Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Thick line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

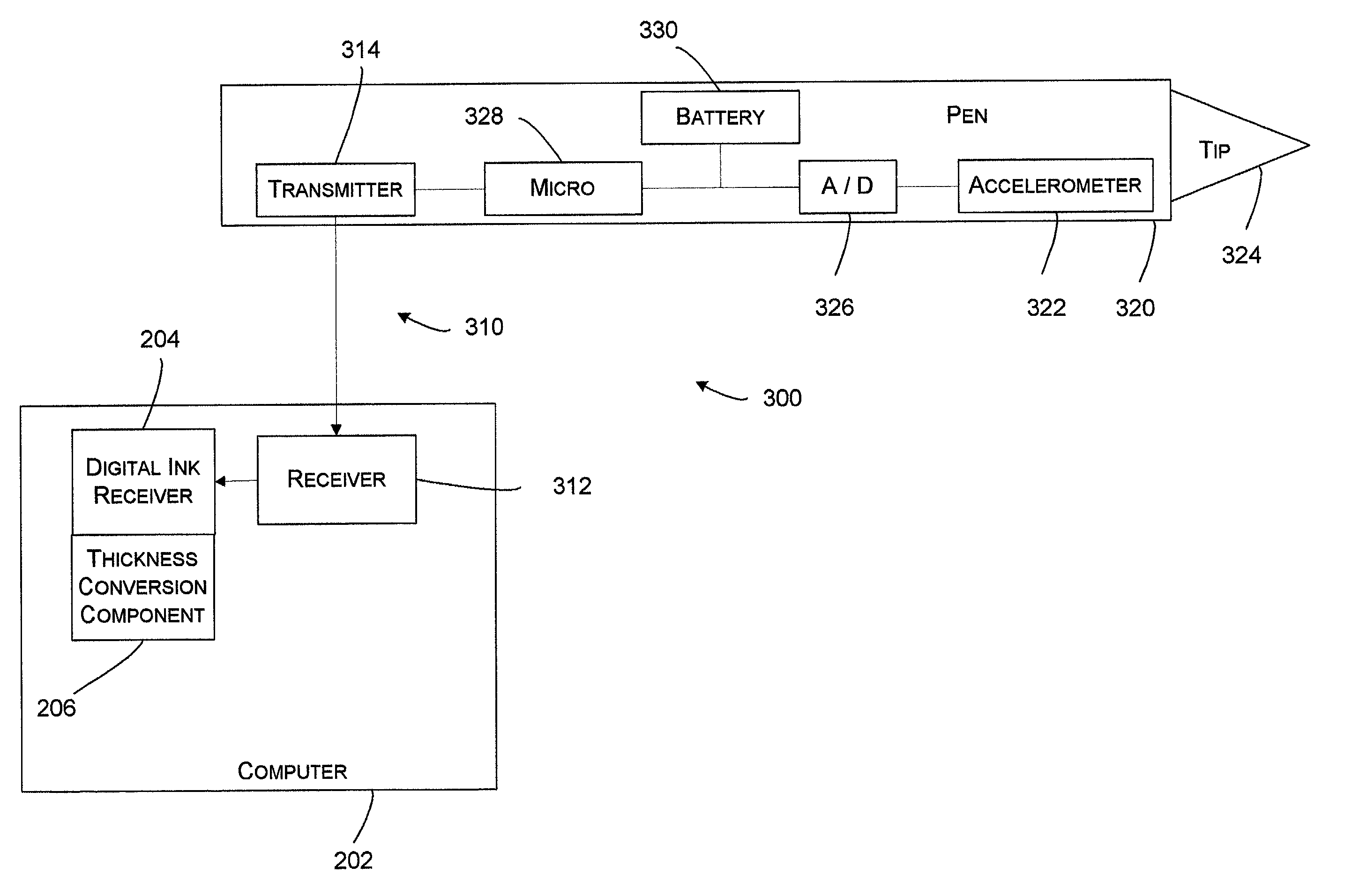

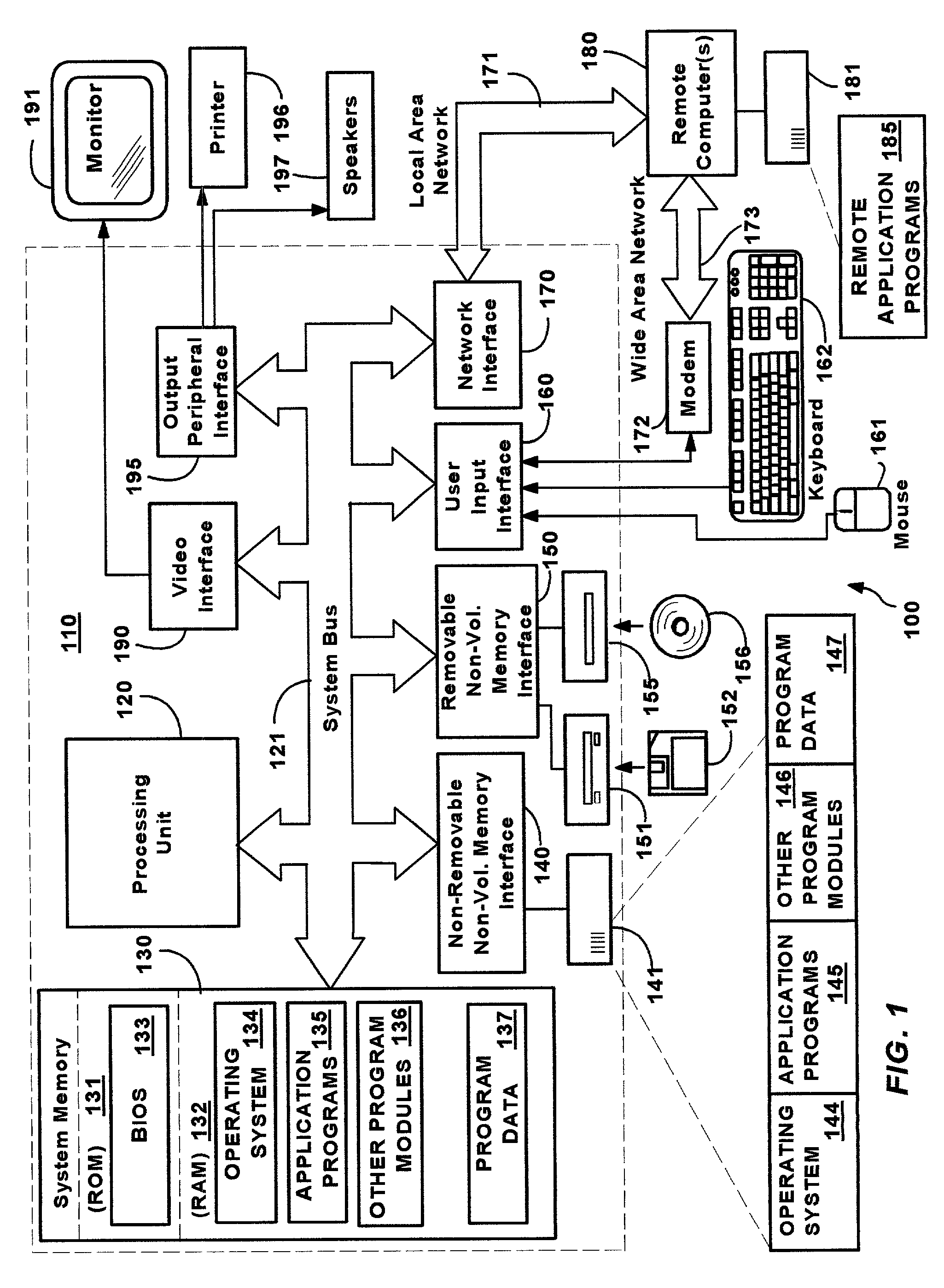

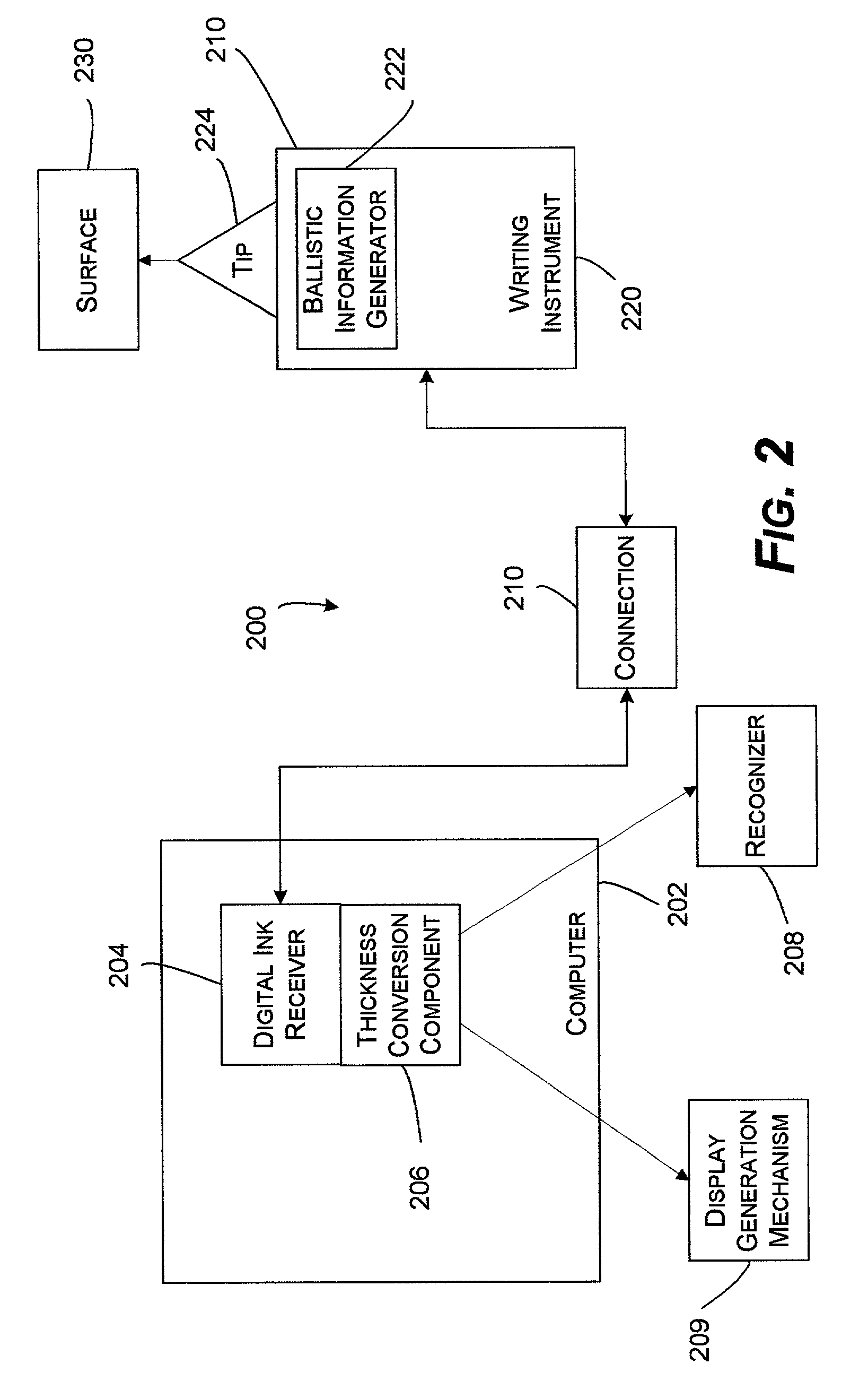

Method of generating digital ink thickness information

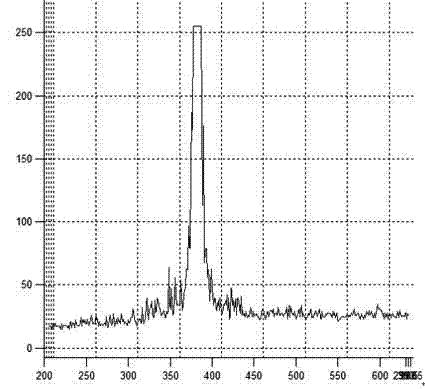

InactiveUS7176906B2Easy to displayEasy to identifyTransmission systemsCathode-ray tube indicatorsThick lineAccelerometer

A method and system that converts ballistic movement of a pen (e.g., movement of a pen point across a surface) into thickness information for digital ink data. The pen includes at least one accelerometer that is used to generate the ballistic information. A thickness conversion component may be located on a computer that is remote from the pen, and the ballistic information is transmitted to the computer via a hardwired or wireless connection. The accelerometer generates the ballistic information in the form of pulses, the width of which is directly related to the acceleration of the pen movements. The thickness conversion component converts the acceleration information, with or without additional information such as coordinate information, into thickness information for digital ink. This thickness information may be used to generate variably thick lines, which may be useful for a variety of applications, for example, better display and improved recognition.

