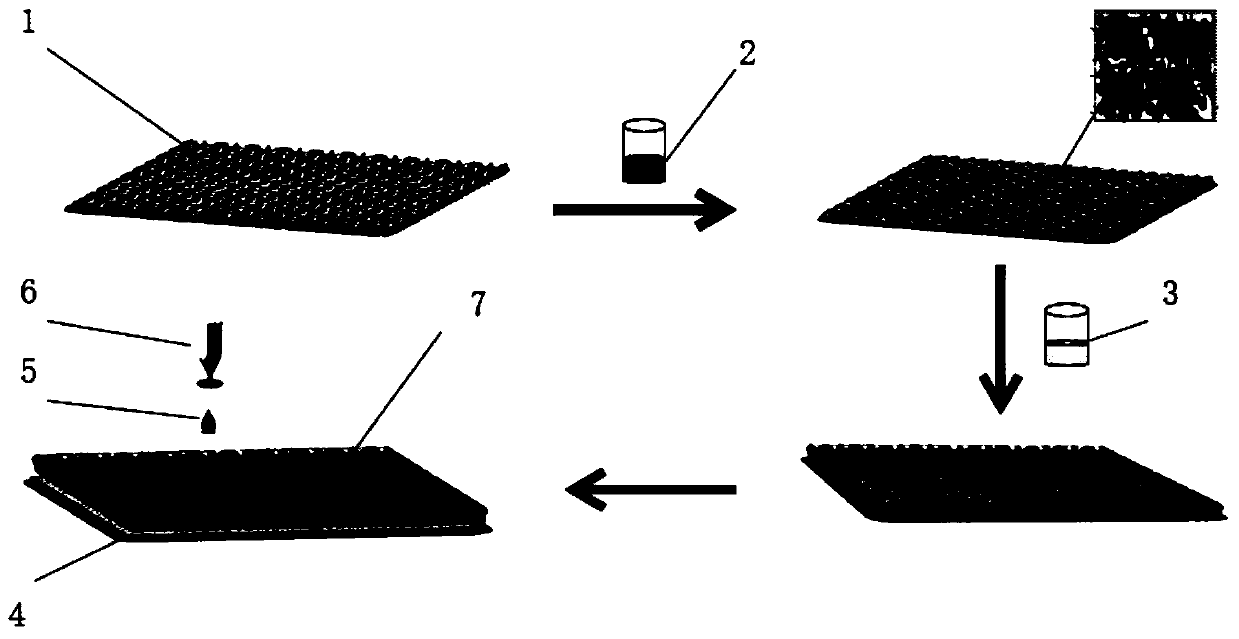

[0050] (1) Preparation of fabric substrate 1

[0051] Select cotton cloth, cut it into a size of 70 mm×70 mm, and then dip it in carbon nanotube solution 2 with a mass volume concentration of 0.5% w / v, evenly dip it in a magnetic stirrer, pick it up and hang it on a stand, Standing and drying at room temperature for 1 hour to obtain a fabric substrate 1 for use; wherein, the rotating speed of the magnetic stirrer is 800 rpm / min, and the temperature is 50° C.;

[0052] (2) Preparation of precursor solution 3

[0053] Dissolve 2 g of glucose in 10 mL of deionized water, stir evenly, and filter with filter paper to obtain precursor solution 3, which is sealed for later use;

[0054] (3) Preparation of ink 5

[0055] Dissolve 2g of silver nitrate powder in 10mL of deionized water, stir evenly, and filter with filter paper to obtain ink 5 with a mass volume concentration of 20% w / v, and set aside;

[0056] (4) print

[0057] Take an appropriate amount of precursor solution 3 to...