Owner:MICROSOFT TECH LICENSING LLC

Three-dimensional information detection method based on two-line laser

InactiveCN102297658AImprove stabilityHigh precisionUsing optical meansThick lineThree dimensional measurement

The invention discloses a three-dimensional information detection method based on dual laser and belongs to the technical field of three-dimensional measurement. The method comprises the following steps of: adopting two lasers, and respectively solving laser plane equations of the first laser and the second laser; collecting an object image containing dual laser by utilizing a camera in the eventof detecting the three-dimensional information of an object, and solving a centre line of each laser thick line; and rebuilding three-dimensional data by utilizing inner parameters of the camera and the laser plane equations of both lasers. Compared with the single-laser measurement method, because of large information amount, the method disclosed by the invention specifically has higher stability, reliability and accuracy; and simultaneously, the operation requirements are simple, thus the method has the important application in detecting the surface three-dimensional information of objects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

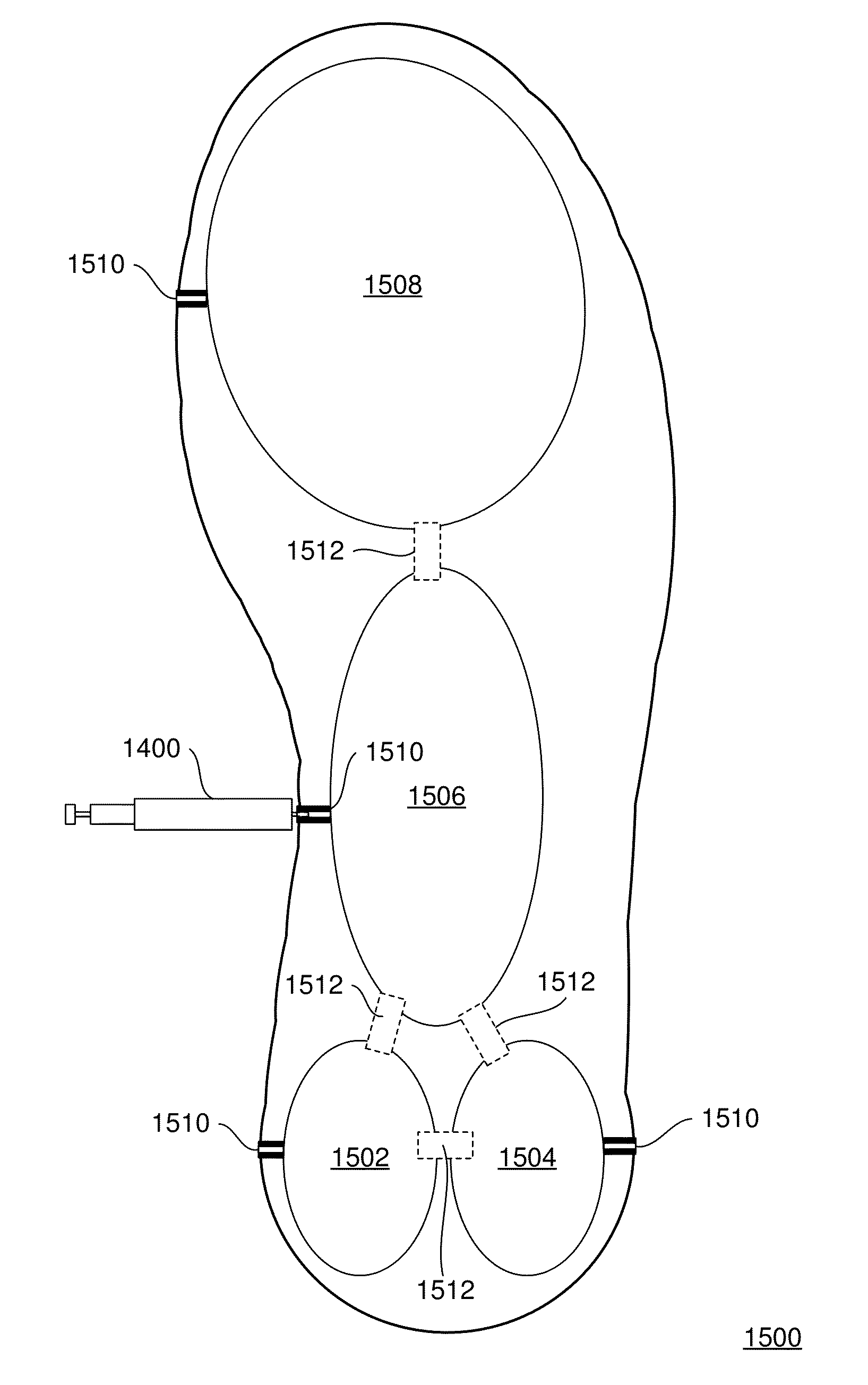

Pneumatically inflatable air bladder devices contained entirely within shoe sole or configured as shoe inserts

A pneumatically cushioned shoe or shoe insert device including a plastic layer forming air bladders; a cloth layer covering a top surface of the plastic layer; a rubber layer covering a toe portion of a bottom surface of the plastic layer; a C shaped indentation on the plastic layer forming an arch region air bladder; and circle or oval shaped indentations forming interconnected air bladder regions having respective air bladders and including an inner heel, outer heel, and metatarsal air bladder regions. The rubber layer including cutting lines for sizing for regular or wide foot sizes and a lower thicker line defining a do not cut below region. The cloth layer including cutting lines for sizing for the other of regular or wide foot sizes. The air bladders pre-filled with air during manufacturing or filled with air by a user.

Owner:DOYLE HAROLD S

Manufacturing method of polished porcelain tile imitating natural marble

ActiveCN101580374AHighlight natureStrong pattern layeringPress rollersClay processing apparatusWrinkle skinThick line

The invention relates to a manufacturing method of a polished porcelain tile imitating natural marbles, which comprises the following steps that: fine powder freely falls onto an inclined conveying belt to form an ultra-thin powder layer; the fine power freely falls onto a roller, and materials are fed according to the layer fall of the roller, proportionally fall first onto a belt below and then onto a transfer trough to form powder blocks on a conveying belt that move with the conveying belt to freely fall onto an inclined conveying belt distributed with the ultra-thin powder layer in the lower layer to form irregular blocky accumulation bodies; and a multi-speed conveying belt carries the irregular blocky accumulation bodies to form irregular flowing wrinkles and dents on the blocky accumulation bodies by rolling and to accumulate the ultra-thin powder layer on the bottom layer along the edges of the wrinkles to freely fall onto a glass plate; and the irregular powder on the glass plate is rolled with a drum. The product manufactured by the method has the advantages of patterns with thin and thick lines and strong layered effect, random, unfixed and naturally connected texture and high stone simulation.

Owner:GUANGDONG JIAJUN CERAMICS

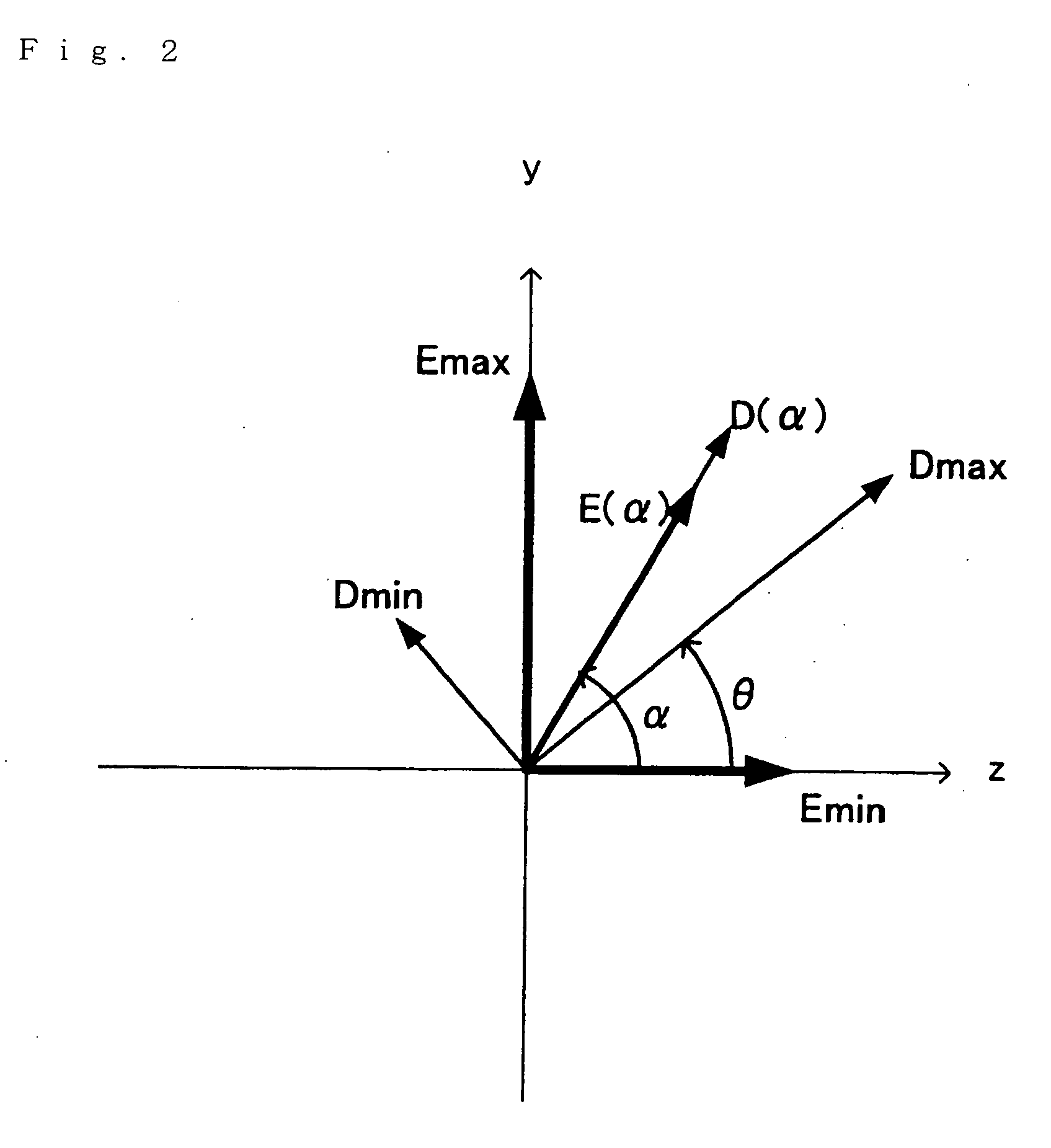

Glasses lens designing method, production method for glasses lens and computer program

InactiveUS20060055877A1Good optical performanceThe result is stableEye diagnosticsOptical partsEyeglass lensesThick line

1 indicates the rotating point of the eyeball, 2 indicates the first eye position, 3 indicates the second eye position, and 4 indicates the third eye position. The lines indicated by thick lines at the respective eye positions are the horizontal meridian and vertical meridian (principal meridian) of the cornea. As is seen from the figure, the directions of the horizontal meridian and vertical meridian of the cornea at the third eye position 4, in particular, do not coincide with the directions of the horizontal meridian and vertical meridian at the first eye position 1. In the present means, in order to perform aberration correction of the ophthalmic lens not only in the first eye position and second eye position but also in the third eye position under conditions that are suited to the prescription of the user and conditions of use, the prescription surface is made aspherical while taking into account the astigmatic axis of the eye at arbitrary eye positions in accordance with the laws of Donders-Listing. As a result, the prescription surface can be designed so that favorable optical characteristics can be obtained in the case of various specifications involving individual information such as the prescription of the ophthalmic lens user.

Owner:NIKON ESSILOR

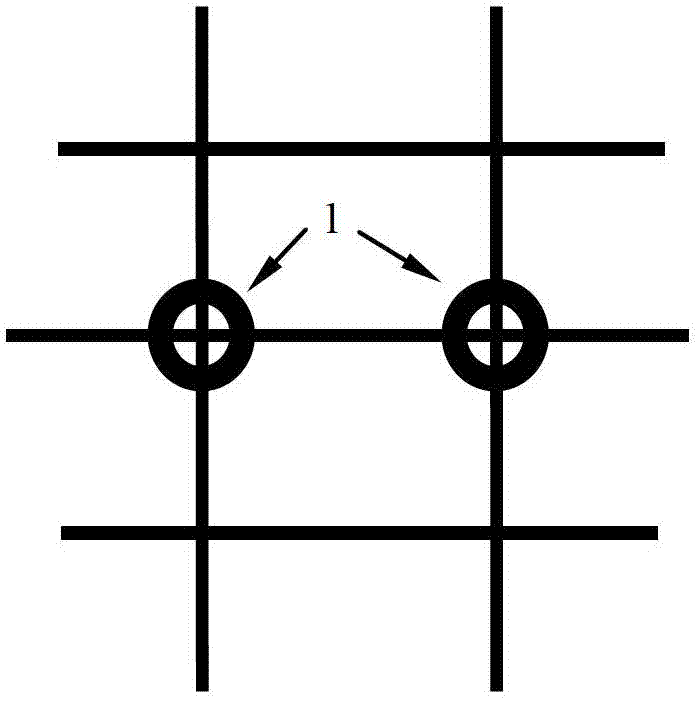

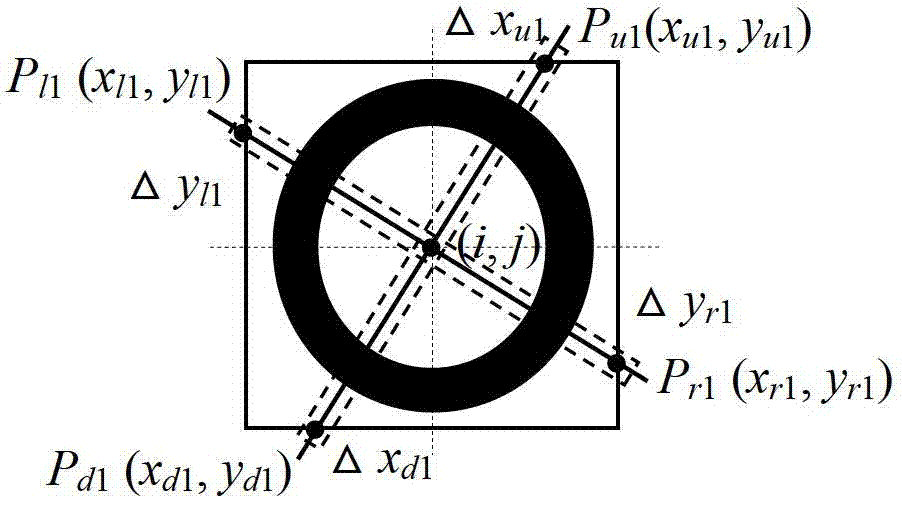

Image detection method of thick line type cross ring mark

The invention provides an image detection method of a thick line type cross ring mark. The method includes the following steps: firstly conducting single pixelate on linear lines with different thicknesses in a mark; then using a detection frame to identify central points of all the cross intersections, namely, the cross intersection central points; finally according to number ratio of black pixels and white pixels inside the detection frame, selecting a cross ring mark, and therefore deciding an accurate position of a central point of the cross ring mark. The image detection method of the thick line type cross ring mark is not influenced by variation of thicknesses of lines after imaging of the marked lines, almost not influenced by illumination variation, has certain robustness to noise, and achieves good detection effect when horizontal shift, revolving and zooming of a detected object after imaging happen.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

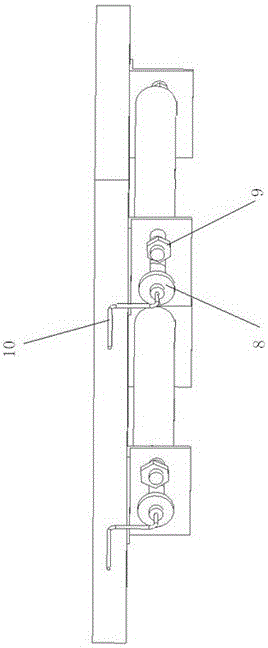

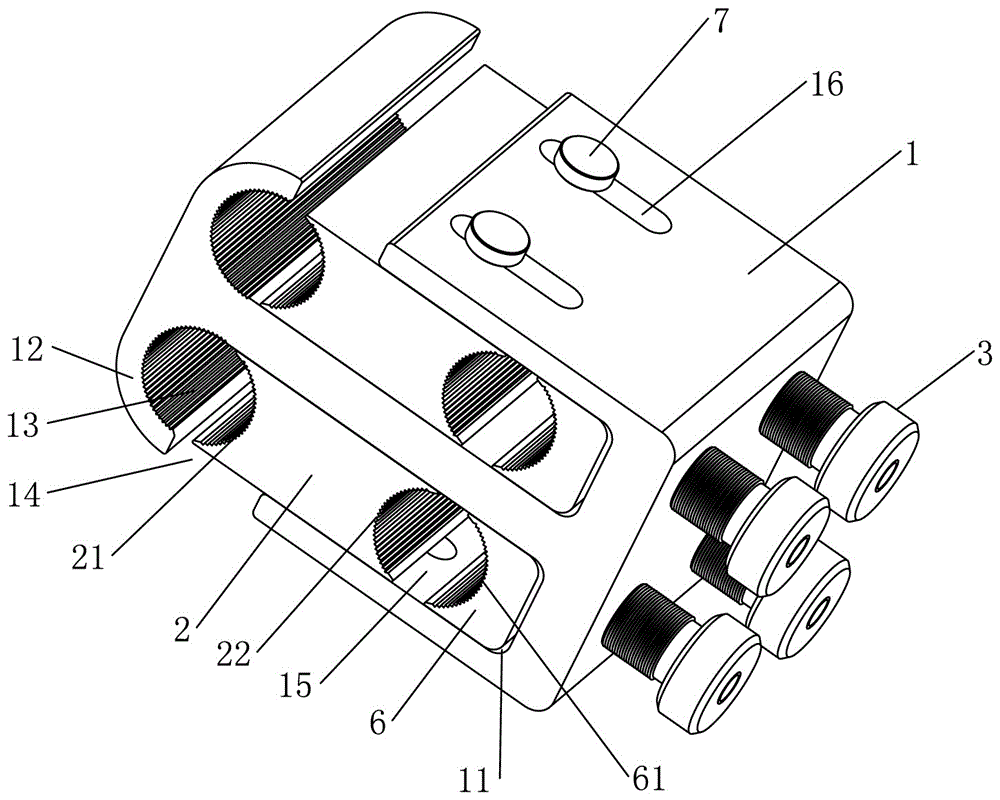

Waste cable recycling device

InactiveCN103996996ASimple structureIngenious designBasic electric elementsApparatus for removing/armouring cablesThick lineThin line

The invention discloses a waste cable recycling device comprising a frame (1). The waste cable recovery device is characterized in that a first-grade tool (2), a first supporting roller (3), a second-grade tool (4), a second supporting roller (5) and a winding mechanism (6) are sequentially arranged on the frame (1), a cable sheath recycling bin (7) is arranged in the lower part of the frame (1), a driving roller (8) and a driven roller (9) which are oppositely arranged are rotationally supported above the cable sheath recycling bin (7), and a crank (10) is arranged at the outer end of the driving roller (8). In view of the problems of the existing waste cable disposing method, a special structure capable of simultaneously disposing thick outer line sheaths and thin inner line sheaths of cables is designed. Semi-automated cable stripping can be realized, the working efficiency of cable disposing is greatly improved, and no pollution is caused to the surrounding environment. Meanwhile, stripped thick line sheaths and thin line sheaths can be collected separately for centralized disposing.

Owner:DALIAN OCEAN UNIV +1

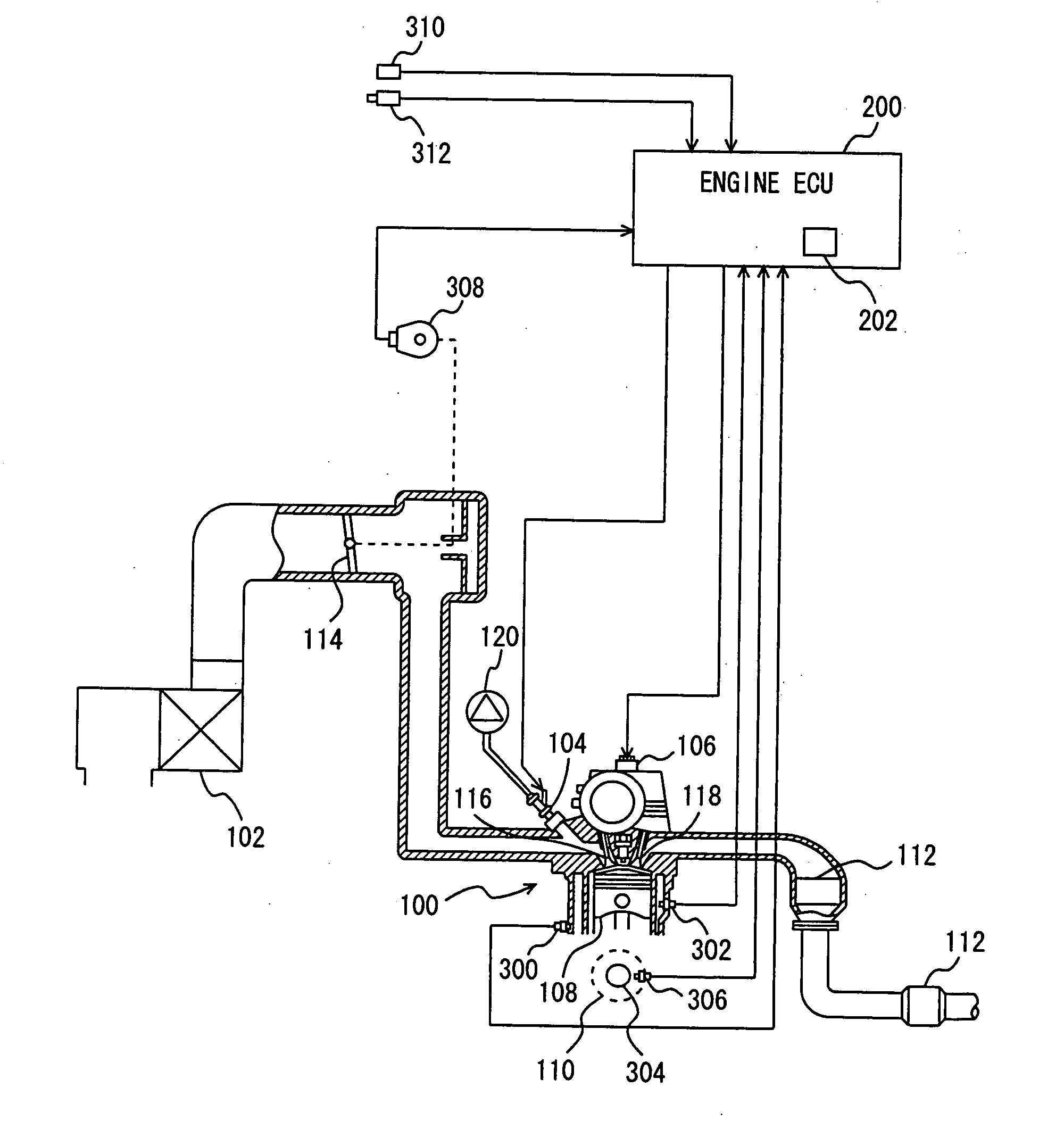

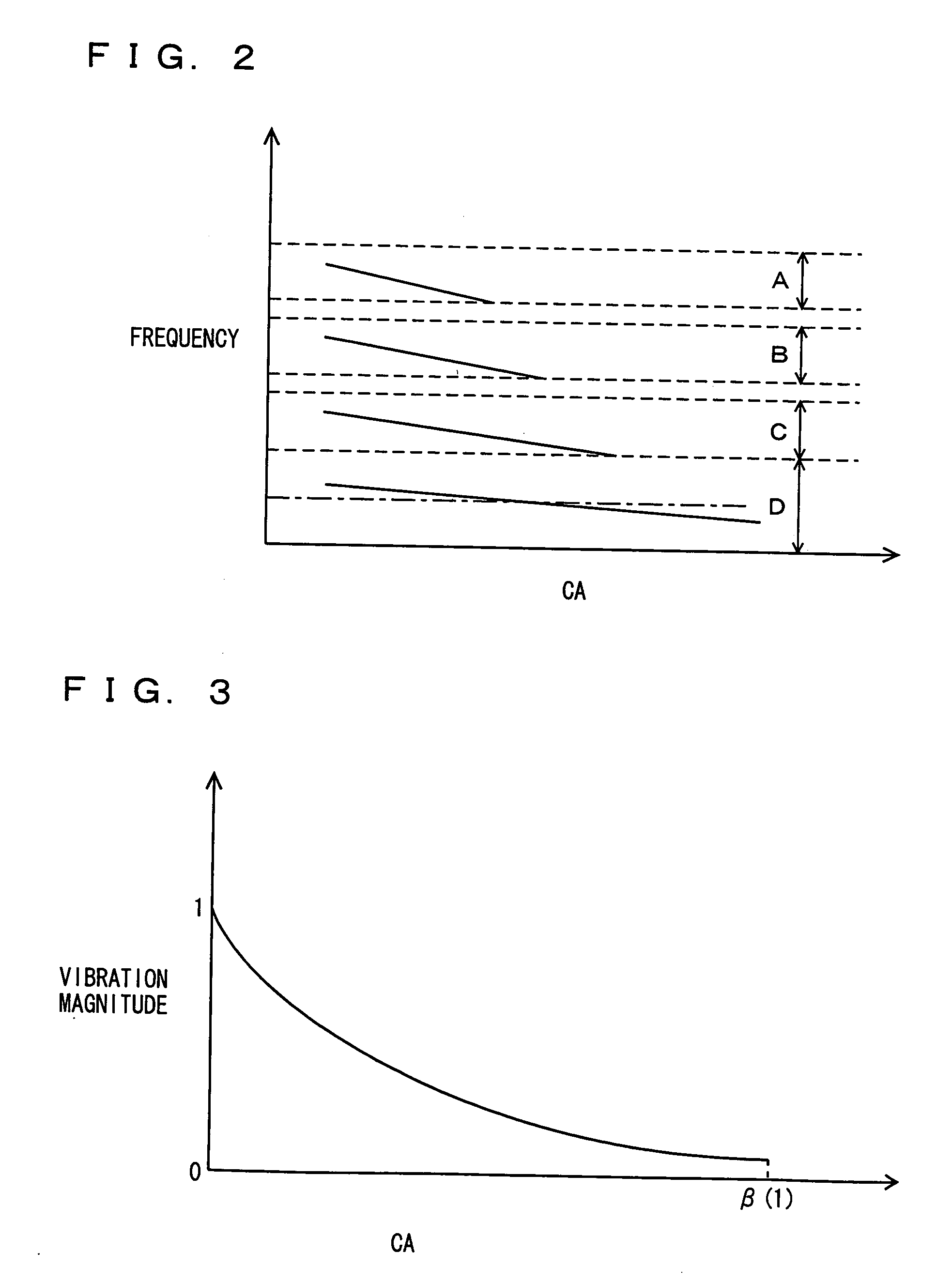

Internal combustion engine knock determination device

InactiveUS20060236753A1Improve accuracyAccurately determineAnalogue computers for vehiclesEngine testingThick lineEngineering

A knock waveform model (thick line) is prepared by correcting a line (thin line) representing an average value of a vibration waveform measured in advance to have more moderate inclination. The knocking determination device determines whether knocking occurred in an engine or not, based on a result of comparison between the knock waveform model and a waveform detected by a knock sensor.

Owner:TOYOTA JIDOSHA KK +2

Solder containing rare earth, tin and zinc, and preparation method thereof

InactiveCN1634677AOutstanding advantagesHighlight positive effectsWelding/cutting media/materialsSoldering mediaRare-earth elementThick line

This invention relates to solder with rare earth tin and zinc and its process materials in electron parts welding technique, which comprises the components as weight percentages as following: zinc for 8í½10 úÑ; mixture rare earth metal with light metal of lanthanum and cerium for 0.01í½0.12 úÑ; the rest are tin and impurity less than 0.12 %. ú¼ The process method comprises the following steps; melting tin and adding zinc ingot; then adding the zinc base middle alloy with rare earth metals after zinc is melt; keeping blending with temperature increasing and drilling into round section pressed stock; then pressing it into thick line stock and into solder with rare earth tin zinc after several drawing.