Embodiment 2

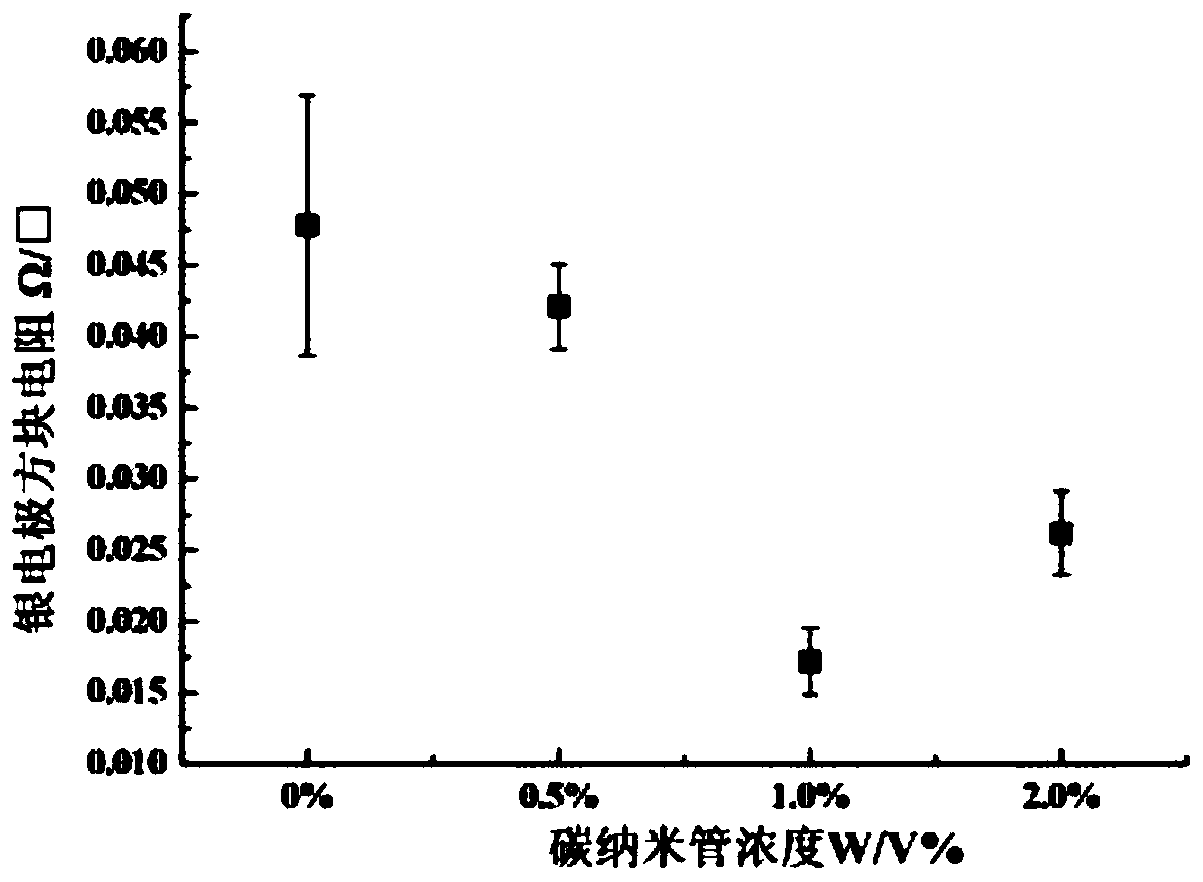

[0061] (1) Preparation of fabric substrate 1

[0062] Select cotton cloth, cut it into a size of 70 mm × 70 mm, and then dip it in carbon nanotube solution 2 with a mass volume concentration of 1% w / v, evenly dip it in a magnetic stirrer, pick it up and hang it on a stand, Standing and drying at room temperature for 1.5 hours to obtain fabric substrate 1 for use; wherein, the rotating speed of the magnetic stirrer is 1000 rpm / min, and the temperature is 50°C;

[0063] (2) Preparation of precursor solution 3

[0064] Dissolve 3 g of ascorbic acid in 10 mL of deionized water, stir evenly, and filter with filter paper to obtain precursor solution 3, which is sealed for later use;

[0065] (3) Preparation of ink 5

[0066] 5g of silver nitrate powder was dissolved in 10mL of deionized water, stirred evenly and then filtered with filter paper to obtain ink 5 with a mass volume concentration of 50% w / v for subsequent use;

[0067] (4) print

[0068] Take an appropriate amount of p...

Embodiment 3

[0072] (1) Preparation of fabric substrate 1

[0073] Select silk, cut it into a size of 70mm×70mm, and then immerse it in a carbon nanotube solution 2 with a mass volume concentration of 1.5% w / v, evenly immerse it in a magnetic stirrer, pick it up and hang it on a stand, Stand and dry at room temperature for 1.3 hours to obtain the fabric substrate 1 for use; wherein, the rotating speed of the magnetic stirrer is 900 rpm / min, and the temperature is 50°C;

[0074] (2) Preparation of precursor solution 3

[0075] Dissolve 5 g of sodium acetate in 10 mL of deionized water, stir evenly, and filter with filter paper to obtain precursor solution 3, which is sealed for later use;

[0076] (3) Preparation of ink 5

[0077] 9g of silver nitrate powder was dissolved in 10mL of deionized water, stirred evenly and then filtered with filter paper to obtain ink 5 with a mass volume concentration of 90% w / v for subsequent use;

[0078] (4) print

[0079] Take an appropriate amount of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com