Owner:戴国水

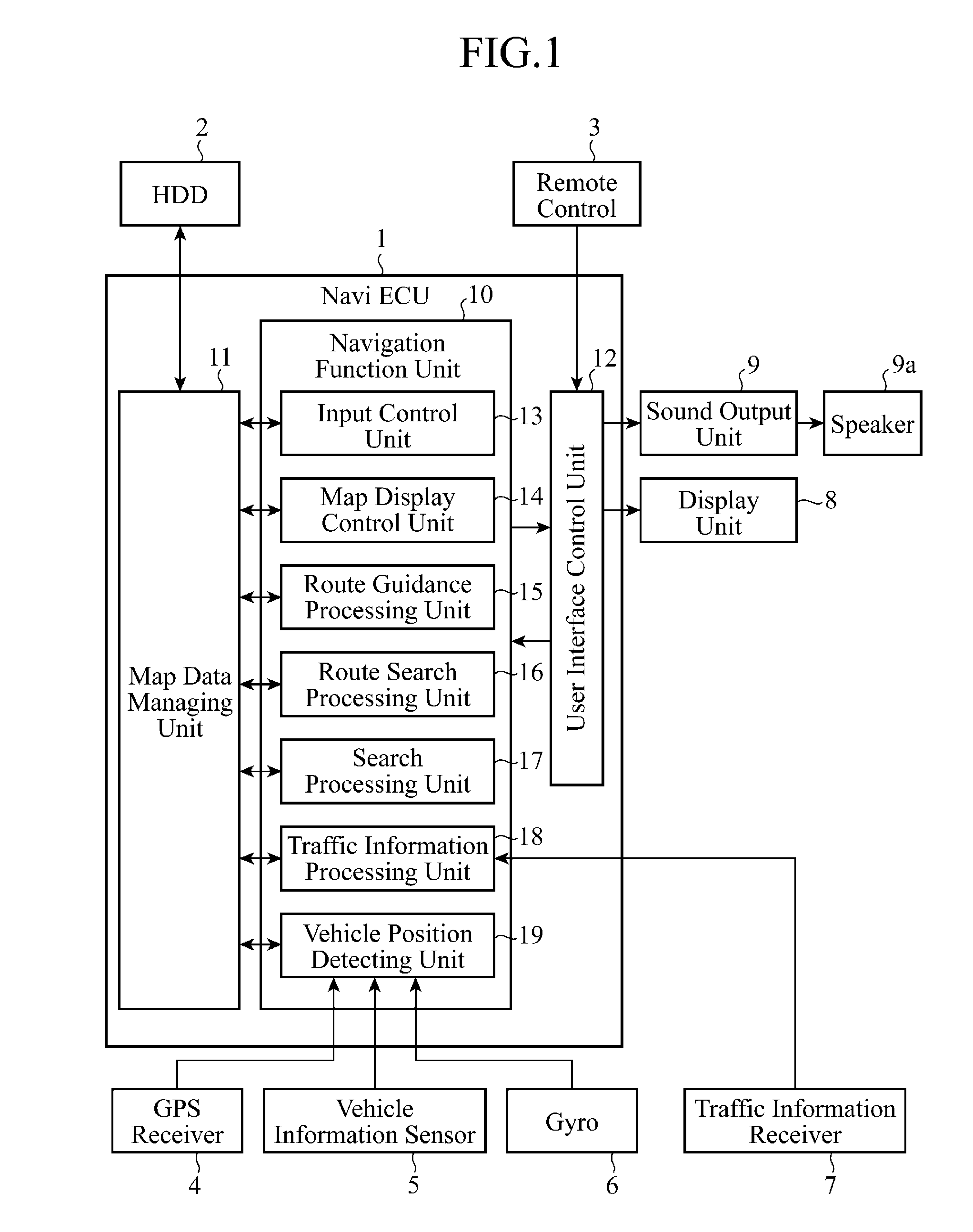

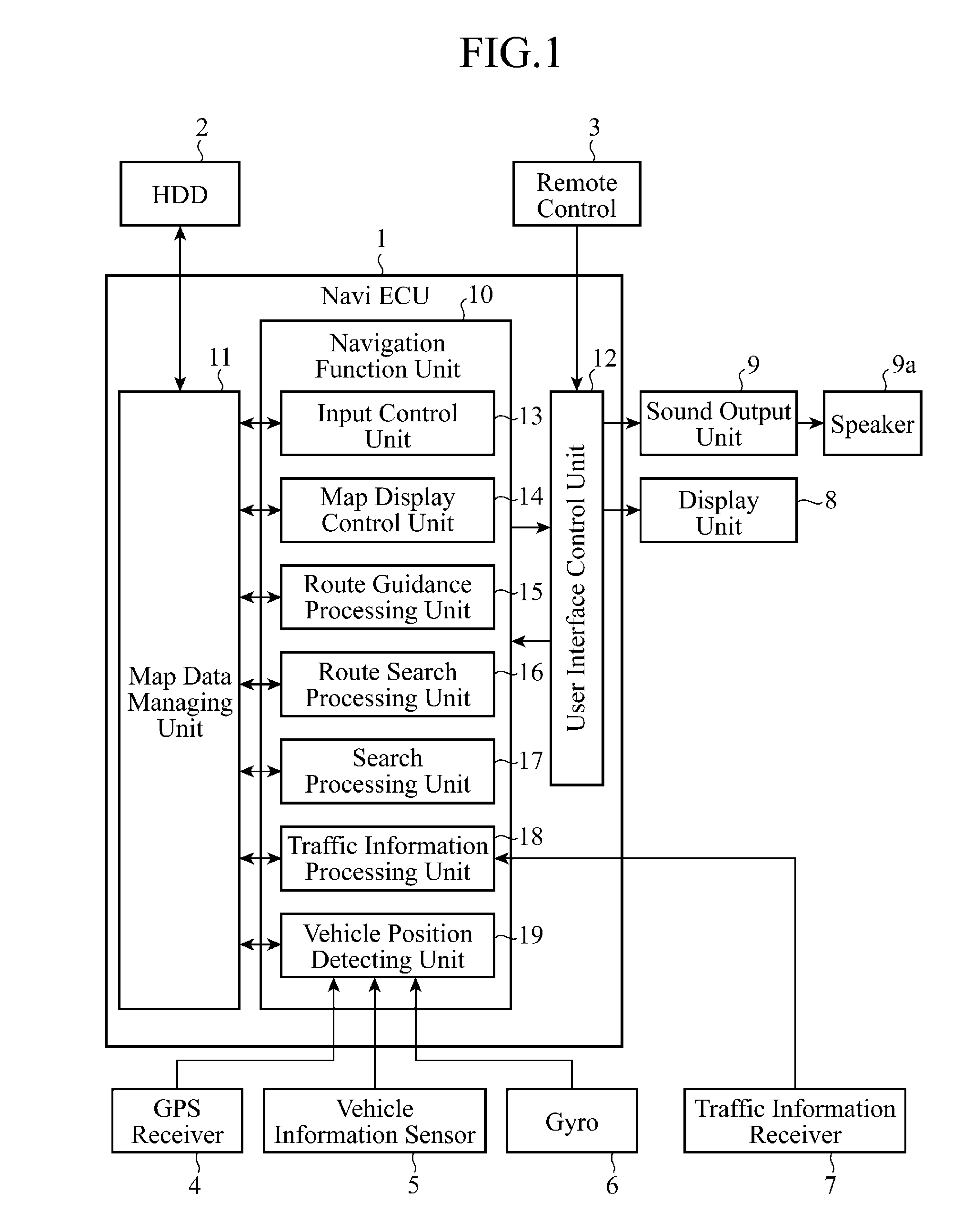

Navigation device

ActiveUS20110015857A1Improve user friendlinessInstruments for road network navigationRoad vehicles traffic controlThick lineComputer science

A navigation device includes: an along-route scroll mode determining unit 44 for determining whether or not a cursor on a screen is placed on a guidance route; a thick line highlight processing unit 45 for, when the cursor is placed on the guidance route, making a transition to an along-route scroll mode to highlight a line segment of the cursor indicating a direction of a destination and another line segment of the cursor extending in a direction opposite to that of the line segment; and a scroll processing unit 46 for, when a direction key indicating the direction of the thick-highlighted line segment indicating the direction of the destination, scrolling the map toward the direction of the destination, and for, when a direction key indicating the direction of the other line segment, scrolling the map toward the direction of a place of departure.

Owner:MITSUBISHI ELECTRIC CORP

Method for processing thick line blank of alloy wire rod made from leadless metal spraying material

The invention discloses a processing method of a coarse blank of a lead-free metal sprayed alloy wire, which belongs to the technical field of spraying metal material processing which is used for spraying end faces of a metalized film capacitor. The invention adopts a horizontal continuous casting technique, which includes the following steps: lead-free metal sprayed alloy melt of prepared portions is transferred into a continuous casting furnace, wherein, the temperature of the alloy melt in the furnace is controlled between 450 and 750 DEG C; then the alloy melt flows into a crystallizer to be cooled to form wire casting blanks with a diameter of 8 to 14 millimeters; and then the alloy melt runs out of the crystallizer with the function of a traction device to form coarse blanks, wherein, the traction speed of the traction device is 0.35 to 0.65 meter per minute, and the diameter of the pressure chuck can be over 100 millimeters. The process of the invention is designed reasonably, and is capable of eliminating the defects of bubbles, oil inclusion, core wrapping, etc, in coarse blanks. The invention provides a new way of processing lead-free metal sprayed materials and can effectively improve product quality.

Owner:戴国水

Applicator

ActiveUS20140050514A1Appropriate stiffnessSatisfiable applicationLiquid surface applicatorsDispensing apparatusThick lineEngineering

An applicator includes a squeezer for pushing out a content liquid to an applicator part, and the shape of a content liquid delivering port of the applicator part is formed to be oval or rectangular while the minor axis and major axis on the delivery port side are specified to be 0.5 to 2 mm and 2 to 8 mm, respectively. In this applicator, large-sized particles can be delivered by enlargement of the bore inside the applicator part. Further, formation of an oval delivering port allows for drawing fine lines in the minor axis direction and thick lines in the major axis direction. Moreover, provision of small-diametric projections at the front end of applicator, enables drawing of long lines and retaining of the liquid cosmetic stored between projections.

Owner:MITSUBISHI PENCIL CO LTD

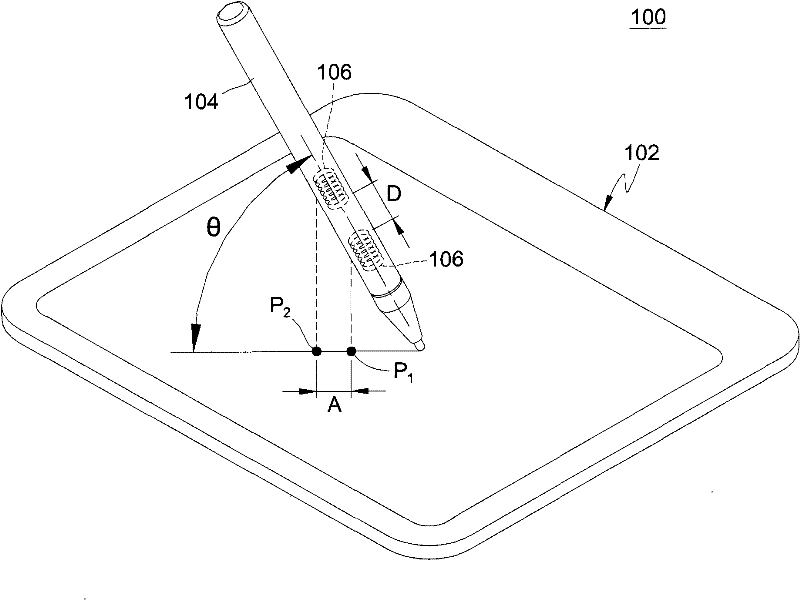

Device, system and method for cursor control

InactiveCN102446000ASolve the displacementSolve wear and tearInput/output processes for data processingUser needsThick line

The invention discloses a device, a system and a method for cursor control. The system for cursor control comprises the cursor control device and a cursor sensing device, wherein the cursor control device comprises two coils. The two coils transmit respectively a first signal and a second signal to the cursor sensing device so that the cursor sensing device can sense a first coordinate and a second coordinate and outputs corresponding control signals according to the distance between the first coordinate and the second coordinate. Therefore, the cursor control system can control operation mode of a cursor by using the size of the included angle formed by the cursor control device and the cursor sensing device. By means of the device, the system and the method for cursor control, the problems that a user needs to draw hard and a digital board and a digital pen are apt to be abraded when the user uses the known cursor control system to draw thick lines can be solved, and the problems that the known cursor control system only changes the included angle formed by the digital pen and the digital board and the cursor generates displacement can be solved.

Owner:KYE SYST CORP

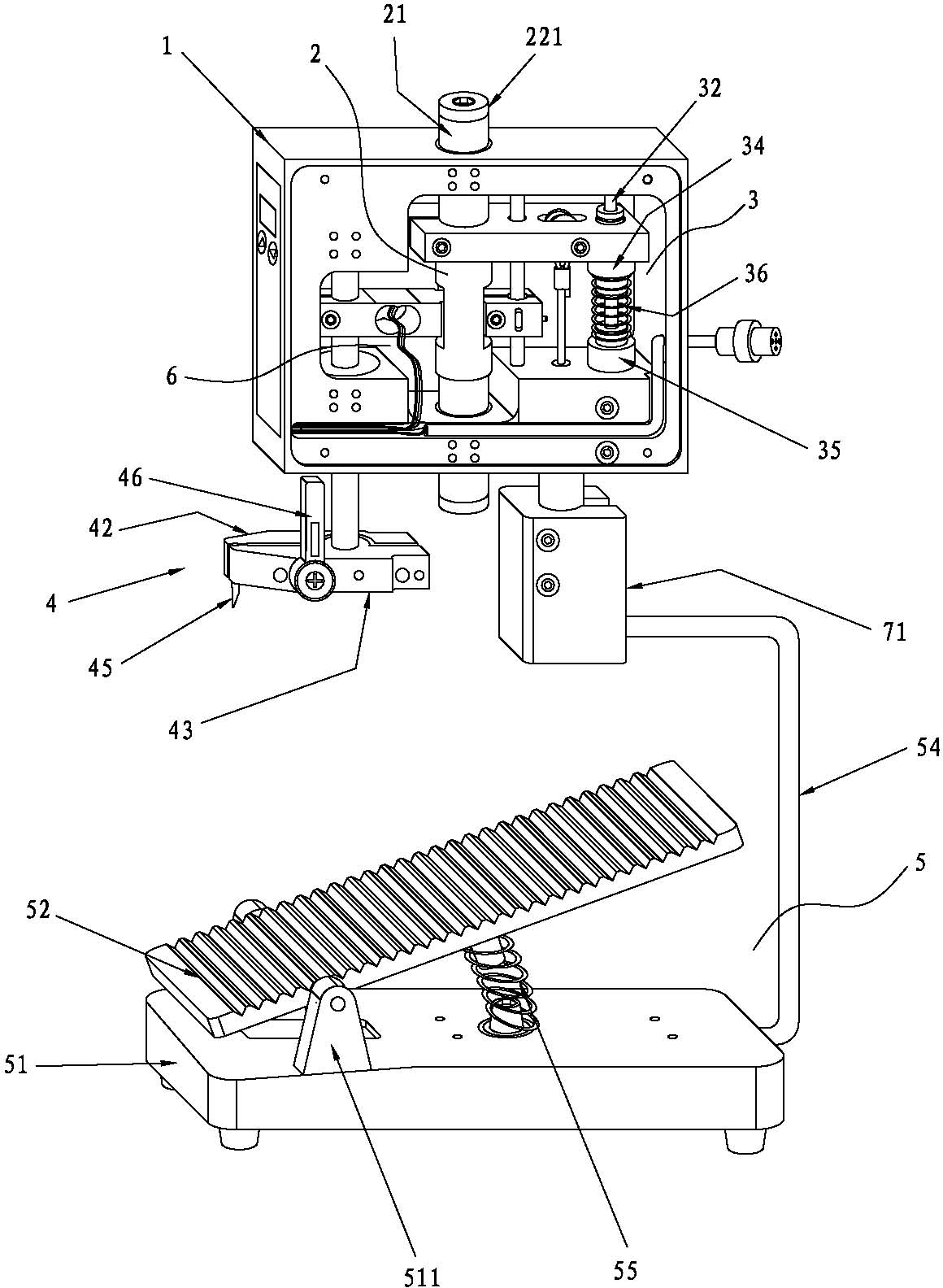

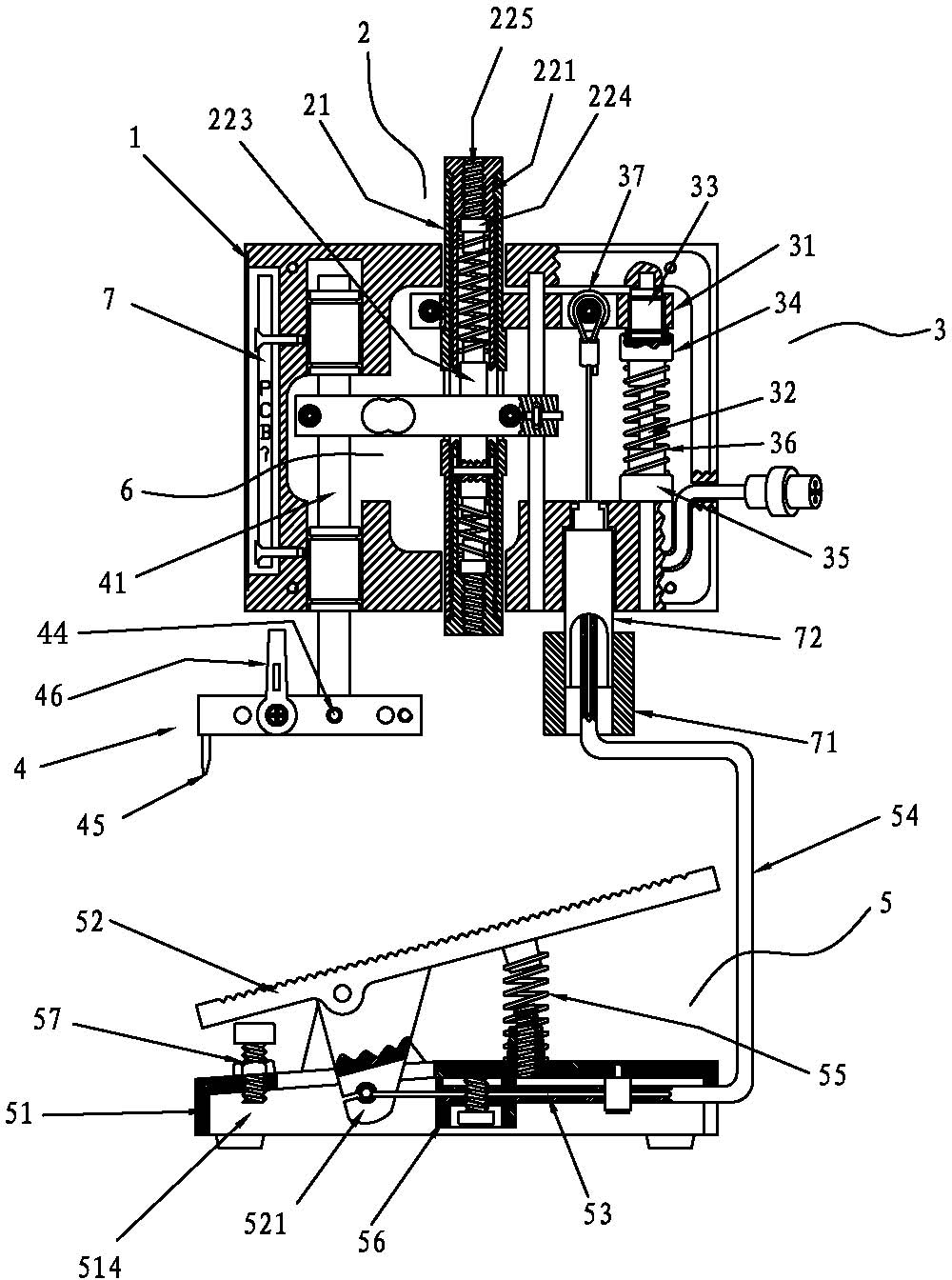

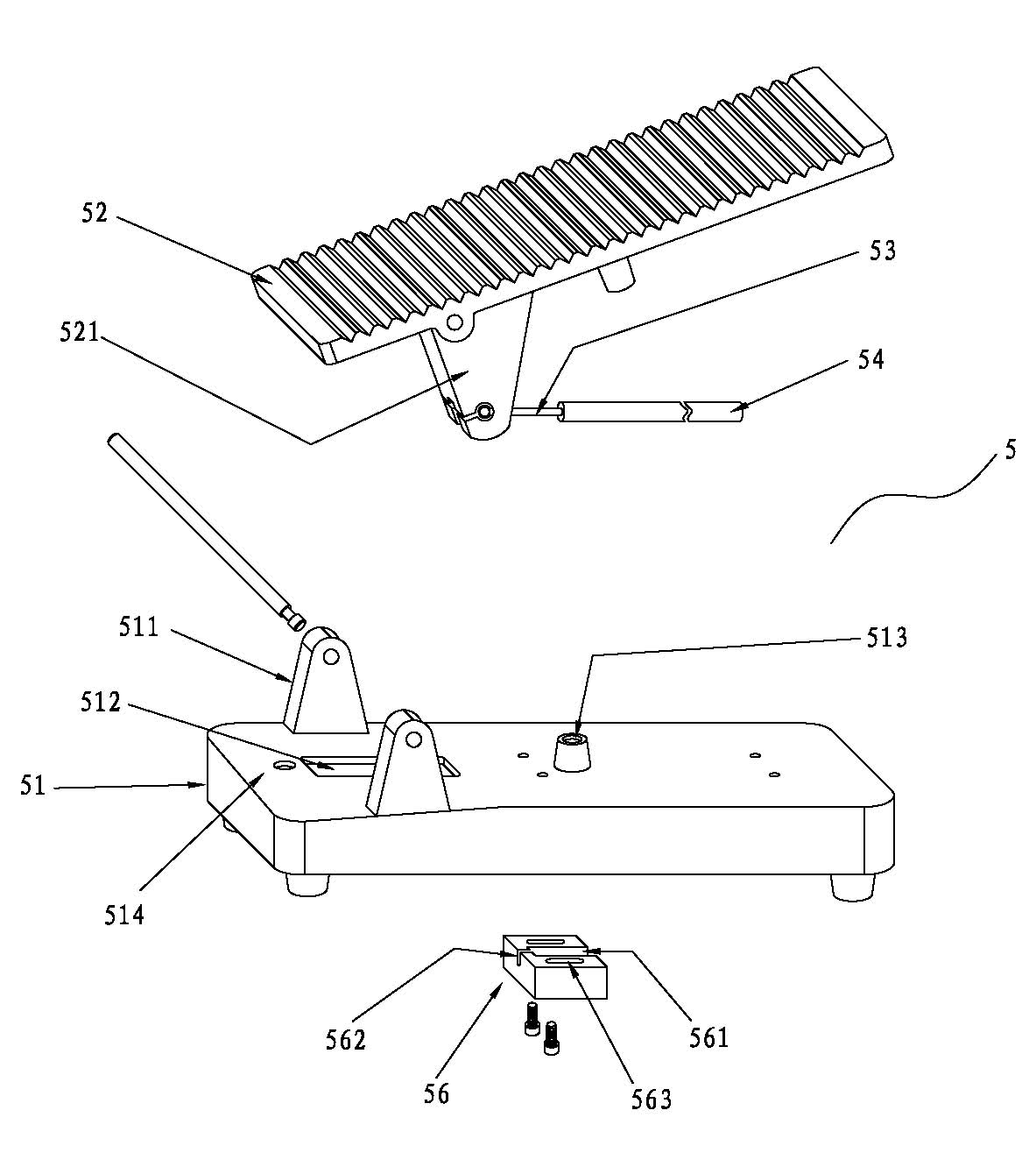

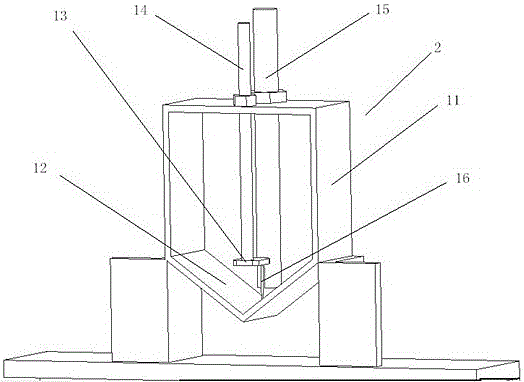

Pedal buffered type electronic spot welding device

ActiveCN102632332AImprove reliabilityAdjust the height at willResistance electrode holdersFine lineThick line

The invention relates to a pedal buffered type electronic spot welding device, in particular to an electronic spot welding machine head and a pedal device. The pedal buffered type electronic spot welding device comprises a machine head, a buffer device, a pressure transmission device, a pressure control device, a welding head clip, a machine head lifting device and the pedal device. The welding pressure can be automatically adjusted by the buffer device according to the size of a welded workpiece, a fine line can be welded perfectly, a thick line can also realize good welding effect, the lines can not be welded to be broken, false weld does not exist, and the welding quality is improved. According to the pedal device, a steel wire rope does non-contact movement in a steel wire slot so that the steel wire rope is durable and the reliability of the pedal device is strengthened. A localizator is installed in the pedal device so that the height of the welding head clip can be adjusted and the diastema of the machine head also can be adjusted.

Owner:ZHONGSHAN VIHAN ELECTRONICS EQUIP

Crystalline silicon solar battery

InactiveCN102157572AImprove conversion efficiencyIncrease the open circuit voltageSemiconductor devicesThick lineOptoelectronics

The invention discloses a crystalline silicon solar battery. The crystalline silicon solar battery comprises an Al electrode, a back ZnO-based thin film layer, a p-type Si substrate layer, an n-type Si diffusion layer, a front ZnO-based thin film layer and an Ag main electrode thick line in turn. The crystalline silicon solar battery has the advantages of high photoelectric conversion efficiency, high stability, simple process, and low production cost, and can improve the performance and prolong the service life of the crystalline silicon solar battery.

Owner:ZHEJIANG UNIV

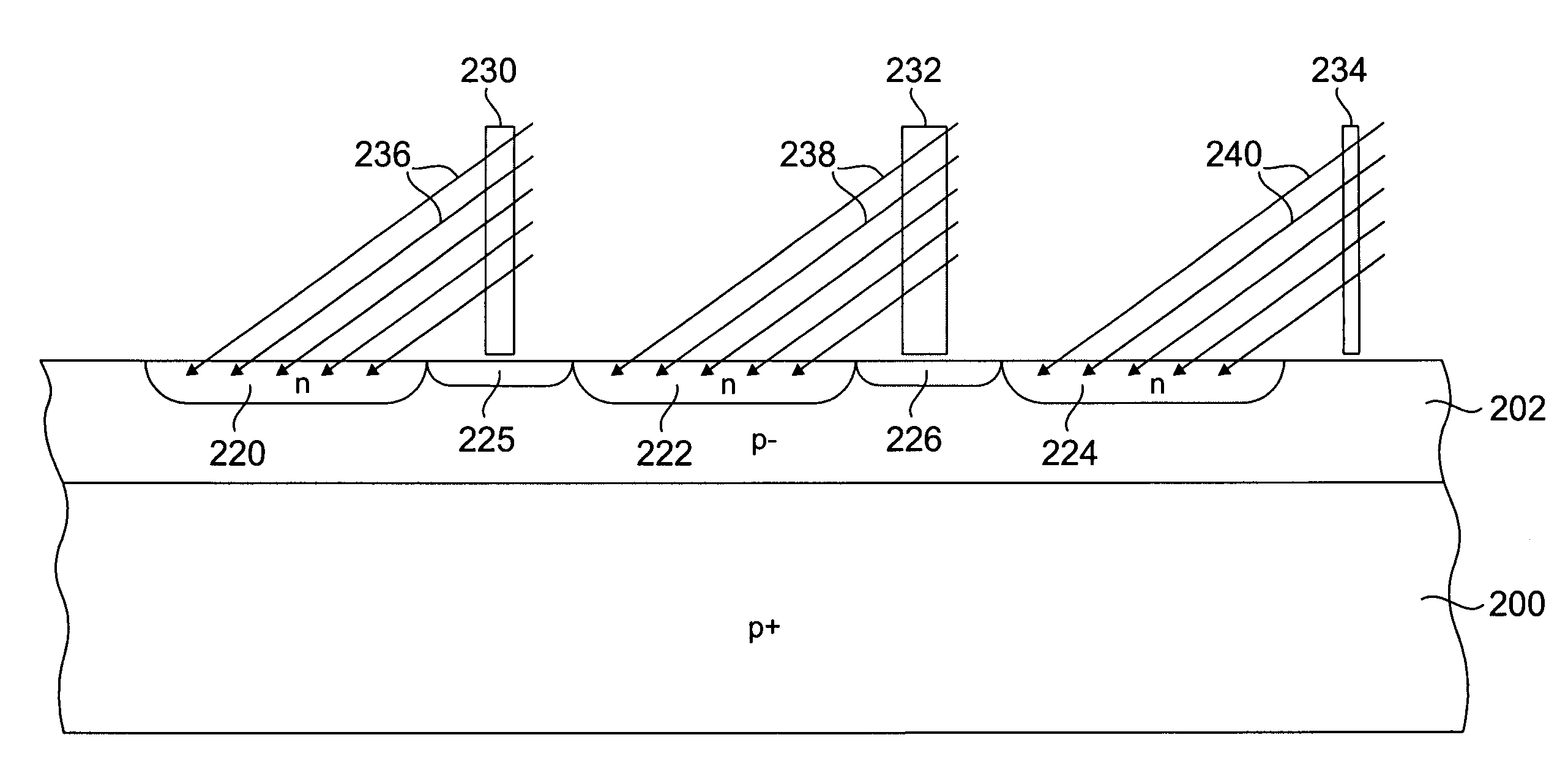

Method of ion implantation for achieving desired dopant concentration

InactiveUS7049199B2Reduces cost and complexityTransistorSemiconductor/solid-state device manufacturingMOSFETThick line

A method for forming a plurality of MOSFETs wherein each one of the MOSFET has a unique predetermined threshold voltage. A doped well or tub is formed for each MOSFET. A patterned mask is then used to form a material line proximate each semiconductor well, wherein the width of the line is dependent upon the desired threshold voltage for the MOSFET. A tilted ion implantation is performed at an acute angle with respect to the substrate surface such that the ion beam passes through the material line. Thicker lines have a lower transmission coefficient for the ion beam and thus the intensity of the ion beam reaching the adjacent semiconductor well is reduced. By appropriate selection of the line width the dopant density in the well, and thus the final MOSFET threshold voltage, is controllable.

Owner:BELL SEMICON LLC

Embroidering method of ribbon embroidery

InactiveCN102758315ALow costImprove labor productivityEmbroidering machines apparatusHand embroideringThick lineEngineering

Owner:JINAN TENGDA TEXTILE PROD

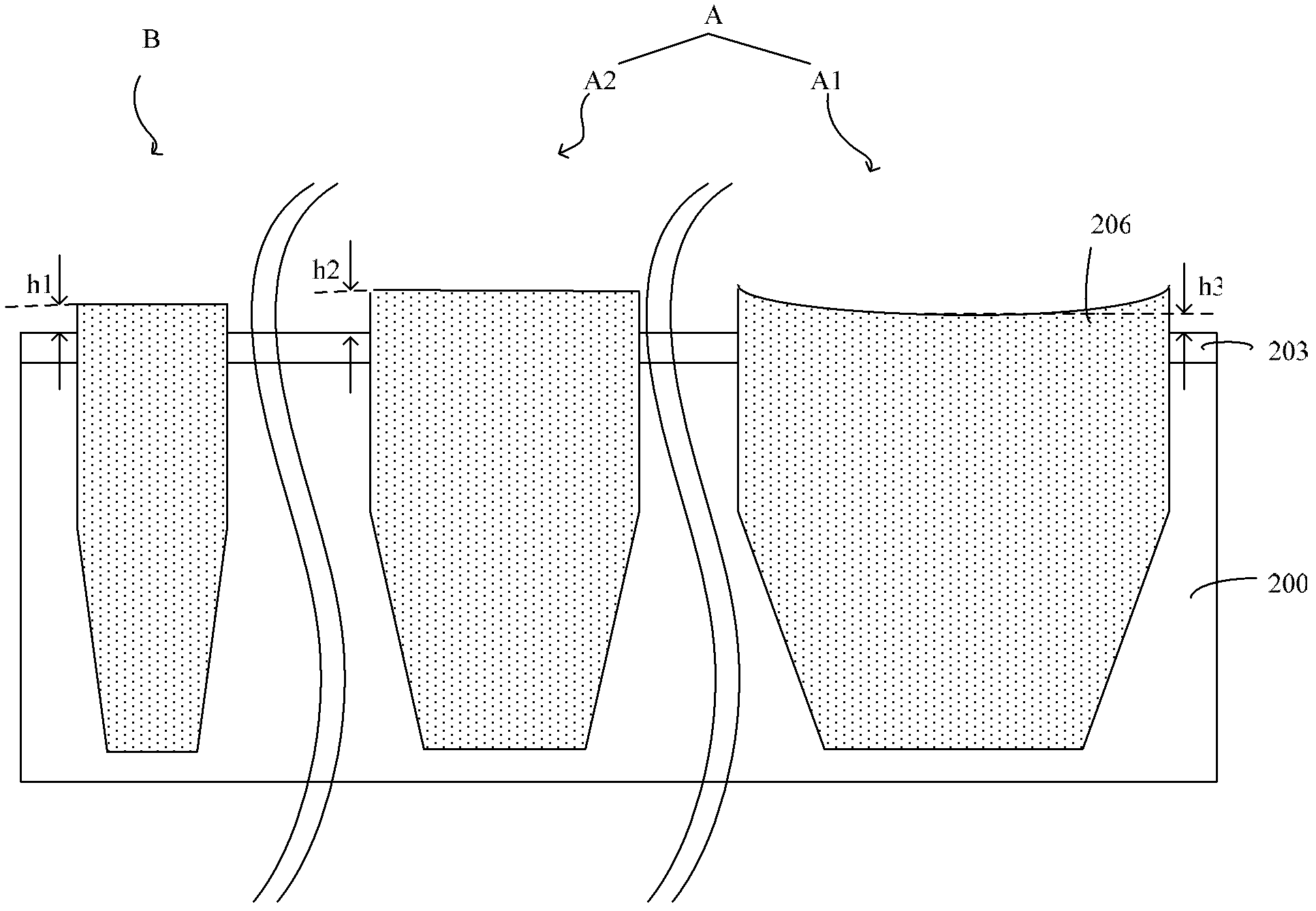

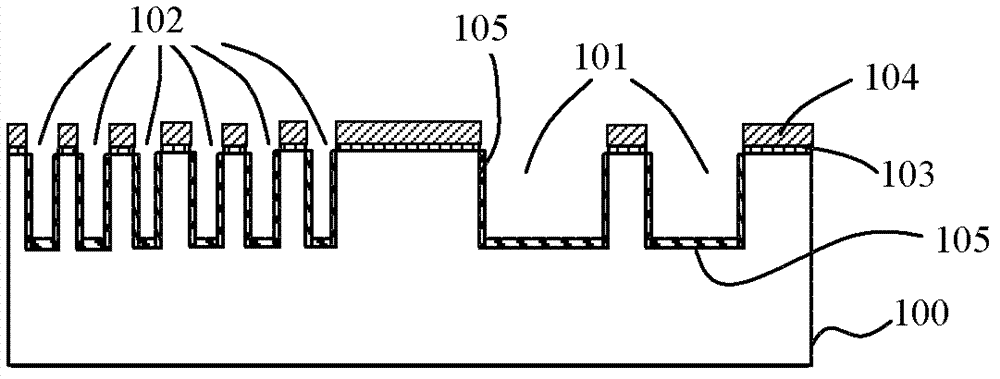

Method for forming shallow groove isolation area

InactiveCN103187353AReduce the depth of the depressionHeight adjustableSemiconductor/solid-state device manufacturingThick lineEngineering

A method for forming a shallow groove isolation area comprises the steps of providing a semiconductor substrate comprising a wide line area and a thick line area; sequentially forming a pad oxide layer, a first grinding stopping layer, an etching stopping layer and a second grinding stopping layer on the semiconductor substrate; etching the pad oxide layer, the first grinding stopping layer, the etching stopping layer, the second grinding stopping layer and the semiconductor substrate to form grooves; forming an insulation oxide layer which at least enables the groove to be fully filled; conducting first grinding on the insulation oxide layer until the second grinding stopping layer exposes; removing the second grinding stopping layer; conducting second grinding on the insulation oxide layer until the first grinding stopping layer exposes; removing the first grinding stopping layer; and removing the pad oxide layer. The method can be used for well controlling the height of an isolation structure of a shallow groove and enables the heights of all isolation structures of the shallow grooves to be same.

Owner:SEMICON MFG INT (SHANGHAI) CORP

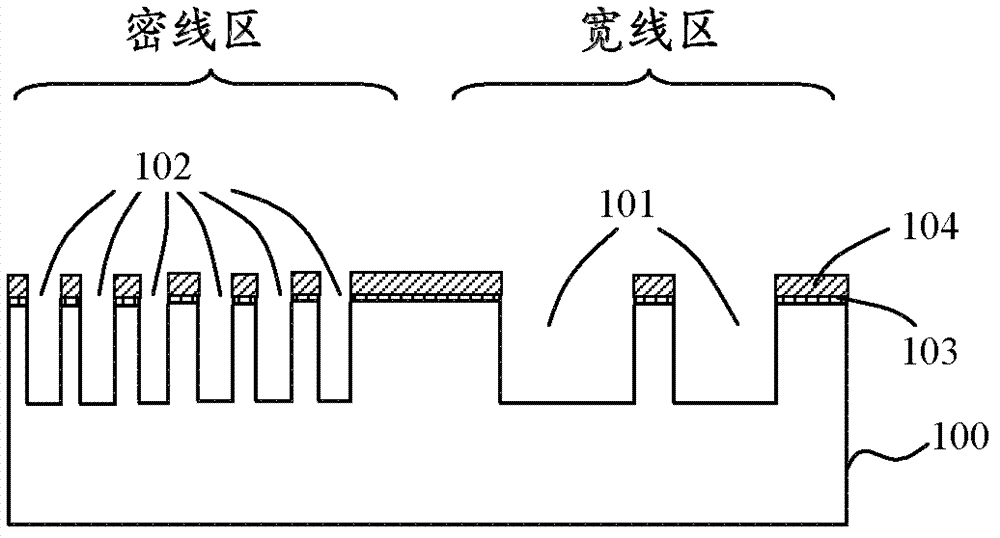

Semiconductor device and manufacturing method thereof

ActiveCN102956535AIncrease deposition rateReduce the differenceSemiconductor/solid-state device manufacturingSemiconductor devicesThick lineInsulation layer

An embodiment of the invention discloses a semiconductor device and a manufacturing method thereof. The manufacturing method includes forming a nitride layer, trenches of a thin line region and trenches of a thick line region are formed on a substrate; forming a first insulation layer on the bottoms and side walls of the formed trenches of the thin line region and the trenches of the thick line region; removing part of or total of the first insulation layer on the trenches of the thin line region only; depositing a second insulating layer to fill the trenches of the thin line region and the trenches of the thick line region; according to chemical mechanical planarization technology, planarizing the second insulation layer outside trenches of the thin line region and the trenches of the thick line region by utilizing the nitride layer as a barrier layer. Since the part of or the total of the first insulation layer at the bottom of the thin trench region is removed in the manufacturing method, deposition rate of the second insulation layer in the thin trench region is increased, difference of the second insulation layer deposited in the thin line region and the thick line region is reduced, and dishing defect caused in the chemical mechanical planarization process is relived or eliminated.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Navigation device for carrying out an along-route scrolling

ActiveUS8234060B2Improve user friendlinessInstruments for road network navigationRoad vehicles traffic controlThick lineScrolling

A navigation device includes: an along-route scroll mode determining unit 44 for determining whether or not a cursor on a screen is placed on a guidance route; a thick line highlight processing unit 45 for, when the cursor is placed on the guidance route, making a transition to an along-route scroll mode to highlight a line segment of the cursor indicating a direction of a destination and another line segment of the cursor extending in a direction opposite to that of the line segment; and a scroll processing unit 46 for, when a direction key indicating the direction of the thick-highlighted line segment indicating the direction of the destination, scrolling the map toward the direction of the destination, and for, when a direction key indicating the direction of the other line segment, scrolling the map toward the direction of a place of departure.

Owner:MITSUBISHI ELECTRIC CORP

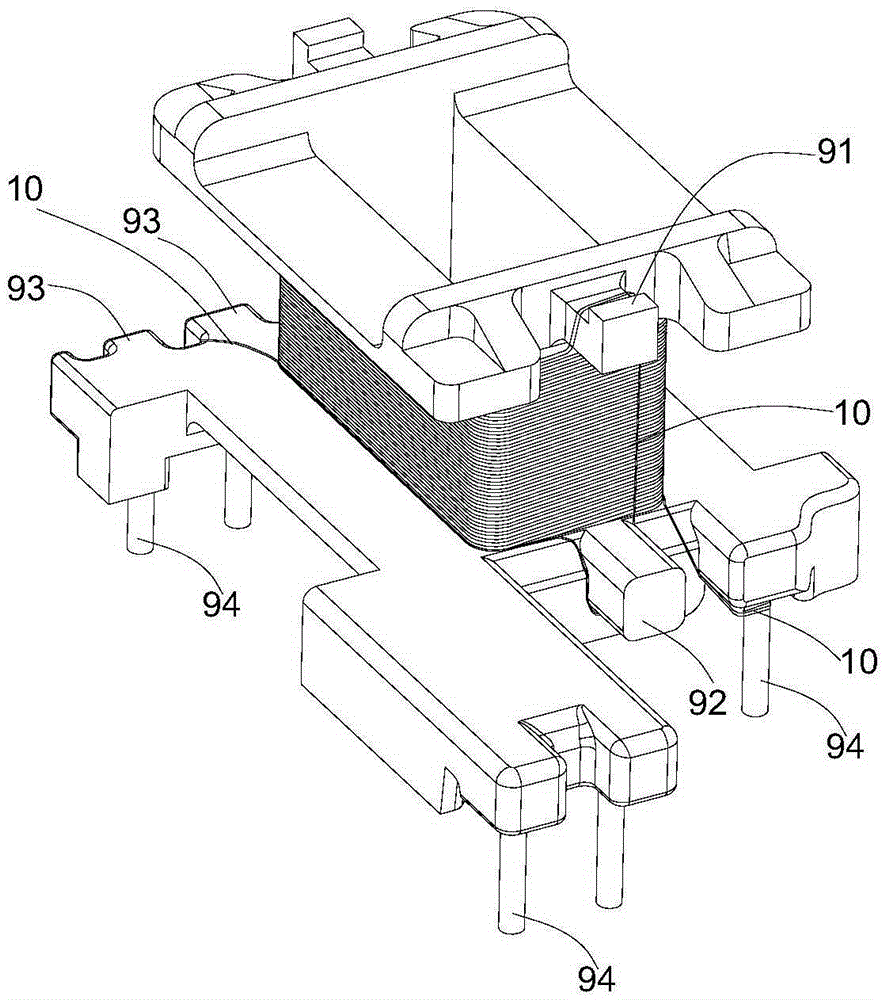

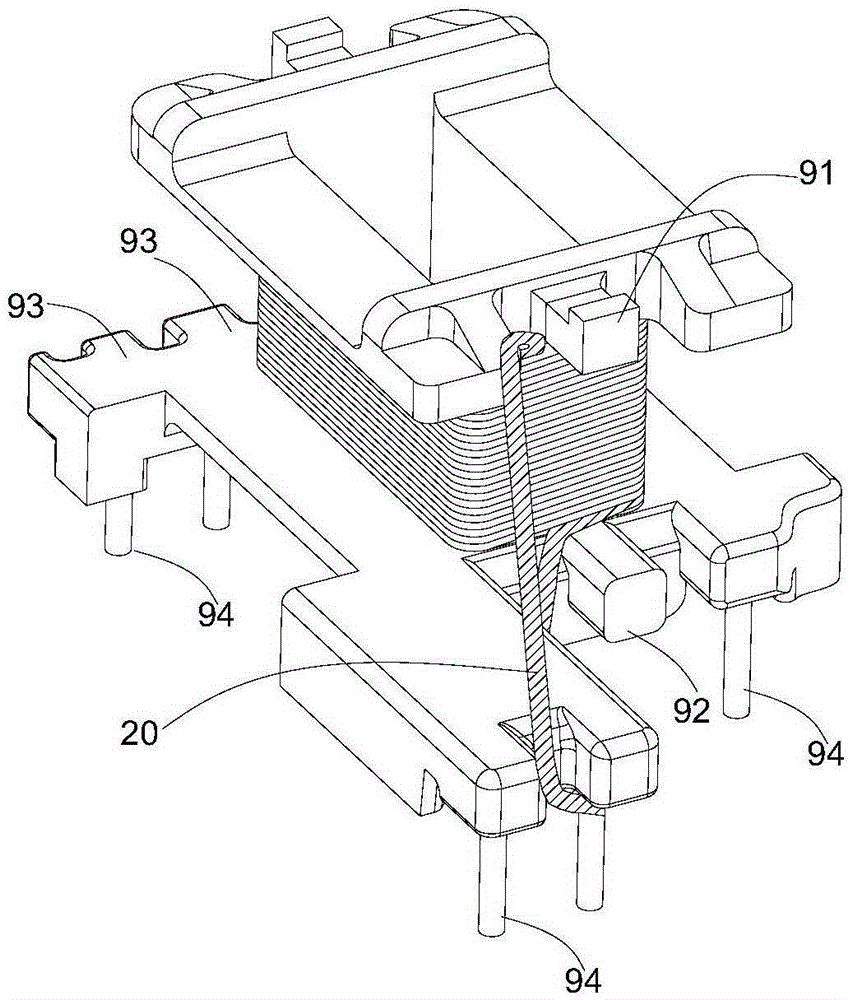

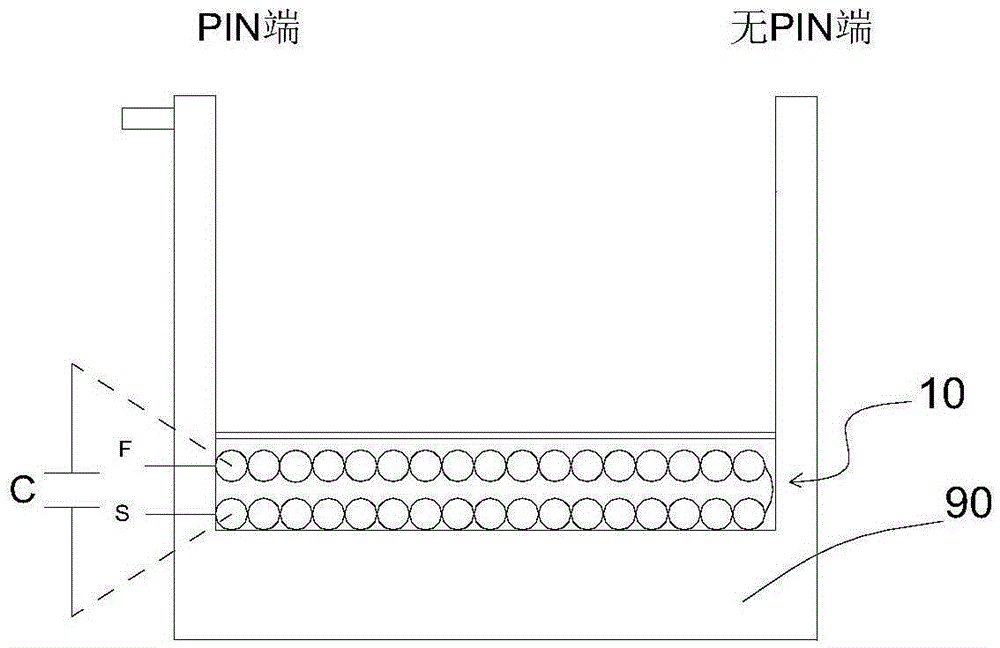

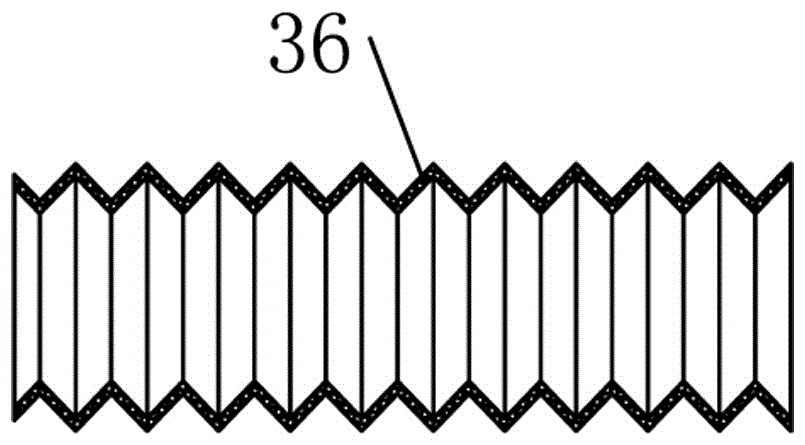

Type-C portable charger capable of reducing common-mode interference and transformer of Type-C portable charger

ActiveCN105405602AMiniaturizationAchieve high efficiencyTransformersTransformers/inductances coils/windings/connectionsWinding machineFine line

The invention discloses a Type-C portable charger capable of being automatically produced and reducing common-mode interference, a transformer and a winding method of the Type-C portable charger. The charger comprises the transformer and a winding structure of the transformer, wherein the transformer is in an EE-type structure, of which the effective sectional area of a magnetic core is greater than or equal to 40 square millimeters and which is small in size and low in cost; the winding structure of the transformer comprises a main winding, an auxiliary wining, a shielding winding and a secondary winding; the main winding is divided into a plurality of sub-windings which are connected in parallel and reduce the common-mode interference by reducing a voltage difference between an initial line and a tail line of the main winding; the sub-windings are in a structure that the sub-windings are individually and tightly wound for one layer; two fine lines, of which the sum of the sectional area is equal to the sectional area of a required single thick line and which can be automatically wound by a winding machine, are adopted by the secondary winding for winding; and outgoing lines of the secondary winding are suspended on PINs of a transformer skeleton, and are distributed at the top part and the bottom part of the transformer skeleton respectively, so as to meet the safe specified distance. Procedures and participants are reduced; the time is saved; winding packets are reduced; and the automatic degree is improved.

Owner:江西吉安奥海科技有限公司

Full-automatic double-head 2.5 flat knitting machine

ActiveCN103132221AReasonable structural designCoordinate closely and orderlyFlat-bed knitting machinesThick lineEngineering

The invention relates to a full--automatic double-head 2.5 flat knitting machine. The full-automatic double-head 2.5 flat knitting machine comprises a rack, machine heads, a machine bridge, a coil holder, a power device, a needle bed machine base, a sensor and a duplex table device. The coil holder, the duplex table device, the machine bridge and the power device are fixedly arranged in the rack. The number of the machine heads is two and the machine heads are installed on the machine bridge. The sensor is installed on the machine heads. The full-automatic double-head 2.5 flat knitting machine is characterized by further comprising pin-arranging board devices, a main roller device, an auxiliary roller device, a sinker device and a triangle device. The number of the pin-arranging board devices is two and the two pin-arranging board devices are mutually installed on the needle bed machine base in a symmetrical mode. The two machine heads are respectively connected with the two pin-arranging board devices. The sinker device and the triangle device are installed in the machine heads. The main roller device is fixed in the needle bed machine base and the auxiliary roller device is installed at the lower end of the rack. The full--automatic double-head 2.5 flat knitting machine is reasonable in structure and each large device is tightly matched in sequence when the whole machine is operated. Technical processing of the full--automatic double-head 2.5 knitting thick line type process weaving jacquard art weave cable is achieved.

Owner:TONGLU YONGSHENG KNITTING MACHINERY

Tambour needle used for thick line and embroidery method thereof

InactiveCN101215765AImprove Embroidery EfficiencyReduce labor intensityEmbroidering machines apparatusHand embroideringThick lineHot-melt adhesive

The invention relates to an embroidery needle for thick lines and a method for embroidering, which relates to an embroidering requisite and a embroidering method, the diameter of an inner cavity of a needle body of the embroidery needle is 1mm-3mm, a round needle hole is opened on the needle body wall on a needle point, an adjusting tube is sleeved on the needle body, and a handle is a through cavity structure. The process comprises firstly, leading the embroidery needle which is threaded with a line to be punched in an awaiting embroidery cloth, secondly, vertically pulling out the embroidery needle when the adjusting tube on the embroidery needle which is punched contacts with embroidery surface, thirdly, vertically punching a second needle at the needle hole with the diameter of the needle to be a distance with the same method, and reciprocating to complete such embroidery, fourth, adhering a bonding fabric which is provided with hot melt adhesive on the embroidery face, and then adopting a flat iron or a heating press to press and adhere, fifth, crispening and sewing cloth which is chosen. The process adopts thick lines which are matched with the cloth to embroider, which solves the difficult problem that thick lines can not be adopted to do hand embroidery.

Owner:夏芬

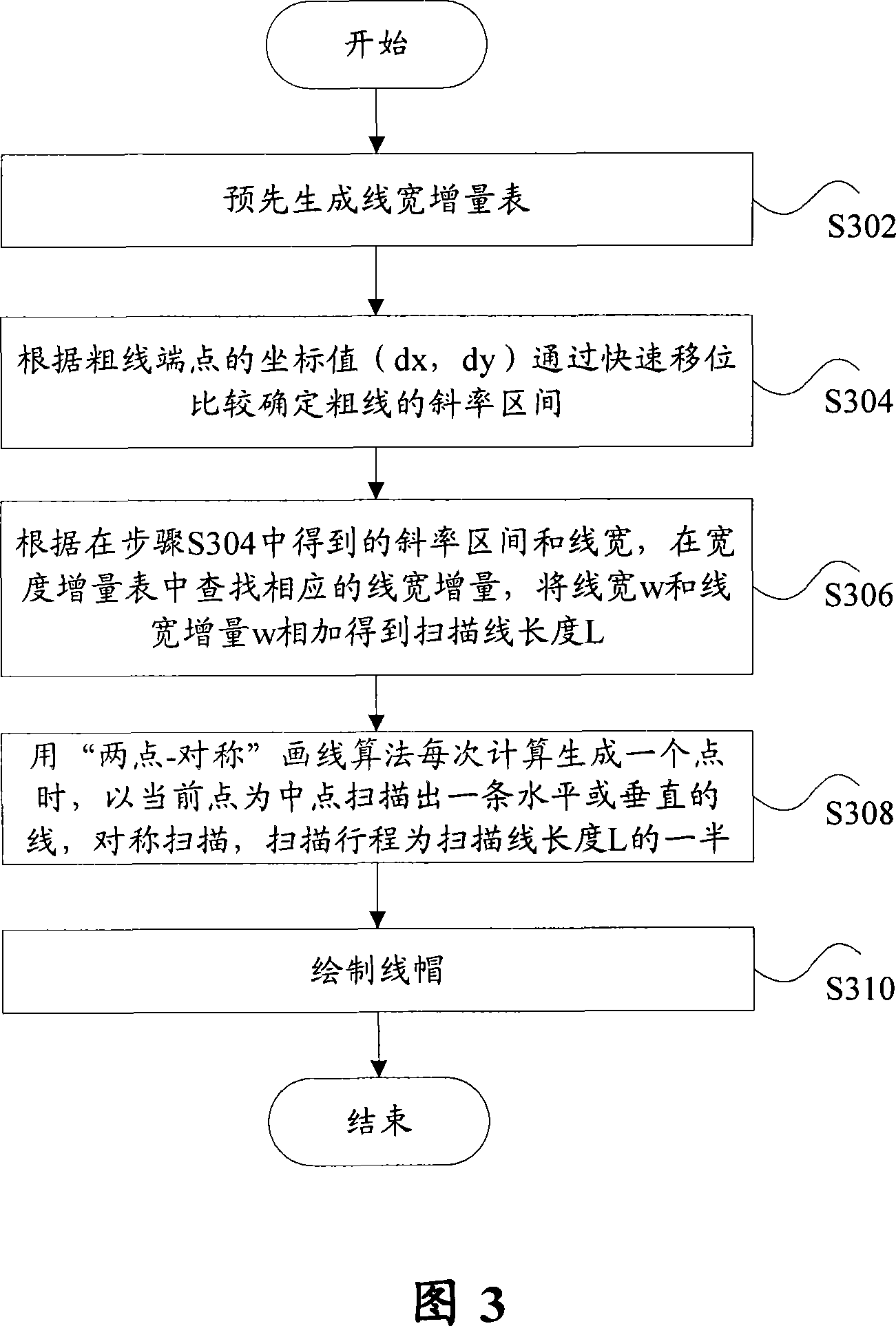

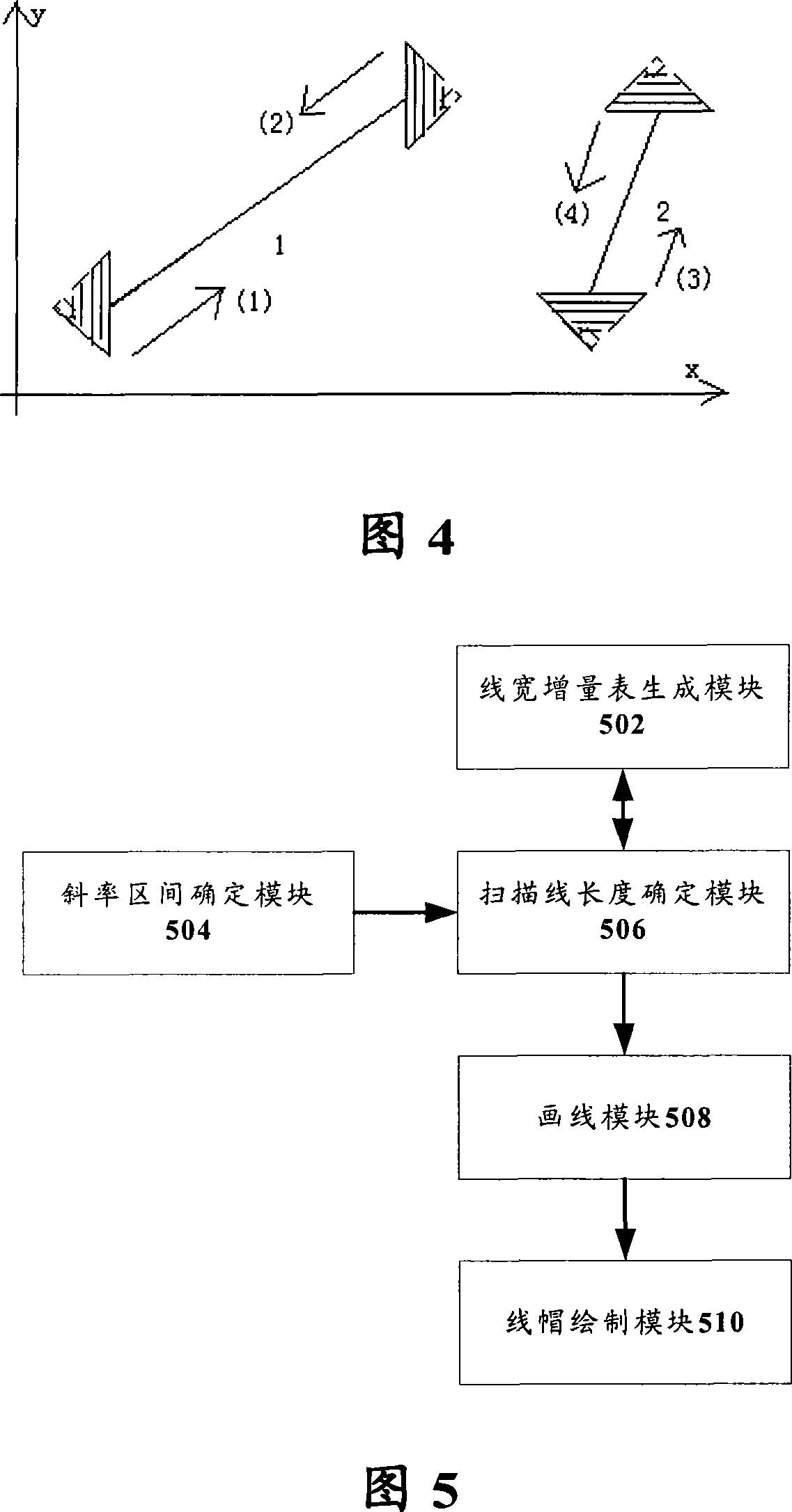

Method and device for creating thick line

ActiveCN101093584AImprove efficiencyReduce computationInstruments for road network navigationDrawing from basic elementsThick lineScan line

A method for generating thick line includes generating line width increment table, confirming slope section of thick line through quick displacement comparison according to coordinate value of thick line end point, seeking relevant line width increment in said table according obtained slope section and line width, adding line width with line width increment to obtain scan line length, using current point as center point to scan out a horizontal line, setting scan range to be half of scan line length to make symmetric scan and plotting out line cup.

Owner:ZTE CORP

Improvement of cross embroidering method

InactiveCN100516340CNot out of shapeMaintain accuracyEmbroidering machines apparatusHand embroideringThick lineWater soluble

An improvement of the cross-stitch embroidery method, which uses machinery or a computer to make an embroidery pattern, marking the positions of the coordinates of the points where the various color lines are located, and the order of embroidery, and according to the marks on the embroidery pattern, use a water-soluble pen to embroider. Mark the coordinate grid with the size of the thick line corresponding to the embroidery pattern on the cloth. During the manual embroidery operation, the embroidery cloth can be compared accurately with the pattern, and the embroidery point can be found quickly. The embroidery point is drawn with a water-soluble pen. After embroidery, the embroidery cloth is washed off the water-soluble pen Color, this method can increase the efficiency of manual embroidery by more than 80%, and it is not easy to make mistakes and rework. In addition, the embroidery sample can also be drawn in the way of enlargement or deformation, and the effect picture will be displayed in advance on the computer after the change. Let cross-stitch manual embroiders adapt to various creative changes in the pattern, the accuracy and speed of embroidering embroidery are greatly improved, and successful embroidery can be obtained.

Owner:陈文泽

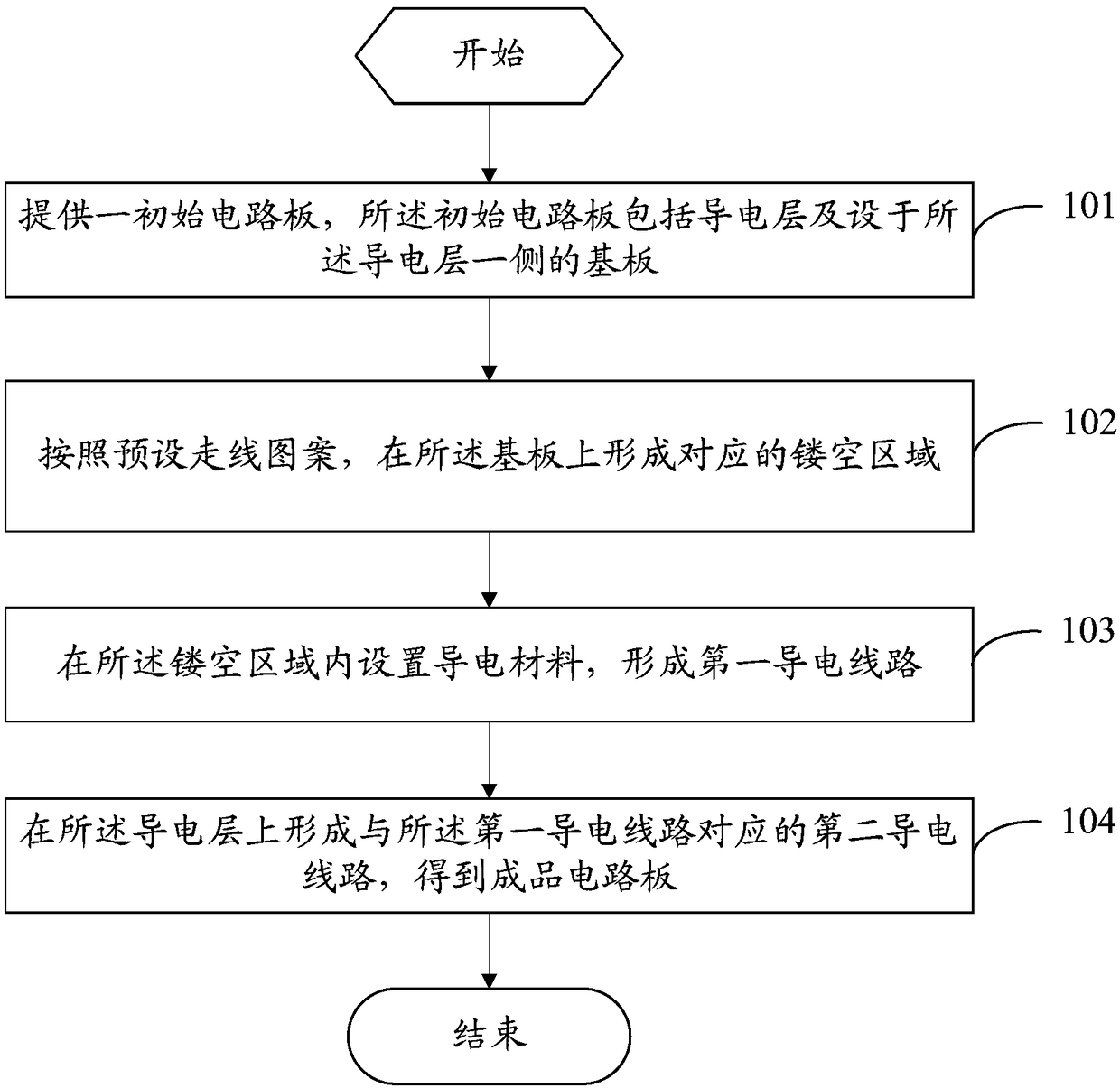

Circuit board manufacturing method, circuit board and mobile terminal

InactiveCN108323027AIncreasing the thicknessMeet needsPrinted circuit aspectsHigh current circuit adaptationsThick lineConductive materials

Owner:VIVO MOBILE COMM CO LTD

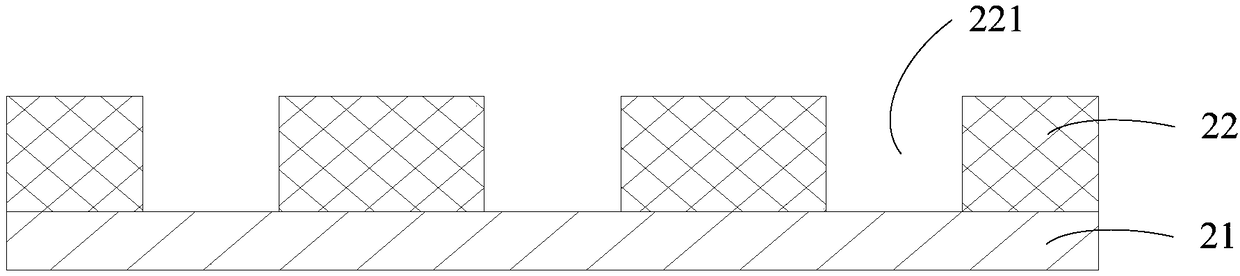

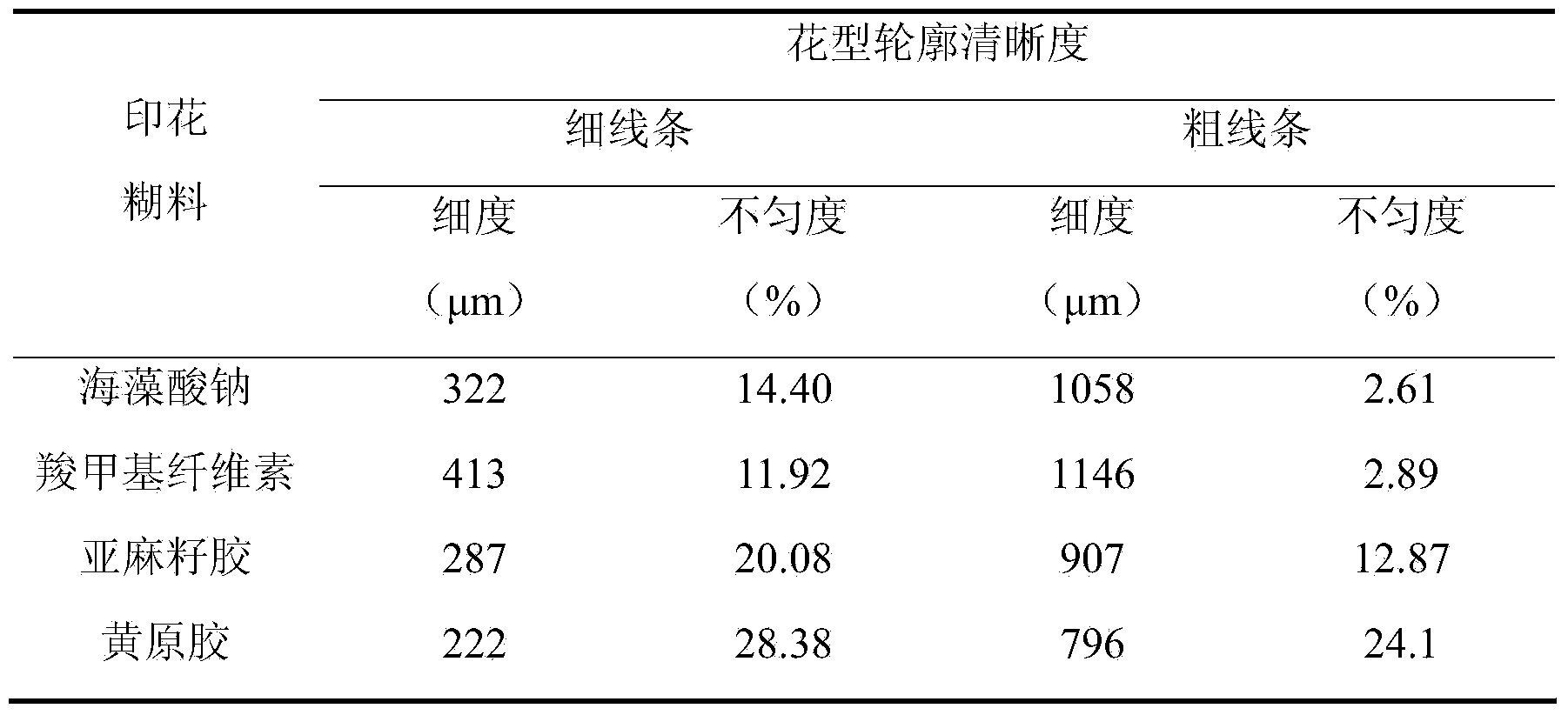

Method for precisely evaluating sharpness of pattern contour of printing gum

InactiveCN103806310AGood outline definitionThere will be no missing warp and weftDyeing processThick lineEngineering

The invention relates to a method for precisely evaluating the sharpness of the pattern contour of printing gum. The method comprises the steps of (1) mixing the printing gum, and printing two groups of straight lines on a fabric, wherein each group consists of three same straight lines which are parallel to one another, one group consists of thin lines which are 10cm long and 100-400 microns thick, and the other group consists of thick lines which are 10cm long and 400-1,000 microns thick; (2) measuring the thicknesses of the lines on the fabric through an electronic microscope after the two groups of printed straight lines are dried, wherein the line thickness of a point is measured on each straight line at an interval of 1cm, and 30 points are measured on each group of straight lines; (3) calculating the line thicknesses and the non-uniformity so as to evaluate the sharpness of the pattern contour of the printing gum. According to the method for precisely evaluating the sharpness of the pattern contour of the printing gum, conventional visual measurement is changed into quantitative research; the method is simple and feasible; the fine pattern printing performance of the gum can be accurately reflected.

Owner:DONGHUA UNIV

Electrothermal film and preparation method

PendingCN107567116AAvoid contact resistanceReduce useless areaOhmic-resistance heating detailsHeating element materialsThick lineNegative power

The invention provides an electrothermal film and a preparation method. The electrothermal film comprises a conductive heating layer having an intermediate broken belt. The conductive heating layer issegmented by the intermediate broken belt into a first conductive part and a second conductive part, which are symmetrical. The electrothermal film comprises a lead layer having a plurality of thickleads and a plurality of thin leads, which are disposed on the surface of the conductive heating layer or embedded in the conductive heating layer for connecting the positive pole and the negative pole of the power supply. The current is introduced into the conductive heating layer so that the heating layer is divided into a plurality of conductive heating units in series connection. The inventionis advantageous in that a larger heating area can be realized under the condition of the same area, and the utilization rate of film can be increased; Compared with the series connection of normal small film heating plates, approximately 20% of lead layer materials (generally silver paste or copper paste) can be saved, and production cost can be reduced.

Owner:WUXI GRAPHENE FILM +1

Waste cable recycling device

InactiveCN103996996BSimple structureIngenious designBasic electric elementsApparatus for removing/armouring cablesFine lineThick line

The invention discloses a waste cable recycling device comprising a frame (1). The waste cable recovery device is characterized in that a first-grade tool (2), a first supporting roller (3), a second-grade tool (4), a second supporting roller (5) and a winding mechanism (6) are sequentially arranged on the frame (1), a cable sheath recycling bin (7) is arranged in the lower part of the frame (1), a driving roller (8) and a driven roller (9) which are oppositely arranged are rotationally supported above the cable sheath recycling bin (7), and a crank (10) is arranged at the outer end of the driving roller (8). In view of the problems of the existing waste cable disposing method, a special structure capable of simultaneously disposing thick outer line sheaths and thin inner line sheaths of cables is designed. Semi-automated cable stripping can be realized, the working efficiency of cable disposing is greatly improved, and no pollution is caused to the surrounding environment. Meanwhile, stripped thick line sheaths and thin line sheaths can be collected separately for centralized disposing.

Owner:DALIAN OCEAN UNIV +1

Double layer quick energy-saving power distribution line deconcentrator

InactiveCN106848619AAchieve clampingEasy to operateElectric connection structural associationsClamped/spring connectionsThick lineEngineering

The invention relates to a double-layer fast energy-saving power distribution line splitter, which includes a main line conductive clip assembly. There is a crimping block assembly for sliding inside; it also includes a plug-in self-locking bolt assembly for pushing the crimping block assembly and connecting the branch line. Point to the other end of the wire crimping block assembly, that is, the self-locking bolt assembly of the plug-in wire is screwed into the screw hole from the outside to the inside, that is, there is a threading hole in the self-locking bolt assembly of the plug-in wire, and the threading hole is at least self-locking with the plug-in wire The outer end of the tightening bolt assembly is connected. The clamping method of each layer of this double-layer fast energy-saving distribution line splitter is the same as that of the single-layer splitter. However, after the two layers are integrated, it can have multiple splitter interfaces and can connect three The thicker sub-line above is suitable for some specific occasions.

Owner:SHAOGUAN FANGSHENG ELECTRIC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com